Effect of carbide ceramic particles on the microstructure and mechanical properties of dual-phase high-entropy alloy matrix composites

-

摘要: 高熵合金拓宽了复合材料中金属基体的选用范围。本文通过外加碳化物陶瓷颗粒,利用电弧熔炼技术制备Fe49.5Mn30Co10Cr10X0.5 (X=B4C、ZrC和TiC)等3种高熵合金复合材料,系统研究3种碳化物陶瓷颗粒对双相高熵合金基复合材料微观组织和力学性能的影响。研究结果表明:掺杂碳化物陶瓷颗粒均可细化高熵合金基体的晶粒尺寸,稳定fcc相,抑制hcp相形成,其中B4C陶瓷颗粒细化晶粒和稳定fcc相效果最显著。掺杂ZrC和B4C陶瓷颗粒样品,力学性能低于高熵合金基体样品,归因于ZrC和B4C陶瓷颗粒与基体之间的界面结合情况不佳,界面处出现孔洞性缺陷;而掺杂TiC陶瓷颗粒样品,其强韧化效果显著,归因于良好的界面结合、细晶强化、弥散强化及颗粒承载强化等。Abstract: The emergence of new high-entropy alloys has broadened the selection range of metal matrix compo-sites. In this study, carbide ceramic particles doped in Fe49.5Mn30Co10Cr10X0.5 (X=B4C, ZrC and TiC) high-entropy alloy composites are prepared by using arc melting technology, and the effects of three carbide ceramic particles on the microstructure and mechanical properties of composite materials were systematically studied. The results show that the doped carbide ceramic particles can refine the matrix grains, stabilize the fcc phase, and inhibit the formation of the hcp phase. Among them, B4C ceramic particles have the most significant effect on refining grains and stabilizing fcc phase. The mechanical properties of the samples doped with ZrC and B4C ceramic particles are lower than the matrix samples, which is attributed to the poor bonding between the ceramic particles and the matrix, and the appearing void defects at the interface. But TiC doped sample, the strengthening and toughening effect is significant, which is attributed to good interface bonding, fine grain strengthening, Orowan strengthening, and load bearing strengthening.

-

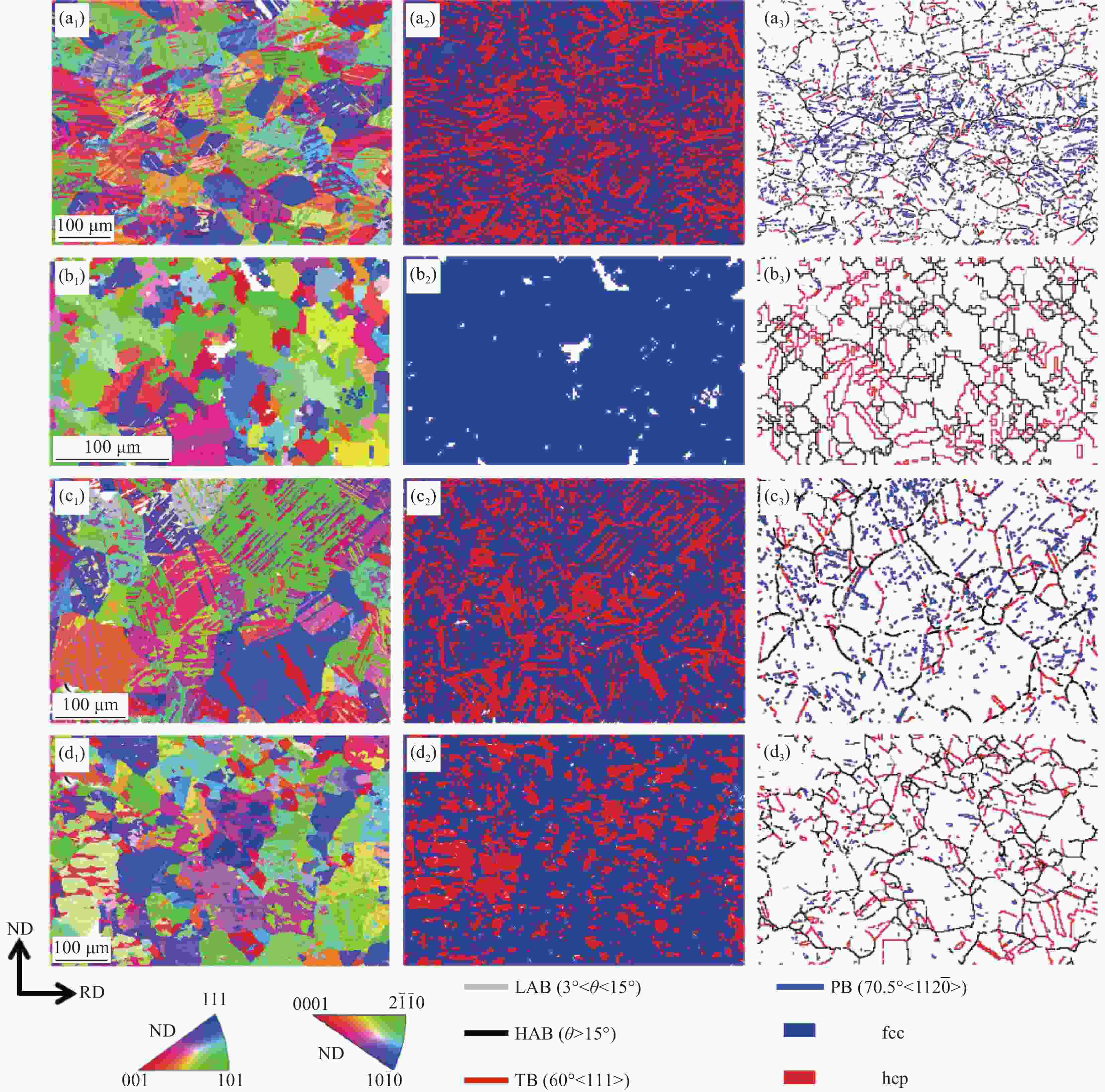

图 4 Fe50Mn30Co10Cr10、Fe50Mn30Co10Cr10(B4C)0.5、Fe50Mn30Co10Cr10(ZrC)0.5和Fe50Mn30Co10Cr10(TiC)0.5 4种均匀态样品的EBSD图:((a1)~(d1)) 反极图;((a2)~(d2)) 相图;((a3)~(d3)) 晶界图

ND—Normal direction; RD—Rolling direction; LAB—Low angle boundary; HAB—High angle boundary; θ—Misorientation angle; TB—Twin boundary; PB—Phase boundary; fcc—Face center cubic; hcp—Hexagonal close packed

Figure 4. EBSD maps of four homogeneous samples, including Fe50Mn30Co10Cr10, Fe50Mn30Co10Cr10(B4C)0.5, Fe50Mn30Co10Cr10(ZrC)0.5 and Fe50Mn30Co10Cr10(TiC)0.5: ((a1)-(d1)) Reverse pole figure; ((a2)-(d2)) Phase map; ((a3)-(d3)) Grain boundary map

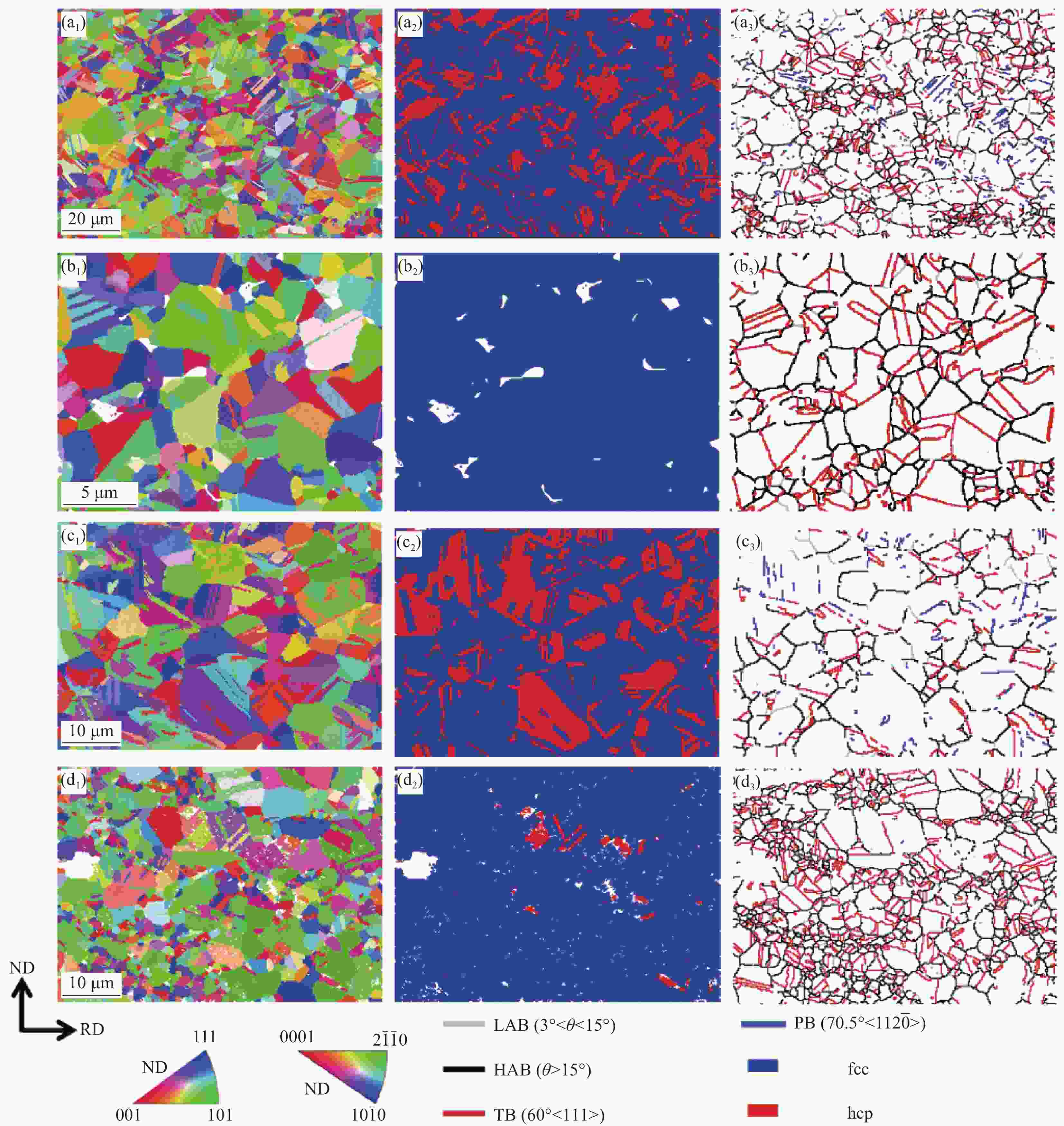

图 5 Fe50Mn30Co10Cr10、Fe50Mn30Co10Cr10(B4C)0.5、Fe50Mn30Co10Cr10(ZrC)0.5和Fe50Mn30Co10Cr10(TiC)0.5 4种再结晶态样品的EBSD图:((a1)~(d1))反极图;((a2)~(d2))相图;((a3)~(d3))晶界图

Figure 5. EBSD maps of four recrystallized samples, including Fe50Mn30Co10Cr10, Fe50Mn30Co10Cr10(B4C)0.5, Fe50Mn30Co10Cr10(ZrC)0.5 and Fe50Mn30Co10Cr10(TiC)0.5: ((a1)-(d1)) Reverse pole map; ((a2)-(d2)) Phase map; ((a3)-(d3)) Grain boundary map

图 6 再结晶态样品的ECC图:((a1), (a2)) Fe50Mn30Co10Cr10;((b1), (b2)) Fe50Mn30Co10Cr10(B4C)0.5;((c1), (c2)) Fe50Mn30Co10Cr10(ZrC)0.5;((d1), (d2)) Fe50Mn30Co10Cr10(TiC)0.5

Figure 6. ECC maps of recrystallized samples: ((a1), (a2)) Fe50Mn30Co10Cr10; ((b1), (b2)) Fe50Mn30Co10Cr10(B4C)0.5; ((c1), (c2)) Fe50Mn30Co10Cr10(ZrC)0.5; ((d1), (d2)) Fe50Mn30Co10Cr10(TiC)0.5

图 7 再结晶态Fe50Mn30Co10Cr10(B4C)0.5样品界面:((a), (b)) B4C陶瓷颗粒与Fe50Mn30Co10Cr10结合的界面 SEM 图像;((c), (d)) SEM-EDS元素线扫描和面扫描图

Figure 7. Interface images of as-recrystallized Fe50Mn30Co10Cr10(B4C)0.5: ((a), (b)) SEM images of the interface between B4C ceramic particles and Fe50Mn30Co10Cr10; ((c), (d)) SEM-EDS element line scan and surface scan images

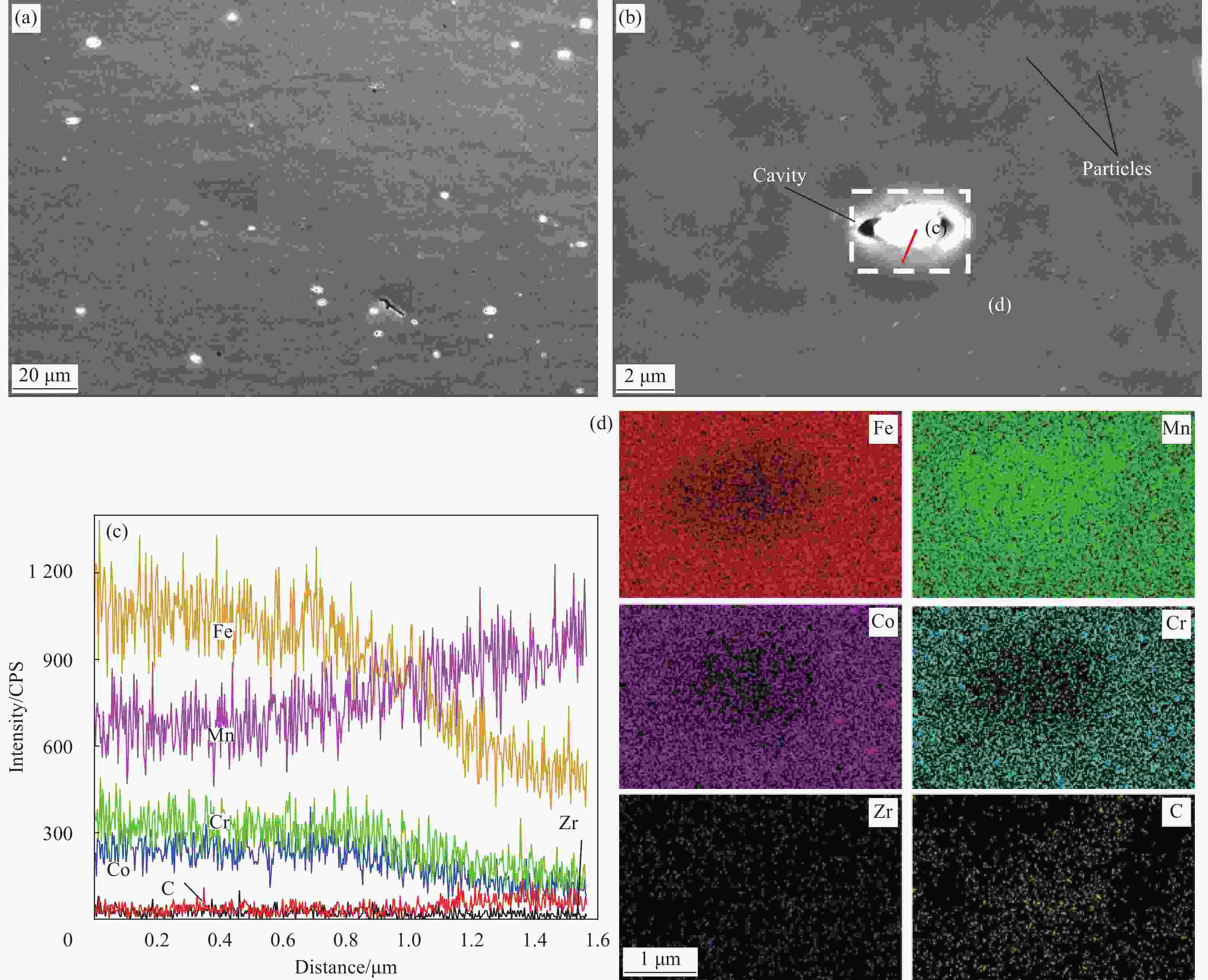

图 8 再结晶态Fe50Mn30Co10Cr10(ZrC)0.5样品界面:((a), (b)) ZrC陶瓷颗粒与Fe50Mn30Co10Cr10结合的界面 SEM 图像;((c), (d)) SEM-EDS元素线扫描和面扫描图

Figure 8. Interface images of as-recrystallized Fe50Mn30Co10Cr10(ZrC)0.5: ((a), (b)) SEM images of the interface between ZrC ceramic particles and Fe50Mn30Co10Cr10; ((c), (d)) SEM-EDS element line scan and surface scan images

图 9 再结晶态Fe50Mn30Co10Cr10(TiC)0.5样品界面:((a), (b)) TiC陶瓷颗粒与Fe50Mn30Co10Cr10结合的界面SEM图像;((c), (d)) SEM-EDS元素线扫描和面扫描图

Figure 9. Interface images of as-recrystallized Fe50Mn30Co10Cr10(TiC)0.5: ((a), (b)) SEM images of the interface between TiC ceramic particles and Fe50Mn30Co10Cr10; ((c), (d)) SEM-EDS element line scan and surface scan images

图 10 (a)工程应力-应变曲线[28];(b)加工硬化曲线;样品的断口形貌:(c) Fe50Mn30Co10Cr10;(d) Fe50Mn30Co10Cr10(B4C)0.5;(e) Fe50Mn30Co10Cr10(ZrC)0.5;(f) Fe50Mn30Co10Cr10(TiC)0.5

Figure 10. (a) Engineering stress-strain curves[28]; (b) Work hardening curves; Fracture morphologies of the samples: (c) Fe50Mn30Co10Cr10; (d) Fe50Mn30Co10Cr10(B4C)0.5; (e) Fe50Mn30Co10Cr10(ZrC)0.5; (f) Fe50Mn30Co10Cr10(TiC)0.5

表 1 粉末的基本参数

Table 1. Basic parameters of powder

Powder Particle size/μm Purity/wt% Fe 0.5 99.9 Mn 0.5 99.9 Co 0.5 99.9 Cr 0.5 99.9 B4C 0.04 99.9 ZrC 0.04 99.9 TiC 0.04 99.9 表 2 Fe50Mn30Co10Cr10、Fe50Mn30Co10Cr10(B4C)0.5、Fe50Mn30Co10Cr10(ZrC)0.5和Fe50Mn30Co10Cr10(TiC)0.54种再结晶态样品的力学性能

Table 2. Mechanical properties of four recrystallized samples of Fe50Mn30Co10Cr10, Fe50Mn30Co10Cr10(B4C)0.5, Fe50Mn30Co10Cr10(ZrC)0.5 and Fe50Mn30Co10Cr10(TiC)0.5

Sample Yield stress/MPa Ultimate tensile strength/MPa Fracture elongation/% Fe50Mn30Co10Cr10 206 747 44 Fe50Mn30Co10Cr10(B4C)0.5 441 837 22 Fe50Mn30Co10Cr10(ZrC)0.5 169 473 19 Fe50Mn30Co10Cr10(TiC)0.5 386 886 47 -

[1] FANG Y, WANG Y Q, ZHANG P, et al. Research on chip formation mechanism and surface morphology of particle-reinforced metal matrix composites[J]. The International Journal of Advanced Manufacturing Technology,2021,117:3793-3804. doi: 10.1007/s00170-021-07921-7 [2] SHUVHO M B A, CHOWDHURY M A, KCHAOU M, et al. Surface characterization and mechanical behavior of aluminum based metal matrix composite reinforced with nano Al2O3, SiC, TiO2 particles[J]. Chemical Data Collections,2020,28:100442. doi: 10.1016/j.cdc.2020.100442 [3] PARIYAR A, PERUGU C S, DASH K, et al. Microstructure and mechanical behavior of high toughness Al-based metal matrix composite reinforced with in-situ formed nickel aluminides[J]. Materials Characterization,2021,171:110766. doi: 10.1016/j.matchar.2020.110766 [4] 徐圣航, 周承商, 刘咏. 金属-金属层状结构复合材料研究进展[J]. 中国有色金属学报, 2019, 29(6):1125-1142. doi: 10.19476/j.ysxb.1004.0609.2019.06.01XU Shenghang, ZHOU Chengshang, LIU Yong. Research progress in metal-metal laminated structural composites[J]. Transactions of Nonferrous Metals Society of China,2019,29(6):1125-1142(in Chinese). doi: 10.19476/j.ysxb.1004.0609.2019.06.01 [5] 康蒙, 程小全, 张纪奎, 等. 高体积分数SiCP/Al复合材料的拉伸、压缩与弯曲特性[J]. 复合材料学报, 2008, 25(3):127-131. doi: 10.3321/j.issn:1000-3851.2008.03.022KANG Meng, CHENG Xiaoquan, ZHANG Jikui, et al. Tensile compressive and flexible properties of high volume fraction SiCP/Al composites[J]. Acta Materiae Compositae Sinica,2008,25(3):127-131(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.03.022 [6] 倪嘉, 柴皓, 史昆, 等. 颗粒增强钛基复合材料的研究进展[J]. 材料导报, 2019, 33(S2):369-373.NI Jia, CHAI Hao, SHI Kun, et al. Research progress of titanium matrix composites reinforced by particle[J]. Materials Reports,2019,33(S2):369-373(in Chinese). [7] 袁秋红, 周国华, 廖琳, 等. 不同纳米碳材料增强镁基复合材料的显微组织与力学性能[J]. 中国有色金属学报, 2021, 31(1):30-41. doi: 10.11817/j.ysxb.1004.0609.2021-36552YUAN Qiuhong, ZHOU Guohua, LIAO Lin, et al. Microstructures and mechanical properties of Mg-based composites reinforced with different nano-carbon materials[J]. Transactions of Nonferrous Metals Society of China,2021,31(1):30-41(in Chinese). doi: 10.11817/j.ysxb.1004.0609.2021-36552 [8] 曹利, 王传英, 邵贝羚, 等. SiCp/Al 复合材料的组织与断口分析[J]. 复合材料学报, 1992, 9(3):19-22.CAO Li, WANG Chuanying, SHAO Beiling, et al. Analysis of microstructure and fracture in SiCP/Al composites[J]. Acta Materiae Compositae Sinica,1992,9(3):19-22(in Chinese). [9] 顾冬冬, 沈以赴. 颗粒增强铜基复合材料的选区激光烧结制备[J]. 复合材料学报, 2007, 24(1):53-59. doi: 10.3321/j.issn:1000-3851.2007.01.009GU Dongdong, SHEN Yifu. Fabrication of particle reinforced copper matrix composites by selective laser sintering[J]. Acta Materiae Compositae Sinica,2007,24(1):53-59(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.009 [10] YE Y F, WANG Q, LU J, et al. High-entropy alloy: Challenges and prospects[J]. Materials Today,2016,19(6):349-362. doi: 10.1016/j.mattod.2015.11.026 [11] MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts[J]. Acta Materialia,2017,122:448-511. [12] GLUDOVATZ B, HOHENWARTER A, CATOOR D, et al. A fracture-resistant high-entropy alloy for cryogenic applications[J]. Science,2014,345(6201):1153-1158. doi: 10.1126/science.1254581 [13] SU J, RAABE D, LI Z. Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy[J]. Acta Materialia,2019,163:40-54. [14] 马国彬, 谭建波. 颗粒增强金属基复合材料的研究现状[J]. 铸造设备与工艺, 2019(2):50-54. doi: 10.16666/j.cnki.issn1004-6178.2019.02.016MA Guobing, TAN Jianbo. Research status of particle reinforced metal matrix composites[J]. Foundry Equipment and Technology,2019(2):50-54(in Chinese). doi: 10.16666/j.cnki.issn1004-6178.2019.02.016 [15] 张洁, 程晓农, 罗锐, 等. 碳化硼对高熵合金结构及性能的影响[J]. 金属热处理, 2020, 45(6):173-177. doi: 10.13251/j.issn.0254-6051.2020.06.036ZHANG Jie, CHENG Xiaonong, LUO Rui, et al. Effect of B4C on microstructure and properties of high-entropy alloy[J]. Heat Treatment of Metal,2020,45(6):173-177(in Chinese). doi: 10.13251/j.issn.0254-6051.2020.06.036 [16] ROGAL Ł, KALITA D, LITYNSKA-DOBRZYNSKA L. CoCrFeMnNi high entropy alloy matrix nanocomposite with addition of Al2O3[J]. Intermetallics,2017,86:104-109. doi: 10.1016/j.intermet.2017.03.019 [17] ROGAL Ł, KALITA D, TARASEK A, et al. Effect of SiC nano-particles on microstructure and mechanical properties of the CoCrFeMnNi high entropy alloy[J]. Journal of Alloys and Compounds,2017,708:344-352. doi: 10.1016/j.jallcom.2017.02.274 [18] 高银, 刘涛, 韩勇, 等. TiC对 W-7 Cu 复合材料组织与性能的影响[J]. 中国有色金属学报, 2020, 30(6):1281-1288. doi: 10.11817/j.ysxb.1004.0609.2020-36394GAO Yin, LIU Tao, HAN Yong, et al. The impact of TiC on microstructure and properties of W-7 Cu composites[J]. Transactions of Nonferrous Metals Society of China,2020,30(6):1281-1288(in Chinese). doi: 10.11817/j.ysxb.1004.0609.2020-36394 [19] WU H, HUANG S R, ZHAO C M, et al. Microstructures and mechanical properties of in-situ FeCrNiCu high entropy alloy matrix composites reinforced with NbC particles[J]. Intermetallics,2020,127:106983. doi: 10.1016/j.intermet.2020.106983 [20] PENG Y, ZHANG W, LI T, et al. Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding[J]. Surface and Coatings Technology,2020,385:125326. doi: 10.1016/j.surfcoat.2019.125326 [21] ZHANG J F, JIA T, QIU H, et al. Effect of cooling rate upon the microstructure and mechanical properties of in-situ TiC reinforced high entropy alloy CoCrFeNi[J]. Journal of Materials Science & Technology,2020,42:122-129. [22] 权高峰, 柴东朗, 宋余九, 等. 增强体种类及含量对金属基复合材料力学性能的影响[J]. 复合材料学报, 1999, 16(2):62-66. doi: 10.3321/j.issn:1000-3851.1999.02.012QUAN Gaofeng, CHAI Donglang, SONG Yujiu, et al. Effect of category and content of reinforcements on mechanical properties of metal matrix composites[J]. Acta Materiae Compositae Sinica,1999,16(2):62-66(in Chinese). doi: 10.3321/j.issn:1000-3851.1999.02.012 [23] 刘怡, 涂坚, 杨威华, 等. 形变及退火工艺对 Fe47Mn30Co10Cr10B3双相高熵合金组织演变的影响[J]. 金属学报, 2020, 56(12):1569-1580.LIU Yi, TU Jian, YANG Weihua, et al. Effect of deformation and annealing treatment on microstructure evolution of Fe47Mn30Co10Cr10B3 dual-phase high-entropy alloy[J]. Acta Metallurgica Sinica,2020,56(12):1569-1580(in Chinese). [24] LIU Y, TU J, DENG L, et al. Characteristics of thermal- and strain-induced ε-martensite in Fe50Mn30Co10Cr10 multi-component alloy: Effect of grain size[J]. Materials Characterization,2021,171:110817. doi: 10.1016/j.matchar.2020.110817 [25] WANG J Y, FANG J H, YANG H L, et al. Mechanical properties and wear resistance of medium entropy Fe40Mn40Cr10Co10/TiC composites[J]. Transactions of Nonferrous Metals Society of China,2019,29(7):1484-1494. doi: 10.1016/S1003-6326(19)65055-7 [26] ZHANG M, LI R D, YUAN T C, et al. Densification and pro-perties of B4C-based ceramics with CrMnFeCoNi high entropy alloy as a sintering aid by spark plasma sintering[J]. Powder Technology,2019,343:58-67. doi: 10.1016/j.powtec.2018.11.005 [27] YIM D, SATHIYAMOORTHI P, HONG S J, et al. Fabrication and mechanical properties of TiC reinforced CoCrFeMnNi high-entropy alloy composite by water atomization and spark plasma sintering[J]. Journal of Alloys and Compounds,2019,781:389-396. doi: 10.1016/j.jallcom.2018.12.119 [28] DENG L, BAI C Y, JIANG Z T, et al. Effect of B4C particles addition on microstructure and mechanical properties of Fe50Mn30Co10Cr10 high-entropy alloy[J]. Materials Science and Engineering: A,2021,822:141642. doi: 10.1016/j.msea.2021.141642 [29] YUE X Y, WANG J J, YU S Y, et al. Microstructure and mechanical properties of a three-layer B4C/Al-B4C/TiB2-B4C composite[J]. Materials & Design,2013,46:285-290. [30] WEI X F, SONG J X, LIU J X, et al. Graphite nanoplatelets toughened zirconium carbide ceramics prepared by spark plasma sintering[J]. Ceramics International,2021,47(6):8461-8467. doi: 10.1016/j.ceramint.2020.11.212 [31] YANG M X, YAN D S, YUAN F P, et al. Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength[J]. Proceedings of the National Academy of Sciences,2018,115(28):7224-7229. doi: 10.1073/pnas.1807817115 [32] FU Z Q, MACDONALD B E, LI Z M, et al. Engineering heterostructured grains to enhance strength in a single-phase high-entropy alloy with maintained ductility[J]. Materials Research Letters,2018,6(11):634-640. doi: 10.1080/21663831.2018.1526222 [33] SUN X D, ZHU H G, LI J L, et al. High entropy alloy FeCoNiCu matrix composites reinforced with in-situ TiC particles and graphite whiskers[J]. Materials Chemistry and Physics,2018,220:449-459. doi: 10.1016/j.matchemphys.2018.09.022 [34] CHENG H, CHEN W, LIU X Q, et al. Effect of Ti and C additions on the microstructure and mechanical properties of the FeCoCrNiMn high-entropy alloy[J]. Materials Science and Engineering: A,2018,719:192-198. doi: 10.1016/j.msea.2018.02.040 [35] LI C, ZHANG F Y, HE J N, et al. Microstructure evolution and mechanical properties of reactive plasma sprayed Ti3SiC2-Ti5Si3-TiC composite coatings[J]. Materials Chemistry and Physics,2020,254:123495. doi: 10.1016/j.matchemphys.2020.123495 [36] ZHU T, WU H, ZHOU R, et al. Microstructures and tribological properties of TiC reinforced FeCoNiCuAl high-entropy alloy at normal and elevated temperature[J]. Metals,2020,10(3):387-401. doi: 10.3390/met10030387 [37] 张堃, 吴姚莎, 刘晓飞, 等. TiB2/AlSi10 Mg 选区激光熔化成形组织与性能[J]. 有色金属工程, 2021, 11(12):43-49. doi: 10.3969/j.issn.2095-1744.2021.12.007ZHANG Kun, WU Yaosha, LIU Xiaofei, et al. Microstructure and properties of TiB2/AlSi10 Mg composite prepared by selective laser melting[J]. Nonferrous Metals Engineering,2021,11(12):43-49(in Chinese). doi: 10.3969/j.issn.2095-1744.2021.12.007 [38] LI G D, LIU M W, LYU S, et al. Simultaneously enhanced strength and strain hardening capacity in FeMnCoCr high-entropy alloy via harmonic structure design[J]. Scripta Materialia,2021,191:196-201. -

下载:

下载: