Microstructure and properties of Ni-nano TiC composite coating prepared by different electrodeposition methods

-

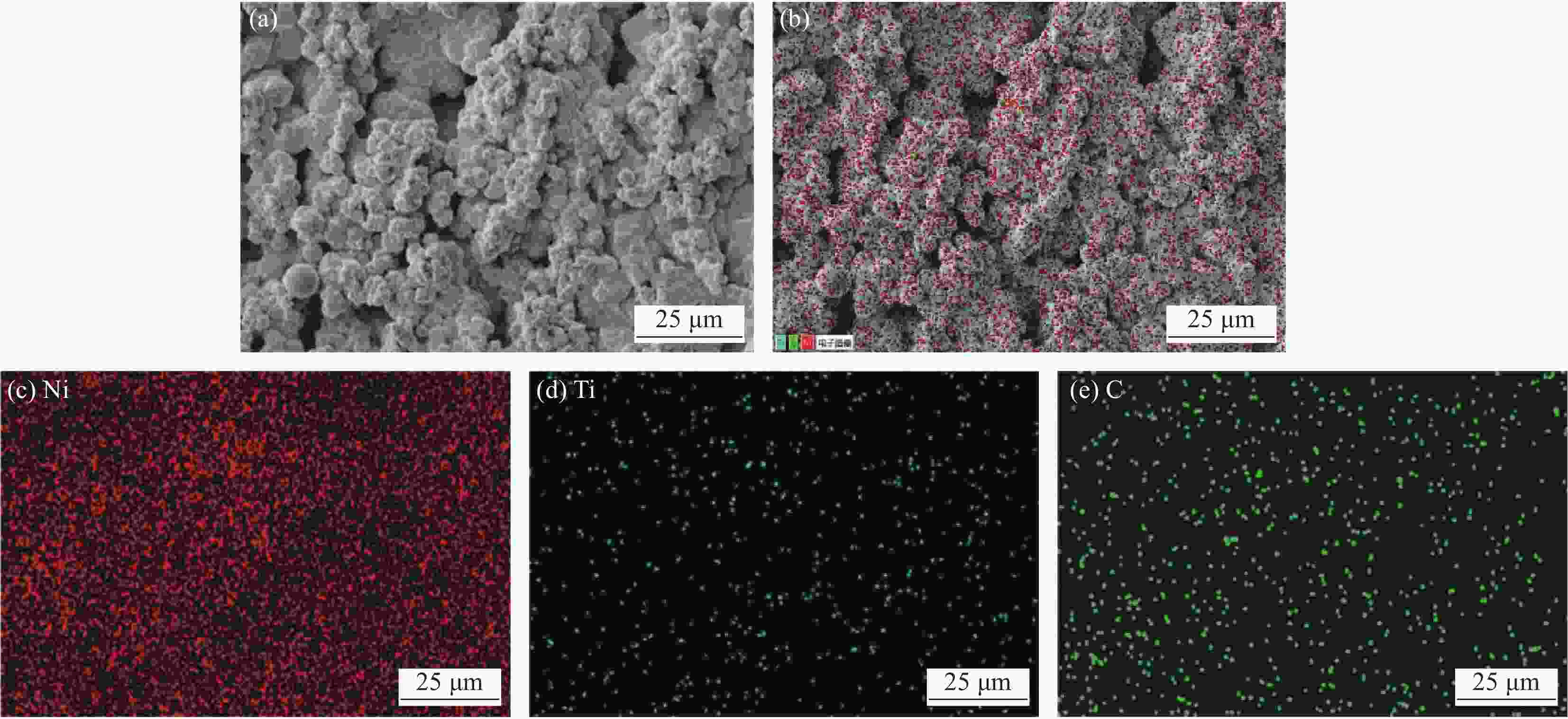

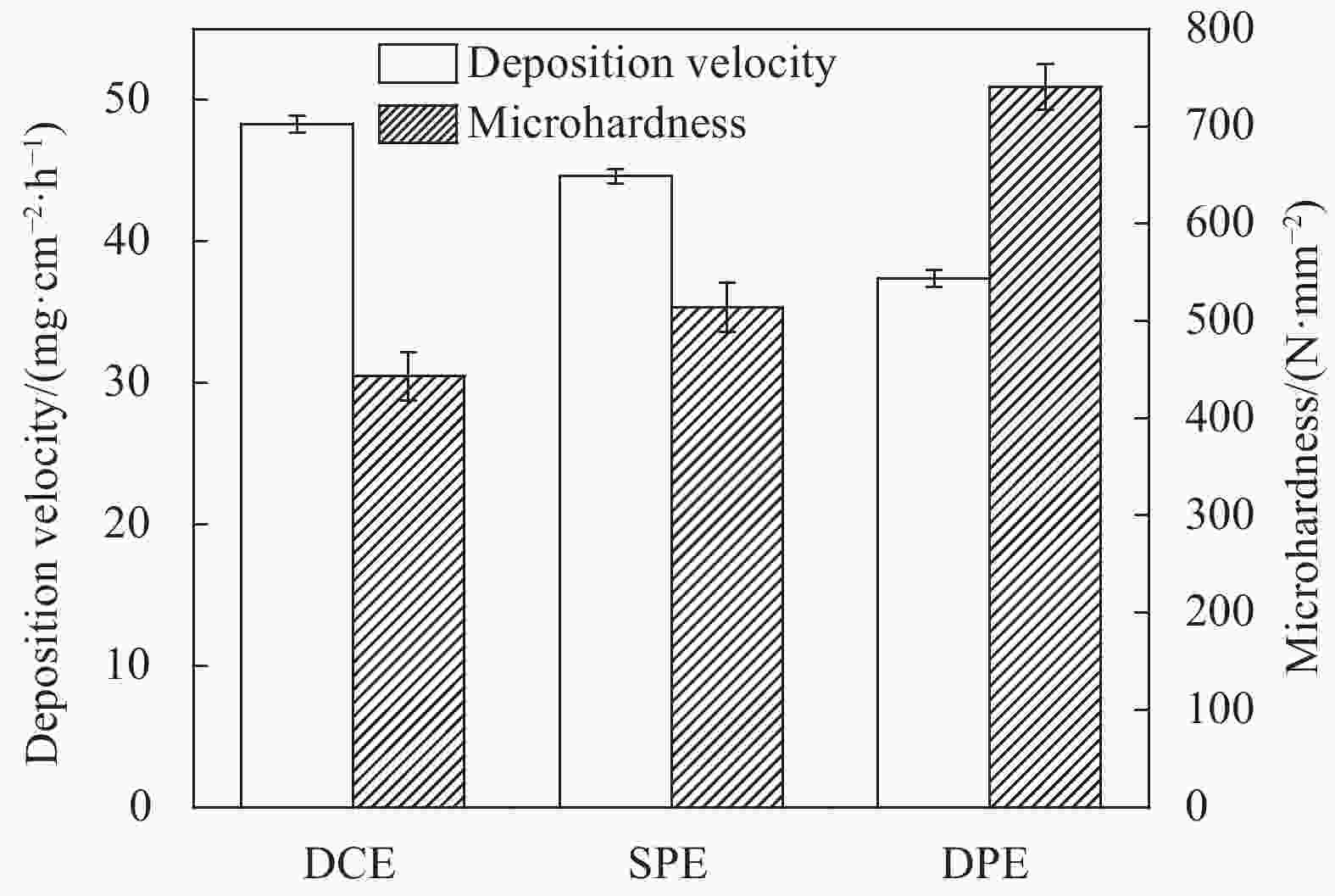

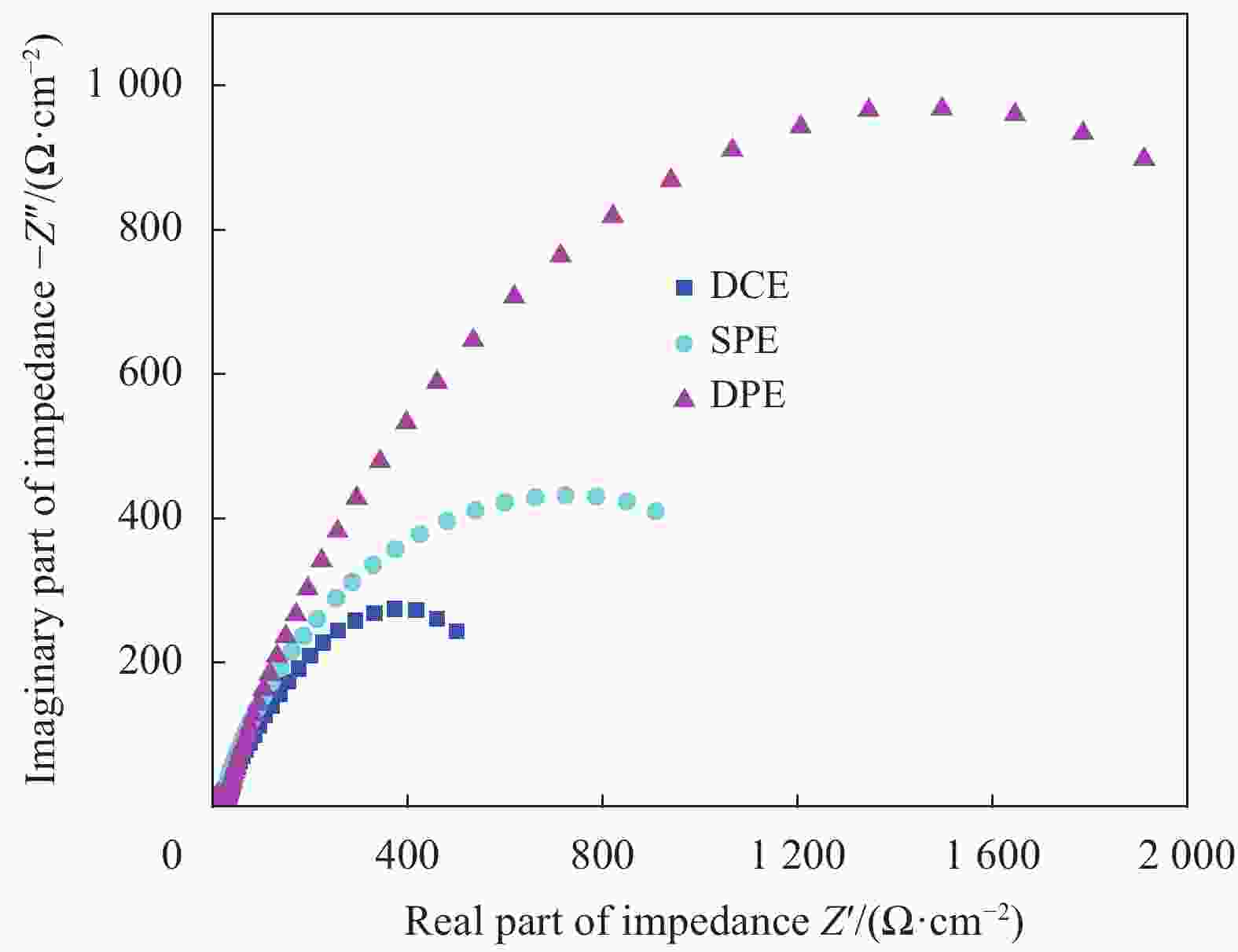

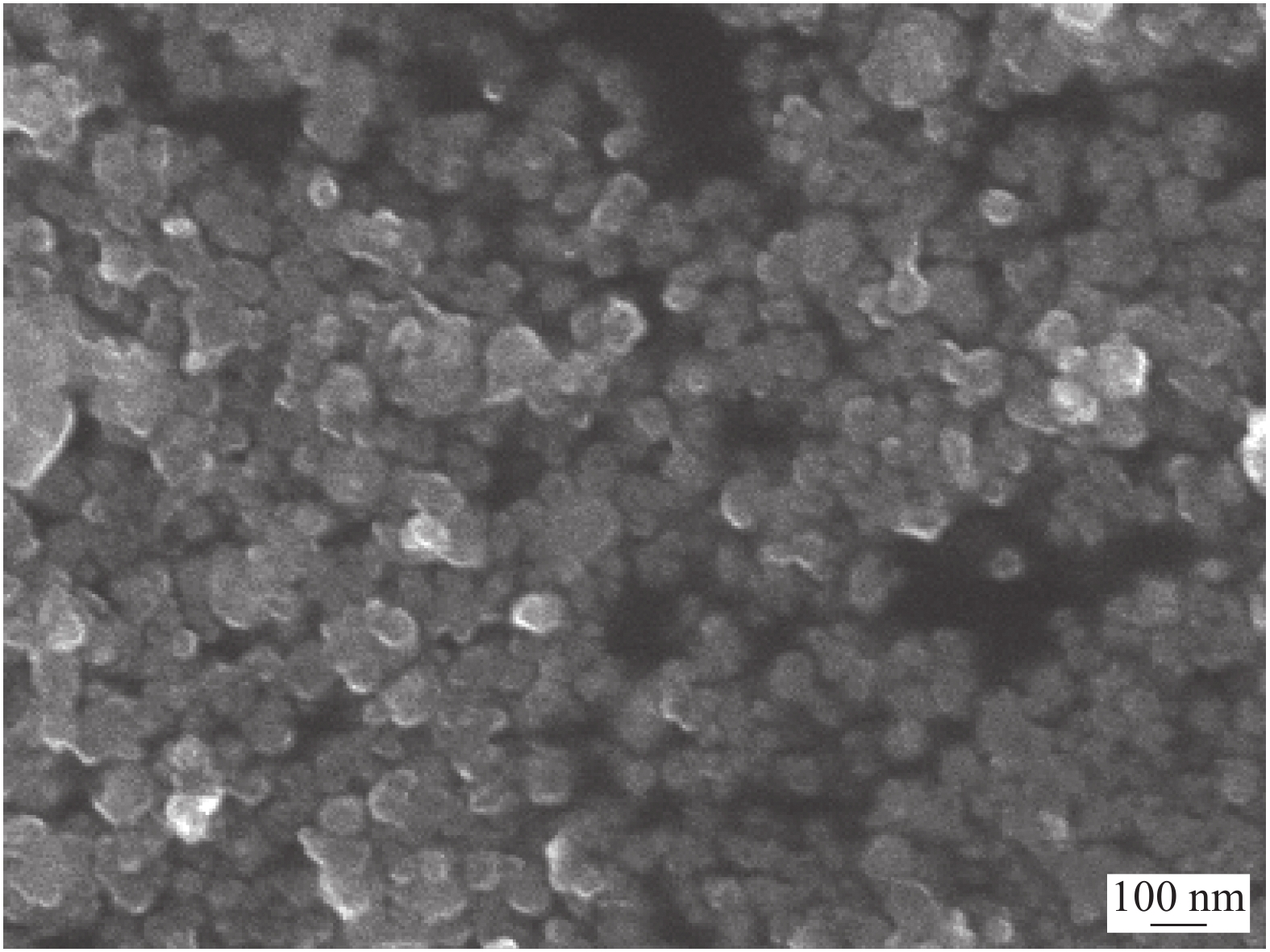

摘要: 为改善电沉积Ni-纳米TiC复合镀层的质量,利用电沉积技术在Q235钢表面制备出Ni-纳米TiC复合镀层,对比分析了直流、单脉冲和双脉冲三种不同电沉积方式对复合镀层的微观组织与表面性能的影响。通过SEM/EDS分析镀层的表面形貌和元素分布,利用XRD研究镀层的物相和估算晶粒大小,分别采用显微硬度计和电化学工作站测试其硬度和腐蚀行为。研究表明,按照直流、单脉冲和双脉冲电沉积方式,复合镀层的致密性和显微硬度依次增加,孔隙率、镀速和晶粒尺寸依次减小。脉冲沉积复合镀层中TiC含量明显少于直流电沉积镀层中的TiC含量。双脉冲电沉积复合镀层的显微硬度为 HV 740.5,比直流电沉积镀层高67%。与直流和单脉冲沉积镀层相比,双脉冲电沉积复合镀层在3.5wt%NaCl 溶液中的自腐蚀电流密度降低了一个数量级(5.275×10−6 A·cm−2),自腐蚀电位明显正移(−0.113 V),电荷转移电阻为最大,表现出最好的耐蚀性。

-

关键词:

- 电沉积 /

- 双脉冲 /

- Ni-纳米TiC复合镀层 /

- 微观结构 /

- 性能

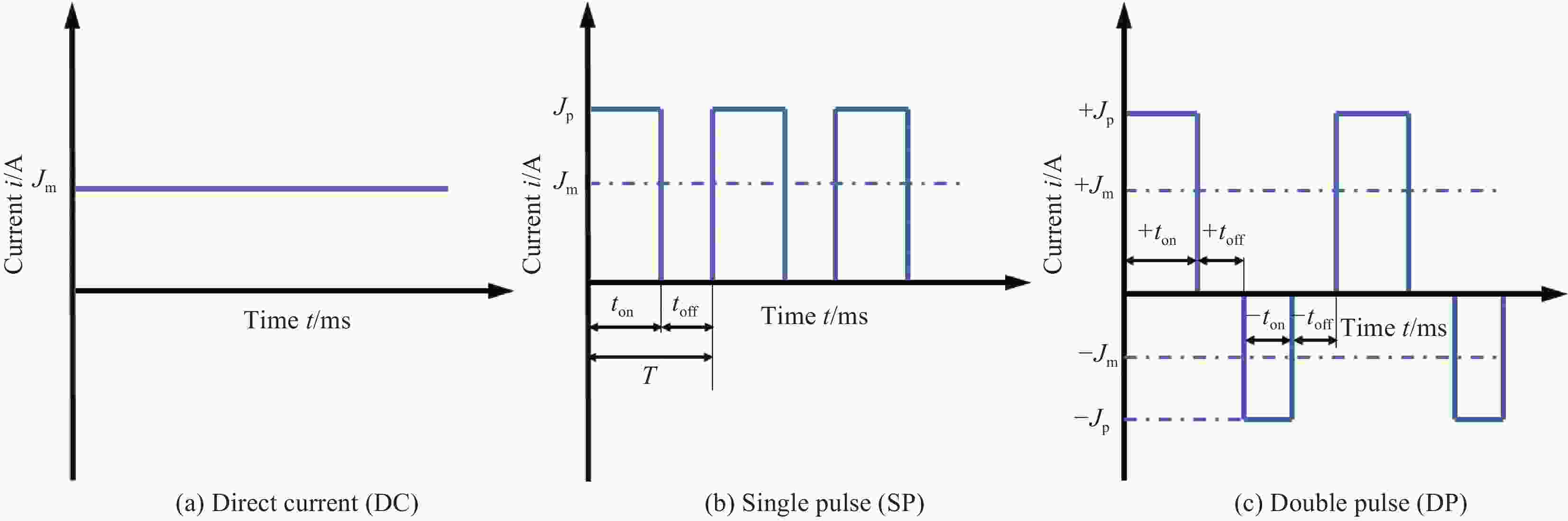

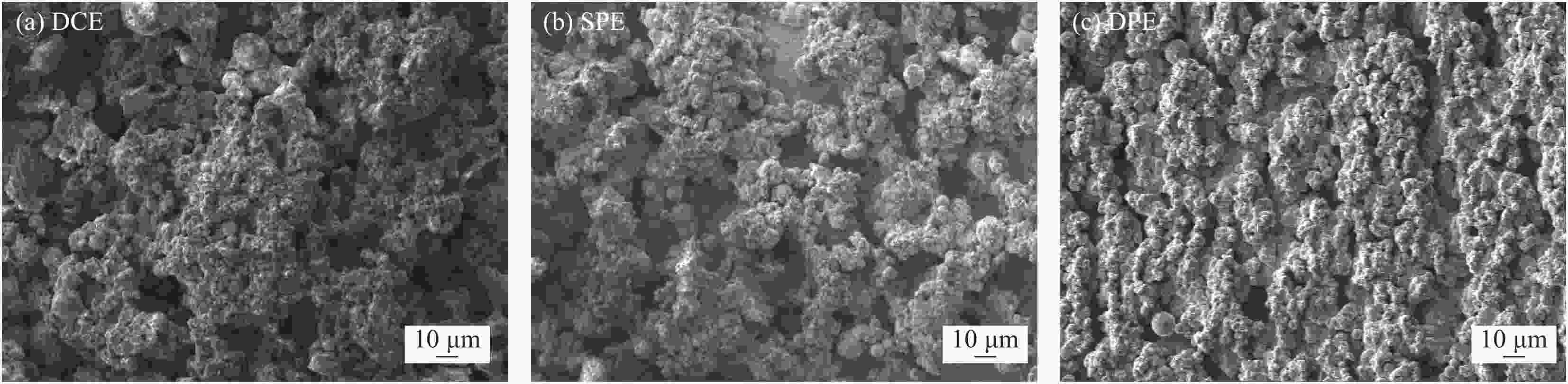

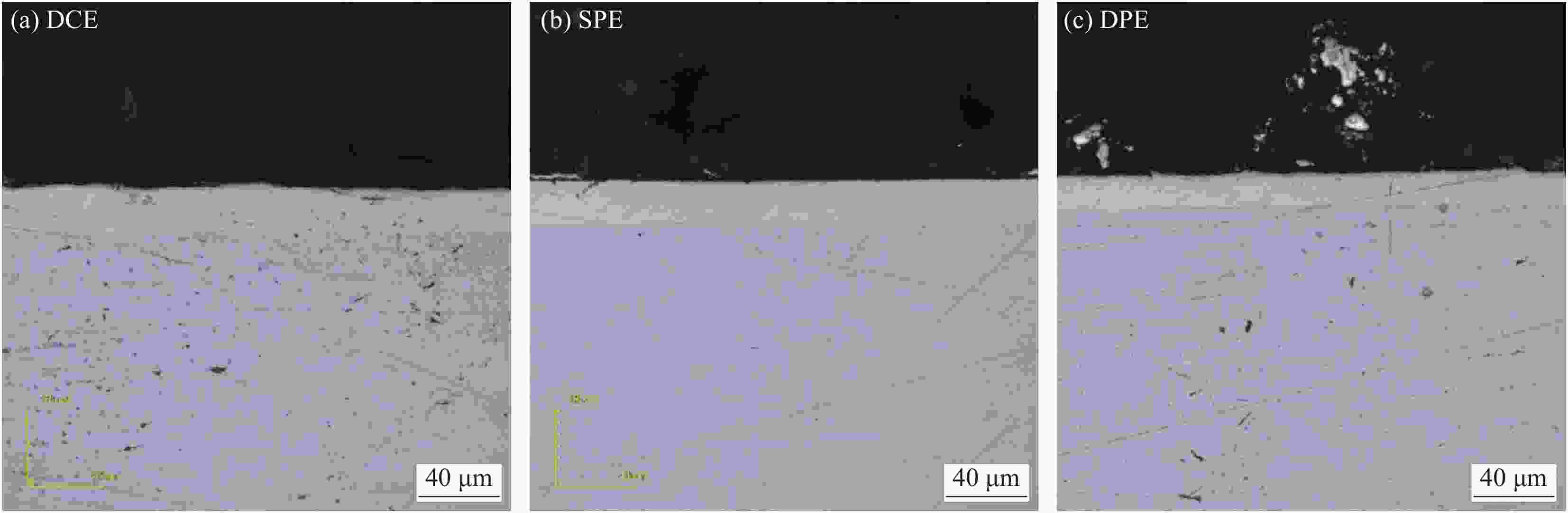

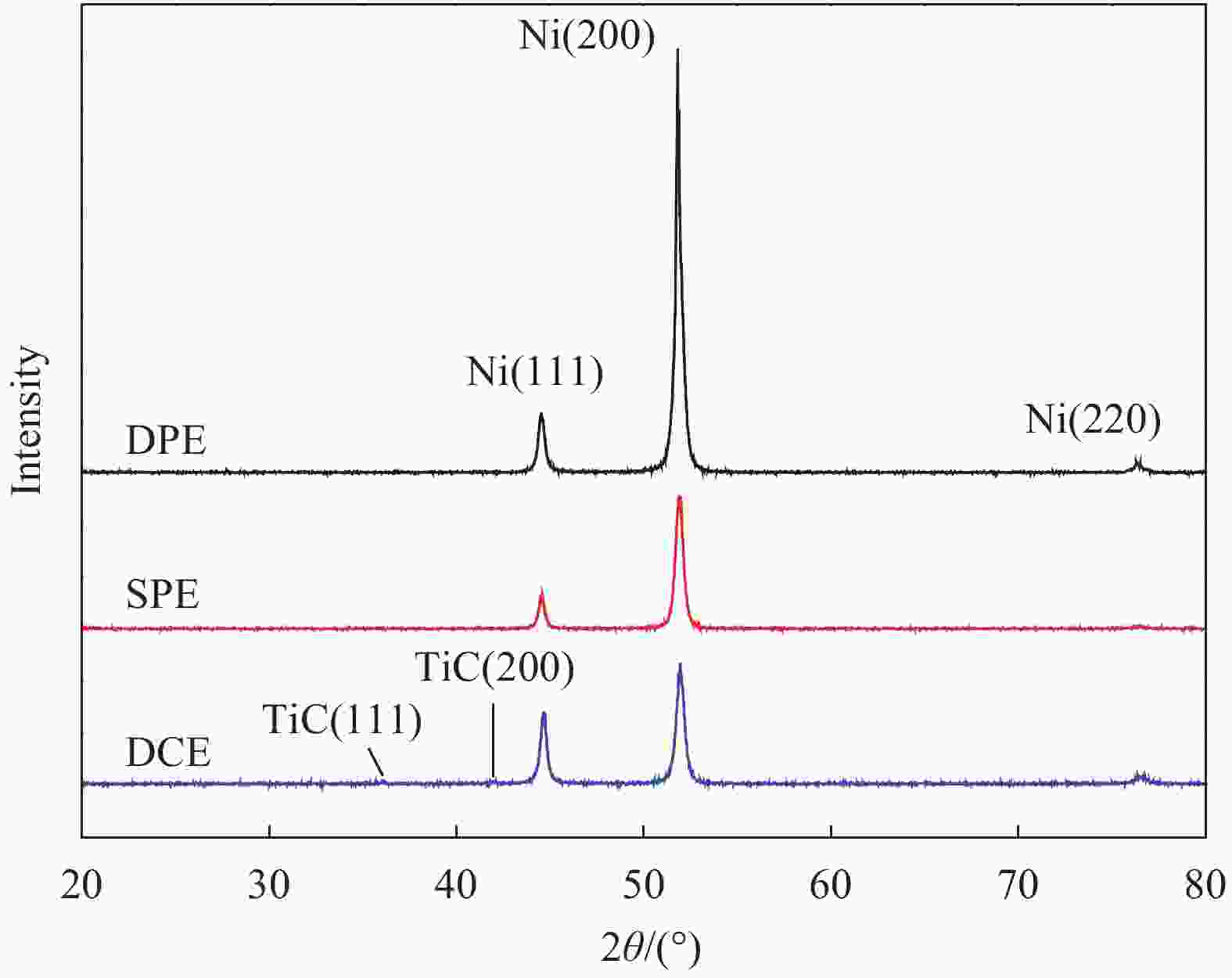

Abstract: To improve the quality of electrodeposited Ni-nano TiC composite coating, the Ni-nano TiC composite coating was prepared on the Q235 steel by electrodeposition. The effects of three different electrodeposition methods of direct current (DC), single pulse and double pulse on the microstructure and surface properties of the composite coating were compared and analyzed. The surface morphology and element distribution of the coatings were analyzed by SEM/EDS. The phase and grain size of the coatings were studied by XRD, and the hardness and corrosion behavior were tested by microhardness tester and electrochemical workstation respectively. The results show that the compactness and microhardness of the composite coating increase in turn, and the porosity, plating rate and grain size decrease in turn according to DC, single pulse and double pulse electrodeposition methods. The content of TiC in pulse deposition composite coating is obviously less than that in DC deposition coating. The microhardness of double pulse electrodeposition composite coating is HV 740.5, which is 67% higher than that of DC electrodeposition coating. Compared with DC and single pulse electrodeposited coatings, the self-corrosion current density of double pulse electrodeposited composite coatings in 3.5wt%NaCl solution decreases by an order of magnitude (5.275×10−6 A·cm−2), the self-corrosion potential shifts positively (−0.113 V), and the charge transfer resistance is the largest, showing the best corrosion resistance.-

Key words:

- electrodeposition /

- double pulse /

- Ni-nano TiC composite coating /

- microstructure /

- properties

-

表 1 不同电沉积方式下 Ni-纳米 TiC复合镀层的晶粒尺寸

Table 1. Grain size of Ni-nano TiC composite coatings in different electrodeposition methods

Settle mode dNi/nm $ {{{\bar d}_{\rm{Ni}}}} $ Error/% (111) (200) (220)

DCE205.6 188.4 213.5 202.5 6.54

SPE95.0 87.9 111.5 98.1 8.27

DPE28.3 21.4 25.5 25.1 4.31 Notes: dNi—Nickel grain size; $ {\bar{d}}_{{\rm{Ni}}} $—Average size of nickel grains. 表 2 不同电沉积方式下Ni-纳米TiC复合镀层的Tafel极化曲线参数拟合结果

Table 2. Fitting results of Tafel polarization curve parameter for Ni-nano TiC composite coatings in different electrodeposition methods

Settle mode Ecorr/V Rp/(Ω∙cm−2) icorr/(A∙cm−2) DCE −0.355 1839.0 1.917×10−5 SPE −0.268 3223.9 1.138×10−5 DPE −0.113 7692.7 5.275×10−6 Notes: Ecorr—Self-corrosion potential; Rp—Polarization resistance; icorr—Self-corrosion current density. -

[1] BORKAR T, SOSA J, HWANG J Y, et al. Laser deposited in situ TiC-reinforced nickel matrix composites: 3D microstructure and tribological properties[J]. JOM,2014,66:935-942. doi: 10.1007/s11837-014-0907-1 [2] CZAGANY M, BAUMLI P. Effect of surfactants on the behavior of the Ni-P bath and on the formation of electroless Ni-P-TiC composite coatings[J]. Surface and Coatings Technology,2019,361(15):42-49. [3] QI Q, WANG L, LIU Y, et al. In-situ TiC-graphite-Ni hybrid composites innovatively fabricated by pressureless reactive infiltration method[J]. Journal of Alloys and Compounds,2018,757:273-278. doi: 10.1016/j.jallcom.2018.05.039 [4] TAN Y, HE L, WANG X, et al. Tribological properties and wear prediction model of TiC particles reinforced Ni-base alloy composite coatings[J]. Transactions of Nonferrous Metals Society of China,2014,24:2566-2573. doi: 10.1016/S1003-6326(14)63384-7 [5] 朱成才, 张自强, 白海明, 等. 激光熔覆Ni-TiC-Cr涂层的耐腐蚀性能研究[J]. 材料保护, 2020, 53(3):71-77.ZHU Chengcai, ZHANG Ziqiang, BAI Haiming, et al. Corrosion resistance of Ni-TiC-Cr coating prepared by laser cladding[J]. Materials Protection,2020,53(3):71-77(in Chinese). [6] 梁宝岩, 张旺玺, 史冬丽, 等. SHS技术在金刚石表面镀覆Ni-TiC复合涂层的研究[J]. 金刚石与磨料磨具工程, 2016, 36(3):50-53.LIANG Baoyan, ZHANG Wangxi, SHI Dongli, et al. Study on the self-propagation high temperature sintering of Ni-TiC-diamond[J]. Diamond and Abrasives Engineering,2016,36(3):50-53(in Chinese). [7] CAMAGU S T, MOTAUNG D E, BOLOKANG A S, et al. Microstructure and hardness of steel/Ni-TiC composite produced by compaction and sintering[J]. Materials Today: Proceedings,2021,38:553-557. doi: 10.1016/j.matpr.2020.02.401 [8] WANG R, ZHU G L, YANG C, et al. Novel selective laser melting processed in-situ TiC particle-reinforced Ni matrix composite with excellent processability and mechanical properties[J]. Materials Science and Engineering A,2020,797(21):140145. [9] SAHU A, RAHEEM A, MASANT M, et al. On the constancy in wear characteristic of large area TiC-Ni coating developed by overlapping of TiC arc scanning[J]. Tribology International,2020,151:106501. doi: 10.1016/j.triboint.2020.106501 [10] LEON-PATINO C A, BRAULIO-SANCHEZ M, AGUILAR-REYES E A, et al. Mechanical and thermal properties of Ni matrix composites reinforced with high-volume TiC[J]. Journal of Alloys and Compounds,2019,792:1102-1111. doi: 10.1016/j.jallcom.2019.04.132 [11] 薛玉君, 刘红彬, 兰明明, 等. 超声场中脉冲电沉积Ni-CeO2纳米复合镀层的耐蚀性[J]. 无机材料学报, 2010, 25(5):522-526. doi: 10.3724/SP.J.1077.2010.00522XUE Yujun, LIU Hongshan, LAN Mingming, et al. Corrosion resistance of Ni-CeO2 nanocomposite coatings prepared by pulse electrodepositon in an ultrasonic field[J]. Journal of Inorganic Materials,2010,25(5):522-526(in Chinese). doi: 10.3724/SP.J.1077.2010.00522 [12] 彭成章, 朱玲玲. 电沉积Ni-P/纳米Al2O3复合镀层的摩擦磨损与耐铝液侵蚀性能[J]. 中国有色金属学报, 2010, 20(6):1177-1182.PENG Chengzhang, ZHU Lingling. Tribological properties and erosion resistance of electroplated Ni-P/nano-Al2O3 composite coatings to aluminum liquid[J]. Chinese Jour-nal of Nonferrous Metals,2010,20(6):1177-1182(in Chinese). [13] LAJEVARDI S A, SHAHRABI T, SZPUNAR J A, et al. Synthesis of functionally graded nano-Al2O3/Ni composite coating by pulse electrodeposition[J]. Applied Surface Science,2013,279(8):180-188. [14] 梅辉, 王扈炜, 丁辉, 等. 不同物相电沉积CNTs对C/SiC复合材料力学性能的影响[J]. 复合材料学报, 2015, 32(2):471-476.MEI Hui, WANG Huwei, DING Hui, et al. Effect of CNTs deposited at different phases on mechanical properties of C/SiC composites[J]. Acta Materiae Compositae Sinica,2015,32(2):471-476(in Chinese). [15] 王子涵, 杨滨, 蒋春丽, 等. 高频脉冲电沉积改善Ni镀层的组织和性能[J]. 中国有色金属学报, 2011, 21(4):829-835.WANG Zihan, YANG Bin, JIANG Chunli, et al. Improvement of microstructure and properties of Ni coating prepared by high frequency pulsed-electrodeposition[J]. Chinese Journal of Nonferrous Metals,2011,21(4):829-835(in Chinese). [16] YILMAZ G, HAPCI G, ORHAN G. Properties of Ni/nano-TiO2 composite coatings prepared by direct and pulse current electroplating[J]. Journal of Materials Engineering and Performance,2015,24(2):709-720. doi: 10.1007/s11665-014-1346-4 [17] 周言敏, 李建芳. 超声条件下脉冲电镀Ni-纳米Al2O3复合镀层及其显微硬度研究[J]. 表面技术, 2015, 44(5):53-57, 82.ZHOU Yanmin, LI Jianfang. Research on microstructure of Ni-nano Al2O3 composite coatings prepared by pulse electroplating under ultrasound condition[J]. Surface Technology,2015,44(5):53-57, 82(in Chinese). [18] 王红星, 毛向阳, 沈彤, 等. 纳米TiC颗粒对Ni-TiC复合镀层组织与性能的影响[J]. 材料工程, 2017, 45(1):52-57.WANG Hongxing, MAO Xiangyang, SHEN Tong, et al. Effect of nano-TiC particles on microstructure and properties of Ni-TiC composite coatings[J]. Journal of Materials Engineering,2017,45(1):52-57(in Chinese). [19] MA C Y, ZHAO D Q, LIU W Q, et al. Magnetic assisted pulse electrodeposition and characterization of Ni-TiC nanocomposites[J]. Ceramics International,2020,46(11):17631-17639. doi: 10.1016/j.ceramint.2020.04.065 [20] SHAHZAD K, RADWAN A B, FAYYAZ O, et al. Effect of concentration of TiC on the properties of pulse electrodepo-sited Ni-P-TiC nanocomposite coatings[J]. Ceramics International,2021,47(13):19123-19133. doi: 10.1016/j.ceramint.2021.03.259 [21] 武汉大学. 分析化学(上册)[M]. 北京: 高等教育出版社, 2016: 171-212.Wuhan University. Chemical analysis (Volume I)[M]. Beijing: Higher Education Press, 2016: 171-212(in Chinese). [22] 张景双, 石金声, 石磊, 等. 电镀溶液与镀层性能测试[M]. 北京: 化学工业出版社, 2003: 58-60.ZHANG Jingshuang, SHI Jinsheng, SHI Lei, et al. Electroplating solution and coating performance test[M]. Beijing: Chemical Industry Press, 2003: 58-60(in Chinese). [23] 中国国家标准化管理委员会. 金属基体上的金属覆盖层 电沉积和化学沉积层 附着强度试验方法评述: GB/T 5270—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Metallic coatings on metallic substrate-Electrodeposited and chemically deposited coatings-Review of methods available for testing adhesion: GB/T 5270—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [24] 苏峰华, 黄平, 林义民. 电沉积方式对纳米晶钴镀层的结构和摩擦学性能影响研究[J]. 摩擦学学报, 2012, 32(1):47-52.SU Fenghua, HUANG Ping, LIN Yimin. Influence of electroeposition methods on the structure and tribological properties of nanocrystalline cobalt deposit[J]. Tribology,2012,32(1):47-52(in Chinese). [25] 郭岚峰, 刘仁龙, 刘作华, 等. 双脉冲参数对金属锰电沉积行为的影响[J]. 中国有色金属学报, 2019, 29(7):1486-1496.GUO Lanfeng, LIU Renlong, LIU Zuohua, et al. Influence of bidirectional pulse parameters on process of manganese electrowinning[J]. Chinese Journal of Nonferrous Metals,2019,29(7):1486-1496(in Chinese). [26] 周楠, 丁毅, 马立群. Q235钢表面电镀镍及其性能的研究[J]. 电镀与环保, 2013, 33(1):4-6. doi: 10.3969/j.issn.1000-4742.2013.01.002ZHOU Nan, DING Yi, MA Liqun. A study of nickel plating on Q235 steel surface and its properties[J]. Electroplating and Pollution Control,2013,33(1):4-6(in Chinese). doi: 10.3969/j.issn.1000-4742.2013.01.002 [27] 徐义库, 范铭远, 罗宇晴, 等. 脉冲电沉积 SiC/TiN 颗粒增强Ni-Mo纳米复合镀层研究[J]. 稀有金属材料工程, 2021, 50(5):1656-1664.XU Yiku, FAN Mingyuan, LUO Yuqing, et al. SiC/TiN particles reinforced Ni-Mo nanocomposite coating prepared by pulse electrodeposition[J]. Rare Metal Materials and Engineering,2021,50(5):1656-1664(in Chinese). [28] 贾卫平, 吴蒙华, 贾振元, 等. 超声功率对多场耦合作用下脉冲电沉积Ni-ZrO2纳米复合镀层性能的影响[J]. 材料导报, 2020, 34(2):2017-2022. doi: 10.11896/cldb.19020070JIA Weiping, WU Menghua, JIA Zhenyuan, et al. Effects of ultrasonic power on the performance of pulse-electrodeposited Ni-ZrO2 nanocomposite coating under magnetic-ultrasonic fields coupling action[J]. Materials Reports,2020,34(2):2017-2022(in Chinese). doi: 10.11896/cldb.19020070 [29] HOSSEIN F N, FARZAD N, ELNAZ M. Pulse electrodeposition and corrosion properties of nanocrystalline nickel-chromium alloy coatings on copper substrate[J]. Journal of Alloys and Compounds,2020,822:153712. doi: 10.1016/j.jallcom.2020.153712 [30] KARTAL M, BUYUKBAYRAM I, ALP A, et al. Production of pulse electrodeposited Ni-TiC nanocomposite coatings[J]. Materials Today: Proceedings,2017,4:6982-6989. doi: 10.1016/j.matpr.2017.07.028 [31] ZHANG Y H, ZHANG S H, HE Y, et al. Mechanical properties and corrosion resistance of pulse electrodeposited Ni-B/B4C composite coatings[J]. Surface & Coatings Technology,2021,421:127458. [32] XU Y K, FAN M Y, LUO Y Q, et al. Tribology and corrosion properties investigation of a pulse electrodeposition duplex hard-particle-reinforced Ni-Mo nanocomposite coating[J]. Surface & Coatings Technology,2020,393:125797. [33] ALVES A C, WENGER F, PONTHIAUX P, et al. Corrosion mechanisms in titanium oxide-based films produced by anodic treatment[J]. Eelectrochimica Acta, 2017, 234: 16-27. -

下载:

下载: