Research progress of fiber reinforced composites by grinding technology for hole making

-

摘要: 纤维增强复合材料具有优良的物理、化学和力学性能,在航空航天、汽车、新能源等高新技术领域应用广泛。相比传统钻铣刀具,磨料工具在纤维增强复合材料制孔时,加工后的分层、毛刺、撕裂及热损伤等缺陷更小,且磨料工具可以稳定加工硬度更高的纤维增强陶瓷基复合材料。首先,综述了纤维增强复合材料在磨削制孔过程中的切屑形成、磨削轴向力、磨削温度等磨削加工机制;其次,探讨了近年来国内外在纤维增强复合材料磨削制孔技术中的制孔加工缺陷及其评价方法;然后,分析了纤维增强复合材料磨削制孔质量及其影响因素;此外,综述了纤维增强复合材料磨削制孔刀具及其磨损机制等方面的研究现状;最后,对纤维增强复合材料磨削制孔加工技术研究进行了总结和展望。Abstract: For the excellent physical, chemical and mechanical properties of fiber reinforced composites, they are widely used in high-tech fields such as aerospace, automobiles, and new energy. Compared with traditional drilling and milling tools, less defects are generated when machining holes of fiber reinforced composites by abrasive tools, such as delamination, burrs, tearing and thermal damage after processing, especially, fiber reinforced ceramic matrix composites with higher hardness could be stably processed when using abrasive tools. In this paper, hole making mechanism of grinding fiber reinforced composites is reviewed, including chip formation, grinding axial force, grinding temperature, and so on. And then, the research status of hole making defects and their evaluation methods are discussed. Subsequently, hole-making quality and its influencing factors are analyzed. Besides, the abrasive tools for grinding fiber reinforced composite holes and their wear mechanisms are summarized. Finally, the development trends of grinding holes for fiber reinforced composites are concluded and forecasted.

-

Key words:

- fiber reinforced composites /

- abrasive tools /

- grinding holes /

- machining defects /

- tool wear

-

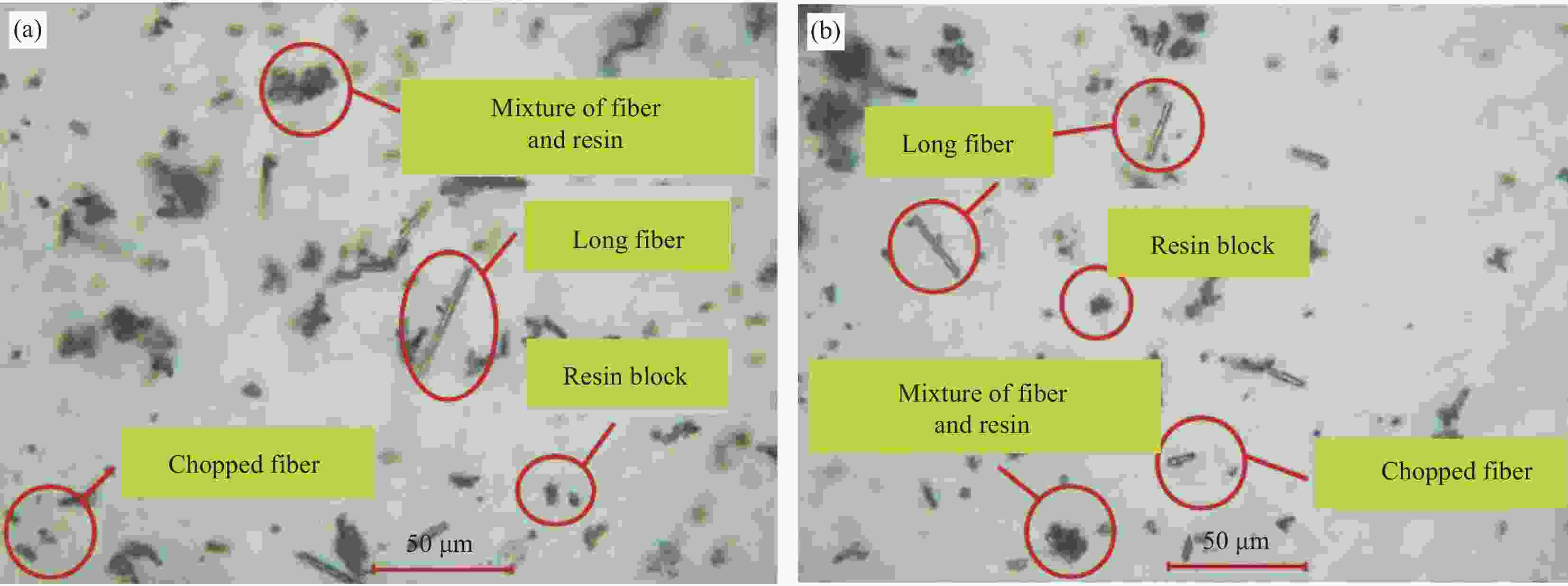

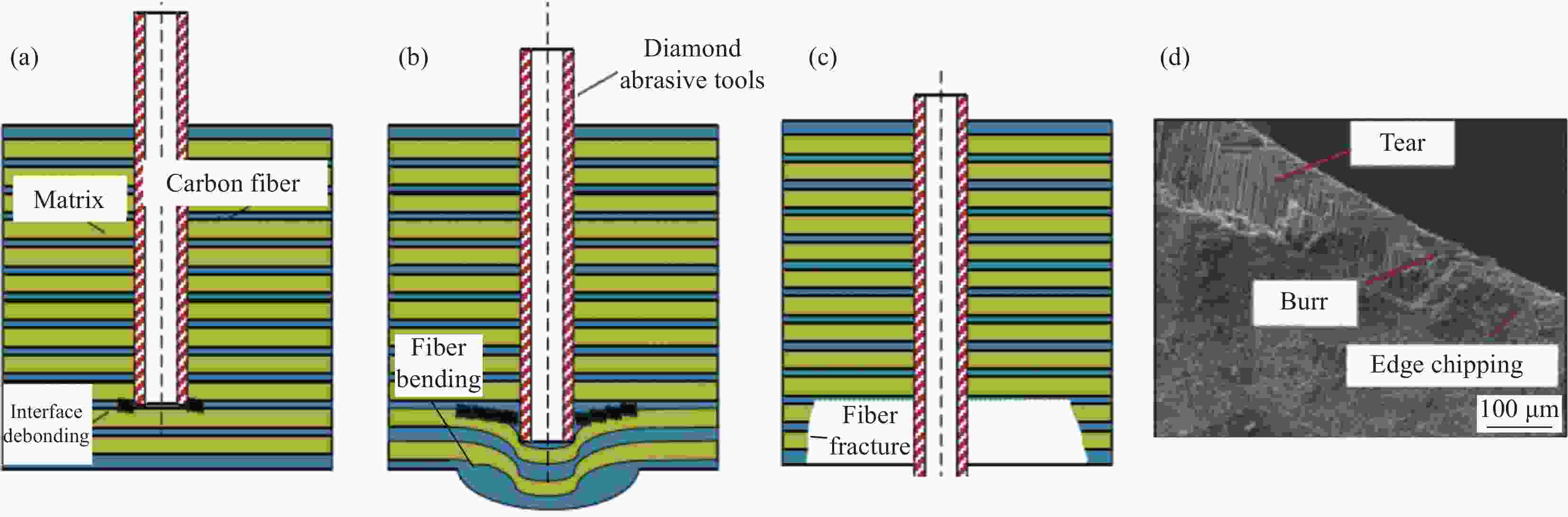

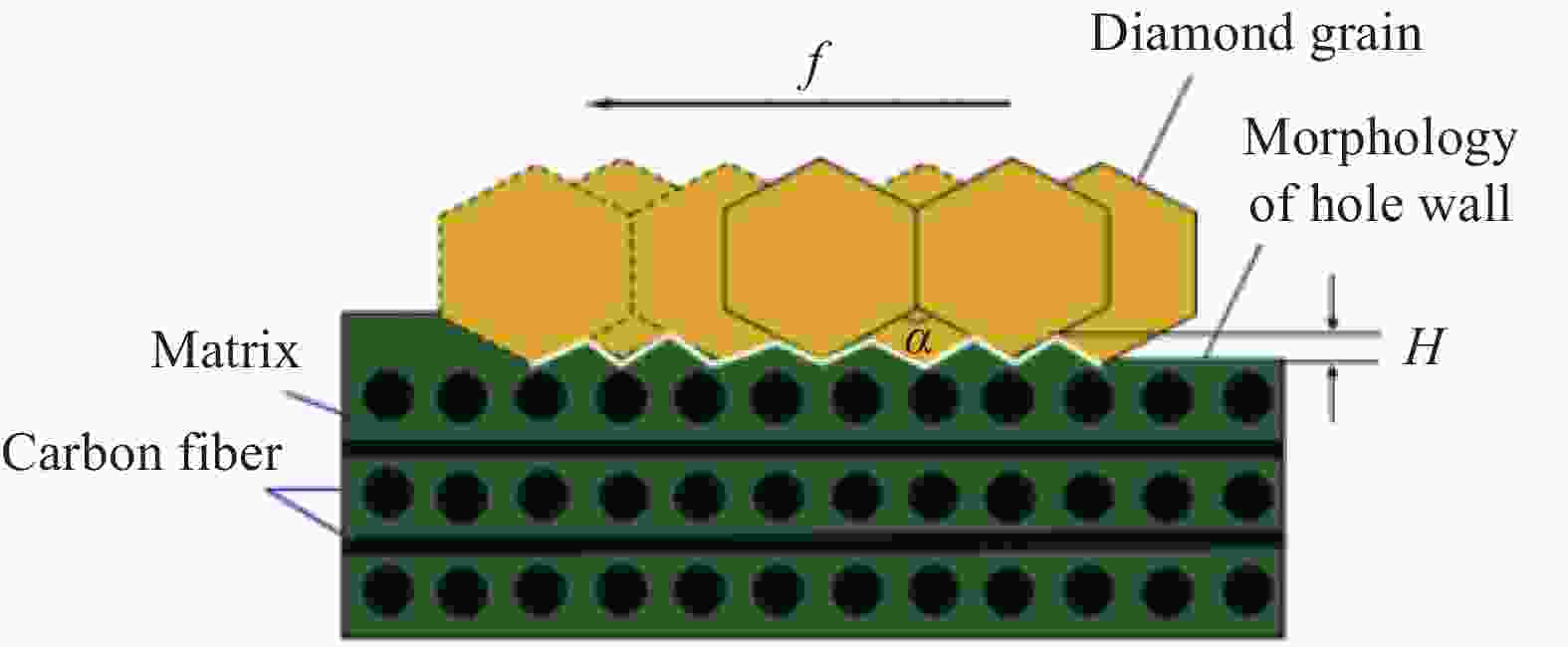

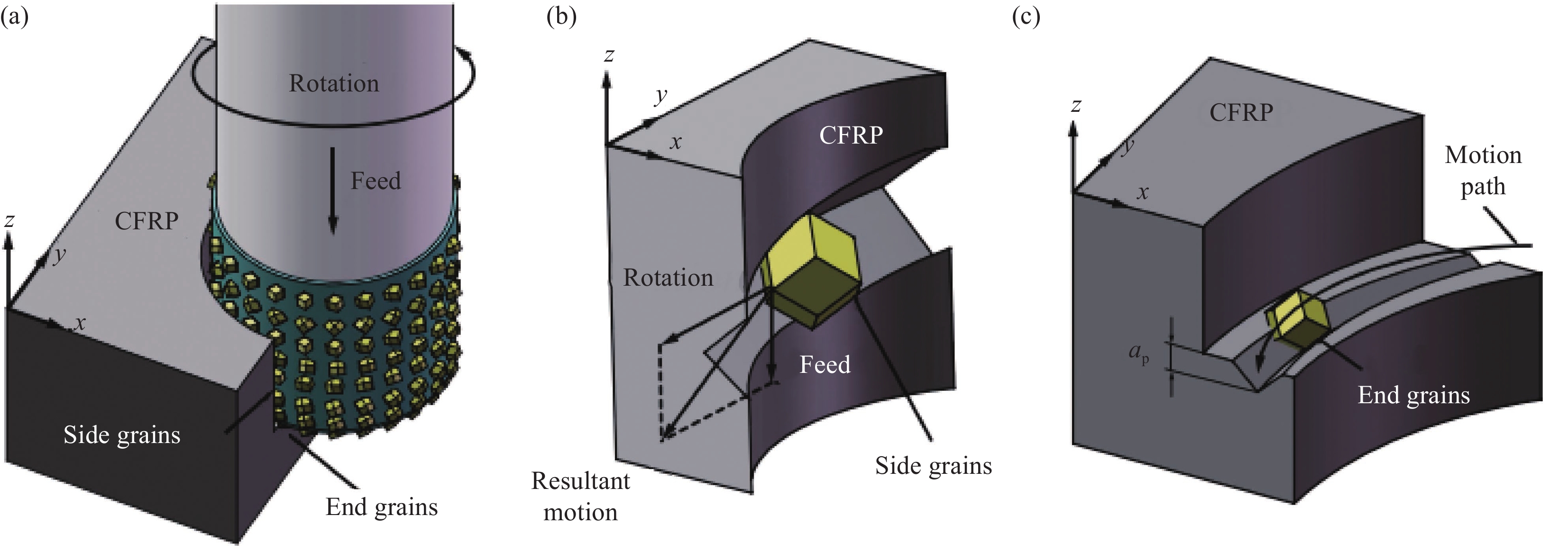

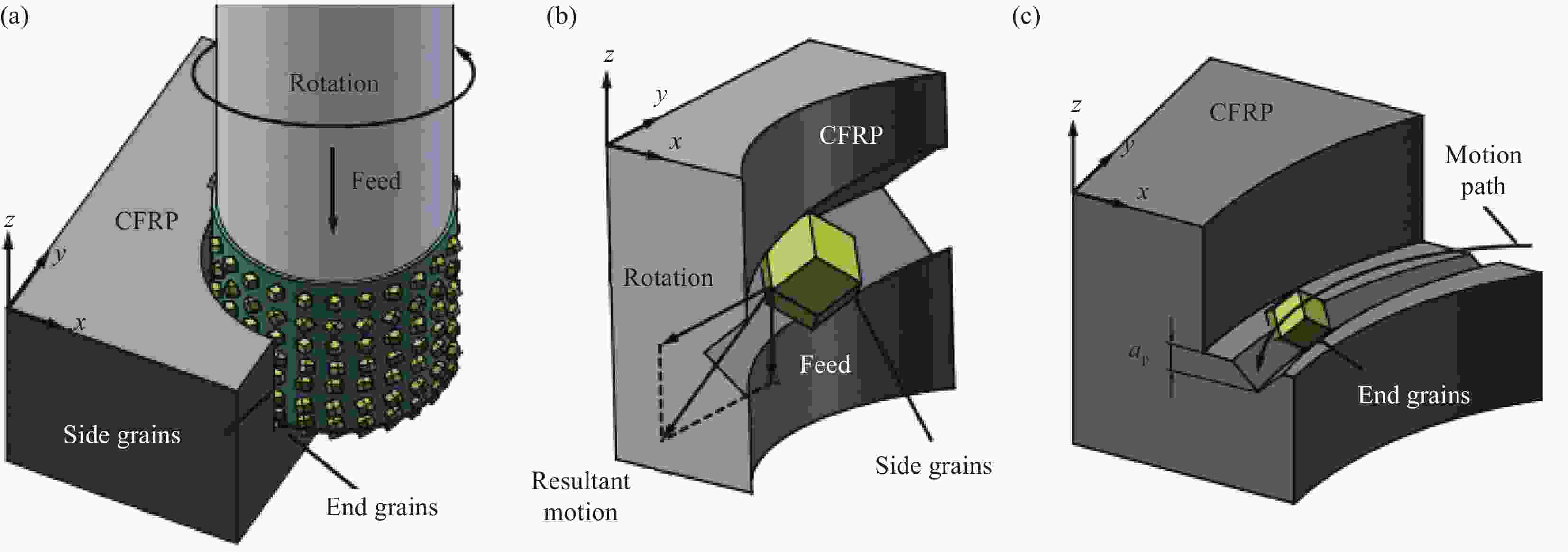

图 1 磨削制孔加工材料去除过程[16]:(a) 磨料工具磨削制孔;(b) 单颗磨粒划切孔壁;(c) 单颗磨粒划切孔底部

Figure 1. Material removal processes for grinding hole making[16]: (a) Abrasive tools grind holes; (b) Single abrasive scratch on the hole wall; (c) Single abrasive scratch on the hole bottom

CFRP—Carbon fiber reinforced plastics; ap—Abrasive cutting depth

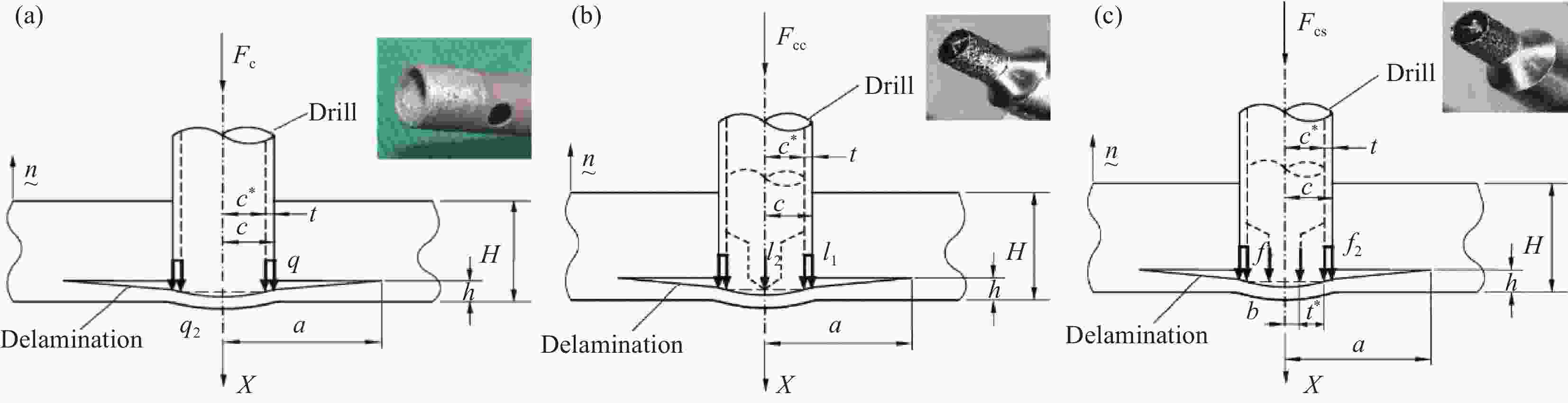

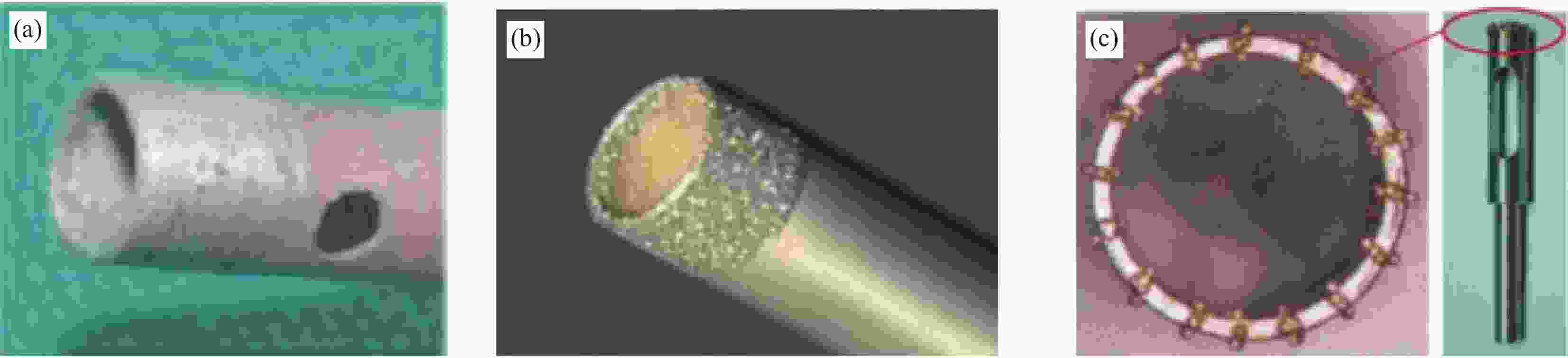

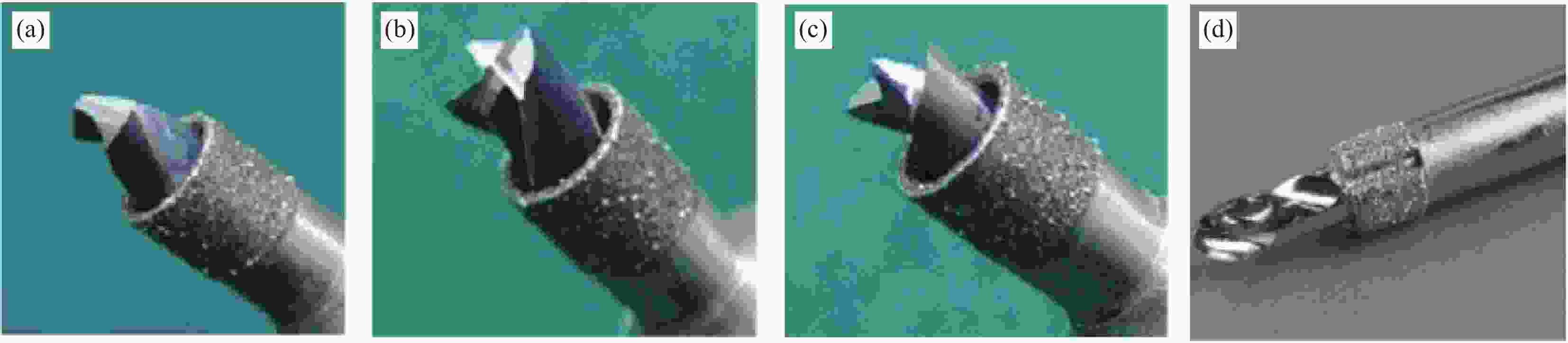

图 3 不同磨料工具的临界轴向力理论模型[5, 33]:(a) 套料钻;(b) 套料-麻花钻;(c) 套料-锯钻

Figure 3. Theoretical model of critical axial force for different abrasive tools[5, 33]:(a) Core drill;(b) Core-center drill;(c) Core-saw drill

Fc—Thrust force of the core drill; Fcc—Thrust force of the core-center drill; Fcs—Thrust force of the core-saw drill; H—Workpiece thickness; h—Uncut depth under tool; q—Annular area force of the core drill; c*—Inner radius of the core drill; c—Outer radius of the core drill; q2—Annular distributed load over a round area of radius a; n—Number of layers of composite material; l1—Annular area force; l2—Central concentrated force; f—Periphery circular force; f2—Annular area force; b—Radius of saw drill; t*—Difference between the outside and inside diameter of the core-saw drill; t—Wall thickness of the drill bit

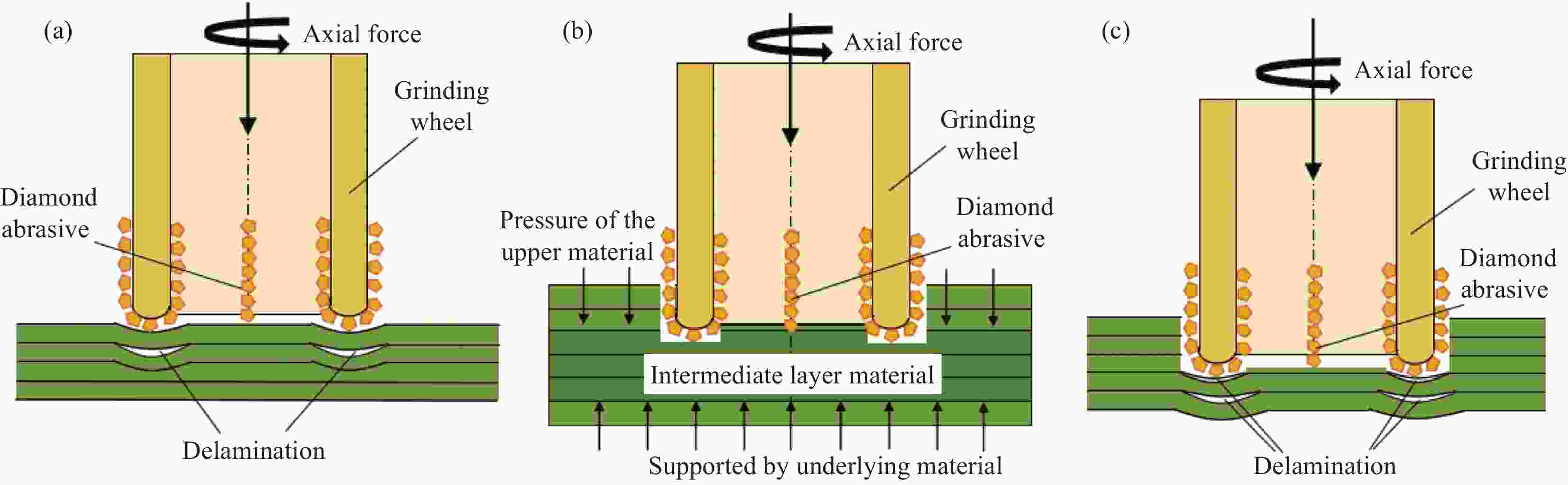

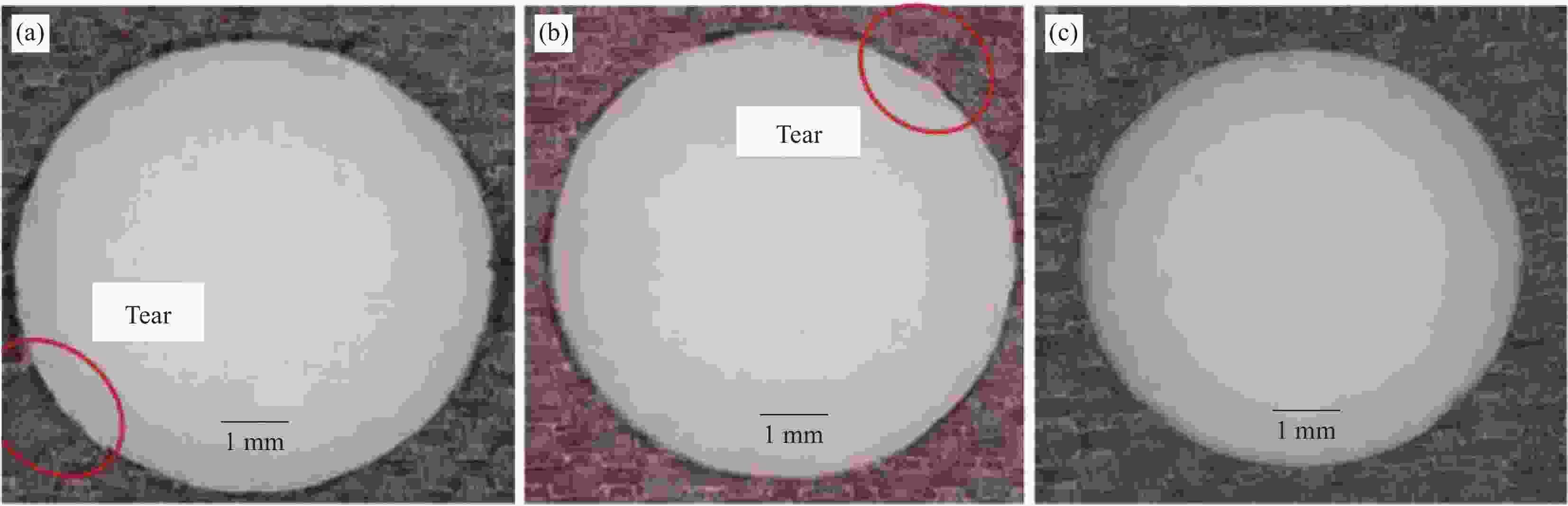

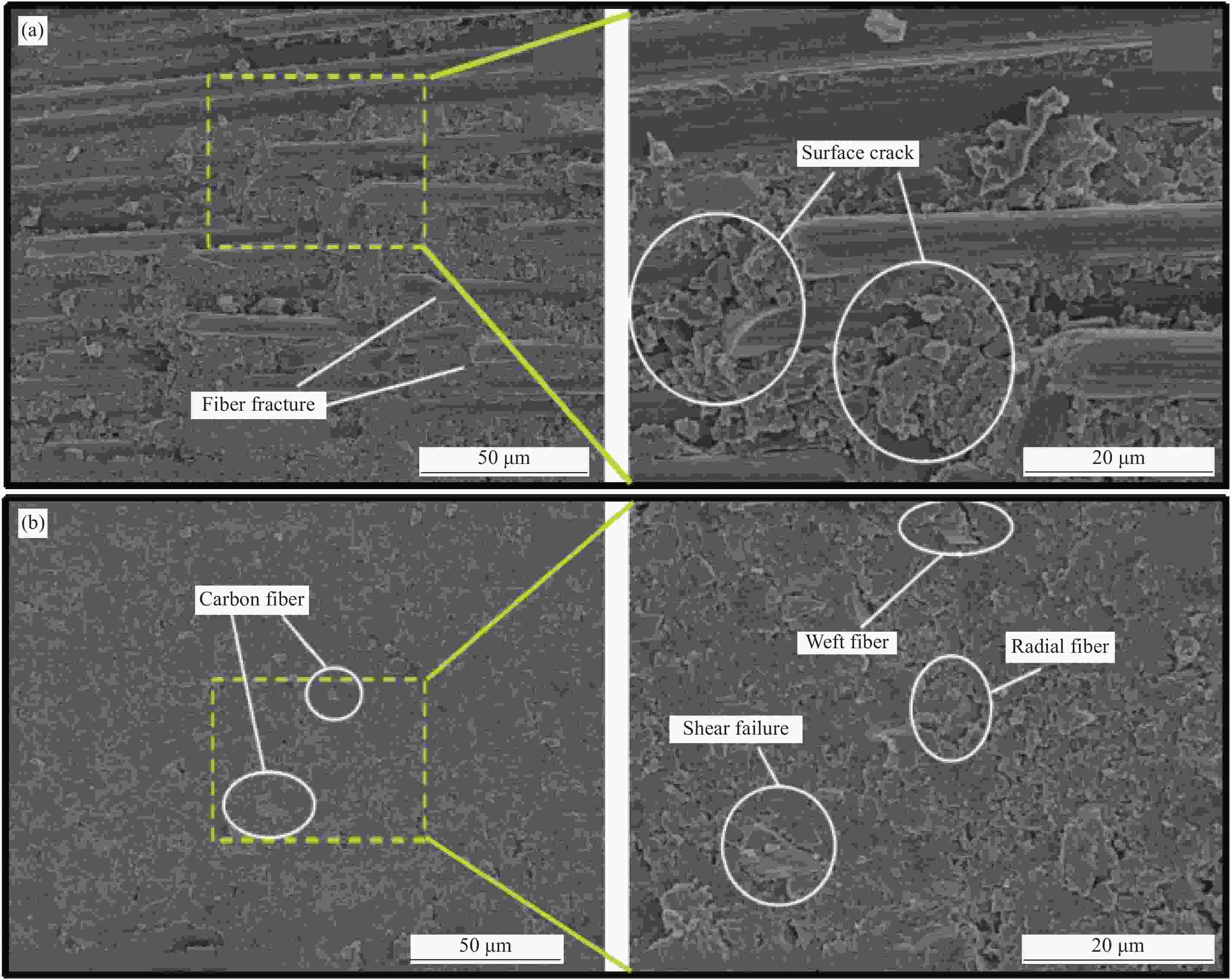

图 10 C/C-SiC制孔入口和出口表面形貌[71]:((a)、(b)) 孔入 口处;((c)、(d)) 孔出口处

Figure 10. Surface topographies of C/C-SiC hole entrance and exit drilled[71]: ((a), (b)) Hole entrance; ((c), (d)) Hole exit

ν—Cutting speed of the tool around the spindle; Cf—Carbon fiber; θ—Angle between cutting direction and fiber orientation on the surface; n—Spindle speed of the tool

Drill

typeAssociated expression Characteristics thrust force Twist

drill$ {F_{\rm A} } = {\text{π} } \sqrt {32{G_{\rm IC} }M} {\text{ = } }{\text{π} } \sqrt {\dfrac{ {8{G_{\rm IC} }E{ { {h} }^3} } }{ {3(1 - {v^2})} } } $ The center of the circular plate is loaded Core

drill${F_{\text{c} } } ={\text{π} } \left( {1{\text{ + } }\alpha } \right)\sqrt {\dfrac{ {32{G_{\rm IC} }M} }{\begin{gathered} 1 +\alpha{^2}(1-2s{^2}+s{^4})\end{gathered} } } , \quad M=\dfrac{Eh^{3} }{12(1-v^{2})}$ The circular plate is clamped and subjected to annular distributed load Core-

center drill${F_{ {\text{cc} } } } = {\text{π} } \left( {1{\text{ + } }\gamma } \right)\sqrt {\dfrac{ {32{G_{\rm IC} }M} }{\begin{gathered} 1 - {\gamma^2}\left[ {\left( {2 - 2\beta + \dfrac{ {3{\beta ^2} } }{2} } \right) + \dfrac{ {4{ {(1 - \beta )}^2} } }{ {\beta (2 - \beta )} }\ln (1 - \beta )} \right]{s^2}+ \\ \left[ {\dfrac{ {\left( {2 - 4\beta + 5{\beta ^2} - 3{\beta ^3} + {\beta ^4} } \right)} }{2} + \dfrac{ {2{ {\left( {1 - \beta } \right)}^2}\left( {2 - 2\beta + {\beta ^2} } \right)} }{ {\beta \left( {2 - \beta } \right)} }\ln \left( {1 - \beta } \right)} \right]{s^4} \\ \end{gathered} } }$ The thrust force can be considered as a concentrated center load plus the annular area load Core-

saw drill${F_{ {\text{cs} } } } = {\text{π}} \left( {1{\text{ + } }\eta } \right)\sqrt {\dfrac{ {32{G_{\rm IC} }M} }{\begin{gathered} 1 - 2{\left( {1 - \beta - \varphi } \right)^2}{s^2} + {(1 - \beta - \varphi )^4}{s^4} + \\ \eta \left\{ 1 - \left[ {\left( {2 - 2\beta + \dfrac{ {3{\beta ^2} } }{2} } \right) + \dfrac{ {4{ {\left( { {\text{1 } -}\beta } \right)}^{\text{2} } } } }{ {\beta \left( { {\text{2 } -}\beta } \right)} }{\text{ln} }\left( {1 - \beta } \right)} \right]{ {{s} }^{\text{2} } } + \right. \\ \left.\left[ {\dfrac{ {\left( { {\text{2 }-{ 4} }\beta {\text{ + 5} }{\beta ^{\text{2} } } - {\text{3} }{\beta ^{\text{3} } }{\text{ + } }{\beta ^{\text{4} } } } \right)} }{ {\text{2} } }{\text{ + } }\dfrac{ { {\text{2} }{ {\left( { {\text{1} } - \beta } \right)}^2}\left( {2 - 2\beta + {\beta ^2} } \right)} }{ {\beta \left( {2 - \beta } \right)} }\ln \left( {1 - \beta } \right)} \right]{s^4} \right\} \end{gathered} } }$ The thrust force can be considered as a periphery circular load plus the annular area load Notes: FA—Thrust force of the twist drill; GIC—Critical crack propagation energy per unit area in mode I; E—Young’s modulus; h—Uncut depth under tool; v—Poisson’s ratio for the material; β—Ratio between thickness (t) and radius of core drill (c); s—Ratio between the radius of saw drill (c) and the radius of delamination (a); γ, η—Ratio between peripheral circular force and central concentrated force; φ—Ratio between thickness (t ) and inner radius of core drill. 表 2 制孔分层评价方法及其特点

Table 2. Evaluation methods of delamination and their characteristics

Delamination factor Associated expression Main characteristics Ref. Fd ${F_{\rm{d}}} = \dfrac{ { {D_{\rm{d}}} } }{ { {D_0} } }$ Simple to evaluate, easy to measure [50] Fa ${F_{\text{a} } } = \dfrac{ { {A_{\rm{d}}} } }{ { {A_{\rm{nom}} } } }$ Without considering length of cracks [51] Fda ${F_{ {\text{da} } } } = {F_{\rm{d}}} + \dfrac{ { {A_{\rm{d}}} } }{ { {A_{\max } } - {A_{\rm{nom}} } } }(F_{\rm{d}}^2 - {F_{\text{d} } })$ Both maximum delamination diameter and area are considered [52] Fed ${F_{ {\text{ed} } } } = \dfrac{ { {D_{\text{e} } } }}{ { {D_0} } }$,${D_{\rm{e}}} = \sqrt {\dfrac{ {4({A_{\rm{d}}} + {A_{\rm{nom}} })} }{\text{π} } }$ Without considering maximum delamination diameter and number of micro cracks [53] f $f = 4\text{π} \dfrac{ { {A_{\rm{e}}} } }{ { {p^2} } }$ Not an independent and valid evaluating method [54] Fv ${F}_{\text{v} }=\dfrac{1}{N}\left({\displaystyle \sum _{{i}=1}^{N}\dfrac{ {A}_{\text{d} }^{i} }{ {A}_{N} } }\right)\text{=}\dfrac{1}{N}{\displaystyle \sum _{{i}=1}^{N}{F}_{\text{a} }^{i} }$ Delamination defects within materials are assessed comprehensively and accurately [55] Notes: Fd—One dimensional delamination factor; Fa—2D area stratification factor; Fda—Adjusting stratification factor; Fed—Equivalent stratification factor; f—Roundness layering factor; Fv—Three dimensional stratification factor; De—Equivalent diameter; p—Perimeter of the area; AN—Nominal area of the hole; Dd—Maximum diameter of the delamination area; D0—Nominal diameter of the drilled hole; Ad—Delamination area; Anom—Nominal area of the drilled hole; Amax—Maximum delamination area; Ae—Area of the delamination area around the hole; N—Total number of the delaminated layers; Adi—Delaminated area of the ith layer; Fai—Signifies the 2D delamination factor of the ith layer. 表 3 磨料工具的种类及特点

Table 3. Types and characteristics of abrasive tools

Types of abrasive tools Structure characteristic Working life Main advantages Main disadvantages Sintered tools Hollow Short Easy to produce Chip is removed difficultly, and tools is centered difficultly Electroplated tools Hollow, solid Short High quality of hole could be obtained Abrasives are easy to peel off Brazed tools Hollow, solid Long Ordering abrasive of tools could be designed Abrasive distribution on tools is inhomogeneous Compound tools Tools with a certain structure Short Procedure of processing hole could be simplified Complex to product -

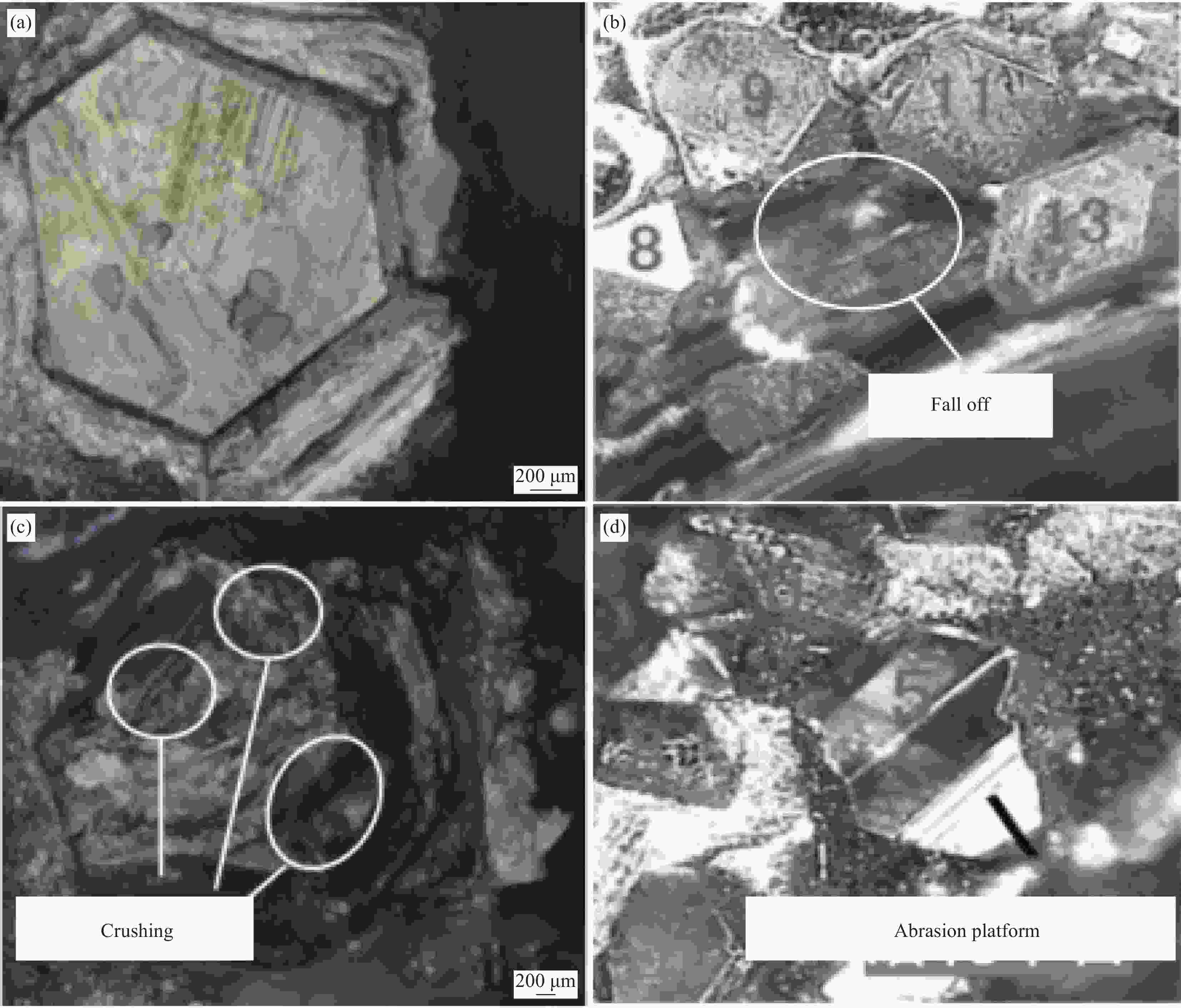

[1] SINGH A P, SHARMA M, SINGH I. A review of modeling and control during drilling of fiber reinforced plastic composites[J]. Composites Part B: Engineering,2013,47:118-125. doi: 10.1016/j.compositesb.2012.10.038 [2] 张立峰. 陶瓷基复合材料界面强度与磨削过程材料去除机理研究[D]. 天津: 天津大学, 2016.ZHANG Lifeng. Research on the interfacial strength and grinding mechanism of material removal for ceramic matrix composites[D]. Tianjin: Tianjin University, 2016(in Chinese). [3] SORRENTINO L, TURCHETTA S, BELLINI C. In process monitoring of cutting temperature during the drilling of FRP laminate[J]. Composite Structures,2017,168:549-561. doi: 10.1016/j.compstruct.2017.02.079 [4] 张孟华, 庞梓玄, 贾云祥, 等. 纤维增强陶瓷基复合材料的加工研究进展与发展趋势[J]. 航空材料学报, 2021, 41(5):14-27. doi: 10.11868/j.issn.1005-5053.2021.000033ZHANG Menghua, PANG Zixuan, JIA Yunxiang, et al. Research progress and development trend of fiber-reinforced ceramic matrix composites[J]. Journal of Aeronautical Materials,2021,41(5):14-27(in Chinese). doi: 10.11868/j.issn.1005-5053.2021.000033 [5] HOCHENG H, TSAO C C. The path towards delamination-free drilling of composite materials[J]. Journal of Materials Processing Technology,2005,167(2-3):251-264. doi: 10.1016/j.jmatprotec.2005.06.039 [6] 张文姣. 纤维增强复合材料的疲劳损伤模型及分析方法[D]. 哈尔滨: 哈尔滨工业大学, 2015.ZHANG Wenjiao. Fatigue damage modelling and analysis for fiber reinforced composite materials[D]. Harbin: Harbin Institute of Technology, 2015(in Chinese). [7] 丁凯, 傅玉灿, 苏宏华, 等. C/SiC复合材料钻削工具载荷及磨损研究[J]. 工具技术, 2016, 50(7):15-19. doi: 10.3969/j.issn.1000-7008.2016.07.003DING Kai, FU Yucan, SU Honghua, et al. Effect of tool form and processing methods on drilling of C/SiC composites[J]. Tool Engineering,2016,50(7):15-19(in Chinese). doi: 10.3969/j.issn.1000-7008.2016.07.003 [8] 焦浩文, 陈冰, 左彬. C/SiC复合材料的制备及加工技术研究进展[J]. 航空材料学报, 2021, 41(1):19-34. doi: 10.11868/j.issn.1005-5053.2020.000067JIAO Haowen, CHEN Bing, ZUO Bing, et al. Research progress in preparation and processing technology of C/SiC composites[J]. Journal of Aeronautical Materials,2021,41(1):19-34(in Chinese). doi: 10.11868/j.issn.1005-5053.2020.000067 [9] 王文杰, 高航, 董波, 等. 电镀金刚石工具“以磨代铣”C/E复合材料的试验研究[J]. 航空制造技术, 2010(22):89-94. doi: 10.3969/j.issn.1671-833X.2010.22.018WANG Wenjie, GAO Hang, DONG Bo, et al. Experimental research on C/E composites grinding instead of milling with electroplated diamond tool[J]. Aeronautical Manufacturing Technology,2010(22):89-94(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.22.018 [10] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316. doi: 10.13801/j.cnki.fhclxb.20150211.002CHEN Yan, GE Ende, FU Yucan, et al. Review and prospect of drilling technologies for carbon fiber reinforced polymer[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese). doi: 10.13801/j.cnki.fhclxb.20150211.002 [11] JAIN S, YANG D C H. Delamination-free drilling of composite laminates[J]. Journal of Engineering for Industry,1994,116(4):475-481. doi: 10.1115/1.2902131 [12] SOO S L, SHYHA I S, BARNETT T, et al. Grinding performance and workpiece integrity when superabrasive edge routing carbon fibre reinforced plastic (CFRP) composites[J]. CIRP Annals,2012,61(1):295-298. doi: 10.1016/j.cirp.2012.03.042 [13] 鲍永杰, 高航, 董波, 等. C/E复合材料“以磨代钻”制孔工艺[J]. 宇航材料工艺, 2010, 40(4):47-49.BAO Yongjie, GAO Hang, DONG Bo, et al. Drilling process of C/E composites with grinding tool[J]. Aerospace Materials and Technology,2010,40(4):47-49(in Chinese). [14] 黄均亮. 芳纶纤维复合材料加工用金刚石磨粒工具的研制[D]. 大连: 大连理工大学, 2013.HUANG Junliang. Development diamond abrasive tools used machining aramid fiber composites[D]. Dalian: Dalian University of Technology, 2013(in Chinese). [15] 毕铭智. C/SiC复合材料钻、铣加工技术的试验研究[D]. 大连: 大连理工大学, 2013.BI Mingzhi. Experimental research on drilling and milling of C/SiC composites[D]. Dalian: Dalian University of Technology, 2013(in Chinese). [16] WU C Q, GAO G L, LI H N, et al. Effects of machining conditions on the hole wall delamination in both conventional and ultrasonic-assisted CFRP drilling[J]. The International Journal of Advanced Manufacturing Technology,2019,104(5):2301-2315. [17] 王伟锋. 钎焊金刚石套料钻钻削CFRP的加工质量研究[D]. 南京: 南京航空航天大学, 2013.WANG Weifeng. Study on quality of CFRP drilled with brazed diamond core drill[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2013(in Chinese). [18] 郑伟. 几种复合材料制孔的若干试验研究[D]. 大连: 大连理工大学, 2007.ZHENG Wei. Experimental study on drilling several composites[D]. Dalian: Dalian University of Technology, 2007(in Chinese). [19] CADORIN N, ZITOUNE R. Wear signature on hole defects as a function of cutting tool material for drilling 3D interlock composite[J]. Wear,2015,332-333:742-751. doi: 10.1016/j.wear.2015.01.019 [20] DU J, ZHANG H, GENG Y, et al. A review on machining of carbon fiber reinforced ceramic matrix composites[J]. Ceramics International,2019,45(15):18155-18166. doi: 10.1016/j.ceramint.2019.06.112 [21] PRIARONE P C, ROBIGLIO M, MELENTIEV R, et al. Diamond drilling of carbon fiber reinforced polymers: Influence of tool grit size and process parameters on workpiece delamination[J]. Procedia CIRP,2017,66:181-186. doi: 10.1016/j.procir.2017.03.296 [22] GUO F L, HUANG P, LI Y Q, et al. Multiscale modeling of mechanical behaviors of carbon fiber reinforced epoxy composites subjected to hygrothermal aging[J]. Composite Structures,2021,256:113098. doi: 10.1016/j.compstruct.2020.113098 [23] 温泉. C/E复合材料制孔损伤形成机理与评价方法研究[D]. 大连: 大连理工大学, 2014.WEN Quan. Study of formation mechanism and evaluation method of C/E composites hole-making damages[D]. Dalian: Dalian University of Technology, 2014(in Chinese). [24] 王文杰. C/E复合材料“以磨代铣”试验研究[D]. 大连: 大连理工大学, 2010.WANG Wenjie. Experimental research on C/E composites grinding instead of milling[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [25] 王福吉, 王东, 殷俊伟, 等. CFRP复合材料铣削表层损伤形成机制分析[J]. 机械工程学报, 2019, 55(13):195-204. doi: 10.3901/JME.2019.13.195WANG Fuji, WANG Dong, YIN Junwei, et al. Analysis of surface damage formation mechanism in milling of CFRPs[J]. Journal of Mechanical Engineering,2019,55(13):195-204(in Chinese). doi: 10.3901/JME.2019.13.195 [26] 罗豪. 碳纤维复合材料旋转超声制孔工艺研究[D]. 武汉: 武汉理工大学, 2018.LUO Hao. Study on drilling process of carbon fiber reinforced plastics in rotary ultrasonic machining[D]. Wuhan: Wuhan University of Technology, 2018(in Chinese). [27] 牟娟. 钎焊金刚石工具钻削碳/环氧复合材料的基础研究[D]. 南京: 南京航空航天大学, 2013.MU Juan. Fundamental research on drilling carbon fiber reinforced plastics with brazed diamond tool[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2013(in Chinese). [28] 赵凡. 超声辅助磨削碳化硅纤维增强碳化硅陶瓷基复合材料试验研究[D]. 大连: 大连理工大学, 2019.ZHAO Fan. Experimental study on ultrasonic assisted grinding of SiC/SiC composites[D]. Dalian: Dalian University of Technology, 2019(in Chinese). [29] 周雯雯. 单颗磨粒划擦碳化硅陶瓷基复合材料划擦力及表面损伤研究[D]. 太原: 中北大学, 2021.ZHOU Wenwen. Research on scratch force and surface damage of single abrasive particle scratching silicon carbide ceramic matrix composite[D]. Taiyuan: North University of China, 2021(in Chinese). [30] LIU Q, HUANG G, XU Y. Investigation of drilling 2D Cf/C-SiC composites with brazed diamond core drills[J]. Mechanical Sciences,2020,11(2):349-356. doi: 10.5194/ms-11-349-2020 [31] 高航, 刘国兴, 张选龙, 等. 电镀金刚石刀具钻削碳纤维复合材料磨粒磨损特征研究[J]. 大连理工大学学报, 2011, 51(5):675-680.GAO Hang, LIU Guoxing, ZHANG Xuanlong, et al. Research on abrasive wear characteristics of electroplateddiamond tool during drilling carbon fiber reinforced plastics[J]. Journal of Dalian University of Technology,2011,51(5):675-680(in Chinese). [32] 牟娟, 陈燕, 徐九华, 等. 钎焊套料钻钻削碳纤维增强复合材料层合板出口撕裂缺陷的成因分析[J]. 中国机械工程, 2013, 24(20):2699-2704. doi: 10.3969/j.issn.1004-132X.2013.20.001MU Juan, CHEN Yan, XU Jiuhua, et al. Analysis on cracking at exit of hole drilled in carbon fiber reinforced plastics laminate with brazed diamond core drill[J]. China Mechanical Engineering,2013,24(20):2699-2704(in Chinese). doi: 10.3969/j.issn.1004-132X.2013.20.001 [33] HOCHENG H, TSAO C C. Comprehensive analysis of delamination in drilling of composite materials with various drill bits[J]. Journal of Materials Processing Technology,2003,140(1-3):335-339. doi: 10.1016/S0924-0136(03)00749-0 [34] 鲍永杰, 高航, 李凤全. 电镀金刚石钻头钻削碳纤维复合材料研究[J]. 金刚石与磨料磨具工程, 2009(3):38-42. doi: 10.3969/j.issn.1006-852X.2009.03.009BAO Yongjie, GAO Hang, LI Fengquan. Researches on drilling CFRP (carbon fiber reinforced plastics) with diamond electropated drill bit[J]. Diamond & Abrasives Engineering,2009(3):38-42(in Chinese). doi: 10.3969/j.issn.1006-852X.2009.03.009 [35] 冉冲, 卢守相, 王东坡, 等. 石英纤维增强陶瓷基复合材料制孔工艺研究[J]. 金刚石与磨料磨具工程, 2016, 36(2):37-42, 48. doi: 10.13394/j.cnki.jgszz.2016.2.0009RAN Chong, LU Shouxiang, WANG Dongpo, et al. Research on drilling technology of quartz fiber reinforced ceramic matrix composites[J]. Diamond & Abrasives Engineering,2016,36(2):37-42, 48(in Chinese). doi: 10.13394/j.cnki.jgszz.2016.2.0009 [36] LIANG Y, CHEN Y, CHEN B, et al. Feasibility of ultrasonic vibration assisted grinding for carbon fiber reinforced polymer with monolayer brazed grinding tools[J]. International Journal of Precision Engineering and Manufacturing,2019,20(7):1083-1094. doi: 10.1007/s12541-019-00135-8 [37] 张国栋. C/C-SiC复合材料钻削加工试验研究[D]. 济南: 山东大学, 2015.ZHANG Guodong. Experimental study on drilling C/C-SiC composites[D]. Jinan: Shandong University, 2015(in Chinese). [38] YASHIRO T, OGAWA T, SASAHARA H. Temperature measurement of cutting tool and machined surface layer in milling of CFRP[J]. International Journal of Machine Tools and Manufacture,2013,70:63-69. doi: 10.1016/j.ijmachtools.2013.03.009 [39] LIU J, CHEN G, JI C, et al. An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP)[J]. International Journal of Machine Tools and Manufacture,2014,86:89-103. doi: 10.1016/j.ijmachtools.2014.06.008 [40] 鲍永杰, 高航, 马海龙, 等. 单向C/E复合材料磨削制孔温度场模型的研究[J]. 机械工程学报, 2012, 48(1):169-176. doi: 10.3901/JME.2012.01.169BAO Yongjie, GAO Hang, MA Hailong, et al. Research on temperature field model during grinding-drilling of unidirectional carbon/epoxy composites[J]. Journal of Mechanical Engineering,2012,48(1):169-176(in Chinese). doi: 10.3901/JME.2012.01.169 [41] GENG D, LU Z, YAO G, et al. Cutting temperature and resulting influence on machining performance in rotary ultrasonic elliptical machining of thick CFRP[J]. International Journal of Machine Tools and Manufacture,2017,123:160-170. doi: 10.1016/j.ijmachtools.2017.08.008 [42] 郑雷, 王亮申, 王保卫, 等. KFRP防护背板的钻孔机理及试验研究[J]. 中国机械工程, 2008, 19(13):1556-1560. doi: 10.3321/j.issn:1004-132X.2008.13.011ZHENG Lei, WANG Liangshen, WANG Baowei, et al. Drilling mechanism and experimental study of KFRP bulletproof backboard[J]. China Mechanical Engineering,2008,19(13):1556-1560(in Chinese). doi: 10.3321/j.issn:1004-132X.2008.13.011 [43] 霍豪闯. 芳纶纤维复合材料高质量制孔工艺研究[D]. 大连: 大连理工大学, 2019.HUO Haochuang. Study on high quality hole making of aramid fiber composites[D]. Dalian: Dalian University of Technology, 2019(in Chinese). [44] 崔西亮, 田彪, 王永国. 碳纤维复合材料钻孔加工的缺陷分析[J]. 机电工程, 2013, 30(2):182-184, 196.CUI Xiliang, TIAN Biao, WANG Yongguo. Carbon fiber reinforced plastic drilling defect analysis[J]. Journal of Mechanical & Electrical Engineering,2013,30(2):182-184, 196(in Chinese). [45] 魏莹莹. 碳纤维增强复合材料孔加工缺陷产生机理、评价与工艺优化研究[D]. 上海: 上海交通大学, 2016.WEI Yingying. The drilling defects machanism, evaluation methodand process optimization on carbon fiber reinforced polymer[D]. Shanghai: Shanghai Jiao Tong University, 2016(in Chinese). [46] HOCHENG H, DHARAN C K H. Delamination during drilling in composite laminates[J]. Journal of Engineering for Industry,1990,112(3):236-239. doi: 10.1115/1.2899580 [47] TSAO C C, CHIU Y C. Evaluation of drilling parameters on thrust force in drilling carbon fiber reinforced plastic (CFRP) composite laminates using compound core-special drills[J]. International Journal of Machine Tools and Manufacture,2011,51(9):740-744. doi: 10.1016/j.ijmachtools.2011.05.004 [48] GIROT F, DAU F, GUTIÉRREZ-ORRANTIA M E. New analytical model for delamination of CFRP during drilling[J]. Journal of Materials Processing Technology,2017,240:332-343. doi: 10.1016/j.jmatprotec.2016.10.007 [49] 朱萍玉, 李永敬, 孙孝鹏, 等. 纤维增强复合材料制孔分层缺陷检测与评价技术研究进展[J]. 中国测试, 2018, 44(1):1-8.ZHU Pingyu, LI Yongjing, SUN Xiaopeng, et al. Research progress on detection and evaluation technology of drilling delamination defect for fiber reinforced plastic[J]. China Measurement,2018,44(1):1-8(in Chinese). [50] CHEN W C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates[J]. International Journal of Machine Tools and Manufacture,1997,37(8):1097-1108. doi: 10.1016/S0890-6955(96)00095-8 [51] FARAZ A, BIERMANN D, WEINERT K. Cutting edge rounding: An innovative tool wear criterion in drilling CFRP composite laminates[J]. International Journal of Machine Tools and Manufacture,2009,49(15):1185-1196. doi: 10.1016/j.ijmachtools.2009.08.002 [52] ZARIF KARIMI N, HEIDARY H, MINAK G, et al. Effect of the drilling process on the compression behavior of glass/epoxy laminates[J]. Composite Structures,2013,98:59-68. doi: 10.1016/j.compstruct.2012.10.044 [53] TSAO C C, KUO K L, HSU I C. Evaluation of a novel approach to a delamination factor after drilling composite laminates using a core-saw drill[J]. The International Journal of Advanced Manufacturing Technology,2012,59(5):617-622. doi: 10.1007/s00170-011-3532-y [54] DURAO L M P, TAVARES J M R S, DE ALBUQUERQUE V H C, et al. Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods[J]. Composite structures,2013,96:576-583. doi: 10.1016/j.compstruct.2012.08.003 [55] 魏莹莹, 安庆龙, 蔡晓江, 等. 碳纤维复合材料超声扫描分层检测及评价方法[J]. 航空学报, 2016, 37(11):3512-3519.WEI Yingying, AN Qinglong, CAI Xiaojiang, et al. CFRP ultrasonic scan delamination detection and evaluation method[J]. Chinese Journal of Aeronautics,2016,37(11):3512-3519(in Chinese). [56] 汪海晋. 树脂基复合材料钻削缺陷产生机理与控制策略研究[D]. 济南: 山东大学, 2016.WANG Haijin. Investigation on generation mechanism and control strategyof defect in drilling of resin-based composite materials[D]. Jinan: Shandong University, 2016(in Chinese). [57] 王健健. 陶瓷基复合/硬脆材料旋转超声制孔损伤机理与抑制策略[D]. 北京: 清华大学, 2017.WANG Jianjian. Damage formation mechanism andsuppression methods in rotary ultrasonic drilling of hard and brittle materials & ceramic matrix composites[D]. Beijing: Tsinghua University, 2017(in Chinese). [58] 鲍永杰. C/E复合材料制孔缺陷成因与高效制孔技术[D]. 大连: 大连理工大学, 2010.BAO Yongjie. The formation mechanism of disfigurements during drilling and the high-efficiency techniques of drilling C/E composite[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [59] 徐九华, 牟娟, 陈燕, 等. 钎焊金刚石套料钻CFRP制孔研究[J]. 南京航空航天大学学报, 2012, 44(5):747-753. doi: 10.3969/j.issn.1005-2615.2012.05.022XU Jiuhua, MU Juan, CHEN Yan, et al. Analys is on CFRP hole making with brazed diamond core drill[J]. Journal of Nanjing University of Aeronautics,2012,44(5):747-753(in Chinese). doi: 10.3969/j.issn.1005-2615.2012.05.022 [60] 周井文, 陈燕, 傅玉灿, 等. 纤维切削角对CFRP加工缺陷的影响规律[J]. 哈尔滨工业大学学报, 2015, 47(7):110-116.ZHOU Jingwen, CHEN Yan, FU Yucan, et al. Influence of fiber cutting angle on the machining defects during slotting of CFRP[J]. Journal of Harbin Institute of Technology,2015,47(7):110-116(in Chinese). [61] 张厚江. 碳纤维复合材料(CFRP)钻削加工技术的研究[D]. 北京: 北京航空航天大学, 1998.ZHANG Houjiang. Study on the drilling technology of CFRP[D]. Beijing: Beihang University, 1998(in Chinese). [62] 李桂玉. 叠层复合材料钻削加工缺陷产生机理及工艺参数优化[D]. 济南: 山东大学, 2011.LI Guiyu. Research on defects generation mechanism and process optimization in drilling laminated composite[D]. Jinan: Shandong University, 2011(in Chinese). [63] 鲍永杰. 碳纤维增强复合材料钻削的若干研究[D]. 大连: 大连理工大学, 2006.BAO Yongjie. Some researches on drilling carbon fiber reinforced composites[D]. Dalian: Dalian University of Technology, 2006(in Chinese). [64] GRILO T J, PAULO R M F, SILVA C R M, et al. Experimental delamination analyses of CFRPs using different drill geometries[J]. Composites Part B: Engineering,2013,45(1):1344-1350. doi: 10.1016/j.compositesb.2012.07.057 [65] 刘雪梅, 孙会来, 贺龙宇, 等. CFRP制孔技术的研究现状与发展趋势[J]. 玻璃钢/复合材料, 2018(3):101-106. doi: 10.3969/j.issn.1003-0999.2018.03.017LIU Xuemei, SUN Huilai, HE Longyu, et al. Research status and development trend of CFRP drilling technology[J]. Fiber Reinforced Plastics/Composites,2018(3):101-106(in Chinese). doi: 10.3969/j.issn.1003-0999.2018.03.017 [66] DAVIM J P, REIS P, ANTÓNIO C C. Experimental study of drilling glass fiber reinforced plastics (GFRP) manufactured by hand lay-up[J]. Composites Science and Technology,2004,64(2):289-297. doi: 10.1016/S0266-3538(03)00253-7 [67] PALANIKUMAR K, KARUNAMOORTHY L, KARTHIKEYAN R. Assessment of factors influencing surface roughness on the machining of glass fiber-reinforced polymer composites[J]. Materials & Design,2006,27(10):862-871. doi: 10.1016/j.matdes.2005.03.011 [68] PERSSON E, ERIKSSON I, ZACKRISSON L. Effects of hole machining defects on strength and fatigue life of composite laminates[J]. Composites Part A: Applied Science and Manufacturing,1997,28(2):141-151. doi: 10.1016/S1359-835X(96)00106-6 [69] 赵冬. C/E复合材料制孔缺陷分析与评价方法研究[D]. 大连: 大连理工大学, 2010.ZHAO Dong. Study on drilling damages and evaluation method of carbon/epoxy composite[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [70] WANG J, ZHANG J, FENG P. Effects of tool vibration on fiber fracture in rotary ultrasonic machining of C/SiC ceramic matrix composites[J]. Composites Part B: Engi-neering,2017,129:233-242. doi: 10.1016/j.compositesb.2017.07.081 [71] XING Y, DENG J, ZHANG G, et al. Assessment in drilling of C/C-SiC composites using brazed diamond drills[J]. Journal of Manufacturing Processes,2017,26:31-43. doi: 10.1016/j.jmapro.2017.01.006 [72] BHATNAGAR N, RAMAKRISHNAN N, NAIK N K, et al. On the machining of fiber reinforced plastic (FRP) composite laminates[J]. International Journal of Machine Tools and Manufacture,1995,35(5):701-716. doi: 10.1016/0890-6955(95)93039-9 [73] TSAO C C. Taguchi analysis of drilling quality associated with core drill in drilling of composite material[J]. The International Journal of Advanced Manufacturing Technology,2007,32(9-10):877-884. doi: 10.1007/s00170-006-0414-9 [74] RAWAT S, ATTIA H. Characterization of the dry high speed drilling process of woven composites using machinability maps approach[J]. CIRP Annals,2009,58(1):105-108. doi: 10.1016/j.cirp.2009.03.100 [75] LIU D, TANG Y, CONG W L. A review of mechanical drilling for composite laminates[J]. Composite Structures,2012,94(4):1265-1279. doi: 10.1016/j.compstruct.2011.11.024 [76] QUAN Y, ZHONG W. Investigation on drilling-grinding of CFRP[J]. Frontiers of Mechanical Engineering in China,2009,4(1):60-63. doi: 10.1007/s11465-009-0008-y [77] SHEIKH-AHMAD J, MOHAMMED J. Optimization of process parameters in diamond abrasive machining of carbon fiber-reinforced epoxy[J]. Materials and Manufacturing Processes,2014,29(11-12):1361-1366. doi: 10.1080/10426914.2014.941869 [78] 牟娟, 陈燕, 徐九华, 等. 不同粒度的金刚石套料钻钻削碳纤维复合材料时对轴向力及出入口质量的影响[J]. 金刚石与磨料磨具工程, 2012, 32(6):15-19.MU Juan, CHEN Yan, XU Jiuhua, et al. Study on drilling thrust force and quality of exit and entrance in drilling carbonfiber reinforced plastics with brazed diamond core drills of different grain sizes[J]. Diamond & Abrasives Engineering,2012,32(6):15-19(in Chinese). [79] 冯平法, 王健健, 张建富, 等. 硬脆材料旋转超声加工技术的研究现状及展望[J]. 机械工程学报, 2017, 53(19):3-21. doi: 10.3901/JME.2017.19.003FENG Pingfa, WANG Jianjian, ZHANG Jianfu, et al. Research status and future prospects of rotary ultrasonic machining of hard and brittle materials[J]. Journal of Mechanical Engineering,2017,53(19):3-21(in Chinese). doi: 10.3901/JME.2017.19.003 [80] LV D, CHEN M, YAO Y, et al. High-frequency vibration effects on the hole integrity in rotary ultrasonic drilling of carbon fiber-reinforced plastic composites[J]. Ultrasonics,2021,115:106448. doi: 10.1016/j.ultras.2021.106448 [81] MAKHDUM F, JENNINGS L, ROY A, et al. Cutting forces in ultrasonically assisted drilling of carbon fibre-reinforced plastics[J]. Journal of Physics: Conference Series,2012,382:012019. doi: 10.1088/1742-6596/382/1/012019 [82] SANDA A, ARRIOLA I, GARCIA NAVAS V, et al. Ultrasonically assisted drilling of carbon fibre reinforced plastics and Ti6Al4V[J]. Journal of Manufacturing Processes,2016,22:169-176. doi: 10.1016/j.jmapro.2016.03.003 [83] BABITSKY V I, ASTASHEV V K, MEADOWS A. Vibration excitation and energy transfer during ultrasonically assisted drilling[J]. Journal of Sound and Vibration,2007,308(3):805-814. doi: 10.1016/j.jsv.2007.03.064 [84] THOMAS P N H, BABITSKY V I. Experiments and simulations on ultrasonically assisted drilling[J]. Journal of Sound and Vibration,2007,308(3):815-830. doi: 10.1016/j.jsv.2007.03.081 [85] NING F D, CONG W L, PEI Z J, et al. Rotary ultrasonic machining of CFRP: A comparison with grinding[J]. Ultrasonics,2016,66:125-132. doi: 10.1016/j.ultras.2015.11.002 [86] FENG Q, CONG W L, PEI Z J, et al. Rotary ultrasonic machining of carbon fiber-reinforced polymer: Feasibility study[J]. Machining Science and Technology,2012,16(3):380-398. doi: 10.1080/10910344.2012.698962 [87] GENG D, TENG Y, LIU Y, et al. Experimental study on drilling load and hole quality during rotary ultrasonic helical machining of small-diameter CFRP holes[J]. Journal of Materials Processing Technology,2019,270:195-205. doi: 10.1016/j.jmatprotec.2019.03.001 [88] 顾钒. 基于工业机器人的陶瓷基复合材料旋转超声制孔关键技术研究[D]. 杭州: 浙江大学, 2020.GU Fan. Study on key techniques of rotary ultrasonic machining of ceramic matrix com posite based on industrial robot[D]. Hangzhou: Zhejiang University, 2020(in Chinese). [89] SULTANA I, SHI Z, ATTIA H, et al. A new hybrid oscillatory orbital process for drilling of composites using superabrasive diamond tools[J]. CIRP Annals,2016,65(1):141-144. doi: 10.1016/j.cirp.2016.04.049 [90] GAO Y, XIONG J, XIAO J, et al. A tilted orbital grinding technique for hole-making of CFRP composite laminates[J]. The International Journal of Advanced Manufacturing Technology,2019,104(1):661-673. doi: 10.1007/s00170-019-03904-x [91] TSAO C C, HOCHENG H. Parametric study on thrust force of core drill[J]. Journal of Materials Processing Technology,2007,192-193:37-40. doi: 10.1016/j.jmatprotec.2007.04.062 [92] QUAN Y M, LIANG L, ZHONG W W. The experimental research on small hole machining in glass using diamond abrasive core-tools[J]. Advanced Materials Research,2009,76-78:491-496. doi: 10.4028/www.scientific.net/AMR.76-78.491 [93] 李泽印, 陈建毅, 黄辉, 等. 钎焊金刚石薄壁钻加工工程陶瓷的试验研究[J]. 工具技术, 2006(9):10-12. doi: 10.3969/j.issn.1000-7008.2006.09.003LI Zeyin, CHEN Jianyi, HUANG Hui, et al. Experimental investigation on drilling of engineering ceramics with brazed diamond thin-wall drill[J]. Tool Engineering,2006(9):10-12(in Chinese). doi: 10.3969/j.issn.1000-7008.2006.09.003 [94] 伍俏平, 赵恒, 王煜, 等. 纤维增强复合材料制孔刀具研究现状与展望[J]. 兵器材料科学与工程, 2018, 41(6):113-118.WU Qiaoping, ZHAO Heng, WANG Yu, et al. Research status and perspectives of cutting tools for drilling fibre reinforced composites[J]. Ordnance Material Science and Engineering,2018,41(6):113-118(in Chinese). [95] 高航, 袁和平. 碳纤维复合材料构件干磨削砂轮研制及其加工性能研究[J]. 兵工学报, 2011, 32(2):186-191.GAO Hang, YUAN Heping. Development of a wheel for dry grinding of CFRP parts and investigation on its machining performance[J]. Acta Armamentarii,2011,32(2):186-191(in Chinese). [96] 孙亮. 钎焊金刚石磨粒刀具的修整及对CFRP加工质量的影响[D]. 南京: 南京航空航天大学, 2020.SUN Liang. Dressing of brazed diamond a brasive tooland its effect on CFRP machining quality[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020(in Chinese). [97] 孙巧如, 刘晓东, 王天晨, 等. 纤维增强复合材料钻削加工技术研究现状[J]. 玻璃钢/复合材料, 2017(9):101-105.SUN Qiaoru, LIU Xiaodong, WANG Tianchen, et al. Current status on drilling technology of fiber reinforced composites[J]. Fiber Reinforced Plastics/Composites,2017(9):101-105(in Chinese). [98] 李凤全. 碳纤维复合材料制孔缺陷及对策的试验研究[D]. 大连: 大连理工大学, 2008.LI Fengquan. Study on the drilled disfigure of carbon fiber reinforced plastics and its countermeasures[D]. Dalian: Dalian University of Technology, 2008(in Chinese). [99] 赵桐. 陶瓷基复合材料异型孔槽加工技术研究[D]. 大连: 大连理工大学, 2015.ZHAO Tong. Study on the machining technology of non-conventional holes and pockets for ceramic matrix composites[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [100] 张红哲, 何文豪, 朱晓春, 等. T800级碳纤维复合材料螺旋铣磨制孔工艺研究[J]. 工具技术, 2021, 55(7):66-70. doi: 10.3969/j.issn.1000-7008.2021.07.012ZHANG Hongzhe, HE Wenhao, ZHU Xiaochun, et al. Study on lightweight spiral milling technology of high strength carbon fiber composites[J]. Tool Engineering,2021,55(7):66-70(in Chinese). doi: 10.3969/j.issn.1000-7008.2021.07.012 [101] 朱学明, 许松岭, 李占杰, 等. 玻璃纤维复合材料钻削轴向力与分层分析[J]. 宇航材料工艺, 2021, 51(1):60-67.ZHU Xueming, XU Songling, LI Zhanjie, et al. Analysis of drilling axial force and delamination during drilling of glass fiber reinforced plastic[J]. Aerospace Materials and Technology,2021,51(1):60-67(in Chinese). [102] TETI R. Machining of composite materials[J]. CIRP Annals,2002,51(2):611-634. doi: 10.1016/S0007-8506(07)61703-X [103] 张健, 李鑫, 徐琦, 等. 钎焊金刚石工具失效机理及其抑制策略研究进展[J]. 材料导报, 2022, 36(15):36-42.ZHANG Jian, LI Xin, XU Qi, et al. Research progress on failure mechanisms and its inhibition strategies of brazed diamond tools[J]. Materials Reports,2022,36(15):36-42(in Chinese). [104] 张辉. 复合装甲制孔机理与工艺参数优化[D]. 济南: 山东大学, 2019.ZHANG Hui. Mechanism of composite armor holes makingand optimization of process parameters[D]. Ji'nan: Shandong University, 2019(in Chinese). [105] 陈玉荣, 苏宏华, 傅玉灿, 等. 超声振动辅助干式钻削SiCf/SiC陶瓷基复合材料试验研究[J]. 航空制造技术, 2018, 61(21):47-51. doi: 10.16080/j.issn1671-833x.2018.21.047CHEN Yurong, SU Honghua, FU Yucan, et al. Experimental study on ultrasonic vibration assisted dry drilling for SiCf/SiC ceramic matrix composites[J]. Aeronautical Manufacturing Technology,2018,61(21):47-51(in Chinese). doi: 10.16080/j.issn1671-833x.2018.21.047 [106] WEINERT K, JANSEN T. Machining aspects for the drilling of C/C-SiC materials[M].Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA, 2008: 287-301. -

下载:

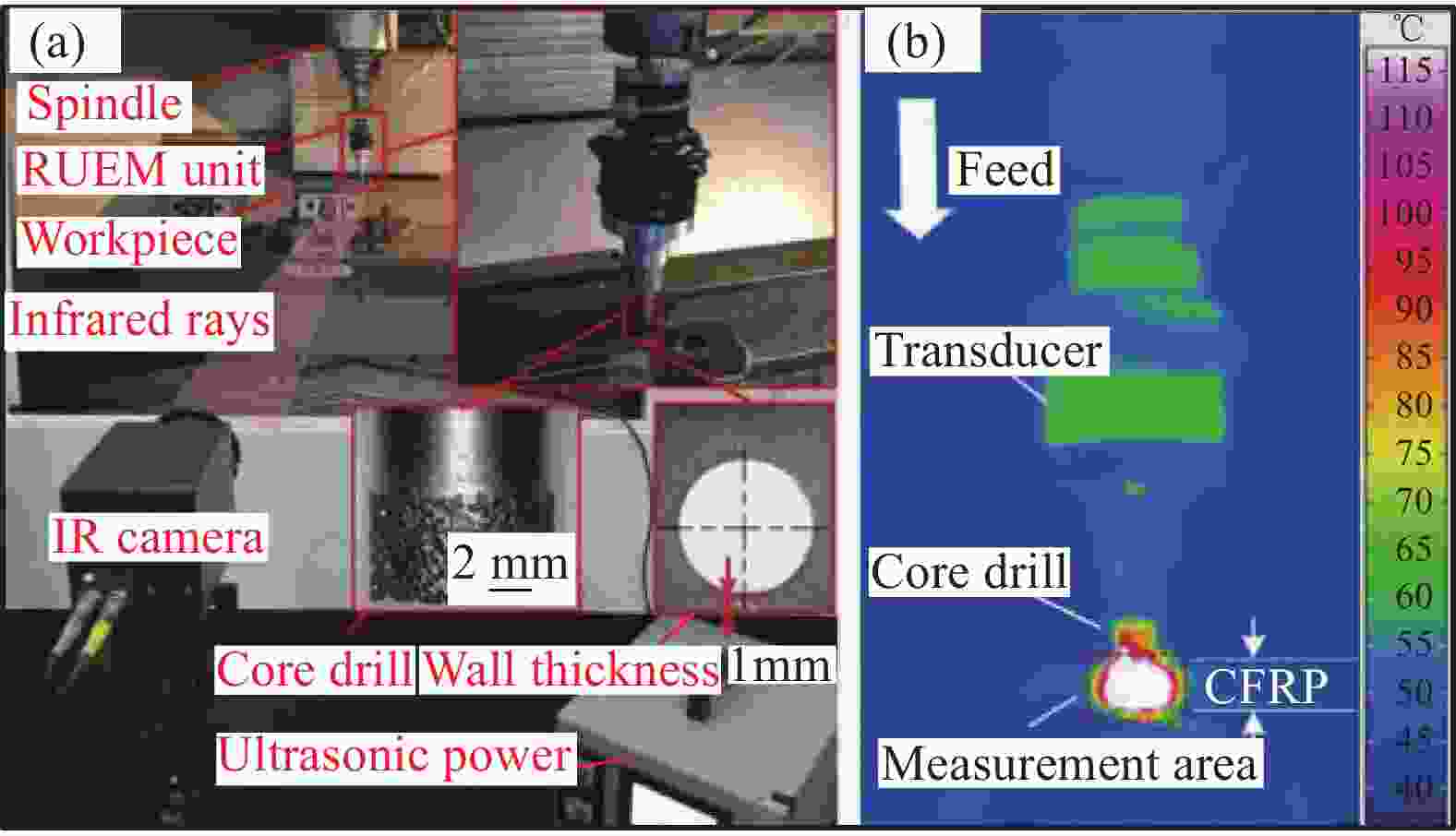

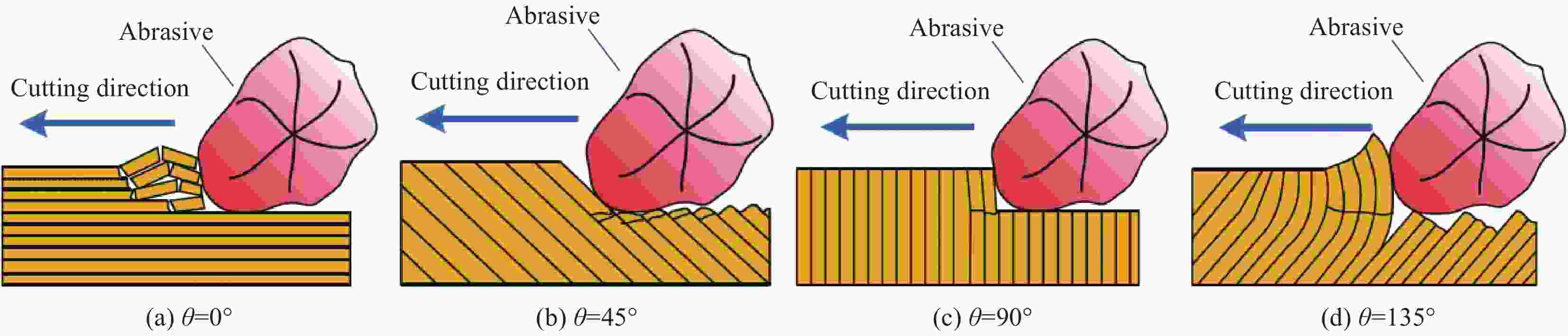

下载: