Interface connection mechanism and fracture behavior of nickel-based composites fabricated by selective laser melting

-

摘要: 基于颗粒增强镍基复合材料优异的结构/功能特性,在航空航天、核电军工和电子电工等领域有着广泛的应用前景。本文选用机械球磨混粉+激光选区熔化方法(SLM)制备了碳化钨(WC)颗粒增强IN718复合材料(WC/IN718),对复合材料内部异质界面连接机制、强化机制和断裂行为进行了分析。研究结果表明:随着WC颗粒含量的增加(0wt%~20wt%),试件成形良好,WC颗粒均匀分布在基体内部,异质界面处无缺陷产生,界面处产生了贫碳的W2C层和碳化物层,基体合金主要呈柱状晶生长。由于熔池内部能量密度分布不同,低温位置WC颗粒的断裂方式为先形成界面反应层后由热应力引起断裂,高温位置WC颗粒优先发生断裂,断裂成小尺寸颗粒,后与熔化的基体合金形成界面反应层,弥散分布在基体内部。随着WC颗粒含量的增加,复合材料的强度呈现升高的趋势,而断裂韧性降低,抗拉强度最高可达1280 MPa,强化机制主要为载荷传递强化,断裂机制为WC颗粒的脆性断裂和基体合金的韧性断裂。

-

关键词:

- WC/IN718复合材料 /

- 异质界面连接 /

- 断裂机制 /

- 强化机制 /

- 颗粒增强镍基复合材料

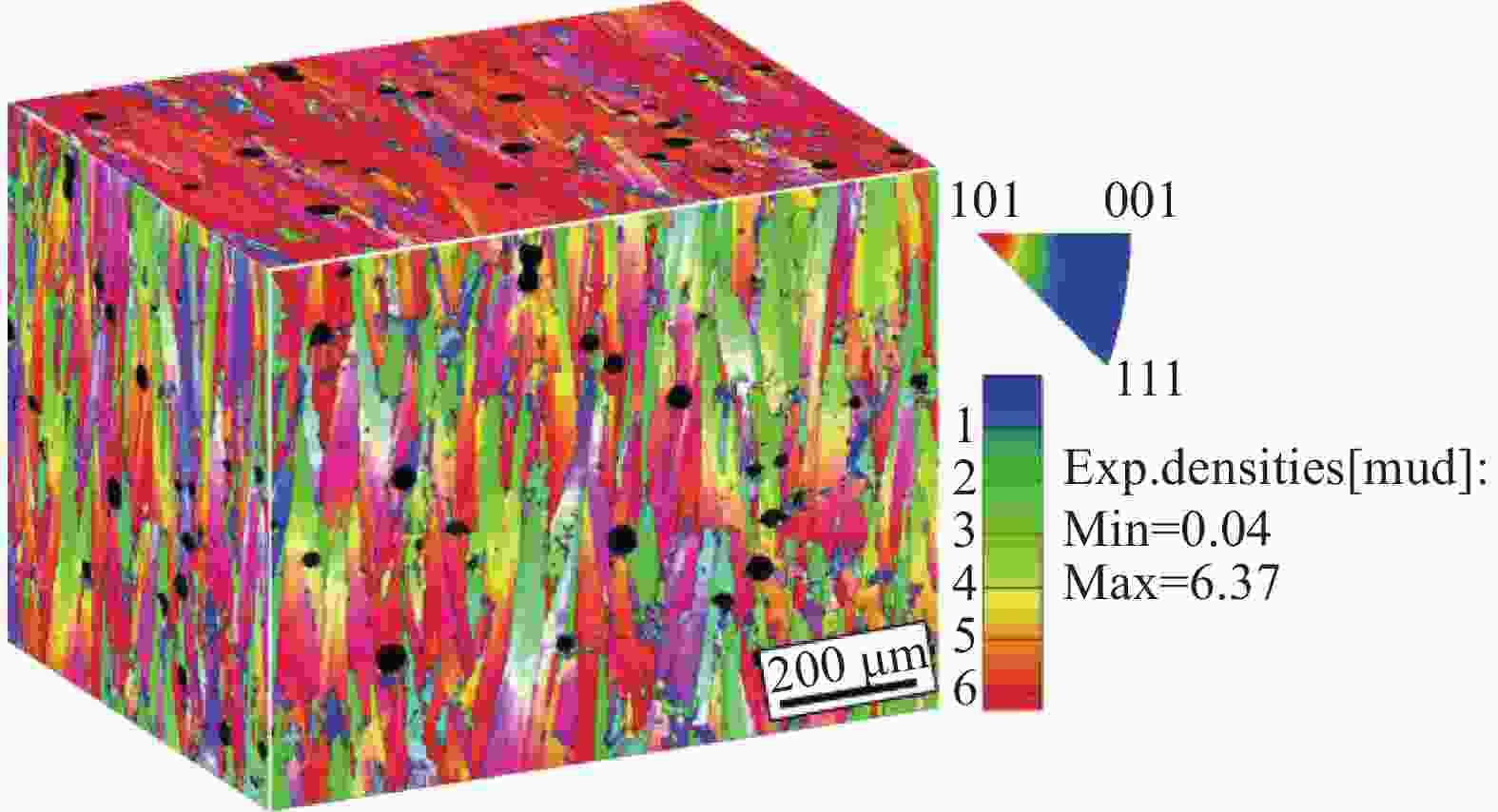

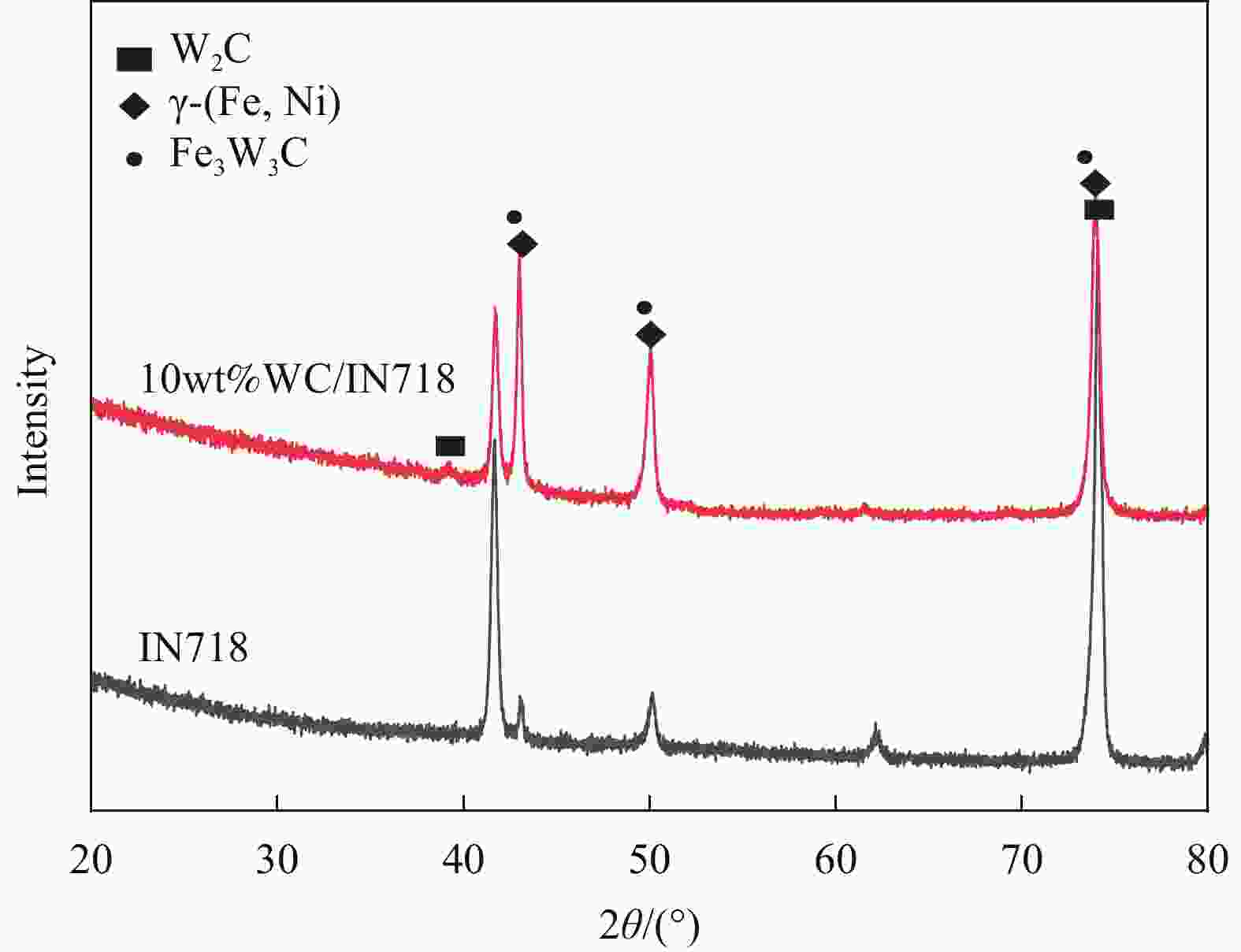

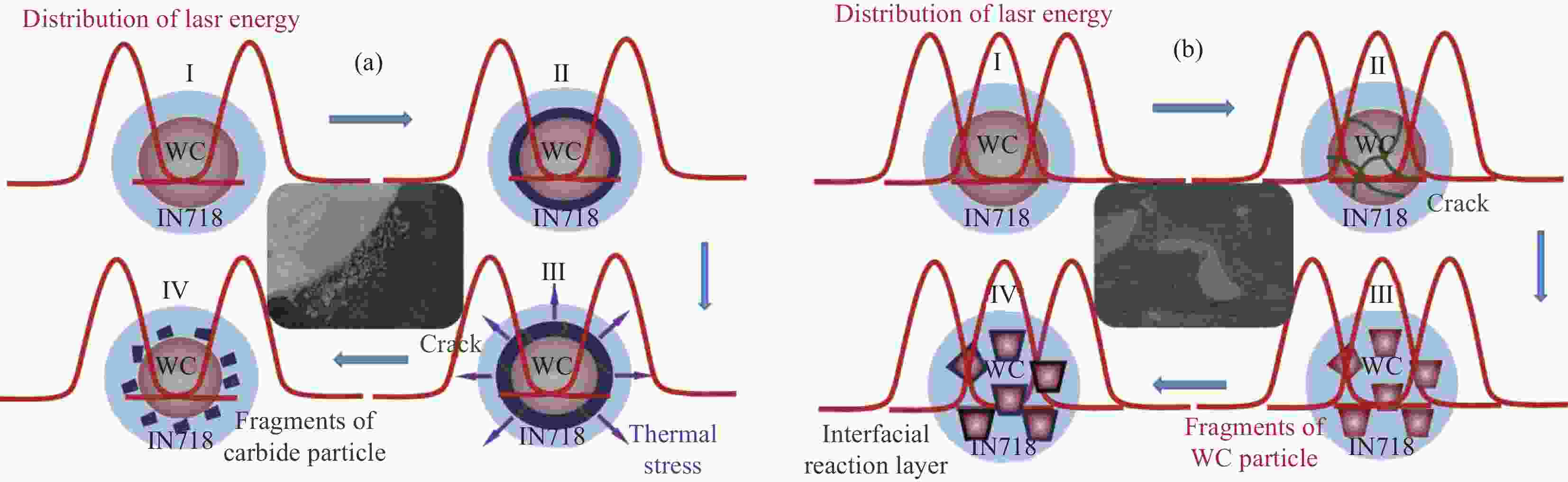

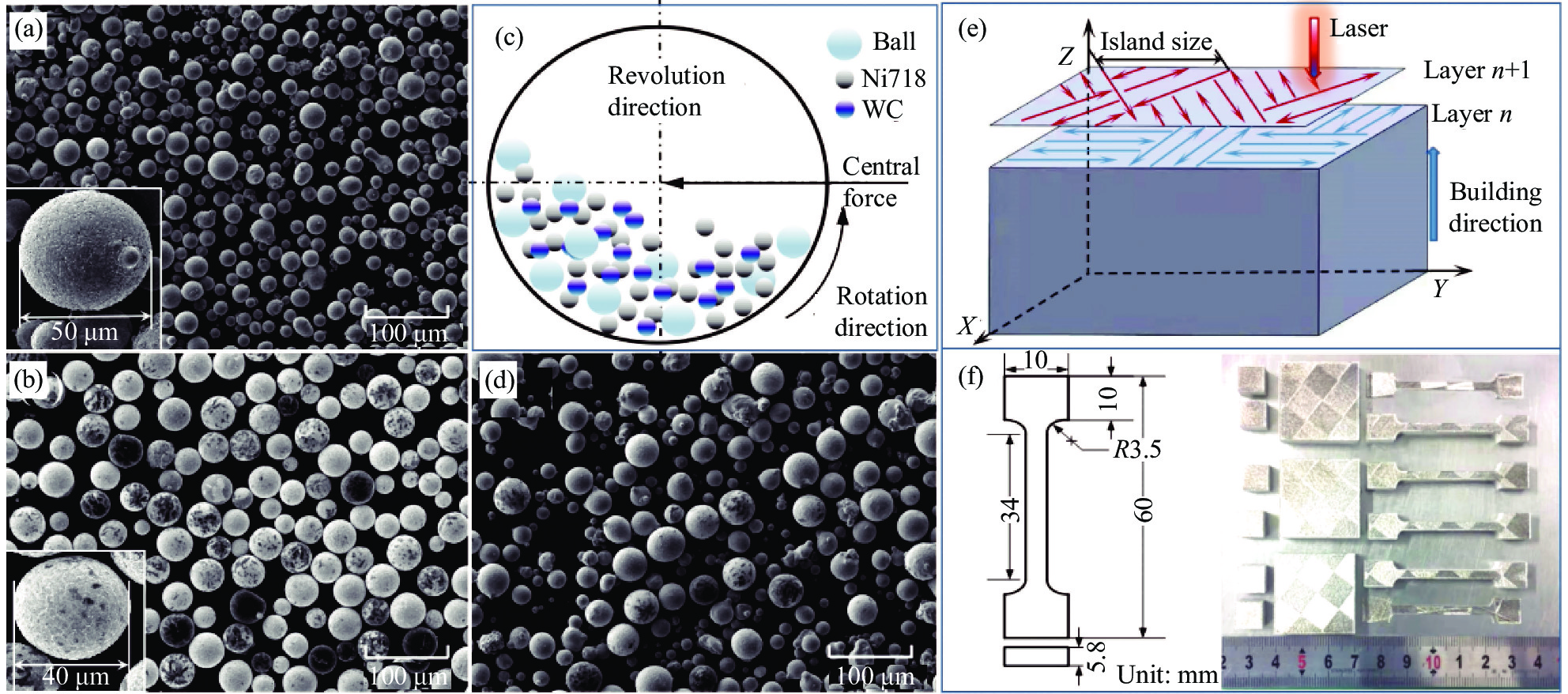

Abstract: Based on the excellent structural/functional properties of particle-reinforced nickel-based composites, they have a wide application prospects in aerospace, nuclear power, military industry and electronics. The internal heterogeneous interface connection mechanism, reinforcement mechanism and fracture behavior of the tungsten carbide (WC) particle-reinforced IN718 composites (WC/IN718) prepared by using the mechanical ball grinding powder+selective laser melting (SLM) was analyzed. The results show that with the increase of WC particles content (0wt%-20wt%), the specimen is well-formed, WC particles are evenly distributed inside the matrix and no defects at the heterogeneous interface, carbon-poor W2C layer and carbide layer are produced at the interface, and the matrix alloy mainly grows at the form of columnar crystals. Due to the different energy density distribution within the melting pool, the fracture mode of WC particles at the low temperature position is that firstly the interface reaction layer form at the periphery of WC particle and then WC are fractured by thermal stress. However, WC particles at the high temperature position preferentially break into small particles in size, and then the interface reaction layer is formed with the molten matrix alloy, which is distributed within the matrix. As the content of WC particles increases, the strength of composites tends to increase, while the fracture toughness is reduced, and the tensile strength can be up to 1280 MPa. The reinforcement mechanism is mainly the load transfer effect, the fracture mechanism is the brittle fracture of WC particles and the toughness fracture of matrix alloy. -

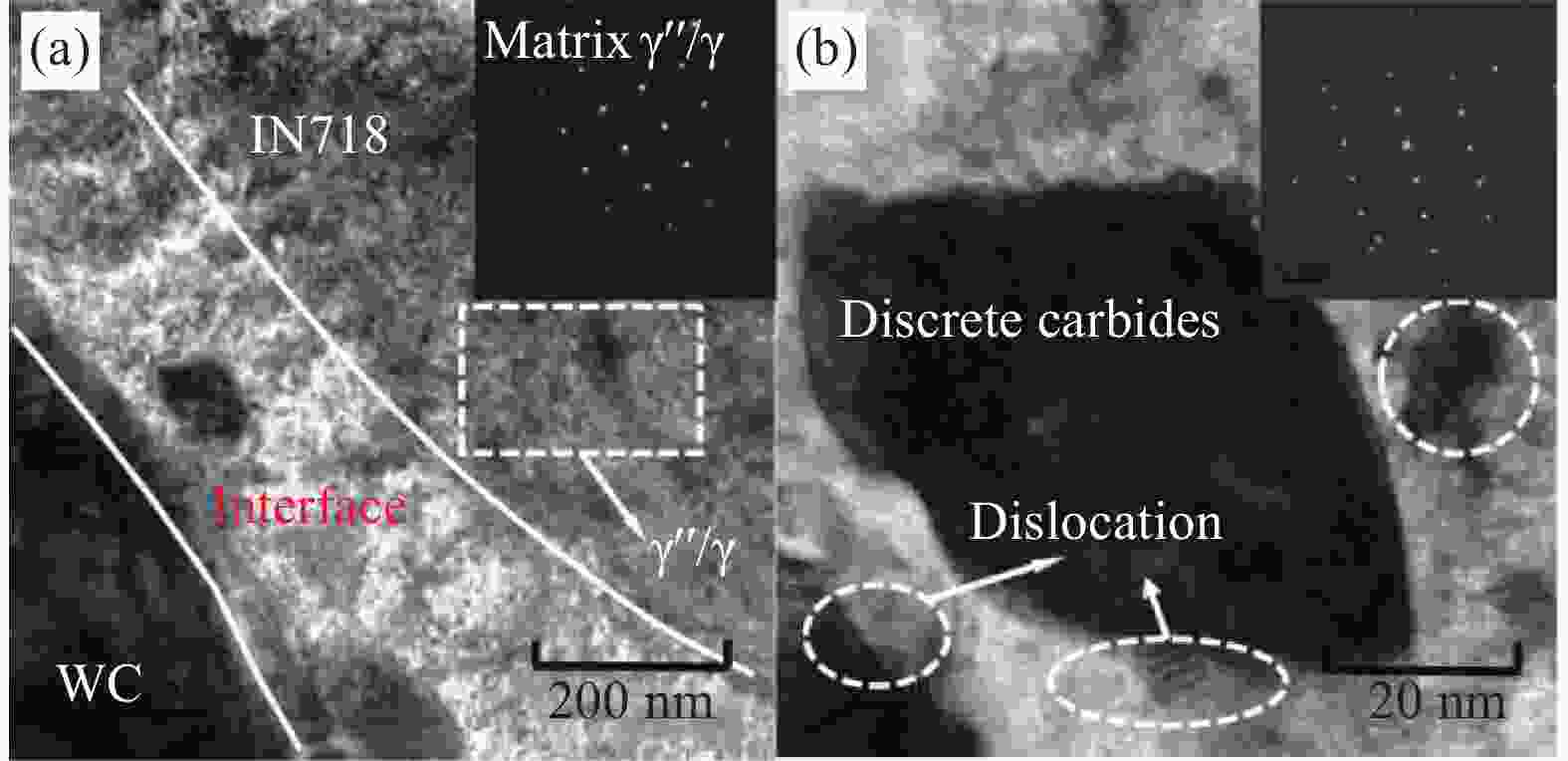

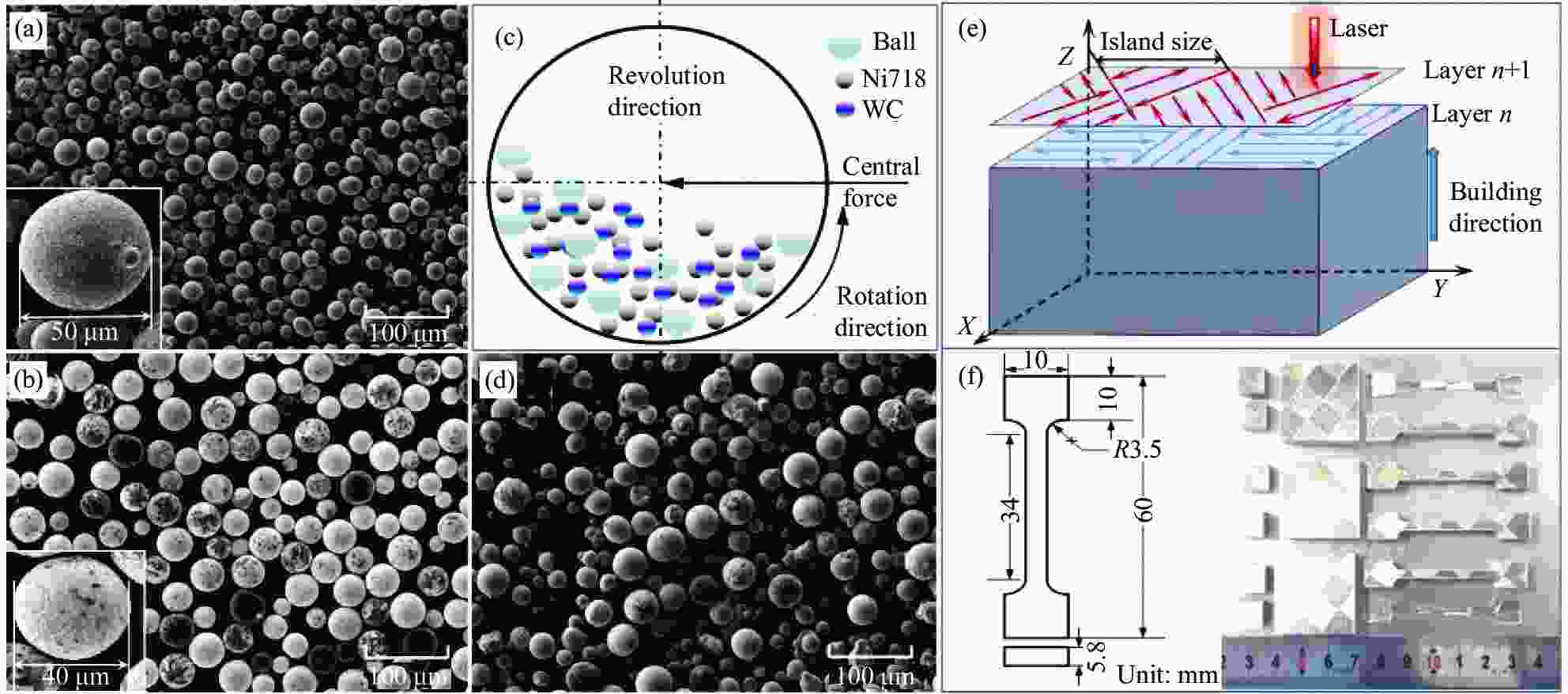

图 1 IN718 (a)、球形碳化钨(WC) (b) 的SEM图像;(c) 异种粉末球磨混合示意图;(d) 20wt%WC/IN718混合粉末的SEM图像;(e) 激光选区熔化法(SLM)路径扫描示意图;(f) 打印的成型件宏观形貌图

Figure 1. SEM images of IN718 (a), spherical tungsten carbide (WC) (b); (c) Heterologous powder ball grinding mixing diagram; (d) SEM image of 20wt%WC/IN718 composites powder by mixing; (e) Illustration of selective laser melting (SLM) scanning path; (f) Macro topography of fabricated composites part

n—Layer; R—Radius

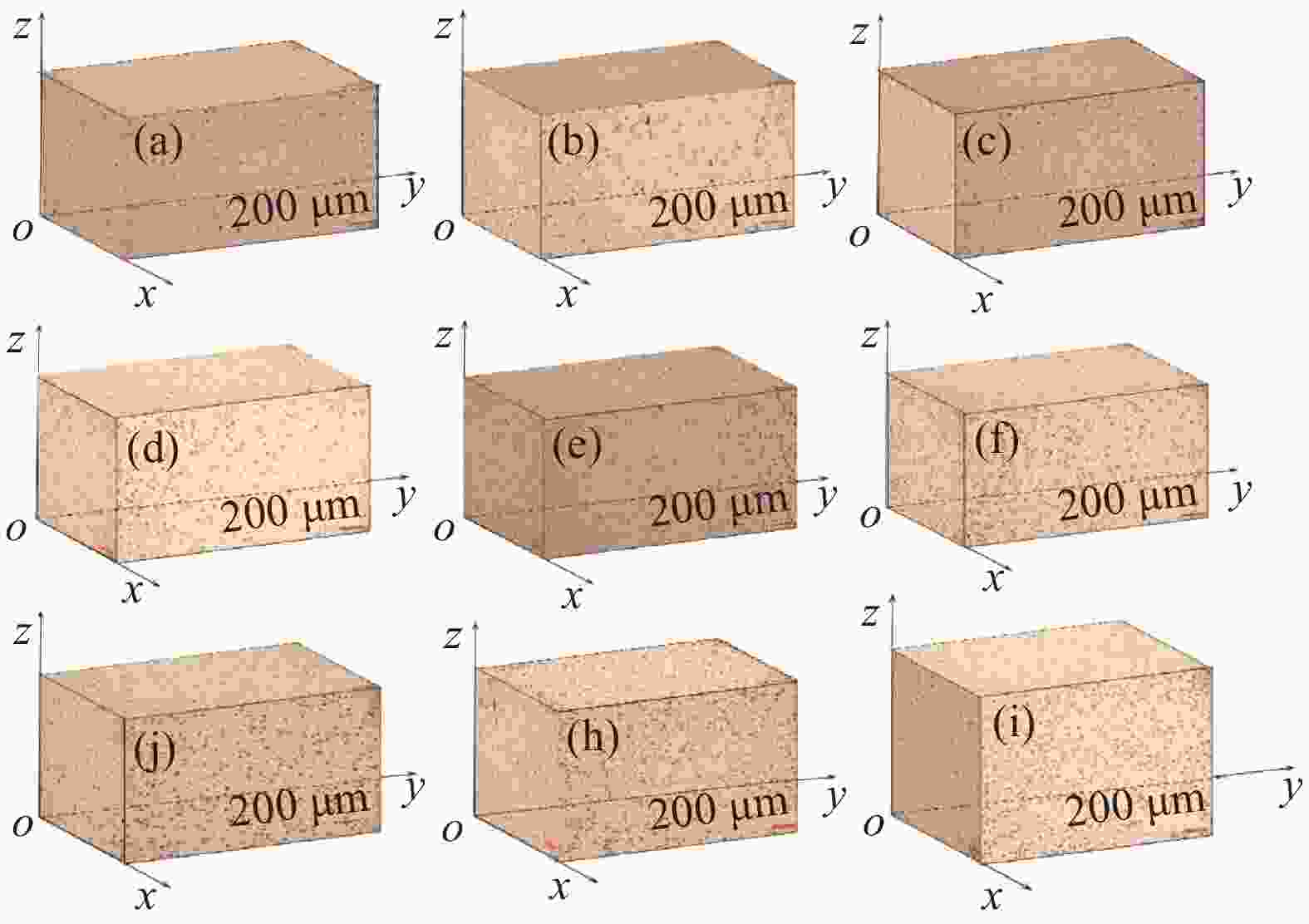

图 2 不同工艺参数下SLM增材制造WC/IN718复合材料金相组织:10%WC/IN718:(a) 190 W;(b) 200 W;(c) 210 W;15%WC/IN718:(d) 190 W;(e) 200 W;(f) 210 W;20%WC/IN718:(j) 190 W;(h) 200 W;(i) 210 W

Figure 2. Microstructures of WC/IN718 composites fabricated by SLM under different process parameters: 10%WC/IN718: (a) 190 W; (b) 200 W; (c) 210 W; 15%WC/IN718: (d) 190 W; (e) 200 W; (f) 210 W; 20%WC/IN718: (j) 190 W; (h) 200 W; (i) 210 W

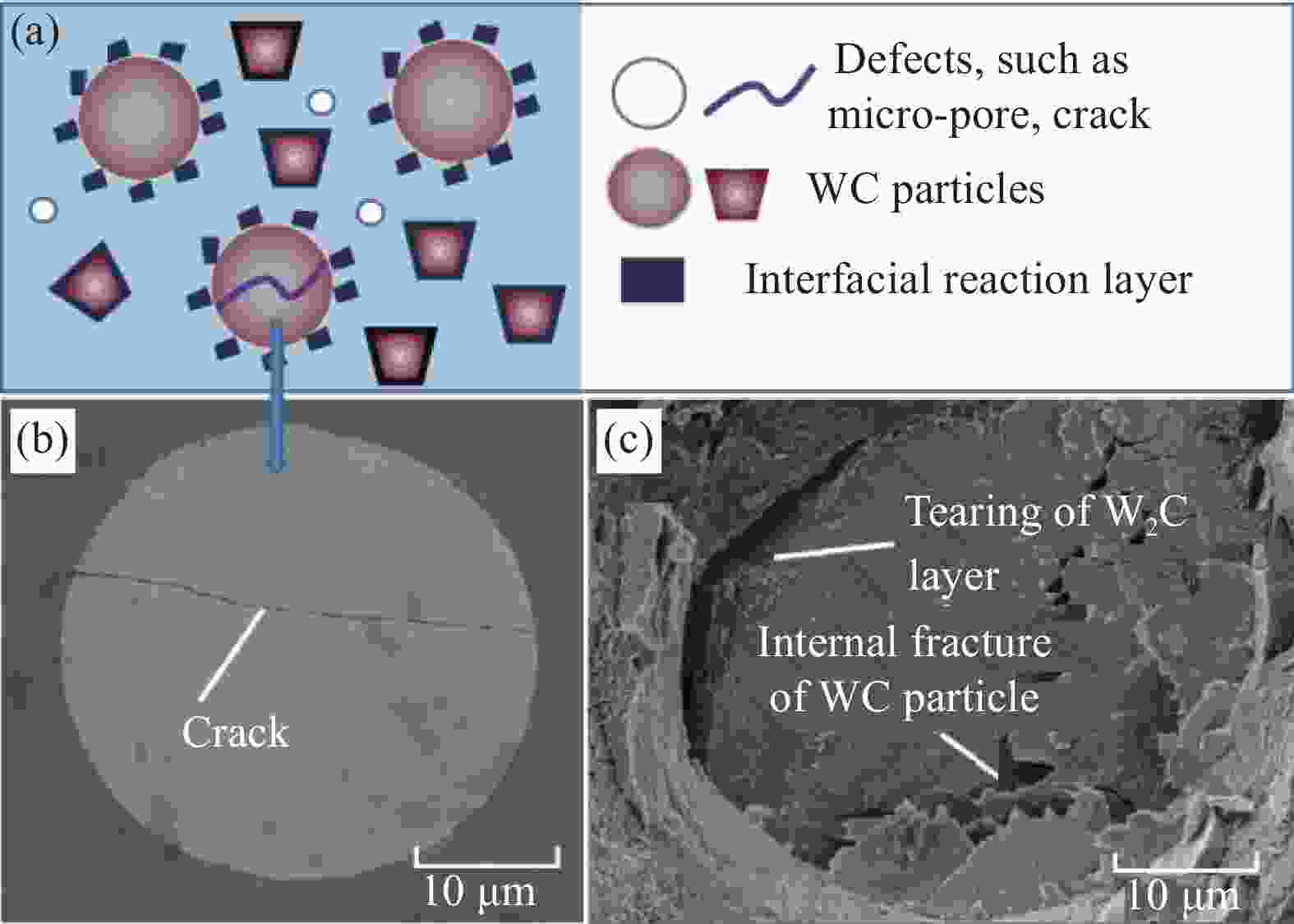

图 6 10wt%WC/IN718复合材料SEM图像:(a) WC颗粒与IN718基体熔融结合界面;(b) 结合界面局部放大图;(c)界面的EDS面扫描图谱;(d)界面的EDS线扫描图谱;(e)图6(b)中界面标定点的EDS点扫描图谱

Figure 6. SEM image of 10wt%WC/IN718 composite: (a) Fusion binding interface between WC particles and IN718 matrix; (b) Local magnification plot of the binding interface; (c) EDS surface scan map of the interface; (d) EDS line scan map of the interface; (e) EDS point scan map of the calibration points in Fig.6 (b)

表 1 球形WC颗粒的化学成分

Table 1. Chemical composition of spherical WC particles

wt% W C Fe Cr Ti Nb Free C Balance 3.90 0.35 0.03 0.03 0.02 0.002 表 3 激光加工基本参数

Table 3. Basic parameters of laser processing

Parameter of the laser Value Laser power P/W 190, 200, 210 Scanning speed v/(mm·s−1) 1000 Thickness t/mm 0.03 Scanning interval h/mm 0.05 表 2 IN718合金的化学成分

Table 2. Chemical composition of IN718 alloy

wt% Ni Cr Nb Mo Ti Co C Al Fe 52 19 5.5 2.5 0.8 0.9 0.05 0.5 Bal -

[1] LI C, CHANG K, YEH A, et al. Microstructure characterization of cemented carbide fabricated by selective laser melting process[J]. International Journal of Refractory Metals and Hard Materials,2018,75:225-233. doi: 10.1016/j.ijrmhm.2018.05.001 [2] TANJA T, JOHANNES S, RAINER V, et al. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting[J]. Materials Letters,2016,164:428-431. doi: 10.1016/j.matlet.2015.10.136 [3] SONG J, GUO Q, OUYANG Q, et al. Influence of interfaces on the mechanical behavior of SiC particulate-reinforced Al-Zn-Mg-Cu composites[J]. Materials Science and Engi-neering: A,2015,644:79-84. doi: 10.1016/j.msea.2015.07.050 [4] DENG L, BAI C, JIANG Z, et al. Effect of B4C particles addition on microstructure and mechanical properties of Fe50Mn30Co10Cr10 high-entropy alloy[J]. Materials Science and Engineering: A,2021,822:141642. doi: 10.1016/j.msea.2021.141642 [5] KHORSHID M, JAHROMI S, MOSHKSAR M. Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron-sized Al2O3 particulates developed by wet attrition milling and hot extrusion[J]. Materials & Design, 2010, 31: 3880-3884. [6] ALMANGOUR B, KIM Y, GRZESIAK D, et al. Novel TiB2-reinforced 316 L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing[J]. Composites Part B: Engineering, 2019, 156: 51-63. [7] CHENC, XIE Y, YAN X, et al. Cold sprayed WC reinforced maraging steel 300 composites: Microstructure characterization and mechanical properties[J]. Journal of Alloys and Compounds,2019,785:499-511. [8] 高颖超, 孙书刚, 钱兵, 等. 粉末烧结法和铸造法制备ZrO2增韧Al2O3陶瓷颗粒增强高铬铸铁基复合材料及其耐磨性能[J]. 复合材料学报, 2021, 38(8):2676-2683.GAO Yingchao, SUN Shugang, QIAN Bing, et al. Preparation of ZrO2 toughened Al2O3 ceramic particles with enhanced high chromium cast iron-based composite material fabricated by powder sintering and casting and its wear resistance[J]. Journal of Composite Materials,2021,38(8):2676-2683(in Chinese). [9] 崔照雯, 李敬仁, 李泽洲, 等. 粉末冶金法CNTs、Al2O3双增强铜基复合材料性能研究[J]. 机械工程学报, 2013, 49(18):52-56. doi: 10.3901/JME.2013.18.052CUI Zhaowen, LI Jingren, LI Zezhou, et al. Study on the properties of CNTs and Al2O3 double-enhanced copper-based composite materials[J]. Journal of Mechanical Engineering,2013,49(18):52-56(in Chinese). doi: 10.3901/JME.2013.18.052 [10] 王刚, 徐磊, 崔玉友, 等. TiAl预合金粉末热等静压致密化机制及热处理对微观组织的影响[J]. 金属学报, 2016, 52(9):1079-1088.WANG Gang, XU Lei, CUI Yuyou, et al. Ther-mal isostatic pressure compaction mechanism of TiAl pre-heated alloy powder and the effect of heat treatment on microstructure[J]. Journal of Metals,2016,52(9):1079-1088(in Chinese). [11] 葛福国, 彭倍, 柯文超, 等. 电弧增材制造NiTi形状记忆合金成形与性能[J]. 机械工程学报, 2020, 56(8):99-106. doi: 10.3901/JME.2020.08.099GE Fuguo, PENG Bei, KE Wenchao, et al. Forming and performance of NiTi shape memory alloy fabricated by arc additive manufacturing[J]. Journal of Mechanical Engineering,2020,56(8):99-106(in Chinese). doi: 10.3901/JME.2020.08.099 [12] 杨素媛, 郭丹, 沈娟, 等. SPS制备TiNi增强镁合金复合材料的微观结构及力学性能[J]. 复合材料学报, 2018, 35(2):371-376.YANG Suyuan, GUO Dan, SHEN Juan, et al. Microstructure and mechanical properties of TiNi-enhanced magnesium alloy composites prepared by SPS[J]. Journal of Compo-site Materials,2018,35(2):371-376(in Chinese). [13] GU D, MA J, CHEN H, et al. Laser additive manufactured WC reinforced Fe-based compo-sites with gradient reinforcement/matrix interface and enhanced performance[J]. Composite Structures,2018,192:387-396. doi: 10.1016/j.compstruct.2018.03.008 [14] MANDAL V, TRIPATHI P, KUMARR A, et al. A study on selective laser melting (SLM) of TiC and B4C reinforced IN718 metal matrix composites (MMCs)[J]. Journal of Alloys and Compounds,2022,901:163527. doi: 10.1016/j.jallcom.2021.163527 [15] MOHAN S, MANTRI S, PANTAWANE M, et al. In situ reactions during direct laser deposition of Ti-B4C composites[J]. Scripta Materialia,2020,183:28-32. doi: 10.1016/j.scriptamat.2020.03.021 [16] HAN C, BABICHEVA R, ZHOU K, et al. Mic-rostructure and mechanical properties of (TiB+TiC)/Ti composites fabricated in situ via selective laser melting of Ti and B4C powders[J]. Additive Manufacturing,2020,36:101466. doi: 10.1016/j.addma.2020.101466 [17] FEREIDUNI E, GHASEMI A, ELBESTAWI M. Unique opportunities for microstructure engineering via trace B4C addition to Ti-6 Al-4 V through laser powder bed fusion process: As-built and heat-treated scenarios[J]. Additive Manu-facturing,2022,50:102557. doi: 10.1016/j.addma.2021.102557 [18] RUEDA C, VALEIRAS E, GARDON M, et al. Effect of ZrH2 particles on the microstructure and mechanical properties of IN718 manufactured by selective laser melting[J]. Materials Science and Engineering: A,2021,813:141123. doi: 10.1016/j.msea.2021.141123 [19] ZHANG H, GU D, MA C, et al. Effect of post heat treatment on microstructure and mechanical properties of Ni-based composites by selective laser melting[J]. Materials Science and Engineering: A,2019,765:138294. doi: 10.1016/j.msea.2019.138294 [20] NGUYEN Q, ZHU Z, CHUA B, et al. Development of WC-Inconel composites using selective laser melting[J]. Archives of Civil and Mechanical Engineering,2018,18:1410-1420. doi: 10.1016/j.acme.2018.05.001 [21] XIA Y, CHEN H, LIANG X, et al. Circular oscillating laser melting deposition of nickel-based superalloy reinforced by WC: Microstructure, wear resistance and electrochemical properties[J]. Journal of Manufacturing Processes,2021,68:1694-1704. doi: 10.1016/j.jmapro.2021.06.074 [22] WANG X, PAN X, SUN P, et al. Significant enhancement in tensile strength and work hardening rate in CoCrFeMnNi by adding TiAl particles via selective laser melting[J]. Materials Science and Engineering: A,2022,831:142285. doi: 10.1016/j.msea.2021.142285 [23] RONG T, GU D. Formation of novel graded interface and its function on mechanical properties of WC1-X reinforced Inconel 718 composites processed by selective laser melting[J]. Journal of Alloys and Compounds,2016,680:333-342. doi: 10.1016/j.jallcom.2016.04.107 [24] YAN X, CHEN C, ZHAO R, et al. Selective laser melting of WC reinforced maraging steel 300: Microstructure characterization and tribological performance[J]. Surface and Coatings Technology,2018,371:355-365. [25] CAO G, SUN T, WANG C, et al. Investigations of γ', γ'' and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting[J]. Materials Characterization,2018,136:398-406. doi: 10.1016/j.matchar.2018.01.006 [26] LIN W, CHANG Y, HSU T, et al. Microstructure and tensile property of aprecipitation strengthened high entropy alloy processed by selective laser melting and post heat treat-ment[J]. Additive Manufacturing,2020,36:101601. [27] HO I, HSU T, CHANG Y, et al. Effects of CoAl2O4 inoculants on microstructure and mechanical properties of IN718 processed by selective laser melting[J]. Additive Manufacturing,2020,35:101328. doi: 10.1016/j.addma.2020.101328 [28] ZHANG S, CHEN Z, WEI P, et al. Microstructure and pro-perties of a nano-ZrO2-reinforced AlSi10 Mg matrix compo-site prepared by selective laser melting[J]. Materials Science and Engineering: A,2022,838:142792. doi: 10.1016/j.msea.2022.142792 [29] LI W, YANG X, XIAO J, et al. Effect of WC mass fraction on the microstructure and friction properties of WC/Ni60 laser cladding layer of brake discs[J]. Ceramics International,2021,47(20):28754-28763. doi: 10.1016/j.ceramint.2021.07.035 [30] CHEN G, WAN J, HE N, et al. Strengthening mechanisms based on reinforcement distribution uniformity for particle reinforced aluminum matrix composites[J]. Transactions of Nonferrous Metals Society of China,2018,28(12):2395-2400. doi: 10.1016/S1003-6326(18)64885-X [31] CHEN L, GU P, GE T, et al. Effect of laser shock peening on microstructure and mechanical properties of TiC strengthened inconel 625 alloy processed by selective laser melting[J]. Materials Science and Engineering: A,2022,835:142610. doi: 10.1016/j.msea.2022.142610 [32] TANG M, ZHANG L, ZHANG N. Microstructural evolution, mechanical and tribological properties of TiC/Ti6 Al4 V composites with unique microstructure prepared by SLM[J]. Materials Science and Engineering: A,2021,814:141187. doi: 10.1016/j.msea.2021.141187 -

下载:

下载: