Bond-slip constitutive relation between FRP bars and coral aggregate seawater concrete

-

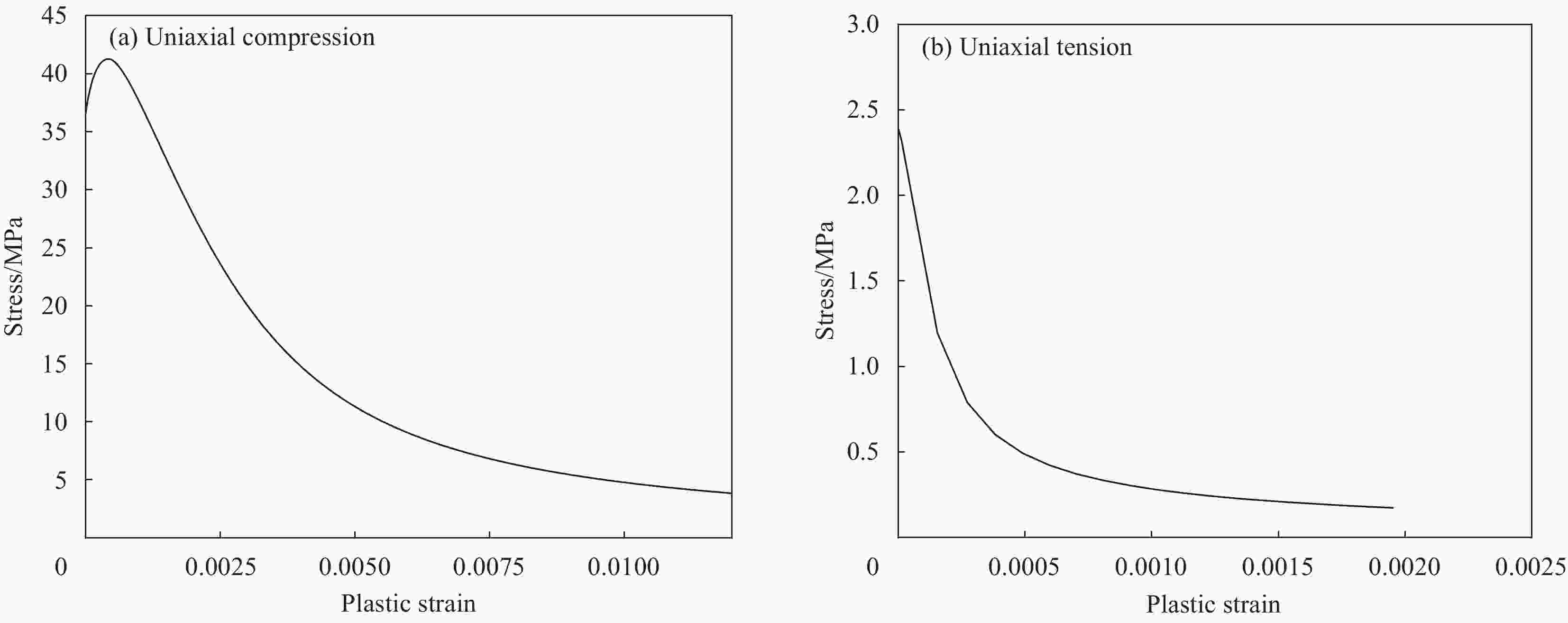

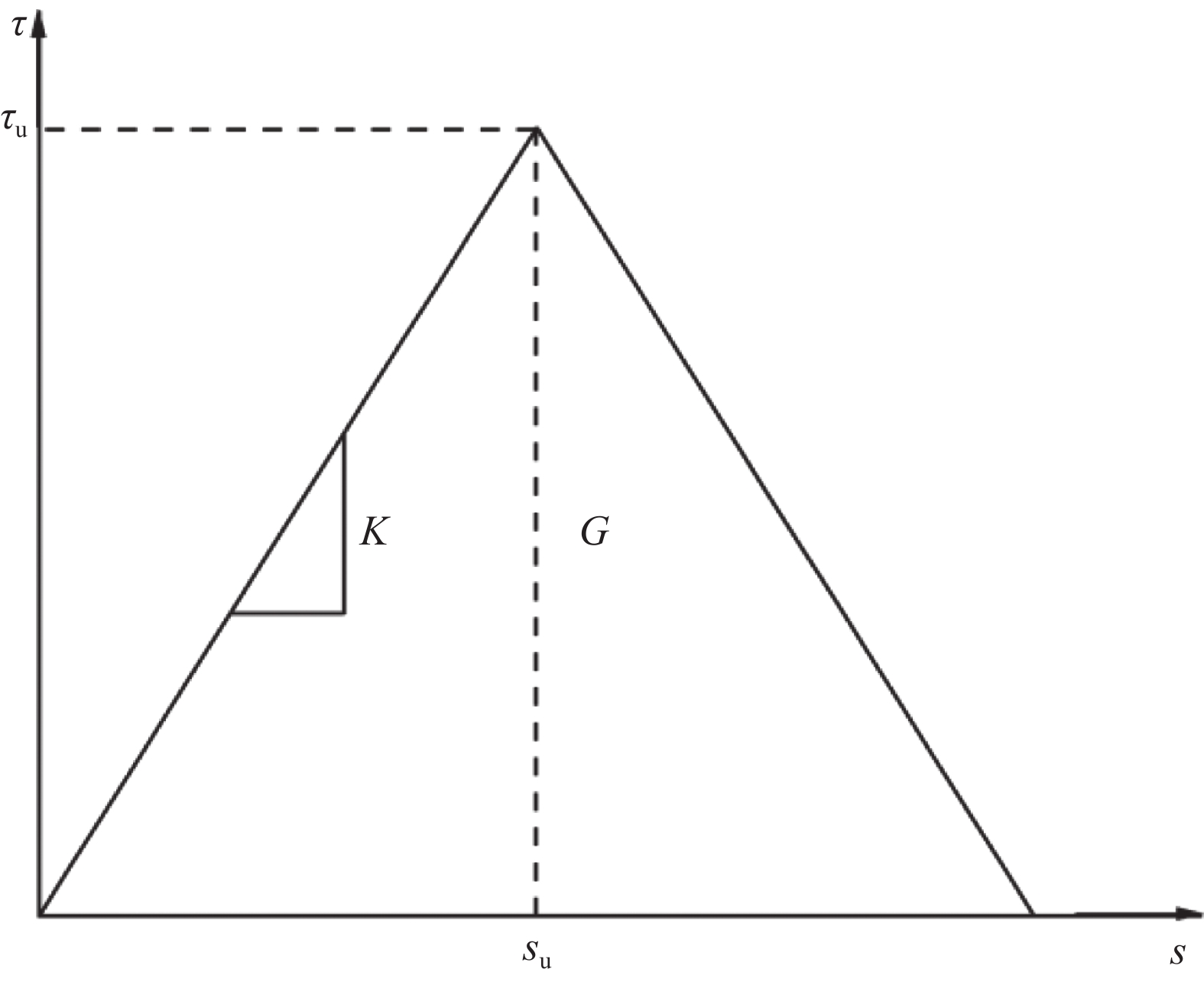

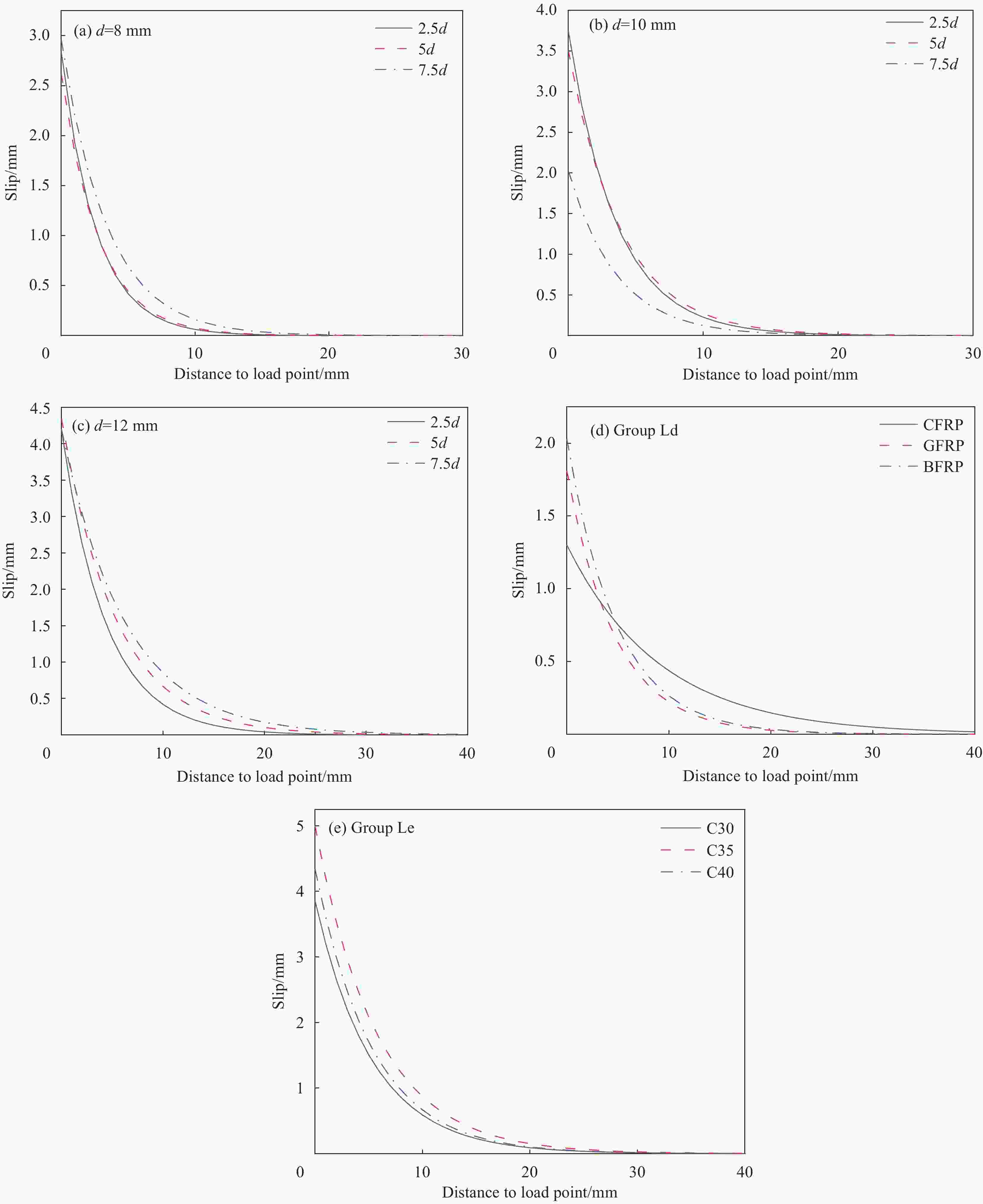

摘要: 纤维增强树脂复合材料(Fiber reinforced polymer,FRP)具有优良的抗腐蚀性能,用其代替普通钢筋能够很好地解决钢筋锈蚀问题。同时我国的珊瑚和海水资源丰富,用其代替传统砂石骨料是解决海岛建设中传统材料稀缺问题的有效方法之一。FRP筋与珊瑚骨料海水混凝土之间的粘结性能是决定其是否能像普通钢筋混凝土一样在实际工程中应用的重要因素之一。目前,关于FRP筋全珊瑚骨料海水混凝土结构的界面粘结性能研究很少,尤其是理论方面。于是,通过试验和数值模拟验证了简化双线性模型的合理性,并在此基础上推导了FRP筋全珊瑚骨料海水混凝土的界面粘结应力τ(x)和相对滑移量s(x)表达式,绘制了界面相对滑移和界面粘结应力的分布图。将采用表达式所得到的理论解与试验和模拟结果进行对比分析,其结果表明:通过理论计算所得的理论解与试验结果吻合度较高;FRP筋直径和粘结长度的增加会导致界面粘结应力和相对滑移的分布更加不均匀;珊瑚骨料混凝土强度的改变对界面粘结应力和相对滑移的分布影响不大;玻璃纤维增强树脂复合材料(GFRP)筋和玄武岩纤维增强树脂复合材料(BFRP)筋珊瑚骨料海水混凝土的界面粘结应力和相对滑移的分布相类似,与碳纤维增强树脂复合材料(CFRP)筋珊瑚骨料海水混凝土相比,前者的分布更加均匀。

-

关键词:

- 全珊瑚骨料海水混凝土 /

- FRP筋 /

- 粘结性能 /

- 本构模型 /

- 理论计算方法

Abstract: Since fiber reinforced polymer (FRP) has excellent corrosion resistance, it can be used to replace ordi-nary steel bars to solve the problem of steel corrosion. Because of the abundant coral and seawater resources in China, using coral instead of traditional sand aggregate is one of the effective methods to solve the problem of scarcity of traditional materials in island construction. Bonding property between FRP bars and coral aggregate seawater concrete is one of the important factors to determine whether FRP reinforced coral aggregate seawater concrete structure can be applied in practical engineering like ordinary reinforced concrete structure. At present, there is little research on the interfacial bonding property of FRP reinforced coral aggregate seawater concrete structure, especially in theory. Therefore, the rationality of the simplified bilinear model will be verified by experiments and numerical simulation. Based on the experiments and numerical simulation, the expressions of interfacial bonding stress and relative slip of FRP reinforced coral aggregate seawater concrete will be derived, and then the distribution maps of interfacial bonding stress and relative slip will be plotted. The theoretical solution obtained by the expression will be compared with the experimental and numerical simulation solution. The results show that the theoretical solution obtained by theoretical calculation is in good agreement with the experimental results. The increase of FRP bar diameter and bonding length will lead to more non-uniform distribution of interfacial bonding stress and relative slip. The change of coral aggregate concrete strength has little effect on the distribution of interfacial bonding stress and relative slip. The interfacial bond stress and relative slip distribution of glass fiber reinforced polymer (GFRP) and basalt fiber reinforced polymer (BFRP) reinforced coral aggregate seawater concrete are similar, and are more uniform than that of carbon fiber reinforced polymer (CFRP) coral aggregate concrete. -

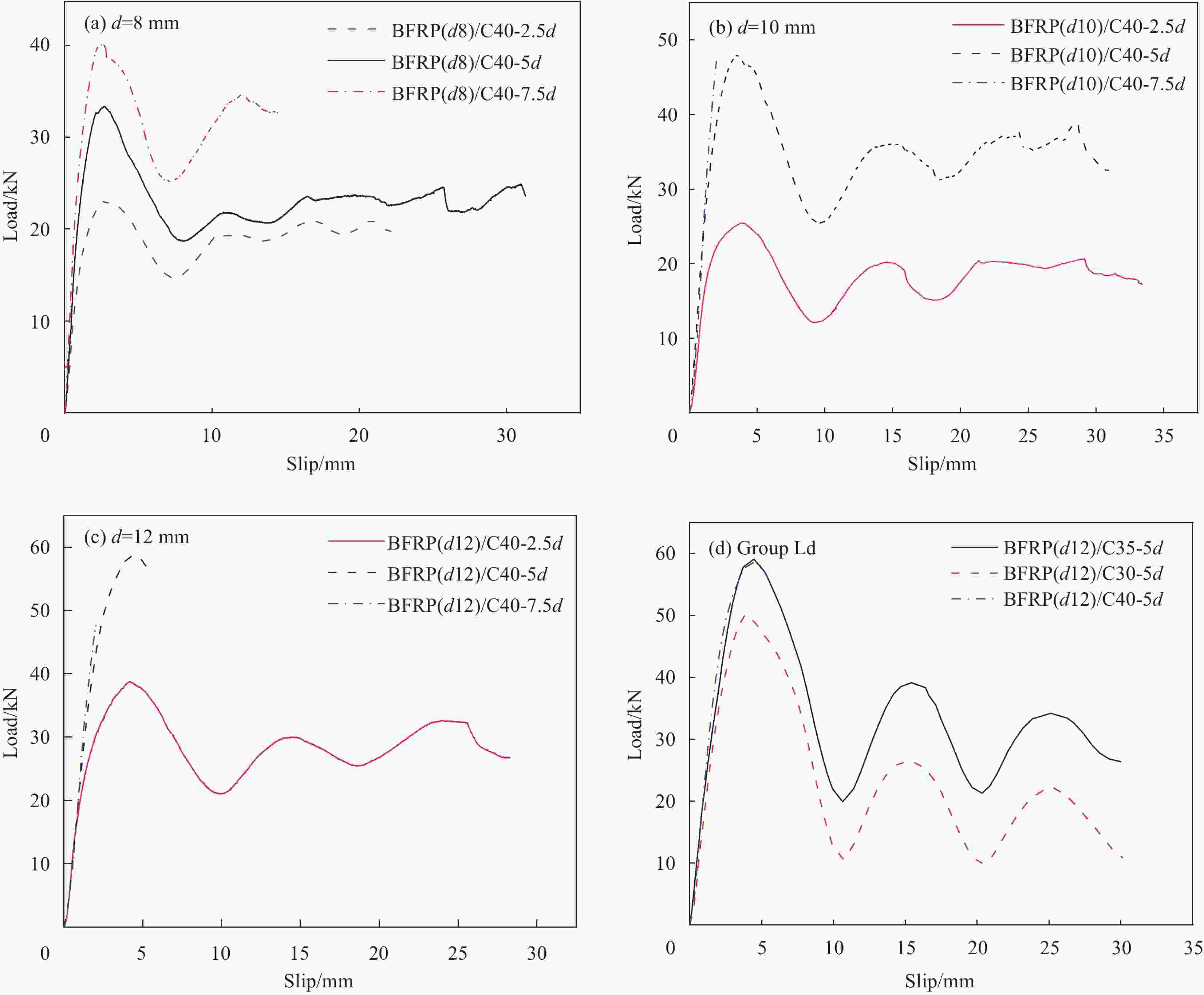

表 1 纤维增强树脂复合材料(FRP)筋全珊瑚骨料海水混凝土构件参数

Table 1. Parameters of fiber reinforced polymer (FRP) reinforced full coral aggregate seawater concrete

Specimen number d/mm Fiber reinforced polymer (FRP) l/mm Coral concrete strength BFRP(d8)/C40-2.5d 8 BFRP 2.5d C40 BFRP(d8)/C40-5d 8 BFRP 5.0d C40 BFRP(d8)/C40-7.5d 8 BFRP 7.5d C40 BFRP(d10)/C40-2.5d 10 BFRP 2.5d C40 BFRP(d10)/C40-5d 10 BFRP 5.0d C40 BFRP(d10)/C40-7.5d 10 BFRP 7.5d C40 BFRP(d12)/C40-2.5d 12 BFRP 2.5d C40 BFRP(d12)/C40-7.5d 12 BFRP 7.5d C40 CFRP(d12)/C40-5d 12 CFRP 5.0d C40 BFRP(d12)/C40-5d 12 BFRP 5.0d C40 GFRP(d12)/C40-5d 12 GFRP 5.0d C40 BFRP(d12)/C30-5d 12 BFRP 5.0d C30 BFRP(d12)/C35-5d 12 BFRP 5.0d C35 Notes: d—Diameter of FRP bars; C—Coral concrete strength grade; l—Bond length; BFRP—Basalt fiber reinforced polymer; CFRP—Carbon fiber reinforced polymer; GFRP—Glass fiber reinforced polymer. 表 2 变形FRP筋材料性能参数

Table 2. Performance parameters of deformed FRP bars

Reinforcement

typeDiameter/

mmYield strength/

MPaStandard value of ultimate

strength/MPaElastic modulus/

GPaElongation/

%BFRP 12 – 1405 53.6 2.63 GFRP 12 – 1021 54.8 1.87 CFRP 12 – 1815 104.5 1.78 表 3 人工海水化学成分(g/L)

Table 3. Chemical composition of artificial seawater (g/L)

NaCl MgCl2 Na2SO4 CaCl2 KCl NaHCO3 22.16 5.265 3.861 1.082 0.745 0.207 表 4 全珊瑚骨料海水混凝土配合比设计

Table 4. Full coral aggregate seawater concrete mix design

Concrete

typeCement/

(kg·m−3)Coarse aggregate/

(kg·m−3)Fine aggregate/

(kg·m−3)Water consumption/

(kg·m−3)Water reducing

agent/(kg·m−3)28-day cube compressive

strength/MPaCoral concrete 540 560 710 220 7.5 41.2 表 5 FRP筋全珊瑚骨料海水混凝土试件拉拔试验结果

Table 5. Drawing test results of FRP reinforced full coral aggregate seawater concrete specimen

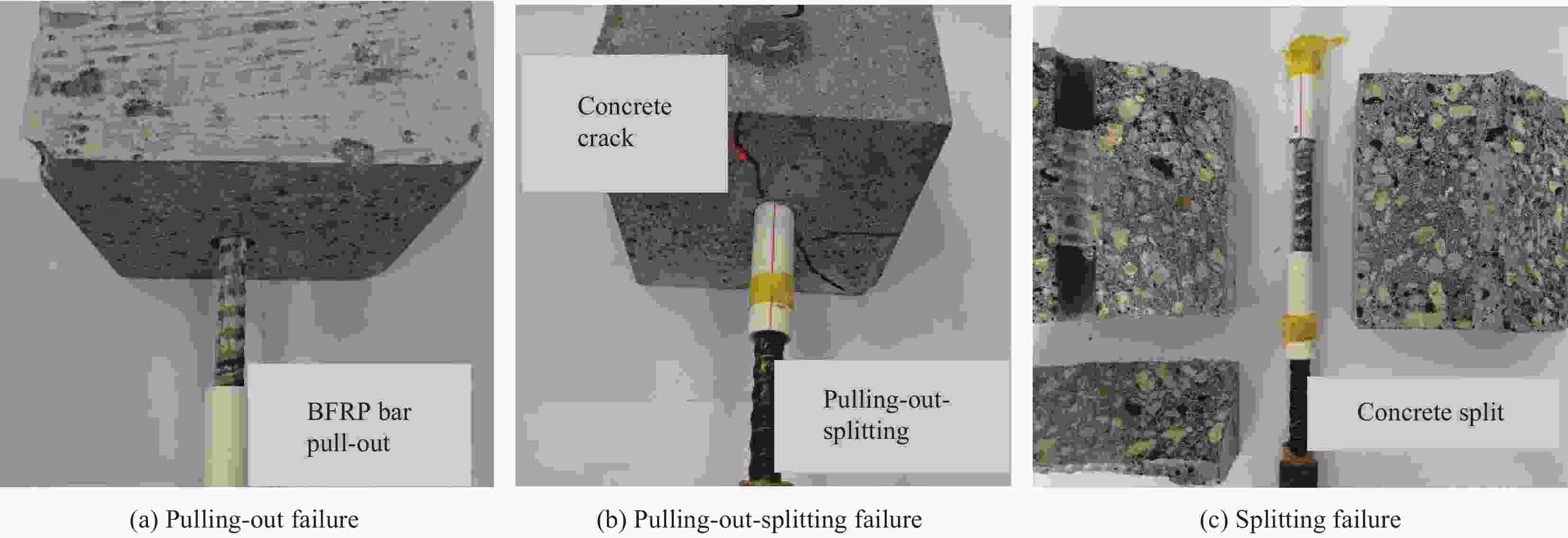

Group

numberSpecimen

numberAverage value

of ultimate

load/kNUltimate load slip amount/mm Average value

of ultimate bond

strength/MPaFailure

modeLa1 BFRP(d8)/C40-2.5d 21.77 2.84 43.32 Pulling-out failure La2 BFRP(d8)/C40-5d 34.68 2.62 34.51 Pulling-out failure La3 BFRP(d8)/C40-7.5d 39.48 2.96 26.19 Pulling-out failure

(one pulling-out-splitting failure)Lb1 BFRP(d10)/C40-2.5d 28.39 3.75 36.16 Pulling-out failure Lb2 BFRP(d10)/C40-5d 44.05 3.51 28.06 Pulling-out failure

(one splitting failure)Lb3 BFRP(d10)/C40-7.5d 45.88 2.03 19.48 Splitting failure Lc1 BFRP(d12)/C40-2.5d 40.12 4.19 35.49 Pulling-out failure

(two splitting failure)Lc3 BFRP(d12)/C40-7.5d 48.93 — 14.43 Splitting failure Ld1 CFRP(d12)/C40-5d 10.48 1.30 4.64 Pulling-out failure Ld2 BFRP(d12)/C40-5d 30.52 1.81 13.50 Pulling-out failure Ld3 GFRP(d12)/C40-5d 29.57 2.03 13.08 Pulling-out failure Le1 BFRP(d12)/C30-5d 49.39 3.86 21.85 Pulling-out failure

(one splitting failure)Le2 BFRP(d12)/C35-5d 61.00 5.00 26.98 Splitting failure

(one pulling-out failure)表 6 FRP筋全珊瑚骨料海水混凝土试件的计算值与试验值对比

Table 6. Comparison of calculated and experimental values of FRP reinforced full coral aggregate seawater concrete specimens

Group number Ptest/kN Pcal/kN Error/% δtest/mm δcal/mm Error/% La1 21.77 21.44 1.53 2.84 2.60 8.51 La2 34.68 33.84 2.42 2.62 2.40 8.32 La3 39.48 38.83 1.64 2.96 2.82 4.61 Lb1 28.39 27.94 1.57 3.75 3.47 7.54 Lb2 44.05 43.49 1.26 3.51 3.20 8.76 Lb3 45.88 43.23 5.77 2.03 1.87 8.12 Lc1 40.12 39.31 2.01 4.19 3.92 6.48 Lc3 57.87 54.67 5.53 – 2.30 – Ld1 10.84 10.64 1.86 1.30 1.20 7.64 Ld2 29.57 28.29 4.32 1.81 1.71 5.34 Ld3 30.52 29.47 3.41 2.03 1.96 3.21 Le1 49.39 46.31 6.23 3.86 3.61 6.52 Le2 55.23 51.30 7.12 5.00 4.76 4.87 Notes: Ptest—Average value of the ultimate load obtained from the test; δtest—Slip value corresponding to the ultimate load obtained in the test; δcal—Slip value corresponding to the ultimate load obtained by numerical simulation. -

[1] 王芳. 新时代海洋强国建设必须走陆海统筹之路[J]. 中国国土资源经济, 2021, 34(2):1.WANG Fang. The construction of a maritime power in the new era must take the road of land and sea coordination[J]. China's Land and Resources Economy,2021,34(2):1(in Chinese). [2] 廖维晓, 李督. 南海海岛资源开发研究[J]. 潍坊工程职业学院学报, 2020, 33(3):73-76. doi: 10.3969/j.issn.1009-2080.2020.03.015LIAO Weixiao, LI Du. Research on the development of south China sea island resources[J]. Journal of Weifang Engineering Vocational College,2020,33(3):73-76(in Chinese). doi: 10.3969/j.issn.1009-2080.2020.03.015 [3] LYU B, WANG A, ZHANG Z, et al. Coral aggregate concrete: Numerical description of physical, chemical and morphological properties of coral aggregate[J]. Cement and Concrete Composites,2019,100:25-34. doi: 10.1016/j.cemconcomp.2019.03.016 [4] LI Y L, ZHAO X L, RAMAN R K S. Behavior of seawater and sea sand concrete filled FRP square hollow sections[J]. Thin-Walled Structures,2020,148:20-30. [5] ZHANG B, ZHU H, SHAH K W, et al. Performance evaluation and microstructure characterization of seawater and coral/sea sand alkali-activated mortars[J]. Construction and Building Materials,2020,259:120403. [6] SUN Z, ZHANG L, NIU D, et al. Time-varying model for predicting the resistivity of coral aggregate concrete[J]. Construction and Building Materials,2020,265(4):120588. doi: 10.1016/j.conbuildmat.2020.120588 [7] 洪乃丰. 混凝土中氯盐与钢筋腐蚀的几个相关问题[J]. 工业建筑, 2003(11):39-42. doi: 10.3321/j.issn:1000-8993.2003.11.011HONG Naifeng. Several related problems of chloride in concrete and corrosion of steel bars[J]. Industrial Building,2003(11):39-42(in Chinese). doi: 10.3321/j.issn:1000-8993.2003.11.011 [8] 吴敬宇. 玄武岩纤维复合筋高温性能研究[D]. 哈尔滨: 中国地震局工程力学研究所, 2011.WU Jingyu. Study on high temperature performance of basalt fiber composite reinforcement[D]. Harbin: Institute of Engineering Mechanics, China Earthquake Administration, 2011(in Chinese). [9] DONG Z, WU G, XU B, et al. Bond durability of BFRP bars embedded in concrete under seawater conditions and the long-term bond strength prediction[J]. Materials & Design,2016,92:552-562. [10] 陈爽. 湿热海洋环境下FRP筋-珊瑚混凝土粘结滑移性能研究[D]. 南宁: 广西大学, 2019.CHEN Shuang. Study on the bond-slip performance of FRP bar-coral concrete under humid and hot ocean environment[D]. Nanning: Guangxi University, 2019(in Chinese). [11] 中国冶金建设协会. 纤维增强复合材料建设工程应用技术规范: GB 50608—2010[S]. 北京: 中国计划出版社, 2010.China Metallurgical Construction Association. Technical specification for fiber-reinforced composite material construction engineering application: GB 50608—2010[S]. Beijing: China Planning Press, 2010(in Chinese). [12] 胡长顺. 全珊瑚骨料海水混凝土与FRP筋粘结性能试验研究[D]. 徐州: 中国矿业大学, 2020.HU Changshun. Experimental study on the bonding pro-perties of all-coral aggregate seawater concrete and FRP bars[D]. Xuzhou: China University of Mining and Technology, 2020(in Chinese). [13] YIN S, HU C, LIANG X. Bonding properties of different kinds of FRP bars and steel bars with all-coral aggregate seawater concrete[J]. Journal of Materials in Civil Engi-neering,2020,32(10):04020282. doi: 10.1061/(ASCE)MT.1943-5533.0003378 [14] 王磊, 吴翔, 曾榕, 等. CFRP筋与珊瑚混凝土的黏结性能试验研究[J]. 中国农村水利水电, 2016(7):127-131. doi: 10.3969/j.issn.1007-2284.2016.07.031WANG Lei, WU Xiang, ZENG Rong, et al. Experimental study on the bonding performance of CFRP bars and coral concrete[J]. China Rural Water and Hydropower,2016(7):127-131(in Chinese). doi: 10.3969/j.issn.1007-2284.2016.07.031 [15] 王磊, 李威, 陈爽, 等. 海水浸泡对FRP筋-珊瑚混凝土粘结性能的影响[J]. 复合材料学报, 2018, 35(12):3458-3465.WANG Lei, LI Wei, CHEN Shuang, et al. The effect of seawater immersion on the bonding properties of FRP tendons and coral concrete[J]. Journal of Composite Materials,2018,35(12):3458-3465(in Chinese). [16] 杨超, 杨树桐, 戚德海. BFRP筋与珊瑚混凝土粘结性能试验研究[J]. 工程力学, 2018, 35(S1):172-180. doi: 10.6052/j.issn.1000-4750.2017.06.S034YANG Chao, YANG Shutong, QI Dehai. Experimental study on the bond performance of BFRP bars and coral concrete[J]. Engineering Mechanics,2018,35(S1):172-180(in Chinese). doi: 10.6052/j.issn.1000-4750.2017.06.S034 [17] 吴翔. 碳纤维筋与珊瑚混凝土粘结性能试验研究[D]. 桂林: 桂林理工大学, 2016.WU Xiang. Experimental study on the bonding perfor-mance of carbon fiber reinforcement and coral concrete[D]. Guilin: Guilin University of Technology, 2016(in Chinese). [18] 王召. FRP筋混凝土界面粘结性能的研究[D]. 大连: 大连理工大学, 2015.WANG Zhao. Study on the bonding properties of FRP bars in concrete interface[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [19] 陈爽. 湿热海洋环境下FRP筋-珊瑚混凝土粘结滑移性能研究[D]. 南宁: 广西大学, 2019.CHEN Shuang. Study on the bond-slip properties of FRP bar-coral concrete in hot and humid marine environment[D]. Nanning: Guangxi University, 2019(in Chinese). [20] ARNAUD R, PIERRE A, KARIM B, et al. Analytical and numerical modeling of the bond behavior between FRP reinforcing bars and concrete[J]. Construction and Building Materials,2020,231:117160. doi: 10.1016/j.conbuildmat.2019.117160 [21] ELIGEHAUSEN R, POPOV E P, BERTERO V V. Local bond stress-slip relationships of deformed bars under genera-lized excitations[M]. California: University of California Press, 1982. [22] COSENZA E, MANFREDI G, REALFONZO R. Analytical modelling of bond between FRP reinforcing bars and concrete[C]//Non-Metallic (FRP) Reinforcement for Concrete Structures Proceedings of the Second International RILEM Symposium. London, 1995: 164-171. [23] MALVAR L J. Bond stress-slip characteristics of FRP rebar[R]. Naval Facilities Engineering Service Center Port Hueneme CA, 1994. [24] COSENZA E, MANFREDI G, REALFONZO R. Behavior and modeling of bond of frp rebars to concrete[J]. Journal of Composites for Construction,1997,1(2):40-51. doi: 10.1061/(ASCE)1090-0268(1997)1:2(40) [25] 高丹盈, 朱海堂, 谢晶晶. 纤维增强塑料筋混凝土粘结滑移本构模型[J]. 工业建筑, 2003, 33(7):41-43. doi: 10.3321/j.issn:1000-8993.2003.07.011GAO Danying, ZHU Haitang, XIE Jingjing. The constitutive model of fiber reinforced plastic bar concrete bond-slip[J]. Industrial Construction,2003,33(7):41-43(in Chinese). doi: 10.3321/j.issn:1000-8993.2003.07.011 [26] YANG S, YU M, DONG K, et al. Properties of alkali-resistant glass fiber reinforced coral aggregate concrete[J]. Materials,2020,13(16):220-230. [27] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Design code for concrete structures: GB 50010—2010[S]. Beijing: China Building Industry Press, 2010(in Chinese). [28] 薛伟辰, 刘华杰, 王小辉. 新型FRP筋粘结性能研究[J]. 建筑结构学报, 2004, 25(2):104-109. doi: 10.3321/j.issn:1000-6869.2004.02.017XUE Weichen, LIU Huajie, WANG Xiaohui. Study on the bonding properties of new FRP bars[J]. Journal of Building Structures,2004,25(2):104-109(in Chinese). doi: 10.3321/j.issn:1000-6869.2004.02.017 -

下载:

下载: