Impact resistance of continuous glass fiber and glass bead co-reinforced Nylon 6 composites

-

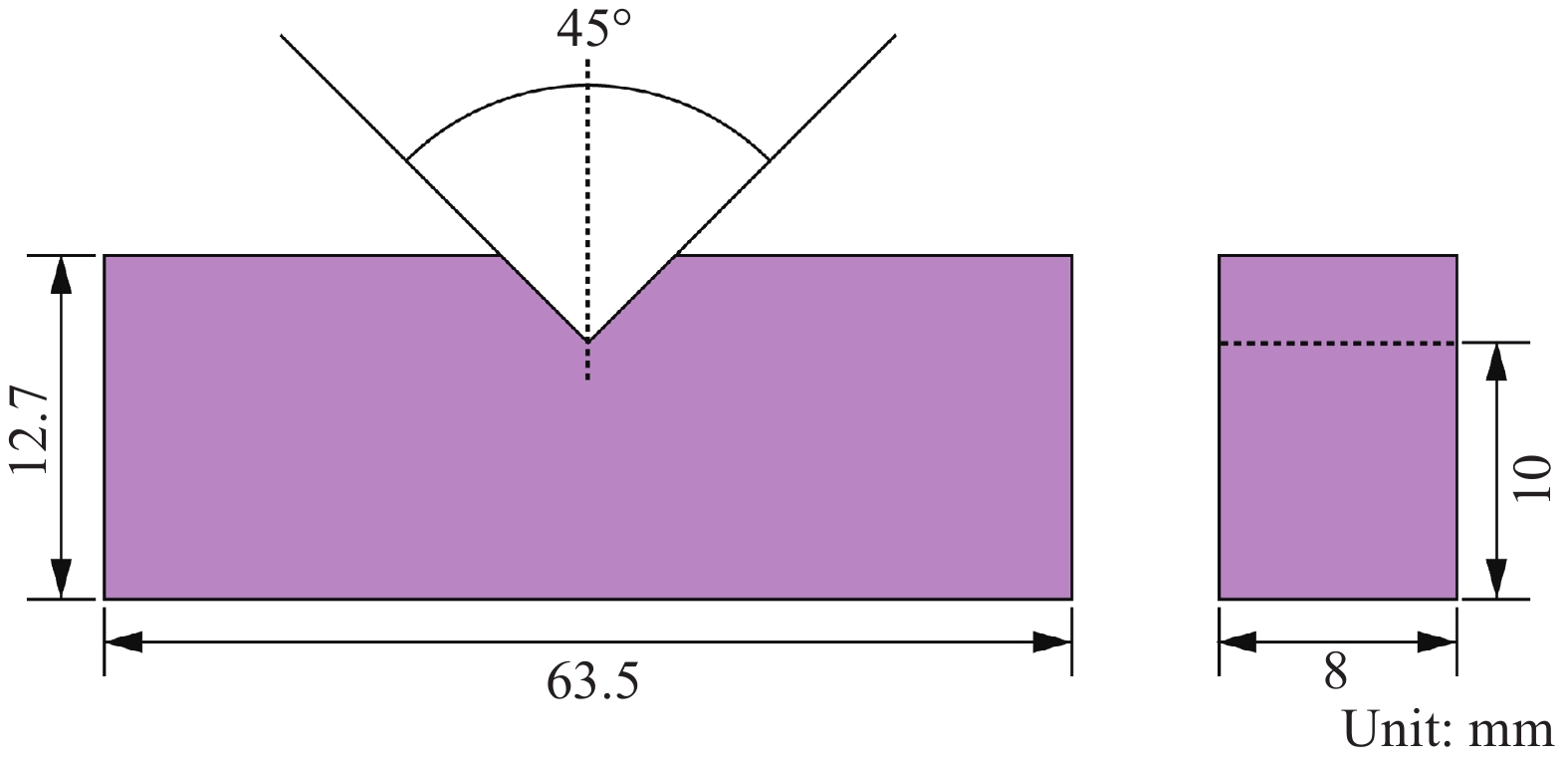

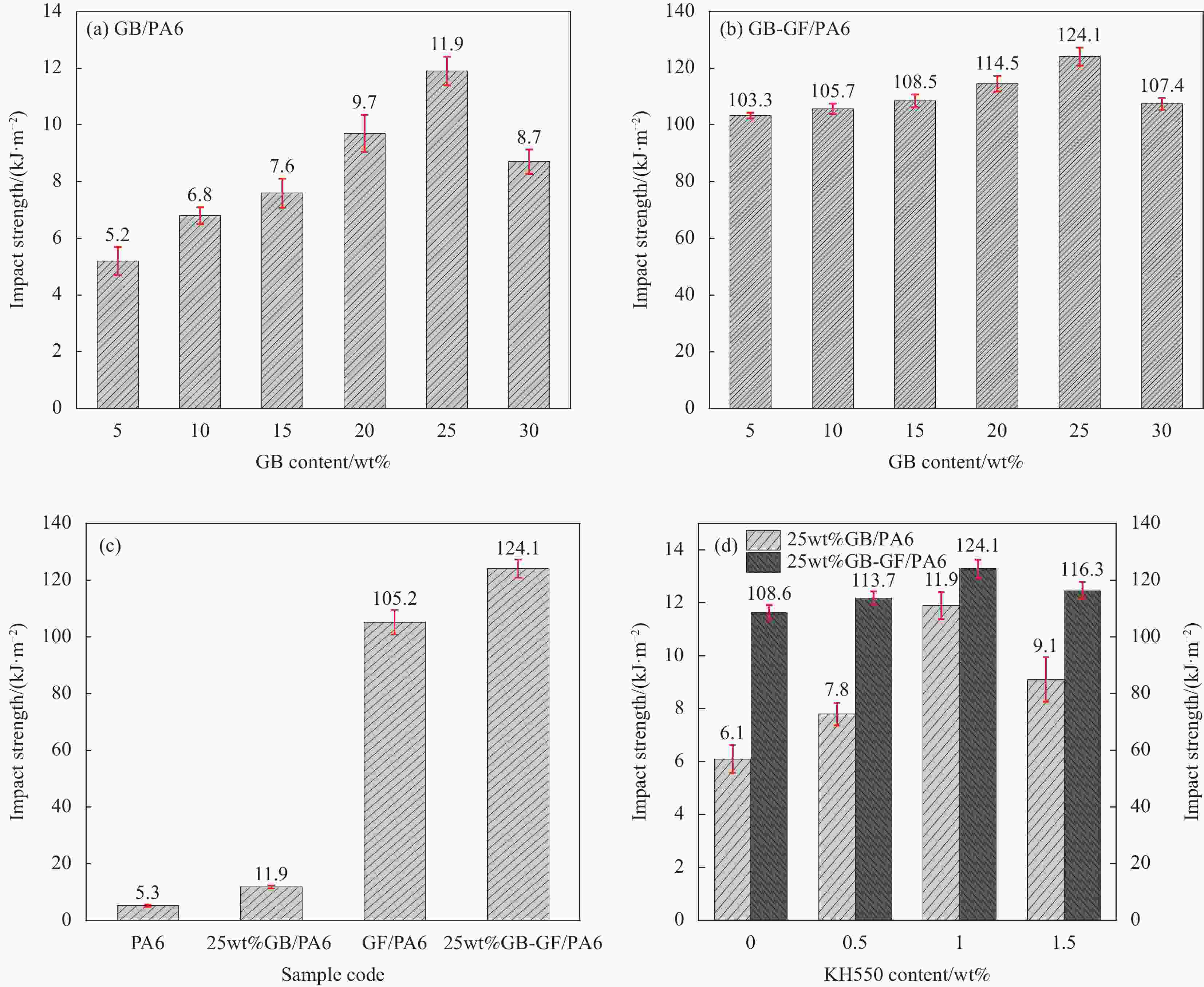

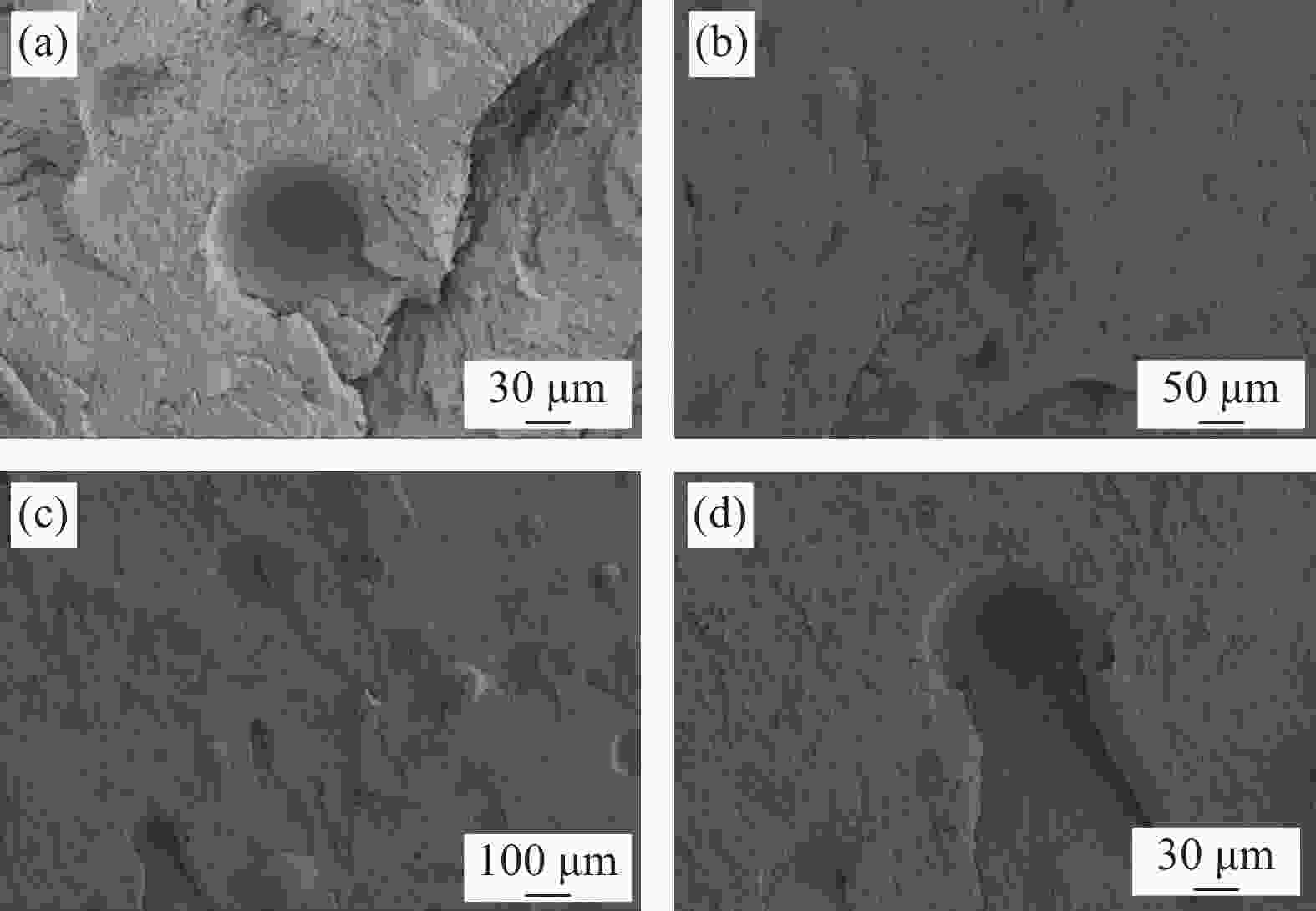

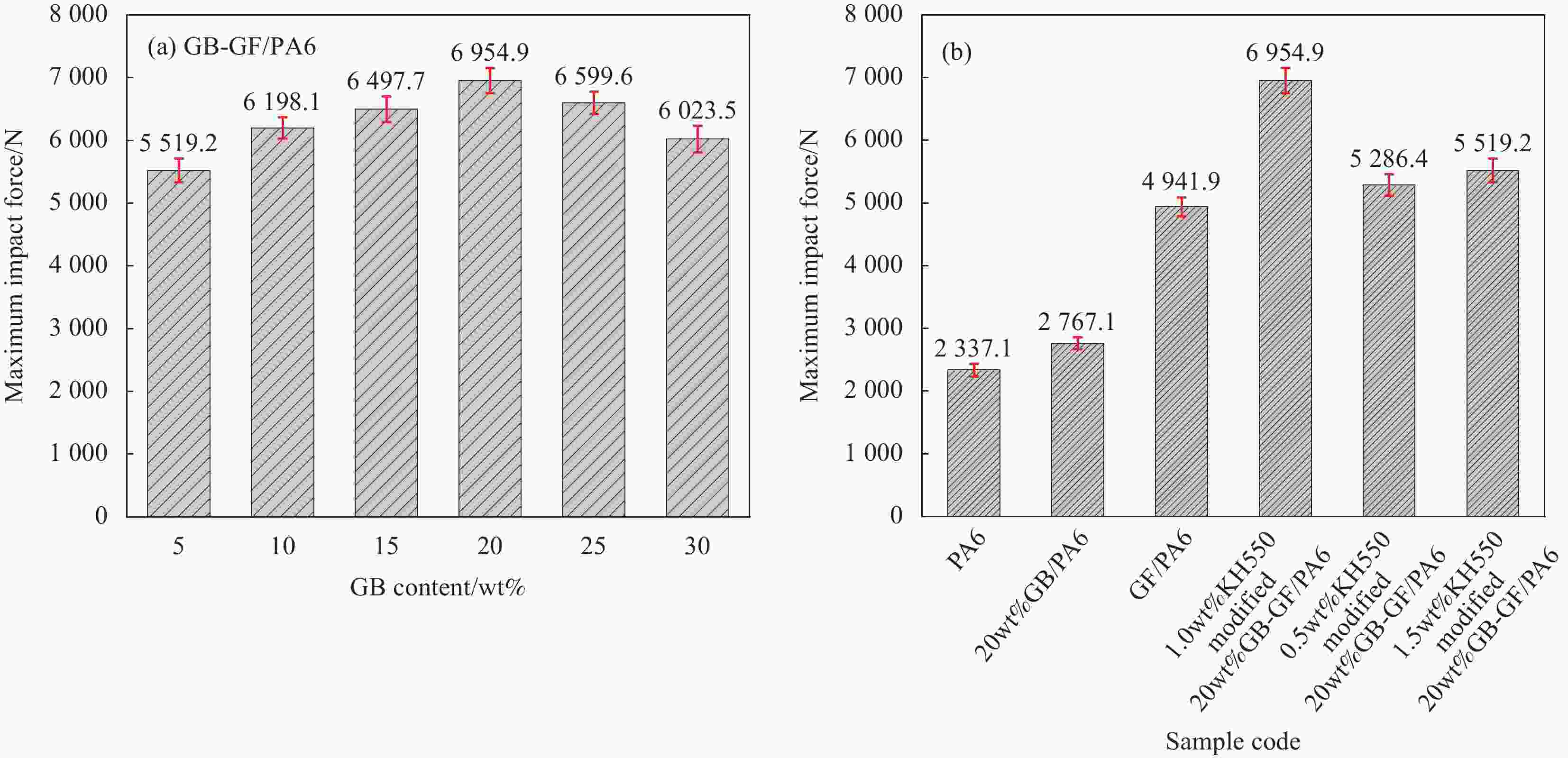

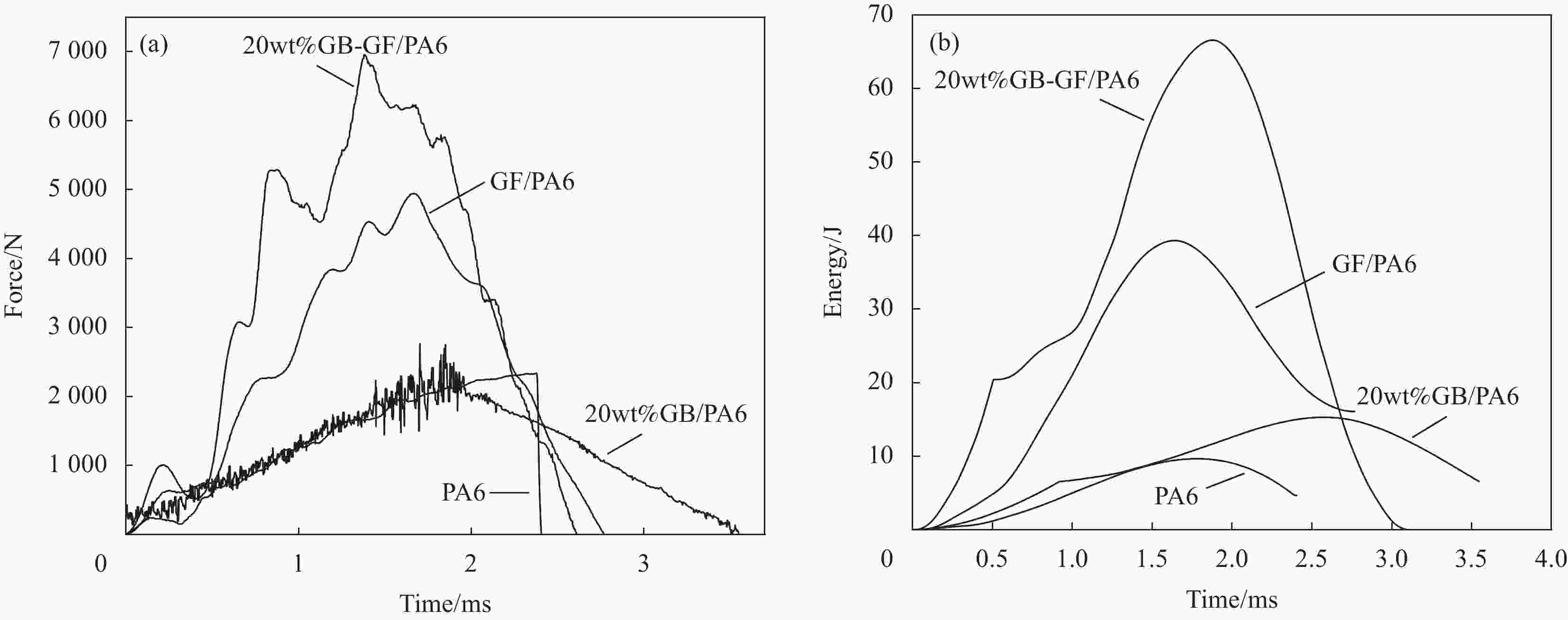

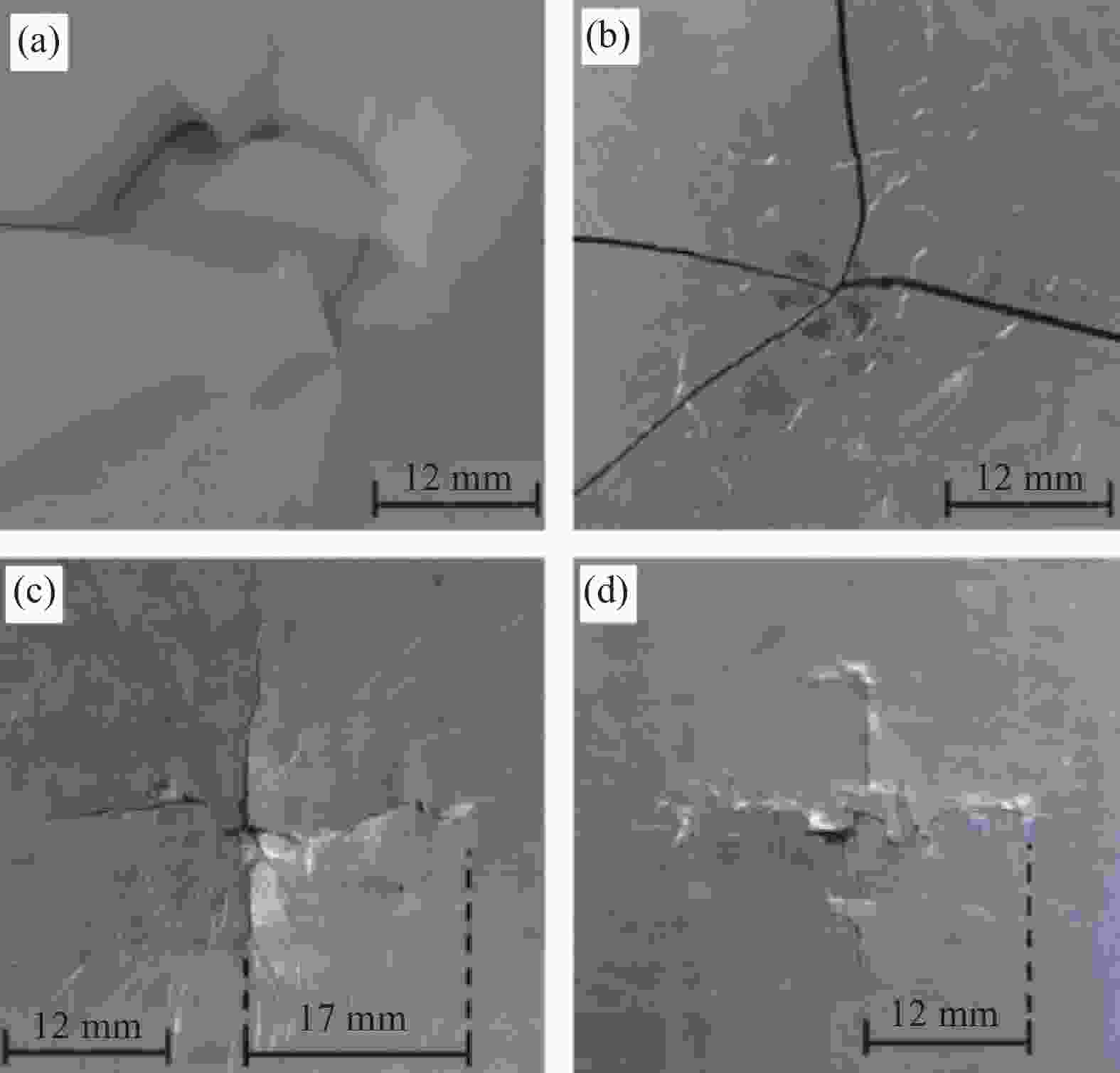

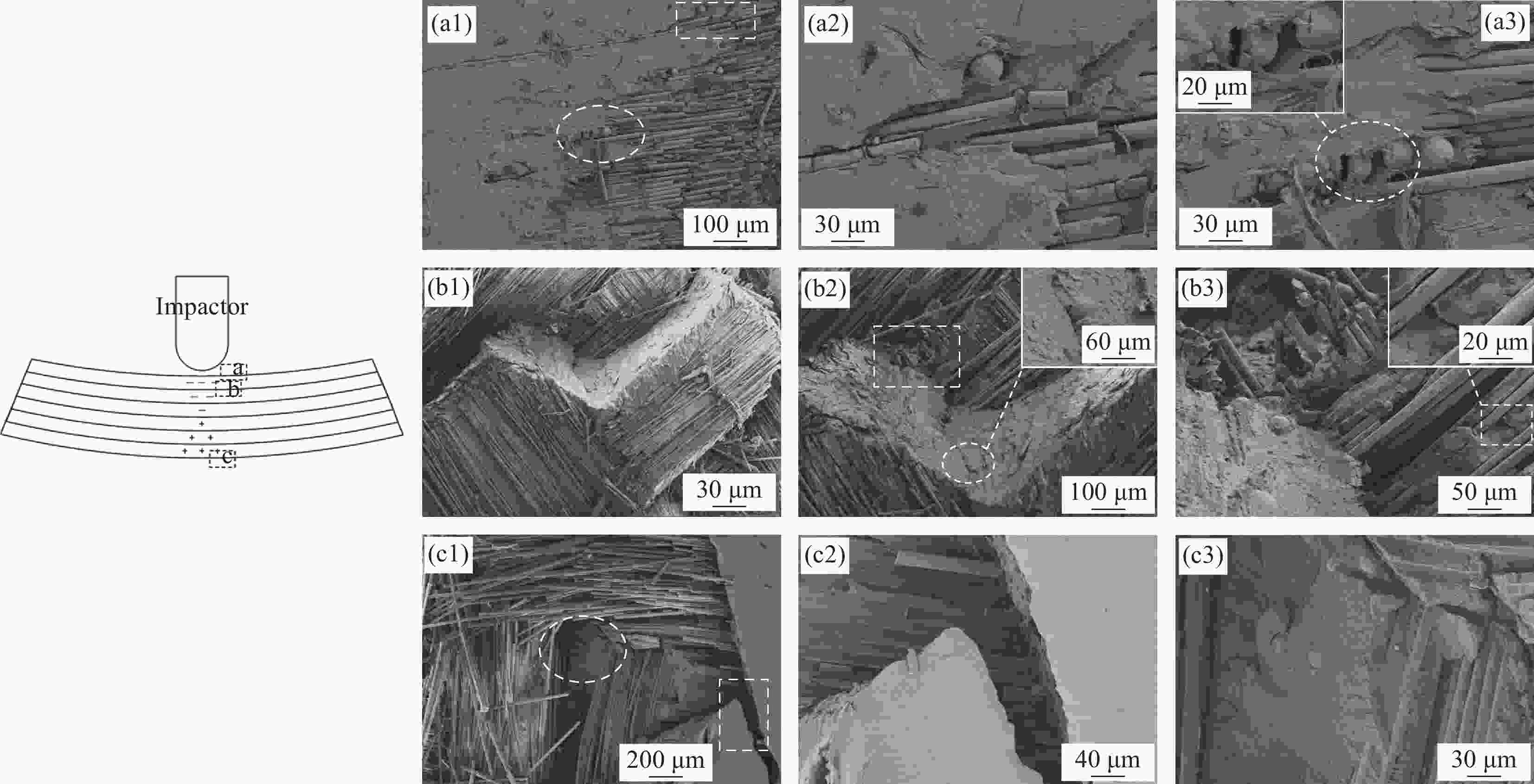

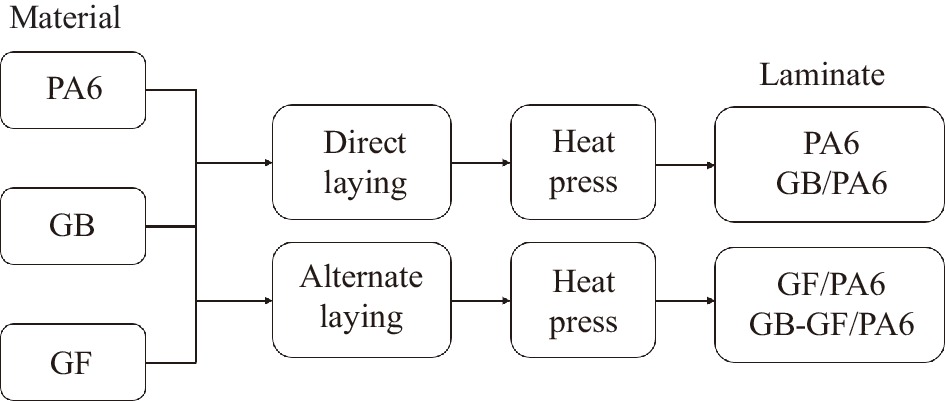

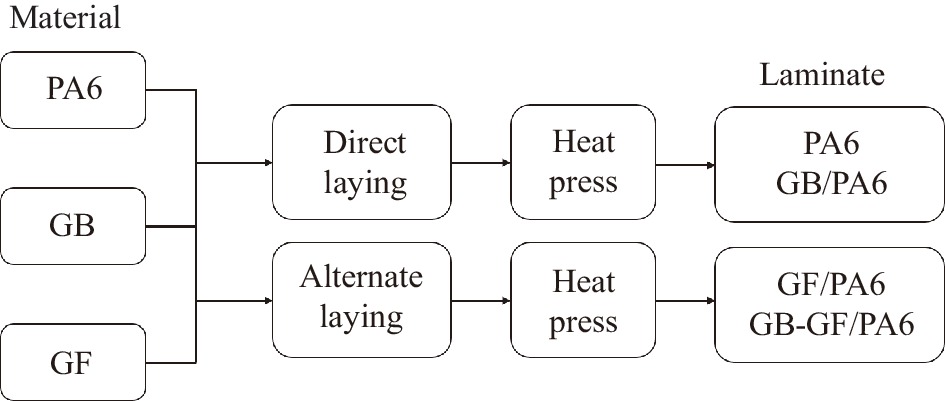

摘要: 低速冲击是聚合物基复合材料在运输和服役过程中常见损伤方式,常造成复合材料结构损伤、性能降低、承载能力下降,影响使用。针对2D纤维增强聚合物基复合材料在冲击载荷作用下抗分层能力差的问题,本文采用熔融挤出结合热压成型法制备了二元和三元尼龙6(PA6)基复合材料,对比研究了连续玻璃纤维(GF)、玻璃微珠(GB)及两者共增强PA6基复合材料的摆锤冲击性能和落锤低速冲击响应。结果表明:(1) GF和GB能显著提高PA6的抗冲击性能,且GF的增强效果明显高于GB;(2) GB增强PA6基复合材料(GB/PA6)的冲击强度随GB加入量增大而先增大后降低,加入量为25wt%时冲击强度最大;冲击载荷作用下,25wt%GB/PA6的耗能机制除了界面脱粘和钉扎效应之外,还发现GB在PA6基体中的滑移耗能新机制;(3) GF和GB共增强PA6复合材料(GB-GF/PA6)中纤维起主要的增强作用,摆锤冲击实验和落锤冲击实验均证明存在协同增强效应;(4) GF和GB共增强的协同增强效应是由于共增强复合材料在冲击载荷作用下,抗Ⅱ型裂纹扩展能力提高,使复合材料抗分层能力得到强化;从而证明在基体中引入适量球形GB是提高2D纤维增强聚合物基复合材料抗低速冲击性能的一条经济和有效途径。Abstract: Low-velocity impact is a common damage mode for polymer matrix composites during transportation and service, often results in structural damage, performance degradation, and loss of load-bearing capacity, which affects the use of the composites. To address the problem of poor delamination resistance of 2D fiber-reinforced polymer matrix composites under impact loading, binary and ternary Nylon 6 (PA6)-based composites were prepared by melt extrusion combined with hot pressing, and the pendulum impact performance and drop hammer low-velocity impact response of continuous glass fiber (GF), glass beads (GB) and both co-reinforced PA6-based composites were comparatively investigated. The results show that: (1) GF and GB can significantly improve the impact resistance of PA6, and the enhancement effect of GF is significantly higher than that of GB; (2) Impact strength of GB-reinforced PA6-based composites (GB/PA6) showed a trend of increasing and then decreasing with increasing GB incorporation, with the maximum impact strength at 25wt% incorporation; the energy dissipation mechanism of 25wt%GB/PA6 under impact loading was found to be a new mechanism of slip energy dissipation of GB in PA6 matrix, in addition to interfacial debonding and pinning effects; (3) The fibers in GF and GB co-reinforced PA6 composites (GB-GF/PA6) play a major reinforcing role, and both pendulum impact tests and drop impact tests demonstrate a synergistic reinforcing effect; (4) The synergistic reinforcing effect of GF and GB co-reinforcement is due to the increased resistance to type II crack expansion of the co-reinforced composites under impact loading, resulting in the reinforcement of the composite against delamination. Thus, demonstrating that the introduction of an appropriate amount of spherical GB into the matrix is an economical and effective way to improve the resistance of 2D fiber-reinforced polymer matrix composites to low-velocity impact.

-

Key words:

- glass bead /

- glass fiber /

- Nylon 6 matrix composites /

- low speed impact /

- synergistic effect

-

表 1 PA6基复合材料冲击凹坑深度、损伤面积和耗损能量

Table 1. Impact pit depth, damage area and absorbed energy of PA6 composites

Sample Pit depth/mm Damage area/mm2 Maximum absorbed energy/J PA6 Breakdown Smash 9.65 20wt%GB/PA6 Breakdown Smash 15.29 GF/PA6 0.42 907 39.32 20wt%GB-GF/PA6 0.26 452 66.57 表 2 PA6基复合材料的冲击破坏能量耗损机制

Table 2. Energy dissipation mechanism for impact damage of PA6-based composites

Material type Matrix Reinforcement Interface Synergistic effect PA6 Matrix tensile and fracture – – – GB/PA6 Matrix tensile and fracture Particle slip and crush Debonding, pinning and deflection – GF/PA6 Matrix tensile and fracture Fiber elongation, bridging, break and pullout Debonding and deflection – GB-GF/PA6 Matrix tensile and fracture Fiber elongation, bridging, break and pullout, particle slip and crush Particle debonding, fiber debonding, crack deflection and pinning Synergistic

enhancement表 3 PA6基复合材料的剪切强度

Table 3. Shear strength of PA6-based composites

Materials Shear strength/MPa Standard deviation Strength increase value/MPa PA6 29.1 0.96 0.0 25wt%GB/PA6 33.7 1.51 4.6 GF/PA6 36.7 1.39 7.6 25wt%GB-GF/PA6 44.1 1.71 15.0 -

[1] NASSIR N A, BIRCH R S, CANTWELL W J, et al. The perforation resistance of glass fibre reinforced PEKK composites[J]. Polymer Testing,2018,72:423-431. doi: 10.1016/j.polymertesting.2018.11.007 [2] SARFRAZ M S, HONG H, KIM S S. Recent developments in the manufacturing technologies of composite components and their cost-effectiveness in the automotive industry: A review study[J]. Composite Structures,2021,266:113864. doi: 10.1016/j.compstruct.2021.113864 [3] LIU P, BARLOW C Y. Wind turbine blade waste in 2050[J]. Waste Management,2017,62:229-240. doi: 10.1016/j.wasman.2017.02.007 [4] SUTHERLAND L S. A review of impact testing on marine composite materials: Part I—Marine impacts on marine composites[J]. Composite Structures,2018,188:197-208. doi: 10.1016/j.compstruct.2017.12.073 [5] RAPONI E, FIUMARELLA D, BORIA S, et al. Methodology for parameter identification on a thermoplastic composite crash absorber by the sequential response surface method and efficient global optimization[J]. Composite Structures,2021,278:114646. doi: 10.1016/j.compstruct.2021.114646 [6] ARIKAN V, SAYMAN O. Comparative study on repeated impact response of E-glass fiber reinforced polypropylene & epoxy matrix composites[J]. Composites Part B: Engineering,2015,83:1-6. doi: 10.1016/j.compositesb.2015.08.051 [7] KANHERE S V, BERMUDEZ V, OGALE A A. Carbon and glass fiber reinforced thermoplastic matrix composites[M]//Fiber Reinforced Composites. Sawston: Woodhead Publishing, 2021: 273-306. [8] BARILE M, LECCE L, IANNONE M, et al. Thermoplastic composites for aerospace applications[M]//Revolutionizing Aircraft Materials and Processes. Cham: Springer, 2020: 87-114. [9] ANDREW J J, SRINIVASAN S M, AROCKIARAJAN A, et al. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review[J]. Composite Structures,2019,224:111007. doi: 10.1016/j.compstruct.2019.111007 [10] YU B, GENG C, ZHOU M, et al. Impact toughness of polypropylene/glass fiber composites: Interplay between intrinsic toughening and extrinsic toughening[J]. Compo-sites Part B: Engineering,2016,92:413-419. doi: 10.1016/j.compositesb.2016.02.040 [11] SHAH S Z H, KARUPPANAN S, MEGAT-YUSOFF P S M, et al. Impact resistance and damage tolerance of fiber reinforced composites: A review[J]. Composite Structures,2019,217:100-121. doi: 10.1016/j.compstruct.2019.03.021 [12] VÁRDAI R, LUMMERSTORFER T, PRETSCHUH C, et al. Comparative study of fiber reinforced PP composites: Effect of fiber type, coupling and failure mechanisms[J]. Composites Part A: Applied Science and Manufacturing,2020,133:105895. doi: 10.1016/j.compositesa.2020.105895 [13] MOURITZ A P. Review of Z-pinned laminates and sandwich composites[J]. Composites Part A: Applied Science and Manufacturing,2020,139:106128. doi: 10.1016/j.compositesa.2020.106128 [14] PEGORIN F, PINGKARAWAT K, DAYNES S, et al. Influence of Z-pin length on the delamination fracture toughness and fatigue resistance of pinned composites[J]. Compo-sites Part B: Engineering,2015,78:298-307. doi: 10.1016/j.compositesb.2015.03.093 [15] CHAZOT C A C, HART A J. Understanding and control of interactions between carbon nanotubes and polymers for manufacturing of high-performance composite materials[J]. Composites Science and Technology,2019,183:107795. doi: 10.1016/j.compscitech.2019.107795 [16] TANG Y, YE L, ZHANG Z, et al. Interlaminar fracture toughness and CAI strength of fibre-reinforced composites with nanoparticles—A review[J]. Composites Science and Technology,2013,86:26-37. doi: 10.1016/j.compscitech.2013.06.021 [17] KHAN M I, UMAIR M, HUSSAIN R, et al. Effect of micro-fillers on the performance of thermoplastic para aramid composites for impact applications[J]. Fibers and Polymers,2021,22(11):3120-3134. doi: 10.1007/s12221-021-0370-x [18] 赖鹏辉, 尹洪峰, 张静, 等. 纳米Al2O3-碳纤维多尺度增强聚酰胺基复合材料的制备及力学性能[J]. 复合材料学报, 2018, 35(3):493-500.LAI Penghui, YIN Hongfeng, ZHANG Jing, et al. Preparation and mechanical properties of nano Al2O3-carbon fiber multi-scale reinforced polyamide composites[J]. Acta Materiae Compositae Sinica,2018,35(3):493-500(in Chinese). [19] 李艳, 尹洪峰, 秦月, 等. 尼龙 6 基复合材料的抗冲击性能与协同增强效应[J]. 复合材料科学与工程, 2020(12):84-91. doi: 10.3969/j.issn.1003-0999.2020.12.014LI Yan, YIN Hongfeng, QIN Yue, et al. Impact properties and synergistic effect of nylon 6 based composites[J]. Composites Science and Engineering,2020(12):84-91(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.12.014 [20] RUSSO P, ACIERNO D, SIMEOLI G, et al. Flexural and impact response of woven glass fiber fabric/polypropylene composites[J]. Composites Part B: Engineering,2013,54:415-421. doi: 10.1016/j.compositesb.2013.06.016 [21] KATUNIN A, PAWLAK S, WRONKOWICZ-KATUNIN A, et al. Damage progression in fibre reinforced polymer composites subjected to low-velocity repeated impact loading[J]. Composite Structures,2020,252:112735. doi: 10.1016/j.compstruct.2020.112735 [22] XIAO L, WANG G H, QIU S, et al. Exploration of energy absorption and viscoelastic behavior of CFRPs subjected to low velocity impact[J]. Composites Part B: Engineering,2019,165:247-254. doi: 10.1016/j.compositesb.2018.11.126 [23] AL-SHAMARY A K J, KARAKUZU R, ÖZDEMIR O. Low-velocity impact response of sandwich composites with different foam core configurations[J]. Journal of Sandwich Structures & Materials,2016,18(6):754-768. [24] 张亚文, 陈秉智, 石姗姗, 等. 格栅-蜂窝混式芯体夹芯结构的低速冲击性能[J]. 复合材料学报, 2022, 39(1):381-389.ZHANG Yawen, CHEN Bingzhi, SHI Shanshan, et al. Low-velocity impact performance of grid-honeycomb hybrid core sandwich structure[J]. Acta Materiae Compositae Sinica,2022,39(1):381-389(in Chinese). [25] YANG Z M, LIU J X, WANG F C, et al. Effect of fiber hybridization on mechanical performances and impact behaviors of basalt fiber/UHMWPE fiber reinforced epoxy compo-sites[J]. Composite Structures,2019,229:111434. doi: 10.1016/j.compstruct.2019.111434 [26] American Society for Testing and Materials. Standard test methods for determining the lzod pendulum impact resistance of plastics: ASTM D256-10[S]. West Conshohocken: American Society for Testing and Materials International, 2018. [27] American Society for Testing and Materials. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136-15[S]. West Conshohocke: American Society for Testing and Materials International, 2015. [28] American Society for Testing and Materials. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344-16[S]. West Conshohockens: American Society for Testing and Materials International, 2016. -

下载:

下载: