Growth mechanism of the compressive strength of expanded perlite internal curing concrete and establishment of mathematical model

-

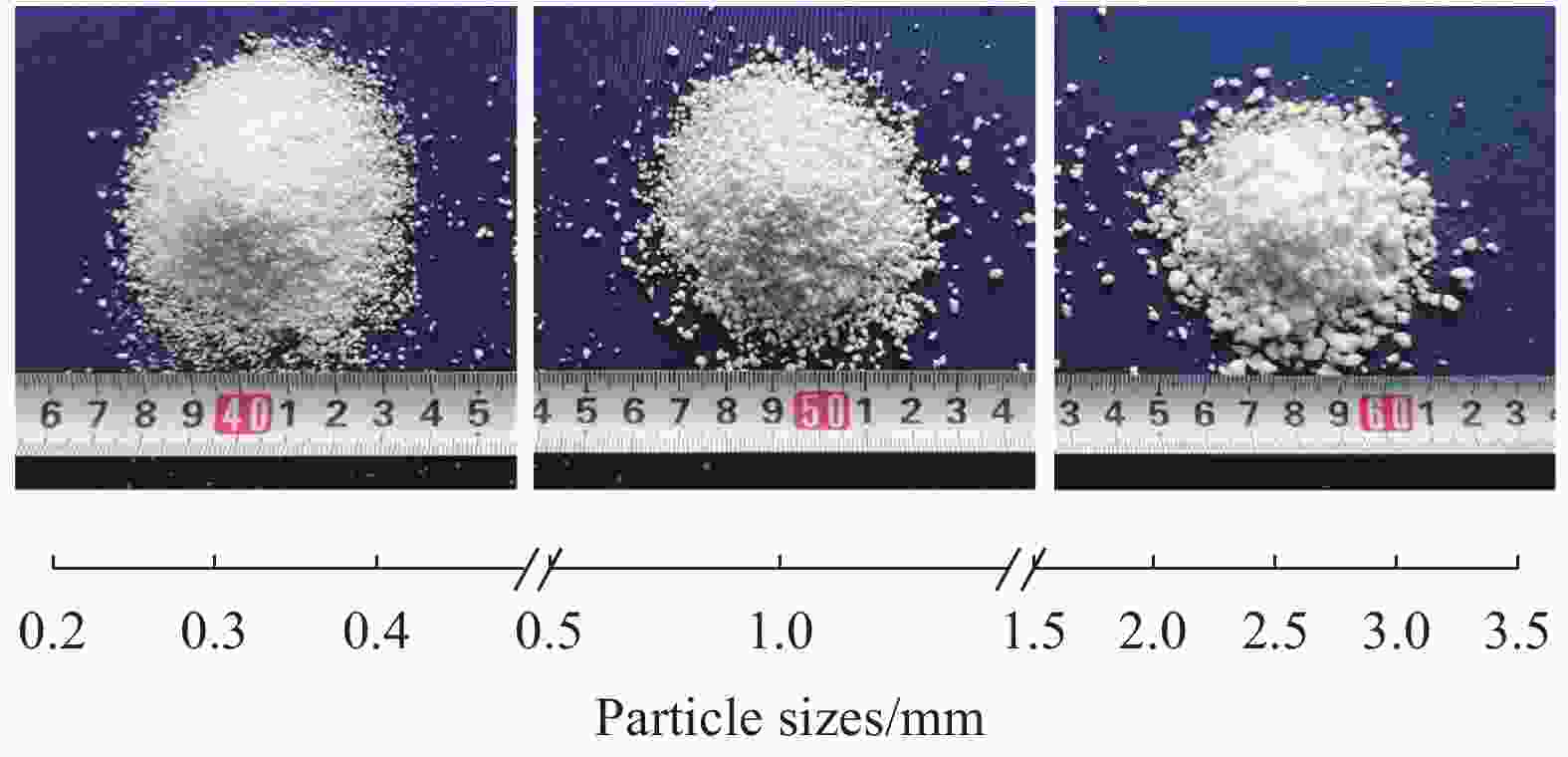

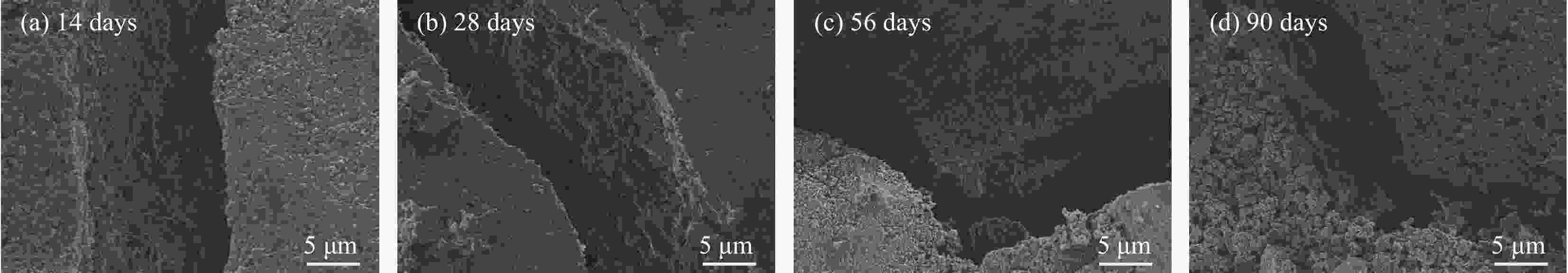

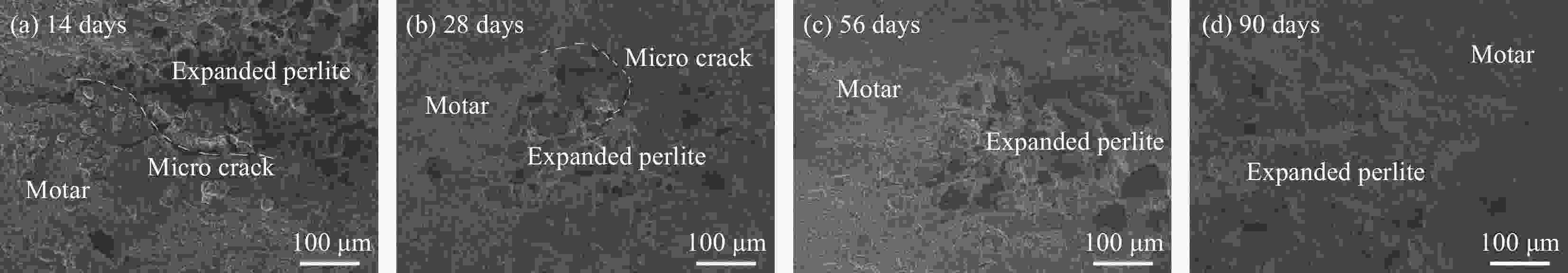

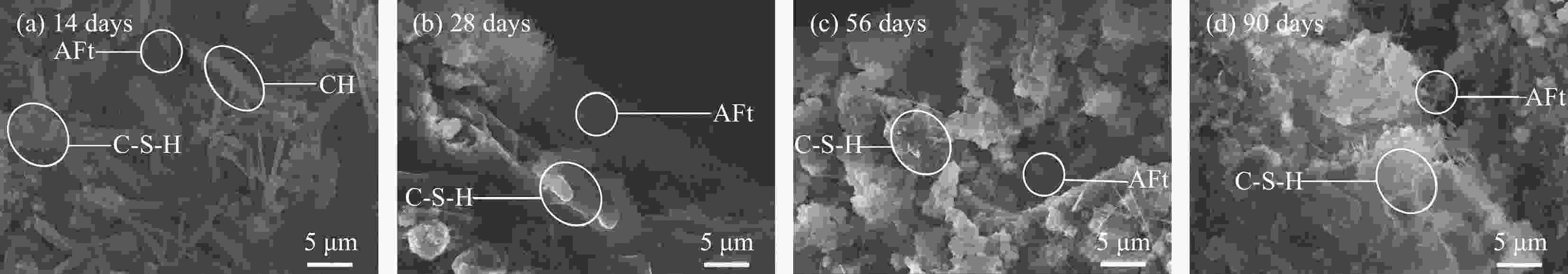

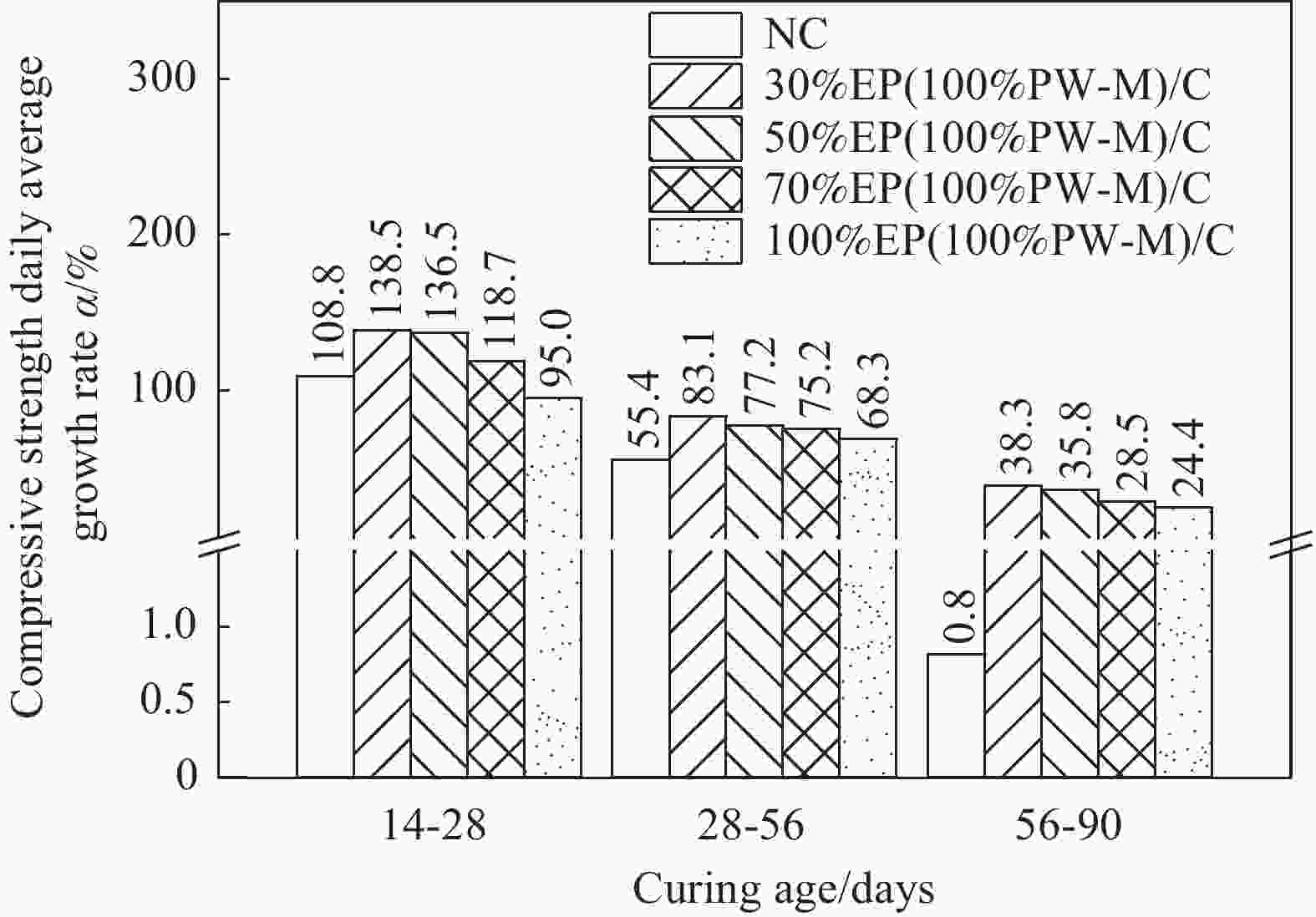

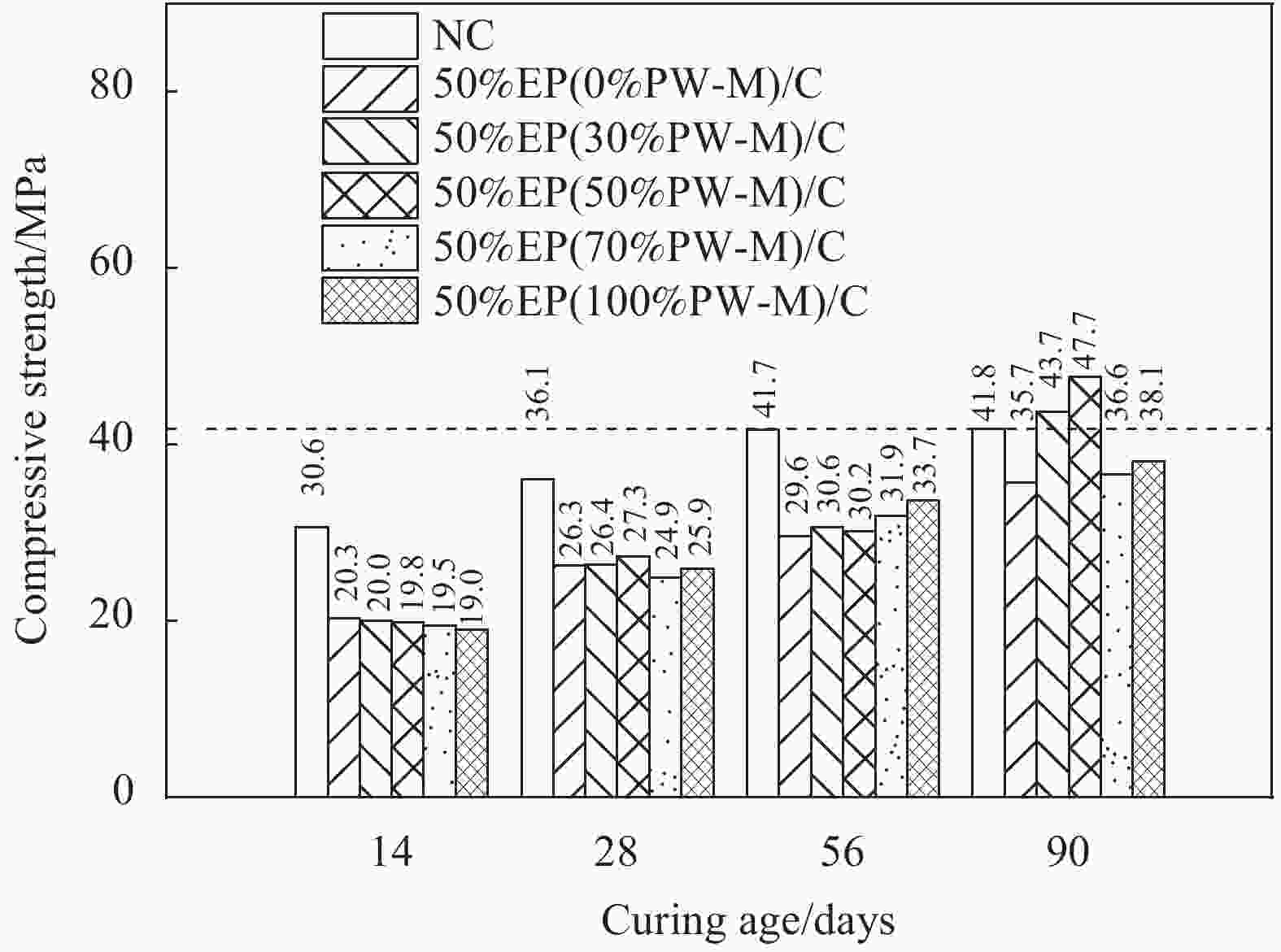

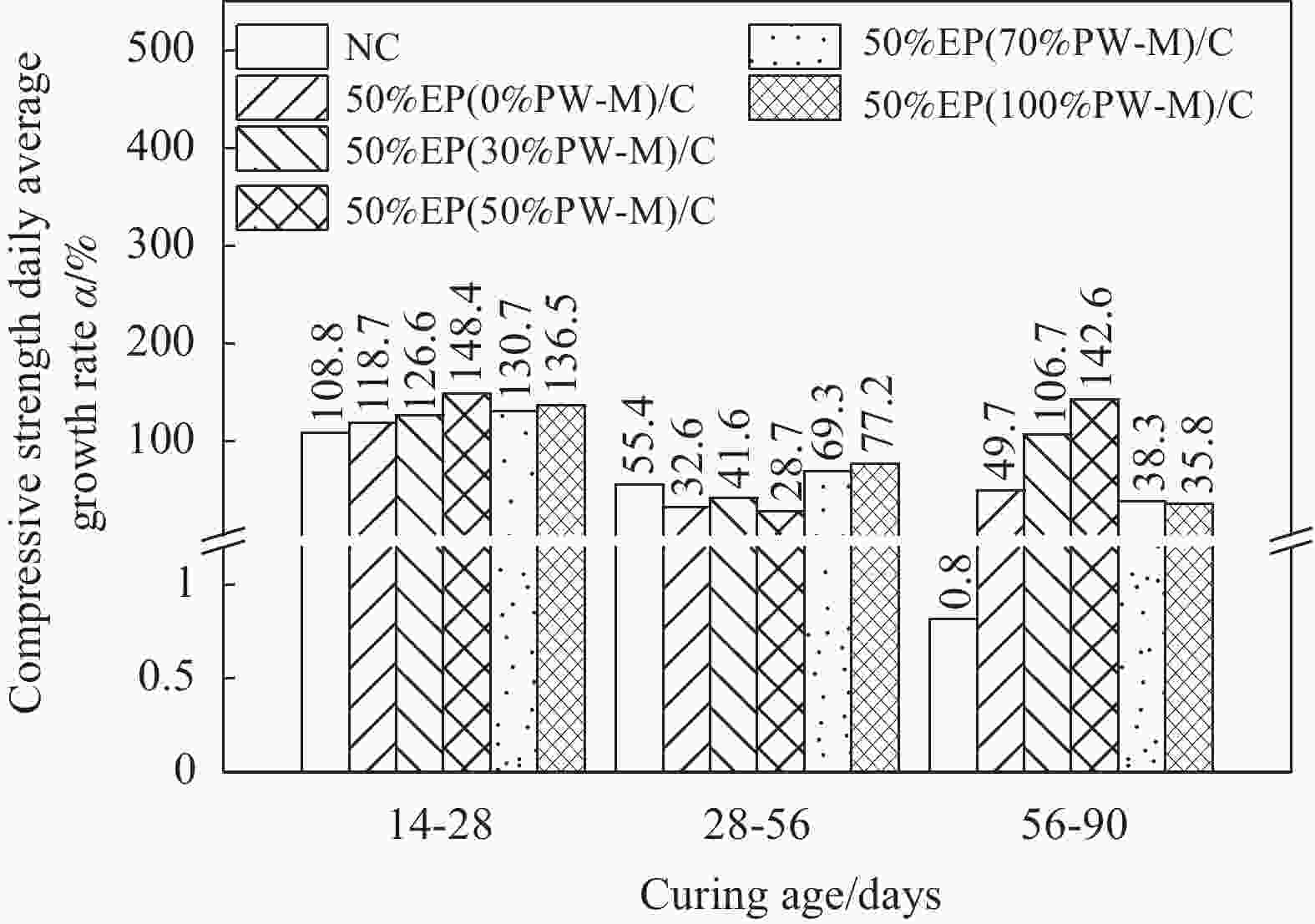

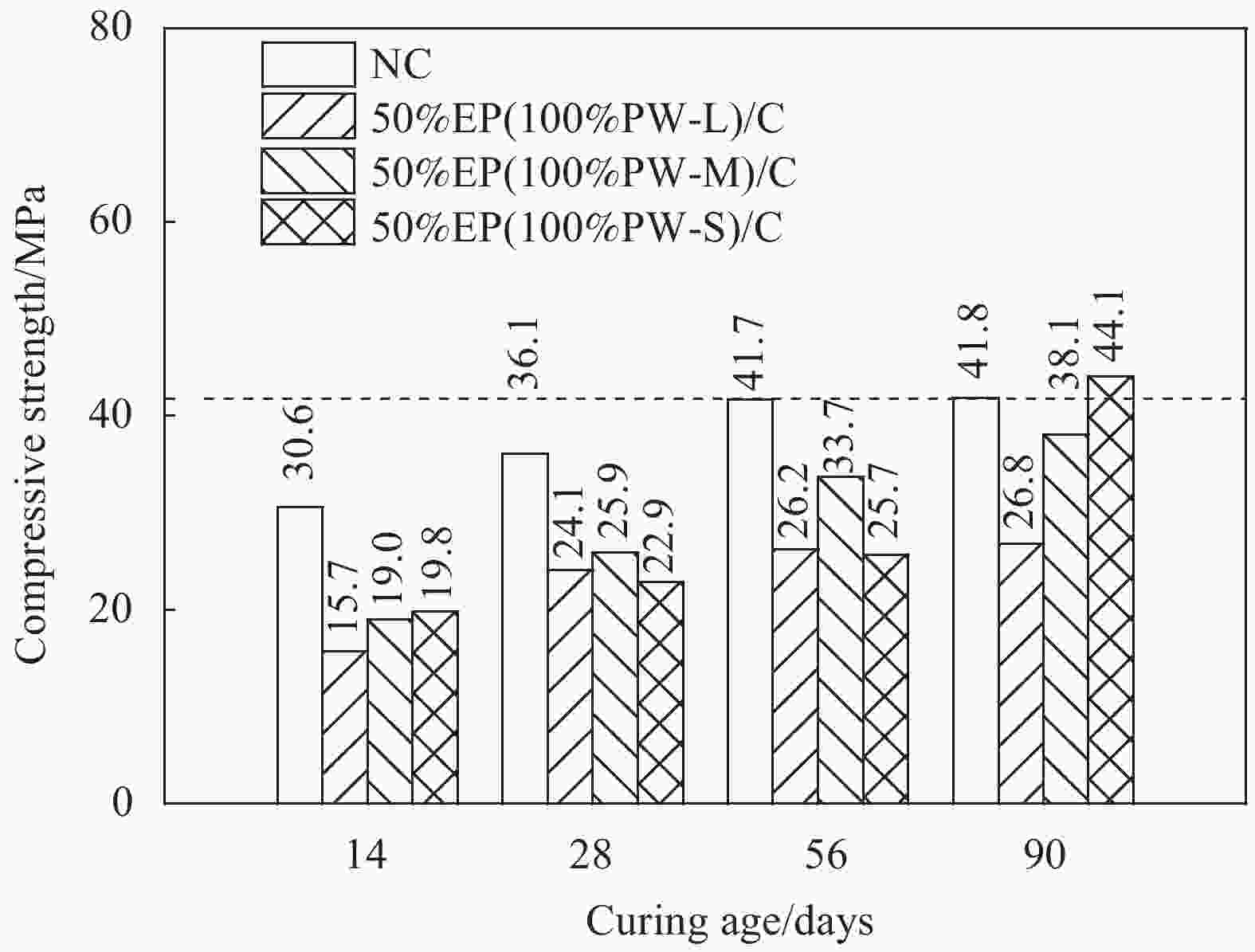

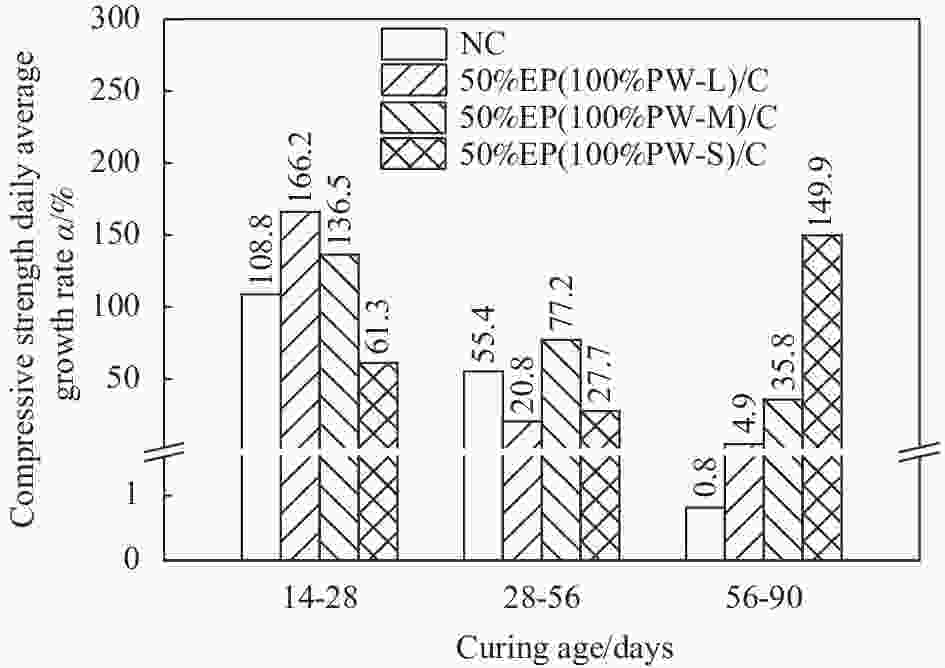

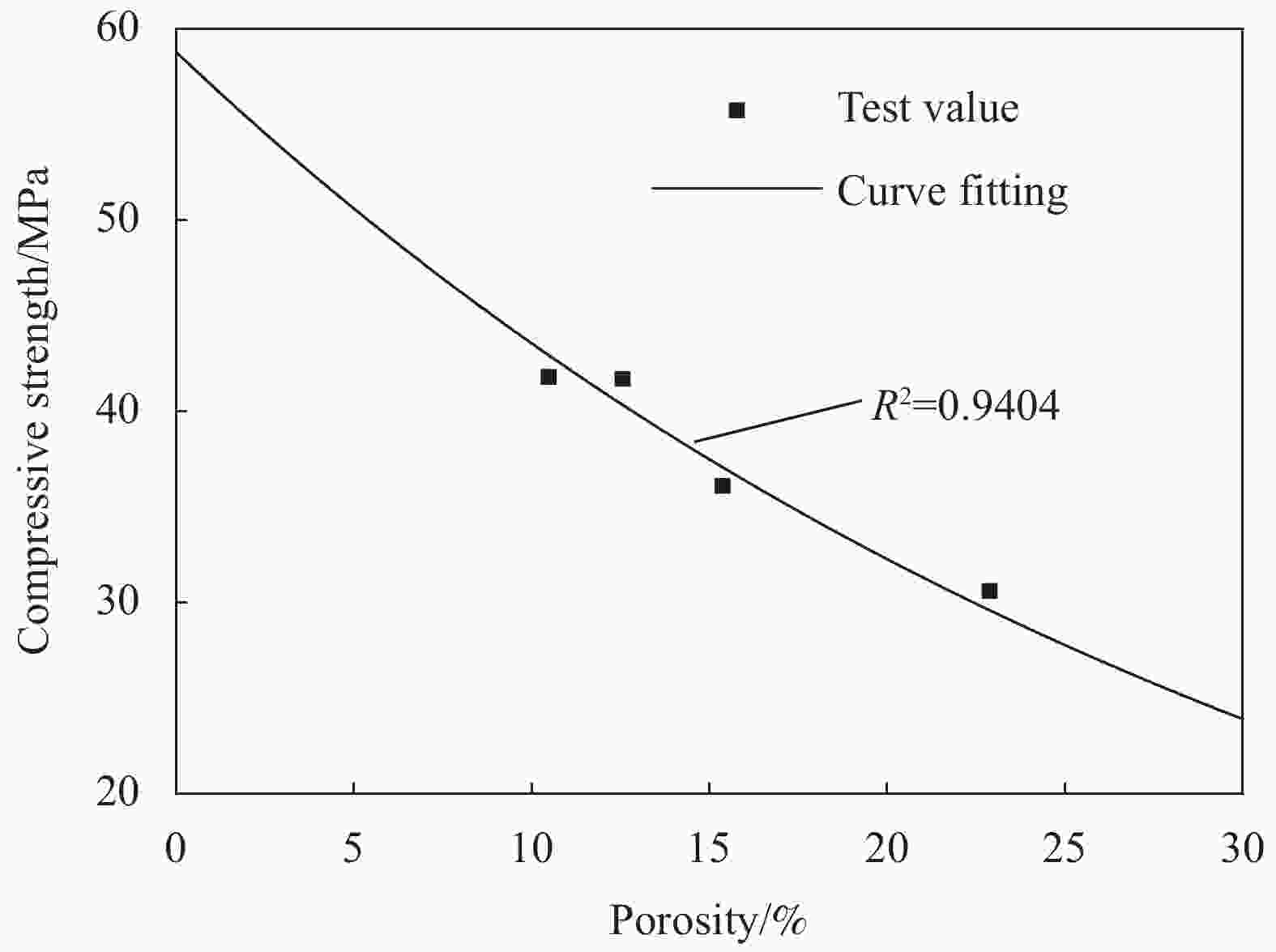

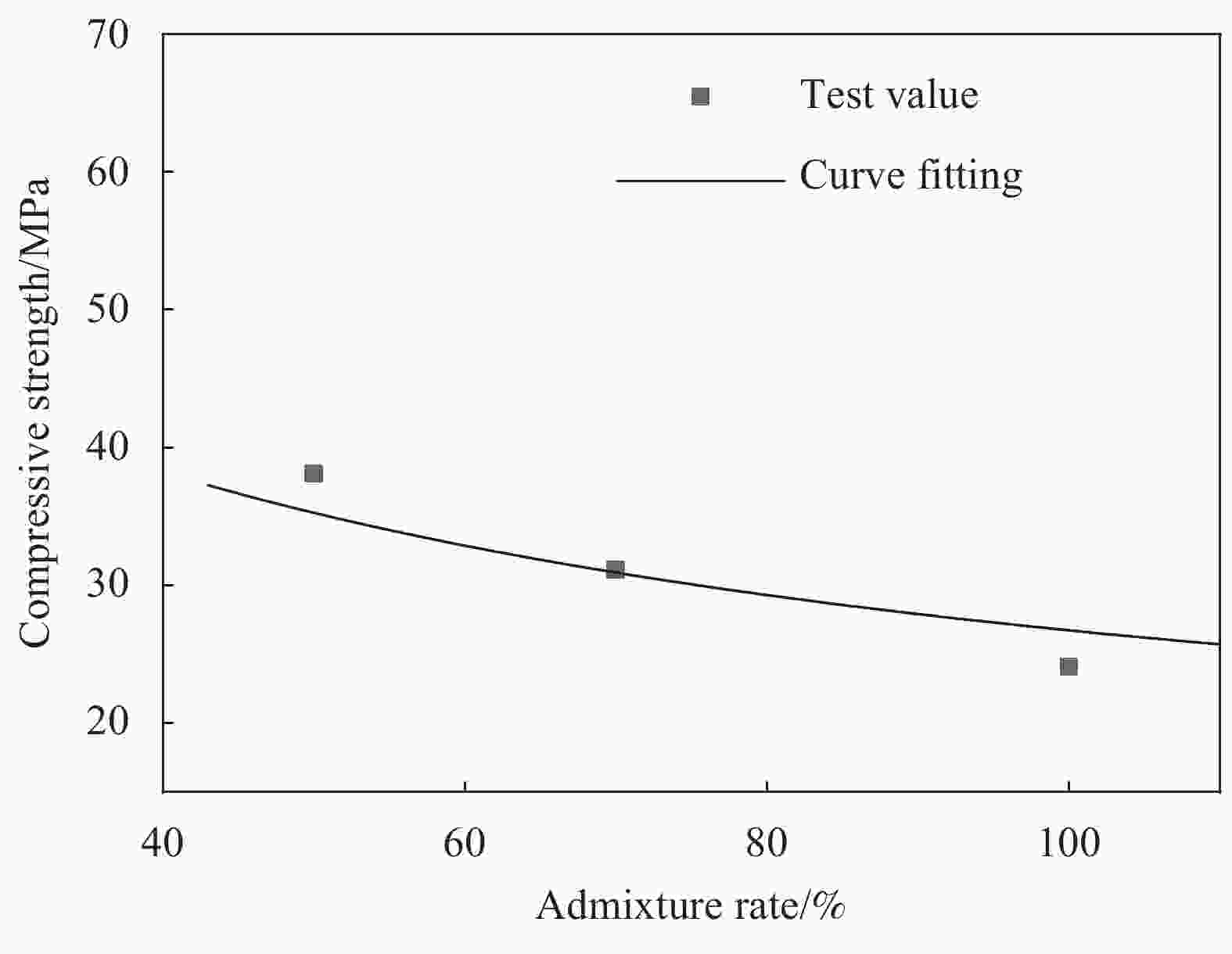

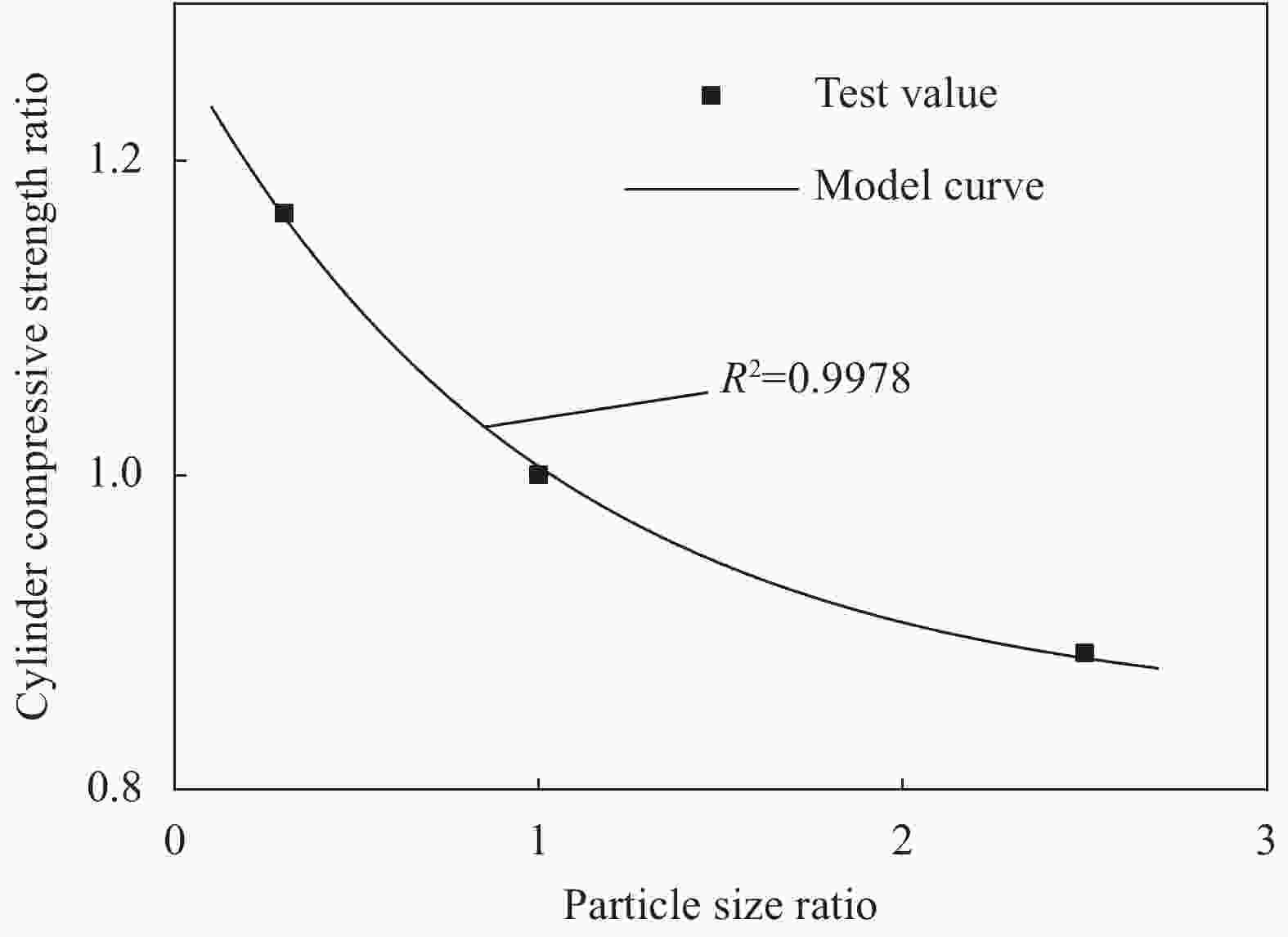

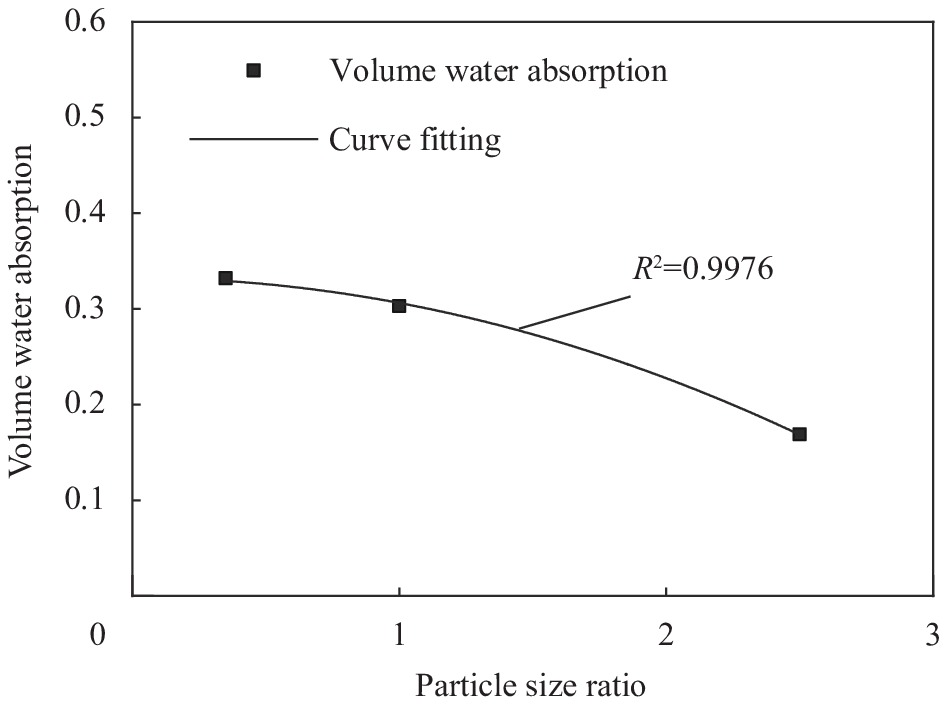

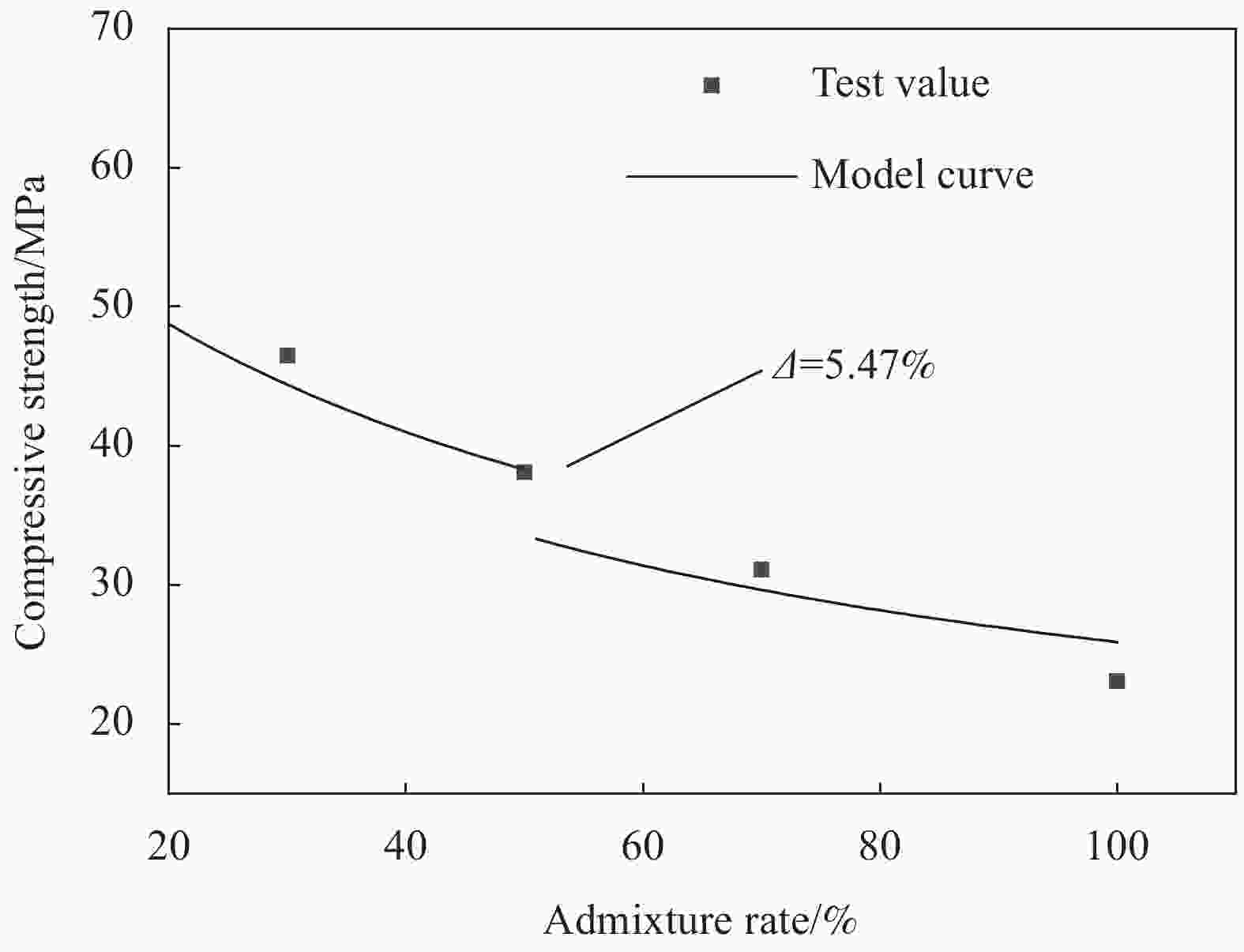

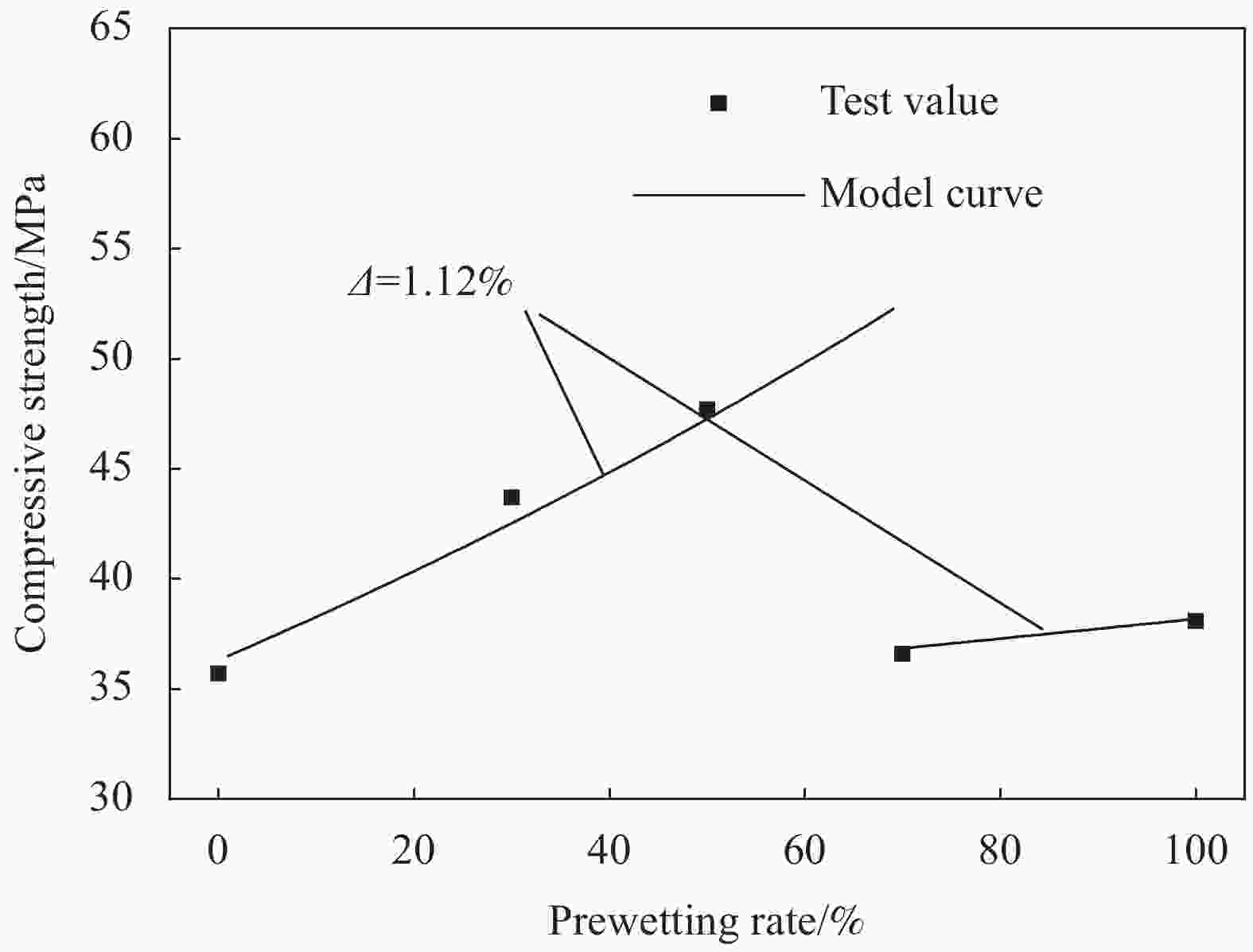

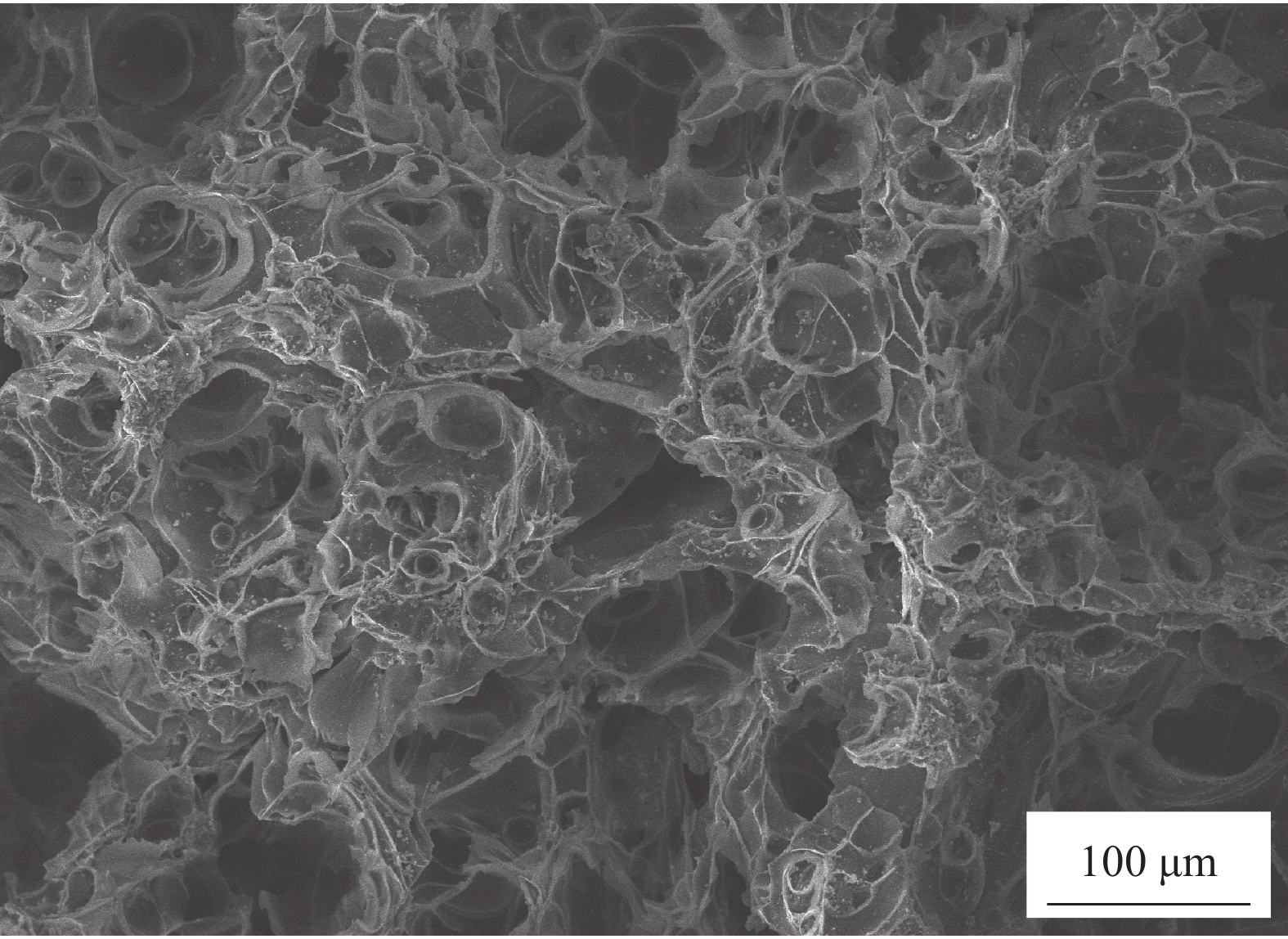

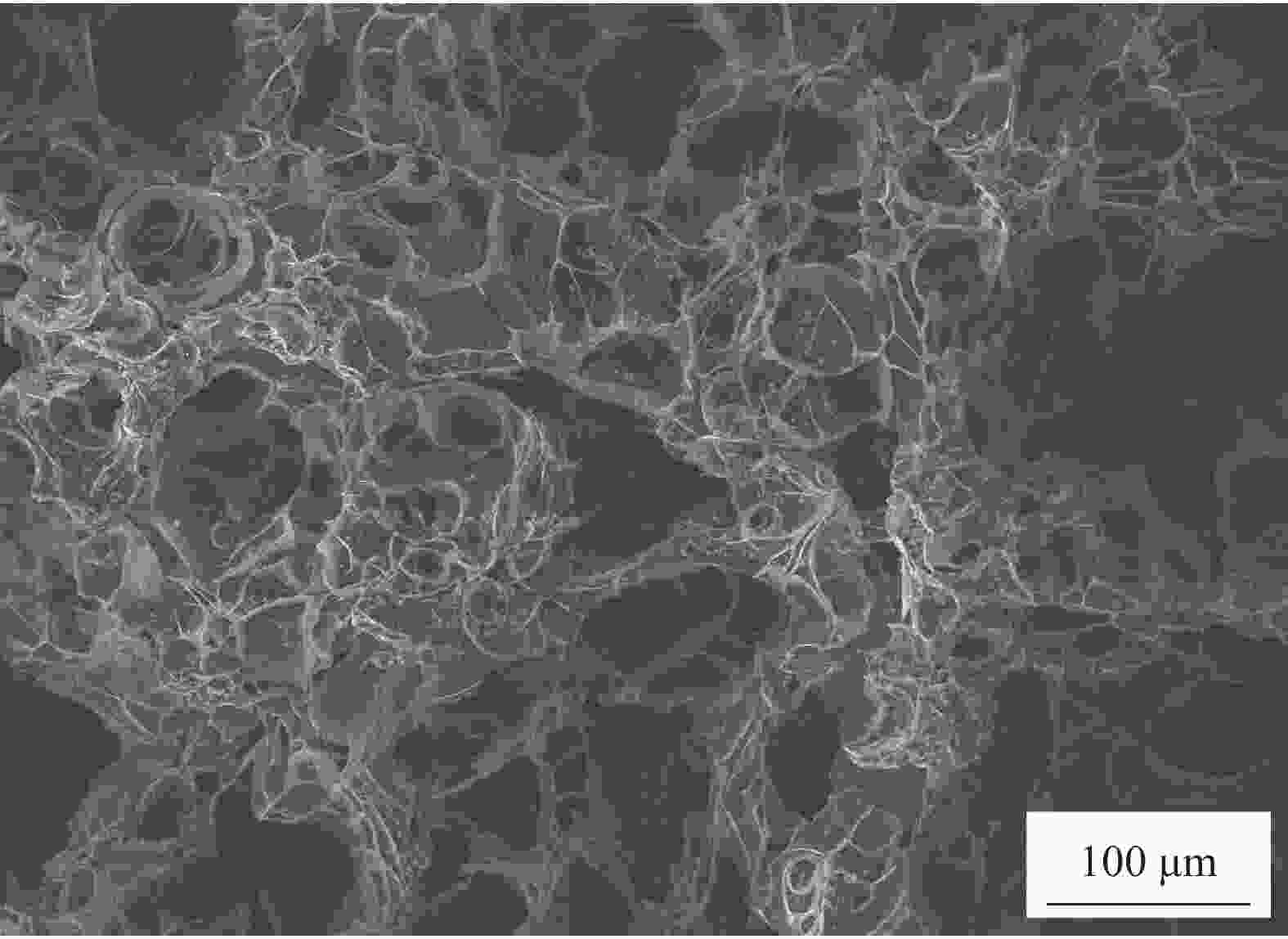

摘要: 采用膨胀珍珠岩(EP)作为内养护材料,进行了混凝土抗压强度试验和EP-混凝土界面SEM试验,研究了EP的体积外掺率、预湿率和粒径对混凝土抗压强度增长的影响,最后经过公式推导,得到了EP的体积外掺率、预湿率和粒径三种因素影响下内养护浆体体积分数和水化反应程度的表达式,并结合Powers模型和混凝土抗压强度与孔隙率模型,建立了EP内养护混凝土抗压强度的数学模型。抗压强度试验结果表明,EP的内养护作用可以提高混凝土抗压强度及其增长速率。EP体积外掺率为30%的混凝土在90天强度会超过同龄期下普通混凝土(NC)的13%;EP预湿率为30%和50%的混凝土90天强度分别超过同龄期NC的6.3%和5.3%,强度增长速率呈先下降后上升的趋势;EP粒径为0.2~0.5 mm的混凝土90天强度超过同龄期NC的6.4%,强度早期增长缓慢,后期增长较快;EP粒径为1.5~3.5 mm和0.5~1.5 mm的混凝土抗压强度在前期增长较快,后期速率逐渐降低、稳定。SEM试验结果表明,EP的内养护作用可以促进水泥继续水化,产物水化硅酸钙(C-S-H)和钙矾石(AFt)数量增加,排列方式更加密集,对EP-混凝土界面微裂缝有填补的作用;EP的孔洞为水化产物提供了生长空间。数学模型验证结果表明,EP内养护混凝土抗压强度的数学模型曲线与90天强度试验值吻合良好,理论值与试验值误差小于12%。Abstract: Using expanded perlite (EP) as the internal curing material, the concrete compressive strength test and EP-concrete interface SEM test were carried out, and the influence of the volume admixture rate, prewetting rate and particle size of EP on the growth of concrete compressive strength was studied. Finally, the expression of the volume fraction of the internal curing paste and the degree of hydration reaction under the influence of the three factors of EP volume admixture rate, prewetting rate and particle size was obtained through formula derivation. And combing with Powers model and the model about concrete compression strength with porosity, a mathematical model of EP internal curing concrete compressive strength was established. The results of the compressive strength test show that the internal curing effect of EP can increase the compressive strength of concrete and its growth rate. The 90 days strength of concrete with EP volume admixture rate of 30% exceeds 13% of normal concrete (NC) at the same age. The 90 days strength of concrete with EP prewetting rate of 30% and 50% exceeds respectively 6.3% and 5.3% of NC at the same age, and the strength growth rate shows a trend of first decline and then rise. The 90 days strength of the concrete with EP particle sizes of 0.2-0.5 mm exceeds 6.4% of the NC at the same age, the strength increases slowly in the early stage and rapidly in the later stage. The 90 days compressive strength of the concrete with EP particle sizes of 1.5-3.5 mm and 0.5-1.5 mm increases rapidly in the early stage, and then gradually decreases and stabilizes in the later stage. The SEM test results show that the internal curing effect of EP can promote the cement hydration continuing. The products of hydrated calcium silicate (C-S-H) and ettringite (AFt) increase in quantity, and their arrangement gets denser, which can fill the micro-cracks of the EP-concrete interface. The pores of EP provide growth space for hydration products. The mathematical model verification results show that the mathematical model curve of the compressive strength of concrete internally cured by EP is in good agreement with the 90 days strength test value, and the error between the theoretical value and the test value is less than 12%.

-

表 1 EP的材料参数

Table 1. Material parameters of EP

Particle

size/mmBulk density/

(kg·m−3)Cylinder compressive

strength/kPa1 h mass water

absorption/%1 h volumetric

water absorption/%0.2-0.5 77.3 72.1 430 33.2 0.5-1.5 81.4 61.8 372 30.3 1.5-3.5 74.4 54.6 228 16.9 表 2 内养护混凝土配合比

Table 2. Mix proportion of internal curing concrete

Group Admixture

rate/%Prewetting (PW)

rate/%Particle

size/mmTotal water consumption/(kg·m−3) Slump/

mmPre-wet water consumption Net water consumption NC 0 — 0.5-1.5 0 240 130 30%EP(100%PW-M)/C 30 100 0.5-1.5 91 176 140 50%EP(100%PW-M)/C 50 100 0.5-1.5 151 125 125 70%EP(100%PW-M)/C 70 100 0.5-1.5 212 102 135 100%EP(100%PW-M)/C 100 100 0.5-1.5 303 23 140 50%EP(0%PW-M)/C 50 0 0.5-1.5 0 378 138 50%EP(30%PW-M)/C 50 30 0.5-1.5 45 198 120 50%EP(50%PW-M)/C 50 50 0.5-1.5 76 177 120 50%EP(70%PW-M)/C 50 70 0.5-1.5 106 172 122 50%EP(100%PW-M)/C 50 100 0.5-1.5 151 125 125 50%EP(100%PW-S)/C 50 100 0.2-0.5 160 130 140 50%EP(100%PW-M)/C 50 100 0.5-1.5 151 125 125 50%EP(100%PW-L)/C 50 100 1.5-3.5 85 185 133 Notes: NC—Normal concrete; S, M and L—Particle sizes like “small”, “medium” and “large”, respectively; C—Concrete. 表 3 NC组混凝土配合比

Table 3. Mix proportion of concrete for NC group

Stone/(kg·m−3) Sand/(kg·m−3) Cement/(kg·m−3) Water/(kg·m−3) Water-cement ratio 997 536 463 240 0.52 -

[1] 缪昌文, 穆松. 混凝土技术的发展与展望[J]. 硅酸盐通报, 2020, 39(1):1-11.LIAO Changwen, MU Song. Development and prospect of concrete technology[J]. Bulletin of the Chinese Ceramic Society,2020,39(1):1-11(in Chinese). [2] 王冲, 蒲心诚, 陈科, 等. 超低水胶比水泥浆体材料的水化进程测试[J]. 材料科学与工程学报, 2008, 26(6):852-857.WANG Chong, PU Xincheng, CHEN Ke, et al. Measurement of hydration progress of cement paste materials with extreme-low W/B[J]. Journal of Materials Science and Engineering,2008,26(6):852-857(in Chinese). [3] 胡姗, 张洋, 燕达, 等. 中国建筑领域能耗与碳排放的界定与核算[J]. 建筑科学, 2020, 36(S2):288-297.HU Shan, ZHANG Yang, YAN Da, et al. Definition and modelling of energy consumption and carbon emissions in China’s building sector[J]. Building Science,2020,36(S2):288-297(in Chinese). [4] MEHTA P K. Materials science of concrete II[J]. Cement and Concrete Composites,1992,14(1):71-72. doi: 10.1016/0958-9465(92)90041-S [5] 胡曙光, 周宇飞, 王发洲, 等. 高吸水性树脂颗粒对混凝土自收缩与强度的影响[J]. 华中科技大学学报(城市科学版), 2008, 25(1):1-4.HU Shuguang, ZHOU Yufei, WANG Fazhou, et al. Influence of super absorbent polymer particles on autogenous shrinkage and compressive strength of concrete[J]. Journal of Huazhong University of Science and Technology Urban Science,2008,25(1):1-4(in Chinese). [6] BALAPOUR M, ZHAO W, GARBOCZI E J, et al. Potential use of lightweight aggregate (LWA) produced from bottom coal ash for internal curing of concrete systems[J]. Cement and Concrete Composites,2019,105:103428. [7] 杨进. 高吸水树脂内养护混凝土的微观结构与性能[D]. 武汉: 武汉理工大学, 2017.YANG Jin. Microstructure and performance of internal curing concrete by SAP[D]. Wuhan: Wuhan University of Technology, 2017(in Chinese). [8] 张磊. 预湿轻骨料内养护自密实混凝土效果评价方法研究[D]. 大连: 大连理工大学, 2020.ZHANG Lei. Evaluation method on the internal curing effect of self-compacting concrete by pre-wet lightweight aggregates[D]. Dalian: Dalian University of Technology, 2020(in Chinese). [9] 易双秦, 刘开志, 邱晶, 等. 吸水珊瑚砂作为超高性能混凝土(UHPC)内养护介质的研究[J]. 硅酸盐通报, 2019, 38(8):2506-2512.YI Shuangqin, LIU Kaizhi, QIU Jing, et al. Study on pre-wet coral sand as internal curing agent in ultra-high-perfor-mance concrete (UHPC)[J]. Bulletin of the Chinese Ceramic Society,2019,38(8):2506-2512(in Chinese). [10] 姜玉丹, 金祖权, 陈永丰, 等. 高吸水树脂对混凝土水化及强度的影响[J]. 材料导报, 2017, 31(24):40-44. doi: 10.11896/j.issn.1005-023X.2017.024.009JIANG Yudan, JIN Zuquan, CHEN Yongfeng, et al. Influence of super-absorbent polymer on hydration and compressive strength of concrete[J]. Materials Review,2017,31(24):40-44(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.024.009 [11] 王奕哲. 内养护高强混凝土性能研究[J]. 新型建筑材料, 2017, 44(10):55-57. doi: 10.3969/j.issn.1001-702X.2017.10.014WANG Yizhe. Study on performance of inner curing high strength concrete[J]. New Building Materials,2017,44(10):55-57(in Chinese). doi: 10.3969/j.issn.1001-702X.2017.10.014 [12] 陈鹏, 金祖权, 李建强, 等. 盐渍土环境下高吸水树脂混凝土抗压强度及氯离子渗透研究[J]. 海洋工程, 2017, 35(2):50-55.CHEN Peng, JIN Zuquan, LI Jianqiang, et al. Compressive strength and chloride penetration of SAP concrete in saline soil environment[J]. Ocean Engineering,2017,35(2):50-55(in Chinese). [13] YANG L, SHI C, LIU J, et al. Factors affecting the effectiveness of internal curing: A review[J]. Construction and Building Materials,2020,267:121017. [14] JIANG L, JIA G, JIANG C, et al. Sugar-coated expanded perlite as a bacterial carrier for crack-healing concrete applications[J]. Construction and Building Materials,2020,232(7):117222. [15] 王柏顺, 张家广, 周梦君, 等. 基于膨胀珍珠岩固载微生物的裂缝自修复混凝土劈裂抗拉强度试验研究[J]. 混凝土, 2020(3):20-23. doi: 10.3969/j.issn.1002-3550.2020.03.006WANG Baishun, ZHANG Jiaguang, ZHOU Mengjun, et al. Experimental study on splitting tensile strength of crack-healing concrete based on immobilizing bacteria in expanded perlite[J]. Concrete,2020(3):20-23(in Chinese). doi: 10.3969/j.issn.1002-3550.2020.03.006 [16] 王文花, 李珠, 张家广, 等. 微生物矿化修复混凝土裂缝抗渗水性能试验研究[J]. 混凝土, 2020(3):29-32. doi: 10.3969/j.issn.1002-3550.2020.03.008WANG Wenhua, LI Zhu, ZHANG Jiaguang, et al. Experimental study on water permeation resistance of concrete crack healed by microbial mineralization[J]. Concrete,2020(3):29-32(in Chinese). doi: 10.3969/j.issn.1002-3550.2020.03.008 [17] 赵福垚. 水泥基材料配合比设计科技建模及智能化前景浅探−基本原则、输入、输出与规律描述方式[J]. 混凝土, 2021(7):34-37. doi: 10.3969/j.issn.1002-3550.2021.07.007ZHAO Fuyao. Superficial discussion on the scientific modeling and intelligentialize of cement-based materials mix proportion design−Basic principles, input, output and description of laws[J]. Concrete,2021(7):34-37(in Chinese). doi: 10.3969/j.issn.1002-3550.2021.07.007 [18] 赵福垚. 水泥基材料配合比设计科技建模及智能化前景浅探−建模以及行业对接的几个问题[J]. 混凝土, 2021(8):60-63.ZHAO Fuyao. Superficial discussion on the scientific modeling and intelligentialize of cement-based materials mix proportion design−Several issues on modeling and industry docking[J]. Concrete,2021(8):60-63(in Chinese). [19] 赵林. 玻化微珠保温混凝土的关键问题研究及工程示范[D]. 太原: 太原理工大学, 2015.ZHAO Lin. Study on the key problems of thermal insulation glazed hollow bead concrete and project demonstration[D]. Taiyuan: Taiyuan University of Technology, 2015(in Chinese). [20] 中华人民共和国住房和城乡建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of ordinary concrete mechanical properties: GB/T 50081—2002[S]. Beijing: China Architecture & Building Press, 2003(in Chinese). [21] 孙诗兵, 聂光临, 姚晓丹, 等. 膨胀珍珠岩掺加量对水泥砂浆性能的影响[J]. 混凝土, 2015(3):114-117. doi: 10.3969/j.issn.1002-3550.2015.03.031SUN Shibin, NIE Guanglin, YAO Xiaodan, et al. Influence of adding amount of expended perlite on the roperties of cement mortar[J]. Concrete,2015(3):114-117(in Chinese). doi: 10.3969/j.issn.1002-3550.2015.03.031 [22] 聂光临, 孙诗兵, 姚晓丹, 等. 膨胀珍珠岩粒径对水泥砂浆性能的影响[J]. 混凝土与水泥制品, 2014(10):21-24. doi: 10.3969/j.issn.1000-4637.2014.10.005NIE Guanglin, SUN Shibing, YAO Xiaodan, et al. Influence of particle size of expended perlite on the properties of cement mortar[J]. China Concrete and Cement Products,2014(10):21-24(in Chinese). doi: 10.3969/j.issn.1000-4637.2014.10.005 [23] 贾冠华, 刘鹏, 李珠. 气凝胶/膨胀珍珠岩的制备及其微观特征对导热性能的影响[J]. 硅酸盐通报, 2018, 37(3):1039-1046.JIA Guanhua, LIU Peng, LI Zhu. Preparation of aerogel/expanded perlite and influence of its microstructure on thermal conductivity[J]. Bulletin of the Chinese Ceramic Society,2018,37(3):1039-1046(in Chinese). [24] ZHUTOVSKY S, KONSTANTIN K, BENTUR A. Assessment of distance of water migration in internal curing of high-strength concrete[J]. American Concrete Institute, 2002, Special Publication: SP-220. [25] BENTZ D P, SNYDER K A. Protected paste volume in concrete: Extension to internal curing using saturated lightweight fine aggregate[J]. Cement and Concrete Research,1999,29(11):1863-1867. doi: 10.1016/S0008-8846(99)00178-7 [26] RYSHKEWITCH E. Compression strength of porous sintered alumina and zirconia[J]. Journal of the American Ceramic Society,1953(36):65-68. [27] 向亚平, 魏亚, 张倩倩, 等. 轻细骨料内养护混凝土抗压强度与模拟[J]. 混凝土, 2013(3):44-47, 51. doi: 10.3969/j.issn.1002-3550.2013.03.012XIANG Yaping, WEI Ya, ZHANG Qianqian, et al. Compressive strength of internal curing concrete with lightweight fine aggregate-experiment and modeling[J]. Concrete,2013(3):44-47, 51(in Chinese). doi: 10.3969/j.issn.1002-3550.2013.03.012 [28] POWERS T C, BROWNYARD T L. Studies of the physical properties of hardened portland cement paste[J]. Concrete International,1946(43):101-132. [29] GARBOCZI E J, BENTZ D P. Analytical formulas for interfacial transition zone properties[J]. Advanced Cement Based Materials,1997,6(3):99-108. [30] 高冲. 内养护水掺量与自收缩相关性的试验与机理研究[D]. 大连: 大连理工大学, 2019.GAO Chong. Experimental and mechanism study on the correlation between internal curing water content and autogenous shrinkage[D]. Dalian: Dalian University of Technology, 2019(in Chinese). -

下载:

下载: