Seismic performance of FRP-confined reinforced concrete columns with different concrete strength

-

摘要: 为了研究纤维增强树脂复合材料(FRP)布约束不同强度混凝土配筋柱的抗震性能,对4根约束柱及2根对比柱进行了低周反复荷载作用下的拟静力试验研究,探讨了混凝土强度和FRP种类等参数对加固柱抗震性能的影响。试验结果表明,加固构件均发生弯曲破坏,其承载、延性和耗能能力均有提高。且当柱混凝土强度大幅提高时,其延性和耗能指标较未加固前的提高率上升明显。在等围压条件下,玄武岩纤维布(BFRP)和碳纤维布(CFRP)约束柱的承载力相近,对于加固普通强度混凝土柱,使用BFRP较CFRP会得到更高的延性和耗能能力提升,但对于混凝土强度等级高至C50的柱,CFRP约束后柱的抗震性能略好。最后分别提出了针对不同FRP加固钢筋混凝土柱的骨架曲线模型,且基于更广泛混凝土强度、纵筋配筋率和轴压比范围下的数值计算结果也验证了试验结论。

-

关键词:

- 纤维增强树脂复合材料 /

- 约束柱 /

- 混凝土强度 /

- 抗震性能 /

- 骨架曲线

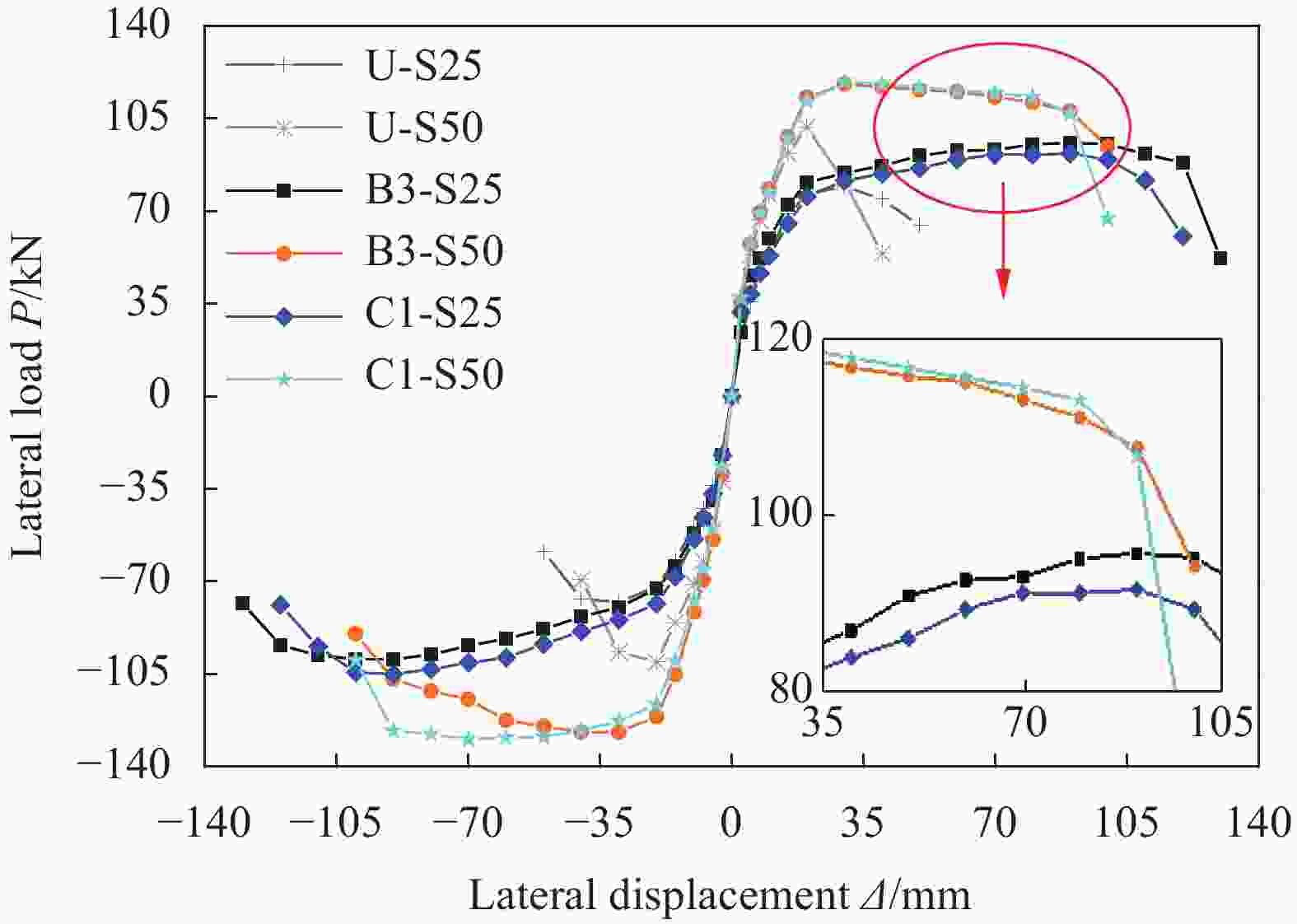

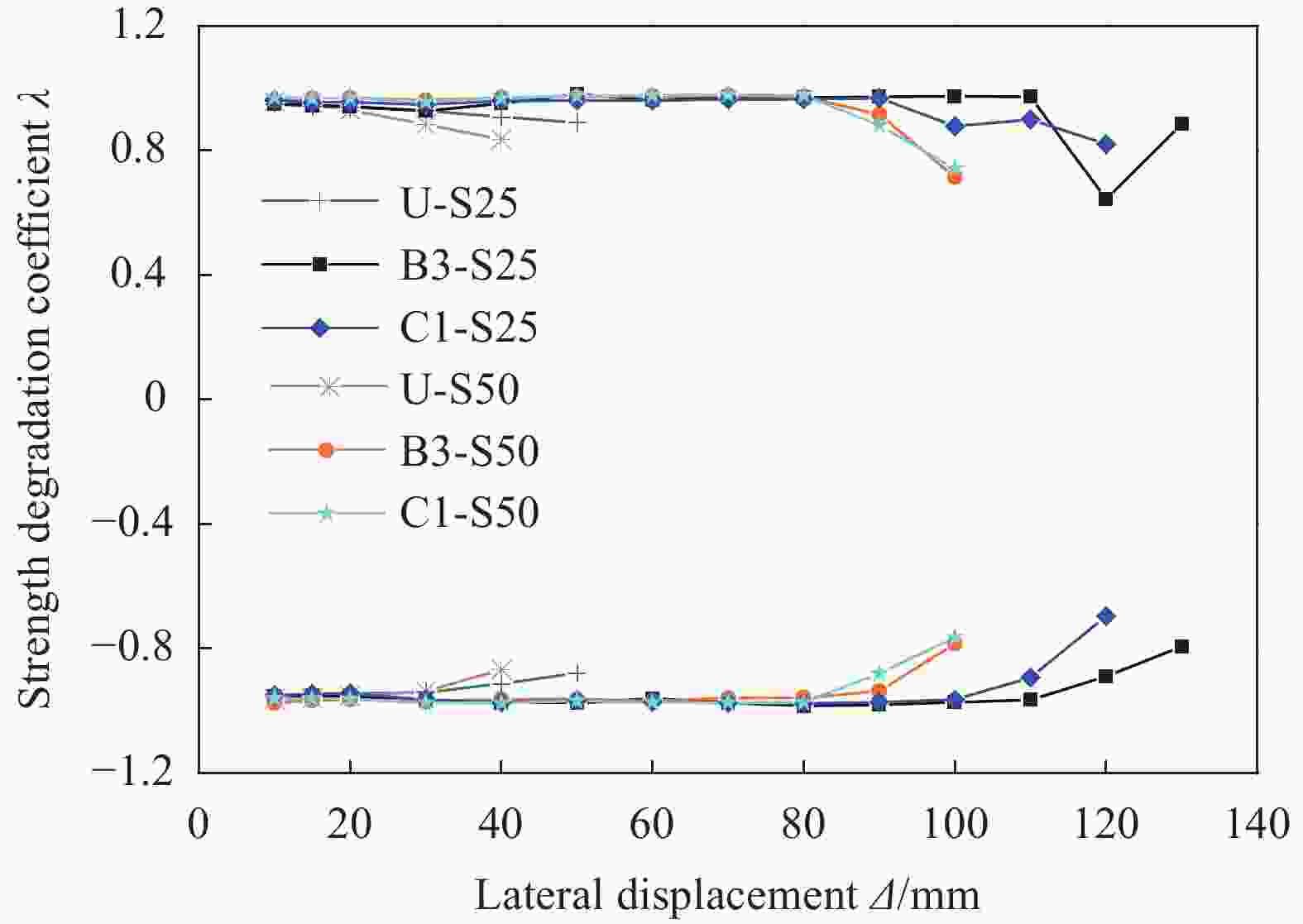

Abstract: To investigate the seismic performance of fiber reinforced polymer (FRP) confined reinforced concrete columns with different concrete strength, the quasi-static test was carried out on four confined columns and two control columns under low cyclic lateral load. The influence of parameters such as concrete strength and FRP type on the test results was investigated. The test results show that the columns have flexural failure after confinement. The strength, ductility and energy dissipation capacity of columns are enhanced. The increments of ductility and energy dissipation indexes are observed to improve significantly when the concrete strength of confined columns increases greatly. With the same confining pressure, the peak loads of basalt fiber reinforced polymer (BFRP) and carbon fiber reinforced polymer (CFRP) confined columns are nearly same. The BFRP-confined normal-strength concrete column has higher ductility and energy dissipation capacity. But the seismic performance of CFRP-confined concrete columns is slightly better when the concrete strength grade reaches C50. The skeleton curve models were proposed for different FRP confined columns. The results of parameter analysis verify the experimental conclusions based on the wider range of concrete strength, longitudinal reinforcement and axial compression ratio.-

Key words:

- FRP /

- confined columns /

- concrete strength /

- seismic performance /

- skeleton curve

-

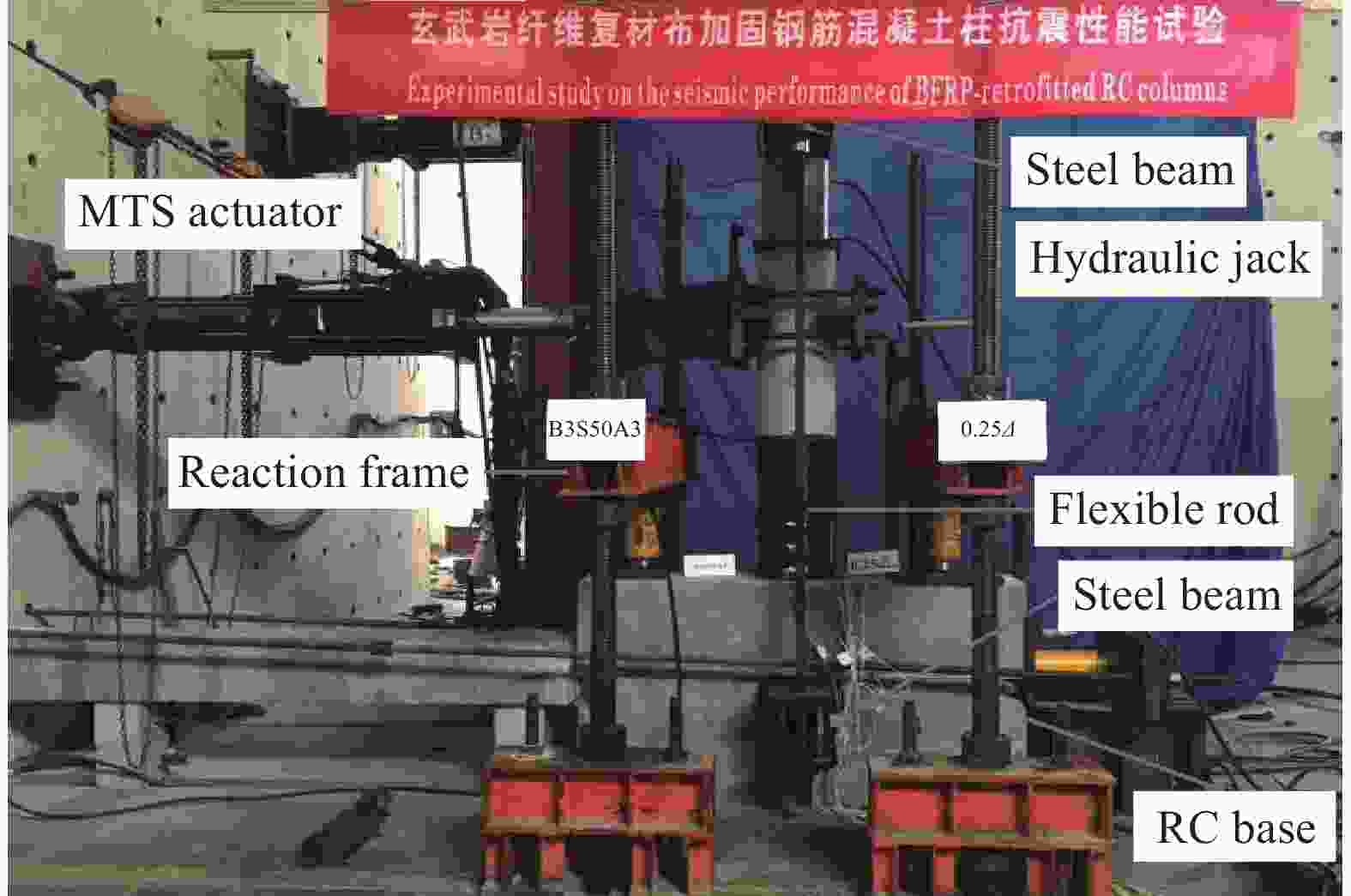

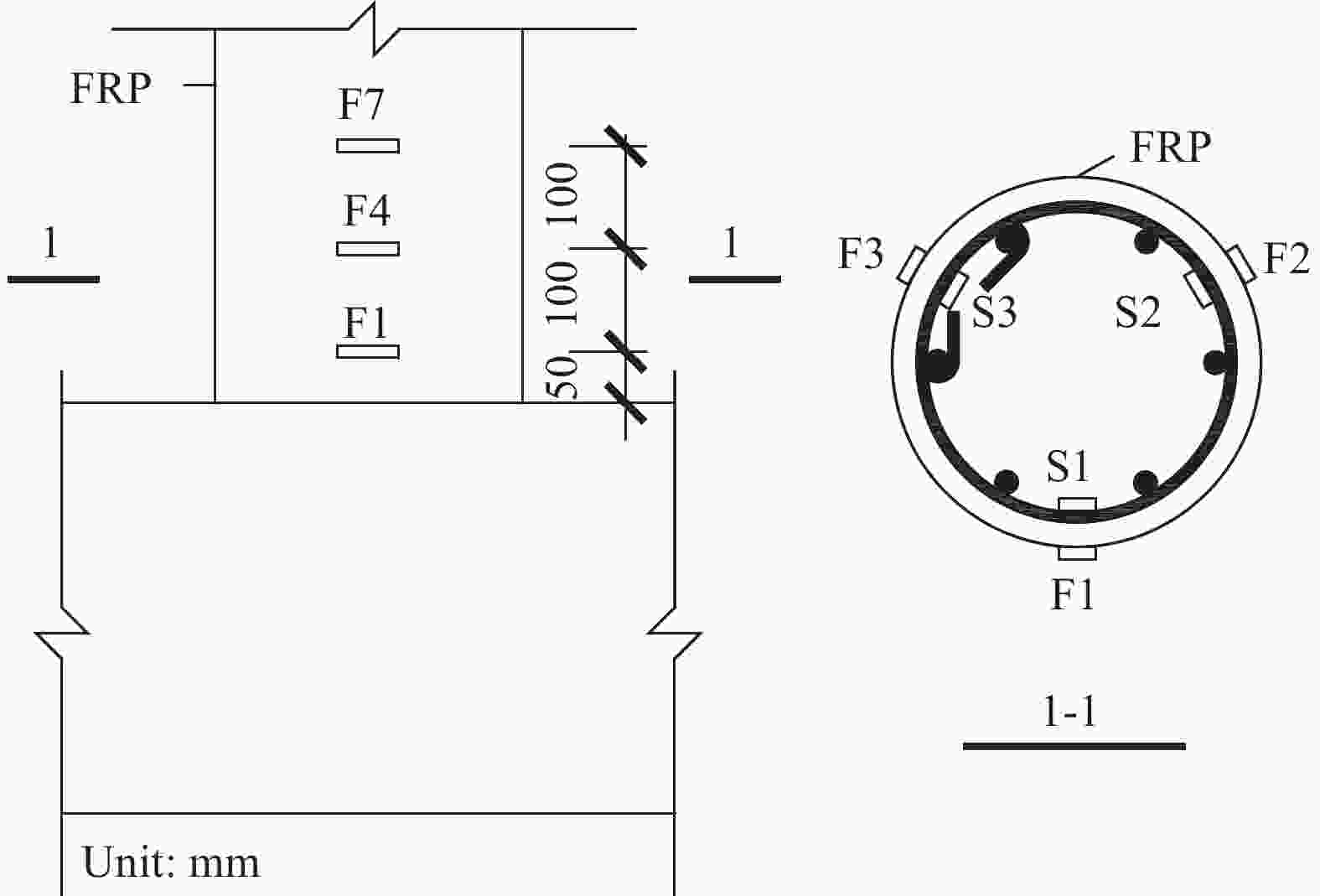

图 9 BFRP和CFRP约束RC柱截面应力-应变分布

Figure 9. Sectional stress and strain distribution of BFRP and CFRP-confined RC columns

D—Diameter of section; dx—Width of concrete strip; h—Height of concrete compression zone; x—Distance from concrete strip to the top of section; $ \varepsilon _{{\text{cc}}}^{{'}} $—Maximum strain of concrete edge in compression zone; $ \varepsilon _{\text{c}}' $—Strain of concrete strip; $ {\varepsilon _{{\text{s}}i}} $—Strain of the ith row of reinforcements; M—Bending moment of section; N—Axial load of section; $ \sigma _{\text{c}}^{{'}} $—Stress of concrete strip; $ {\sigma _{{\text{s}}i}} $—Stress of the ith row of reinforcements; Asi—Area of the ith row of reinforcements

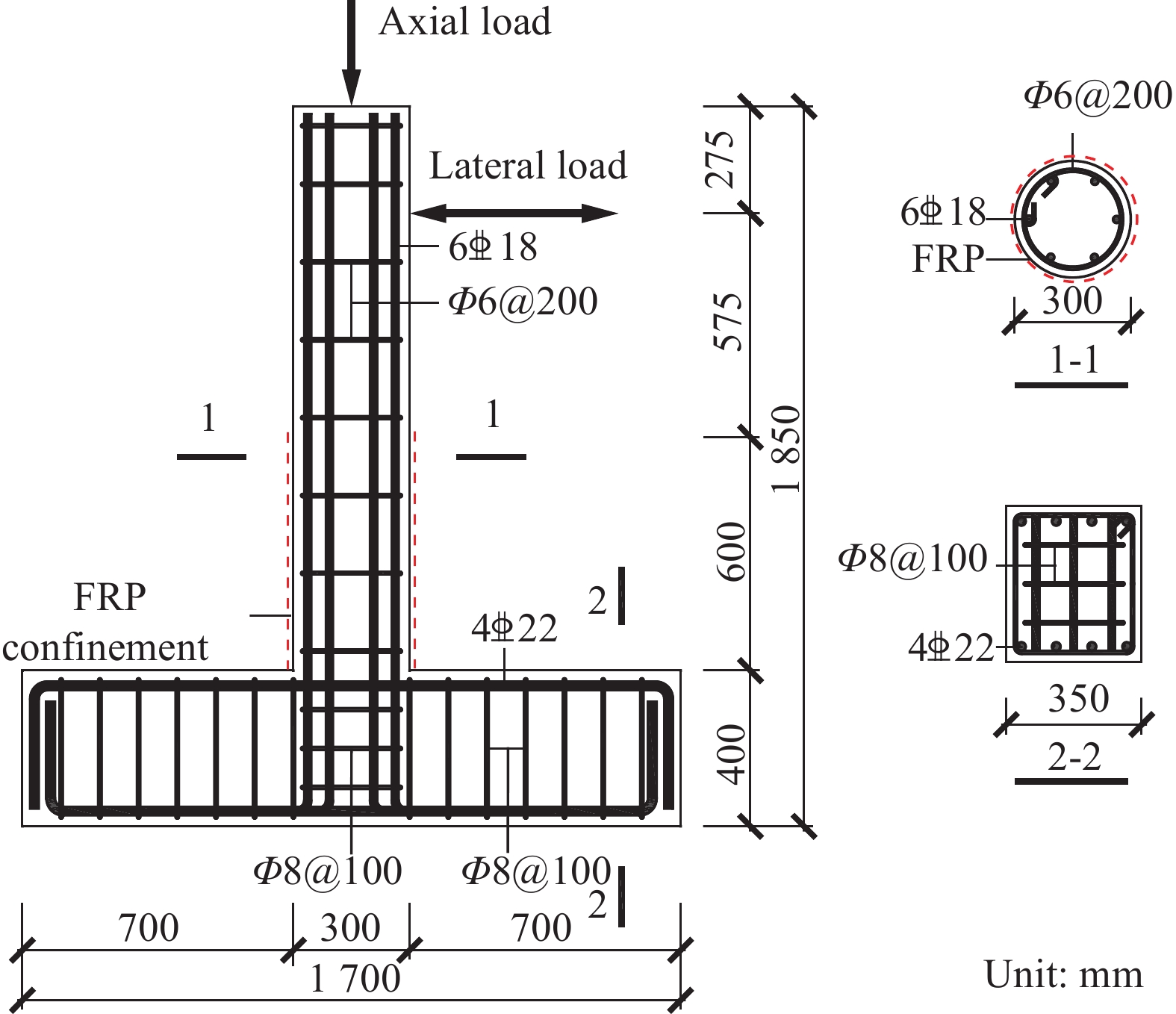

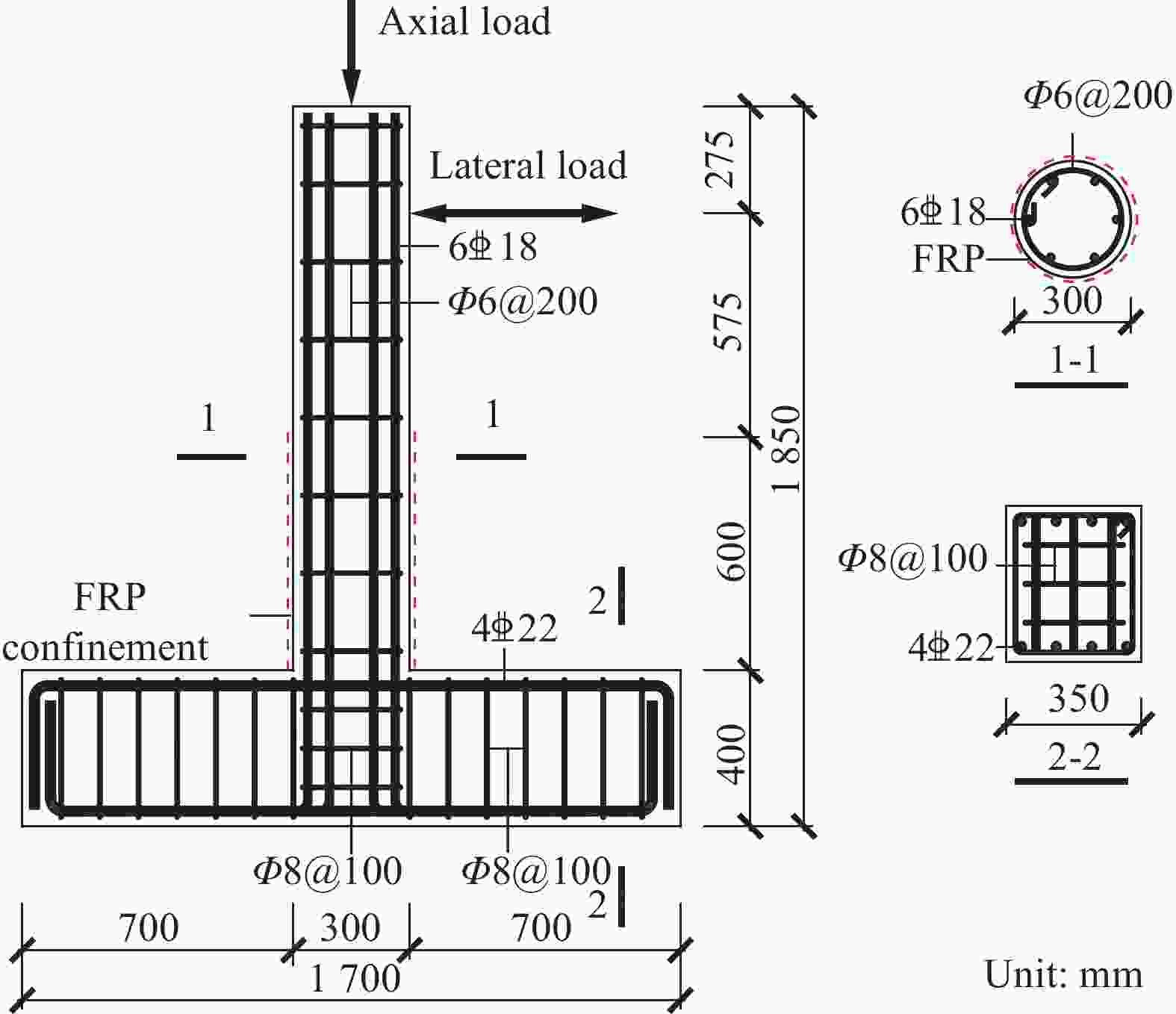

表 1 BFRP和CFRP约束RC柱主要设计参数

Table 1. Main design parameter of BFRP and CFRP-confined RC columns

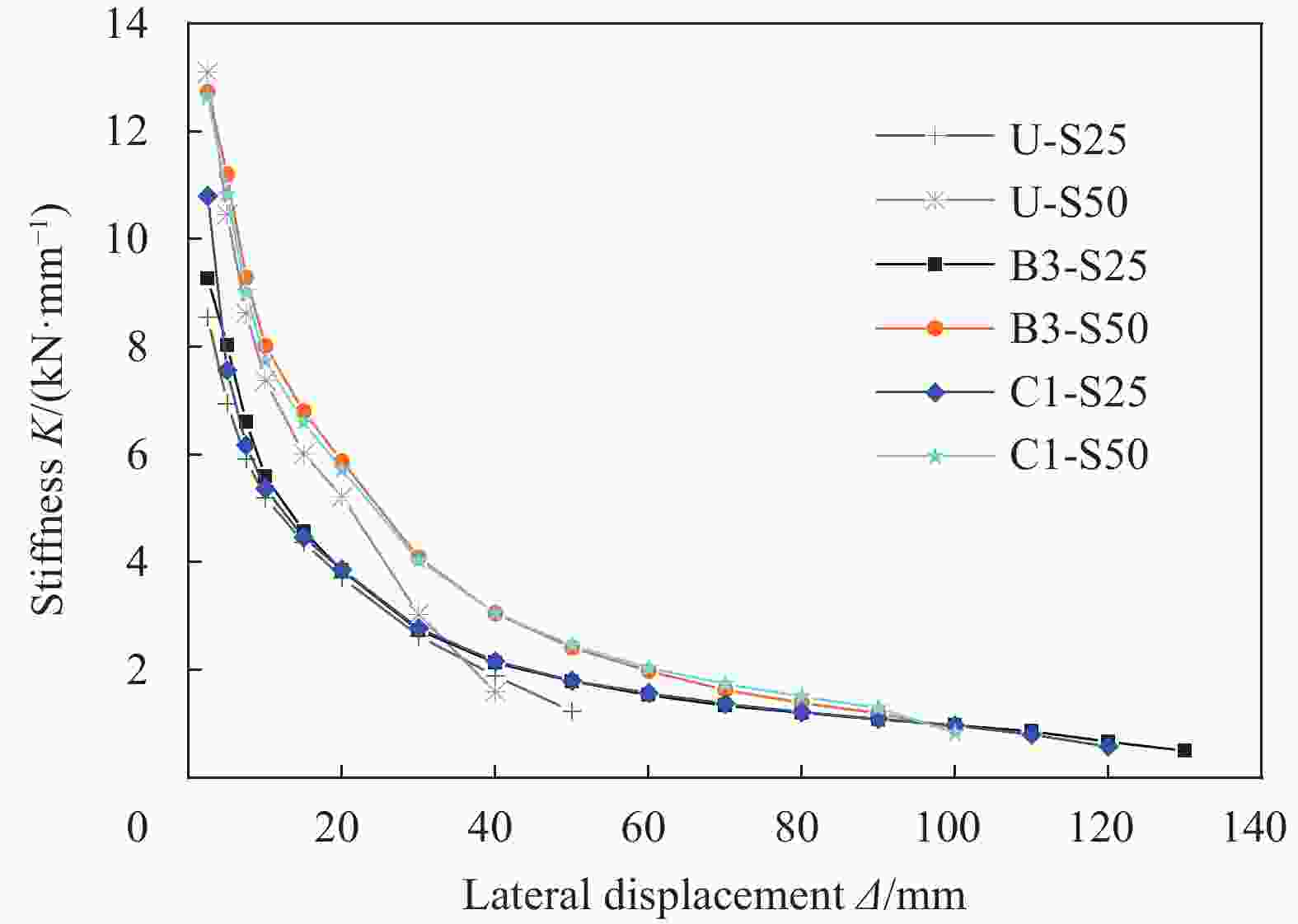

Specimen Axial load N/kN FRP layer fcu/MPa U-S25 252.3 – 31.4 U-S50 489.9 – 57.8 B3-S25 252.3 3-layer BFRP 31.4 B3-S50 489.9 3-layer BFRP 57.8 C1-S25 252.3 1-layer CFRP 31.4 C1-S50 489.9 1-layer CFRP 57.8 Notes: fcu—Concrete compressive strength; U—Unconfined; B or C—BFRP or CFRP; S—Concrete strength. The numeral after B or C represents the number of FRP layers. The numeral after S denotes grade of concrete strength. 表 2 钢筋的力学性能指标

Table 2. Mechanical properties of reinforcements

Diameter

/mmStrength grade Yield strength

fy/MPaUltimate strength

fu/MPaElastic modulus

Es/GPaDuctility

εu/%18 HRB400 477.3 626.5 208.2 30.0 6 HPB300 393.3 519.6 215.0 25.5 表 3 FRP布的力学性能指标

Table 3. Mechanical properties of FRP sheets

Type Thickness

t/mmTensile strength

ffrp/MPaElastic modulus

Efrp/GPaRupture strain

εfrp/%BFRP 0.107 1857.3 79.4 2.4 CFRP 0.167 3629.9 245.5 1.5 表 4 BFRP和CFRP约束不同强度混凝土配筋柱的抗震试验结果

Table 4. Seismic test results of BFRP and CFRP-confined RC columns with different concrete strength

Specimen Yield point Peak point Ultimate point μΔ Esum

/

(kN·mm)ξe Δy/mm Py/kN Δc/mm Pc/kN Δu/mm Pu/kN U-S25 14.65 64.33 29.94 78.67 46.34 66.87 3.17 37465 0.322 U-S50 11.94 79.42 19.96 101.12 30.71 85.95 2.57 36684 0.336 B3-S25 18.15 73.68 89.92 97.71 123.92 83.06 6.91 278986 0.348 B3-S50 15.02 101.51 34.96 122.56 91.40 104.18 6.13 210566 0.377 C1-S25 17.40 71.38 89.90 98.40 112.46 83.64 6.64 236945 0.344 C1-S50 15.49 99.87 49.96 124.40 93.66 105.74 6.14 240994 0.380 Notes: Δy—Yield placement; Py—Yield load; Pc—Peak load; Δc—Peak placement; Pu—Ultimate load; Δu—Ultimate displacement; μΔ—Displacement ductility factor; Esum—Total accumulative dissipated energy at the ultimate state; ξe—Equivalent viscous damping ratio at the ultimate state. 表 5 BFRP和CFRP约束RC柱计算与试验结果比较

Table 5. Comparison between calculated and test results of BFRP and CFRP-confined RC columns

Specimen Pc, cal

/kNPc, exp/kN Pc, exp/Pc, cal Δu, cal

/mmΔu, exp

/mmΔu, exp/Δu, cal U-S25 72.66 78.67 1.08 48.20 46.34 0.96 U-S50 93.98 101.12 1.08 33.97 30.71 0.90 B3-S25 86.07 97.71 1.14 121.64 123.92 1.02 B3-S50 111.64 122.56 1.10 103.55 91.40 0.88 C1-S25 85.02 98.40 1.16 115.23 112.46 0.98 C1-S50 110.67 124.40 1.12 102.17 93.66 0.92 Notes: Pc, cal—Calculated peak load; Pc, exp—Experimental peak load; Δu, cal—Calculated ultimate displacement; Δu, exp—Experimental ultimate displacement. 表 6 BFRP和CFRP约束RC柱计算参数及结果

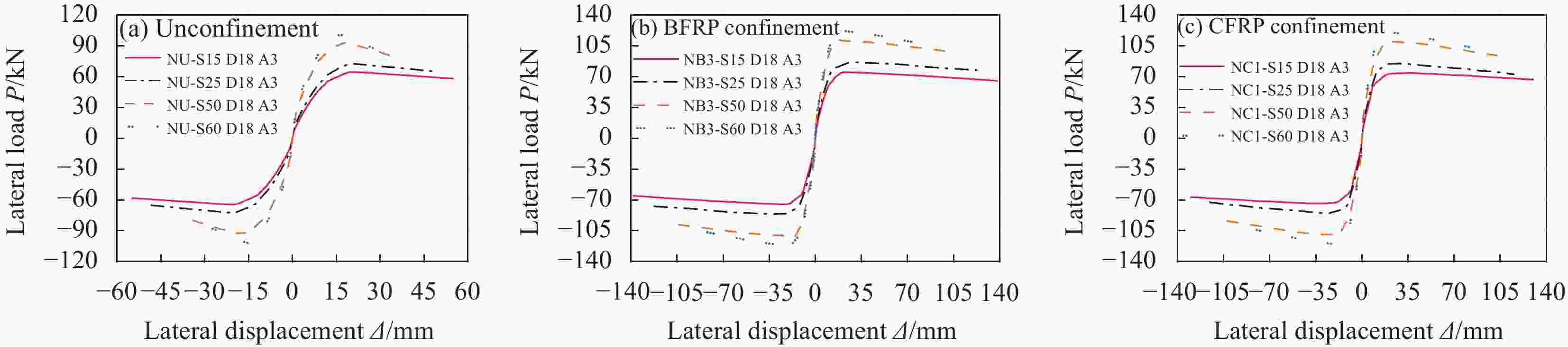

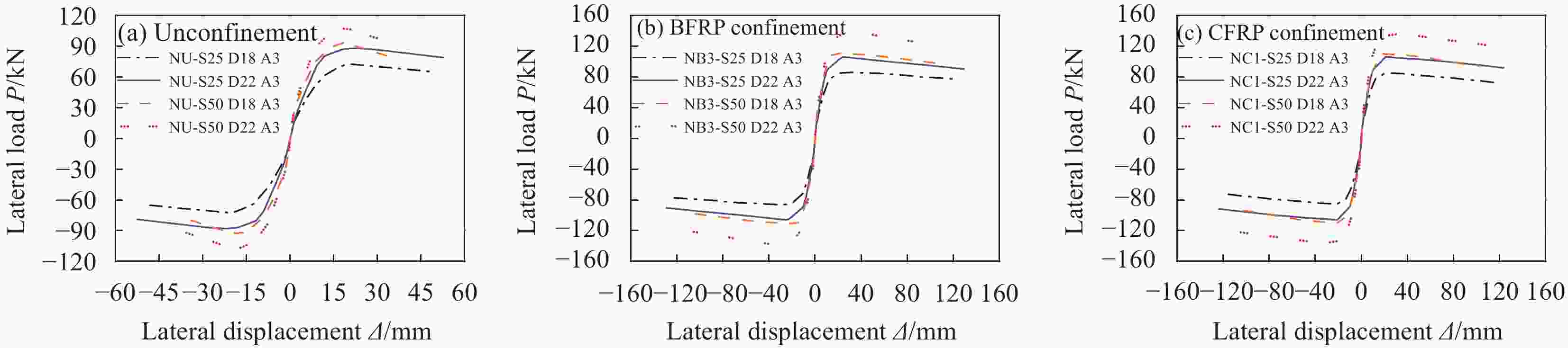

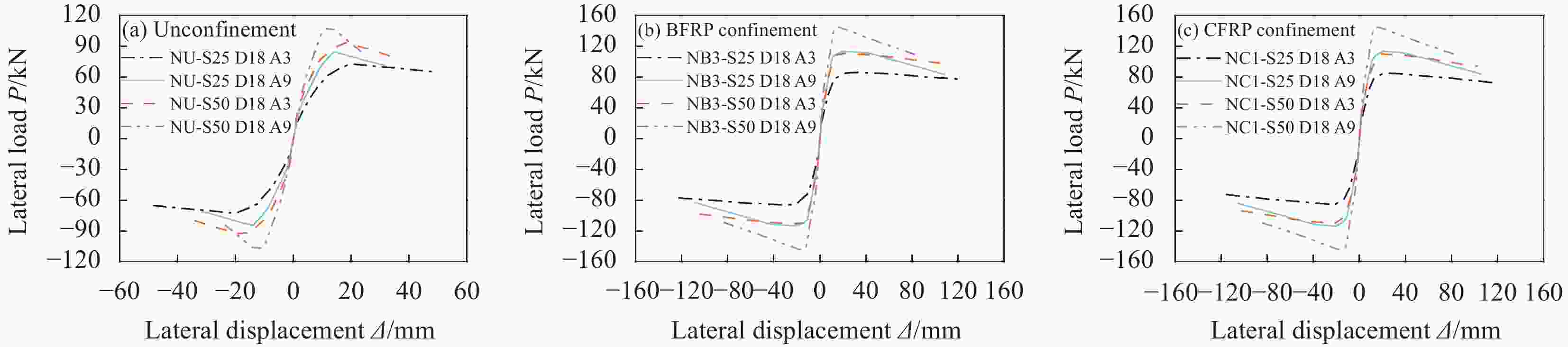

Table 6. Calculated parameters and results of BFRP and CFRP-confined RC columns

Group Specimen FRP layer fcu/

MPaD/

mmρs/

%n Py,cal/

kNΔy,cal/

mmPc,cal/

kNIncr. of Pc,cal/% Δu,cal/

mmIncr. of

Δu,cal/%Concrete strength NU-S15 D18 A3 – 22.4 18 2.16 0.3 49.94 10.15 64.56 – 54.77 – NU-S25 D18 A3 – 31.3 18 2.16 0.3 55.63 9.96 72.66 – 48.20 – NU-S50 D18 A3 – 57.8 18 2.16 0.3 75.37 8.74 93.98 – 33.97 – NU-S60 D18 A3 – 69.7 18 2.16 0.3 76.86 7.88 102.37 – 28.37 – NB3-S15 D18 A3 3-layer BFRP 22.4 18 2.16 0.3 62.55 11.33 75.00 16.2 137.94 151.9 NB3-S25 D18 A3 3-layer BFRP 31.3 18 2.16 0.3 73.04 11.16 86.17 18.6 122.18 153.5 NB3-S50 D18 A3 3-layer BFRP 57.8 18 2.16 0.3 95.54 10.48 112.14 19.3 103.93 205.9 NB3-S60 D18 A3 3-layer BFRP 69.7 18 2.16 0.3 101.46 10.19 122.17 19.3 84.50 197.8 NC1-S15 D18 A3 1-layer CFRP 22.4 18 2.16 0.3 63.72 11.11 74.04 14.7 129.78 137.0 NC1-S25 D18 A3 1-layer CFRP 31.3 18 2.16 0.3 75.21 11.04 85.02 17.0 115.23 139.1 NC1-S50 D18 A3 1-layer CFRP 57.8 18 2.16 0.3 88.99 10.32 110.67 17.8 102.17 200.8 NC1-S60 D18 A3 1-layer CFRP 69.7 18 2.16 0.3 104.53 10.01 120.41 17.6 82.35 190.3 Longitudinal reinforcement

ratioNU-S25 D22 A3 – 31.3 22 3.23 0.3 75.38 10.35 87.96 – 52.48 – NU-S50 D22 A3 – 57.8 22 3.23 0.3 87.81 8.40 107.94 – 36.78 – NB3-S25 D22 A3 3-layer BFRP 31.3 22 3.23 0.3 90.82 11.61 105.82 20.3 128.96 145.7 NB3-S50 D22 A3 3-layer BFRP 57.8 22 3.23 0.3 113.63 10.75 137.83 27.2 108.20 194.2 NC1-S25 D22 A3 1-layer CFRP 31.3 22 3.23 0.3 91.05 11.35 106.11 20.6 123.56 135.4 NC1-S50 D22 A3 1-layer CFRP 57.8 22 3.23 0.3 113.43 10.65 135.74 25.8 107.48 192.2 Axial compression

ratioNU-S25 D18 A9 – 31.3 18 2.16 0.9 71.03 9.70 84.42 – 31.42 – NU-S50 D18 A9 – 57.8 18 2.16 0.9 97.86 9.09 108.01 – 23.53 – NB3-S25 D18 A9 3-layer BFRP 31.3 18 2.16 0.9 102.43 10.39 113.18 34.1 108.04 243.9 NB3-S50 D18 A9 3-layer BFRP 57.8 18 2.16 0.9 123.28 10.17 145.08 34.3 83.15 253.4 NC1-S25 D18 A9 1-layer CFRP 31.3 18 2.16 0.9 98.86 10.48 113.62 34.6 105.40 235.5 NC1-S50 D18 A9 1-layer CFRP 57.8 18 2.16 0.9 127.28 10.14 145.65 34.8 83.91 256.6 Notes: N—Numerical calculated column; fcu—Concrete compressive strength; D—Diameter of longitudinal reinforcement; ρs—Longitudinal reinforcement ratio; n—Axial compression ratio; Py,cal—Calculated yield load; Δy,cal—Calculated yield displacement; Pc,cal—Calculated peak load; Δu,cal—Calculated ultimate displacement; Incr.—Increment in performance index after FRP confinement. -

[1] 佟旋, 胡利, 张兴富. 城市更新中结构改造与加固技术及应用[J]. 工程抗震与加固改造, 2021, 43(2):125-129.TONG Xuan, HU Li, ZHANG Xingfu. Structural alteration and reinforcement technology in urban renewal and its application[J]. Earthquake Resistant Engineering and Retrofitting,2021,43(2):125-129(in Chinese). [2] 祖坤, 熊二刚, 宋良英, 等. 高强混凝土构件力学性能研究综述[J]. 硅酸盐通报, 2019, 38(10):3178-3192. doi: 10.16552/j.cnki.issn1001-1625.2019.10.021ZU Kun, XIONG Ergang, SONG Liangying, et al. Review on mechanical properties of high-strength concrete members[J]. Bulletin of the Chinese Ceramic Society,2019,38(10):3178-3192(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2019.10.021 [3] 冯鹏, 陆新征, 叶列平. 纤维增强复合材料建设工程应用技术[M]. 北京: 中国建筑工业出版社, 2011.FENG Peng, LU Xinzheng, YE Lieping. Application of fiber reinforced polymer in construction[M]. Beijing: China Architecture and Building Press, 2011(in Chinese). [4] 王作虎, 杨菊, 崔宇强, 等. 碳纤维增强树脂复合材料加固钢筋混凝土柱抗震性能的尺寸效应试验[J]. 复合材料学报, 2020, 37(10):2645-2655. doi: 10.13801/j.cnki.fhclxb.20200212.001WANG Zuohu, YANG Ju, CUI Yuqiang, et al. Experiment on the size effect of seismic behavior for reinforced concrete columns strengthened by carbon fiber reinforced plastics[J]. Acta Materiae Compositae Sinica,2020,37(10):2645-2655(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200212.001 [5] ILKI A, DEMIR C, BEDIRHANOGLU I, et al. Seismic retrofit of brittle and low strength RC columns using fiber reinforced polymer and cementitious composites[J]. Advances in Structural Engineering,2009,12(3):325-347. doi: 10.1260/136943309788708356 [6] WANG J Z, YANG J L, CHENG L. Experimental study of seismic behavior of high-strength RC columns strengthened with CFRP subjected to cyclic loading[J]. Journal of Structural Engineering, 2019, 145(2): 04018240. [7] WANG D Y, WANG Z Y, SMITH S T, et al. Seismic perfor-mance of CFRP-confined circular high-strength concrete columns with high axial compression ratio[J]. Construction and Building Materials,2017,134:91-103. doi: 10.1016/j.conbuildmat.2016.12.108 [8] HOU D X, WU Z M, ZHENG J J, et al. Seismic rehabilitation of substandard RC columns with partially deteriorated concrete using CFRP composites[J]. Computers and Concrete,2015,15(1):1-20. doi: 10.12989/cac.2015.15.1.001 [9] MONALDO E, NERILLI F, VAIRO G. Basalt-based fiber-reinforced materials and structural applications in civil engineering[J]. Composites Structures,2019,214:74-94. [10] DHAND V, MITTAL G, RHEE K Y, et al. A short review on basalt fiber reinforced polymer composites[J]. Compo-sites Part B: Engineering,2015,73:166-180. [11] 吴刚, 魏洋, 吴智深, 等. 玄武岩纤维与碳纤维加固混凝土矩形柱抗震性能比较研究[J]. 工业建筑, 2007, 37(6):14-18, 69. doi: 10.3321/j.issn:1000-8993.2007.06.005WU Gang, WEI Yang, WU Zhishen, et al. Comparative study on seismic performance of rectangular concrete columns strengthened with BFRP and CFRP composites[J]. Industrial Construction,2007,37(6):14-18, 69(in Chinese). doi: 10.3321/j.issn:1000-8993.2007.06.005 [12] OUYANG L J, GAO W Y, ZHEN B, et al. Seismic retrofit of square reinforced concrete columns using basalt and carbon fiber-reinforced polymer sheets: A comparative study[J]. Composite Structures,2017,162:294-307. doi: 10.1016/j.compstruct.2016.12.016 [13] LI Y, XIE M F, LIU J B. Experimental study on the seismic behaviour of reinforced concrete bridge piers strengthened by BFRP sheets[J]. Advances in Civil Engi-neering,2019,2019:4169421. doi: 10.1155/2019/4169421 [14] JIANG S F, ZENG X G, SHEN S, et al. Experimental studies on the seismic behavior of earthquake-damaged bridge by using BFRP bars with external BFRP sheets jacketing[J]. Engineering Structures,2016,106:317-331. doi: 10.1016/j.engstruct.2015.10.037 [15] 邓宗才, 李建辉. 混杂FRP加固腐蚀混凝土柱恢复力模型研究[J]. 工程力学, 2011, 28(8):151-159.DENG Zongcai, LI Jianhui. Study on restoring force model of RC corroded columns strengthened with hybrid FRP[J]. Engineering Mechanics,2011,28(8):151-159(in Chinese). [16] 董振华, 杜修力, 韩强. FRP约束钢筋混凝土矩形空心桥墩的滞回模型[J]. 中国公路学报, 2015, 28(1):30-37. doi: 10.3969/j.issn.1001-7372.2015.01.005DONG Zhenhua, DU Xiuli, HAN Qiang. Hysteretic model of FRP confined RC bridge piers with rectangular hollow section[J]. China Journal of Highway and Transport,2015,28(1):30-37(in Chinese). doi: 10.3969/j.issn.1001-7372.2015.01.005 [17] 王代玉. FRP加固非延性钢筋混凝土框架结构抗震性能试验与分析[D]. 哈尔滨: 哈尔滨工业大学, 2012.WANG Daiyu. Experimental and analytical investigation of seismic performace of nonductile RC frames retrofitted with FRP[D]. Harbin: Harbin Institute of Technology, 2012(in Chinese). [18] 王庆利, 牛献军, 冯立明. 圆CFRP-钢管混凝土压弯构件滞回性能的参数分析与恢复力模型[J]. 工程力学, 2017, 34(S1):159-166.WANG Qingli, NIU Xianjun, FENG Liming. Parameyric analysis and restoring force model of hysteretic behavior of circular concrete filled CFRP-steel tubular beam-column[J]. Engineering Mechanics,2017,34(S1):159-166(in Chinese). [19] JIANG C, WU Y F, WU G. Plastic hinge length of FRP-confined square RC columns[J]. Journal of Composites for Construction,2014,18(4):04014003. doi: 10.1061/(ASCE)CC.1943-5614.0000463 [20] YOUSSF O, ELGAWADY M A, MILLS J E. Displacement and plastic hinge length of FRP-confined circular reinforced concrete columns[J]. Engineering Structure,2015,101:465-476. doi: 10.1016/j.engstruct.2015.07.026 [21] 中华人民共和国住房和城乡建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2016[S]. 北京: 中国建筑工业出版社, 2016.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of mechanical properties on ordinary concrete: GB/T 50081—2016[S]. Beijing: China Architecture and Building Press, 2016(in Chinese). [22] 中国国家标准化管理委员会. 金属材料室温拉伸试验方法: GB/T 228—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of the People’s Republic of China. Tensile test method for metallic material at room temperature: GB/T 228—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [23] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People’s Republic of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [24] 冯鹏, 强翰霖, 叶列平. 材料、构件、结构的“屈服点”定义与讨论[J]. 工程力学, 2017, 34(3):36-46. doi: 10.6052/j.issn.1000-4750.2016.03.0192FENG Peng, QIANG Hanlin, YE Lieping. Discussion and definition on yield points of materials, members and structures[J]. Engineering Mechanics,2017,34(3):36-46(in Chinese). doi: 10.6052/j.issn.1000-4750.2016.03.0192 [25] CLOUGH R W, PENZIEN J. Dynamics of structures[M]. New York: McGraw Hill Incorporation, 2003. [26] 中华人民共和国住房和城乡建设部. 建筑抗震试验规程: JGJ/T 101—2015[S]. 北京: 中国建筑工业出版社, 2015.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Specification for seismic test of buidings: JGJ/T 101—2015[S]. Beijing: China Architecture and Building Press, 2015(in Chinese). [27] TENG J G, JIANG T, LAM L, et al. Refinement of a design-oriented stress-strain model for FRP-confined concrete[J]. Journal of Composites for Construction,2009,13(4):269-278. doi: 10.1061/(ASCE)CC.1943-5614.0000012 [28] HUANG J T, LI T, ZHU D Y, et al. Compressive behavior of circular and square concrete column externally confined by different types of basalt fiber-reinforced polymer[J]. Advances in Structural Engineering,2020,23(8):1534-1547. doi: 10.1177/1369433219898086 [29] 过镇海, 时旭东. 钢筋混凝土原理与分析[M]. 北京: 清华大学出版社, 2003.GUO Zhenhai, SHI Xudong. Principle and analysis of reinforced concrete[M]. Beijing: Tsinghua University Press, 2003(in Chinese). [30] GU D S, WU Y F, WU G, et al. Plastic hinge analysis of FRP confined circular concrete columns[J]. Construction and Building Materials,2012,27(1):223-233. doi: 10.1016/j.conbuildmat.2011.07.056 [31] PAULAY T, PRIESTLEY M J N. Seismic design of reinforced concrete and masonry buildings[M]. New York: John Wiley & Sons Incorporation, 1992. -

下载:

下载: