Impact resistance of horn-inspired tubular composite structure

-

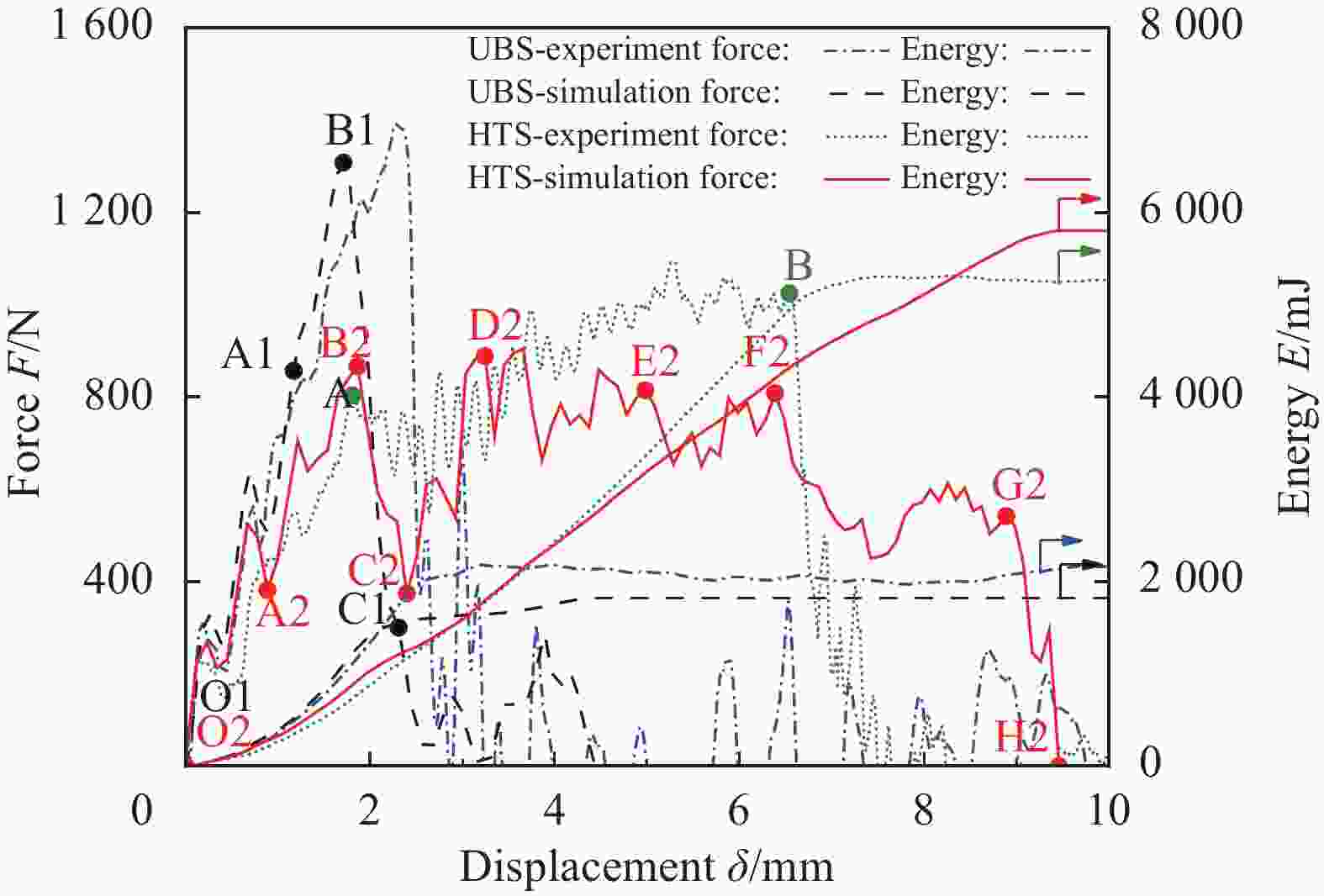

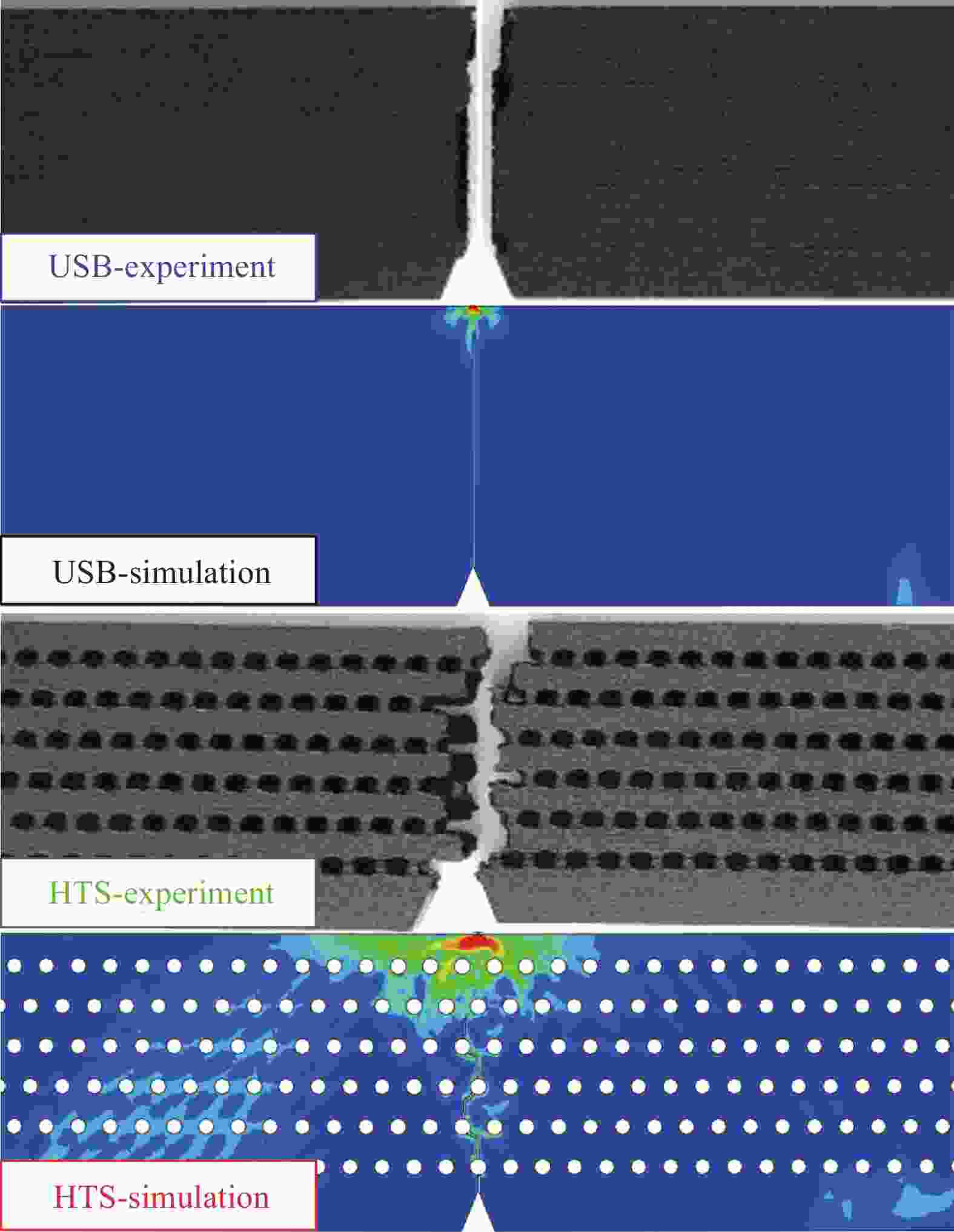

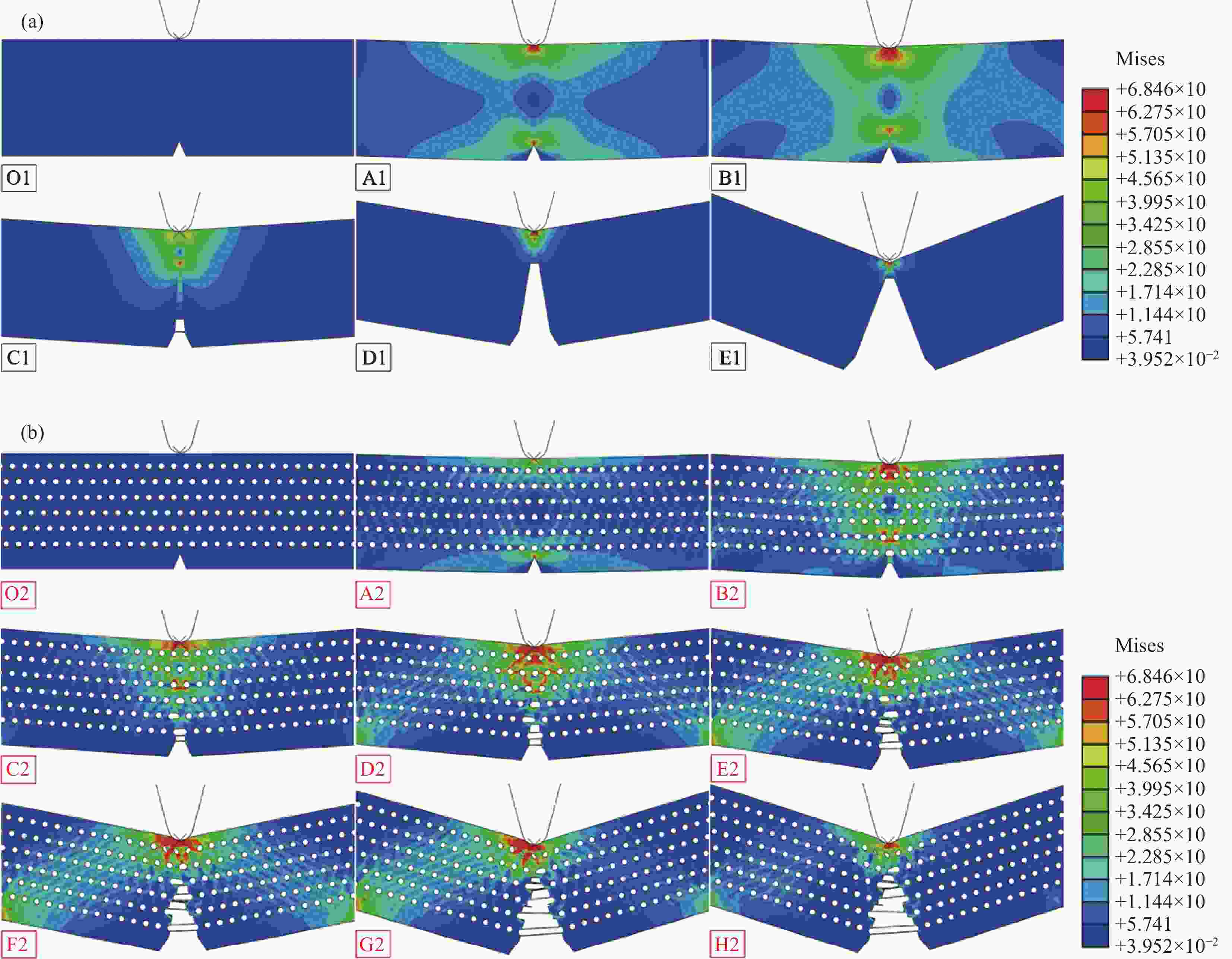

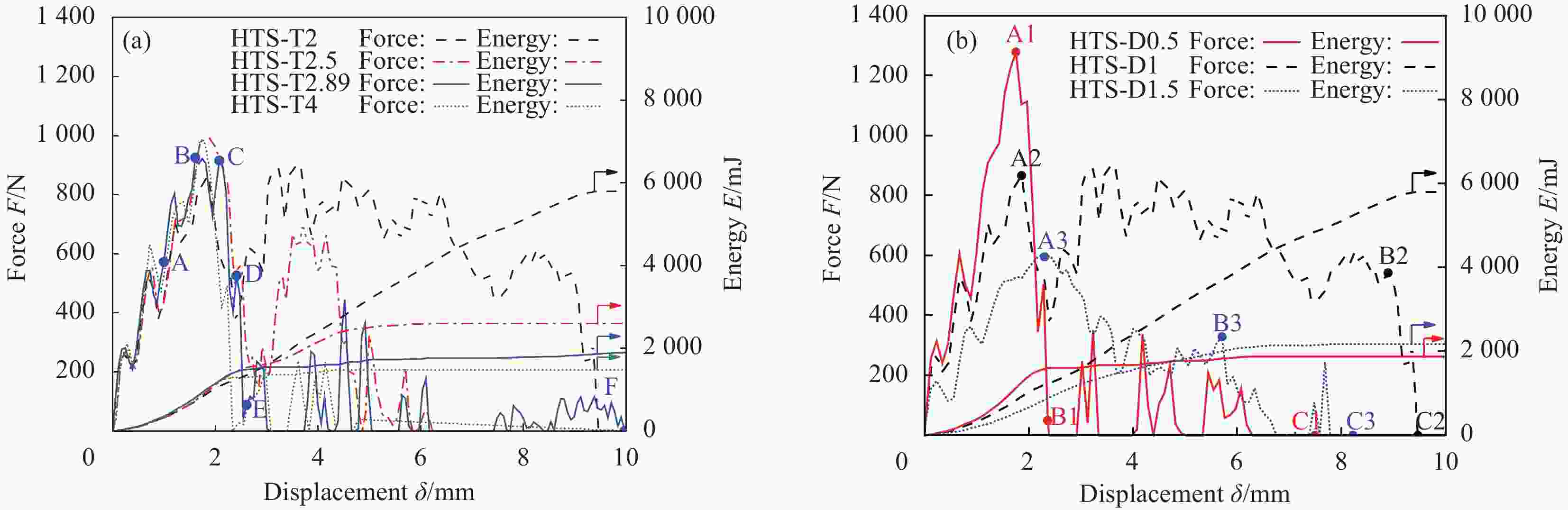

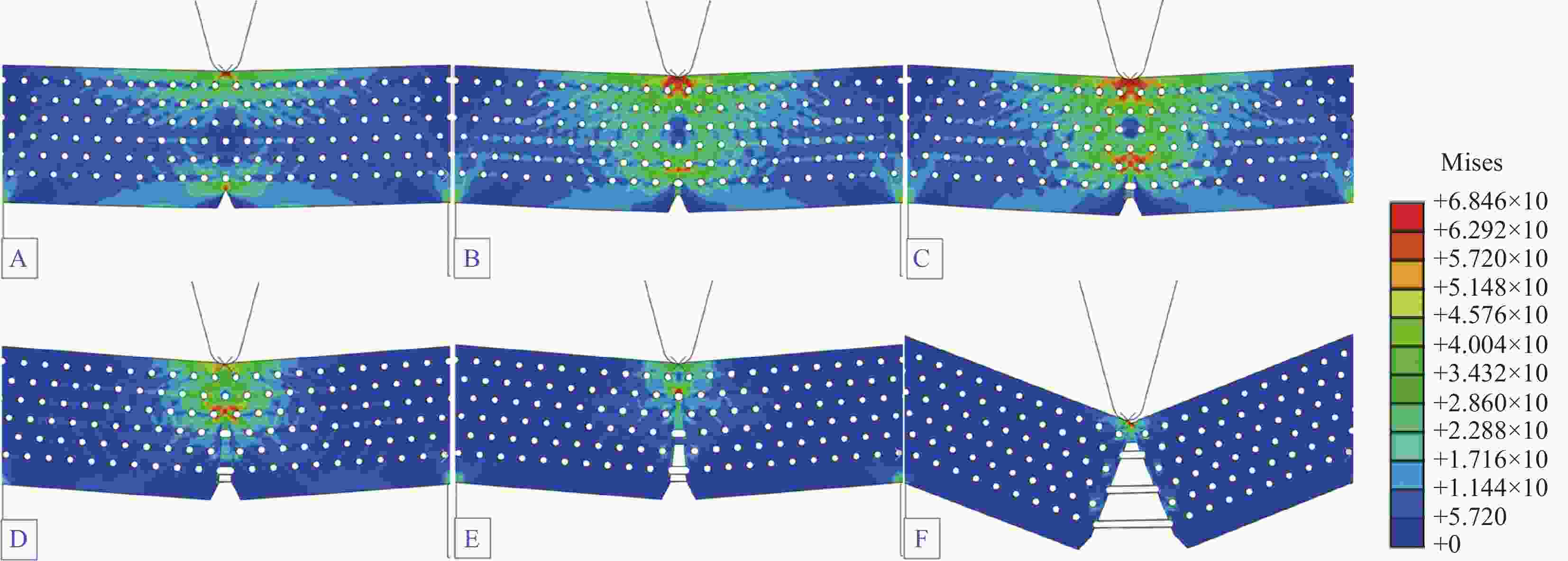

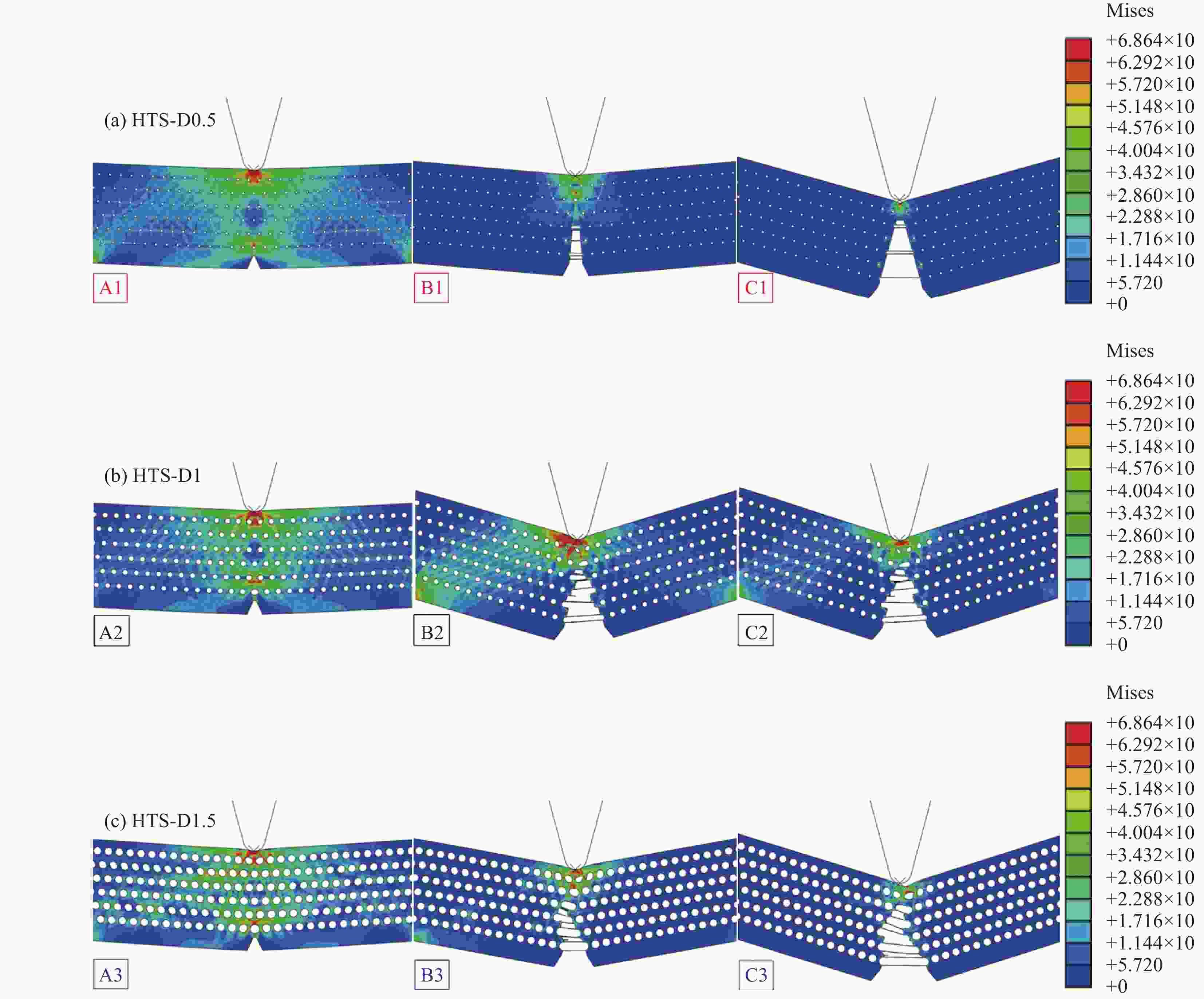

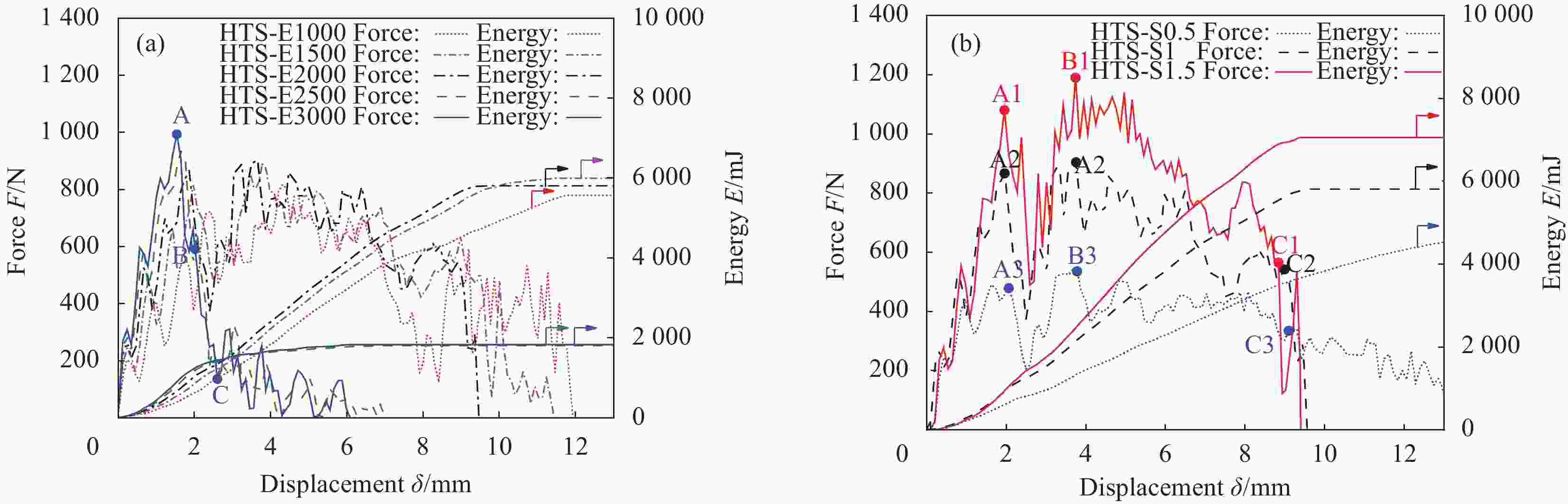

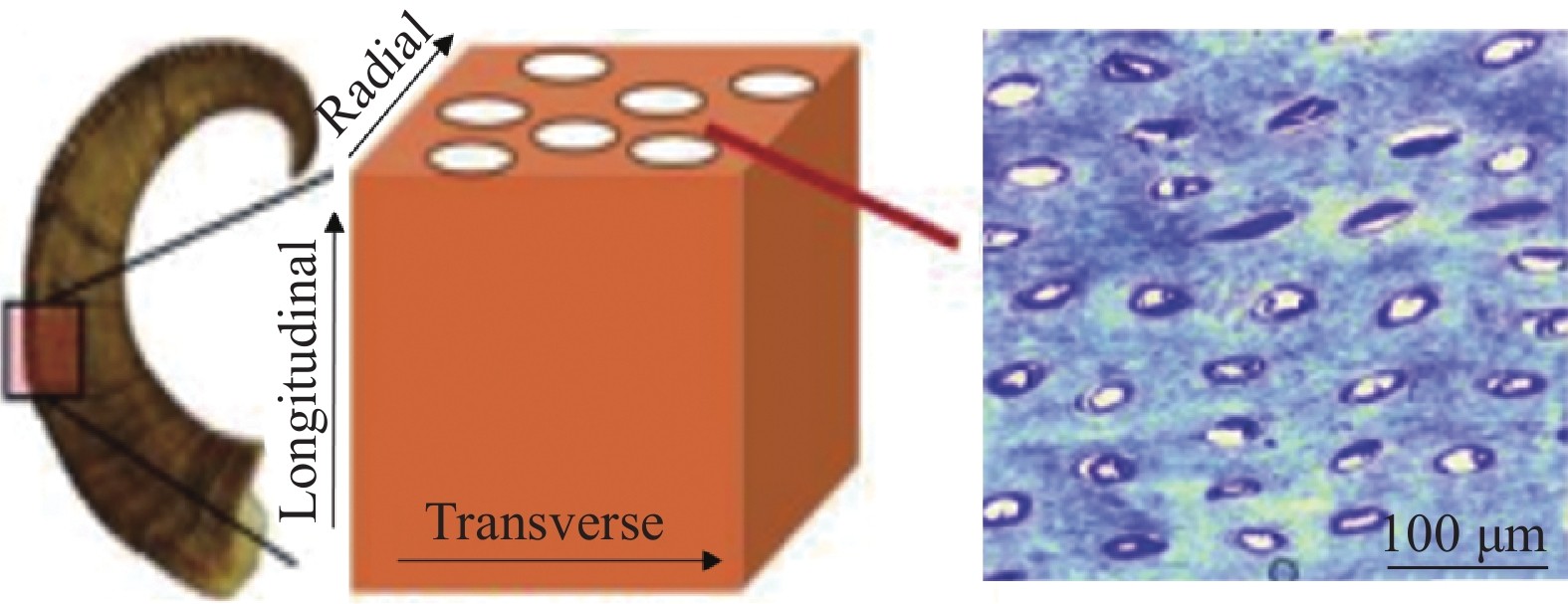

摘要: 羊角因其独特的管状微观结构显示出优异的抗冲击性能。本文从羊角微观结构汲取灵感,设计了仿羊角管状结构。基于3D打印熔融沉积技术,采用短切碳纤维增强尼龙复合材料制备了仿羊角管状结构(HTS)。冲击实验结果表明HTS试样的冲击载荷-位移曲线中存在较长的高载荷平台区,在此阶段吸收了大量的冲击能量,较非仿生样品吸能提升了143.9%,比吸能值提升了178.8%。提出了HTS冲击有限元模型,仿真预测结果和实验获得的冲击响应及裂纹扩展路径结果吻合较好,验证了该模型的有效性。采用该模型分析发现:在冲击过程中细管周围产生较大的应力集中,使裂纹发生偏转进而捕获裂纹,并在细管其他位置重新萌生新的裂纹并朝下一个细管扩展,这个过程不断重复,从而吸收了大量的冲击能量。最后,基于该有限元模型探索了几何参数和材料性能对HTS冲击吸能的影响规律。该研究探索了仿羊角管状复合材料结构冲击吸能特性和吸能机制,对新型抗冲击装备的设计和制备具有重要意义。Abstract: Horns exhibit excellent impact resistance due to their unique tubular microstructure. This study draws inspiration from the microstructure of horns and designs a tubular structure. Based on 3D printing fused deposition technology, a horn-inspired tubular structure (HTS) was fabricated using chopped carbon fiber reinforced nylon composites. The impact test results show that there is a long high-load platform region in the impact force-displacement curve of HTS, which absorbs a large amount of impact energy at this stage. Compared with the un-biomimetic structure sample, the energy absorption of HTS sample increases by 143.9%, and the specific energy absorption value increases by 178.8%. The HTS impact finite element model was proposed, and the simulation prediction results are in good agreement with the experimental results of the impact response and crack propagation path, which verifies the validity of the model. Based on the analysis of the model, it is found that a large stress concentration is generated around the tube during the impact process, which deflects the crack and captures the crack, and re-initiates new cracks in other positions of the tube and expands toward the next tube. This process is repeated to absorb a large amount of impact energy. Finally, the influences of geometric parameters and material properties on impact energy absorption of HTS were explored based on the finite element model. This study explored the impact energy absorption characteristics and energy absorption mechanism of the horn-inspired tubular composite structure, which was of great significance for the design and manufacture of new impact-resistant equipment.

-

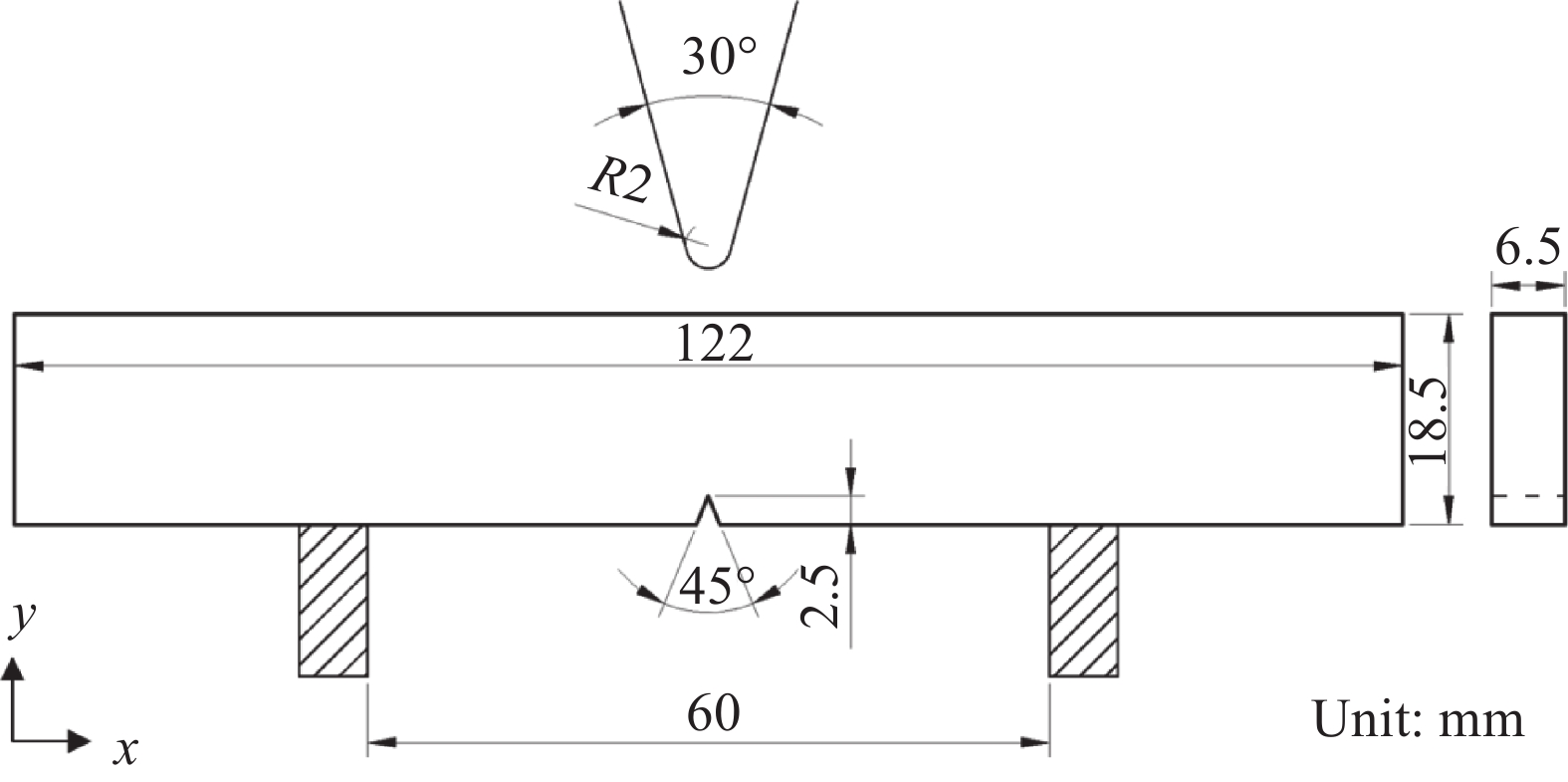

表 1 未仿生结构(UBS)与仿羊角管状结构(HTS)几何参数

Table 1. Geometric parameters of un-biomimetic structure (UBS) and horn-inspired tubular structure (HTS)

Tube diameter/mm Longitudinal spacing/mm Transverse spacing/mm UBS — — — HTS 1 2.5 2 表 2 OnyxTM材料的弹性性能

Table 2. Elastic properties of OnyxTM material

Density/(kg·m−3) Elastic modulus/GPa Poisson's ratio Yield stress/MPa Fracture strain/% Fracture energy/(kJ·m2) 1200 2.0 0.3 54.17 20.55 20 表 3 OnyxTM材料在真实应力应变下的塑性性能

Table 3. Plastic properties of OnyxTM material in terms of true stress and strain

Yield stress/MPa 54.17 58.17 60.24 61.23 62.01 64.15 66.62 68.64 Plastic strain/% 0 0.5 1 1.5 2.5 7.5 12.5 17.5 表 4 有限元模型不同横向间距的 HTS系列(HTS-T)与不同细管直径的 HTS系列(HTS-D)几何参数

Table 4. Geometric parameters of HTS series with different transverse spacing (HTS-T) and HTS series with different tube diameter (HTS-D) finite element model

Sample Tube diameter/mm Longitudinal spacing/mm Transverse spacing/mm HTS-T2 1 2.5 2 HTS-T2.5 1 2.5 2.5 HTS-T2.89 1 2.5 2.89 HTS-T4 1 2.5 4 HTS-D0.5 0.5 2.5 2 HTS-D1 1 2.5 2 HTS-D1.5 1.5 2.5 2 表 5 有限元模型不同弹性模量HTS系列(HTS-E)与不同屈服强度的HTS系列(HTS-S)材料性能

Table 5. Material properties of HTS series with different modulus of elasticity (HTS-E) and HTS with different yield strengths (HTS-S) finite element model

Sample Elastic modulus/GPa Plastic properties HTS-E1000 1.0 Same as Table 3 HTS-E1500 1.5 Same as Table 3 HTS-E2000 2.0 Same as Table 3 HTS-E2500 2.5 Same as Table 3 HTS-E3000 3.0 Same as Table 3 HTS-S0.5 2.0 The yield strength is one-half of OnyxTM material (as shown in Table 6) HTS-S1 2.0 The yield strength is consistent with OnyxTM material (as shown in Table 3) HTS-S1.5 2.0 The yield strength is 1.5 times that of OnyxTM material (as shown in Table 6) 表 6 有限元模型HTS-S0.5和HTS-S1.5系列的材料塑性性能参数

Table 6. Plastic properties of HTS-S0.5 and HTS-S1.5 finite element model series

HTS-S0.5 Yield stress/MPa 27.09 29.09 30.12 30.62 31.01 32.08 33.31 34.32 Plastic strain/% 0 0.5 1 1.5 2.5 7.5 12.5 17.5 HTS-S1.5 Yield stress/MPa 81.26 87.26 90.36 91.85 93.02 96.23 99.93 102.96 Plastic strain/% 0 0.5 1 1.5 2.5 7.5 12.5 17.5 -

[1] WEGST U G K, BAI H, SAIZ E, et al. Bioinspired structural materials[J]. Nature Materials,2015,14(1):23-36. doi: 10.1038/nmat4089 [2] JI B H, GAO H J. Mechanical principles of biological nanocomposites[J]. Annual Review of Materials Research,2010,40:77-100. doi: 10.1146/annurev-matsci-070909-104424 [3] MEYERS M A, CHEN P Y, LIN Y M, et al. Biological materials: Structure and mechanical properties[J]. Progress in Materials Science,2008,53(1):1-206. doi: 10.1016/j.pmatsci.2007.05.002 [4] WEGST U G K, ASHBY M F. The mechanical efficiency of natural materials[J]. Philosophical Magazine,2004,84(21):2167-2186. doi: 10.1080/14786430410001680935 [5] WEGST U G K. Bamboo and wood in musical instruments[J]. Annual Review of Materials Research,2008,38:323-349. doi: 10.1146/annurev.matsci.38.060407.132459 [6] WEAVER J C, MILLIRON G W, MISEREZ A, et al. The stomatopod dactyl club: A formidable damage-tolerant biological hammer[J]. Science,2012,336(6086):1275-1280. doi: 10.1126/science.1218764 [7] LAUNEY M E, BUEHLER M J, RITCHIE R O. On the mechanistic origins of toughness in bone[J]. Annual Review of Materials Research,2010,40:25-53. doi: 10.1146/annurev-matsci-070909-104427 [8] WANG R Z, GUPTA H S. Deformation and fracture mechanisms of bone and nacre[J]. Annual Review of Materials Research,2011,41:41-73. doi: 10.1146/annurev-matsci-062910-095806 [9] 朱体朋. 牛科动物犄角宏微观力学行为研究[D]. 重庆: 重庆大学, 2017.ZHU Tipeng. Investigation of macro-micro mechanical behaviors of bovid horns[D]. Chongqing: Chongqing University, 2017(in Chinese). [10] CHEN P Y, MCKITTRICK J, MEYERS M A. Biological materials: Functional adaptations and bioinspired designs[J]. Progress in Materials Science,2012,57(8):1492-1704. doi: 10.1016/j.pmatsci.2012.03.001 [11] STUDART A R. Towards high-performance bioinspired composites[J]. Advanced Materials,2012,24(37):5024-5044. doi: 10.1002/adma.201201471 [12] HUANG W, RESTREPO D, JUNG J Y, et al. Multiscale toughening mechanisms in biological materials and bioinspired designs[J]. Advanced Materials,2019,31(43):1901561. doi: 10.1002/adma.201901561 [13] NALEWAY S E, PORTER M M, MCKITTRICK J, et al. Structural design elements in biological materials: Application to bioinspiration.[J]. Advanced Materials,2015,27(37):5455-5476. doi: 10.1002/adma.201502403 [14] 阿拉腾沙嘎. 仿珍珠贝Al合金/SiC层状复合材料的制备、组织与性能[D]. 长春: 吉林大学, 2016.ALATENG Shaga. Fabrication of nacre-inspired Al alloy/SiC lamellar composites and their microstructures and properties[D]. Changchun: Jilin University, 2016(in Chinese). [15] 张学骜, 刘长利, 王建方, 等. 仿珍珠层自组装制备有机/无机纳米复合薄膜[J]. 复合材料学报, 2006, 23(4):47-51. doi: 10.3321/j.issn:1000-3851.2006.04.009ZHANG Xueao, LIU Changli, WANG Jianfang, et al. Self-assembled organic/inorganic nanocomposite thin film of mimic nacre[J]. Acta Materiae Compositae Sinica,2006,23(4):47-51(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.04.009 [16] ZHANG P, HEYNE M A, TO A C. Biomimetic staggered composites with highly enhanced energy dissipation: Design, modeling, and test[J]. Journal of the Mechanics & Physics of Solids,2015,83:285-300. [17] GU G X, TAKAFFOLI M, HSIEH A J, et al. Biomimetic additive manufactured polymer composites for improved impact resistance[J]. Extreme Mechanics Letters,2016,9:317-323. doi: 10.1016/j.eml.2016.09.006 [18] KO K, JIN S, LEE S E, et al. Impact resistance of nacre-like composites diversely patterned by 3D printing[J]. Composite Structures,2020,238:111951. doi: 10.1016/j.compstruct.2020.111951 [19] GRUNENFELDER L K, SUKSANGPANYA N, SALINAS C, et al. Bio-inspired impact-resistant composites[J]. Acta Biomaterialia,2014,10(9):3997-4008. doi: 10.1016/j.actbio.2014.03.022 [20] SUKSANGPANYA N, YARAGHI N A, PIPES R B, et al. Crack twisting and toughening strategies in Bouligand architectures[J]. International Journal of Solids and Structures,2018,150:83-106. doi: 10.1016/j.ijsolstr.2018.06.004 [21] RIBBANS B, LI Y J, TAN T. A bioinspired study on the interlaminar shear resistance of helicoidal fiber structures[J]. Journal of the Mechanical Behavior of Biomedical Materials,2016,56:57-67. doi: 10.1016/j.jmbbm.2015.11.004 [22] YARAGHI N A, GUARIN-ZAPATA N, GRUNENFELDER L K, et al. A sinusoidally-architected helicoidal biocomposite[J]. Advanced Materials,2016,28(32):6835-6844. doi: 10.1002/adma.201600786 [23] REN L Q, ZHOU X L, LIU Q P, et al. 3D magnetic printing of bio-inspired composites with tunable mechanical properties[J]. Journal of Materials Science,2019,53(20):14274-14286. [24] TOMBOLATO L, NOVITSKAYA E E, CHEN P Y, et al. Microstructure, elastic properties and deformation mechanisms of horn keratin[J]. Acta Biomaterialia,2010,6(2):319-330. doi: 10.1016/j.actbio.2009.06.033 [25] HUANG W, ZAHERI A, JUNG J Y, et al. Hierarchical structure and compressive deformation mechanisms of bighorn sheep (Ovis canadensis) horn[J]. Acta Biomaterialia,2017,64:1-14. doi: 10.1016/j.actbio.2017.09.043 [26] KITCHENER A. An analysis of the forces of fighting of the blackbuck (Antilope cervicapra) and the bighorn sheep (Ovis canadensis) and the mechanical design of the horn of bovids[J]. Journal of Zoology,1988,214(1):1-20. doi: 10.1111/j.1469-7998.1988.tb04983.x [27] KASAPI M A. Design for fracture control and the mechanical properties of the equine hoof wall[D]. Vancouver: University of British Columbia, 1998. [28] KASAPI M A, GOSLINE J M. Micromechanics of the equine hoof wall: Optimizing crack control and material stiffness through modulation of the properties of keratin[J]. Journal of Experimental Biology,1999,202(4):377-391. doi: 10.1242/jeb.202.4.377 [29] HUANG W. Impact resistant and energy absorbent natural keratin materials: Horns and hooves[D]. San Diego: University of California San Diego, 2018. [30] WANG B F, ZHOU B Q, ZHANG X Y. A high toughness and light weight armor structure bioinspired design based on a bovine hoof wall[J]. Materials Letters,2020,264:127296. doi: 10.1016/j.matlet.2020.127296 [31] INGROLE A, AGUIRRE T G, FULLER L, et al. Bioinspired energy absorbing material designs using additive manufacturing[J]. Journal of the Mechanical Behavior of Biomedical Materials,2021,119:104518. doi: 10.1016/j.jmbbm.2021.104518 [32] American Society of Testing Materials. Standard test method for determining the Charpy impact resistance of notched specimens of plastics: ASTM D6110—2018[S]. West Conshohocken: ASTM International, 2018. [33] HETRICK D R, SANEI S H R, BAKIS C E, et al. Evaluating the effect of variable fiber content on mechanical properties of additively manufactured continuous carbon fiber composites[J]. Journal of Reinforced Plastics and Composites,2020,40(9-10):365-377. [34] SAUER M. Evaluation of the mechanical properties of 3D printed carbon fiber composites[D]. Vermillion: University of South Dakota, 2018. [35] WRIGHT W J, KOERNER H, RAPKING D, et al. Rapid fiber alignment quantification in direct write printing of short fiber reinforced composites[J]. Composites Part B: Engineering,2022,236:109814. doi: 10.1016/j.compositesb.2022.109814 [36] NTENGA R, LAHE S F, ATEBA J A, et al. Numerical simulations of Azobé/urea formaldehyde wood plastic composite behaviors under Charpy impact and low-velocity drop weight tests[J]. Journal of Composites Science,2018,2(4):60. doi: 10.3390/jcs2040060 [37] MIZUKAMI K, FUNABA K, OGI K. Design and three-dimensional printing of carbon-fiber-composite elastic metamaterials with inertial amplification mechanisms[J]. Journal of Sound and Vibration,2021,513:116412. doi: 10.1016/j.jsv.2021.116412 [38] KRZIKALLA D, MESICEK J, HALAMA R, et al. On flexural properties of additive manufactured composites: Experimental, and numerical study[J]. Composites Science and Technology,2022,218:109182. doi: 10.1016/j.compscitech.2021.109182 [39] American Society of Testing Materials. Standard test method for tensile properties of plastics: ASTM D638—2014[S]. West Conshohocken: ASTM International, 2014. -

下载:

下载: