Axial compressive property of circular steel tubular stub column filled with basalt fiber reinforced recycled concrete

-

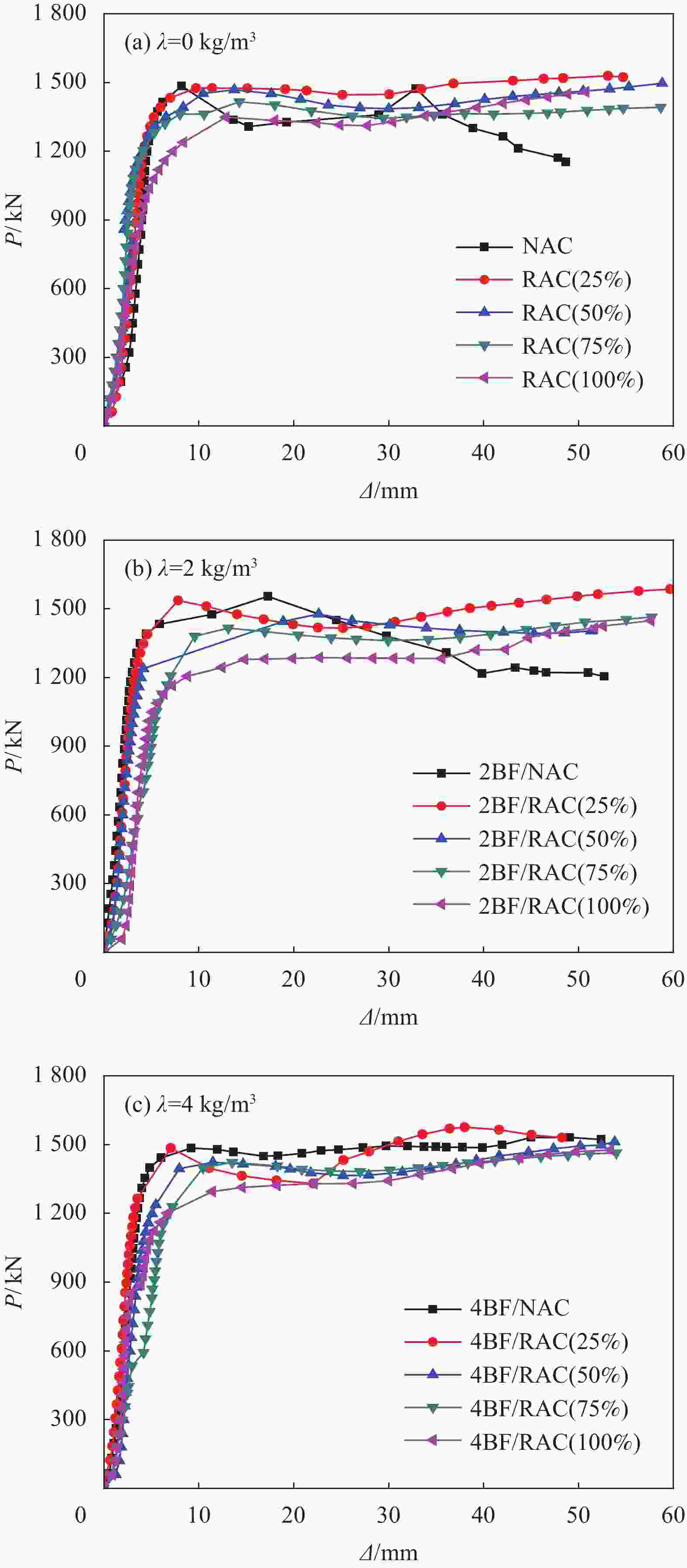

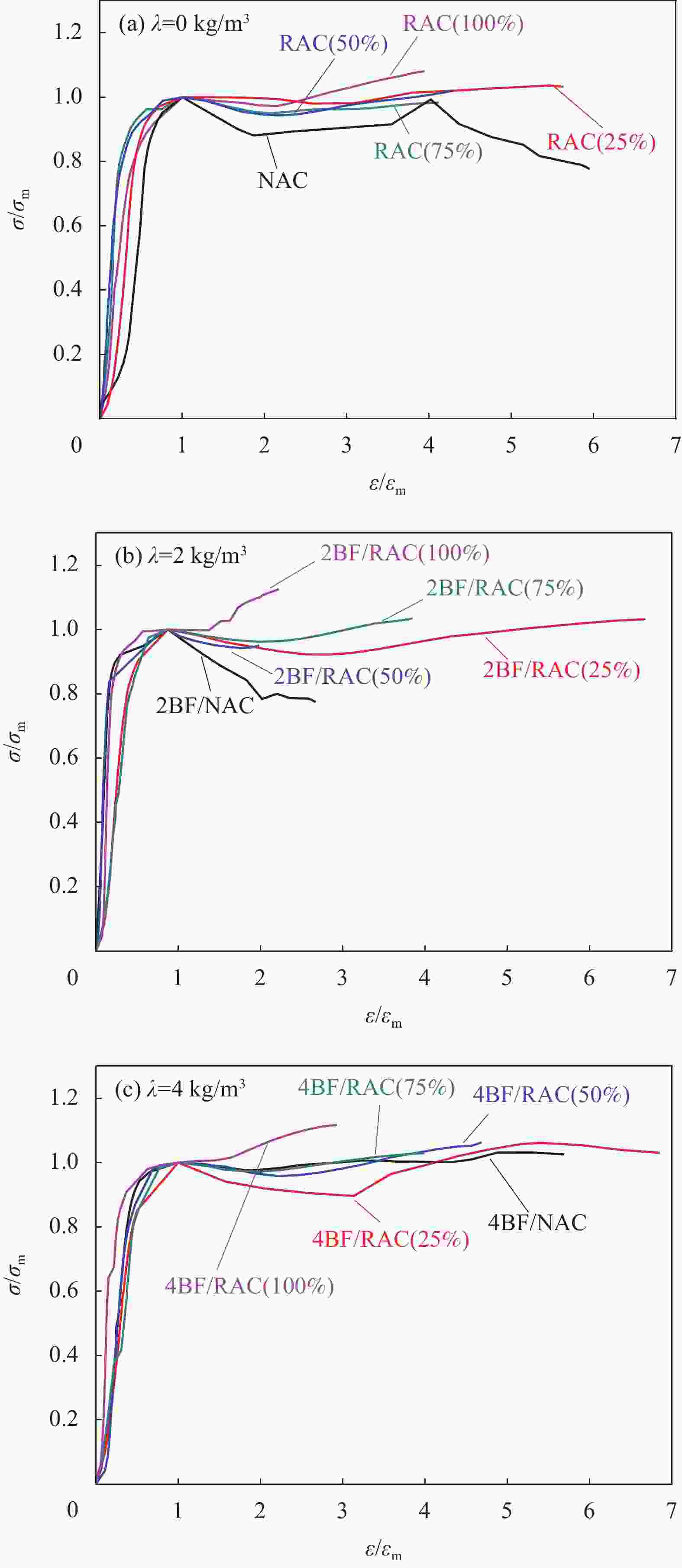

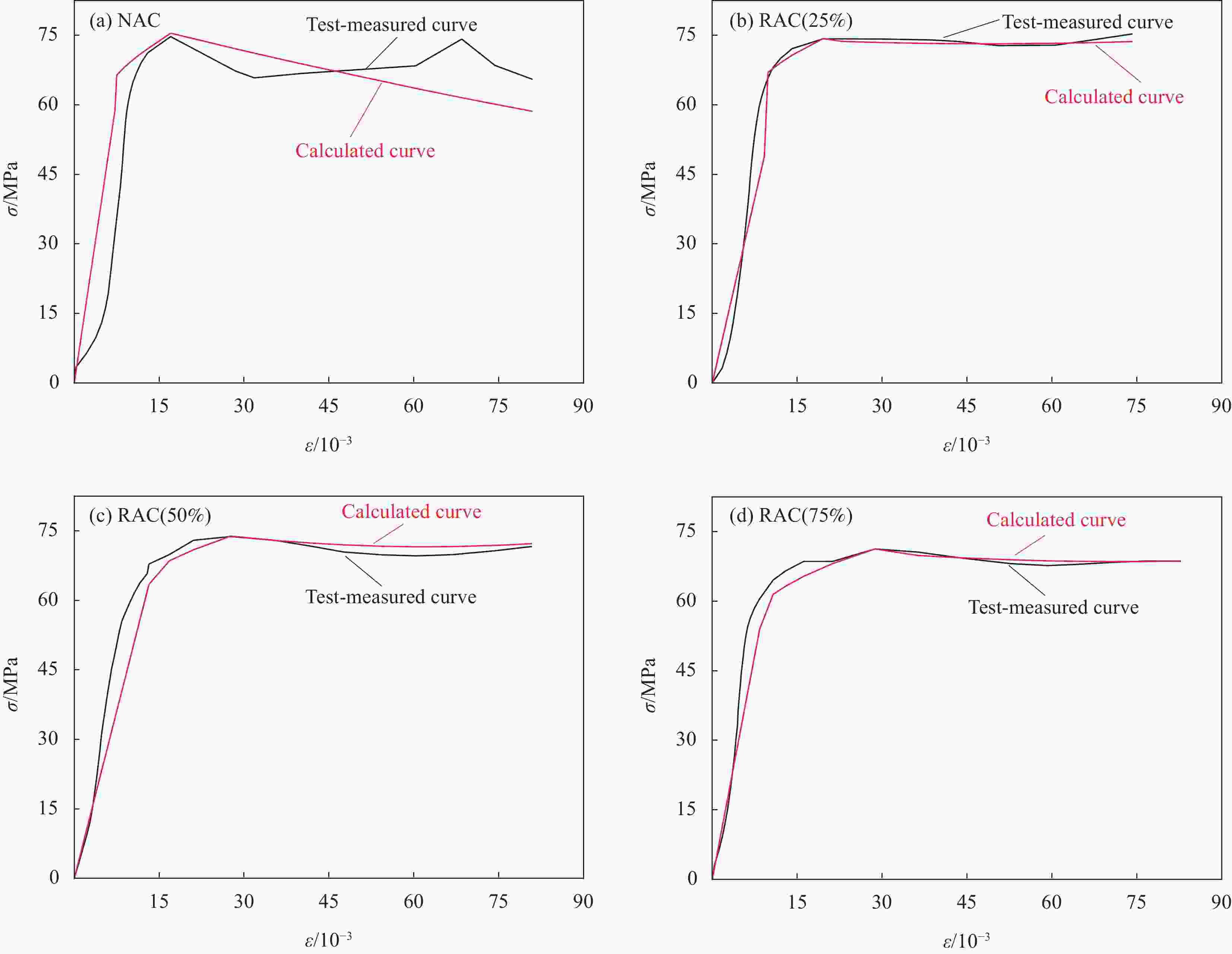

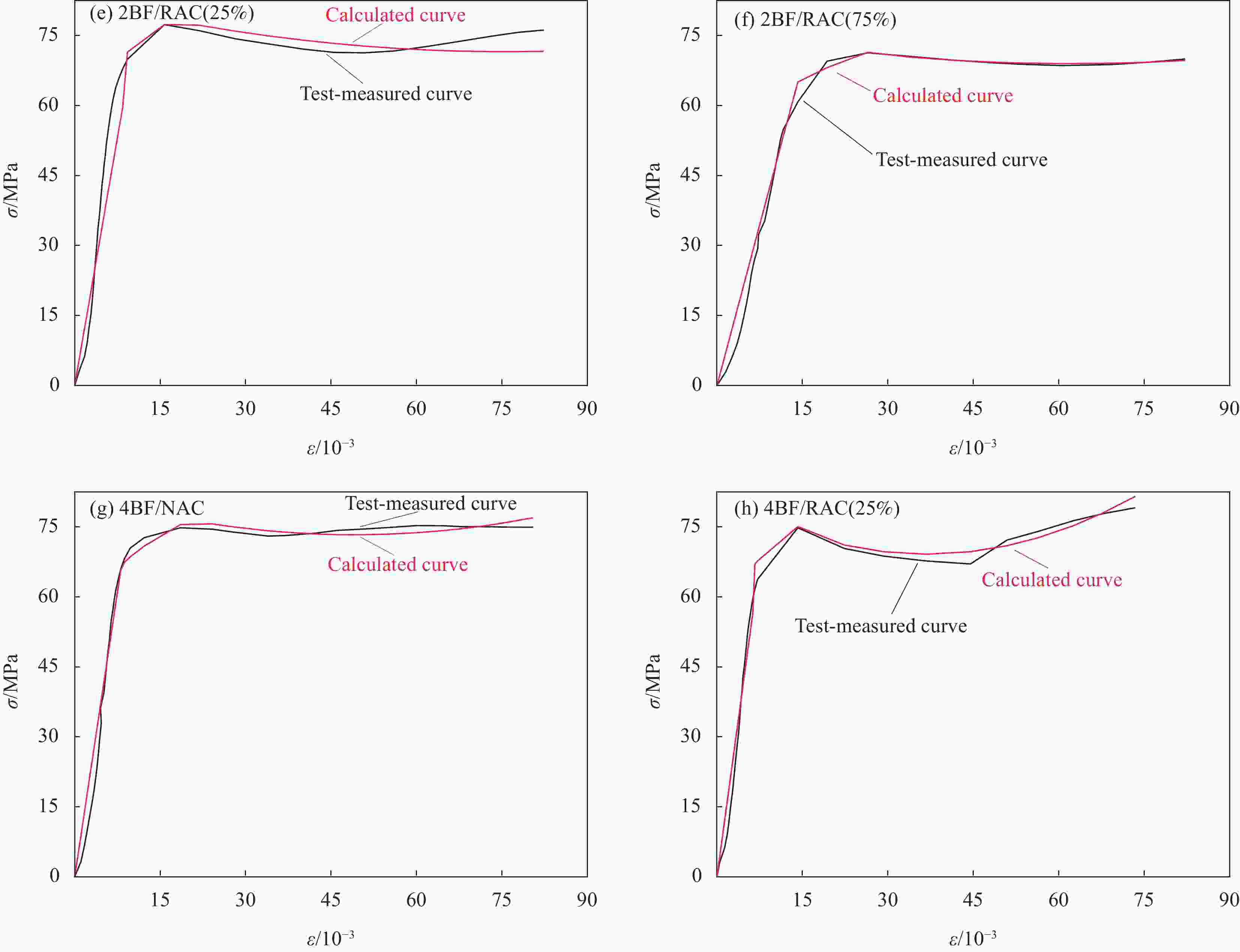

摘要: 为研究圆钢管玄武岩纤维再生混凝土(BFRRC)短柱的轴压力学性能,以再生粗骨料取代率和玄武岩纤维掺量为变化参数,设计并完成了15根圆钢管BFRRC短柱试件的轴压试验。观察了试件的受力全过程及破坏形态,获取了试件的荷载-位移曲线及荷载-应变曲线,分析了变化参数对圆钢管BFRRC短柱轴压性能的影响,建立了可行的组合截面应力-应变全过程曲线方程。研究表明:试件均发生鼓曲破坏,但核心混凝土在钢管约束下处于碎而不散状态;随着再生粗骨料取代率的增大,试件的耗能性能、延性系数逐渐增大,耗能因子、延性系数提升幅度最高可达1.84%和10.36%,承载力逐渐降低,降低幅度最大达5.03%;随着玄武岩纤维掺量的增大,试件的耗能性能、延性系数逐渐增大,增加幅度最高可达2.97%和4.93%,承载力提高幅度不大;不同的玄武岩纤维掺量下,试件实测的荷载-位移曲线饱满,且具有较长的变形流幅,延性较好。

-

关键词:

- 圆钢管玄武岩纤维再生混凝土 /

- 短柱 /

- 轴向受压 /

- 力学性能 /

- 组合截面应力-应变全过程曲线

Abstract: To study the axial compressive performance of basalt fiber reinforced recycled concrete (BFRRC)-filled circular steel tubular stub columns, the replacement ratio of recycled coarse aggregate and the content of basalt fiber were designed as the variable parameters and the axial compression performance tests on 15 BFRRC-filled circular steel tubular stub column specimens were carried out. The failure mode and whole loading process of the specimen were characterized. The load-displacement and load-strain curves of the specimen were obtained. The influence of design parameter on the BFRRC-filled circular steel tubular stub column specimens was analyzed. A feasible full-curve equation of composite-section stress versus strain was established. It is observed that the specimen undergoes buckling damage, but the internal BFRRC is crushed but “broken and not scattered”. On increasing the replacement ratio of recycled coarse aggregate, the energy dissipation capacity and ductility coefficient of the specimen are gradually increased, the maximum increasing extent for energy dissipation capacity and ductility coefficient are 1.84% and 10.36%, respectively, whereas the bearing capacity is gradually decreased, and the maximum increasing extent of bearing capacity is 5.03%. On increasing the basalt fiber content, the energy dissipation capacity and ductility coefficient of the specimen are gradually increased, the maximum increasing extent for energy dissipation capacity and ductility coefficient are 2.97% and 4.93%, respectively, whereas little increase appears about the bearing capacity. The measured load-displacement curve of the specimen with different basalt fiber content is full, and it has a long deformation flow, which presents satisfactory ductility. -

表 1 再生混凝土(RAC)的配合比

Table 1. Mix ratio of recycled aggregate concrete (RAC)

δ/% Water-binder

ratioSand ratio/% Net water/

(kg·m−3)Additional water/

(kg·m−3)Cement/

(kg·m−3)Fly-ash/

(kg·m−3)Recycled coarse

aggregate/

(kg·m−3)Nature coarse

aggregate/

(kg·m−3)Sand/

(kg·m−3)Water reducer/

(kg·m−3)0 0.40 31 205 0.0 427.1 85.4 0.0 1115.2 501 2.56 25 0.40 31 205 15.6 427.1 85.4 278.8 836.4 501 2.56 50 0.40 31 205 31.2 427.1 85.4 557.6 557.6 501 2.56 75 0.40 31 205 46.8 427.1 85.4 836.4 278.8 501 2.56 100 0.40 31 205 62.5 427.1 85.4 1115.2 0.0 501 2.56 Note: δ—Replacement ratio of recycled coarse aggregate. 表 2 RAC实测强度指标

Table 2. Measured strength index of RAC

Specimen δ/% λ/(kg·m−3) fcu/MPa fc/MPa fc/fcu Ec/GPa v NAC 0 0 37.4 31.8 0.85 24.70 0.20 RAC(25%) 25 0 36.5 28.5 0.78 16.80 0.23 RAC(50%) 50 0 34.2 26.0 0.76 16.60 0.25 RAC(75%) 75 0 32.9 23.8 0.72 13.30 0.26 RAC(100%) 100 0 32.7 23.2 0.71 15.20 0.27 2BF/NAC 0 2 37.9 32.9 0.87 24.80 0.16 2BF/RAC(25%) 25 2 37.0 29.0 0.78 19.01 0.17 2BF/RAC(50%) 50 2 34.9 26.7 0.77 18.48 0.19 2BF/RAC(75%) 75 2 33.8 24.6 0.73 14.60 0.20 2BF/RAC(100%) 100 2 33.1 23.7 0.72 13.42 0.22 4BF/NAC 0 4 38.7 33.1 0.86 28.40 0.14 4BF/RAC(25%) 25 4 37.6 29.4 0.78 21.47 0.16 4BF/RAC(50%) 50 4 36.2 27.5 0.76 18.91 0.18 4BF/RAC(75%) 75 4 35.1 25.8 0.74 19.06 0.19 4BF/RAC(100%) 100 4 34.2 24.0 0.70 18.27 0.21 Notes: λ—Mass of basalt fiber added to 1 m3 RAC; fcu—Cubic compressive strength; fc—Axial compressive strength; Ec—Elastic modulus, which is the secant modulus of the stress-strain curve from origin to 0.4 fc; v—Poisson’s ratio, which is the ratio of the transverse strain to the longitudinal strain of basalt fiber reinforced recycledconcrete (BFRRC) at 0.4 fc stress. 表 3 圆钢管玄武岩纤维再生混凝土(BFRRC)短柱具体设计参数及实测峰值承载力

Table 3. Specific design parameters and measured peak bearing capacity of the basalt fiber reinforced recycled concrete (BFRRC)-filled circular steel tubular stub column specimens

Specimen α ξ fc/MPa Nu/kN NAC 0.0942 0.997 31.8 1484.0 RAC(25%) 0.0942 1.113 28.5 1475.0 RAC(50%) 0.0942 1.220 26.0 1470.2 RAC(75%) 0.0942 1.332 23.8 1415.4 RAC(100%) 0.0942 1.367 23.2 1357.1 2BF/NAC 0.0942 0.964 32.9 1554.2 2BF/RAC(25%) 0.0942 1.093 29.0 1536.7 2BF/RAC(50%) 0.0942 1.188 26.7 1468.2 2BF/RAC(75%) 0.0942 1.289 24.6 1418.1 2BF/RAC(100%) 0.0942 1.338 23.7 1346.8 4BF/NAC 0.0942 0.958 33.1 1499.2 4BF/RAC(25%) 0.0942 1.079 29.4 1490.4 4BF/RAC(50%) 0.0942 1.153 27.5 1446.7 4BF/RAC(75%) 0.0942 1.229 25.8 1426.9 4BF/RAC(100%) 0.0942 1.321 24.0 1369.9 Notes: α—Steel ratio, α=As/Ac, where As and Ac are the cross-sectional area of the steel tube and internal concrete, respectively; ξ—Confinement coefficient, ξ=αfy/fc; Nu—Test value of the ultimate bearing capacity of the specimen; NAC—Natural aggregate concrete; fy—Yield strength of steel tube. In the naming method of a specimen, for example, in 2BF/RAC(25%), 2 represents the basalt fiber content of 2 kg/m3, 25% is the replacement ratio of recycled coarse aggregate. 表 4 圆钢管BFRRC短柱各应力值、承载力退化幅度和回升幅度

Table 4. Stress values, degradation amplitude and rebound amplitude for bearing capacity of the BFRRC-filled circular steel tubular stub column specimens

Specimen σ1 σ2 σ3 λ1 λ2 NAC 74.74 65.85 74.21 0.88 0.99 RAC(25%) 74.29 72.79 76.94 0.98 1.04 RAC(50%) 74.04 69.75 75.37 0.94 1.02 RAC(75%) 71.28 67.69 70.10 0.95 0.98 RAC(100%) 68.35 66.07 73.47 0.97 1.07 Average — — — 0.94 1.02 2BF/NAC 78.27 61.34 62.61 0.78 0.80 2BF/RAC(25%) 77.39 71.32 79.83 0.92 1.03 2BF/RAC(50%) 73.94 70.14 71.06 0.95 0.96 2BF/RAC(75%) 71.42 68.57 73.73 0.96 1.03 2BF/RAC(100%) 67.83 64.63 72.92 0.95 1.08 Average — — — 0.91 0.98 4BF/NAC 75.50 73.03 77.17 0.97 1.02 4BF/RAC(25%) 75.06 67.04 79.41 0.89 1.06 4BF/RAC(50%) 72.86 68.77 76.21 0.94 1.05 4BF/RAC(75%) 71.86 69.67 73.73 0.97 1.03 4BF/RAC(100%) 68.99 66.61 74.42 0.97 1.08 Average — — — 0.95 1.05 Notes: σ1, σ2 and σ3—First peak stress, the valley stress, and secondary peak stress, respectively; λ1 and λ2—Degradation amplitude and rebound amplitude for bearing capacity. 表 5 圆钢管BFRRC短柱轴压性能指标

Table 5. Axial compression performance index of BFRRC-filled circular steel tubular stub column specimens

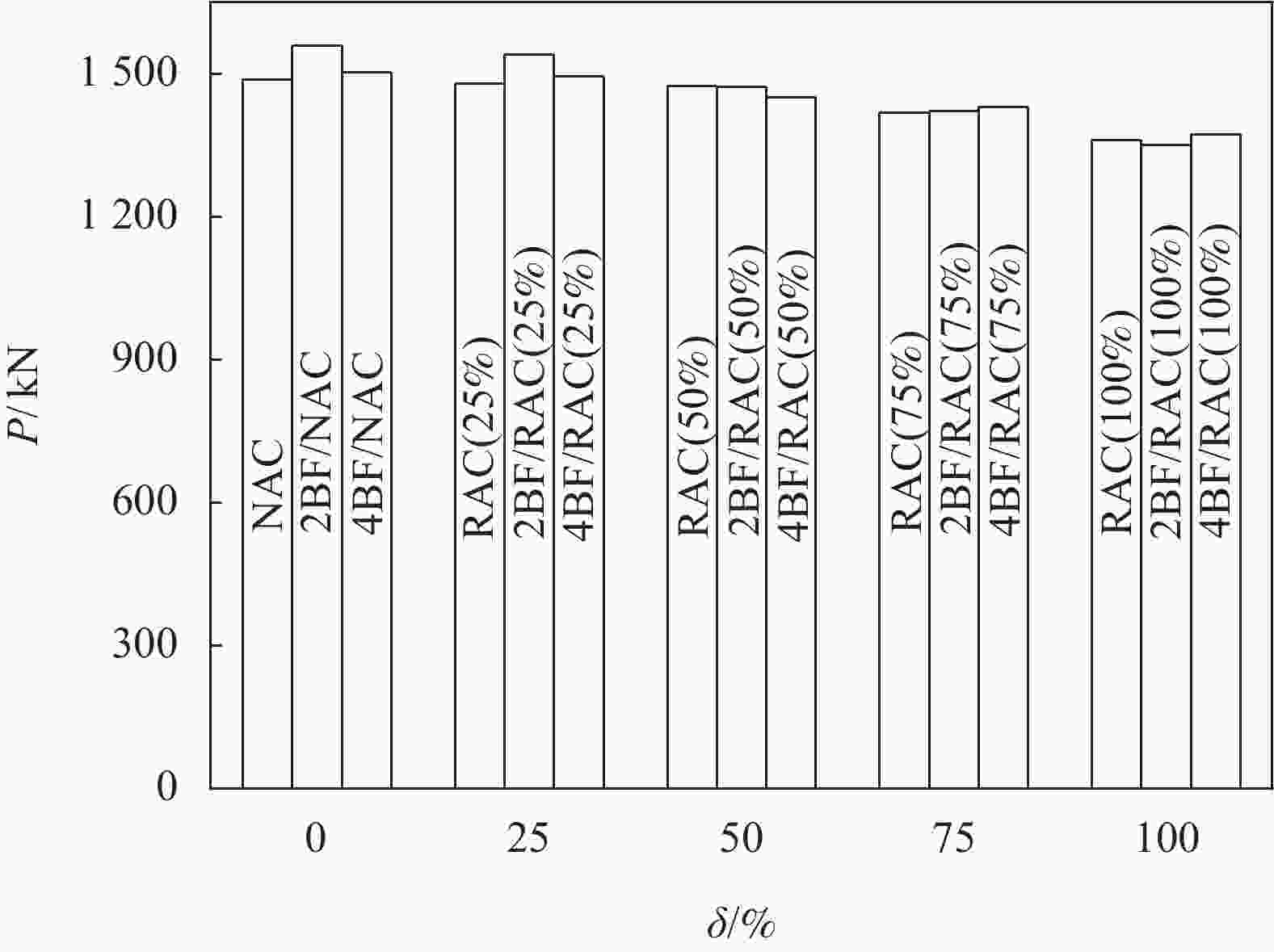

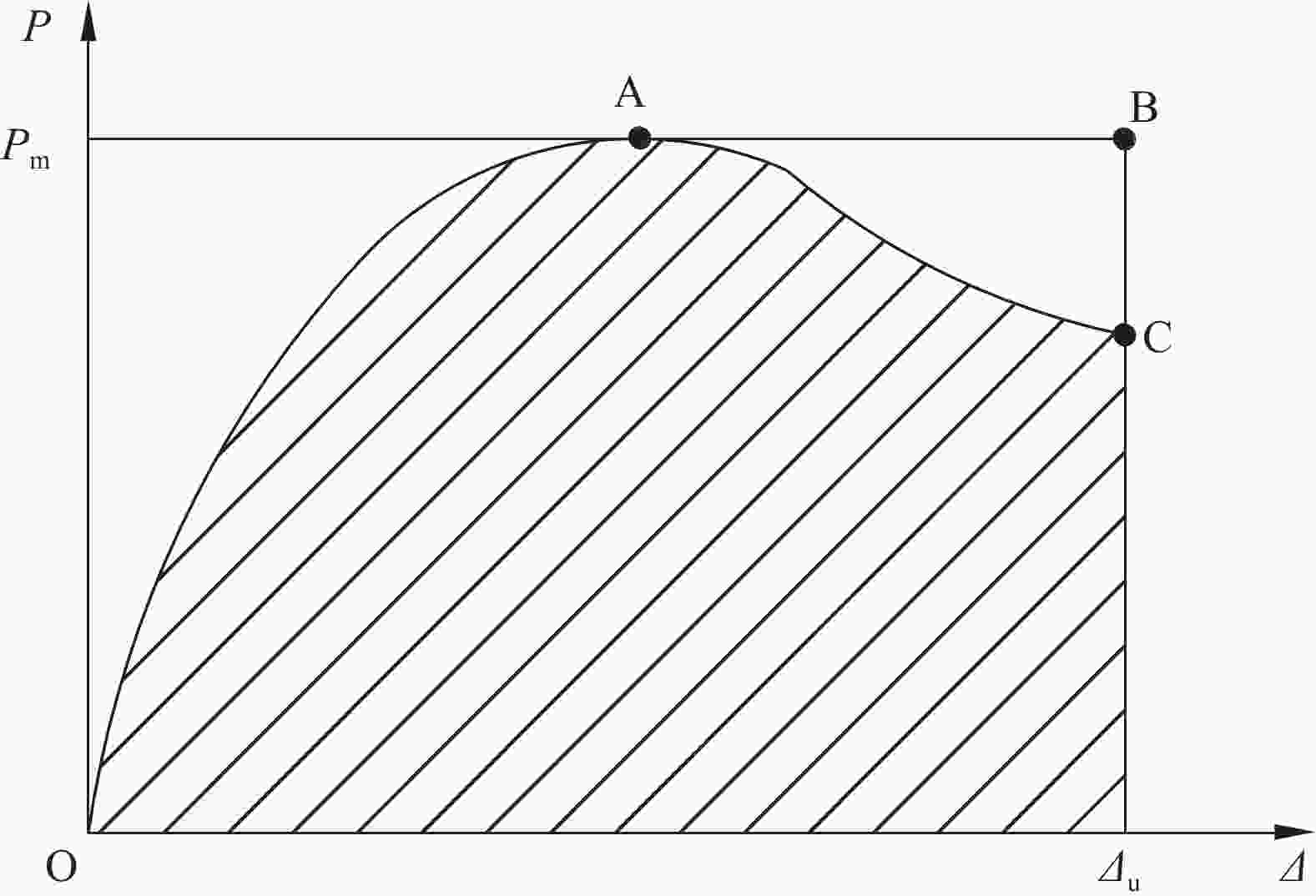

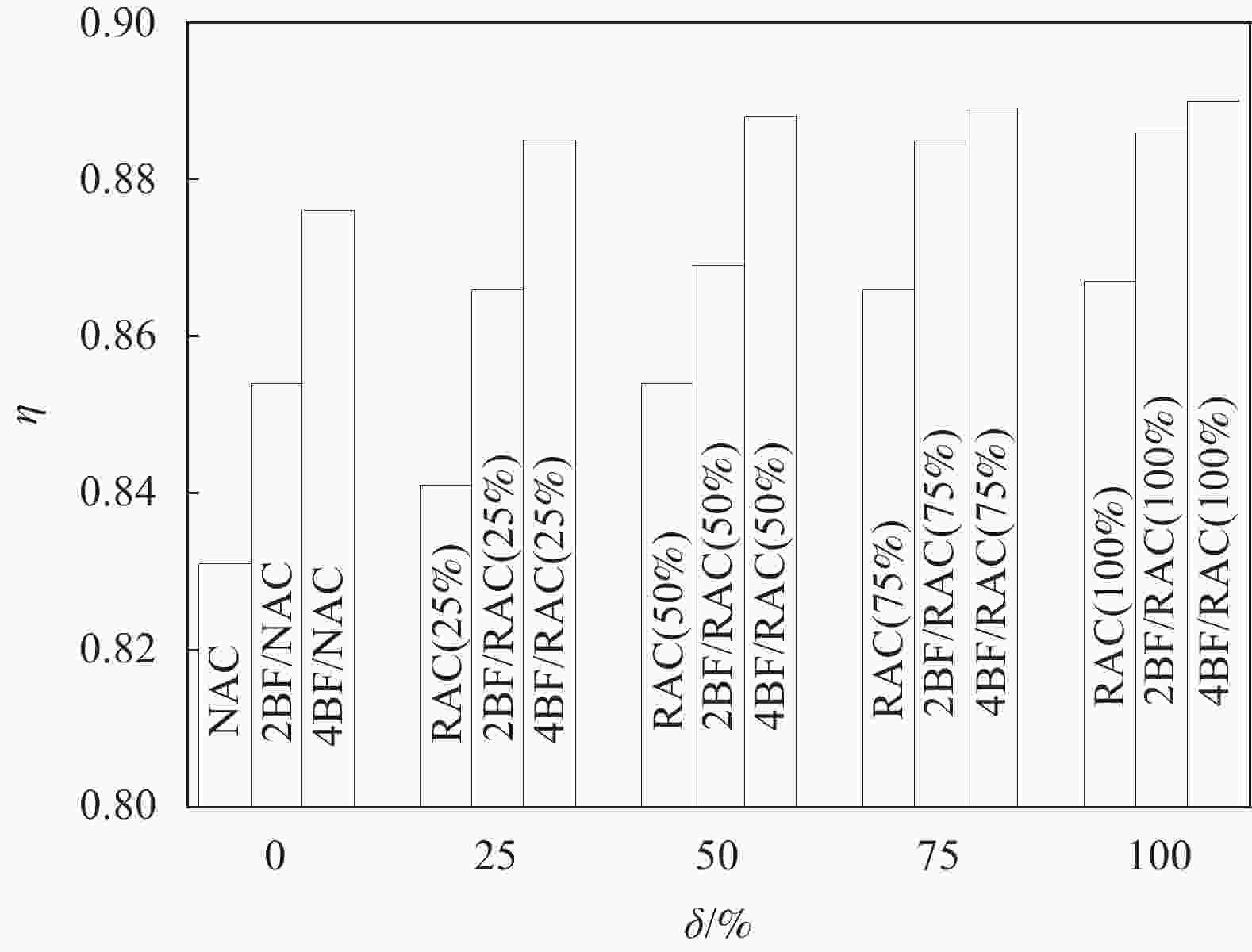

Specimen Pm/kN η μ NAC 1484.0 0.831 1.87 RAC(25%) 1475.0 0.841 1.99 RAC(50%) 1470.2 0.854 2.09 RAC(75%) 1415.4 0.866 2.18 RAC(100%) 1357.1 0.867 2.26 2BF/NAC 1554.2 0.854 1.89 2BF/RAC(25%) 1536.7 0.866 2.03 2BF/RAC(50%) 1468.2 0.869 2.10 2BF/RAC(75%) 1418.1 0.885 2.28 2BF/RAC(100%) 1346.8 0.886 2.37 4BF/NAC 1499.2 0.876 1.93 4BF/RAC(25%) 1490.4 0.885 2.13 4BF/RAC(50%) 1446.7 0.888 2.20 4BF/RAC(75%) 1426.9 0.889 2.30 4BF/RAC(100%) 1369.9 0.890 2.48 Notes: Pm—Test value of ultimate bearing capacity; η—Energy dissipation factor; μ—Ductility coefficient. -

[1] 商效瑀, 杨经纬, 李江山. 基于CT图像的再生混凝土细观破坏裂纹分形特征[J]. 复合材料学报, 2020, 37(7):1774-1784. doi: 10.13801/j.cnki.fhclxb.20190917.002SHANG Xiaoyu, YANG Jingwei, LI Jiangshan. Fractal characteristics of meso-failure crack in recycled coarse aggregate concrete based on CT image[J]. Acta Materiae Compositae Sinica,2020,37(7):1774-1784(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190917.002 [2] 陈守开, 刘新飞, 郭磊, 等. 再生骨料掺配比对再生透水混凝土性能的影响[J]. 复合材料学报, 2018, 35(6):1590-1598. doi: 10.13801/j.cnki.fhclxb.20180207.003CHEN Shoukai, LIU Xinfei, GUO Lei, et al. Influence of recycled aggregate proportion on performance of recycled pervious concrete[J]. Acta Materiae Compositae Sinica,2018,35(6):1590-1598(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180207.003 [3] 王玉梅, 邓志恒, 肖建庄, 等. 再生混凝土压-剪应力下受力性能与破坏准则[J]. 建筑结构学报, 2020, 41(S1):373-380. doi: 10.14006/j.jzjgxb.2020.S1.042WANG Yumei, DENG Zhiheng, XIAO Jianzhuang, et al. Mechanical properties and failure criterion of recycled aggregate concrete under compressive-shear stress state[J]. Journal of Building Structures,2020,41(S1):373-380(in Chinese). doi: 10.14006/j.jzjgxb.2020.S1.042 [4] 关博文, 吴佳育, 陈华鑫, 等. 再生骨料残余砂浆覆盖率测试及其对混凝土渗透性的影响[J]. 中国公路学报, 2021, 34(10):155-165. doi: 10.3969/j.issn.1001-7372.2021.10.013GUAN Bowen, WU Jiayu, CHEN Huaxin, et al. Test of coverage rate of residual mortar on recycled aggregate and its influence on permeability of concrete[J]. China Journal of Highway and Transport,2021,34(10):155-165(in Chinese). doi: 10.3969/j.issn.1001-7372.2021.10.013 [5] 陈宗平, 周春恒, 李伊, 等. 高温后再生混凝土力学性能研究[J]. 建筑结构学报, 2017, 38(12):105-113. doi: 10.14006/j.jzjgxb.2017.12.012CHEN Zongping, ZHOU Chunheng, LI Yi, et al. Research on mechanical behavior of recycled aggregate concrete after high temperatures[J]. Journal of Building Structures,2017,38(12):105-113(in Chinese). doi: 10.14006/j.jzjgxb.2017.12.012 [6] 段珍华, 江山山, 肖建庄, 等. 再生粗骨料含水状态对混凝土性能的影响[J]. 建筑材料学报, 2021, 24(3):545-550.DUAN Zhenhua, JIANG Shanshan, XIAO Jianzhuang, et al. Effect of moisture condition of recycled coarse aggregate on the properties of concrete[J]. Journal of Building Materials,2021,24(3):545-550(in Chinese). [7] WU B, LIN L, ZHAO J X, et al. Creep behavior of thin-walled circular steel tubular columns filled with demolished concrete lumps and fresh concrete[J]. Construction and Building Materials,2018,187:773-790. doi: 10.1016/j.conbuildmat.2018.07.222 [8] 蔡敏伟, 王卫华, 丁启荣, 等. 复式不锈钢管再生块体混凝土短柱轴压试验研究[J]. 建筑结构学报, 2019, 40(S1):226-233. doi: 10.14006/j.jzjgxb.2019.S1.030CAI Minwei, WANG Weihua, DING Qirong, et al. Tests on composite-sectioned stainless CFST columns filled with demolished concrete lumps under axial compression[J]. Journal of Building Structures,2019,40(S1):226-233(in Chinese). doi: 10.14006/j.jzjgxb.2019.S1.030 [9] 贾恒瑞, 陈宗平, 陈俊睿. 高温后圆钢管再生混凝土界面黏结滑移性能及本构方程研究[J]. 工程力学, 2021, 38(10):119-133. doi: 10.6052/j.issn.1000-4750.2020.09.0691JIA Hengrui, CHEN Zongping, CHEN Junrui. Research on interfacial bond behavior and constitutive equation of recycled aggregate concrete filled circle steel tube after exposure to high temperature[J]. Engineering Mechanics,2021,38(10):119-133(in Chinese). doi: 10.6052/j.issn.1000-4750.2020.09.0691 [10] ZENG L, LI L J, SU Z, et al. Compressive test of GFRP-recycled aggregate concrete-steel tubular long columns[J]. Construction and Building Materials,2018,176:295-312. doi: 10.1016/j.conbuildmat.2018.05.068 [11] ZHANG X G, GAO X. The hysteretic behavior of recycled aggregate concrete-filled square steel tube columns[J]. Engineering Structures,2019,198:109523. doi: 10.1016/j.engstruct.2019.109523 [12] CHEN Z P, JING C G, XU J J, et al. Seismic performance of recycled concrete-filled square steel tube columns[J]. Earthquake Engineering and Engineering Vibration,2017,16(1):119-130. doi: 10.1007/s11803-017-0372-2 [13] 马辉, 郭婷婷, 李哲, 等. 圆钢管型钢再生混凝土组合柱轴压性能及承载力计算[J]. 建筑结构学报, 2018, 39(2):97-105. doi: 10.14006/j.jzjgxb.2018.02.011MA Hui, GUO Tingting, LI Zhe, et al. Axial compression performance and bearing capacity calculation of recycled concrete filled circular steel tube-profile steel composite columns[J]. Journal of Building Structures,2018,39(2):97-105(in Chinese). doi: 10.14006/j.jzjgxb.2018.02.011 [14] 陈梦成, 方苇, 黄宏, 等. 锈蚀圆钢管再生混凝土轴压短柱受力性能研究[J]. 建筑结构学报, 2019, 40(12):138-146. doi: 10.14006/j.jzjgxb.2018.0235CHEN Mengcheng, FANG Wei, HUANG Hong, et al. Axial compressive behavior of recycled concrete filled corroded circular steel tubular columns[J]. Journal of Building Structures,2019,40(12):138-146(in Chinese). doi: 10.14006/j.jzjgxb.2018.0235 [15] 柯晓军, 但宇, 龙虹任, 等. 冷却方式对高温后方钢管再生混凝土短柱轴压性能的影响[J]. 应用基础与工程科学学报, 2021, 29(1):182-192. doi: 10.16058/j.issn.1005-0930.2021.01.016KE Xiaojun, DAN Yu, LONG Hongren, et al. Influence of cooling methods on axial compressive performance of RACFSST short columns after high temperatures[J]. Jour-nal of Basic Science and Engineering,2021,29(1):182-192(in Chinese). doi: 10.16058/j.issn.1005-0930.2021.01.016 [16] 杨有福, 黄翔宇. 矩形钢管再生混凝土短柱的轴压性能[J]. 华南理工大学学报(自然科学版), 2017, 45(12):121-127.YANG Youfu, HUANG Xiangyu. Compressive behavior of rectangular recycled aggregate concrete-filled steel-tubular stub columns[J]. Journal of South China University of Technology (Natural Science Edition),2017,45(12):121-127(in Chinese). [17] 刘坚, 张鹏程, 江进, 等. 圆钢管H型钢再生混凝土短柱的轴压承载力分析[J]. 西南交通大学学报, 2020, 55(6):1280-1286.LIU Jian, ZHANG Pengcheng, JIANG Jin, et al. Axial bearing capacity analysis of H-section steel-reinforced recycled aggregate concrete filled circular steel tube stub columns[J]. Journal of Southwest Jiaotong University,2020,55(6):1280-1286(in Chinese). [18] LI W G, LUO Z Y, TAO Z, et al. Mechanical behavior of recycled aggregate concrete-filled steel tube stub columns after exposure to elevated temperatures[J]. Construction and Building Materials,2017,146:571-581. doi: 10.1016/j.conbuildmat.2017.04.118 [19] ZHANG X G, KUANG X M, WANG F, et al. Strength indices and conversion relations for basalt fiber-reinforced recycled aggregate concrete[J]. Dyna,2019,94(1):82-87. doi: 10.6036/8986 [20] ALNAHHAL W, ALJIDDA O. Flexural behavior of basalt fiber reinforced concrete beams with recycled concrete coarse aggregates[J]. Construction and Building Materials,2018,169:165-178. doi: 10.1016/j.conbuildmat.2018.02.135 [21] KATKHUDA H, SHATARAT N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment[J]. Construction and Building Materials,2017,140:328-335. doi: 10.1016/j.conbuildmat.2017.02.128 [22] WANG Y Y, CHEN J, GENG Y. Testing and analysis of axially loaded normal-strength recycled aggregate concrete filled steel tubular stub columns[J]. Engineering Structures,2015,86:192-212. doi: 10.1016/j.engstruct.2015.01.007 [23] CHEN J, LIU X, LIU H W, et al. Axial compression behavior of circular recycled concrete-filled steel tubular short columns reinforced by silica fume and steel fiber[J]. Steel and Composite Structures,2018,27(2):193-200. doi: 10.12989/scs.2018.27.2.193 [24] HOU M, DONG J F, LI L, et al. Experimental research on AFRP reinforced recycled steel tube columns subjected to axial compression[J]. Advanced Composites Letters,2017,26(6):198-201. [25] XU J J, CHEN Z P, ZHAO X Y, et al. Seismic performance of circular recycled aggregate concrete-filled steel tubular columns: FEM modelling and sensitivity analysis[J]. Thin-Walled Structures,2019,141:509-525. doi: 10.1016/j.tws.2019.04.016 [26] KURDA R, DE BRITO J, SILVESTRE J D, et al. Combined influence of recycled concrete aggregates and contents of fly ash on concrete properties[J]. Construction and Building Materials,2017,157:554-572. doi: 10.1016/j.conbuildmat.2017.09.128 [27] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [28] 中国国家标准化管理委员会. 金属材料 拉伸试验 第1部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2011.Standardization Administration of the People’s Republic of China. Metallic materials—Tensile testing—Part 1: Method of test at room temperature: GB/T 228.1—2010[S]. Beijing: China Standards Press, 2011(in Chinese). [29] 韩林海. 钢管混凝土结构—理论与实践[M]. 3版. 北京: 科学出版社, 2018: 222-259.HAN Linhai. Concrete filled steel tube structures—Theory and practice[M]. 3rd edition. Beijing: Science Press, 2018: 222-259(in Chinese). [30] 柯晓军, 陈宗平, 薛建阳, 等. 方钢管再生混凝土短柱轴压承载性能试验研究[J]. 工程力学, 2013, 30(8):35-41. doi: 10.6052/j.issn.1000-4750.2011.11.0759KE Xiaojun, CHEN Zongping, XUE Jianyang, et al. Experimental study on the bearing capacity of recycled aggregate concrete-filled square steel tube short columns under axial compression[J]. Engineering Mechanics,2013,30(8):35-41(in Chinese). doi: 10.6052/j.issn.1000-4750.2011.11.0759 -

下载:

下载: