Tensile behavior and failure mechanism of C/SiC composite based on digital image technology

-

摘要: 本文通过二维平纹编织C/SiC复合材料的准静态单轴拉伸试验的数字图像相关(DIC)技术分析,研究损伤与应变的关系及最大应变处与断裂位置的关系。通过对材料的孔隙分析及断口分析,探究材料在损伤演化过程中内部结构的变化。结果表明,拉伸载荷作用下,材料的应变并不均匀。而层与层间损伤差异及相互影响导致最大应变位置一直变化。随着损伤的不断累积,最大应变位置处先发生断裂;材料的断裂失效位置往往与其结构薄弱程度及应力应变水平密切相关;断裂瞬间,多重拔出机制及各层结构差异性导致层与层的失效位置不同,造成分层失效。

-

关键词:

- 平纹编织C/SiC复合材料 /

- 最大应变位置 /

- 断裂位置 /

- 损伤演化 /

- 分层失效

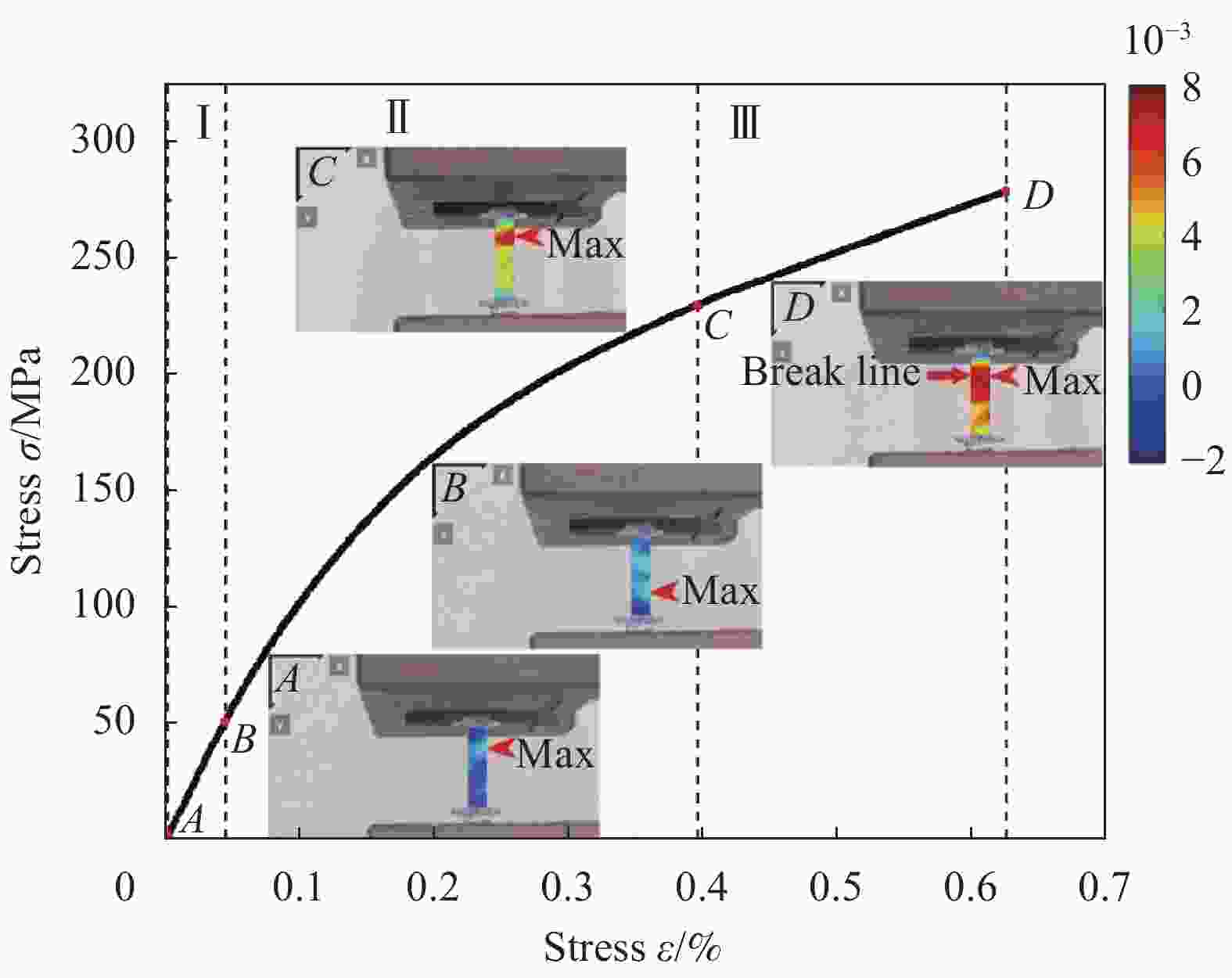

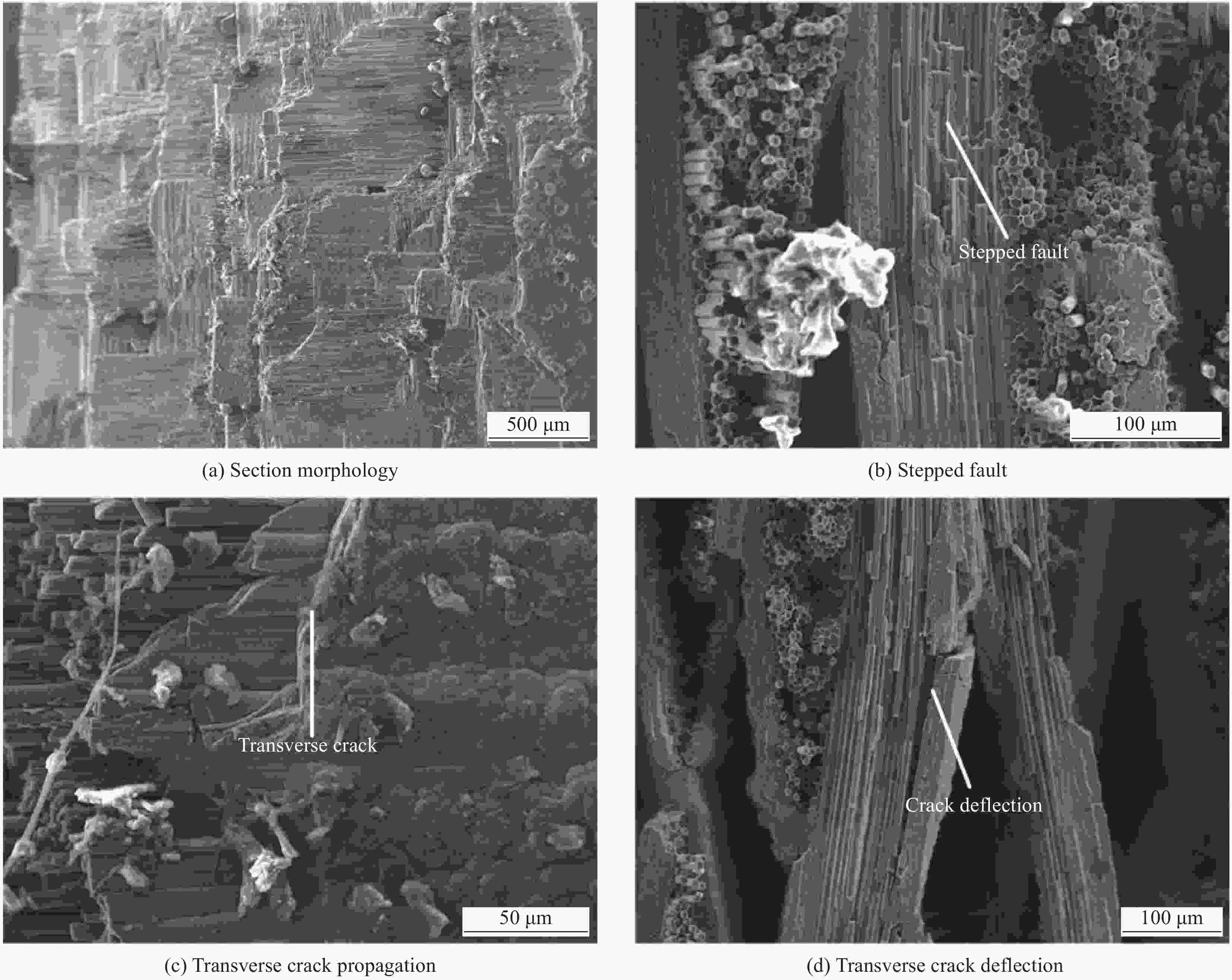

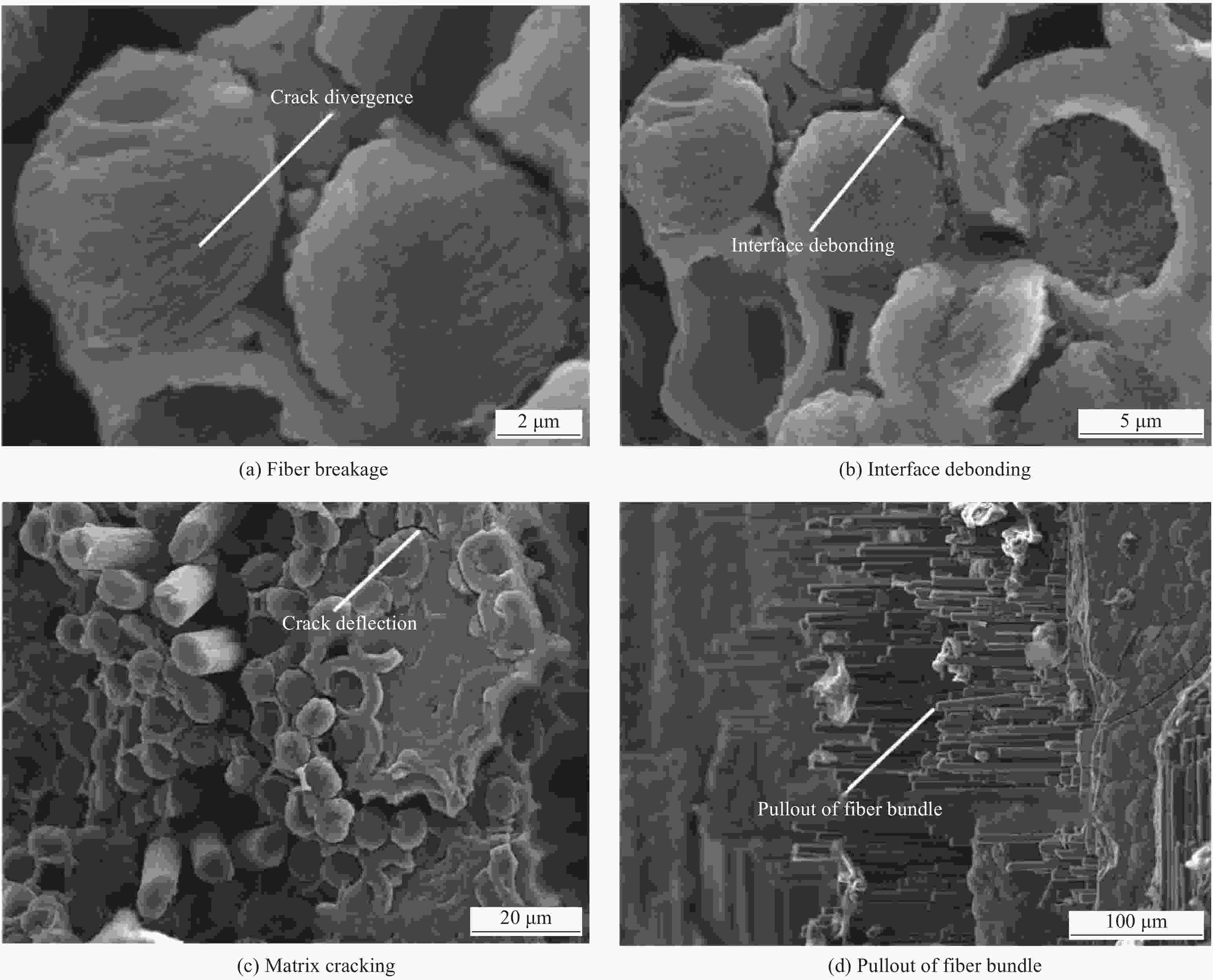

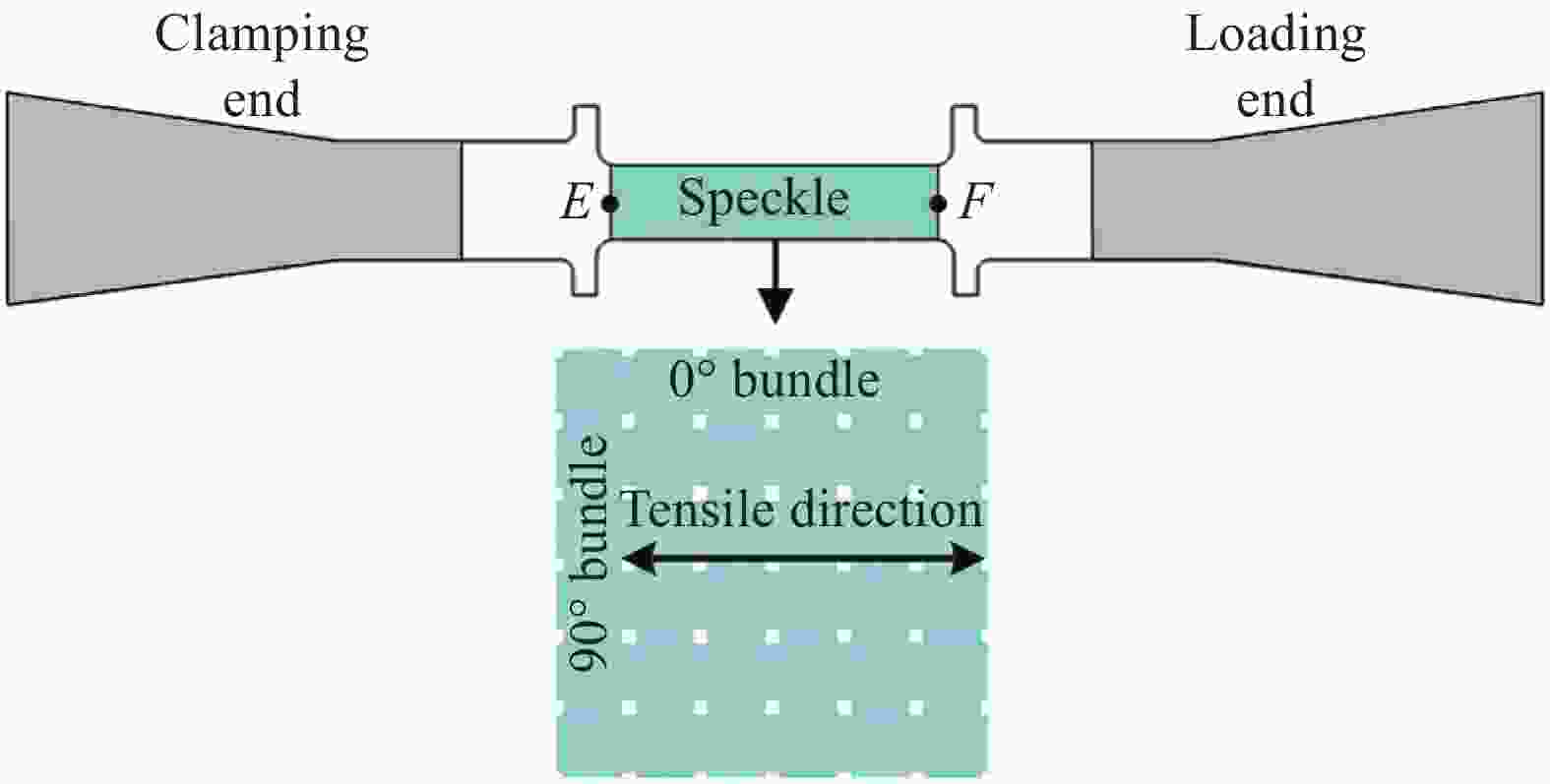

Abstract: The relationship between the damage and strain as well as the relationship between the maximum strain and fracture position were investigated by the quasi-static uniaxial tensile test of plain weave C/SiC composite using digital image correlation (DIC) technology analysis. The variation of material’s internal structure during the damage evolution has been explored by analyzing the material’s pore and fracture. The results show that the strain of the material under tensile load is not well-distributed. The damage difference between layers and their inter-action result in the constant variation of maximum strain position. With the accumulation of damage, fracture occurs first to the position of maximum strain and the fracture failure location of this material is often closely related to its structural weakness and the stress and strain level. At the moment of material fracture, the multiple pull-out mechanism and the structural difference in each of layers lead to different failure positions among layers, resulting in delamination failure. -

表 1 二维平纹编织C/SiC复合材料拉伸性能

Table 1. Mechanical properties of 2D plain weave C/SiC composites under tensile load

Number of sample Tensile modulus/GPa Tensile strength/MPa Strain/% T1 151.60 261.35 0.553 T2 113.46 279.43 0.580 T3 113.89 278.63 0.626 表 2 拉伸各阶段二维平纹编织C/SiC复合材料DIC应变云图的变化

Table 2. Variation of DIC strain nephogram of 2D plain weave C/SiC composite at different stretching stages

Stage (${\varepsilon _{yy\max }} = 0.626\% $) (I)

${\varepsilon _{yy}}$ $0$ $0.025{\varepsilon _{yy\max }}$ $0.05{\varepsilon _{yy\max }}$ (Ⅱ)

${\varepsilon _{yy}}$ $0.2{\varepsilon _{yy\max }}$ $0.4{\varepsilon _{yy\max }}$ $0.6{\varepsilon _{yy\max }}$ (Ⅲ)

${\varepsilon _{yy}}$ $0.8{\varepsilon _{yy\max }}$ $0.9{\varepsilon _{yy\max }}$ ${\varepsilon _{yy\max }}$ Notes: ${\varepsilon _{yy}}$—Strain of the specimen in the loading direction; ${\varepsilon _{yy\max }}$—Fracture strain. 表 3 同一阶段二维平纹编织C/SiC复合材料试样DIC应变云图的变化

Table 3. Variation of DIC strain nephogram of 2D plain weave C/SiC composite specimen at the same stage

Stage ${\varepsilon _{yy}}$ T1(${\varepsilon _{yy\max }} = 0.553\% $) T2(${\varepsilon _{yy\max }} = 0.580\% $) T3(${\varepsilon _{yy\max }} = 0.626\% $) (Ⅱ) $0.2{\varepsilon _{yy\max }}$

$0.4{\varepsilon _{yy\max }}$

$0.6{\varepsilon _{yy\max }}$

(Ⅲ) $0.8{\varepsilon _{yy\max }}$

$0.9{\varepsilon _{yy\max }}$

${\varepsilon _{yy\max }}$

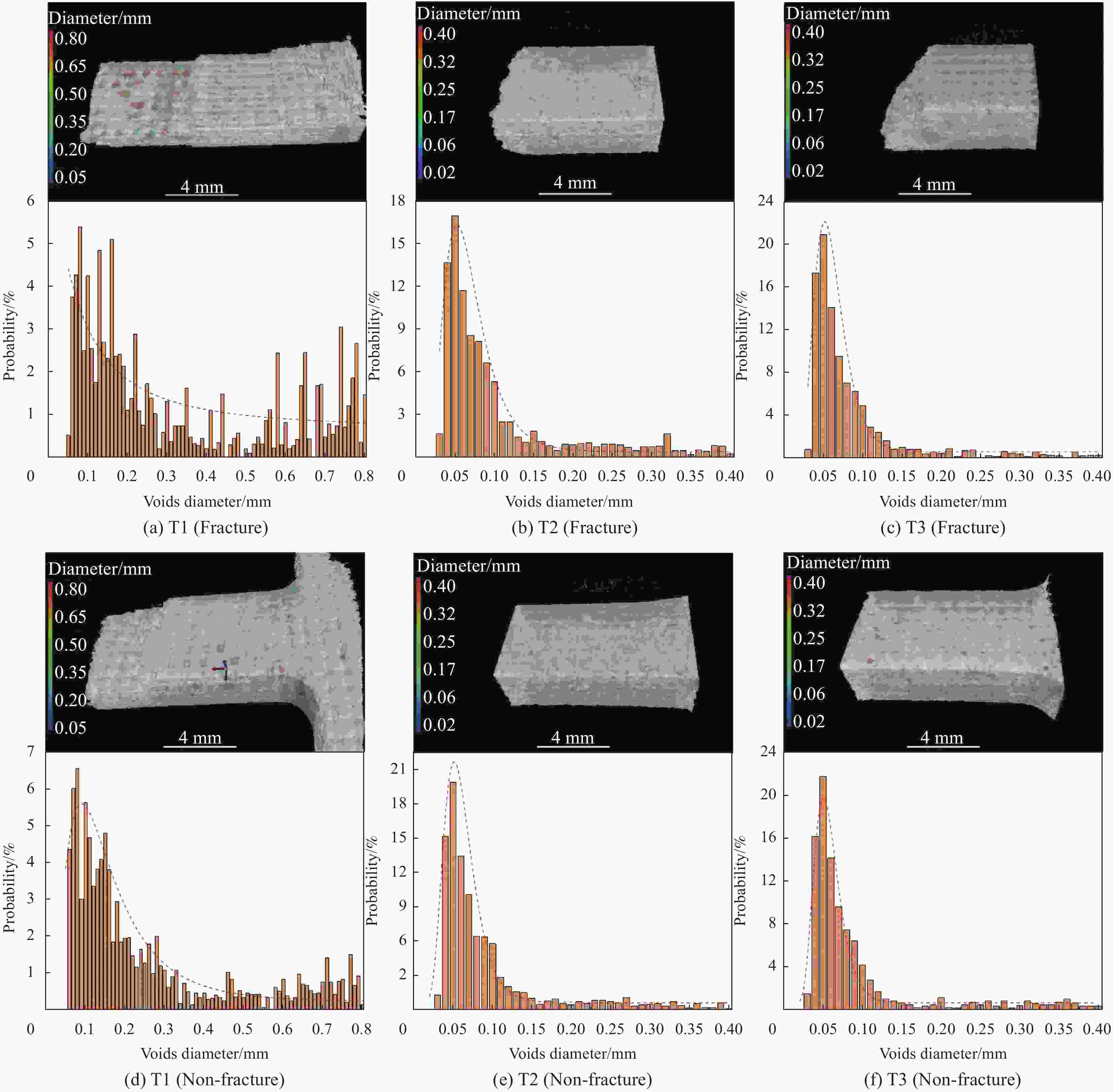

表 4 二维平纹编织C/SiC复合材料试样孔隙直径的对数正态分布特征参数

Table 4. Lognormal distribution characteristic of pore diameter of 2D plain weave C/SiC composite specimen

Sample $\mu $ $\sigma $ T1(Fracture) 0.1318 1.3864 T1(Non-fracture) 0.1394 0.6603 T2(Fracture) 0.0632 0.4356 T2(Non-fracture) 0.0579 0.3466 T3(Fracture) 0.0578 0.3398 T3(Non-fracture) 0.0582 0.2414 Note: $\mu $ and $\sigma $—Mean and variance of lognormal distribution, respectively. -

[1] 陈素芳, 谭志勇, 姜东, 等. 高温环境下纤维增强复合材料等效参数预测[J]. 振动与冲击, 2018, 37(11):216-224.CHEN Sufang, TAN Zhiyong, JIANG Dong, et al. Equivalent parametric prediction for fiber reinforced composites under high temperature environments[J]. Journal of Vibration and Shock,2018,37(11):216-224(in Chinese). [2] 张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展[J]. 航空制造技术, 2003(1):24-32. doi: 10.3969/j.issn.1671-833X.2003.01.009ZHANG Litong, CHENG Laifei, XU Yongdong. Research progress of new silicon carbide ceramic matrix compo-sites[J]. Aviation Manufacturing Technology,2003(1):24-32(in Chinese). doi: 10.3969/j.issn.1671-833X.2003.01.009 [3] 管国阳, 矫桂琼, 张增光. 2D-C/SiC复合材料的宏观拉压特性和失效模式[J]. 复合材料学报, 2005(4):81-85. doi: 10.3321/j.issn:1000-3851.2005.04.014GUAN Guoyang, JIAO Guiqiong, ZHANG Zengguang. Macroscopic tensile and compression characteristics and failure modes of 2D-C/SiC composites[J]. Acta Materiae Compositae Sinica,2005(4):81-85(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.04.014 [4] JACOBSEN T K, BRØNDSTED P. Mechanical properties of two plain-woven chemical vapor infiltrated silicon carbide-matrix composites[J]. Journal of the American Ceramic Society, 2001, 84(5): 1043-1051. [5] YU G, GAO X, FANG G, et al. Strain field evolution of 2D needled C/SiC composites under tension[J]. Journal of the European Ceramic Society,2017,37(2):531-537. doi: 10.1016/j.jeurceramsoc.2016.09.030 [6] 杨成鹏, 矫桂琼, 王波. 2D-C/SiC复合材料的单轴拉伸力学行为及其强度[J]. 力学学报, 2011, 43(2):330-337.YANG Chengpeng, JIAO Guiqiong, WANG Bo. Uniaxial tensile mechanical behavior and strength of 2D-C/SiC composites[J]. Chinese Journal of Theoretical and Applied Mechanics,2011,43(2):330-337(in Chinese). [7] LI T, DUAN Y, JIN K, et al. Dynamic compressive fracture of C/SiC composites at different temperatures: microstructure and mechanism[J]. International Journal of Impact Engineering,2017,109:391-399. doi: 10.1016/j.ijimpeng.2017.08.001 [8] CAMUS G. Modelling of the mechanical behavior and damage processes of fibrous ceramic matrix composites: Application to a 2-D SiC/SiC[J]. International Journal of solids and Structures,2000,37(6):919-942. doi: 10.1016/S0020-7683(99)00065-7 [9] HU W, HUANG J, ZHANG C, et al. Effect of shear strain rate on interlaminar shear behavior of 2D-C/SiC composites: A damage transition from notch ends initiation to gauge section initiation[J]. Carbon,2020,167:770-784. doi: 10.1016/j.carbon.2020.05.067 [10] ZHANG Y, ZHANG L, YIN X, et al. Effects of porosity on in-plane and interlaminar shear strengths of two-dimensional carbon fiber reinforced silicon carbide composites[J]. Materials & Design,2016,98:120-127. [11] ZHANG Y, ZHANG L, LIU Y, et al. Oxidation effects on in-plane and interlaminar shear strengths of two-dimensional carbon fiber reinforced silicon carbide composites[J]. Carbon,2016,98:144-156. doi: 10.1016/j.carbon.2015.10.091 [12] 卢广达, 陈建兵. 基于一类非局部宏-微观损伤模型的裂纹模拟[J]. 力学学报, 2020, 52(3):749-762. doi: 10.6052/0459-1879-19-319LU Guangda, CHEN Jianbing. Crack simulation based on a non-local macro-micro damage model[J]. Chinese Jour-nal of Theoretical and Applied Mechanics,2020,52(3):749-762(in Chinese). doi: 10.6052/0459-1879-19-319 [13] 王勃, 张阳博, 左宏, 等. 压应力对压剪裂纹扩展的影响研究[J]. 力学学报, 2019, 51(3):845-851.WANG Bo, ZHANG Yangbo, ZUO Hong, et al. Study on the effect of compressive stress on the growth of compressive shear cracks[J]. Chinese Journal of Theoretical and Applied Mechanics,2019,51(3):845-851(in Chinese). [14] 刘海龙, 张大旭, 祁荷音, 等. 基于X射线CT原位试验的平纹SiC/SiC复合材料拉伸损伤演化[J]. 上海交通大学学报, 2020, 54(10):1074-1083.LIU Hailong, ZHANG Daxu, QI Heyin, et al. Tensile damage evolution of plain weave SiC/SiC composites based on In-situ X-ray CT test[J]. Journal of Shanghai Jiaotong University,2020,54(10):1074-1083(in Chinese). [15] 曾增, 张庆茂, 刘伟先, 等. 单向C/SiC陶瓷基复合材料基体失效机制与强度预测[J]. 复合材料学报, 2015, 32(4):1075-1082.ZENG Zeng, ZHANG Qingmao, LIU Weixian, et al. Matrix failure mechanism and strength prediction of unidirectional C/SiC ceramic matrix composites[J]. Acta Materiae Compositae Sinica,2015,32(4):1075-1082(in Chinese). [16] 曹明月, 张启, 吴建国, 等. 缝合式C/SiC复合材料非线性本构关系及断裂行为研究[J]. 力学学报, 2020, 52(4):1095-1105.CAO Mingyue, ZHANG Qi, WU Jianguo, et al. Nonlinear constitutive relationship and fracture behavior of stitched C/SiC composites[J]. Chinese Journal of Theoretical and Applied Mechanics,2020,52(4):1095-1105(in Chinese). [17] 孙轩, 王雅萍, 王博怀. 数字图像相关法变形测量系统的研究与应用[J]. 机械设计与制造, 2019(3):149-152, 157.SUN Xuan, WANG Yaping, WANG Bohuai. Research and application on digital image correlation deformation measurement system[J]. Machinery Design & Manufacture,2019(3):149-152, 157(in Chinese). [18] HE W, WANG C, WANG S, et al. Characterizing and predicting the tensile mechanical behavior and failure mechanisms of notched FMLs—Combined with DIC and numerical techniques[J]. Composite Structures,2020,254:112893. doi: 10.1016/j.compstruct.2020.112893 [19] TABRIZI I E, KHAN R M A, MASSARWA E, et al. Determining tab material for tensile test of CFRP laminates with combined usage of digital image correlation and acoustic emission techniques[J]. Composites Part A: Applied Science and Manufacturing,2019,127:105623. doi: 10.1016/j.compositesa.2019.105623 [20] YU G, GAO X, XIE C, et al. In-plane shear damage behaviours of 2D needled C/SiC composites[J]. Fatigue& Fracture of Engineering Materials & Structures,2019,42(2):454-465. [21] GAO X, YU G, XUE J, et al. Failure analysis of C/SiC composites plate with a hole by the PFA and DIC method[J]. Ceramics International,2017,43(6):5255-5266. doi: 10.1016/j.ceramint.2017.01.051 [22] 胡殿印, 曾雨琪, 张龙, 等. 二维编织SiC/SiC陶瓷基复合材料宏观弹性常数预测及模态试验研究[J]. 推进技术, 2018, 39(2):465-472.HU Dianyin, ZENG Yuqi, ZHANG Long, et al. Effective elastic constants prediction and modal test of 2D braided SiC/SiC ceramic matrix composites[J]. Journal of Propulsion Technology,2018,39(2):465-472(in Chinese). [23] 王怀文, 亢一澜, 谢和平. 数字散斑相关方法与应用研究进展[J]. 力学进展, 2005(2):195-203.WANG Huaiwen, KANG Yilan, XIE Heping. Research progress of digital speckle correlation method and its application[J]. Advances in Mechanics,2005(2):195-203(in Chinese). [24] PAN B. Recent progress in digital image correlation[J]. Experimental Mechanics,2011,51(7):1223-1235. doi: 10.1007/s11340-010-9418-3 [25] 史俊伟, 刘松平, 荀国立. 复合材料孔隙超声反射法和穿透法检测对比分析[J]. 航空材料学报, 2020, 40(2):89-99.SHI Junwei, LIU Songping, XUN Guoli. Comparative analysis of composite material pores by ultrasonic reflection method and penetration method[J]. Journal of Aeronautical Materials,2020,40(2):89-99(in Chinese). [26] 陆铭慧, 张雪松, 郑善朴, 等. 基于超声的碳纤维复合材料孔隙率表征方法对比研究[J]. 玻璃钢/复合材料, 2018(7):42-48.LU Minghui, ZHANG Xuesong, ZHENG Shanpu, et al. Comparative study on the porosity characterization methods of carbon fiber composites based on ultrasound[J]. Glass Fiber Reinforced Plastics/composites,2018(7):42-48(in Chinese). [27] 刘继忠, 周晓军, 蒋志峰. 碳纤维复合材料孔隙率超声衰减测试研究[J]. 材料科学与工艺, 2017(2):260-263.LIU Jizhong, ZHOU Xiaojun, JIANG Zhifeng. Research on ultrasonic attenuation test of porosity of carbon fiber composites[J]. Materials Science and Technology,2017(2):260-263(in Chinese). -

下载:

下载: