Nonlinear regression models of compressive performance and pore structure of rubber aggregate alkaline mortar

-

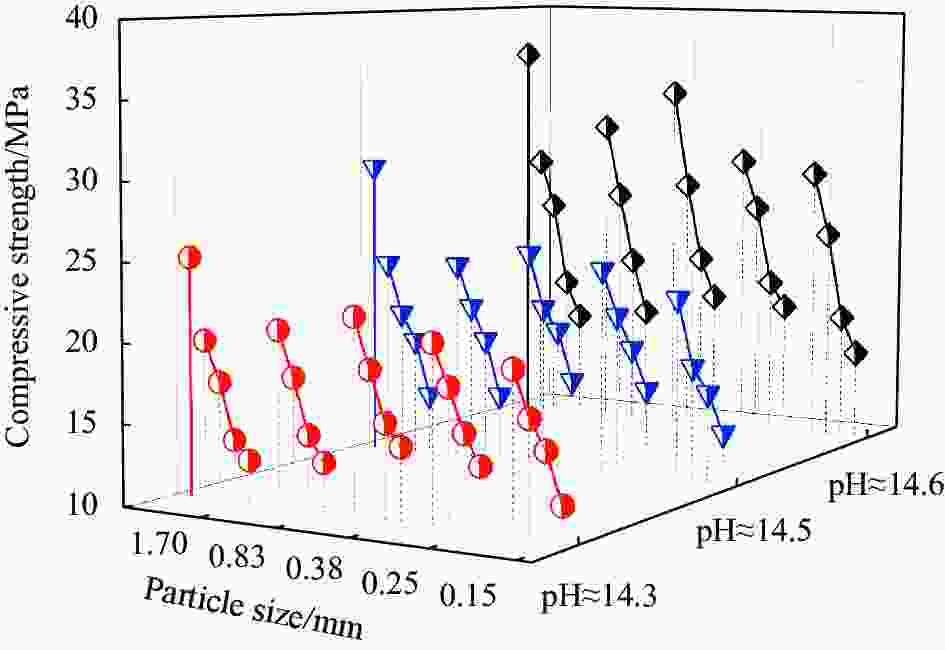

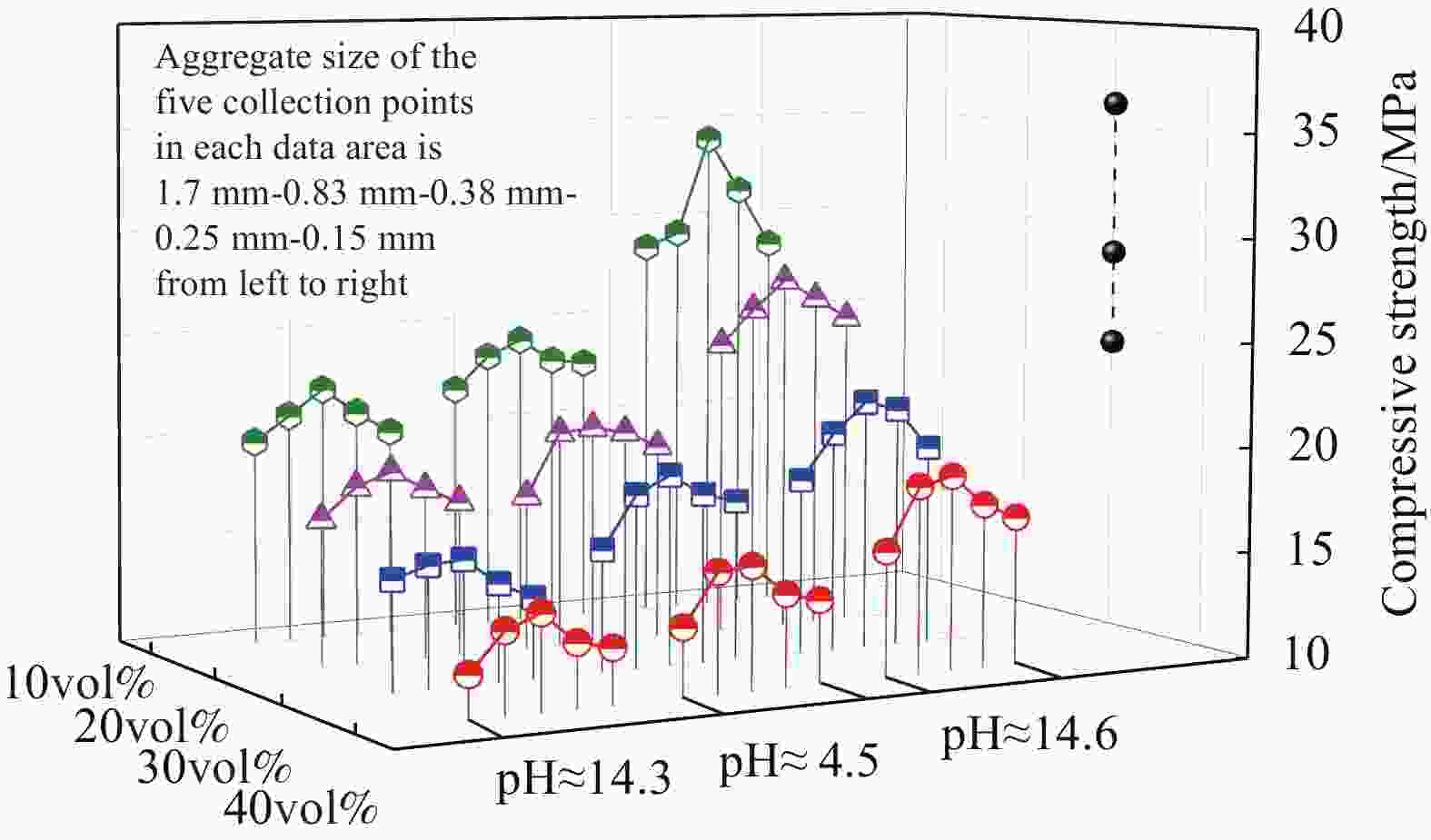

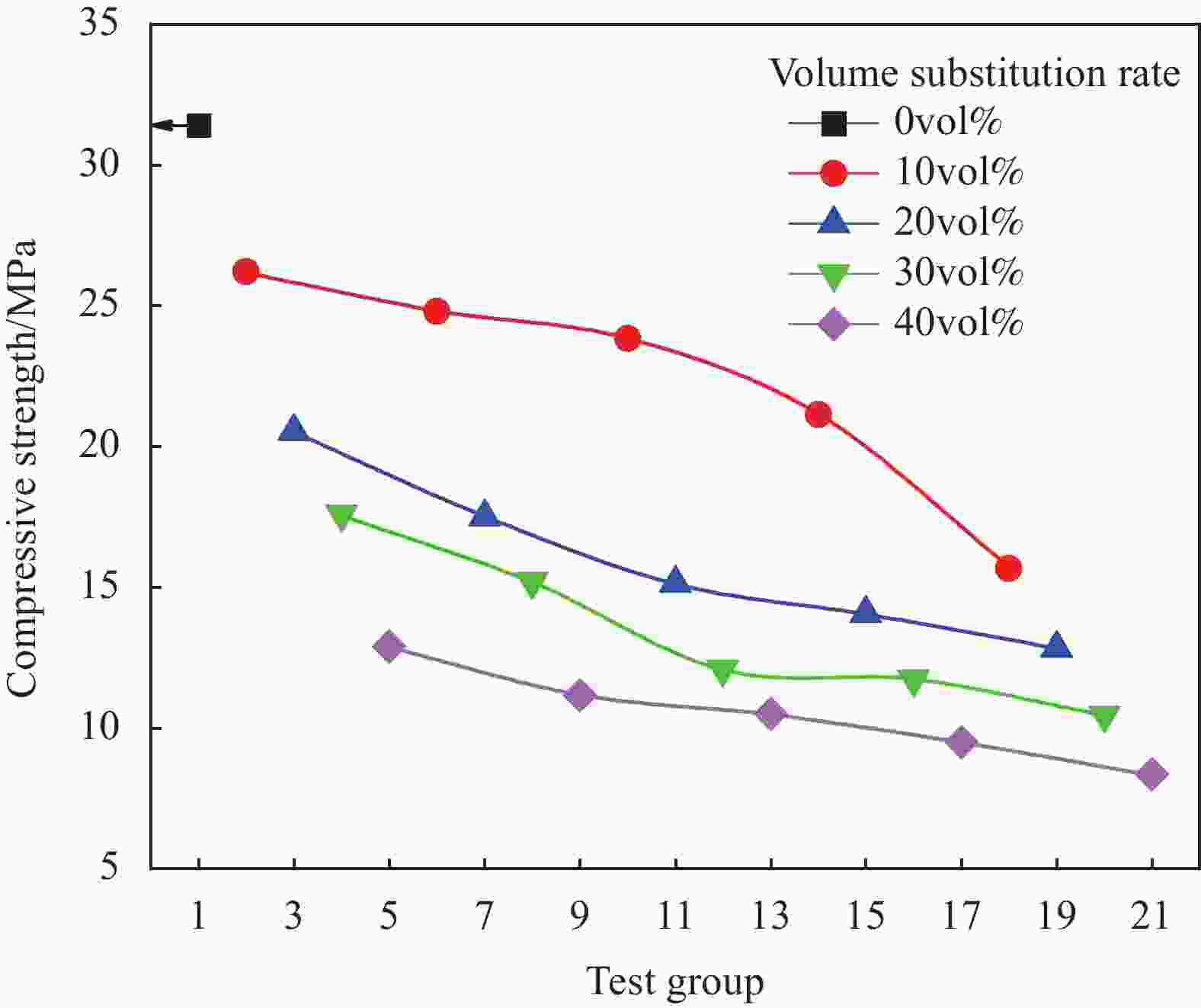

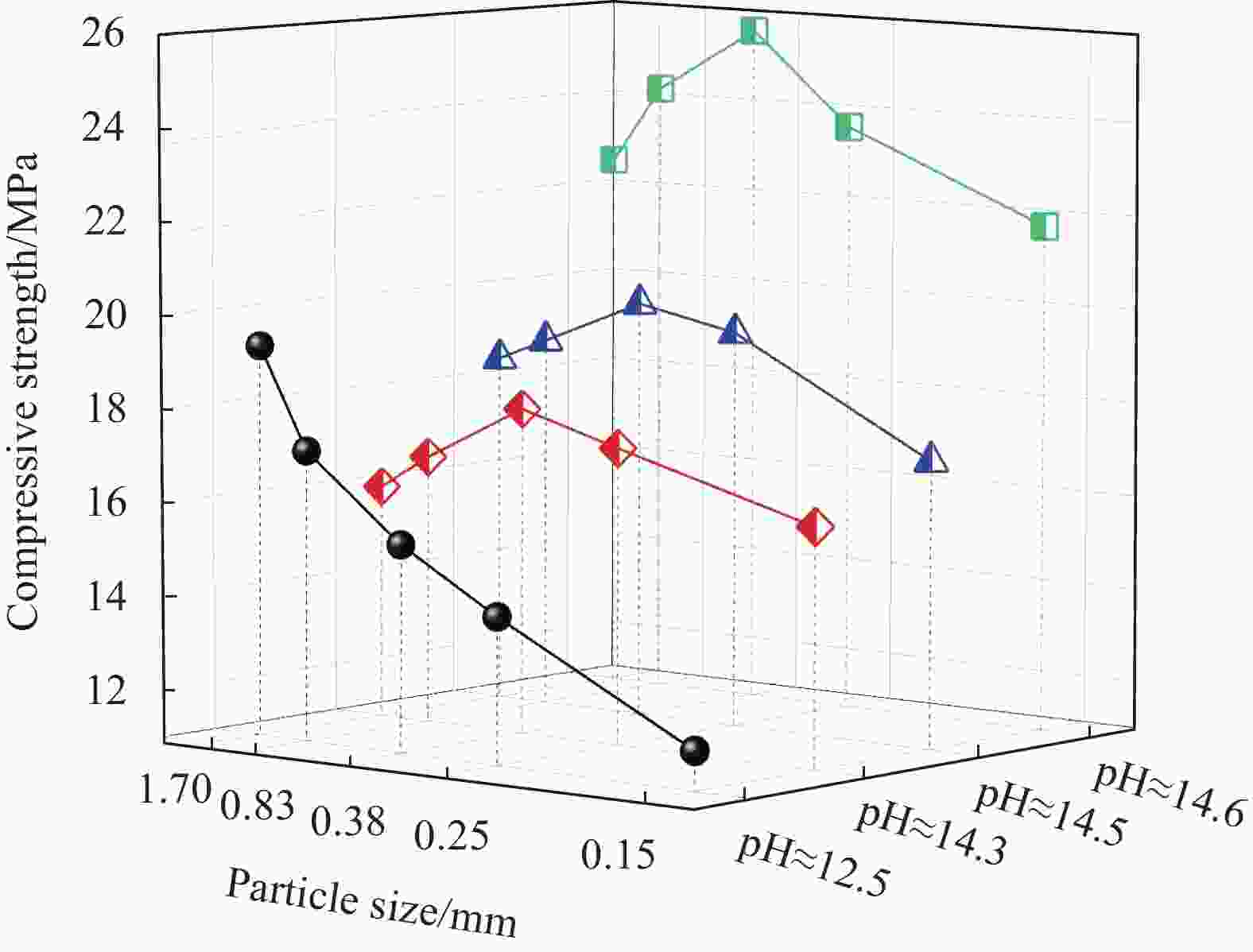

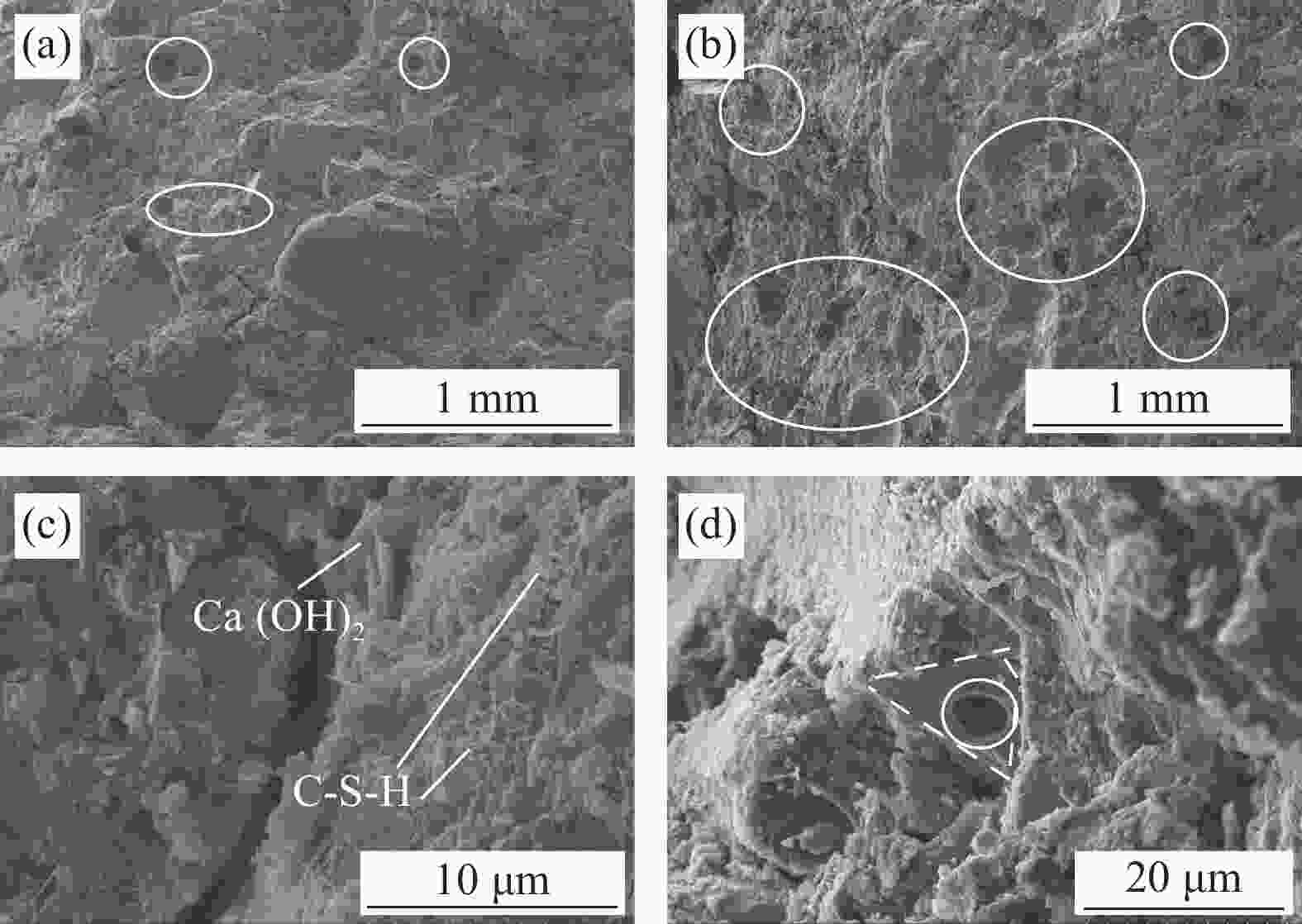

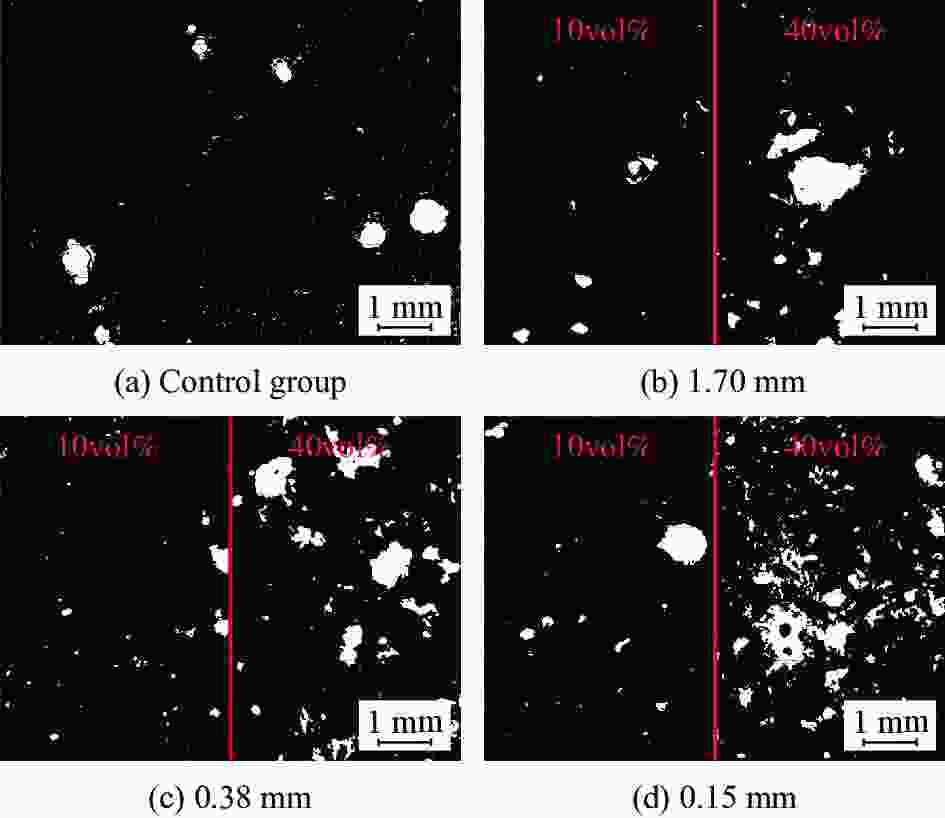

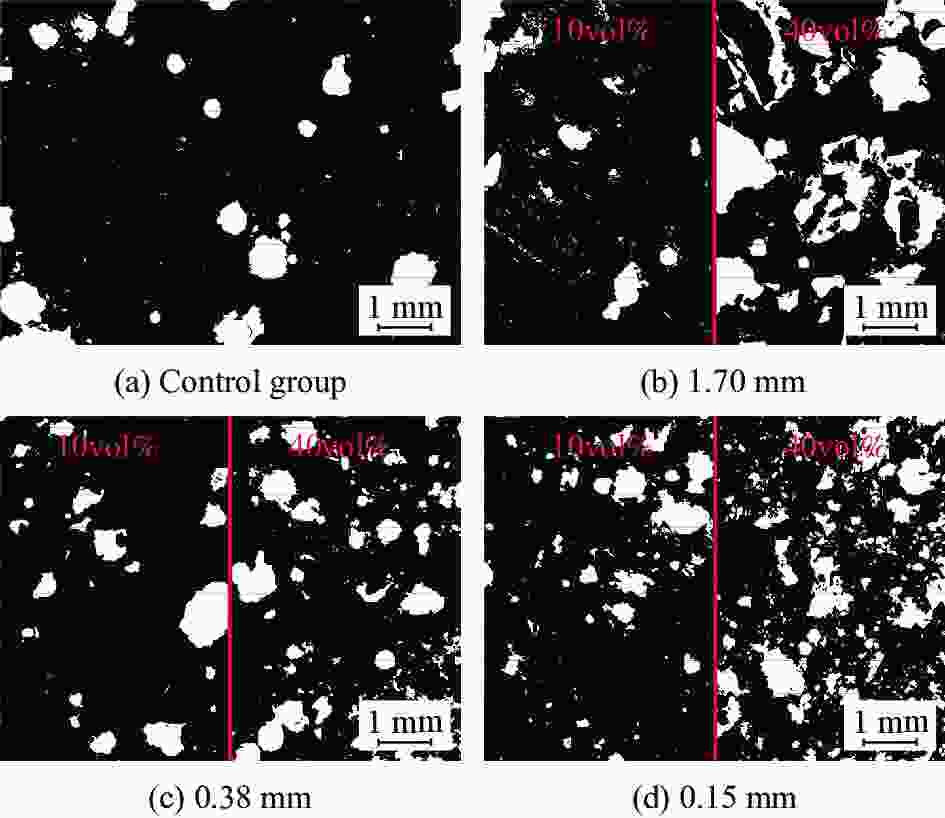

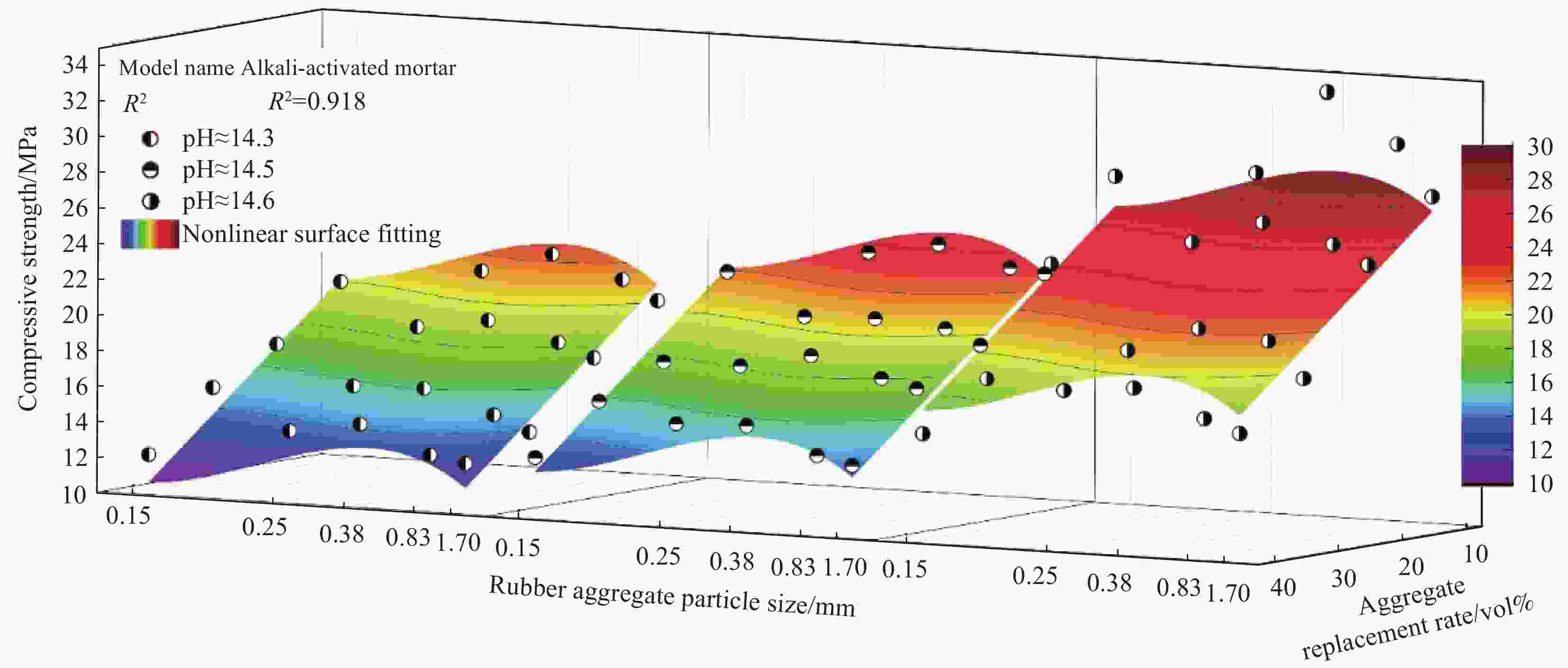

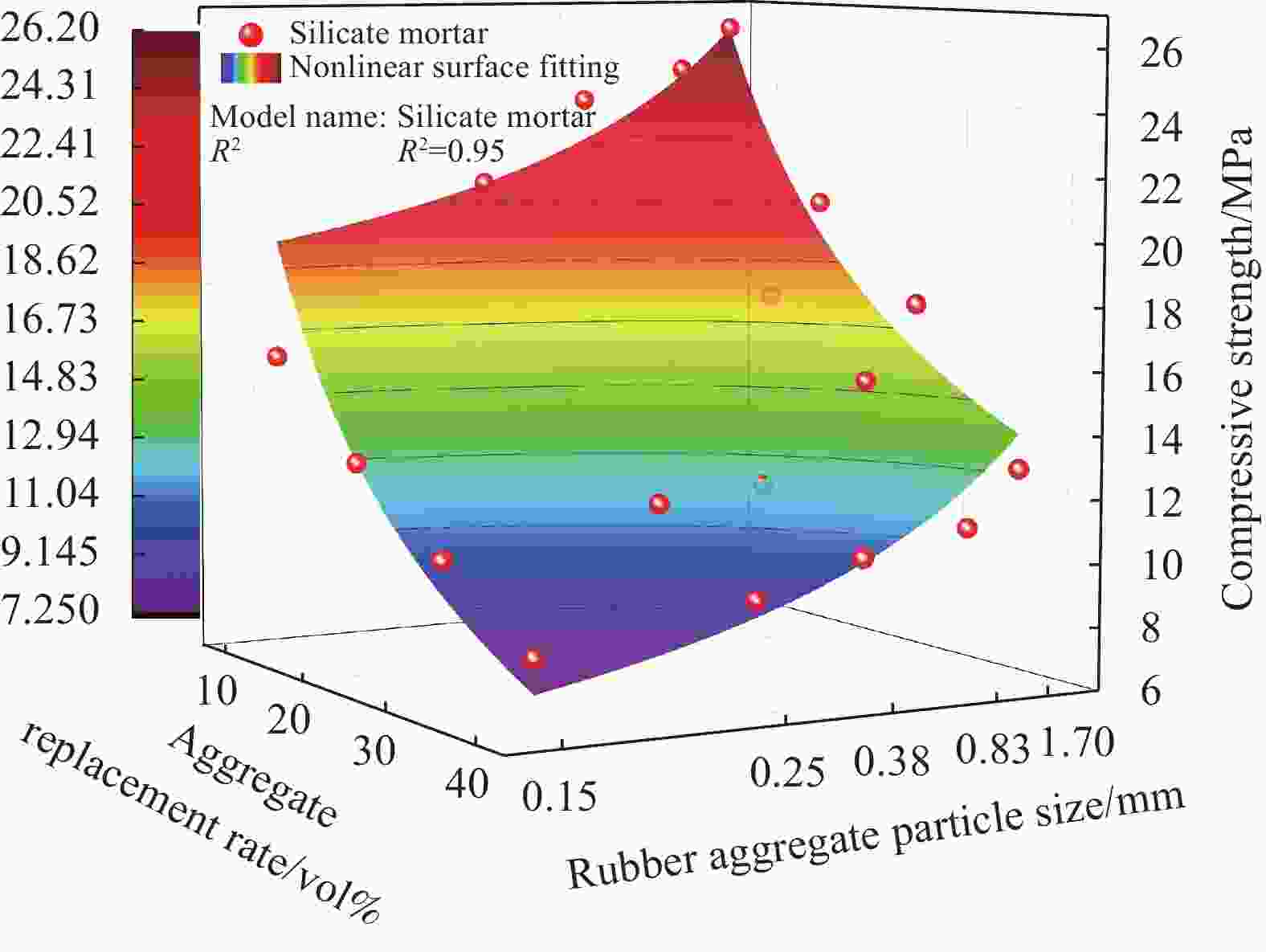

摘要: 废旧轮胎的弃置会导致诸多环境问题,而粉碎制得的橡胶粉可在建筑砂浆中替代细骨料。砂浆中橡胶骨料的掺量和粒径是橡胶混凝土强度的主要影响因素,利用碱激发矿渣材料可替代普通硅酸盐水泥,提升砂浆的环境友好性。研究多因素耦合作用对橡胶骨料砂浆抗压性能的影响,通过测试砂浆的抗压强度,对试验结果进行显著性分析及多元非线性回归,建立了多因素与砂浆抗压强度的多元非线性回归模型。对砂浆试样进行细观孔隙测量和SEM表征,探究橡胶骨料对砂浆抗压强度的劣化机制。结果表明:砂浆中橡胶骨料掺量的提升会造成砂浆抗压强度的下降,40vol%骨料替代率下碱激发类砂浆抗压强度均值相比对照组降低了49.93%,硅酸盐类降低了66.62%;在碱激发类砂浆的高碱性环境下,使用0.38 mm粒径橡胶骨料的砂浆抗压强度均值为对照组的69.65%,取得试验组中最优值;而在硅酸盐类砂浆的低碱性环境中,随着橡胶骨料粒径的减小,砂浆抗压强度均值由对照组的61.46%降至37.98%。Abstract: The disposal of used tires causes many environmental problems, and the crushed rubber powder can replace fine aggregate in building mortar. The content and particle size of rubber aggregate in mortar are the main factors affecting the strength of rubber concrete. Alkali-activated slag can replace ordinary Portland cement and improve the environmental friendliness of mortar. The influence of multi-factor coupling on the compressive properties of rubber aggregate mortar was studied. By testing the compressive strength of mortar, significance analysis of the test results was completed and the multivariate nonlinear regression model was established. The microscopic pore measurement and SEM test of mortar samples were carried out to explore the degradation mechanism of rubber aggregate on the compressive strength of mortar. The results show that the increase of rubber aggregate content in mortar will cause the decrease of compressive strength of mortar. Compared with the control group, the average compressive strength of alkali activated mortar decreases by 49.93% and the silicate mortar decreases by 66.62% under 40vol% aggregate replacement rate. Under the high alkaline environment of alkali-activated mortar, the average compressive strength of mortar using 0.38 mm rubber aggregate is 69.65% of the control group, which is the optimal value in the test group. In the low alkaline environment of silicate mortar, with the decrease of rubber aggregate size, the average compressive strength of mortar decreased from 61.46% of the control group to 37.98%.

-

表 1 高炉矿渣主要氧化物成分

Table 1. Main oxide components of blast furnace slag

Oxide component CaO SiO2 Al2O3 MgO SO3 TiO2 Fe2O3 Content/wt% 49.51 25.61 13.23 5.51 2.34 2.131 0.421 表 2 碱激发类砂浆变量名称分类

Table 2. Designation and classification of alkali-activated mortar group's variables

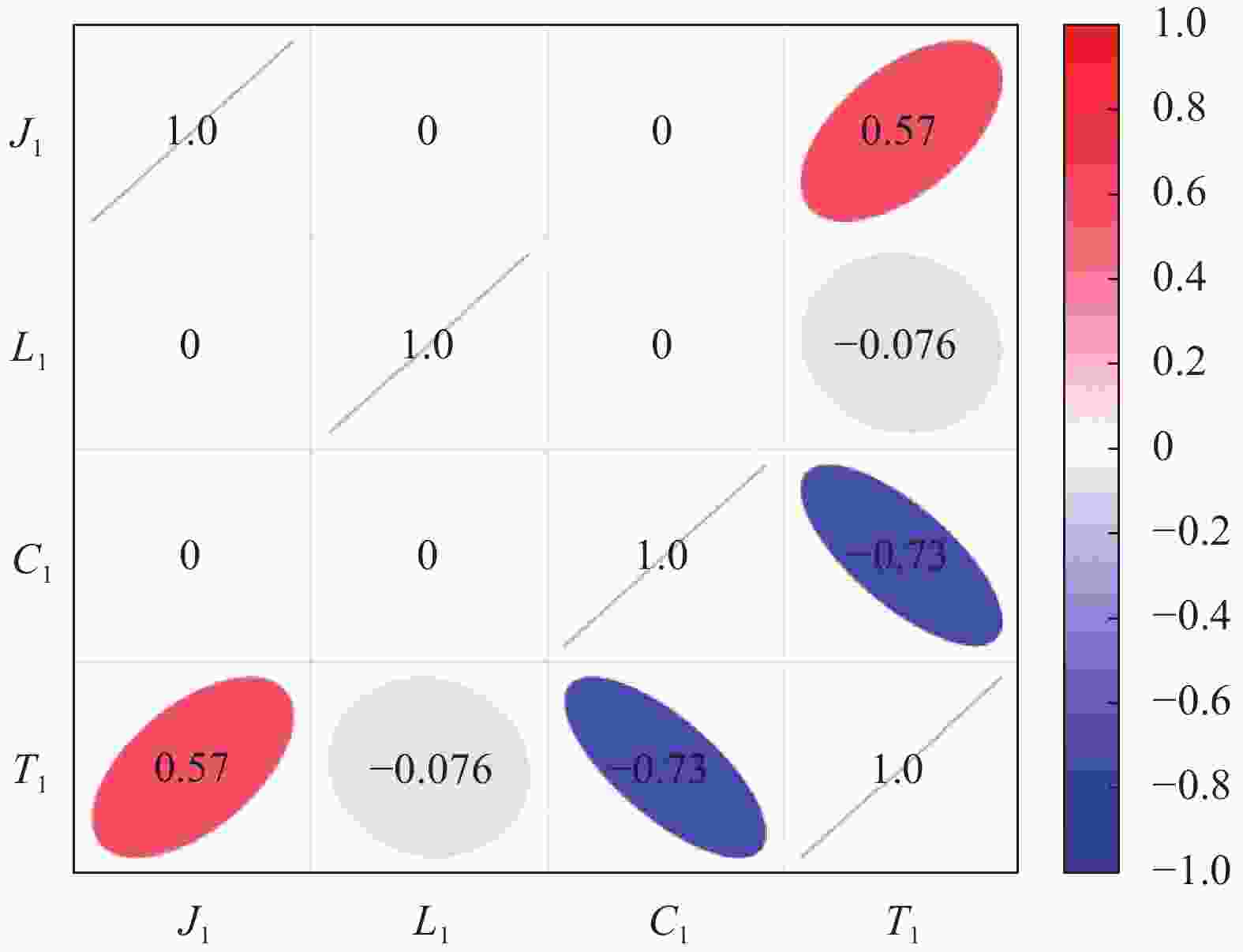

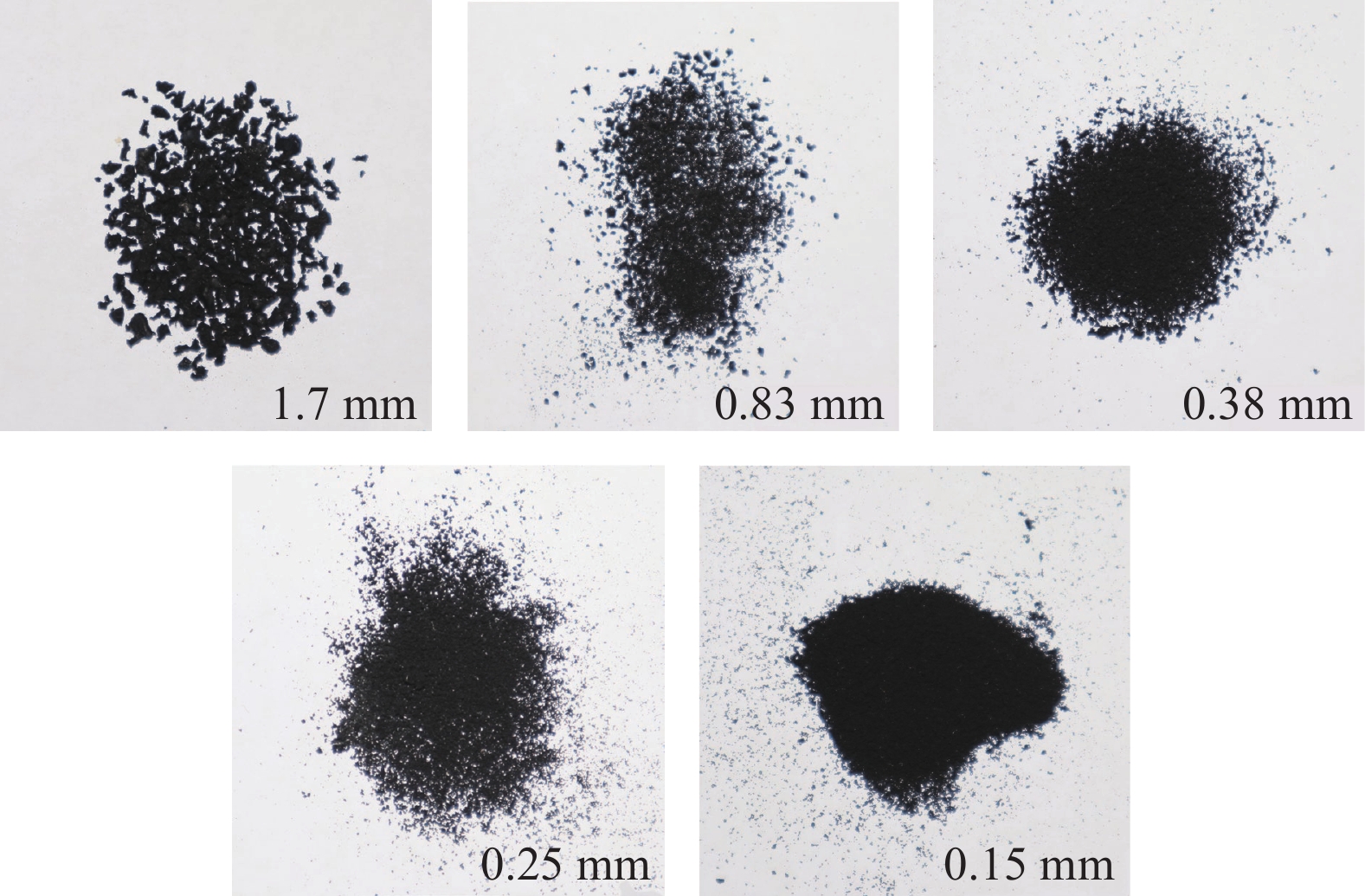

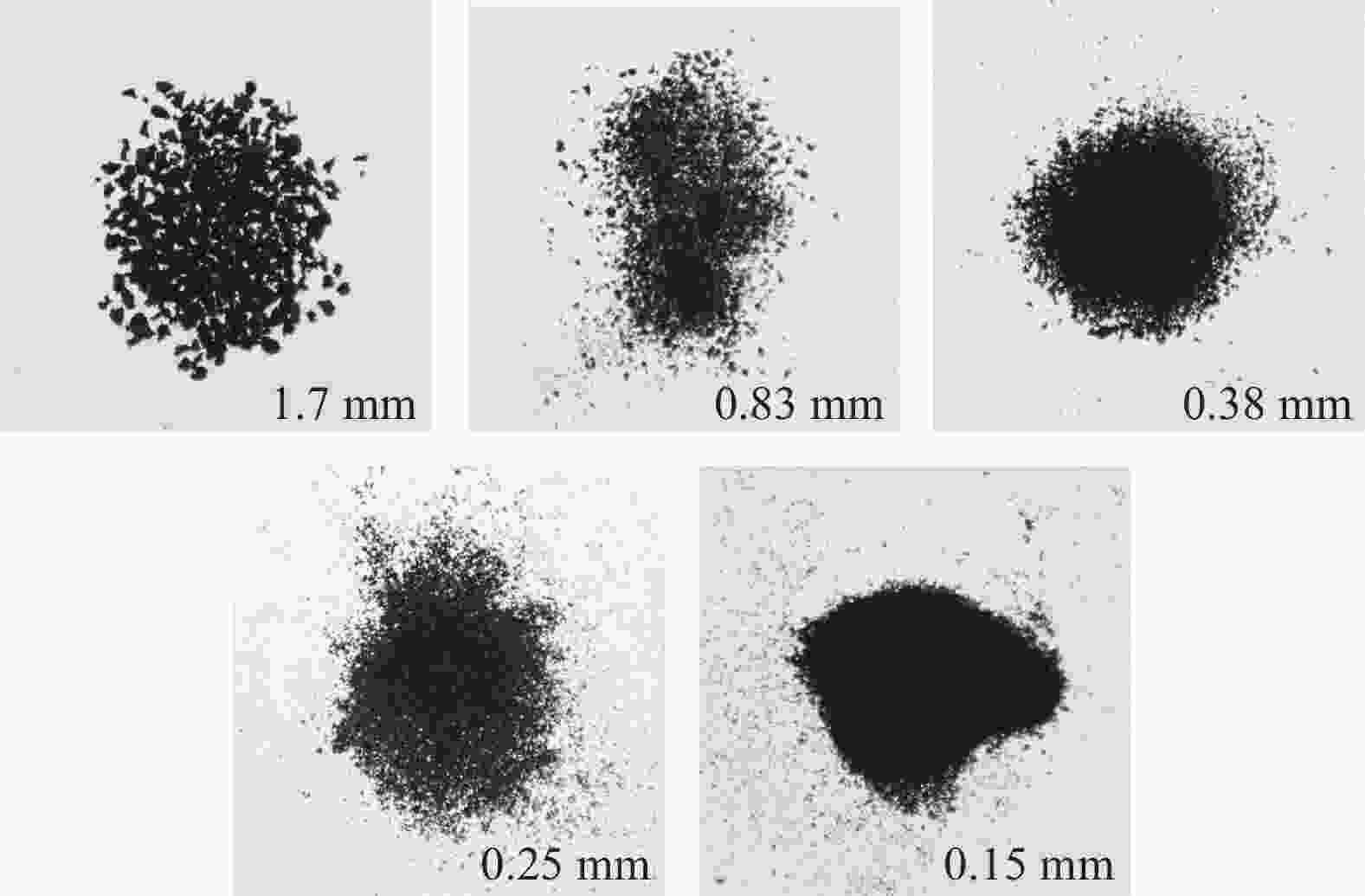

Factor Symbol of variable Level Designation pH value of sodium

hydroxide solutionJ1 1 pH≈14.3 2 pH≈14.5 3 pH≈14.6 Volume substitution

rate of rubber aggregateC1 1 10vol% 2 20vol% 3 30vol% 4 40vol% Particle size of

rubber aggregateL1 1 1.70 mm 2 0.83 mm 3 0.38 mm 4 0.25 mm 5 0.15 mm 表 3 硅酸盐类砂浆变量名称分类

Table 3. Designation and classification of silicate mortar group's variables

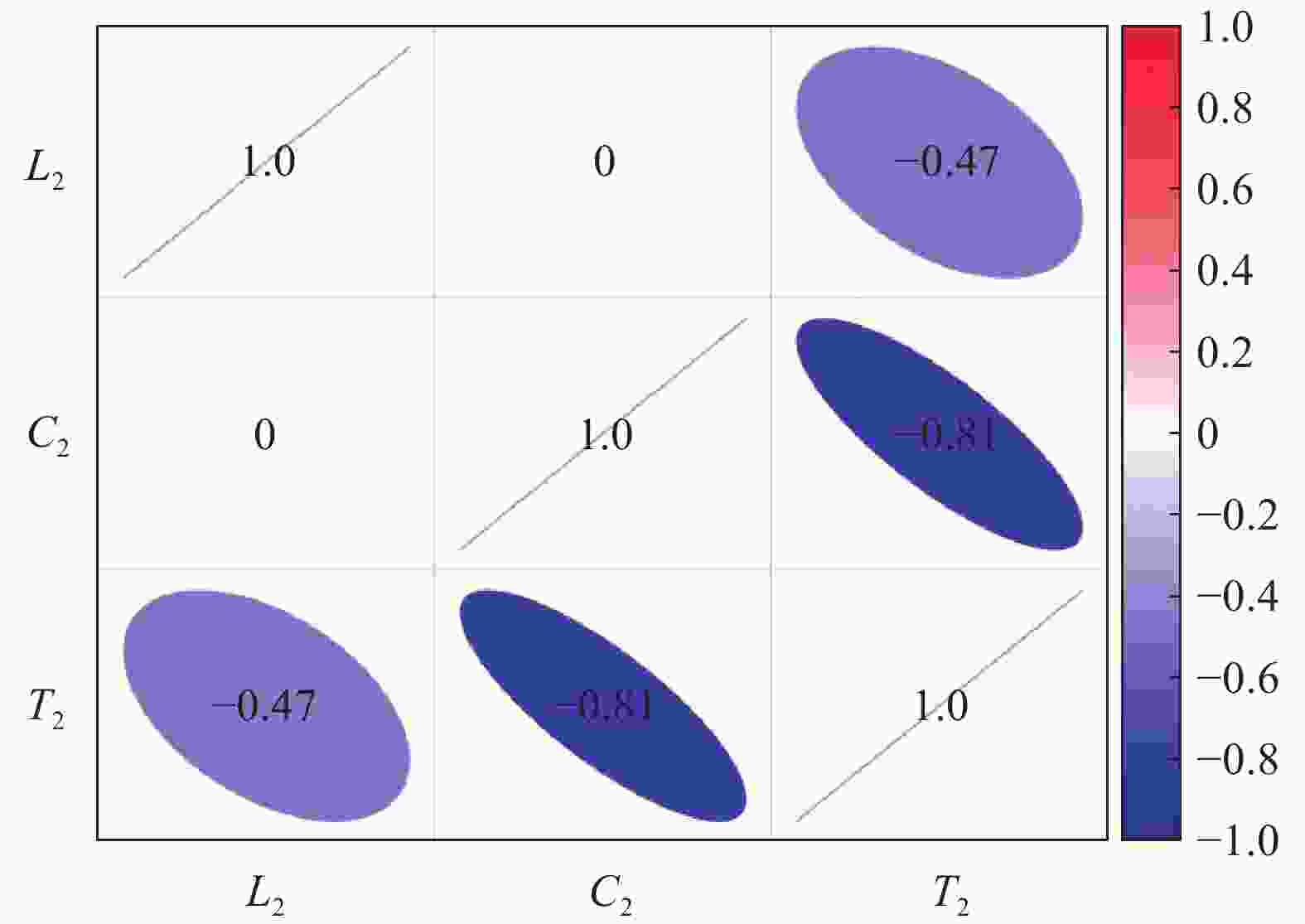

Factor Symbols of variable Level Designation Volume substitution

rate of rubber aggregateC2 1 10vol% 2 20vol% 3 30vol% 4 40vol% Particle size of

rubber aggregateL2 1 1.70 mm 2 0.83 mm 3 0.38 mm 4 0.25 mm 5 0.15 mm 表 4 碱激发类砂浆因素显著性分析

Table 4. Significance analysis of alkali-activated mortar's factors

Source Sum of squares Degree of freedom Mean square F-value Significance J1 1464.388 2 732.194 758.883 *** L1 171.936 4 42.984 44.551 *** C1 2313.327 3 771.109 799.216 *** J1 L1 23.364 8 2.920 3.027 *** L1C1 13.789 12 1.149 1.191 // J1C1 160.447 6 26.741 27.716 *** J1L1C1 20.204 24 0.842 0.873 *** Error 115.780 120 0.965 — — Total 74288.445 180 — — — Notes: ***—Significant factor; //—Not significant factor; F—Test results of homogeneity of variance. 表 5 硅酸盐类砂浆因素显著性分析

Table 5. Significance analysis of silicate mortar’s factors

Source Sum of squares Degree of

freedomMean

squareF-value Significance L2 391.441 4 97.860 61.322 *** C2 1173.307 3 391.102 245.077 *** L2C2 72.638 12 6.053 3.793 *** Error 63.833 40 1.596 — — Total 16296.580 60 — — — -

[1] 姚韦靖, 刘雨姗, 王婷雅, 等. 橡胶/混凝土盐冻循环后性能劣化及微观结构[J]. 复合材料学报, 2021, 38(12):4294-4304.YAO Weijing, LIU Yushan, WANG Tingya, et al. Performance degradation and microscopic structure of rubber/concrete after salt freeze-thaw cycles[J]. Acta Materiae Compositae Sinica,2021,38(12):4294-4304(in Chinese). [2] BRAVO M, DE BRITO J. Concrete made with used tyre aggregate: Durability-related performance[J]. Journal of Cleaner Production,2012,25:42-50. doi: 10.1016/j.jclepro.2011.11.066 [3] SIDDIKA A, AL MAMUN M A, ALYOUSEF R, et al. Properties and utilizations of waste tire rubber in concrete: A review[J]. Construction and Building Materials,2019,224:711-731. doi: 10.1016/j.conbuildmat.2019.07.108 [4] KHALOOA R, DEHESTANI M, RAHMAYABADI P. Mechanical properties of concrete containing a high volume of tire–rubber particles[J]. Waste Management,2008,28(12):2472-2482. doi: 10.1016/j.wasman.2008.01.015 [5] GIRSKAS G, NAGROCKIENĖ D. Crushed rubber waste impact of concrete basic properties[J]. Construction and Building Materials,2017,140:36-42. doi: 10.1016/j.conbuildmat.2017.02.107 [6] GUPTA T, CHAUDHARY S, SHARMA R K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate[J]. Construction and Building Materials,2014,73:562-574. doi: 10.1016/j.conbuildmat.2014.09.102 [7] INCE C, SHEHATA B M H, DEROGAR S, et al. Towards the development of sustainable concrete incorporating waste tyre rubbers: A long-term study of physical, mechanical & durability properties and environmental impact[J]. Journal of Cleaner Production,2022,334:130223. doi: 10.1016/j.jclepro.2021.130223 [8] VALENTE M, SAMBUCCI M, CHOUGAN M, et al. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber[J]. Journal of Cleaner Production,2022,333:130013. doi: 10.1016/j.jclepro.2021.130013 [9] SHAO J, ZHU H, XUE G, et al. Mechanical and restrained shrinkage behaviors of cement mortar incorporating waste tire rubber particles and expansive agent[J]. Construction and Building Materials,2021,296:123742. doi: 10.1016/j.conbuildmat.2021.123742 [10] LIU M, LU J, MING P, et al. Study of fracture properties and post-peak softening process of rubber concrete based on acoustic emission[J]. Construction and Building Materials,2021,313:125487. doi: 10.1016/j.conbuildmat.2021.125487 [11] SHAO J, ZHU H, ZHAO B, et al. Combined effect of recycled tire rubber and carbon nanotubes on the mechanical properties and microstructure of concrete[J]. Construction and Building Materials,2022,322:126493. doi: 10.1016/j.conbuildmat.2022.126493 [12] GRAVINA R J, XIE T. Toward the development of sustainable concrete with crumb rubber: Design-oriented models, life-cycle-assessment and a site application[J]. Construction and Building Materials,2022,315:125565. doi: 10.1016/j.conbuildmat.2021.125565 [13] NOCERA F, WANG J, FALESCHINI F, et al. Probabilistic models of concrete compressive strength and elastic modulus with rubber aggregates[J]. Construction and Building Materials,2022,322:126145. doi: 10.1016/j.conbuildmat.2021.126145 [14] AL-FASIH M Y M, HUSEIEN G F, BIN IBRAHIM I S, et al. Synthesis of rubberized alkali-activated concrete: Experimental and numerical evaluation[J]. Construction and Building Materials,2021,303:124526. doi: 10.1016/j.conbuildmat.2021.124526 [15] SOUZA T B, LIMA V M E, ARAÚJO F W C, et al. Alkali-activated slag cellular concrete with expanded polystyrene (EPS)-physical, mechanical, and mineralogical properties[J]. Journal of Building Engineering,2021,44:103387. doi: 10.1016/j.jobe.2021.103387 [16] WANG H, WU Y, CHENG B. Mechanical properties of alkali-activated concrete containing crumb rubber particles[J]. Case Studies in Construction Materials,2022,16:e00803. doi: 10.1016/j.cscm.2021.e00803 [17] KONG L, ZHAO W, XUAN D, et al. Application potential of alkali-activated concrete for antimicrobial induced corrosion: A review[J]. Construction and Building Materials,2022,317:126169. doi: 10.1016/j.conbuildmat.2021.126169 [18] BANDYOPADHYAY S, DE P P, TRIPATHY D K, et al. Influence of surface oxidation of carbon black on its interaction with nitrile rubbers[J]. Polymer,1996,37(2):353-357. doi: 10.1016/0032-3861(96)81110-4 [19] DOU Y, FENG G, XU L, et al. Modification of rubber particles and its application in rubberized concrete[J]. Journal of Building Engineering,2022,51:104346. doi: 10.1016/j.jobe.2022.104346 [20] MA D D, ZHANG W P, WANG X P, et al. Effects of curing temperature on mechanical properties and pore size distribution of cement clay modified by metakaolin and basalt fiber[J]. Journal of Building Engineering, 2023, 68: 106232. [21] SEGRE N, MONTEIRO P J M, SPOSITO G. Surface characterization of recycled tire rubber to be used in cement paste matrix[J]. Journal of Colloid and Interface Science,2002,248(2):521-523. doi: 10.1006/jcis.2002.8217 [22] AMRAN M, FEDIUK R, ABDELGADER H S, et al. Fiber-reinforced alkali-activated concrete: A review[J]. Journal of Building Engineering,2022,45:103638. doi: 10.1016/j.jobe.2021.103638 [23] MOHAMMED A, RAFIQ S, SIHAG P, et al. ANN, M5 P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash[J]. Journal of Materials Research and Technology,2020,9(6):12416-12427. doi: 10.1016/j.jmrt.2020.08.083 [24] GOLAFSHANI E M, BEHNOOD A, ARASHPOUR M. Predicting the compressive strength of normal and high-performance concretes using ANN and ANFIS hybridized with grey wolf optimizer[J]. Construction and Building Materials,2020,232:117266. doi: 10.1016/j.conbuildmat.2019.117266 [25] XIAO Y, MENG M, CHEN H, et al. Nonlinear regression model for peak-failure strength of rockfill materials in general stress space[J]. Geoscience Frontiers,2018,9(6):1699-1709. doi: 10.1016/j.gsf.2017.07.001 [26] XU J, ZHAO X, YU Y, et al. Parametric sensitivity analysis and modelling of mechanical properties of normal-and high-strength recycled aggregate concrete using grey theory, multiple nonlinear regression and artificial neural networks[J]. Construction and Building Materials,2019,211:479-491. doi: 10.1016/j.conbuildmat.2019.03.234 [27] ASTM. Standard test method for compressive strength of hydraulic cement mortars: ASTM C109/C109 M-02[S]. West Conshohocken: ASTM International, 2002. -

下载:

下载: