Tensile failure mechanism of RTM-made asymmetric composite T-joint

-

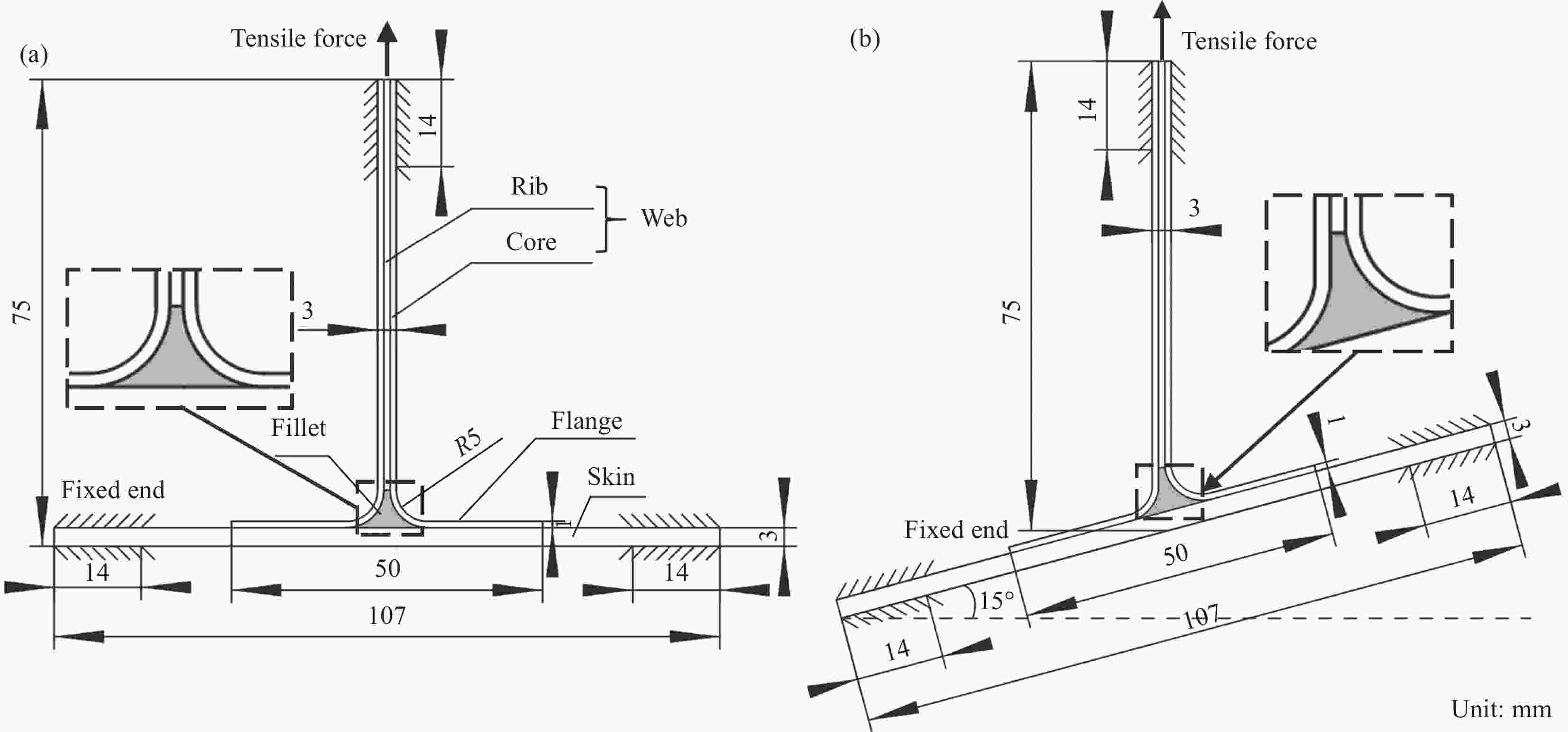

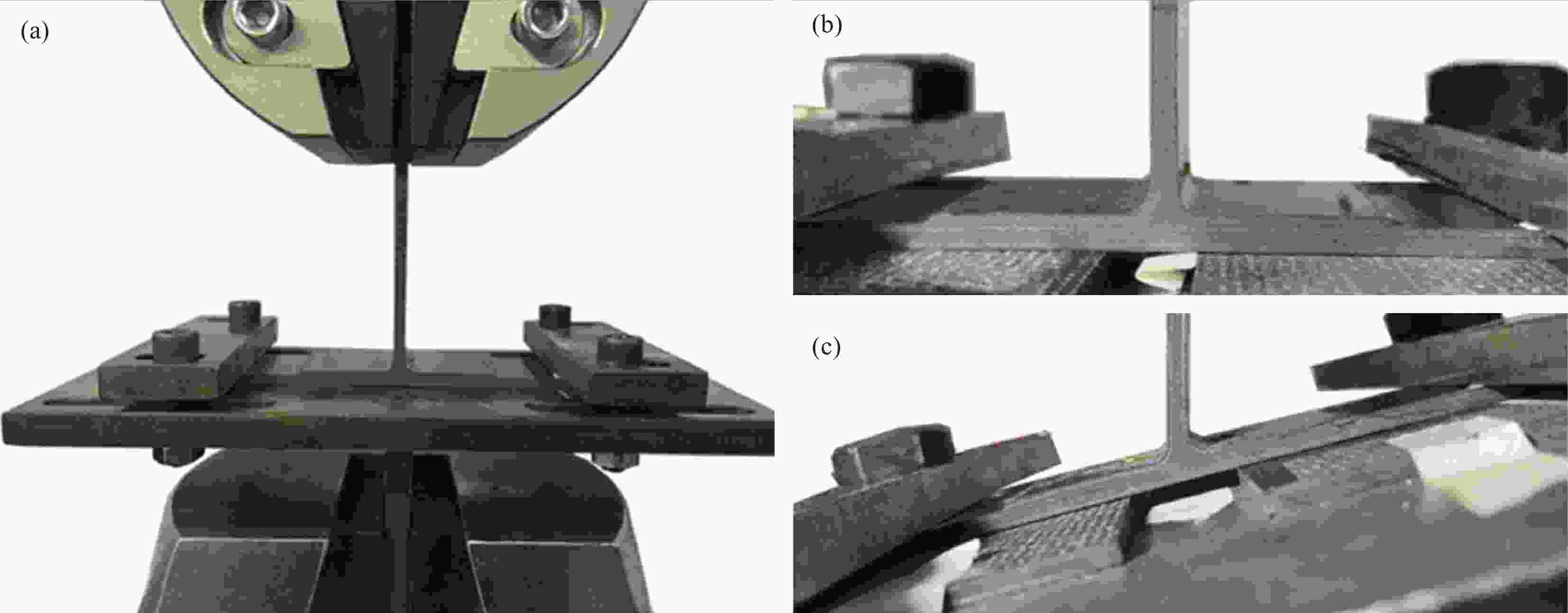

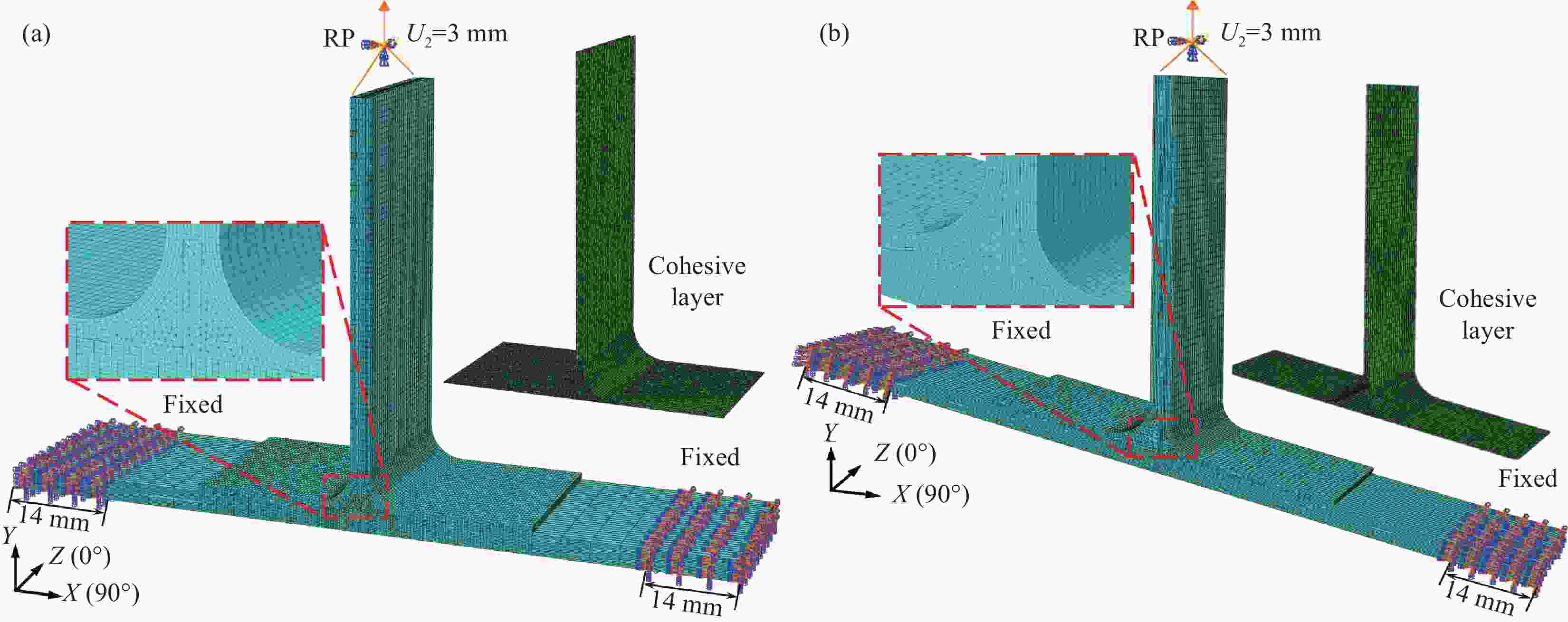

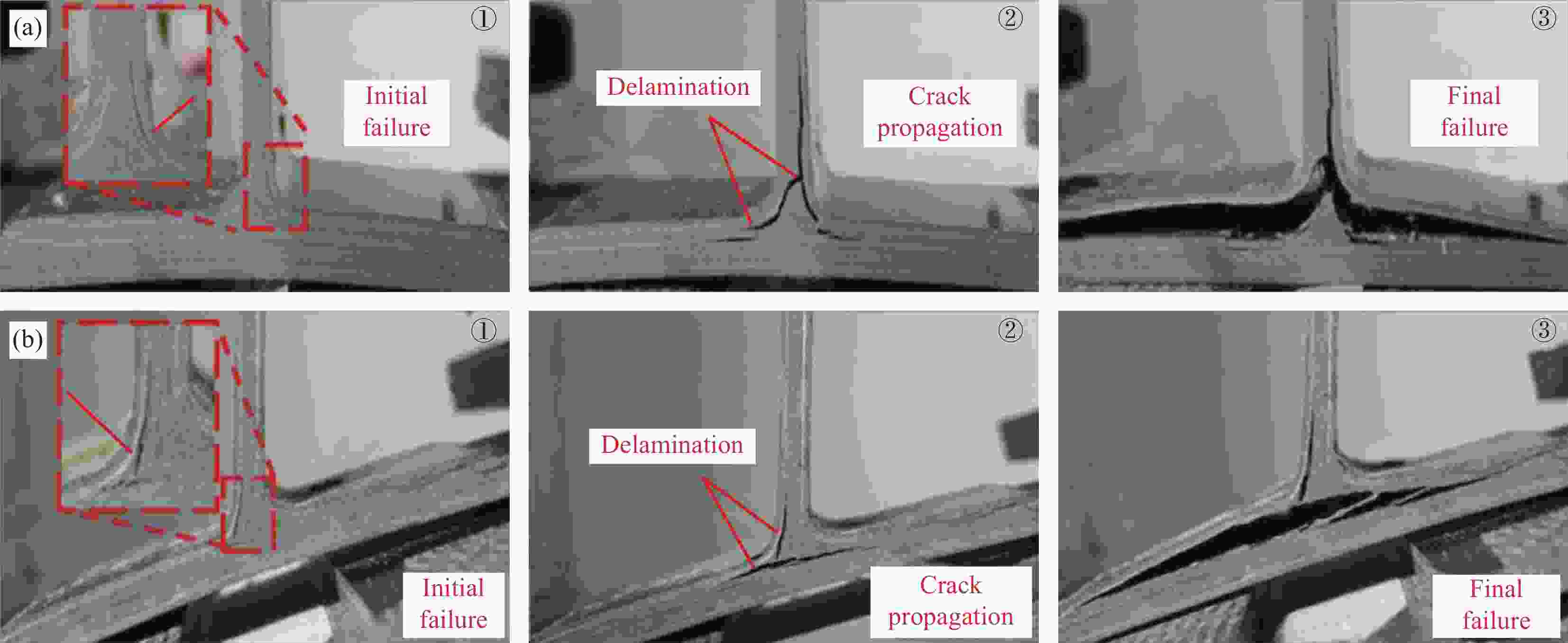

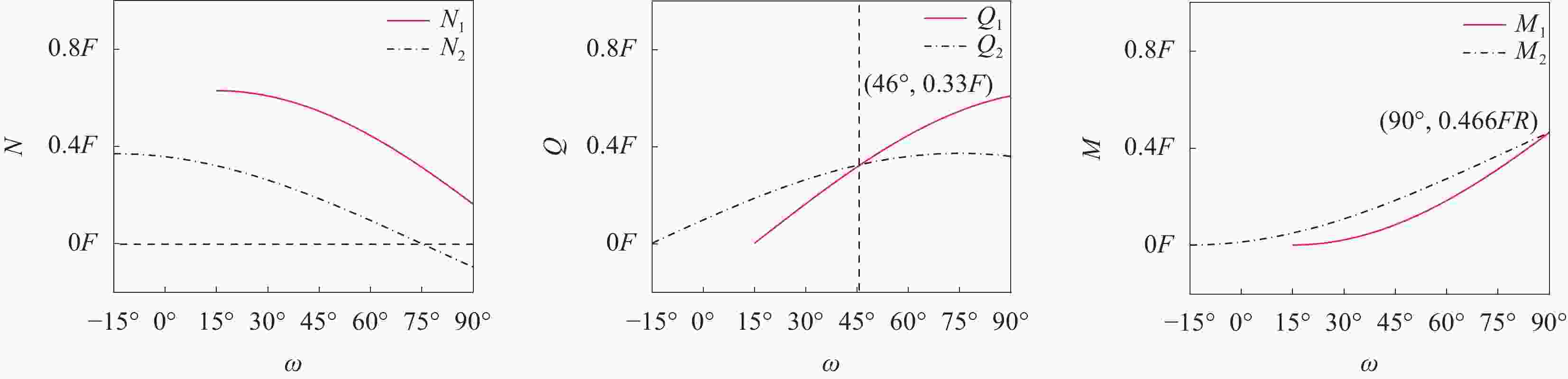

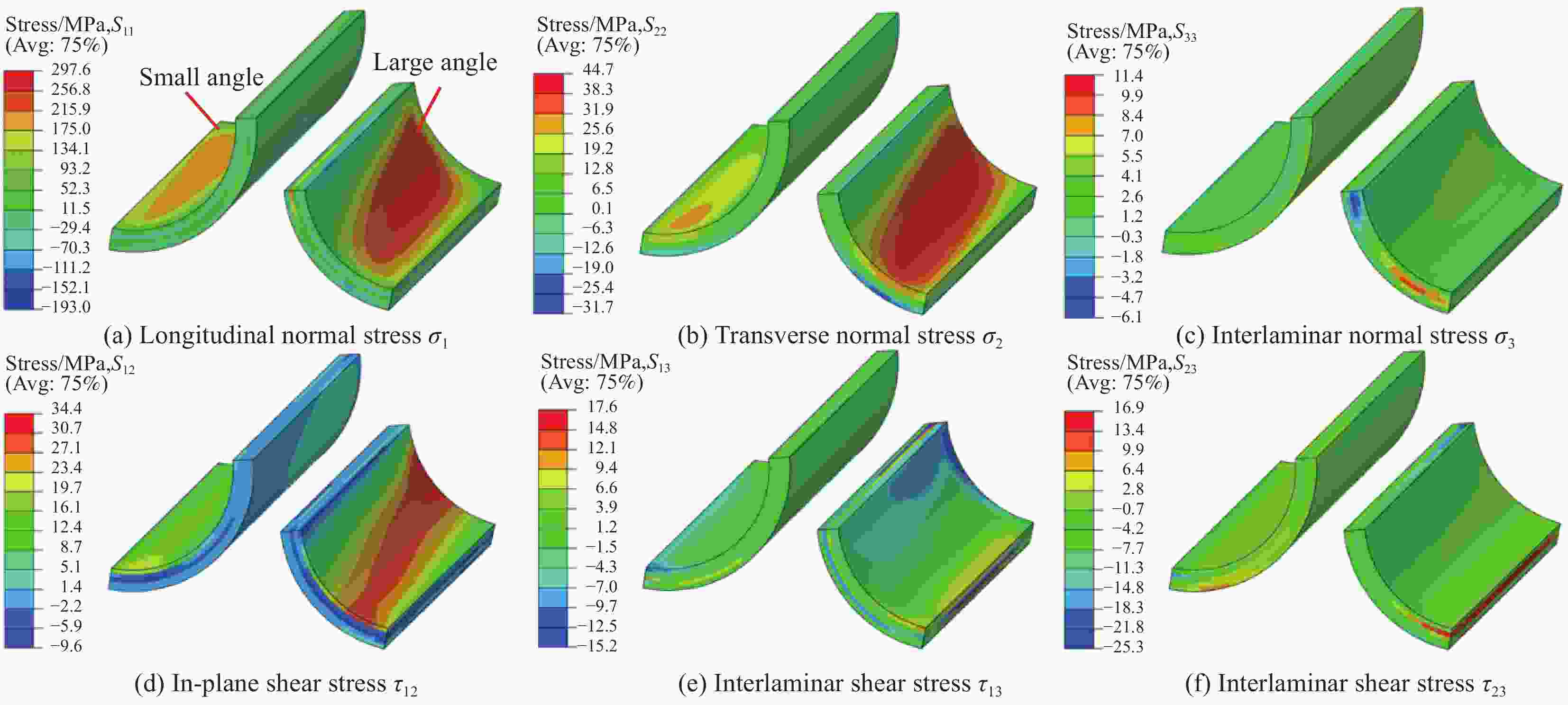

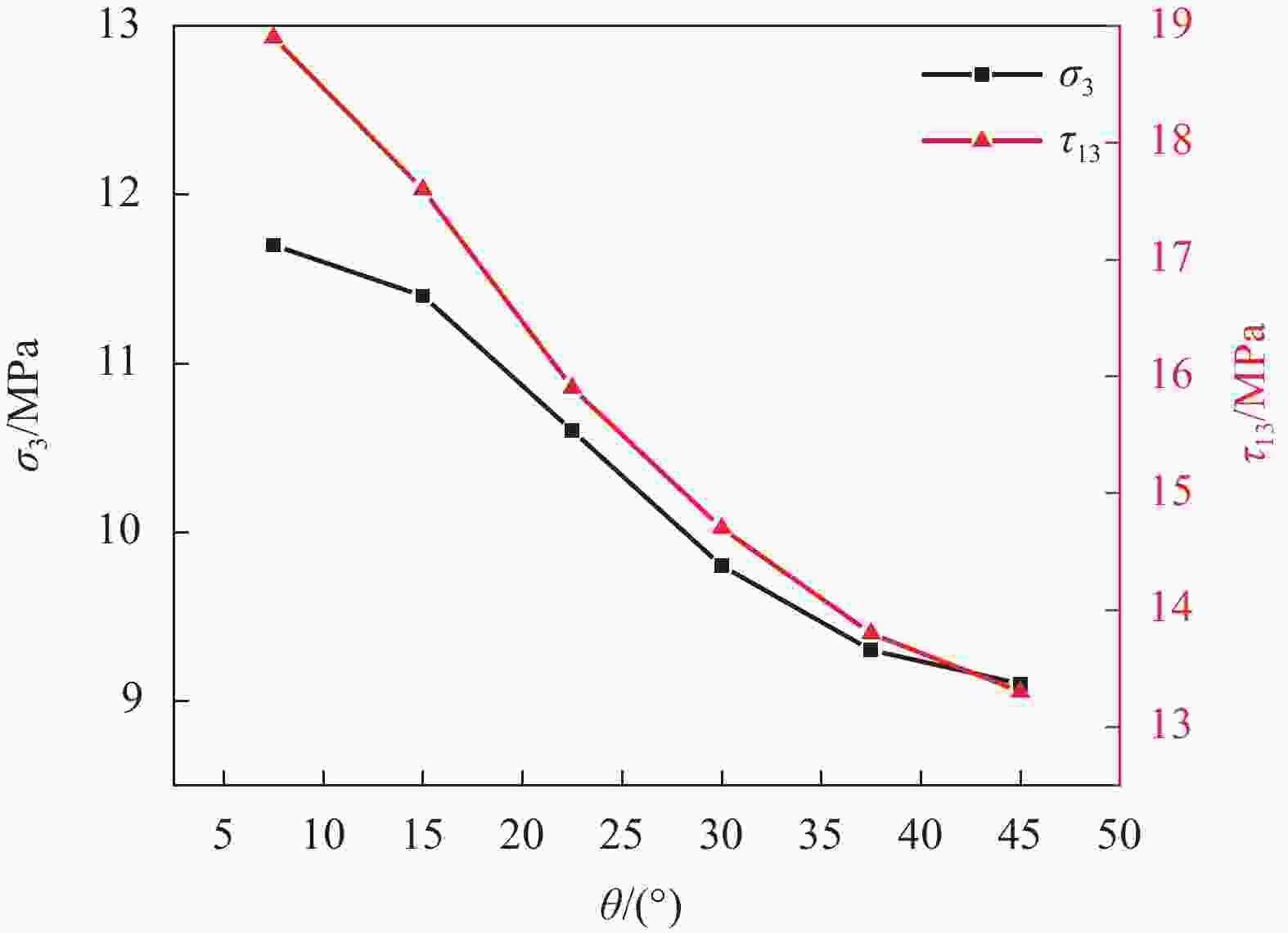

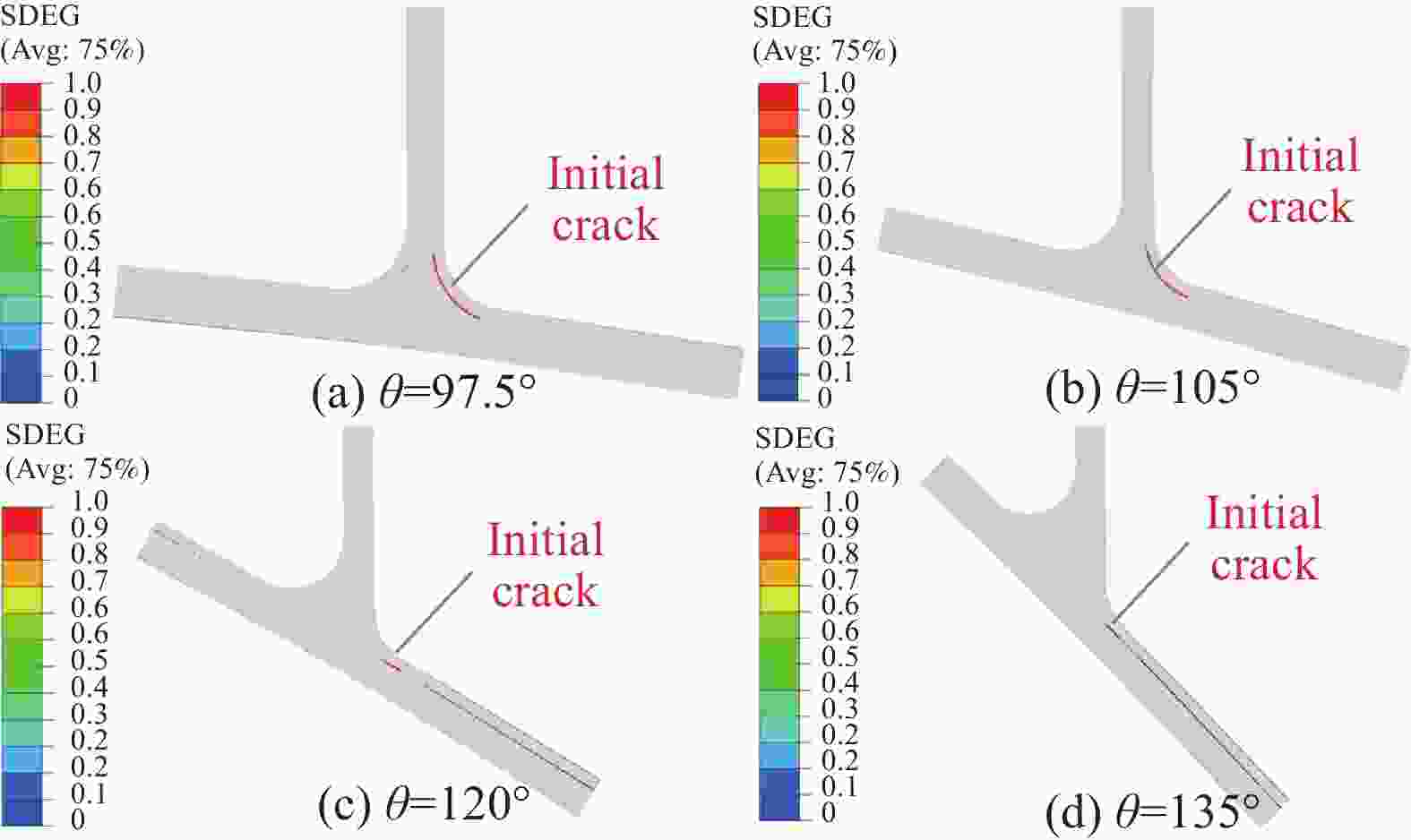

摘要: 采用树脂传递模塑(RTM)工艺制备了结构对称和非对称两种复合材料T型接头试样,并对其进行了静态拉伸力学试验,对比分析了两种结构的拉伸破坏模式、结构刚度及破坏载荷。同时基于T接头内聚力模型(CZM),研究了两种不同结构T型接头的拉伸破坏过程及失效机制,并对比分析了不同偏转角下T接头的层间应力。结果表明:不同结构T型接头的拉伸破坏模式不同,偏转角的存在使结构非对称T型接头夹角大侧圆弧受力明显高于小侧圆弧,导致接头首先在大侧夹角圆弧与三角区界面定向萌生初始裂纹,随后裂纹主要沿大侧腹板翻边与蒙皮的界面扩展,进而导致接头最终破坏,最终失效载荷较对称T型接头提高了15.3%,且结构刚度更大。有限元结果表明T型接头三角区的初始失效主要由层间正应力及剪应力引起,有限元分析的失效模式与试验一致,结构对称及非对称T型接头最终失效载荷与试验值均吻合较好;且随着偏转角的增加,腹板圆弧处层间应力逐渐减小,初始失效载荷将随之增大;初始破坏位置将转移至大侧夹角圆弧末端。Abstract: The tensile tests of structural symmetric and asymmetric composite T-joints prepared by resin transfer moulding (RTM) process were carried out, respectively. The failure process, structure stiffness and failure load of these composite T-joints were compared and analyzed. At the same time, the cohesive zone models (CZM) of composite T-joints were established and the failure process and failure mechanism of these two type T-joints were studied. The interlaminar stress of T-joints with different deflection angles were also compared. The test results show that the failure mode of structural asymmetric T-joint is different from that of symmetric T-joint. The existence of deflection angle causes higher stress at the large angle curved web than that of the small angle curved web, as a result, the initial crack of asymmetric T-joints orientationally occurs at the interface of triangular zone/curved web with large deflection angle. And then the crack directly propagates to the interface of large deflection angle flange/skin with 15.3% higher peak failure load than that of symmetric T-joints. The small bending deformation of the skin of asymmetric T-joint leads to the larger overall stiffness of the structure. The debonding of flange and skin is the prominent reason to the final failure of T-joint. The finite element analysis results show that the simulated peak failure loads of symmetric and asymmetric T-joints are within deviation. The simulated failure mode is in good agreement with the experiment. As the deflection angle increases, the interlaminar stress at the curved web of asymmetric T-joint decreases gradually, which indicates that the initial failure load of asymmetric T-joint may increase correspondingly. The position of initial crack will be shifted to the end of curved web at the same time.

-

Key words:

- composite /

- T-joint /

- failure mechanism /

- finite element analysis /

- resin transfer moulding

-

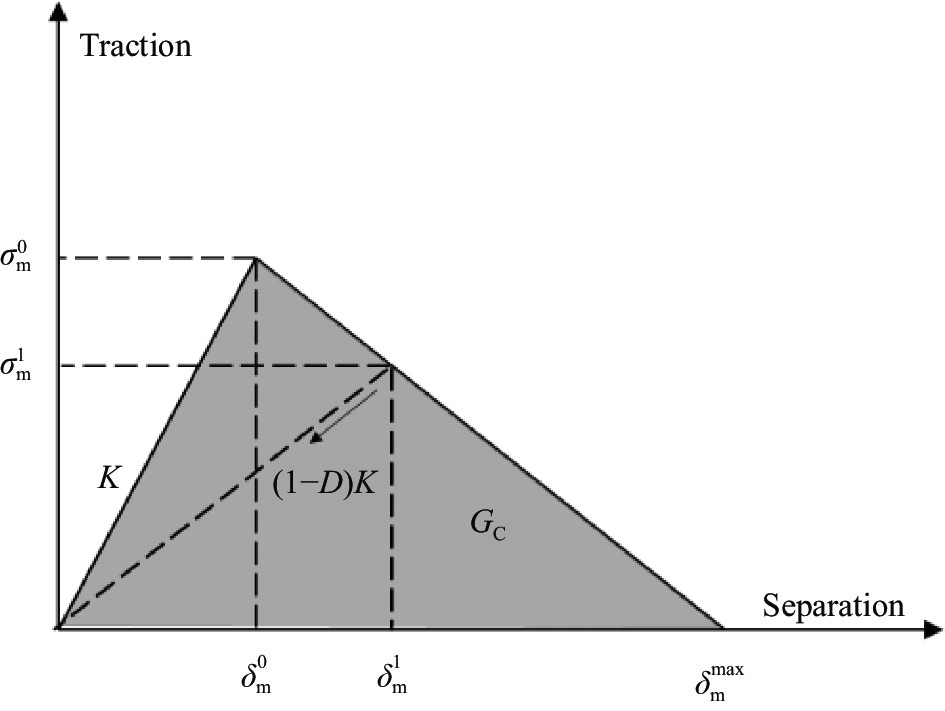

图 5 内聚力双线性本构模型[24]

Figure 5. Cohesive bilinear constitutive model[24]

$ \sigma _{\text{m}}^0 $, $ \delta _{\text{m}}^0 $—Critical failure strength and critical failure displacement; $ \sigma _{\text{m}}^1 $, $ \delta _{\text{m}}^1 $—Failure strength and failure displacement after degradation; $ \delta _{\text{m}}^{\max } $—Critical displacement; K—Interface stiffness; D—Damage coefficient; GC—Critical strain energy release rate

图 8 B型T接头受力模型:(a) 弯曲变形示意图;(b) 受力简图;(c) 任意角度内力关系

Figure 8. Loading models of B-type T-joint: (a) Schematic of bending deformation; (b) Loading schematic; (c) Internal force relationship at any angle

F—Tensile force; l—Span; θ—Deflection angle; △—Distance; F1—Force at large arc; F2—Force at small arc; f1——Force at large arc; f2——Force at small arc; N1, N2—Axial force; Q1, Q2—Shear force; M1, M2—Moment; FQ, FN—Separation force in vertical and parallel to the skin direction; α—Angle between F2 and vertical direction; β—Angle between F1 and vertical direction; ω—Angle between force and horizontal direction; φ1, φ2—Angle between f and the normal direction

表 1 材料力学性能参数

Table 1. Mechanical property parameters of materials

Material E1/GPa E2/GPa E3/GPa ν12 ν13 ν23 G12/GPa G13/GPa G23/GPa U-8190/5284RTM 156.0 9.0 9.0 0.30 0.15 0.15 4.3 3.5 3.5 CCF800H/AC531 159.3 8.3 8.3 0.25 0.10 0.10 4.6 3.5 3.5 Notes: U-8190/5284RTM—Unidirectional carbon fiber fabric reinforced epoxy composite; CCF800H/AC531—Carbon fiber reinforced epoxy prepreg; E1, E2, E3—Modulus of elasticity; ν12, ν13, ν23—Poisson ratio; G12, G13, G23—Modulus of shearing. Parameter Value E11/MPa 3000 G13/MPa 1200 G23/MPa 1200 $ {\sigma }_{\text{n}}^{\text{0}}/{\rm{MPa}} $ 15 $ {\sigma }_{\text{s}}^{\text{0}}/{\rm{MPa}} $ 30 $ {\sigma }_{\text{t}}^{\text{0}}/{\rm{MPa}} $ 30 GIC/(J·m−2) 580 GIIC/(J·m−2) 1900 GIIIC/(J·m−2) 1900 Notes: E11—Tensile modulus; G13, G23—Shear modulus; ${\sigma }_{\text{n}}^{\text{0}} $—Normal tensile stress; ${\sigma }_{\text{s}}^{\text{0}} $, ${\sigma }_{\text{t}}^{\text{0}} $—Transverse shear stress; GIC, GIIC, GIIIC—Normal and tangential critical strain energy release rate. 表 3 T型接头拉伸试验结果与有限元(FE)结果

Table 3. Experimental and finite element (FE) results of T-joints tensile tests

T-joint Category Initial failure load/N Peak failure load/N A Experiment 767 952 975 975 892 892 941 1006 Average 894 956 FE 936 940 Deviation 4.7% 1.7% B Experiment 1121 1121 1088 1088 849 1026 1172 1172 Average 1058 1102 FE 1136 1136 Deviation 7.4% 3.1% -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 沈真, 杨胜春. 飞机结构用复合材料的力学性能要求[J]. 材料工程, 2007(S1):248-252. doi: 10.3969/j.issn.1001-4381.2007.z1.056SHEN Zhen, YANG Shengchun. Mechanical properties of composites for aircraft structure[J]. Journal of Materials Engineering,2007(S1):248-252(in Chinese). doi: 10.3969/j.issn.1001-4381.2007.z1.056 [3] 周长庚, 荀国立, 邱启艳, 等. 航空复合材料整体成型技术应用现状与分析[J]. 新材料产业, 2016(5):52-57. doi: 10.3969/j.issn.1008-892X.2016.05.011ZHOU Changgeng, XUN Guoli, QIU Qiyan, et al. Application status and analysis of aeronautical composite integral forming technology[J]. New Materials Industry,2016(5):52-57(in Chinese). doi: 10.3969/j.issn.1008-892X.2016.05.011 [4] 叶金蕊, 张博明. 复合材料蒙皮加筋壁板结构成本-质量优化设计[J]. 复合材料学报, 2009, 26(2):187-194. doi: 10.3321/j.issn:1000-3851.2009.02.033YE Jinrui, ZHANG Boming. Cost-quality optimization design of composites skin reinforcement panel structure[J]. Acta Materiae Compositae Sinica,2009,26(2):187-194(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.02.033 [5] 段友社, 周晓芹, 侯军生. 大飞机复合材料机翼研制技术现状[J]. 航空制造技术, 2012(18):34-37. doi: 10.3969/j.issn.1671-833X.2012.18.003DUAN Youshe, ZHOU Xiaoqin, HOU Junsheng. Research status of composite wing technology for large aircraft[J]. Aeronautical Manufacturing Technology,2012(18):34-37(in Chinese). doi: 10.3969/j.issn.1671-833X.2012.18.003 [6] 盛仪, 熊克, 卞侃, 等. 拉伸状态下碳纤维复合材料T型接头的断裂行为[J]. 复合材料学报, 2013, 30(6):185-190. doi: 10.3969/j.issn.1000-3851.2013.06.027SHENG Yi, XIONG Ke, BIAN Kan, et al. Fracture behavior of carbon fiber T-joints under tensile load[J]. Acta Materiae Compositae Sinica,2013,30(6):185-190(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.06.027 [7] LUO C Y, XIONG J J. Static pull and push bending properties of RTM-made TWF composite Tee-joints[J]. Chinese Journal of Aeronautics,2012,25(2):198-207. doi: 10.1016/S1000-9361(11)60379-8 [8] THAWRE M M, PANDEY K N, DUBEY A, et al. Fatigue life of a carbon fiber composite T-joint under a standard fighter aircraft spectrum load sequence[J]. Composite Structures,2015,127:260-266. doi: 10.1016/j.compstruct.2015.03.026 [9] EARL J S, DULIEU B J M, SHENOI R A. Determination of hygrothermal ageing effects in sandwich construction joints using thermoelastic stress analysis[J]. Composites Science and Technology,2003,63(2):211-223. doi: 10.1016/S0266-3538(02)00252-X [10] STEIN N, ROSENDAHL P L, BECKER W. Homogenization of mechanical and thermal stresses in functionally graded adhesive joints[J]. Composites Part B: Engineering,2017,111:279-293. doi: 10.1016/j.compositesb.2016.11.061 [11] 李陵, 徐峰, 郑绍文. 复合材料T型接头力学性能分析与优化研究[J]. 玻璃钢/复合材料, 2015(4):41-46. doi: 10.3969/j.issn.1003-0999.2015.04.008LI Ling, XU Feng, ZHENG Shaowen. Research and analysis on the mechanical properties and optimization for composite T-joint[J]. Fiber Reinforced Plastics/Composites,2015(4):41-46(in Chinese). doi: 10.3969/j.issn.1003-0999.2015.04.008 [12] 马金瑞, 黄峰, 赵龙, 等. 填充物对RTM复合材料T型接头拉伸性能影响[J]. 长春工业大学学报, 2015, 36(4):451-455. doi: 10.15923/j.cnki.cn22-1382/t.2015.4.18MA Jinrui, HUANG Feng, ZHAO Long, et al. Effect of filler on tensile properties of RTM composite T-joint[J]. Journal of Changchun University of Technology,2015,36(4):451-455(in Chinese). doi: 10.15923/j.cnki.cn22-1382/t.2015.4.18 [13] 胡孝才, 戴棣, 姚学锋, 等. T接头初始破坏位置研究[J]. 航空制造技术, 2009(z1):152-154, 157. doi: 10.3969/j.issn.1671-833X.2009.z1.047HU Xiaocai, DAI Di, YAO Xuefeng, et al. Study on initial failure location of T-joint[J]. Aeronautical Manufacturing Technology,2009(z1):152-154, 157(in Chinese). doi: 10.3969/j.issn.1671-833X.2009.z1.047 [14] 崔卫军, 李庆飞, 周凯华. 复合材料T型接头承载能力设计研究[J]. 民用飞机设计与研究, 2012(z1):94-98. doi: 10.3969/j.issn.1674-9804.2012.z1.023CUI Weijun, LI Qingfei, ZHOU Kaihua. Research on load capacity design of composite T-joint[J]. Civil Aircraft Design and Research,2012(z1):94-98(in Chinese). doi: 10.3969/j.issn.1674-9804.2012.z1.023 [15] BAI J B, CHEN H D, XIONG J J. Progressive damage behaviour of RTM-made composite T-joint under tensile[J]. Composites Part B: Engineering,2019,160:488-497. doi: 10.1016/j.compositesb.2018.12.069 [16] WU H, XIAO J Y, XING S L, et al. Numerical and experimental investigation into failure of T700/bismaleimide composite T-joints under tensile loading[J]. Composite Structures,2015,130:63-74. doi: 10.1016/j.compstruct.2015.04.019 [17] 文立伟, 余坤, 宦华松. 缝合复合材料T型接头拉伸载荷下的有限元数值模拟[J]. 航空学报, 2021, 42(2):136-143.WEN Liwei, YU Kun, HUAN Huasong. Finite element numerical simulation of stitched composite T-joint under tensile load[J]. Acta Aeronautica et Astronautica Sinica,2021,42(2):136-143(in Chinese). [18] 李梦佳, 陈普会, 孔斌, 等. 缝合参数对复合材料T型接头拉脱承载能力的影响[J]. 复合材料学报, 2016, 33(3):681-688. doi: 10.13801/j.cnki.fhclxb.20151013.004LI Mengjia, CHEN Puhui, KONG Bin, et al. Effects of parameters of stitching on pull-off carrying capacity of composite T-joint[J]. Acta Materiae Compositae Sinica,2016,33(3):681-688(in Chinese). doi: 10.13801/j.cnki.fhclxb.20151013.004 [19] 齐红宇, 王天龙, 梁晓波, 等. 弯曲载荷下机织复合材料T型接头渐进失效分析[J]. 复合材料学报, 2016, 33(6):1161-1167. doi: 10.13801/j.cnki.fhclxb.20160324.001QI Hongyu, WANG Tianlong, LIANG Xiaobo, et al. Progressive failure analysis of woven composite T-joints under bending load[J]. Acta Materiae Compositae Sinica,2016,33(6):1161-1167(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160324.001 [20] 朱亮, 崔浩, 李玉龙, 等. 含缺陷复合材料T型接头失效数值分析[J]. 航空学报, 2012, 33(2):287-296. doi: 11-1929/V.20111107.1045.008ZHU Liang, CUI Hao, LI Yulong, et al. Numerical simulation of the failure of composite T-joints with defects[J]. Acta Aeronautica et Astronautica Sinica,2012,33(2):287-296(in Chinese). doi: 11-1929/V.20111107.1045.008 [21] BARZEGAR M, DAVOODI M, MOKHTARI M. Progressive damage analysis of an adhesively bonded composite T-joint under bending considering micro-scale effects of fiber volume fraction of adherends[J]. Composite Structures,2021,258:113374. doi: 10.1016/j.compstruct.2020.113374 [22] LI G C, XUE P, LUO G, et al. Shear behavior and failure analysis of a composite T-joint with a cutout[J]. Journal of Composite Materials,2015,49(19):2307-2315. doi: 10.1177/0021998314545 [23] HOU W B, XU X Z, SANG L, et al. Failure of single hat-shaped thin-walled tubular composite T-joints under impact loading[J]. Thin-Walled Structures,2020,154:106815. doi: 10.1016/j.tws.2020.106815 [24] 崔浩, 李玉龙, 刘元镛, 等. 基于粘聚区模型的含填充区复合材料接头失效数值模拟[J]. 复合材料学报, 2010, 27(2):161-168.CUI Hao, LI Yulong, LIU Yuanyong, et al. Numerical simulation of composites joints failure based on cohesive zone model[J]. Acta Materiae Compositae Sinica,2010,27(2):161-168(in Chinese). [25] BENZEGGAH M L, KENANE M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J]. Composites Science and Technology,1996,56(4):439-449. doi: 10.1016/0266-3538(96)00005-X [26] 孙文博, 马玉娥. 填充物、胶膜和Z-pin对复合材料T型接头强度影响对比[J]. 复合材料学报, 2018, 35(1):110-116. doi: 10.13801/j.cnki.fhclxb.20170417.001SUN Wenbo, MA Yu’e. Effects of adhesive, filler and Z-pin on strength of composite T-joint[J]. Acta Materiae Compositae Sinica,2018,35(1):110-116(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170417.001 [27] SHINSAKU H, SHU M, NOBUO T. Cure-induced strain and failure in deltoid of composite T-joints[J]. Composites Part A: Applied Science and Manufacturing,2021,141:106210. doi: 10.1016/j.compositesa.2020.106210 [28] ANIL R R, RAJ B L, CHUN H W, et al. Strengthening of composite T-joints using 1D and 2D carbon nanoparticles[J]. Composite Structures,2021,255:112982. doi: 10.1016/j.compstruct.2020.112982 [29] ROBERT D C. Advanced mechanics of materials[M]. New York: Macmillan Publishing Company, 1985: 240-241. [30] DATOO M H. Mechanics of fibrous composites[M]. New York: Elsevier Science Publishing CO., INC., 1991: 150-152. [31] DANIEL I S, ISHAI O. Engineering mechanical of composite materials[M]. New York: Oxford University Press, 2006: 282-284. -

下载:

下载: