Model for stress-strain curves of concrete filled steel tube-seawater and sea sand concrete filled FRP tube composite columns under axial load

-

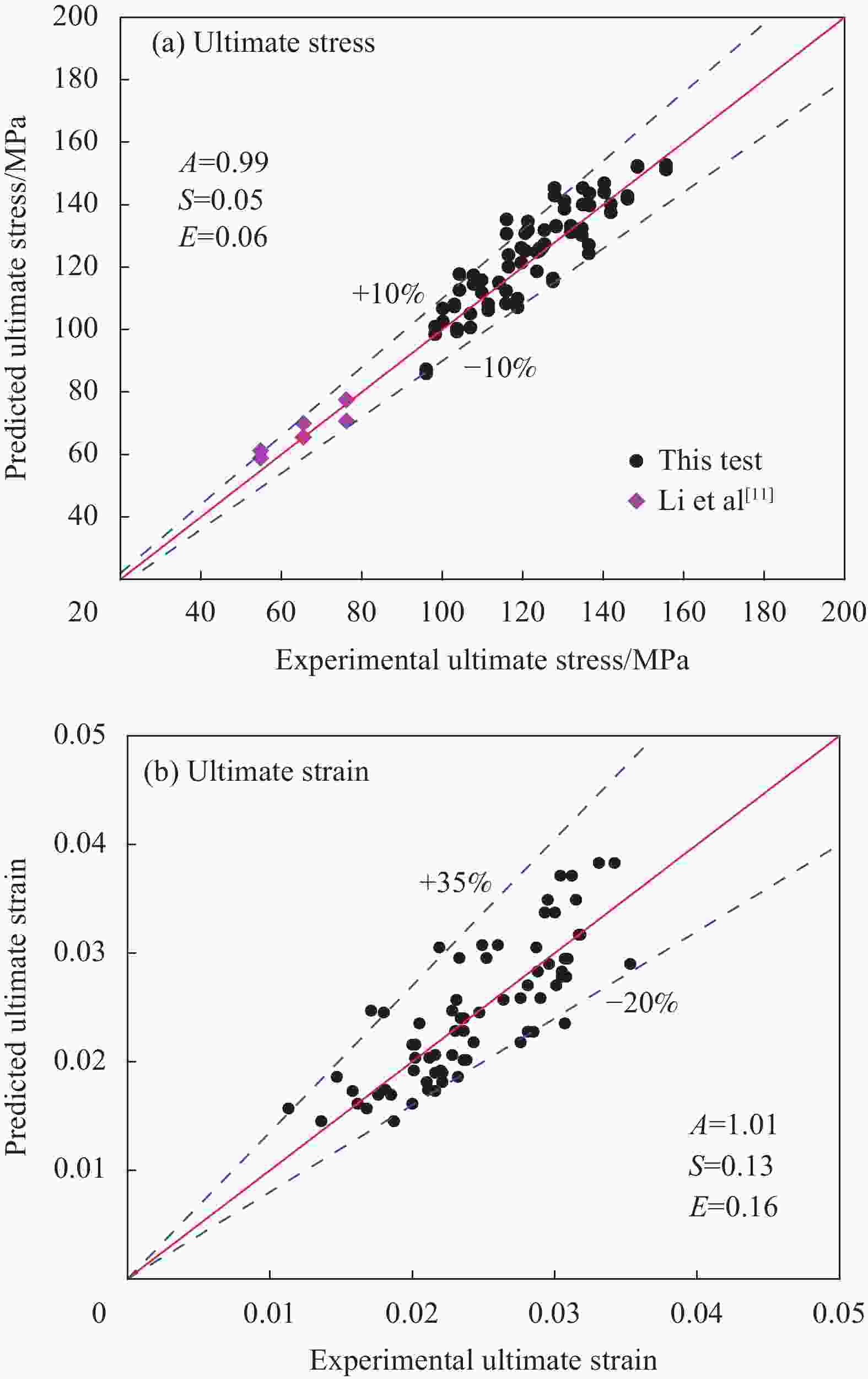

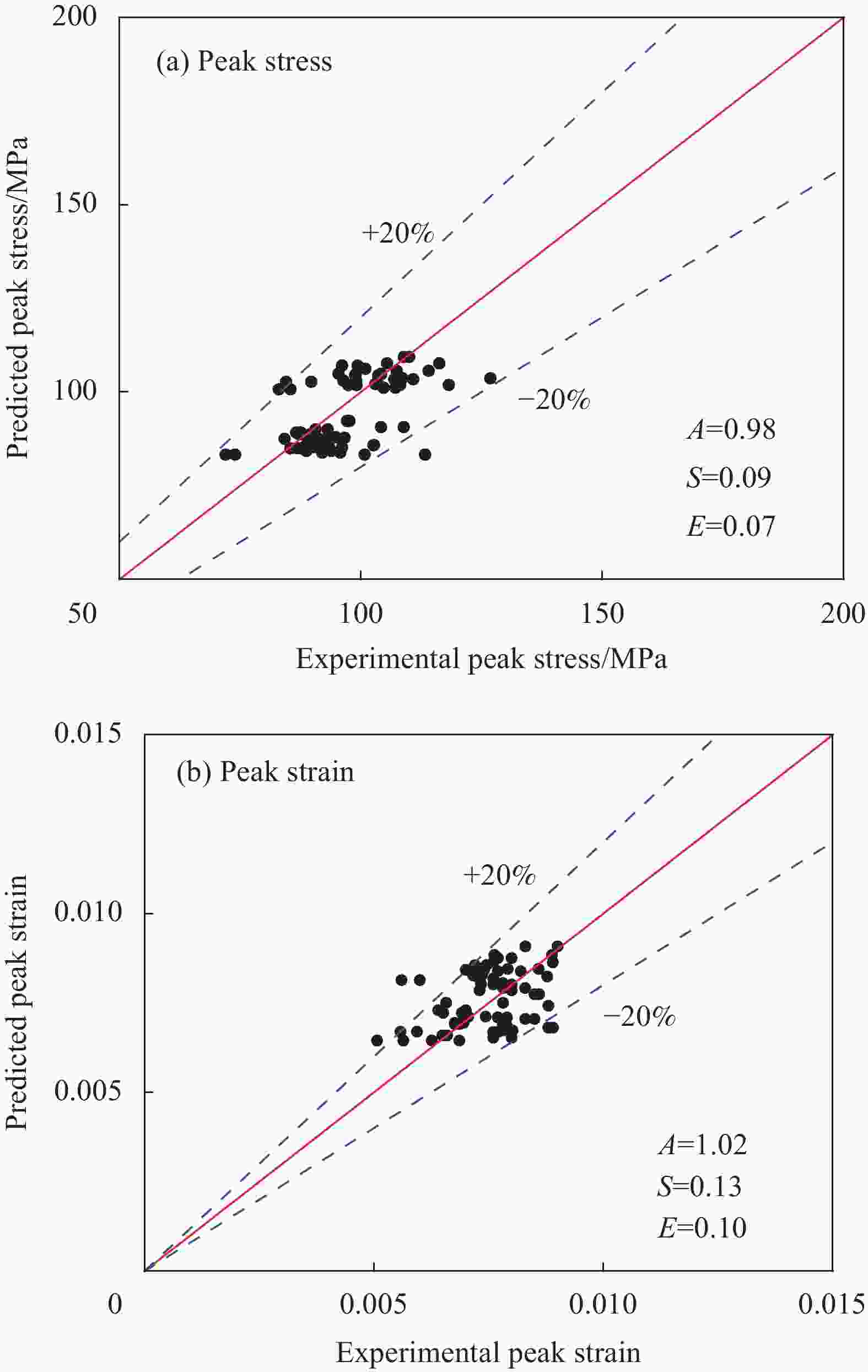

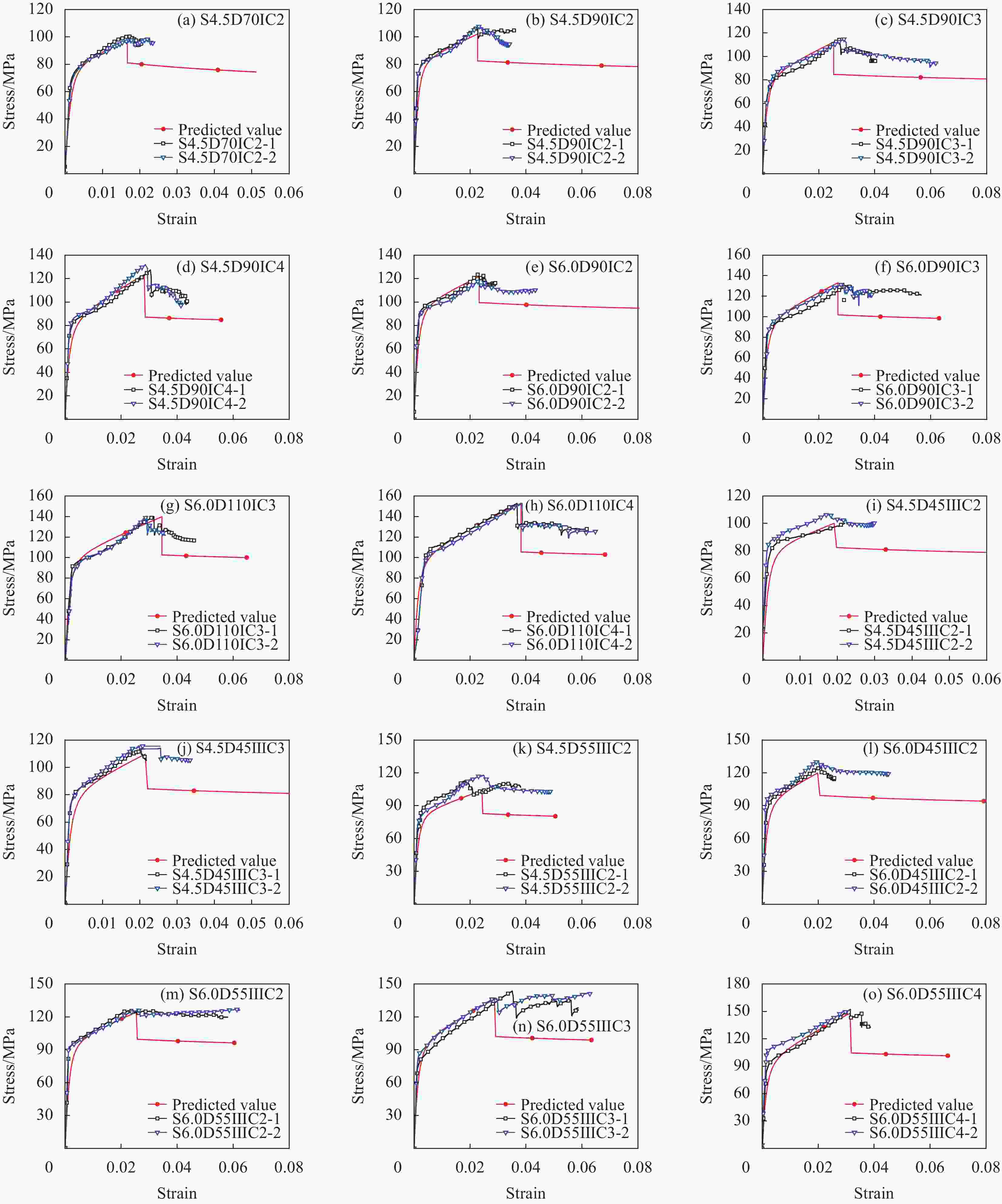

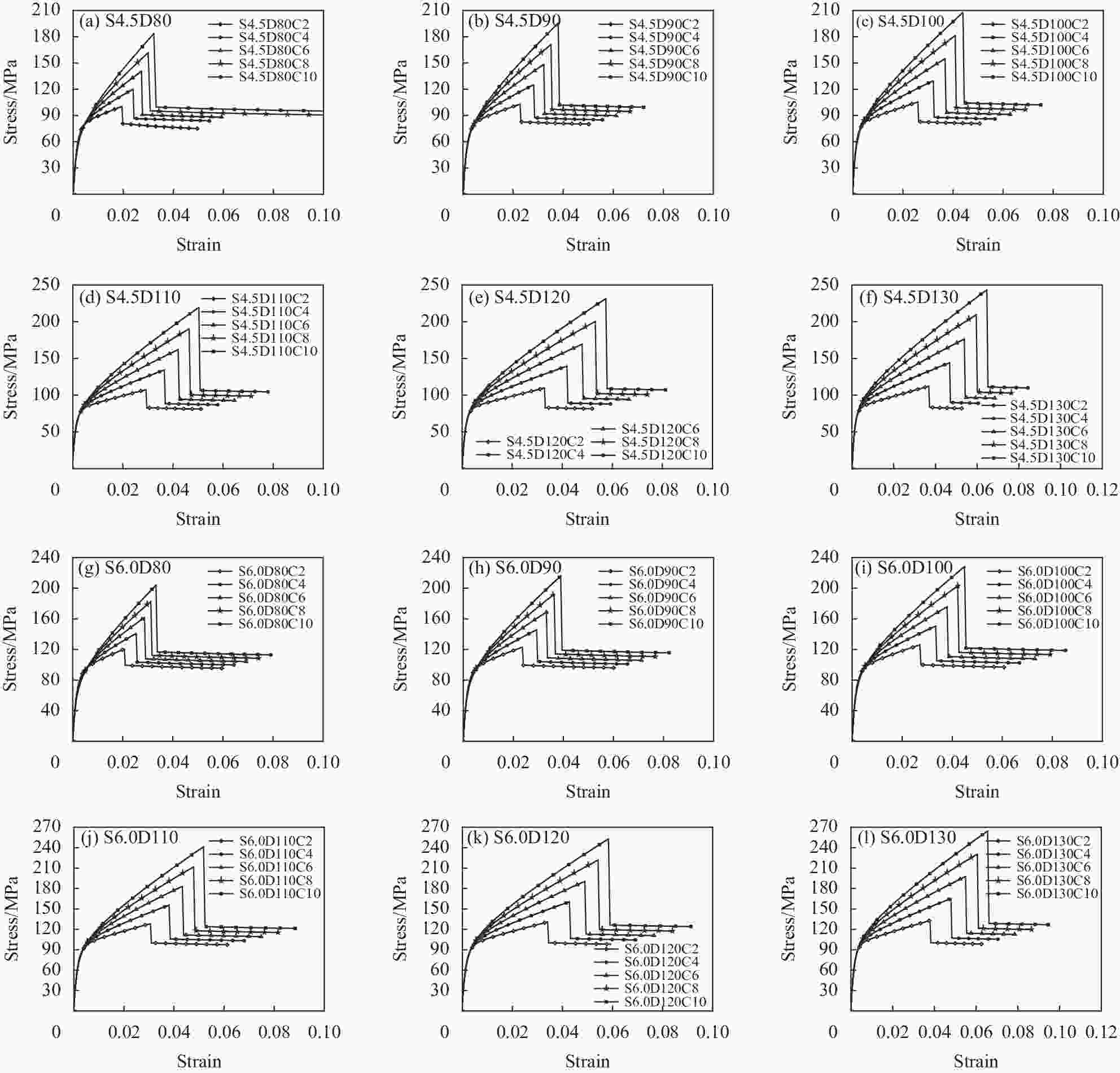

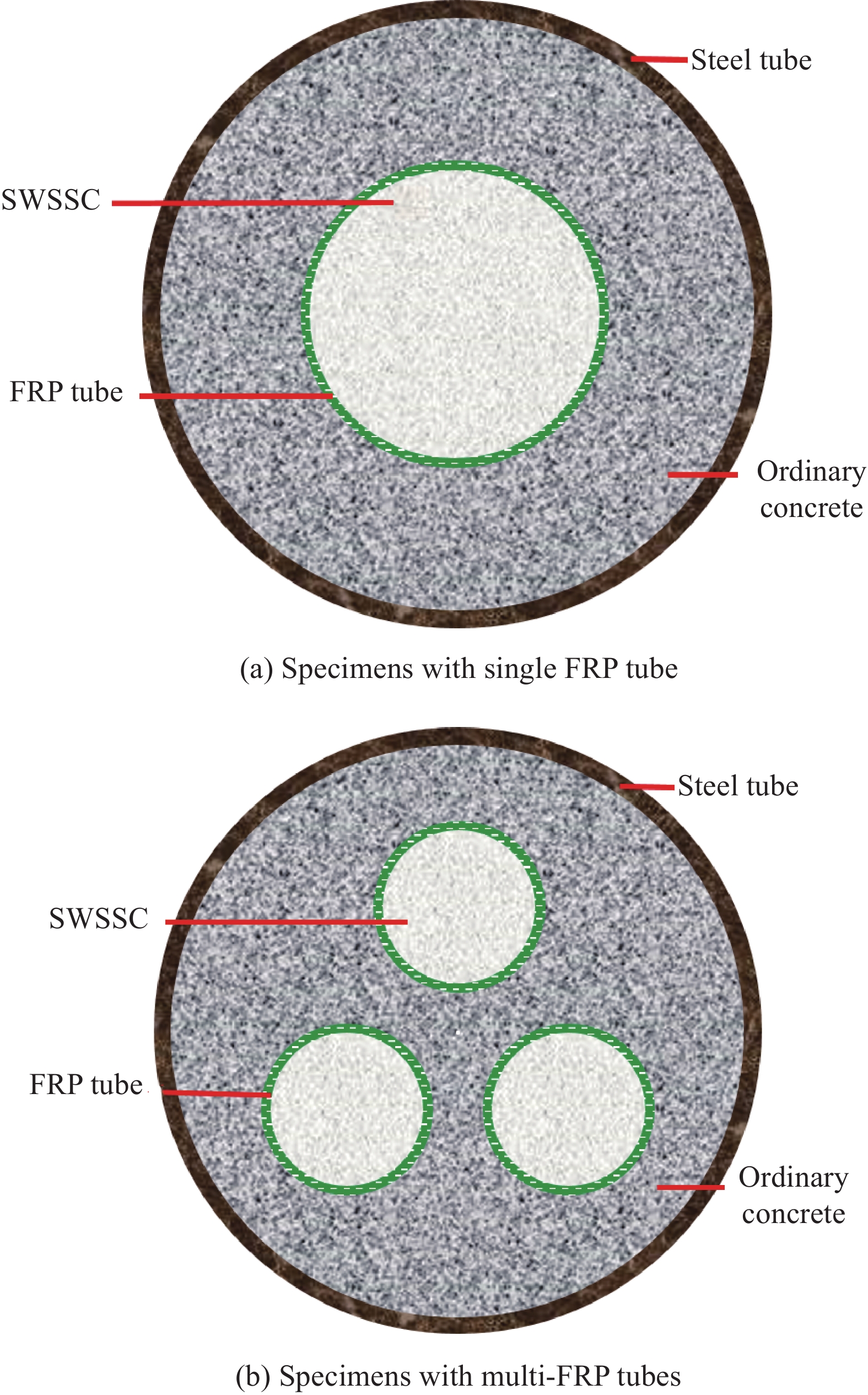

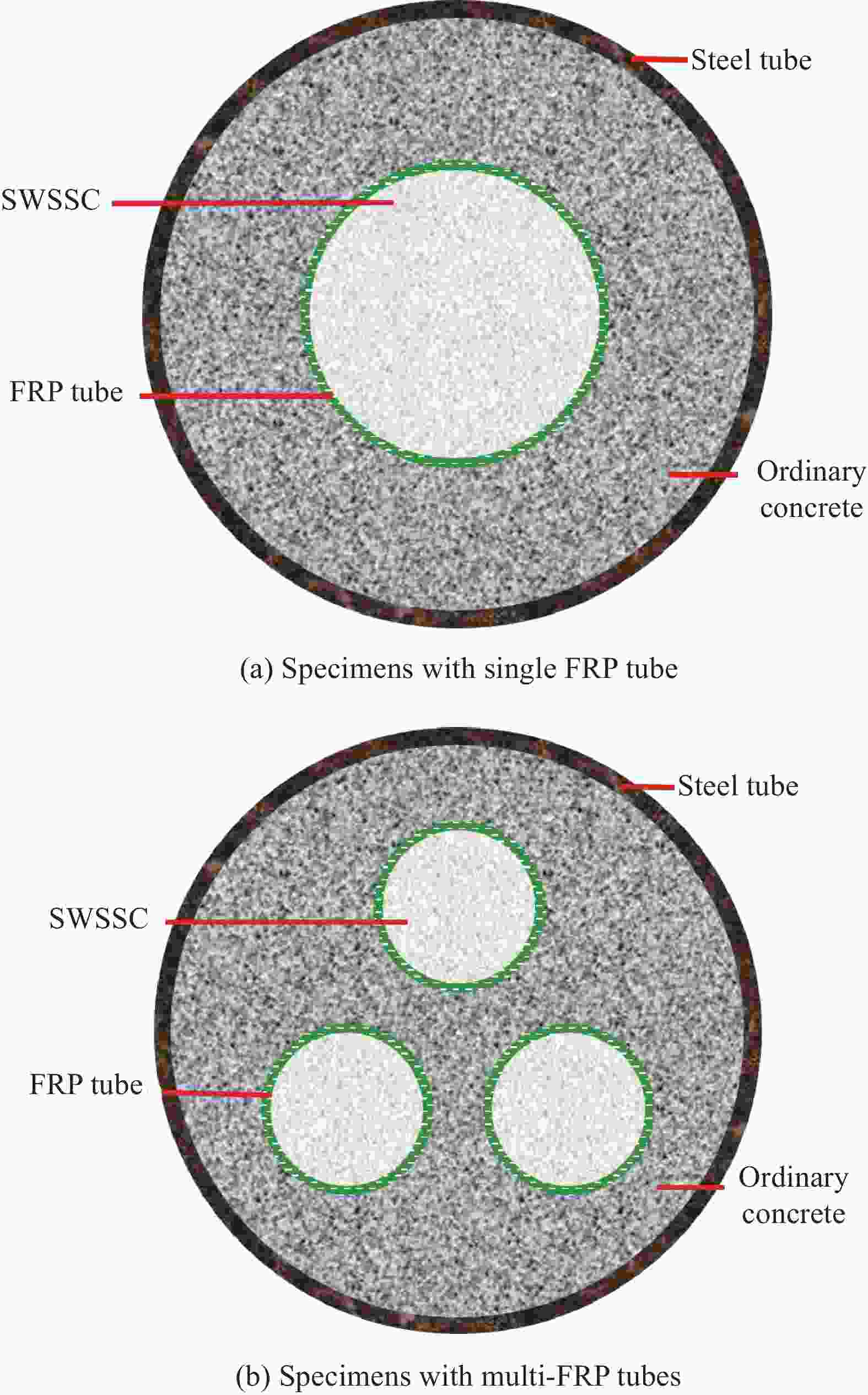

摘要: 提出一种钢管混凝土-纤维增强复合材料(FRP)管海水海砂混凝土(SWSSC)组合柱新型结构,其由外侧钢管、夹层普通混凝土、内侧FRP管和核心SWSSC构成。在轴向荷载作用下,夹层普通混凝土受到钢管的约束,而核心SWSSC受到钢管和FRP管的共同约束,考虑到两部分混凝土的不同约束机制,在现有的FRP-钢复合管约束混凝土的计算模型的基础上,本文提出了钢管混凝土-FRP管SWSSC组合柱的峰值点和极限点的计算模型;并利用FRP-钢复合管约束混凝土的应力-应变曲线模型,得到了钢管混凝土-FRP管SWSSC组合柱的应力-应变预测曲线;在72个钢管混凝土-FRP管SWSSC组合柱的轴压试验结果的基础上,对建议的模型进行了验证与评估。结果表明,提出的模型可以较好地预测钢管混凝土-FRP管SWSSC组合柱的应力-应变曲线。最后,利用提出的应力-应变曲线模型对钢管混凝土-FRP管SWSSC组合柱的轴压性能进行了参数化分析。Abstract: A novel structure termed as concrete filled steel tube-seawater and sea sand concrete (SWSSC) filled fiber reinforced polymer (FRP) tube composite columns was proposed, which was composed of outer steel tube, sandwiched ordinary concrete, inner FRP tube and core SWSSC. The sandwiched ordinary concrete was confined by the outer steel tube, while the core SWSSC was confined by both steel tube and FRP tube under axial compression. Considering the different confinement mechanism of two kinds of concrete, the calculation models of peak point and ultimate point of concrete filled steel tube-SWSSC filled FRP tube composite columns were proposed based on the existing calculation model of concrete-filled FRP-steel composite tube columns. And the predicted stress-strain curve model was obtained by using the stress-strain curve model of concrete-filled FRP-steel compo-site tube columns. The proposed model was verified and evaluated on the basis of the existing test results. The results show that the proposed model can predict the stress-strain curve of concrete filled steel tube-SWSSC filled FRP tube composite columns well. Finally, based on the proposed stress-strain model, the axial compression behavior of concrete filled steel tube-SWSSC filled FRP tube composite columns with different parameters was analyzed.

-

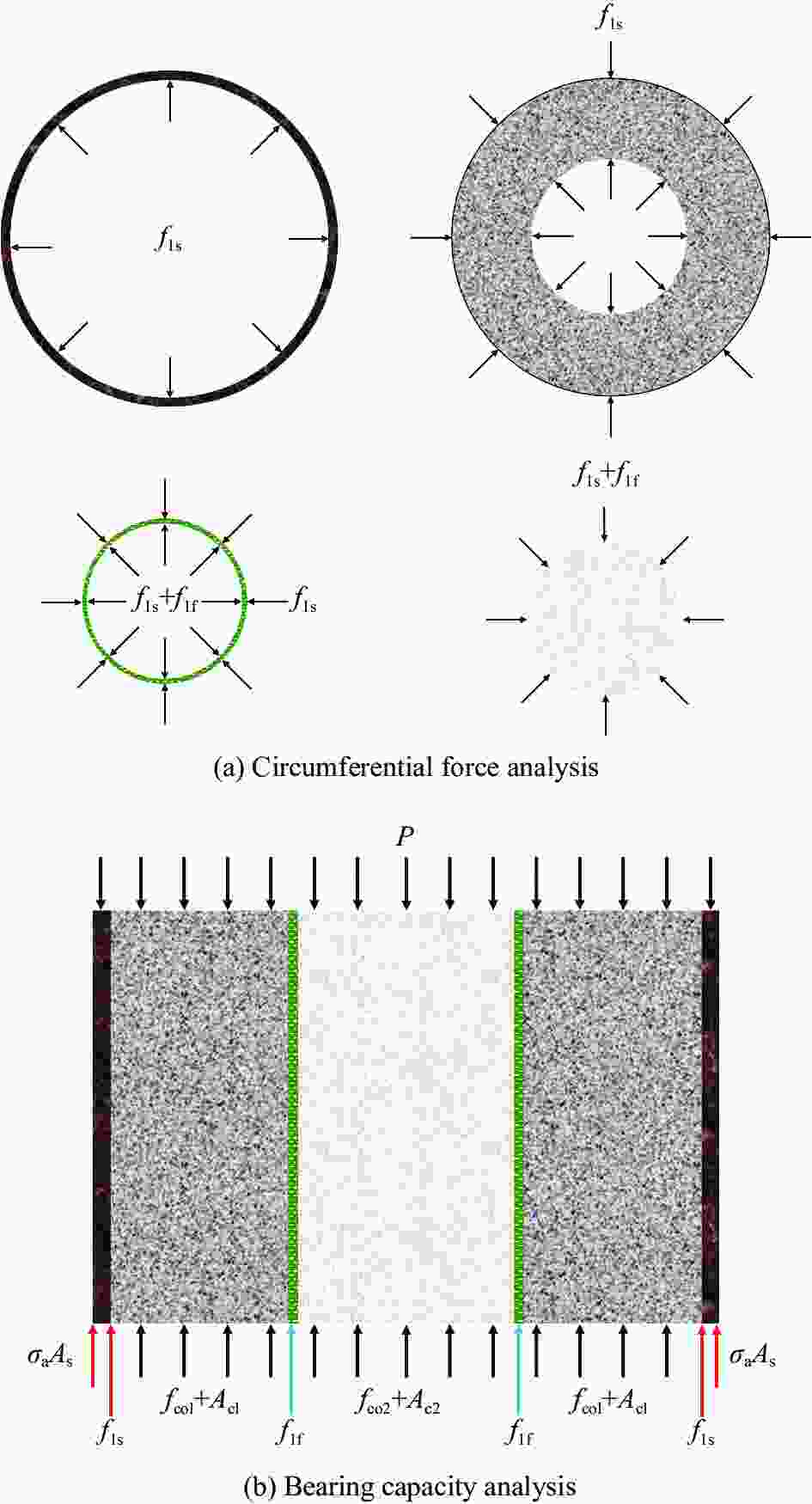

图 2 钢管混凝土-FRP管SWSSC组合柱约束机制分析图

Figure 2. Analysis diagram of confinement mechanism for concrete filled steel tube-SWSSC filled FRP tube composite columns

P—Axial load; flf—Confining pressure provided by FRP tube; fls—Confining pressure provided by the steel tube; σa—Axial stress of steel tube; As—Sectional area of steel tube; fco1—Compressive strength of sandwiched concrete; Ac1—Sectional area of sandwiched concrete; fco2—Compressive strength of core concrete; Ac2—Sectional area of core concrete

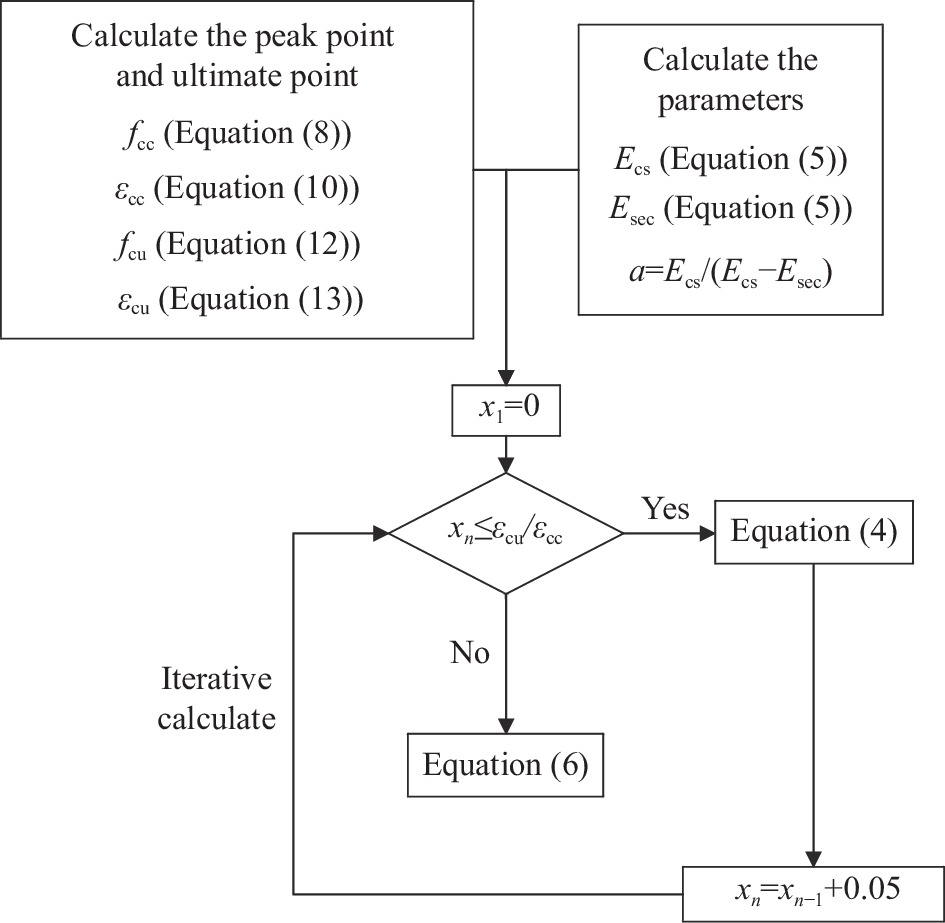

图 7 钢管混凝土-FRP管SWSSC组合柱计算流程图

Figure 7. Flow chart of model calculation for concrete filled steel tube-SWSSC filled FRP tube composite columns

Ecs—Initial stiffness of stress-strain curves (i.e. the slope of initial stage of stress-strain curves); Esec—Second stiffness of stress-strain curves (i.e. the slope of second linear strengthening stage of stress-strain curves); xn—nth iteration point

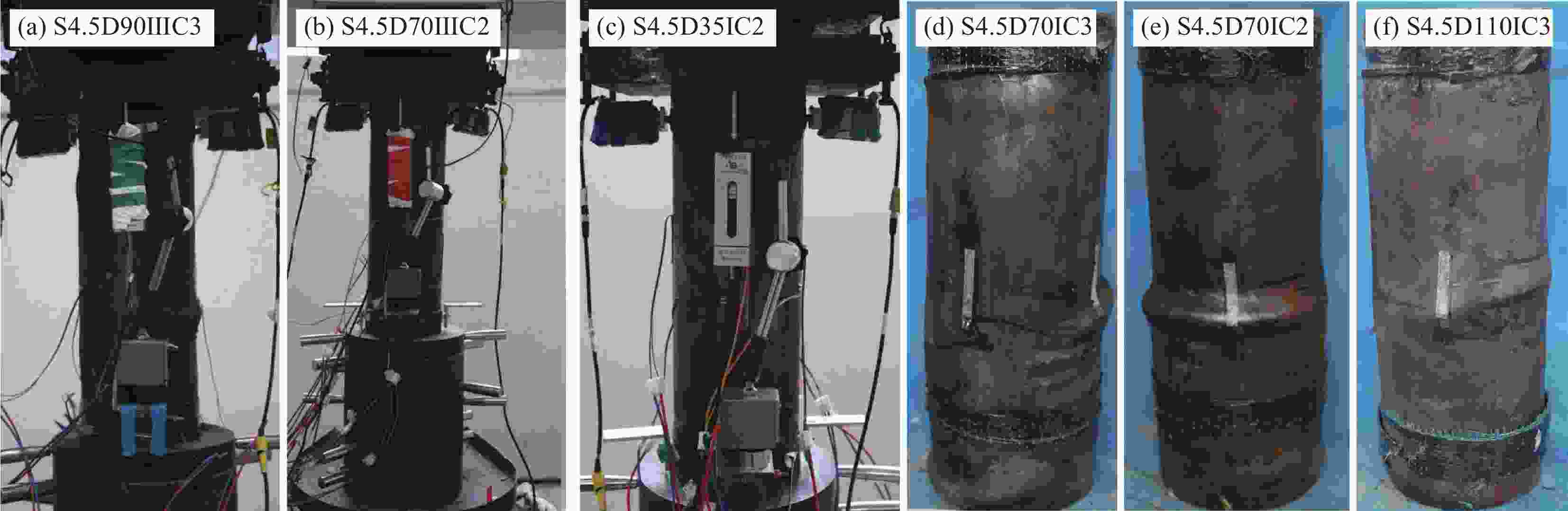

表 1 钢管混凝土-FRP管SWSSC组合柱试件的具体参数

Table 1. Detailed parameters of concrete filled steel tube-SWSSC filled FRP tube composite columns

Specimens Steel thickness/

mmFRP tube diameter/

mmFRP tube layers FRP tube numbers Specimens Steel thickness/

mmFRP tube diameter/

mmFRP tube layers FRP tube numbers S4.5D70IC2 4.5 70 2 1 S4.5D35IIIC2 4.5 35 2 3 S4.5D70IC3 4.5 70 3 1 S4.5D35IIIC3 4.5 35 3 3 S4.5D70IC4 4.5 70 4 1 S4.5D35IIIC4 4.5 35 4 3 S4.5D90IC2 4.5 90 2 1 S4.5D45IIIC2 4.5 45 2 3 S4.5D90IC3 4.5 90 3 1 S4.5D45IIIC3 4.5 45 3 3 S4.5D90IC4 4.5 90 4 1 S4.5D45IIIC4 4.5 45 4 3 S4.5D110IC2 4.5 110 2 1 S4.5D55IIIC2 4.5 55 2 3 S4.5D110IC3 4.5 110 3 1 S4.5D55IIIC3 4.5 55 3 3 S4.5D110IC4 4.5 110 4 1 S4.5D55IIIC4 4.5 55 4 3 S6.0D70IC2 6.0 70 2 1 S6.0D35IIIC2 6.0 35 2 3 S6.0D70IC3 6.0 70 3 1 S6.0D35IIIC3 6.0 35 3 3 S6.0D70IC4 6.0 70 4 1 S6.0D35IIIC4 6.0 35 4 3 S6.0D90IC2 6.0 90 2 1 S6.0D45IIIC2 6.0 45 2 3 S6.0D90IC3 6.0 90 3 1 S6.0D45IIIC3 6.0 45 3 3 S6.0D90IC4 6.0 90 4 1 S6.0D45IIIC4 6.0 45 4 3 S6.0D110IC2 6.0 110 2 1 S6.0D55IIIC2 6.0 55 2 3 S6.0D110IC3 6.0 110 3 1 S6.0D55IIIC3 6.0 55 3 3 S6.0D110IC4 6.0 110 4 1 S6.0D55IIIC4 6.0 55 4 3 Notes: Labels of the specimens are as follows: The first letter “S” denotes steel tube, the second number such as “6.0” denotes the thickness of the steel tube; the second letter and number such as “D90” denotes the diameter of the FRP tube; the number “I” denotes the number of the FRP tube; the third letter and number such as “C2” denotes the number of FRP layers. For example, “S6.0D55IIIC3” indicates that the thickness of the steel tube is 6.0 mm, diameter of the FRP tube is 55 mm, the number of FRP tube is 3, and number of layers of the FRP tube is 3. 表 2 钢管混凝土-FRP管SWSSC组合柱参数变化的影响

Table 2. Influence of parameter variation of concrete filled steel tube-SWSSC filled FRP tube composite columns

Specimens Two-layers Four-layers Six-layers Eight-layers Ten-layers Ultimate stress/MPa Increase ratio/% Ultimate stress/MPa Increase ratio/% Ultimate stress/MPa Increase ratio/% Ultimate stress/MPa Increase ratio/% Ultimate stress/MPa Increase ratio/% S4.5D80 100.62 − 120.64 − 141.30 − 162.61 − 184.59 − S4.5D90 103.01 2.37 125.40 3.95 148.44 5.06 172.13 5.86 196.49 6.45 S4.5D100 105.39 2.31 130.16 3.80 155.58 4.81 181.66 5.53 208.39 6.06 S4.5D110 107.77 2.26 134.93 3.66 162.73 4.59 191.18 5.24 220.30 5.71 S4.5D120 110.15 2.21 139.69 3.53 169.88 4.39 200.71 4.98 232.21 5.41 S4.5D130 112.53 2.16 144.46 3.41 177.02 4.21 210.24 4.75 244.12 5.13 S6.0D80 121.11 − 141.23 − 162.01 − 183.44 − 205.54 − S6.0D90 123.50 1.98 146.02 3.39 169.19 4.44 193.02 5.22 217.51 5.82 S6.0D100 125.90 1.94 150.81 3.28 176.38 4.25 202.60 4.96 229.49 5.51 S6.0D110 128.29 1.90 155.61 3.18 183.57 4.08 212.19 4.73 241.47 5.22 S6.0D120 130.69 1.87 160.40 3.08 190.76 3.92 221.78 4.52 253.45 4.96 S6.0D130 133.09 1.83 165.19 2.99 197.95 3.77 231.36 4.32 265.44 4.73 Notes: The labels of the specimens are as follows: the first letter “S” denotes steel tube, the second number such as “6.0” denotes the thickness of the steel tube; the second letter and number such as “D90” denotes the diameter of the FRP tube. For example, “S6.0D90” indicates that the thickness of the steel tube is 6.0 mm, diameter of the FRP tube is 90 mm. -

[1] 韦建刚, 周俊, 罗霞, 等. 高强钢管超高强混凝土柱抗震性能试验研究[J]. 工程力学, 2021, 38(7):30-40, 51.WEI J G, ZHOU J, LUO X, et al. Experimental study on quasi-static behavior of ultrahigh strength concrete filled high strength steel tubular columns[J]. Engineering Mechanics,2021,38(7):30-40, 51(in Chinese). [2] 颜燕祥. 方钢管UHPC短柱轴压性能试验研究[J]. 建筑结构, 2021, 51(12):117-123.YAN Y X. Experimental study on behavior of square UHPC filled short steel tube columns subjected to axial compression[J]. Building Structure,2021,51(12):117-123(in Chinese). [3] 魏洋, 柏佳文, 张依睿, 等. 矩形开槽钢管混凝土柱的受压承载性能[J]. 东南大学学报(自然科学版), 2020, 50(2):237-243. doi: 10.3969/j.issn.1001-0505.2020.02.005WEI Y, BAI J W, ZHANG Y R, et al. Compressive behaviors of rectangular concrete-filled slotted steel tubular columns[J]. Journal of Southeast University (Natural Science Edition),2020,50(2):237-243(in Chinese). doi: 10.3969/j.issn.1001-0505.2020.02.005 [4] 郭晓云, 陈杰, 唐永明. 不同纤维增强复合材料加固混凝土短柱轴心受压承载力试验研究[J]. 复合材料科学与工程, 2021, 8:66-72.GUO X Y, CHEN J, TANG Y M. Experimental study on axial compression bearing capacity of concrete short column strengthened with different fiber reinforced composites[J]. Composites Science and Engineering,2021,8:66-72(in Chinese). [5] 马高, 曾志虎. BFRP约束损伤混凝土棱柱体轴压力学性能研究[J]. 防灾减灾工程学报, 2020, 40(6):910-918.MA G, ZENG Z H. Axial compression behavior of pre-damaged concrete prisms confined with BFRP[J]. Journal of Disaster Prevention and Mitigation Engineering,2020,40(6):910-918(in Chinese). [6] WEI Y, XU P F, ZHANG Y R, et al. Compressive behaviour of FRP-steel wire mesh composite tubes filled with seawater and sea sand concrete[J]. Construction and Building Materials, 2021, 314(Part B): 125608. [7] 赵均海, 张焕青, 李莹萍. 等角八边形中空夹层钢管混凝土短柱承载力统一解[J]. 应用力学学报, 2021, 38(3):1054-1061.ZHAO J H, ZHANG H Q, LI Y P. Unified solutions on bearing capacity of concrete-filled double skin steel tubular stub column with equal-angle octagon[J]. Chinese Jour-nal of Applied Mechanics,2021,38(3):1054-1061(in Chinese). [8] LONG Y L, LI W T, DAI J G, et al. Experimental study of concrete-filled CHS stub columns with inner FRP tubes[J]. Thin-Walled Structures,2018,122:606-621. doi: 10.1016/j.tws.2017.10.046 [9] ZHANG Y R, WEI Y, BAI J W, et al. A novel seawater and sea sand concrete filled FRP-carbon steel composite tube column: Concept and behavior[J]. Composite Structures,2020,246(8):112421. [10] 柏佳文, 魏洋, 张依睿, 等. 新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J]. 复合材料学报, 2021, 38(9):3084-3093.BAI J W, WEI Y, ZHANG Y R, et al. Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J]. Acta Materiae Compositae Sinica,2021,38(9):3084-3093(in Chinese). [11] 李广悦. 圆截面钢-混凝土-CFRP-混凝土实心组合短柱轴压力学性能研究[D]. 沈阳: 沈阳建筑大学, 2011.LI G Y. Study on mechanical properties of circular steel-concrete-CFRP-concrete solid composite short columns under axial compression[D]. Shenyang: Shenyang Jianzhu University, 2011(in Chinese). [12] LI G C, LANG Y, YANG Z J. Behavior of high strength CFSST stub columns with inner CFRP tube under axial compres-sive load[J]. Advanced Steel Construction,2011,7(3):239-254. [13] LI Y L, ZHAO X L. Hybrid double tube sections utilising seawater and sea sand concrete, FRP and stainless steel[J]. Thin-Walled Structures,2020,149:106643. doi: 10.1016/j.tws.2020.106643 [14] 张海镇. 内置FRP-UHPC芯柱的钢管混凝土组合柱轴压力学性能研究[D]. 西安: 西安建筑科技大学, 2017.ZHANG H Z. Research on the mechanical properties of concrete-filled steel tube columns with FRP-UHPC core columns subjected to axial compression[D]. Xi’an: Xi’an University of Architecture and Technology, 2017(in Chinese). [15] 陶毅, 张海镇, 史庆轩, 等. 内置FRP约束混凝土的方钢管混凝土轴压承载力[J]. 土木建筑与环境工程, 2017, 39(2):43-49.TAO Y, ZHANG H Z, SHI Q X, et al. Bearing capacity of steel tube-concrete-FRP-concrete composite columns[J]. Journal of Civil and Environmental Engineering,2017,39(2):43-49(in Chinese). [16] ZHANG Y R, WEI Y, BAI J W, et al. Stress-strain model of an FRP-confined concrete filled steel tube under axial compression[J]. Thin-Walled Structures,2019,142:149-159. doi: 10.1016/j.tws.2019.05.009 [17] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485.ZHANG Y R, WEI Y, BAI J W, et al. Models for predicting axial compression behavior of fiber reinforced polymer-steel composite circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2478-2485(in Chinese). [18] YU T, TENG J G, WONG Y L. Stress-strain behavior of concrete in hybrid FRP-concrete-steel double-skin tubular columns[J]. Journal of Structural Engineering,2010,136:379-389. doi: 10.1061/(ASCE)ST.1943-541X.0000121 [19] WEI Y, JIANG C, WU Y F. Confinement effectiveness of circular concrete-filled steel tubular columns under axial compression[J]. Journal of Constructional Steel Research,2019,158:15-27. doi: 10.1016/j.jcsr.2019.03.012 [20] 曾翔, 吴晚博, 霍静思, 等. 圆铝合金管混凝土短柱轴心受压承载力研究[J]. 工程力学, 2021, 38(2):52-60.ZENG X, WU W B, HUO J S, et al. The axial strength of concrete-filled aluminum alloy circular tubular stub columns[J]. Engineering Mechanics,2021,38(2):52-60(in Chinese). [21] HAN L H, YAO G H, ZHAO X L. Tests and calculations for hollow structural steel (HSS) stub columns filled with self-consolidating concrete (SCC)[J]. Journal of Constructional Steel Research,2005,61:1241-1269. doi: 10.1016/j.jcsr.2005.01.004 [22] HAN L H, YAO G H, ZHONG T. Performance of concrete-filled thin-walled steel tubes under pure torsion[J]. Thin-Walled Structures,2007,45:24-36. doi: 10.1016/j.tws.2007.01.008 [23] JIANG T, TENG J G. Analysis-oriented stress-strain models for FRP-confined concrete[J]. Engineering Structures, 2007, 29: 2968-2986. [24] POPOVICS S. A numerical approach to the complete stress-strain curve of concrete[J]. Cement & Concrete Research,1973,3(5):583-599. [25] WEI Y, WU G, LI G F. Performance of circular concrete-filled fiber-reinforced polymer-steel composite tube columns under axial compression[J]. Journal of Reinforced Plastics and Composites,2014,33:1911-1928. doi: 10.1177/0731684414550836 -

下载:

下载: