Experimental study on the shear performance of concrete beams reinforced with new type closed winding GFRP stirrups

-

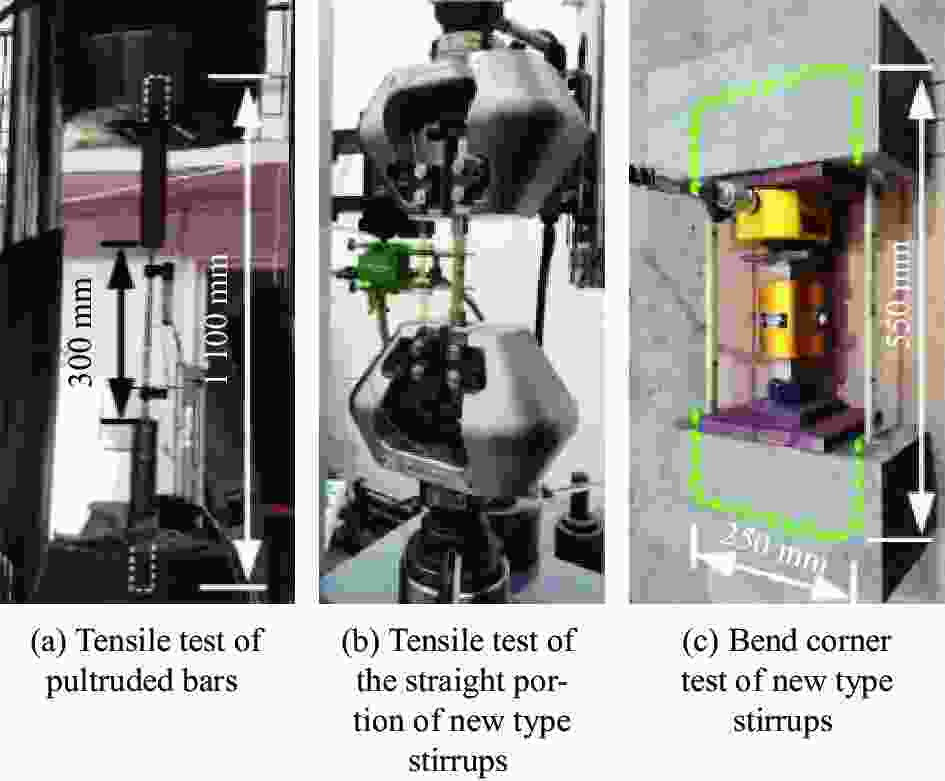

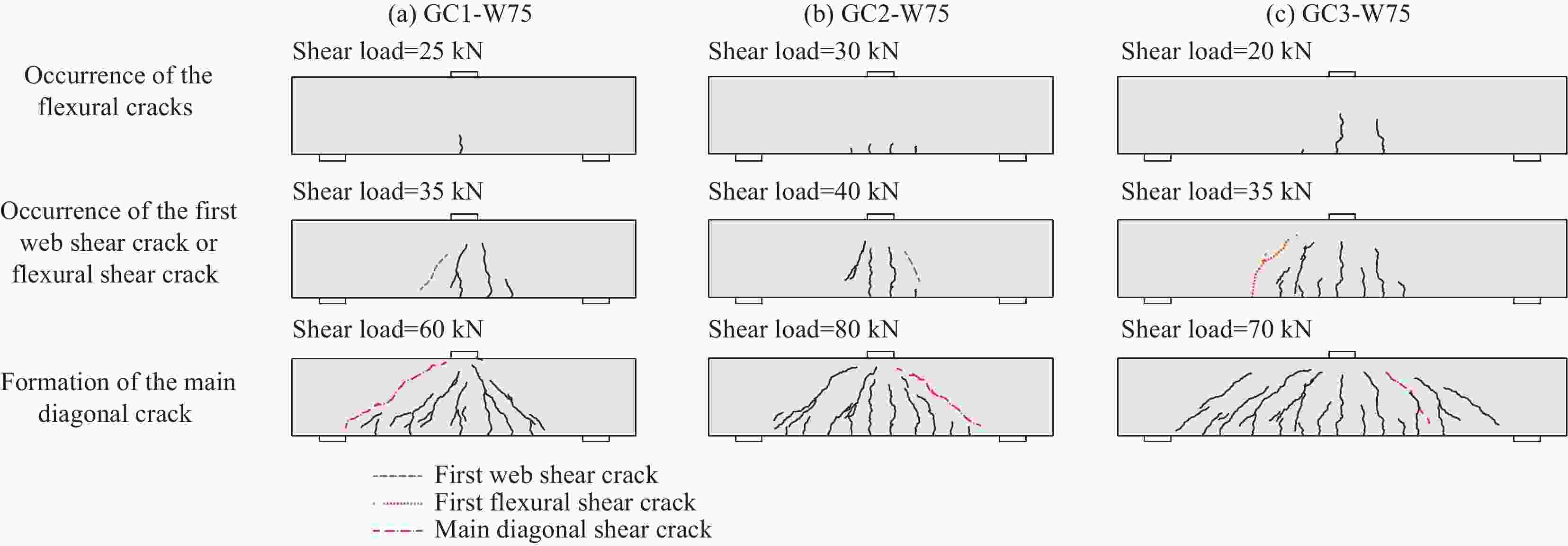

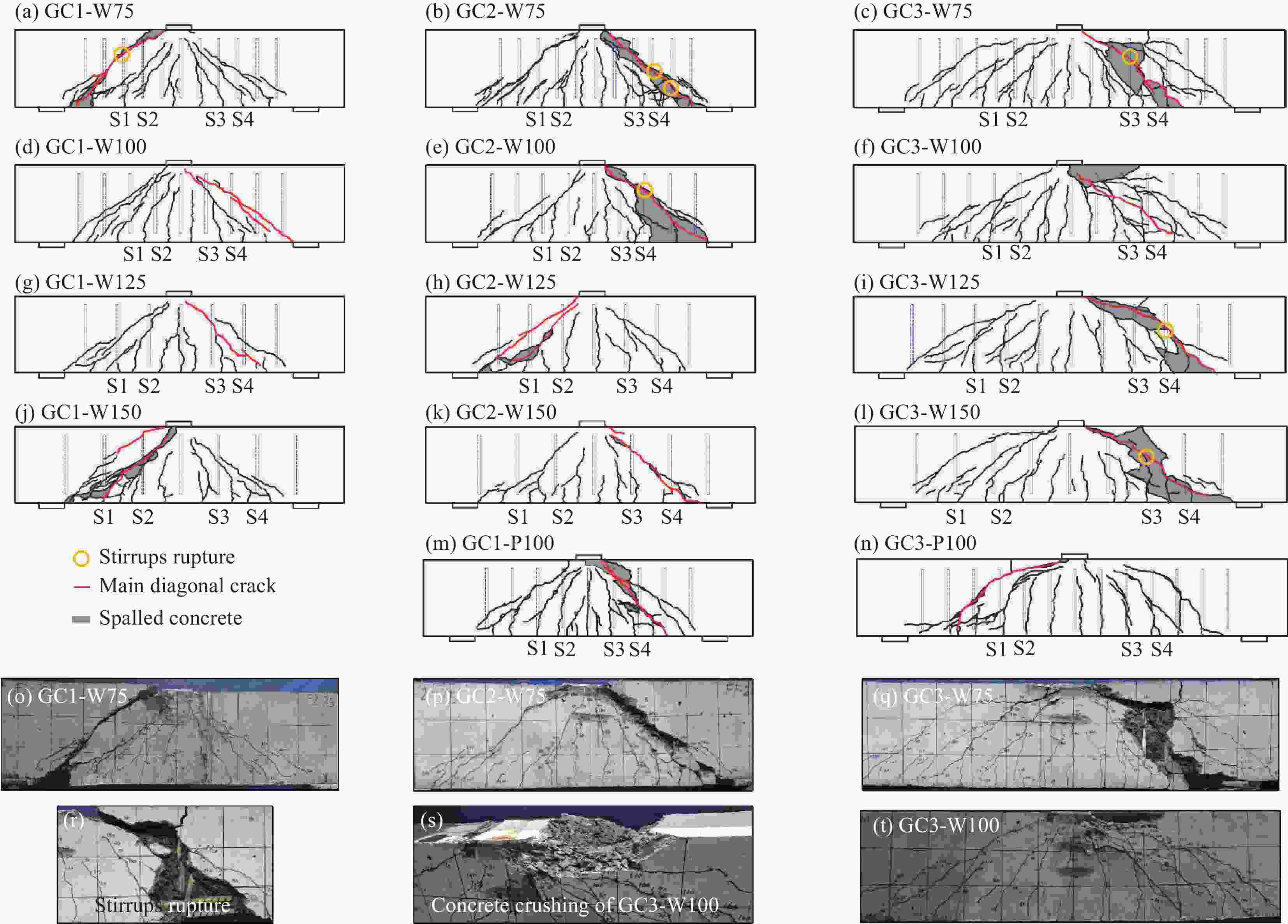

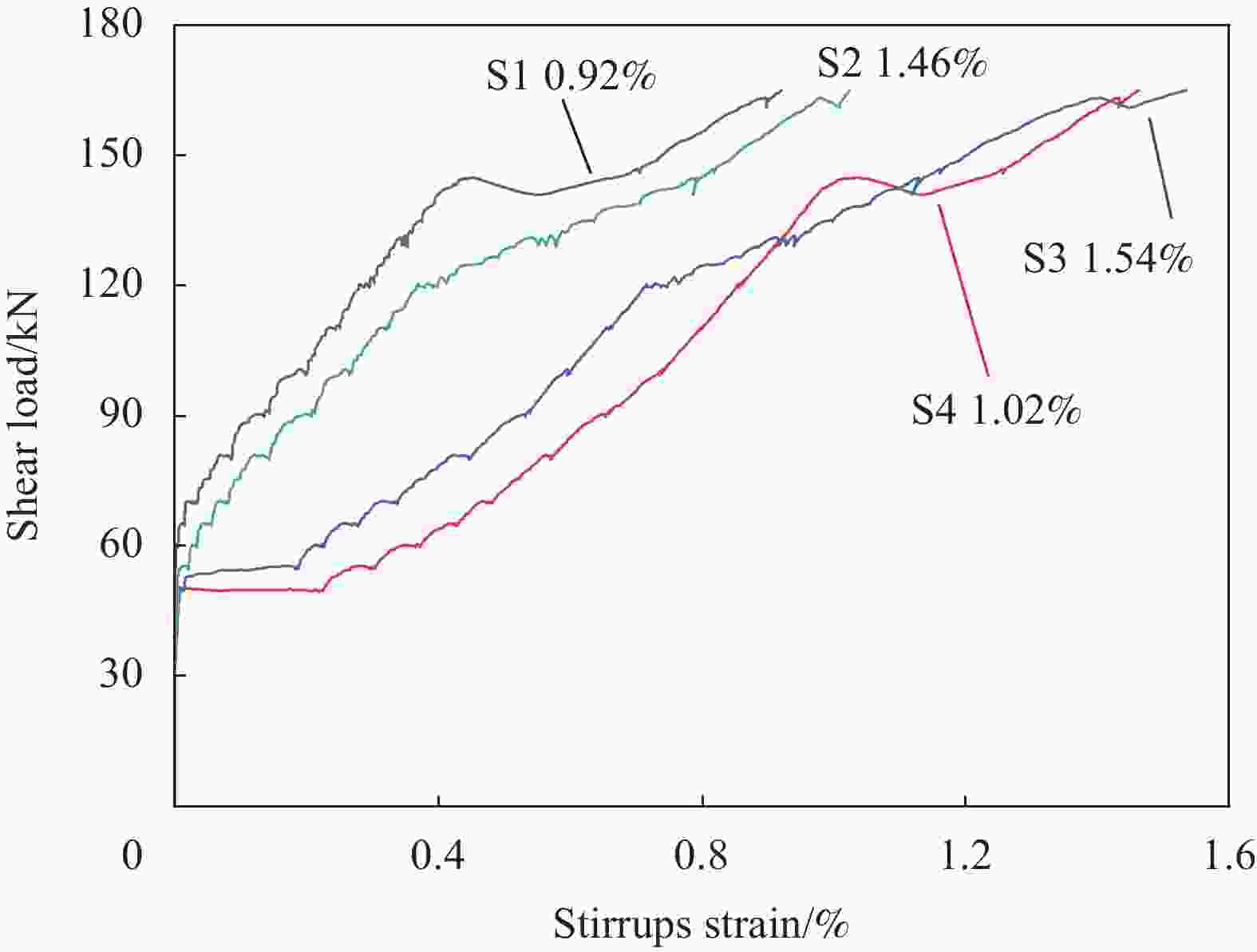

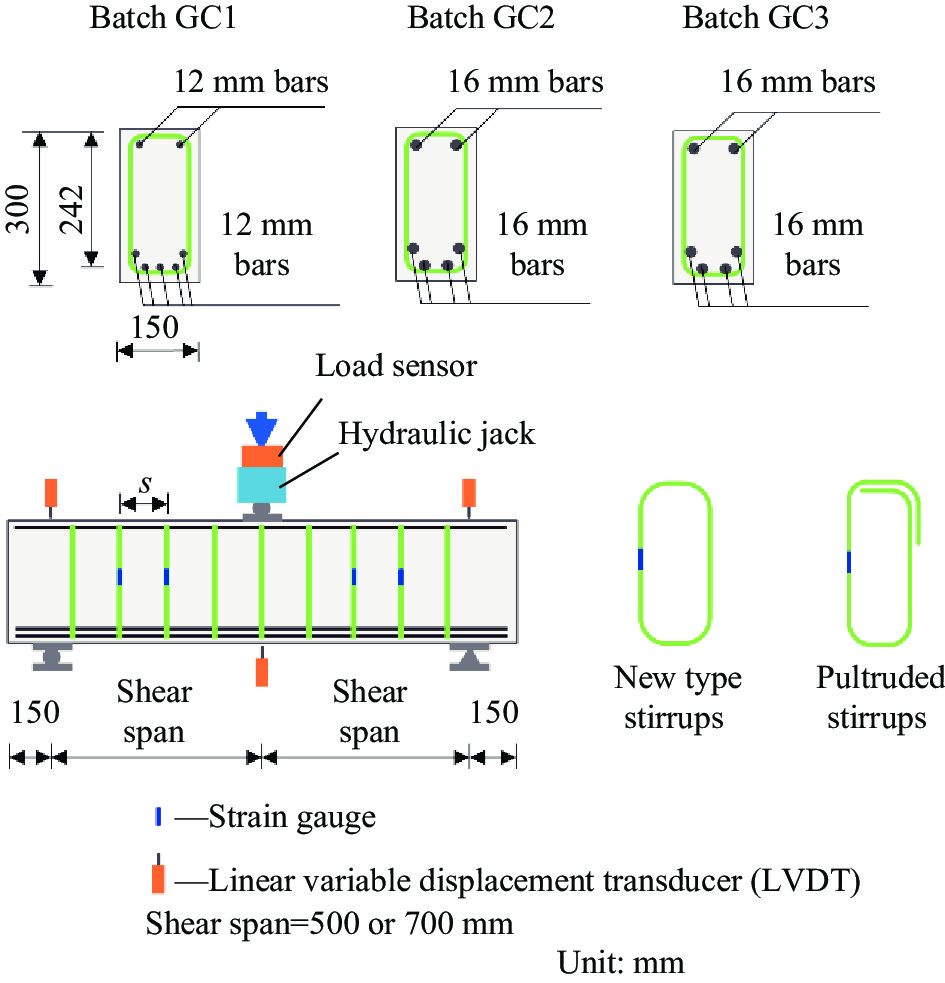

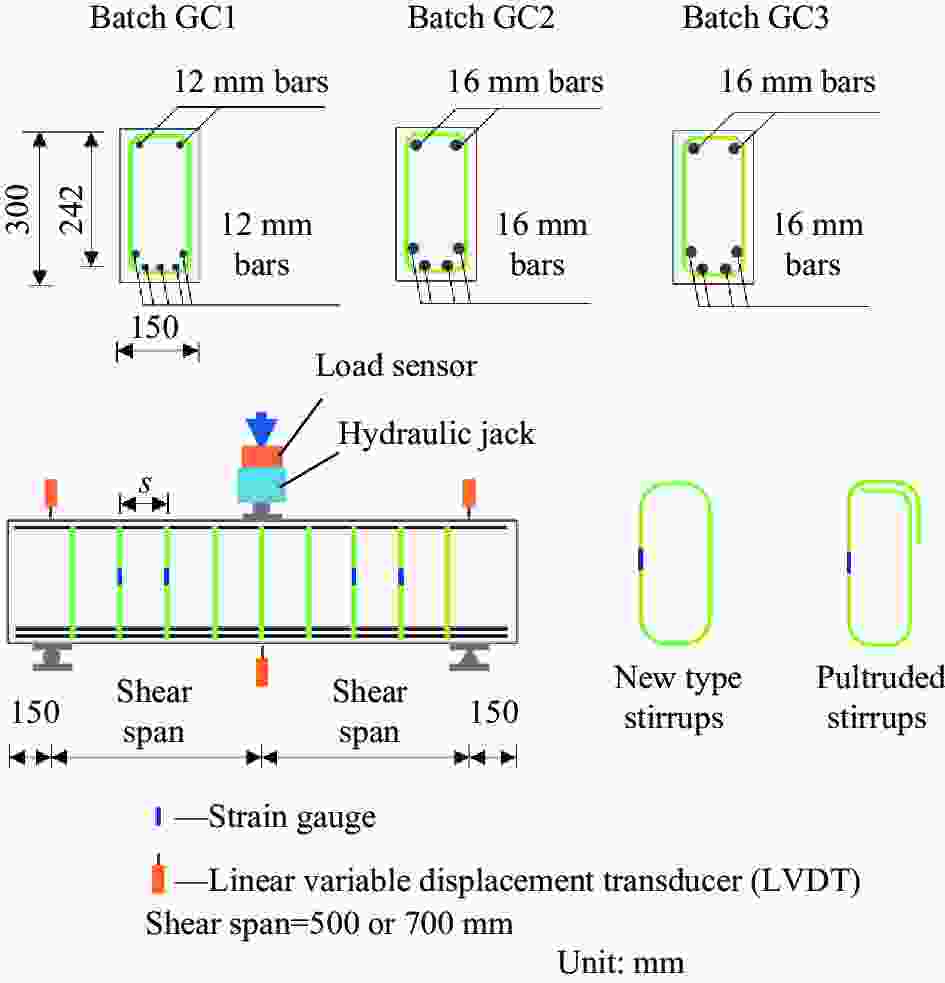

摘要: 对采用新型封闭缠绕式玻璃纤维增强树脂复合材料(GFRP)箍筋的混凝土梁进行了三点加载试验,考察了箍筋形式、纵筋配筋率、剪跨比、箍筋间距对配置新型封闭缠绕式GFRP箍筋混凝土梁受剪性能的影响规律。试验结果表明,新型封闭缠绕式GFRP箍筋的弯曲段强度与平直段受拉强度之比达到0.81,是拉挤成型箍筋的2.07倍。剪跨比和箍筋间距相同时,新型封闭缠绕式GFRP箍筋混凝土梁的受剪性能更好,其材料利用效率显著高于拉挤成型箍筋。梁的抗剪承载力随纵筋配筋率增加的提高幅度不大,但梁的延性有较明显改善。当箍筋间距为75 mm,新型封闭缠绕式GFRP箍筋的应变显著增大,同时对剪压区混凝土产生一定的约束作用,提升了受剪承载力。采用中国(GB 50608—2020)、美国(ACI 440.1R-15)、加拿大(CSA S806-12)、英国(BISE—1999)和日本(JSCE—1997)五种纤维增强树脂复合材料(FRP)筋混凝土结构设计规范计算的受剪承载力显著低于试验值,建议适当提高新型封闭缠绕式GFRP箍筋的断裂应变限值。Abstract: This experimental study conducted a three-point loading test of concrete beams reinforced with a new type closed winding glass fiber-reinforced polymer (GFRP) stirrups, the effects of the form of stirrups, longitudinal reinforcement ratio, shear-span ratio and stirrups spacing on the shear behavior of concrete beams reinforced with new type closed winding GFRP stirrups were investigated. The test results indicate that the ratio of bend strength over tensile strength at the straight portion of new type closed winding GFRP stirrups is 0.81, which is 2.07 times higher than that of pultruded stirrups. When the shear-span ratio and the stirrups spacing are identical, beams with new type closed winding GFRP stirrups show improved shear performance compared with beams with pultruded stirrups. The increase in longitudinal reinforcement ratio has a minor effect on the shear capacity but could significantly improve the ductility of beams. When the spacing of the stirrups is 75 mm, new type closed winding GFRP stirrups produce greater stirrups strain and strongly confine the shear-compression zone of the concrete beam, which significantly enhances the shear capacity. The calculated shear capacities according to five fiber reinforced resin composite (FRP) reinforced concrete design codes of Chinese code (GB 50608—2020), American code (ACI 440.1R-15), Canadian code (CSA S806-12), British code (BISE—1999) and Japanese code (JSCE—1997) are significantly lower than the experimental results. It is suggested that the strain limit in design codes should be appropriately increased.

-

Key words:

- shear behavior /

- concrete beams /

- FRP reinforcement /

- shear-span ratio /

- stirrups

-

表 1 试验工况

Table 1. Test matrix

Specimen Stirrups type s/mm ρ/% ρv/% λ GC1-P100 Pultruded 100 1.54 0.67 2.1 GC1-W75 New type 75 1.54 0.48 2.1 GC1-W100 New type 100 1.54 0.36 2.1 GC1-W125 New type 125 1.54 0.29 2.1 GC1-W150 New type 150 1.54 0.24 2.1 GC2-W75 New type 75 2.21 0.48 2.1 GC2-W100 New type 100 2.21 0.36 2.1 GC2-W125 New type 125 2.21 0.29 2.1 GC2-W150 New type 150 2.21 0.24 2.1 GC3-P100 Pultruded 100 2.21 0.67 2.9 GC3-W75 New type 75 2.21 0.48 2.9 GC3-W100 New type 100 2.21 0.36 2.9 GC3-W125 New type 125 2.21 0.29 2.9 GC3-W150 New type 150 2.21 0.24 2.9 Notes: ρ—Longitudinal reinforcement ratio; ρv—Shear reinforcement ratio; λ—Shear-span ratio; GC—Glass fiber-reinforced polymer (GFRP) stirrups reinforced concrete beams; P—Pultruded GFRP stirrups; W—Closed winding stirrups; s—Stirrups spacing. 表 2 FRP筋材力学性能参数

Table 2. Mechanical properties of FRP reinforcements

Material GFRP bar Pultruded stirrups New type stirrups d/mm or w×t/mm2 16 8 9×3 A/mm2 201 50 27 E/MPa 47.2 50.2 55.0 ffu/MPa 889 1059 1096 $ {\varepsilon _{{\text{fu}}}} $/% 1.88 2.12 1.99 ffb/MPa − 415 892 ffb/ffu − 0.39 0.81 Notes: d—Diameter of pultruded GFRP bar or stirrups; w and t—Width and thickness of new type stirrups; A—Cross-sectional area of reinforcement; E—Elastic modulus; ffu—Tensile strength of the straight portion of reinforcements; $ {\varepsilon _{{\text{fu}}}} $—Ultimate strain at the straight portion; ffb—Bend corner strength of stirrups. 表 3 GFRP筋混凝土梁受剪试验结果

Table 3. Shear test result of GFRP reinforced concrete beams

Beam Vu/kN Δp/mm Δu/mm Ks/(kN·mm−1) $ {\varepsilon _{{\text{max}}}} $/% $ {\varepsilon _{{\text{avg}}}} $/% $ {\varepsilon _{{\text{avg}}}}/{\varepsilon _{{\text{fu}}}} $ Stirrups ruptured

or notGC1-P100 139.6 10.28 11.75 26.8 1.01 0.60 0.28 No GC1-W75 151.4 13.02 13.02 33.8 1.36 0.94 0.47 Yes GC1-W100 140.6 10.25 10.25 30.3 0.95 0.73 0.37 No GC1-W125 131.6 9.51 9.51 28.8 0.89 0.67 0.34 No GC1-W150 135.7 10.82 10.82 30.8 1.11 0.62 0.31 No GC2-W75 168.4 15.93 15.93 46.4 1.54 1.23 0.62 Yes GC2-W100 137.4 8.42 10.31 45.8 − − − Yes GC2-W125 139.9 8.17 13.05 46.1 1.14 0.60 0.30 No GC2-W150 103.5 6.39 10.51 36.1 1.06 0.53 0.27 No GC3-P100 101.8 17.08 17.08 12.6 1.12 0.68 0.32 No GC3-W75 147.9 32.78 32.78 16.6 1.59 1.24 0.62 Yes GC3-W100 117.5 27.46 27.46 14.9 1.09 0.86 0.43 No GC3-W125 102.4 24.23 24.23 15.2 1.54 1.04 0.52 Yes GC3-W150 92.9 15.28 15.28 15.7 1.31 1.11 0.56 Yes Notes: Vu—Shear capacity; Δp—Midspan deflection at peak load; Δu—Midspan deflection at final failure (for the specimens failed at peak load, Δu is equal to the Δp); Ks—Stiffness after shear cracking, which was calculated as the slope of the line connecting the two points with loads of 40 kN and 90 kN respectively; $ {\varepsilon _{{\text{max}}}} $—Maximal stirrups strain at ultimate; $ {\varepsilon _{{\text{avg}}}} $—Average stirrups strain at ultimate; $ {\varepsilon _{\text{f}}}_{\text{u}} $—Ultimate strain. The strain gauges of GC2-W100 were damaged prior to the failure. 表 4 规范中的FRP筋混凝土梁受剪承载力计算公式

Table 4. Code formula for calculating the shear capacity of FRP reinforced concrete beams

Design code Concrete contribution Shear reinforcement contribution GB 50608—2020[19] ${V_{\text{c}}} = 0.86{f_{\text{t}}}bc$

$c = k{h_{\text{0}}}$

$k = \sqrt {2{\rho _{\text{f}}}{\alpha _{\text{E}}} + {{\left( {{\rho _{\text{f}}}{\alpha _{\text{E}}}} \right)}^2}} - {\rho _{\text{f}}}{\alpha _{\text{E}}}$

${\rho _{\text{f}}} = {A_{\text{f}}}/b{h_{\text{0}}}$${V_{\text{f} } } = \dfrac{ { {A_{ {\text{fv} } } }{f_{ {\text{fv} } } }{h_{\text{0} } } }}{s}$

${f_{ {\text{fv} } } } = \min \left( {0.004{E_{ {\text{fv} } } },(0.05\dfrac{ { {r_{\text{b} } } }}{ { {d_{\text{b} } } }} + 0.3){f_{ {\text{fu} } } }} \right)$ACI 440.1 R-15[20] ${V_{\text{c} } } = \dfrac{2}{5}\sqrt { { {f}_{\rm{c}}'} } bk{h_{\text{0} } }$

$k = \sqrt {2{\rho _{\text{f}}}{\alpha _{\text{E}}} + {{\left( {{\rho _{\text{f}}}{\alpha _{\text{E}}}} \right)}^2}} - {\rho _{\text{f}}}{\alpha _{\text{E}}}$${V_{\text{f} } } = \dfrac{ { {A_{ {\text{fv} } } }{f_{ {\text{fv} } } }{h_{\text{0} } } }}{s}$

${f_{ {\text{fv} } } } = \min \left( {0.004{E_{ {\text{fv} } } },(0.05\dfrac{ { {r_{\text{b} } } }}{ { {d_{\text{b} } } }} + 0.3){f_{ {\text{fu} } } }} \right)$CSA S806-12[21] $ {V_{\text{c}}} = 0.05{k_{\text{m}}}{k_{\text{r}}}{k_{\text{a}}}{k_{\text{s}}}{\left( {{{f}_{\rm{c}}'}} \right)^{\frac{1}{3}}}b{h_{\text{0}}} $

$ 0.11\sqrt {{{f}_{\rm{c}}'}} b{h_{\text{v}}} \leqslant {V_{\text{f}}} \leqslant 0.22\sqrt {{{f}_{\rm{c}}'}} b{h_{\text{v}}} $

${k_{\text{m} } } = \sqrt {\dfrac{ { { {\text{V} } }{h_{\text{0} } } }}{ { {M } } } } \leqslant 1.0$

$ {k_{\text{r}}} = 1 + {\left( {{E_{\text{f}}}{\rho _{\text{f}}}} \right)^{\frac{1}{3}}} $

${k_{\text{a} } } = \dfrac{ {2.5{V }h_0} }{ { {M } }} \leqslant 2.5$

${k_{\text{s} } } = \dfrac{ {750} }{ {450 + {h_{ {\text{0} } } } } } \leqslant 1.0$${V } = \dfrac{ { {A_{ {\text{fv} } } }{f_{ {\text{fv} } } }{h_{\text{v} } }\cot \theta } }{s}$

$ \theta = 30 + 7000{\varepsilon _x} $

${\varepsilon _x} = \dfrac{ {M/{{h_0} } + V} }{ {2{E_{\text{f} } }{A_{\text{f} } } }}$

$ {h_{\text{v}}} = \min \left( {0.9{h_0},0.72 h} \right) $

$ {f_{{\text{fv}}}} = \min \left( {0.005{E_{{\text{fv}}}},0.4{f_{{\text{fu}}}},1\;200\;{\text{MPa}}} \right) $BISE—1999[22] ${V_{\text{c} } } = 0.79{\left( {100{\rho _{\text{f} } }\dfrac{ { {E_{\text{f} } } }}{ { {E_{\text{s} } } } } } \right)^{\frac{1}{3} } }{\left( {\dfrac{ {400} }{ { {h_0} } } } \right)^{\frac{1}{4} } }{\left( {\dfrac{ {1.25{f_{\text{c} }' } } }{ {25} } } \right)^{\frac{1}{3} } }b h_0$ ${V_{\text{f} } } = \dfrac{ {0.0025{A_{ {\text{fv} } } }{E_{ {\text{fv} } } }{h_0} } }{s}$ JSCE—1997[23] $ {V_{\text{c}}} = {\beta _{\text{d}}}{\beta _{\text{p}}}{{{f}}_{{\rm{vcd}}}}b{h_{\text{0}}} $

${\beta _{\text{d} } } = {\left( {\dfrac{ {1000} }{ { {h_0} } } } \right)^{\frac{1}{4} } } \leqslant 1.5$

${\beta _{\text{p} } }{\text{ = } }{\left( {1000 \times \dfrac{ { {\rho _{\text{f} } }{E_{\text{f} } } }}{ { {E_{\text{s} } } } } } \right)^{\frac{1}{3} } } \leqslant 1.5$

$f_{\mathrm{vcd} }=0.2 f_{c}^{\prime \frac{1}{3} } \leqslant 0.72 \mathrm{~N} / \mathrm{mm}^{2}$${V_{\text{f} } } = \dfrac{ { {A_{ {\text{fv} } } }{E_{ {\text{fv} } } }{\varepsilon _{\text{f} } }_{\text{v} }z} }{s}$

$ z{\text{ = }}{h_0}/1.15 $

${\varepsilon _{\text{f} } }_{\text{v} } = \sqrt { { {\left( {\dfrac{h}{ {0.3} } } \right)}^{ - \frac{1}{ {10} } } }{f_{\text{c} }' } \dfrac{ { {\rho _{\text{f} } }{E_{\text{f} } } }}{ { {\rho _{ {\text{fv} } } }{E_{ {\text{fv} } } } } } } \times {10^{ - 4} }$Notes: ft—Tensile strength of concrete; b—Width of concrete beam; h—Depth of the beam; h0—Distance from compression fiber to the centroid of tension reinforcement; k—Ratio of depth of neutral axis to reinforcement depth; ${\alpha _{\text{E}}}$—Ratio of modulus of elasticity of FRP bars to modulus of elasticity of concrete; Af, Ef and $ {\rho _{\text{f}}} $—The area, the modulus of elasticity and the reinforcement ratio of longitudinal bars; Afv, Efv, ffv and $ {\rho _{\text{f}}}_{\text{v}} $—The area, the modulus of elasticity, the stress of FRP and the reinforcement ratio shear reinforcement; rb and db—Radius of the bend corner and the bar diameter of the pultruded stirrups; $ {f'_{\text{c}}} $—Cylinder compressive strength of concrete; ka—Coefficient taking into account the effect of arch action; ks—Coefficient taking into account the effect of member size; km—Coefficient taking into account the effect of the moment at section; $ \theta $—Angle between the diagonal shear crack and the horizontal axis; $ {\varepsilon _x} $—Longitudinal strain at mid-depth of the section; Es—Modulus of elasticity of steel; s—Spacing of stirrups; M—Moment acting on the beam; V—Shear force acting on the beam; Vc—Shear force resisted by concrete; Vf—Shear force resisted by stirrups; ffu—Tensile strength of the straight portion of stirrups. 表 5 不同规范对FRP筋混凝土梁受剪承载力预测结果

Table 5. Different code predictions of the shear capacity for FRP reinforced concrete beams

Experi-mental results GB 50608—2020 ACI 440.1 R-15 CSA S806-12 BISE—1999 JSCE—1997 Beam Vu/kN Vpre/kN Vpre/Vu Vpre, m/kN Vpre,m/Vu Vpre/kN Vpre/Vu Vpre,m/kN Vpre,m/Vu Vpre/kN Vpre/Vu Vpre,m/kN Vpre,m/Vu Vpre/kN Vpre/Vu Vpre,m/kN Vpre,m/Vu Vpre/kN Vpre/Vu Vpre,m Vpre,m/Vu GC1-P100 139.6 72.0 0.52 − − 72.0 0.52 − − 84.7 0.61 − − 62.9 0.45 − − 63.1 0.45 − − GC1-W75 151.4 57.1 0.38 162.6 1.07 57.1 0.38 162.5 1.07 68.0 0.45 114.4 0.76 53.7 0.35 170.6 1.13 60.5 0.40 176.5 1.17 GC1-W100 140.6 47.5 0.34 126.7 0.90 47.5 0.34 126.6 0.90 62.7 0.45 95.8 0.68 47.7 0.34 135.4 0.96 59.6 0.42 145.8 1.04 GC1-W125 131.6 41.8 0.32 105.1 0.80 41.8 0.32 105.0 0.80 59.2 0.45 84.6 0.64 44.1 0.33 114.2 0.87 59.0 0.45 127.5 0.97 GC1-W150 135.7 38.0 0.28 90.7 0.67 38.0 0.28 90.7 0.67 56.3 0.41 77.1 0.57 41.7 0.31 100.1 0.74 58.6 0.43 115.2 0.85 GC2-W75 168.4 60.3 0.36 165.8 0.98 60.3 0.36 165.7 0.98 80.4 0.48 118.9 0.71 57.4 0.34 174.3 1.03 61.7 0.37 176.5 1.05 GC2-W100 137.4 50.7 0.37 129.8 0.94 50.7 0.37 129.7 0.94 73.0 0.53 103.3 0.75 51.4 0.37 139.1 1.01 60.7 0.44 145.8 1.06 GC2-W125 139.9 44.9 0.32 108.3 0.77 44.9 0.32 108.2 0.77 68.2 0.49 95.7 0.68 47.8 0.34 117.9 0.84 60.0 0.43 127.5 0.91 GC2-W150 103.5 41.1 0.40 93.9 0.91 41.1 0.40 93.8 0.91 64.8 0.63 89.7 0.87 45.4 0.44 103.8 1.00 59.5 0.57 115.2 1.11 GC3-P100 101.8 75.2 0.74 − − 75.2 0.74 − − 80.3 0.79 − − 66.7 0.65 − − 61.6 0.61 − − GC3-W75 147.9 60.3 0.41 165.8 1.12 60.3 0.41 165.7 1.12 70.8 0.48 112.1 0.76 57.4 0.39 174.3 1.18 61.7 0.42 176.5 1.19 GC3-W100 117.5 50.7 0.43 129.8 1.10 50.7 0.43 129.7 1.10 64.4 0.55 93.4 0.79 51.4 0.44 139.1 1.18 60.7 0.52 145.8 1.24 GC3-W125 102.4 44.9 0.44 108.3 1.06 44.9 0.44 108.2 1.06 59.8 0.58 82.8 0.81 47.8 0.47 117.9 1.15 60.0 0.59 127.5 1.24 GC3-W150 92.9 41.1 0.44 93.9 1.01 41.1 0.44 93.8 1.01 56.6 0.61 78.5 0.84 45.4 0.49 103.8 1.12 59.5 0.64 115.2 1.24 Notes: Vu—Shear capacity; Vpre—Predicted shear capacity by design codes; Vpre, m—Predicted shear capacity using the average stirrups strain of the ruptured stirrup. -

[1] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485.ZHANG Yirui, WEI Yang, BAI Jiawen, et al. Models for predicting axial compression behavior of fiber reinforced polymer-steel composite circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2478-2485(in Chinese). [2] 缪坤廷, 魏洋, 朱超, 等. 钢管混凝土-FRP管海水海砂混凝土组合柱轴压模型[J]. 复合材料学报, 2022, 39(11): 5405-5416.MIAO Kunting, WEI Yang, ZHU Chao, et al. Model for stress-strain curves of concrete filled steel tube-seawater and sea sand concrete filled FRP tube composite columns under axial load[J]. Acta Materiae Compositae Sinica, 2022, 39(11):5405-5416(in Chinese). [3] 柏佳文, 魏洋, 张依睿, 等. 新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J]. 复合材料学报, 2021, 38(9):3084-3093.BAI Jiawen, WEI Yang, ZHANG Yirui, et al. Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J]. Acta Materiae Compositae Sinica,2021,38(9):3084-3093(in Chinese). [4] 叶列平, 冯鹏. FRP 在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-36. doi: 10.3321/j.issn:1000-131X.2006.03.004YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-36(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [5] BENMOKRANE B, MOHAMED H M. Use of fibre-reinforced polymer (FRP) rebars for building durable concrete infrastructure[C]//ALPHOSE Z. Insights and Innovations in Structural Engineering, Mechanics and Computation. Cape Town: CRC Press, 2016: 1518-1523. [6] 尹世平, 华云涛, 徐世烺. FRP配筋混凝土结构研究进展及其应用[J]. 建筑结构学报, 2021, 42(1):134-150.YIN Shiping, HUA Yuntao, XU Shilang. A review on research progress and application of concrete structures internally reinforced with FRP bars[J]. Journal of Building Structures,2021,42(1):134-150(in Chinese). [7] MARANAN G B, MANALO A C, BENMOKRANE B, et al. Shear behavior of geopolymer concrete beams reinforced with glass fiber-reinforced polymer bars[J]. ACI Structural Journal,2017,114(2):337-348. [8] ALI M A, EL-SALAKAWY E. Seismic performance of GFRP-reinforced concrete rectangular columns[J]. Journal of Composites for Construction,2016,20(3):04015074. doi: 10.1061/(ASCE)CC.1943-5614.0000637 [9] SHEHATA E, MORPHY R, RIZKALLA S. Fibre reinforced polymer shear reinforcement for concrete members: Behaviour and design guidelines[J]. Canadian Journal of Civil Engineering, 2000, 27(5): 859-872. [10] EL-SAYED A K, EL-SALAKAWY E, BENMOKRANE B. Mechanical and structural characterization of new carbon FRP stirrups for concrete members[J]. Journal of Compo-sites for Construction,2007,11(4):352-362. doi: 10.1061/(ASCE)1090-0268(2007)11:4(352) [11] AHMED E, EL-SAYED A, EL-SALAKAWY E, et al. Bend strength of FRP stirrups: Comparison and evaluation of testing methods[J]. Journal of Composites for Construction,2009,14(1):3-10. [12] PENG F, XUE W C. Evaluation of bend strength calculation of fiber-reinforced polymer stirrups[C]//WU Z S. Joint Conference of the 12th International Symposium on Fiber Reinforced Polymers for Reinforced Concrete Structures (FRPRCS-12) & the 5th Asia Pacific Conference on Fiber Reinforced Polymers in Structures (APFIS-2015). Nanjing: Southeast University, 2015: 21. [13] IMJAI T, GUADAGNINI M, PILAKOUTAS K. Curved FRP as concrete reinforcement[J]. Proceedings of the Institution of Civil Engineers-Engineering and Computational Mechanics,2009,162(3):171-178. doi: 10.1680/eacm.2009.162.3.171 [14] JUMAA G B, YOUSIF A R. Size effect on the shear failure of high-strength concrete beams reinforced with basalt FRP bars and stirrups[J]. Construction and Building Materials,2019,209(10):77-94. [15] 康明睿, 薛伟辰. 配FRP箍筋混凝土梁的抗剪性能研究进展[J]. 华北水利水电学院学报, 2015, 36(2): 15-20.KANG Mingrui, XUE Weichen. A review on research progress of shear behavior of concrete beams reinforced with FRP stirrups[J]. Journal of North China University of Water Resources and Electric Power, 2015, 36(2): 15-20(in Chinese). [16] 侯慕轶. 碳纤维筋混凝土梁受剪性能试验研究[D]. 绵阳: 西南科技大学, 2017.HOU Muyi. Experiment studies on the shear performance of concrete beam with CFRP bars[D]. Mianyang: Southwest University of Science and Technology, 2017(in Chinese). [17] 彭俊桢. 玄武岩纤维(BFRP)筋混凝土梁的受剪性能研究[D]. 厦门: 厦门大学, 2019.PENG Junzhen. Research on shear performance of BFRP reinforced concrete beams[D]. Xiamen: Xiamen University, 2019(in Chinese). [18] WHITEHEAD P A, IBELL T J. Novel shear reinforcement for fiber-reinforced polymer-reinforced and prestressed concrete[J]. ACI Structural Journal,2005,102(2):286-294. [19] 中华人民共和国住房和城乡建设部. 纤维增强复合材料建设工程应用技术规范: GB 50608—2020[S]. 北京: 中国标准出版社, 2010.Ministry of Housing and Urban-Rural Development of People’s Republic of China. Technical standard for fiber reinforced polymer (FRP) in construction: GB 50608—2020[S]. Beijing: China Standards Press, 2020(in Chinese). [20] American Concrete Institute. Guide for the design and construction of structural concrete reinforced with fiber reinforced polymer (FRP) bars: ACI 440.1 R-15[S]. Farmington Hills: American Concrete Institute, 2015. [21] Canadian Standard Association. Design and construction of building components with fibre reinforced polymers: CSA S806-12[S]. Toronto: Canadian Standards Association International, 2012. [22] British Institution of Structural Engineers. Interim guidance on the design of reinforced concrete structures using fiber composite reinforcement: BISE—1999[S]. London: British Institution of Structural Engineers, 1999. [23] Japan Society of Civil Engineers. Recommendation for design and construction of concrete structures using continuous fiber reinforcing materials: JSCE—1997[S]. Tokyo: Japan Society of Civil Engineers, 1997. [24] DONG H, WANG D, WANG Z, et al. Axial compressive behavior of square concrete columns reinforced with innovative closed-type winding GFRP stirrups[J]. Compo-site Structures,2018,192:115-125. doi: 10.1016/j.compstruct.2018.02.092 [25] 董恒磊. 配置GFRP纵筋与新型箍筋的混凝土墩柱约束机理与抗震性能[D]. 哈尔滨: 哈尔滨工业大学, 2020.DONG Henglei. Confinement mechanism and seismic performance of concrete piers reinforced with GFRP rebars and innovativeties[D]. Harbin: Harbin Institute of Technology, 2020(in Chinese). [26] 中国国家标准化管理委员会. 纤维增强复合材料筋基本力学性能试验方法: GB/T 30022—2013[S]. 北京: 中国标准出版社, 2013.Standardization Administration of China. Test method for basic mechanical properties of fiber reinforced polymer bar: GB/T 30022—2013[S]. Beijing: Standards Press of China, 2013(in Chinese). [27] American Society of Testing Materials. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/3039 M-00[S]. West Conshohocken: American Society of Testing Materials International, 2000. [28] American Concrete Institute. Guide test methods for fiber reinforced polymer (FRP) composites for reinforcing or strengthening concrete and masonry structures: ACI 440.3 R-12[S]. Farmington Hills: American Concrete Institute, 2012. [29] MIHAYLOV B I, BENTZ E C, COLLINS M P. Behavior of large deep beams subjected to monotonic and reversed cyclic shear[J]. ACI Structural Journal, 2010, 107(6): 726-734. [30] JEONG J P, KIM W. Shear resistant mechanism into base components: Beam action and arch action in shear-critical RC members[J]. International Journal of Concrete Structures and Materials,2014,8(1):1-14. doi: 10.1007/s40069-013-0064-x [31] HU B, WU Y F. Effect of shear span-to-depth ratio on shear strength components of RC beams[J]. Engineering Structures,2018,168:770-783. doi: 10.1016/j.engstruct.2018.05.017 [32] 易伟建, 谭童. 钢筋混凝土有腹筋梁受剪机理试验研究[J]. 建筑结构学报, 2022, 43(9): 210-221.YI Weijian, TAN Tong. Experimental study on shear mechanism of reinforced concrete beams with stirrups[J]. Journal of Building Structures, 2022, 43(9): 210-221(in Chinese) [33] ALI A H, MOHAMED H M, BENMOKRANE B. Shear behavior of circular concrete members reinforced with GFRP bars and spirals at shear span-to-depth ratios between 1.5 and 3.0[J]. Journal of Composites for Construction,2016,20(6):04016055. doi: 10.1061/(ASCE)CC.1943-5614.0000707 [34] RAZAQPUR A G, SPADEA S. Shear strength of FRP reinforced concrete members with stirrups[J]. Journal of Composites for Construction,2015,19(1):04014025. doi: 10.1061/(ASCE)CC.1943-5614.0000483 [35] JOHNSON D T, SHEIKH S A. Experimental investigation of glass fiber-reinforced polymer-reinforced normal-strength concrete beams[J]. ACI Structural Journal,2016,113(6):1165-1174. [36] SPADEA S, ORR J, NANNI A, et al. Wound FRP shear reinforcement for concrete structures[J]. Journal of Compo-sites for Construction,2017,21(5):04017026. doi: 10.1061/(ASCE)CC.1943-5614.0000807 -

下载:

下载: