Calculation of whisker Poisson’s ratio and hardnessprediction of whisker-reinforced ceramic composites

-

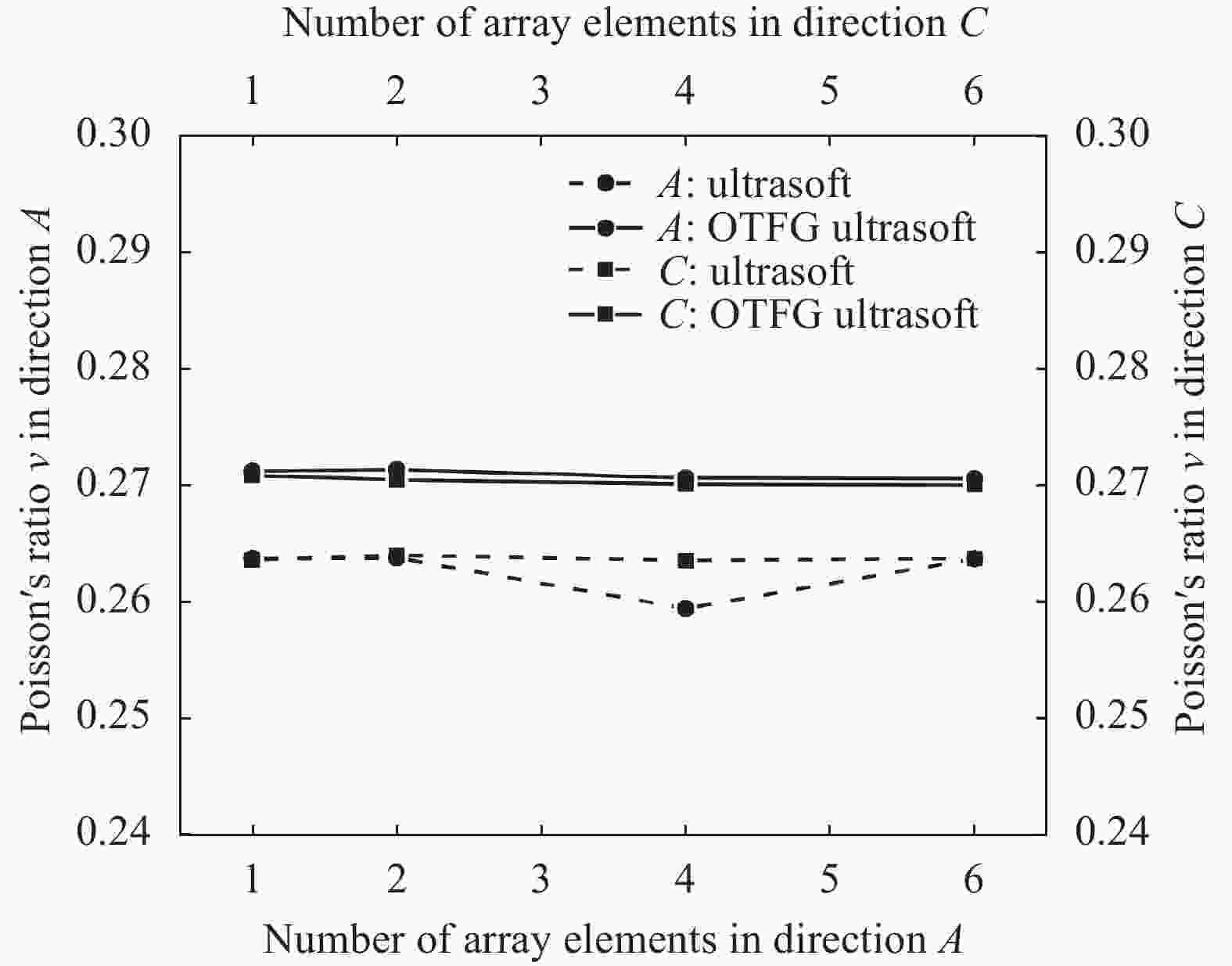

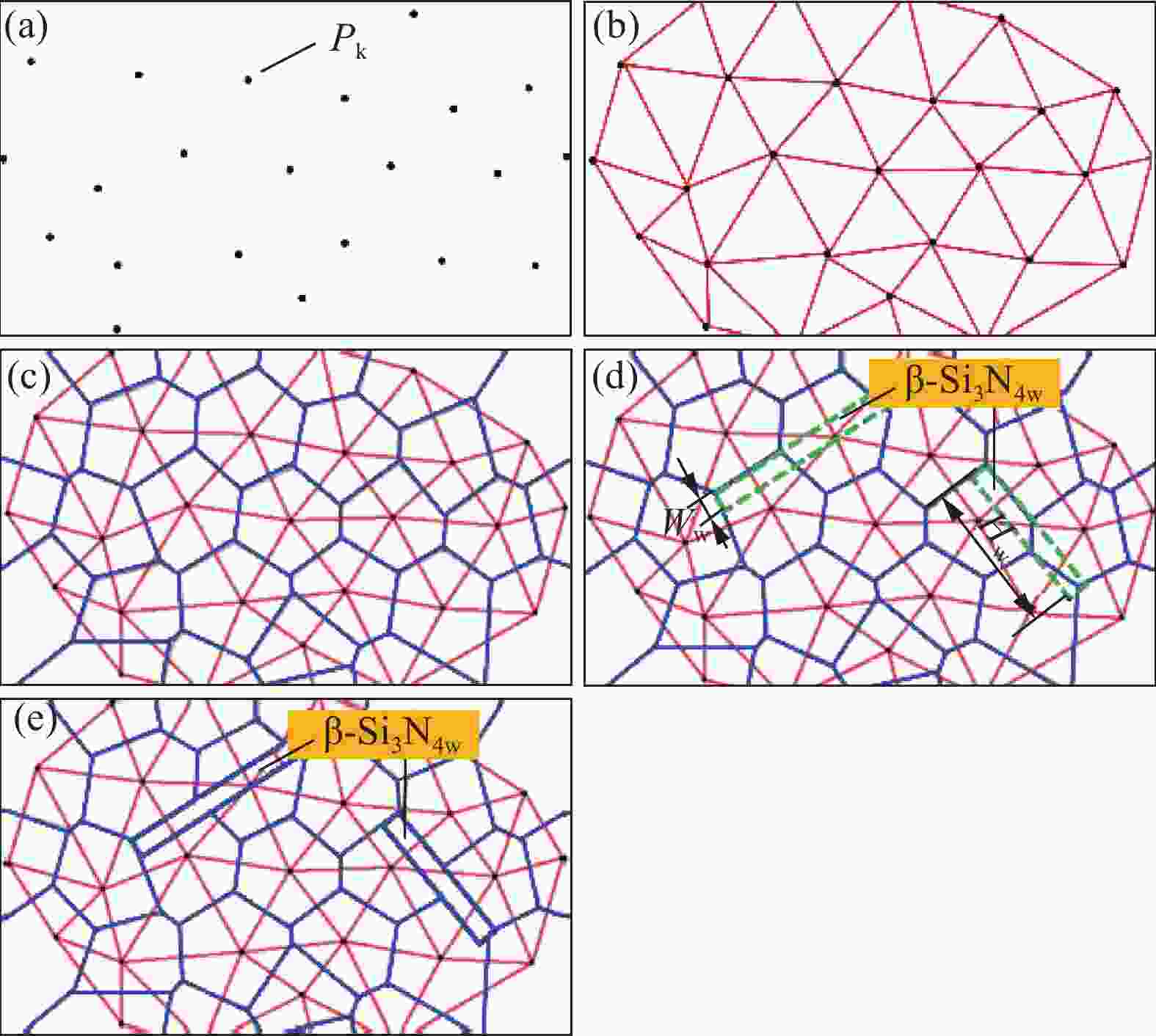

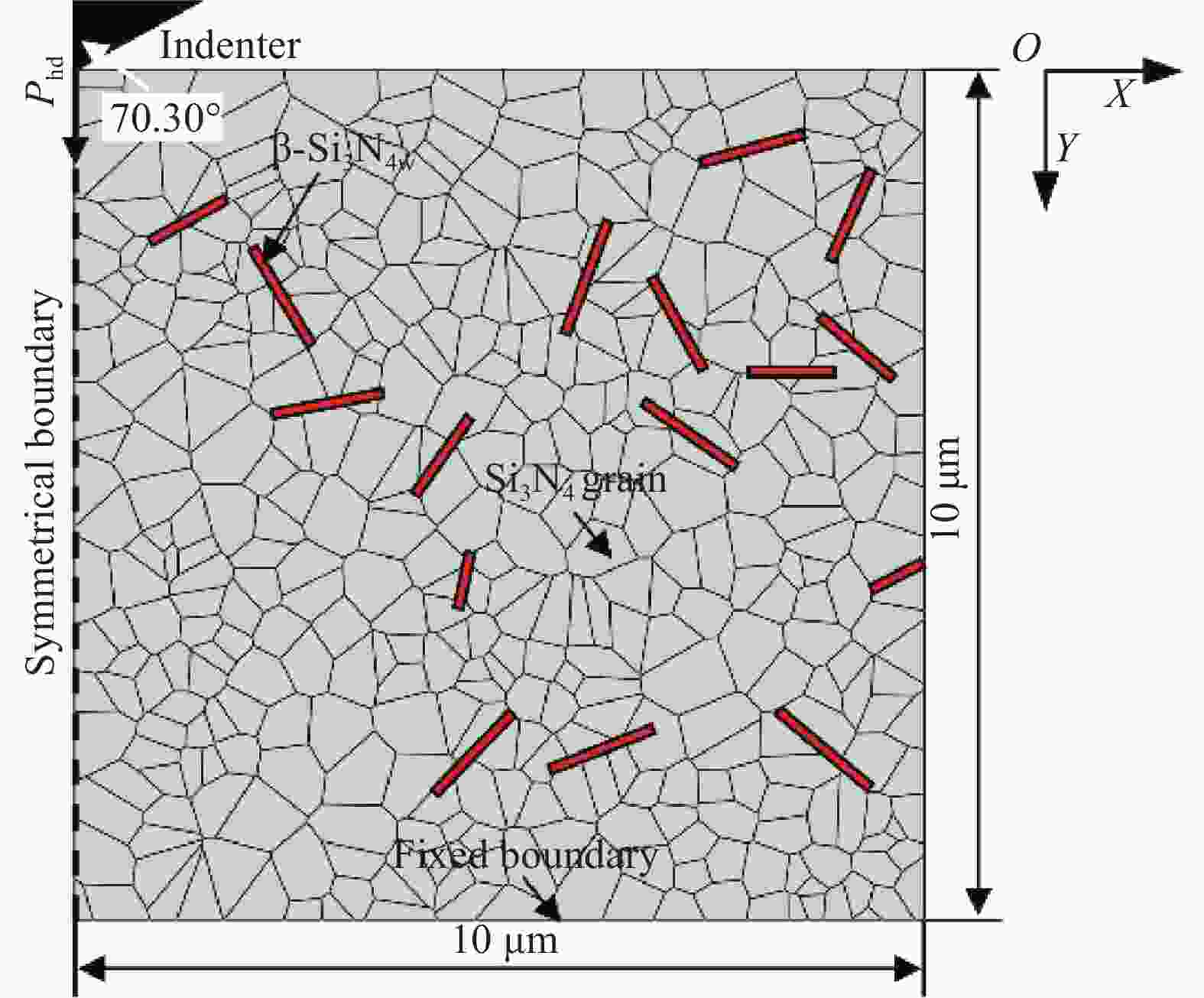

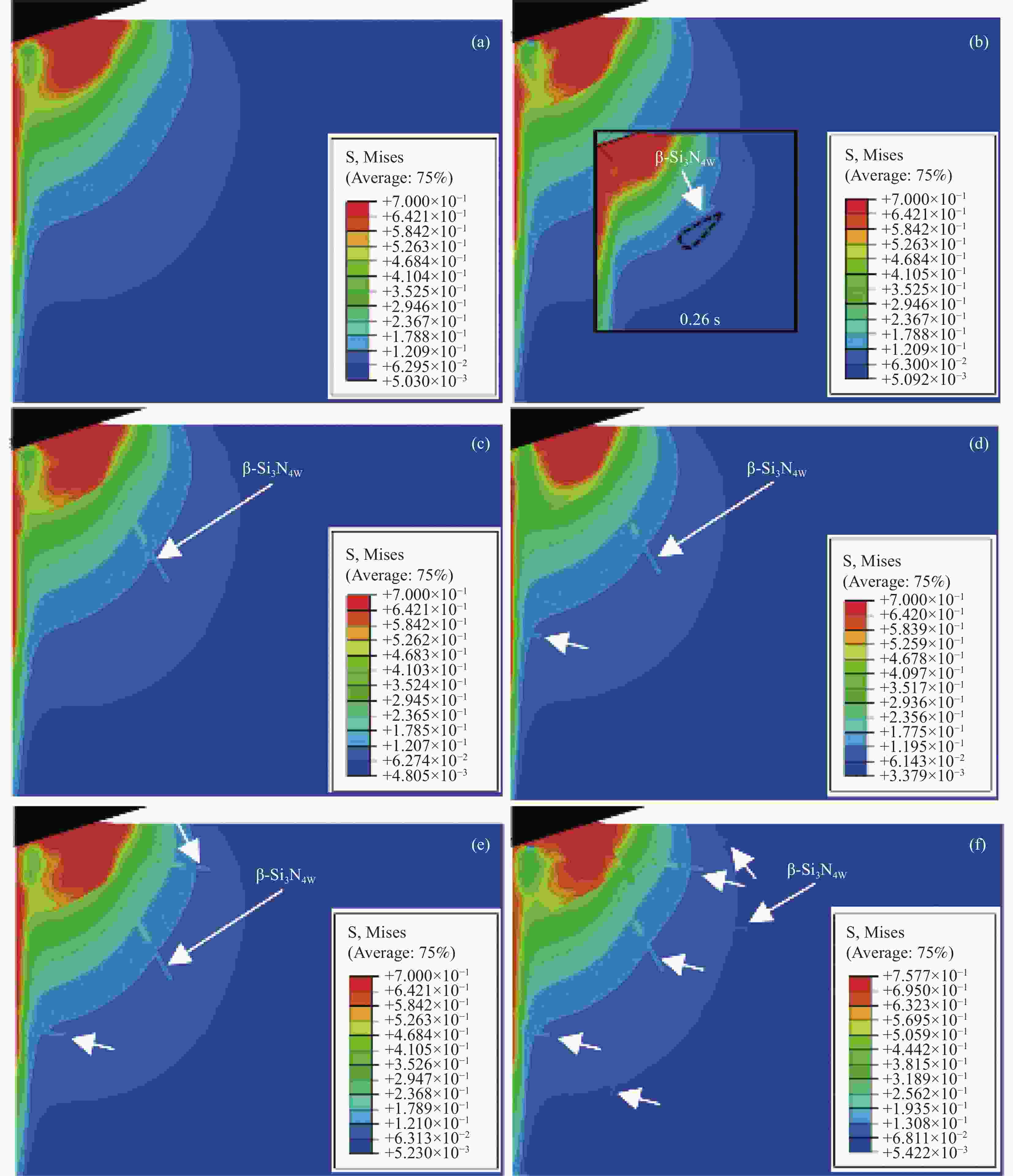

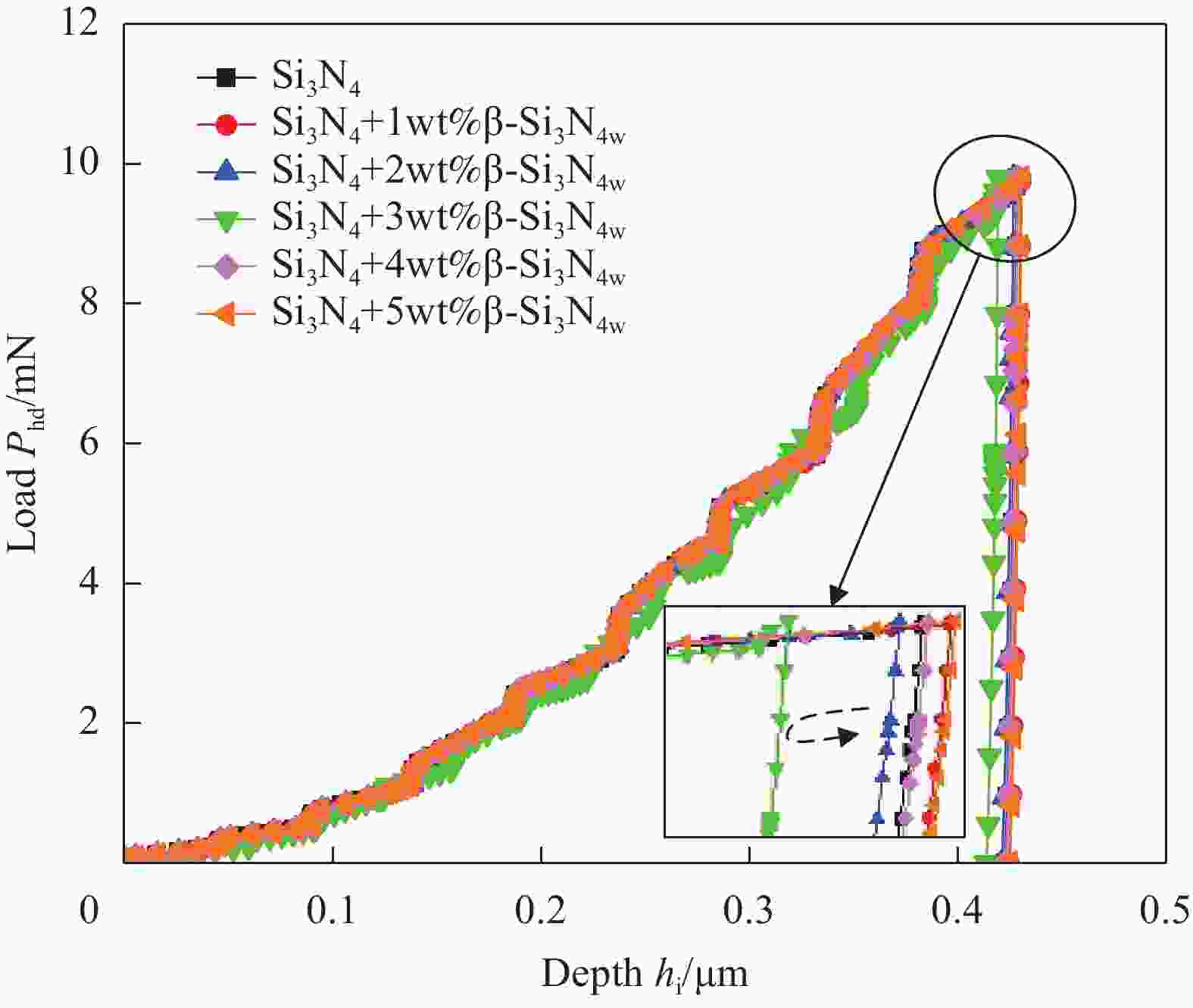

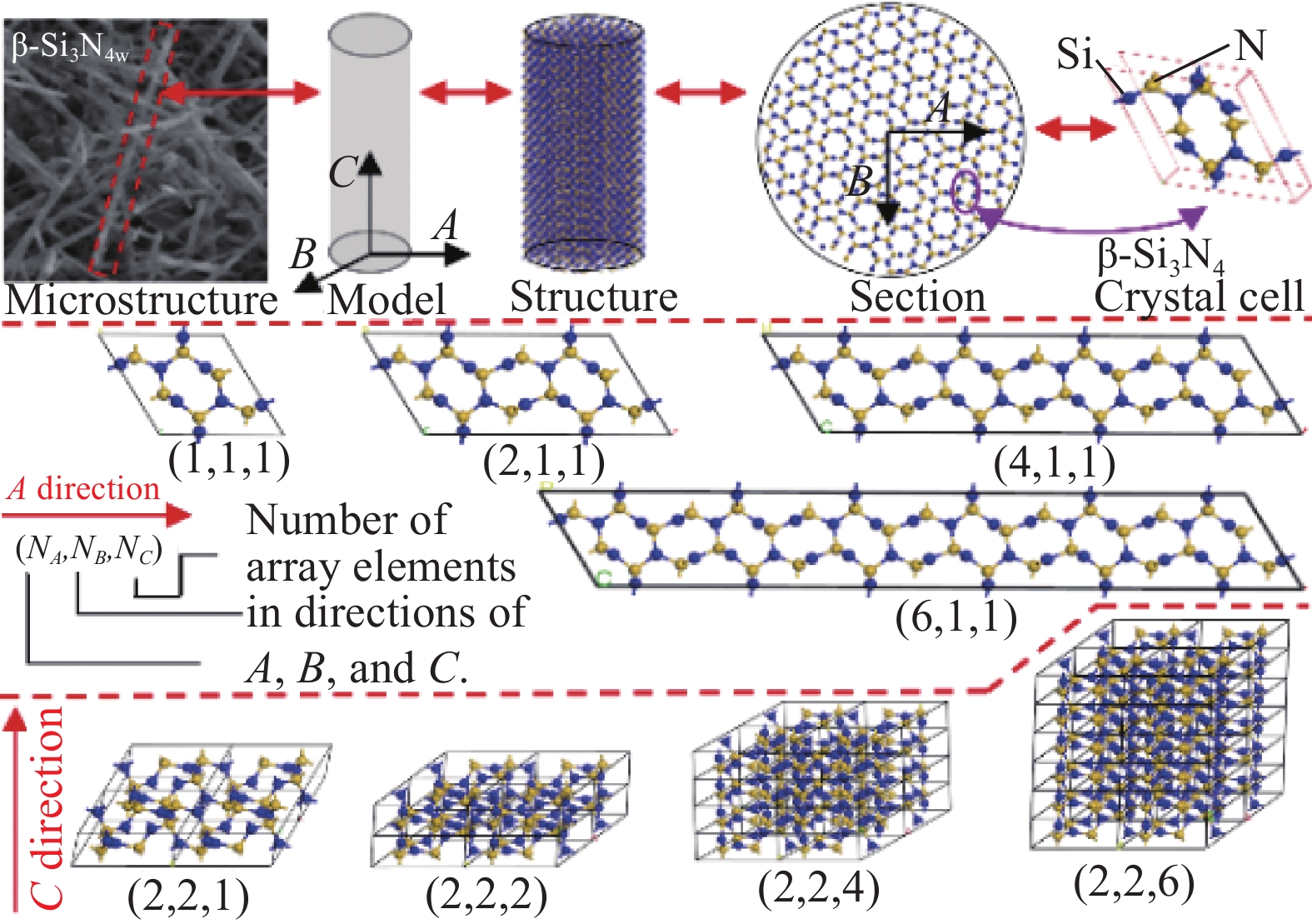

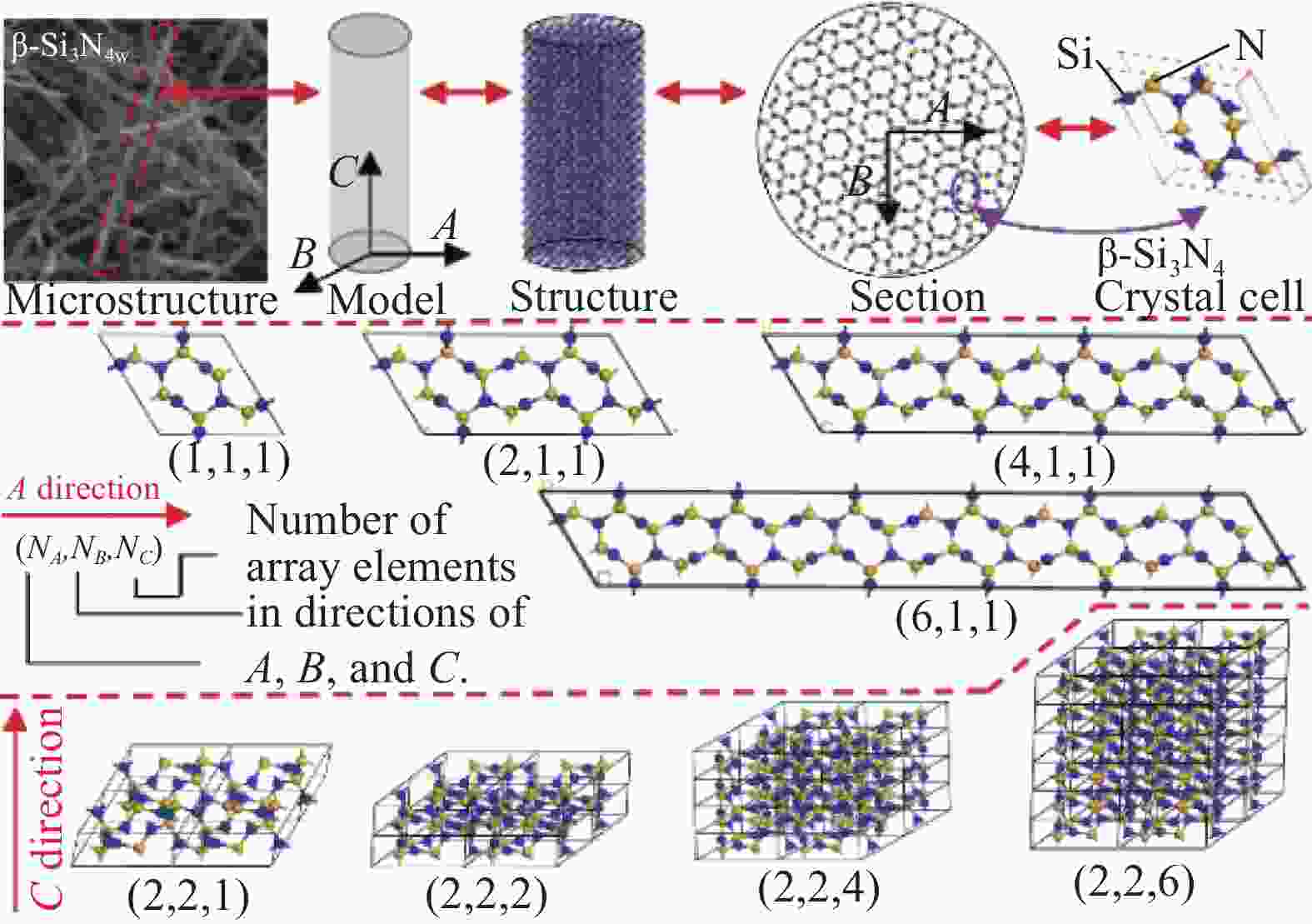

摘要: 晶须在强化陶瓷材料强度和韧性的同时能显著提高材料硬度,在解决陶瓷硬度不足上具有突出优势。针对目前实验法研究晶须增强陶瓷材料中存在组分设计盲目性大、试样制备耗时费力等问题,以β-Si3N4晶须(β-Si3N4w)增强Si3N4陶瓷为对象,提出了一种计算晶须泊松比的双向随机建模方法,并基于密度泛函理论(DFT)框架下平面超软赝势法和广义梯度近似(GGA)中的Perdew-Wang 91(PW91)函数,对β-Si3N4超晶胞泊松比进行了计算。以此为基础,提出了运用德劳内(Delaunay)三角剖分法和伪随机函数法建立β-Si3N4w增强Si3N4陶瓷微观结构模型的方法,对模型硬度进行了预报并对β-Si3N4w增硬机制进行了探讨。结果表明,β-Si3N4w泊松比约为0.27。β-Si3N4w增强Si3N4陶瓷硬度预报值与相关实验测试值存在较好一致性,这表明了晶须泊松比计算模型和晶须强韧陶瓷微观结构建模法的有效性。在β-Si3N4w含量为3wt%时,硬度达到最大值22.80 GPa。应力分析表明β-Si3N4w各向分布性分散了应力集中作用区并依靠β-Si3N4w高强度特性承载了大量应力的作用,这是硬度提高的主要原因。Abstract: Whisker is able to enhance remarkably the hardness of ceramics while strengthening their strength and toughness, and has outstanding advantages in solving the lack of hardness. Aiming at the problems of high blindness of component design and time-consuming of specimen preparation in the current experimental method to investigate whisker-reinforced ceramics, a bidirectional stochastic modeling method to calculate the whisker Poisson’s ratio was proposed taking β-Si3N4w-reinforced Si3N4 ceramic as the object. Based on the plane super-soft pseudopotential method under the framework of density functional theory (DFT) and Perdew-Wang 91 (PW-91) function in the generalized gradient approximation (GGA), the β-Si3N4 supercell Poisson’s ratio was calculated. Further, an approach to establish the two-dimensional microstructure of β-Si3N4w-reinforced Si3N4 ceramics was presented by using Delaunay triangulation rule and pseudo-random function method. Then, the model hardness was predicted and the hardening mechanism of β-Si3N4w was discussed. Results show that the Poisson’s ratio of β-Si3N4w is about 0.27. The predicted hardness values of β-Si3N4w-reinforced Si3N4 ceramics are in good consistent with the related experimental test values, which demonstrates the validity of whisker Poisson’s ratio calculation model and whisker-reinforced ceramic microstructure modeling method. The hardness of Si3N4-based ceramics reaches the maximum value of 22.80 GPa at 3wt% β-Si3N4w content. Stress analysis shows that the anisotropic distribution of β-Si3N4w disperses the stress concentration area and with stands a large amount of stress depending on its high strength characteristics, which is the main reason for the increase in hardness.

-

Key words:

- whisker /

- ceramics /

- Poisson’s ratio /

- first principle /

- hardness

-

图 3 随机种子点集V (a)、Delaunay三角网 (b)、Voronoi 图 (c)、β-Si3N4w种子 (d) 和β-Si3N4w增强Si3N4陶瓷微观结构模型 (e)

Figure 3. Random seed point set V (a), Delaunay triangulation (b), Voronoi diagram (c), β-Si3N4w seeds (d) and β-Si3N4w-reinforced Si3N4 ceramic microstructure model (e)

Pk—Point of kth random seed; Ww—Width of whiskers; Hw—Height of whiskers

表 1 β-Si3N4w及Si3N4晶粒参数

Table 1. β-Si3N4w and Si3N4 grain parameters

-

[1] 李庆辉, 孔维纳, 李喆, 等. 基于高Q腔法测试氮化硅纤维的介电性能[J]. 复合材料学报, 2020, 37(9):2240-2249.LI Qinghui, KONG Weina, LI Zhe, et al. Dielectric properties measurements on silicon nitride fiber based on high-Q cavity method[J]. Acta Materiae Compositae Sinica,2020,37(9):2240-2249(in Chinese). [2] SHI H T, LI Y Y, BAI X T, et al. Investigation of the orbit-spinning behaviors of the outer ring in a full ceramics ball bearing-steel pedestal system in wide temperature ranges[J]. Mechanical Systems and Signal Processing,2021,149:107317. doi: 10.1016/j.ymssp.2020.107317 [3] WALKER L S, MAROTTO V R, RAFIEE M A, et al. Toughening in graphene ceramic composites[J]. ACS Nano,2011,5(4):3182-3190. doi: 10.1021/nn200319d [4] BÓDIS E, TAPASZTÓ O, KÁROLY Z, et al. Spark plasma sintering of Si3N4/multilayer graphene composites[J]. Open Chemistry,2015,13(1):484-489. [5] FAN X Y, SUN R J, DONG J, et al. Fabrication and thermal shock behavior of Si3N4 whiskers toughened γ-Y2Si2O7 coating on porous Si3N4 ceramics[J]. Ceramics International,2020,46(13):21681-21688. doi: 10.1016/j.ceramint.2020.05.275 [6] 范星宇, 王红洁, 温江波, 等. 多孔氮化硅表面γ-Y2Si2O7陶瓷涂层的制备及抗热震性能[J]. 复合材料学报, 2016, 33(5):1097-1103.FAN Xingyu, WANG Hongjie, WEN Jiangbo, et al. Preparation and thermal shock resistance property of γ-Y2Si2O7 ceramic coating on surface of porous silicon nitride[J]. Acta Materiae Compositae Sinica,2016,33(5):1097-1103(in Chinese). [7] LIANG Z H, ZHANG H L, GUI L C, et al. Effects of whisker-like β-Si3N4 seeds on phase transformation and mechanical properties of α/β-Si3N4 composites using MgSiN2 as additives[J]. Ceramics International,2013,39:2743-2751. doi: 10.1016/j.ceramint.2012.09.041 [8] ZOU B, HUANG C Z, CHEN M. Study on the mechanical properties, microstructure and oxidation resistance of Si3N4/Si3N4w/Ti(C7N3) nanocomposites ceramic tool materials[J]. International Journal of Refractory Metals and Hard Materials,2009,27:52-60. [9] CHEN F, YAN K, SUN J L, et al. From the research state of the thermal properties of graphene reinforced ceramics to the future of computer simulation[J]. Ceramics International,2020,46(11):18428-18445. doi: 10.1016/j.ceramint.2020.04.265 [10] 王东, 赵军, 曹岩, 等. 微纳米复合陶瓷刀具材料计算机辅助设计和制备[J]. 机械工程学报, 2018, 54(7):223-232. doi: 10.3901/JME.2018.07.223WANG Dong, ZHAO Jun, CAO Yan, et al. Computer-aided design and preparation for micro-nano-composite ceramic tool materials[J]. Journal of Mechanical Engineering,2018,54(7):223-232(in Chinese). doi: 10.3901/JME.2018.07.223 [11] LI Z L, ZHAO J, SUN J L, et al. Reinforcing effect of graphene on the mechanical properties of Al2O3/TiC ceramics[J]. International Journal of Minerals, Metallurgy and Materials,2017,24(12):1403-1411. doi: 10.1007/s12613-017-1533-z [12] CHEN F, YAN K, ZHANG X H, et al. Microscale simulation method for predication of mechanical properties and composition design of multilayer graphene-reinforced ceramic bearings[J]. Ceramics International,2021,47(12):17531-17539. doi: 10.1016/j.ceramint.2021.03.071 [13] 周沙溆, 胡宏玖, 李洁, 等. 基于纳米压痕的线性黏弹材料泊松比的测试方法[J]. 润滑与密封, 2010, 35(1):37-40. doi: 10.3969/j.issn.0254-0150.2010.01.010ZHOU Shaxu, HU Hongjiu, LI Jie, et al. Measurement of Poisson’s ratio of linear viscoelastic materials by nano-indentation[J]. Lubrication Engineering,2010,35(1):37-40(in Chinese). doi: 10.3969/j.issn.0254-0150.2010.01.010 [14] 刘其军, 刘正堂, 冯丽萍, 等. 四方晶相HfO2电子结构和弹性常数的第一性原理计算[J]. 北京联合大学学报, 2009, 23(3):76-80.LIU Qijun, LIU Zhengtang, FENG Liping, et al. First priciples calculation of electronic structure and elastic constants of tetragonal HfO2 crystal[J]. Journal of Beijing Uion University,2009,23(3):76-80(in Chinese). [15] 蔺玲, 邵淑英, 李静平. 单斜相HfO2薄膜弹性常数的第一性原理计算[J]. 光学学报, 2013, 33(1):281-288.LIN Ling, SHAO Shuying, LI Jingping. First principles calculation of elastic constants of monoclinic HfO2 thin film[J]. Acta Optica Sinica,2013,33(1):281-288(in Chinese). [16] HIROSAKI N, OGATA S, KOCER C, et al. Molecular dynamics calculation of the ideal thermal conductivity of single-crystal α- and β-Si3N4[J]. Physical Review B,2002,65:134110. doi: 10.1103/PhysRevB.65.134110 [17] 张铭, 郑茂盛, 何家文. 多晶材料弹性矩阵的几何平均模型[J]. 自然科学进展, 2001, 11(5):518-521. doi: 10.3321/j.issn:1002-008X.2001.05.012ZHANG Ming, ZHENG Maosheng, HE Jiawen. Geometrial average model of polycrystal material elastic constants[J]. Process in Natural Science,2001,11(5):518-521(in Chinese). doi: 10.3321/j.issn:1002-008X.2001.05.012 [18] PONCE C A, CASALI R A, CARAVACA M A. Ab initio study of mechanical and thermos-acoustic properties of tough ceramics: applications to HfO2 in its cubic and orthorhombic phase[J]. Journal of Physics-Condensed Matter,2008,20(4):045213. doi: 10.1088/0953-8984/20/04/045213 [19] HAROA N H, CASTROA J O, MARTYNOV Y B, et al. DFT prediction of band gap in organic-inorganic metal halide perovskites: An exchange-correlation functional benchmark study[J]. Chemical Physics,2019,516(4):225-231. [20] AZEGGAGH A, JOLY-POTTUZ L, CHEVALIER J, et al. Indentation strength of silicon nitride ceramics processed by spark plasma sintering technique[J]. Materials Science & Engineering A,2015,644:159-170. [21] REBAY S. Efficient unstructured mesh generation by means of Delaunay triangulation and Bowyer-Watson Algorithm[J]. Journal of Computational Physics,1993,106(1):125-138. doi: 10.1006/jcph.1993.1097 [22] ZUO K H, LU L M, ZENG Y P. Themechanical properties of β-Si3N4 whiskers-reinforced dental resin composites[J]. Journal of Applied Polymer Science,2014,131(17):40692. [23] 王焕磊, 王伟, 王金亮. 氮化硅晶须的研究现状[J]. 化工新型材料, 2005, 33(6):9-11. doi: 10.3969/j.issn.1006-3536.2005.06.004WANG Huanlei, WANG Wei, WANG Jinliang. The development of researches on Si3N4 whisker[J]. New Chemical Materials,2005,33(6):9-11(in Chinese). doi: 10.3969/j.issn.1006-3536.2005.06.004 [24] HOMENY J, NEERGAARD L J. Mechanical properties of β-Si3N4-whisker/Si3N4-matrix composites[J]. Journal of the American Ceramic Society,1990,73(11):3493-3496. doi: 10.1111/j.1151-2916.1990.tb06482.x [25] 曾东, 方岱宁. 用界面元分析层状陶瓷的三点弯曲断裂性能[J]. 应用基础与工程科学学报, 2000, 8(4):398-404. doi: 10.3969/j.issn.1005-0930.2000.04.009ZENG Dong, FANG Daining. Numerical analysis of fracture behavior of laminated ceramic in three-point bending[J]. Journal of Basic Science and Engineering,2000,8(4):398-404(in Chinese). doi: 10.3969/j.issn.1005-0930.2000.04.009 [26] SATO Y, MOTOI S. Studies of the state of iron contained in α- and β-silicon nitride by Mössbauer and Raman effects[J]. Journal of Physics & Chemistry of Solids,1979,40(1):1-7. [27] ASTM. Standard test method forvickers indentation hardness of advanced ceramics: ASTM C1327-15[S]. West Conshohocken: ASTM, 2015. [28] LEE H C, GURLAND J. Hardness and deformation of cemented tungsten carbide[J]. Materials Science and Engineering,1978,33(1):125-133. doi: 10.1016/0025-5416(78)90163-5 [29] BOLGARU K, REGER A, VERESHCHAGIN V, et al. Combustion synthesis of porous ceramic β-Si3N4-based compo-sites with the use of ferroalloys [J]. Ceramics International, 2021, 47(24): 34765-34773. [30] YU J J, WEI W X, GUO W M, et al. Enhanced mechanical properties of Si3N4 ceramics with ZrB2-B binary additives prepared at low temperature[J]. Journal of the European Ceramic Society,2019,39:5102-5105. doi: 10.1016/j.jeurceramsoc.2019.07.028 [31] LIN R L, BAO W C, YU J J, et al. Effect of ZrB2 and its oxide impurities (ZrO2 and B2O3) on hot-pressed Si3N4 ceramics at low temperature[J]. Journal of the European Ceramic Society,2021,41(13):6763-6766. doi: 10.1016/j.jeurceramsoc.2021.06.041 -

下载:

下载: