Experimental study on flexural performance of novel pultruded sandwich spar caps of wind turbine blades

-

摘要: 采用玻璃纤维增强树脂复合材料(GFRP)拉挤条板制造风电叶片夹芯梁帽可以克服传统纤维布铺设工艺中存在的褶皱、气泡等制造缺陷,提升材料模量和强度,减少纤维缝编工序和节约材料成本,是未来风电叶片梁帽发展的趋势之一。以GFRP双轴布为面层、GFRP拉挤条板和方格布为夹芯层的叶片主梁梁帽局部梁段作为研究对象。为研究面层厚度及剪跨比对新型拉挤夹芯梁帽承载能力和破坏模式的影响,开展四点弯曲试验。结果表明:随着面层厚度的增加,拉挤夹芯梁帽的破坏模式从无面层试件的拉挤条板拉裂破坏,发展为单层面层试件的面层拉裂或拉断破坏及多面层试件的下面层剥离破坏。合理设计面层和夹芯的比例,能够控制夹芯结构的破坏模式;拉挤夹芯梁帽的初始刚度随着面层厚度增加及剪跨比减小而增加;面层厚度的增加可以大幅提升结构的承载能力,延缓胶缝的开裂,减小破坏时的承载力损失,并在一定程度上改善结构的脆性行为。

-

关键词:

- 玻璃纤维增强复合材料 /

- 风电叶片 /

- 拉挤夹芯梁帽 /

- 弯曲试验 /

- 破坏模式

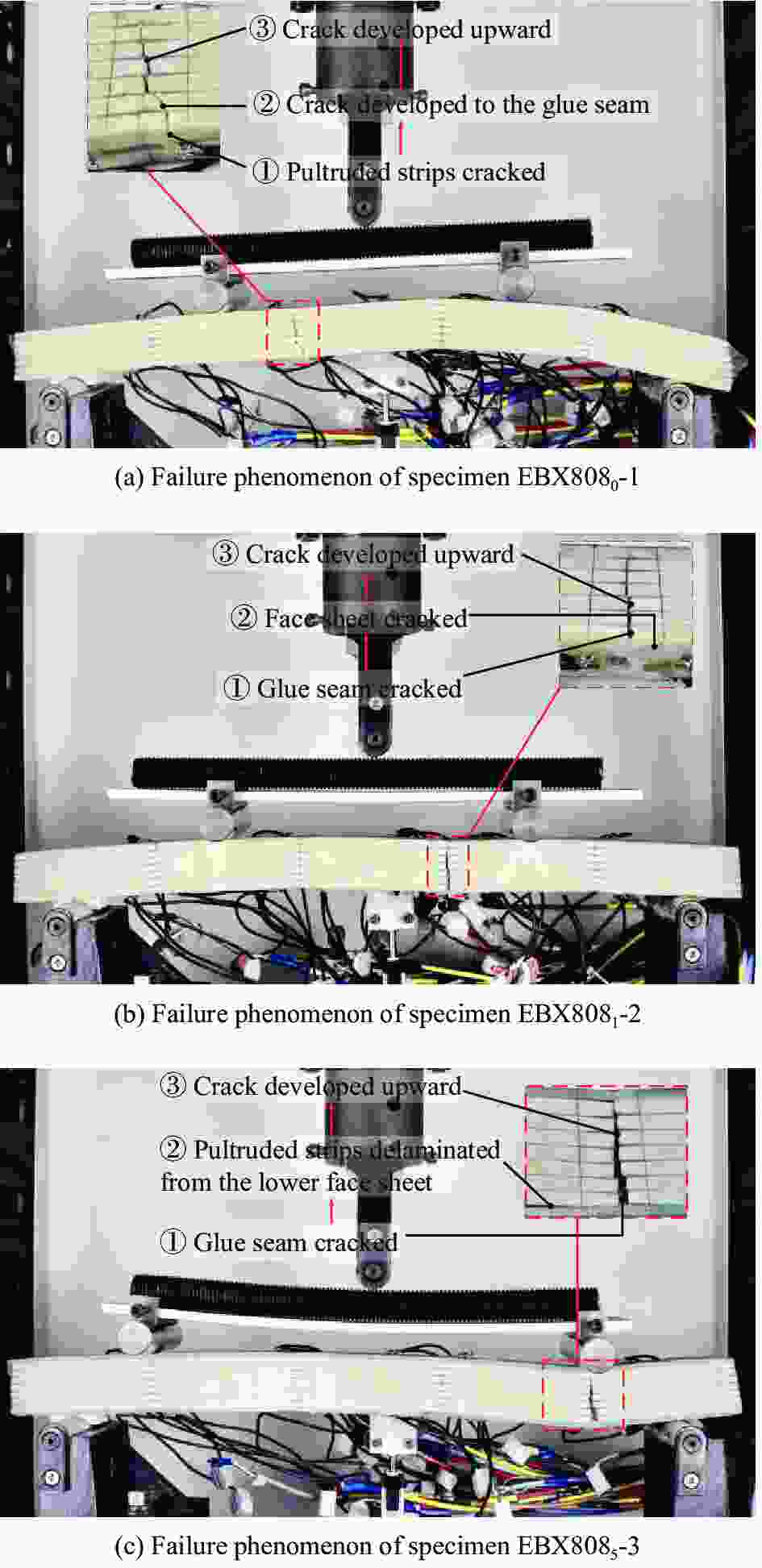

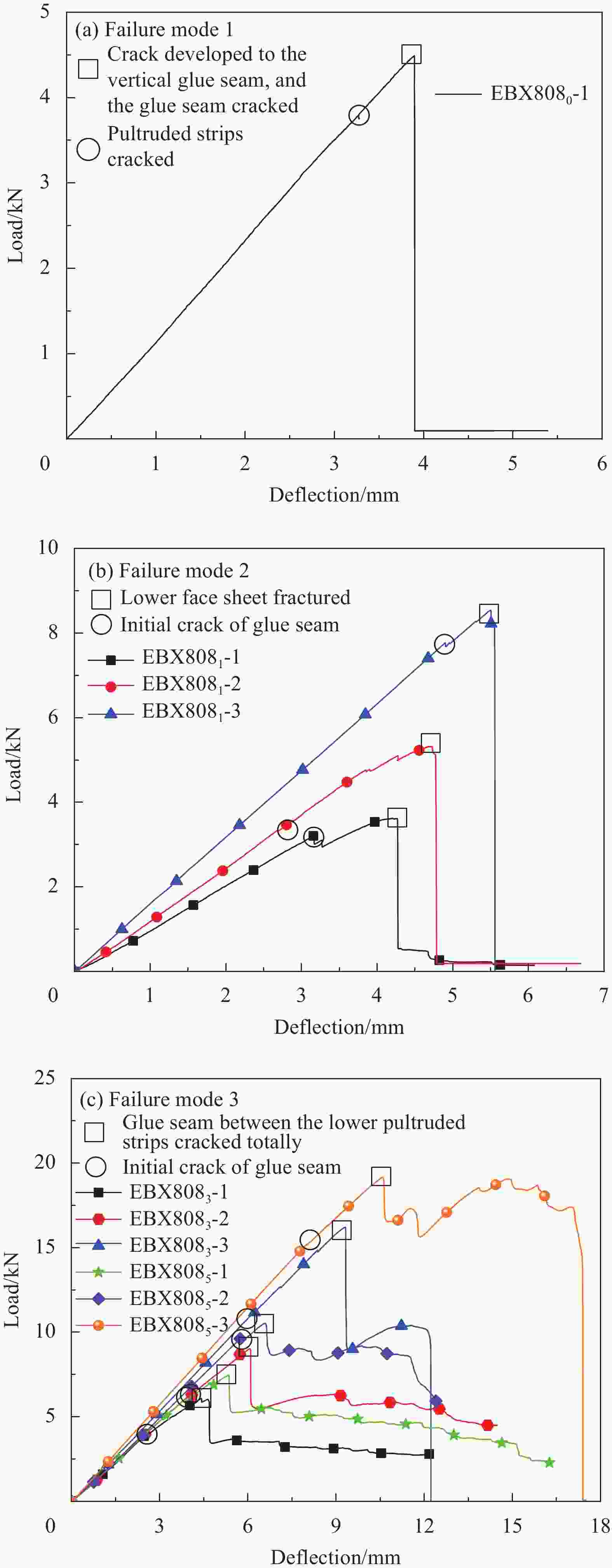

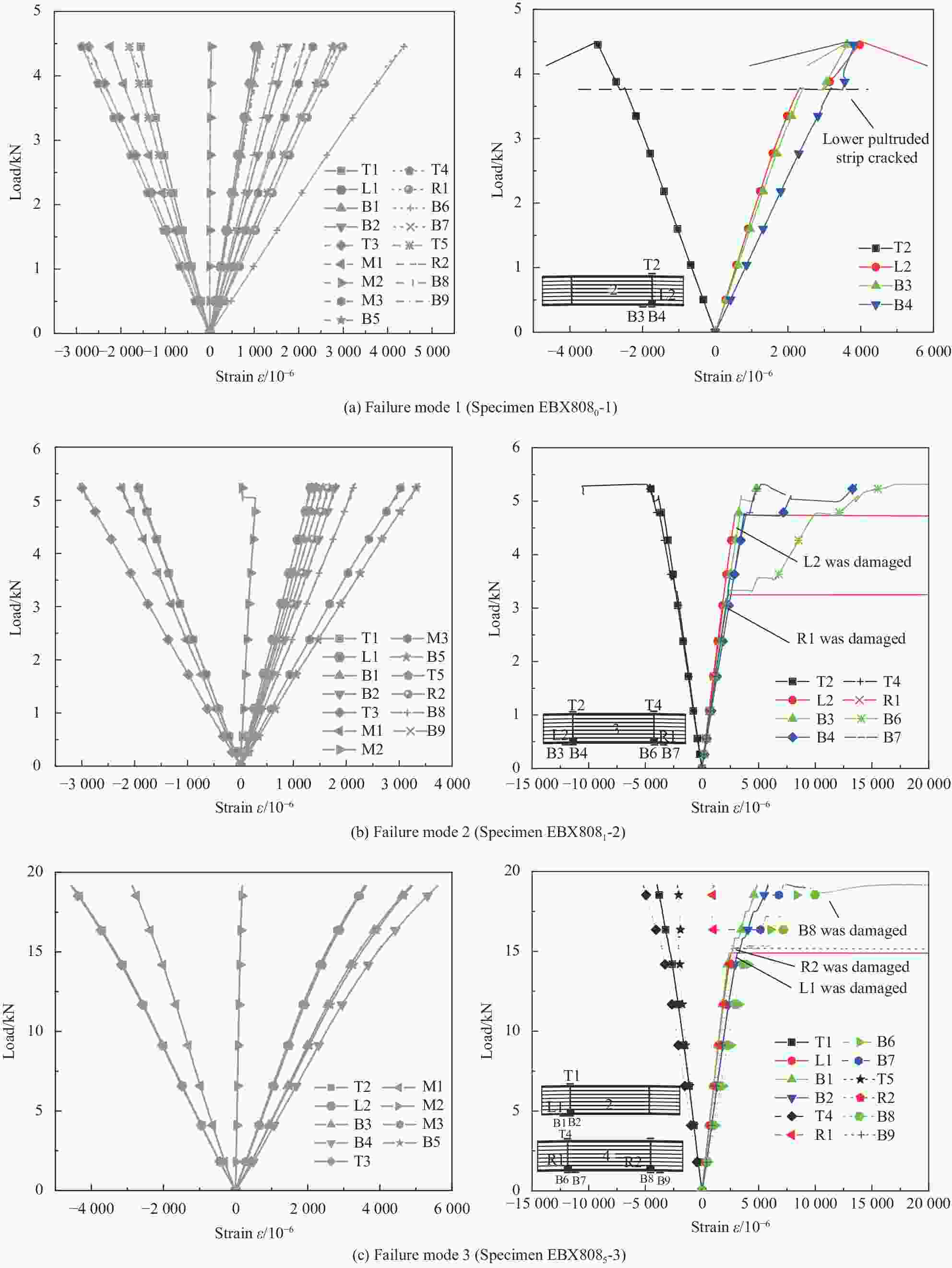

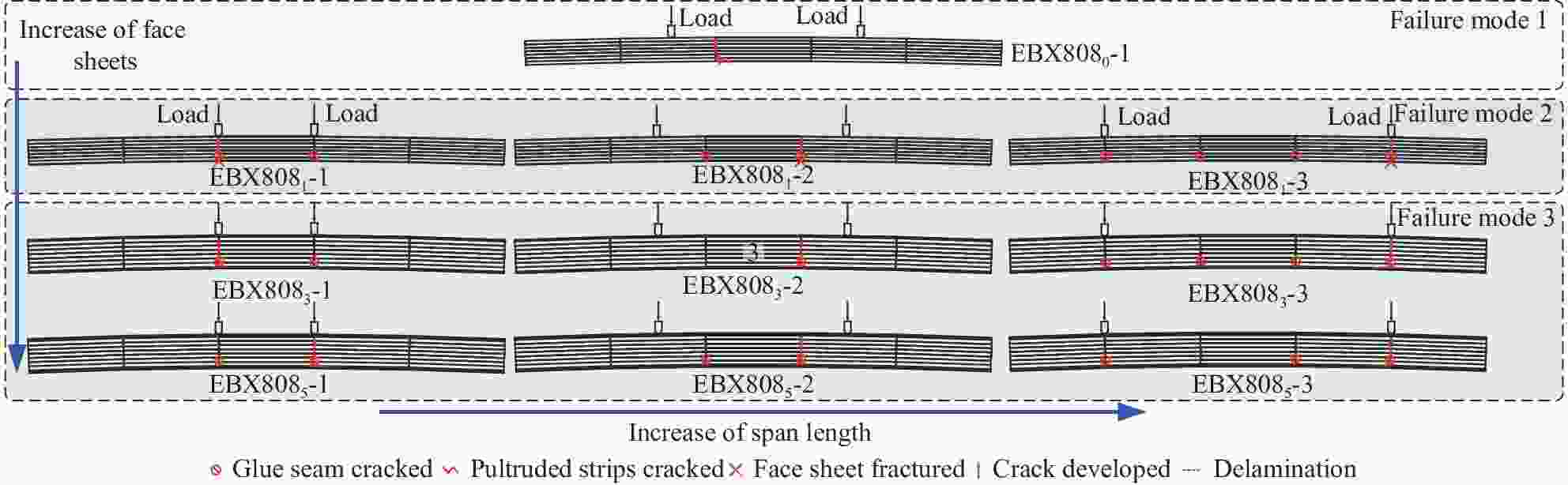

Abstract: The use of pultruded glass fiber-reinforced polymer (GFRP) strips as sandwich spar caps of wind turbine blades can overcome the manufacturing defects such as wrinkles and bubbles caused by conventional fiber cloth laying process. It can also improve the modulus and strength of the material as well as reduce the manufacturing cost, and hence becomes one of the promising manufacturing techniques for wind blades in the future. To investi-gate the influence of the face sheet thickness and the shear-span ratio on the strength and failure modes of the sandwich spar cap, a series of sandwich specimens with biaxial GFRP face sheets and pultruded GFRP strips core were tested by four-point bending. The test results show that with the increase of the face sheet, the failure mode of the specimen changes from the rupture of pultruded GFRP strip for the specimen without face sheet, to the damage or rupture of GFRP face sheet for the specimen with single layer face sheet, and to the delamination for the specimen with multilayer face sheets. The failure mode could be controlled by proper design of the ratio between the core and face sheets. Also, the initial stiffness of the sandwich spar cap increases with the increase of the face sheet thickness and with the decrease of the shear-span ratio. Increasing the face sheet thickness could improve both strength and ductility of the test specimens, and could delay the cracking of the glue seam as well as reduce the sudden loss of maximum load. -

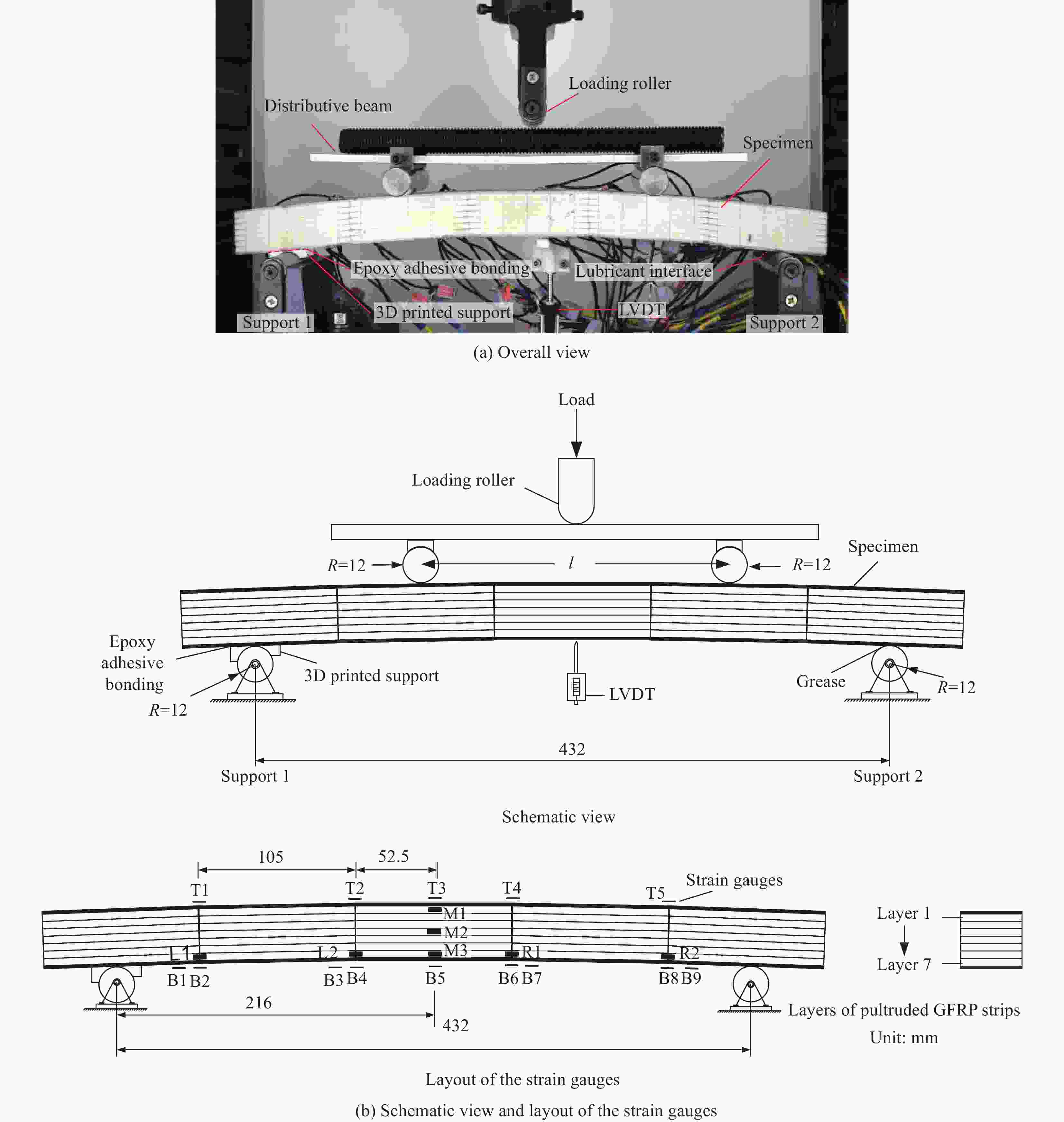

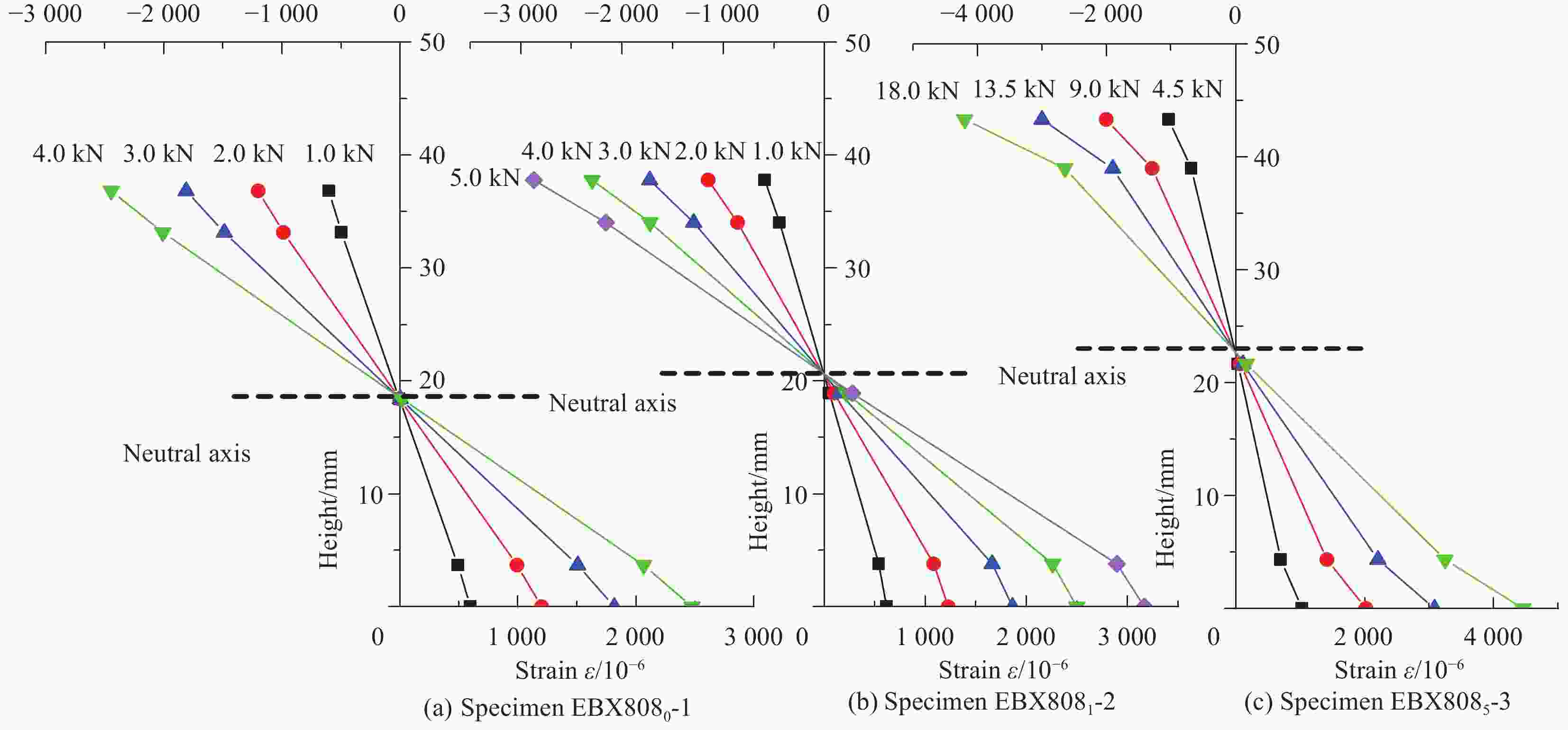

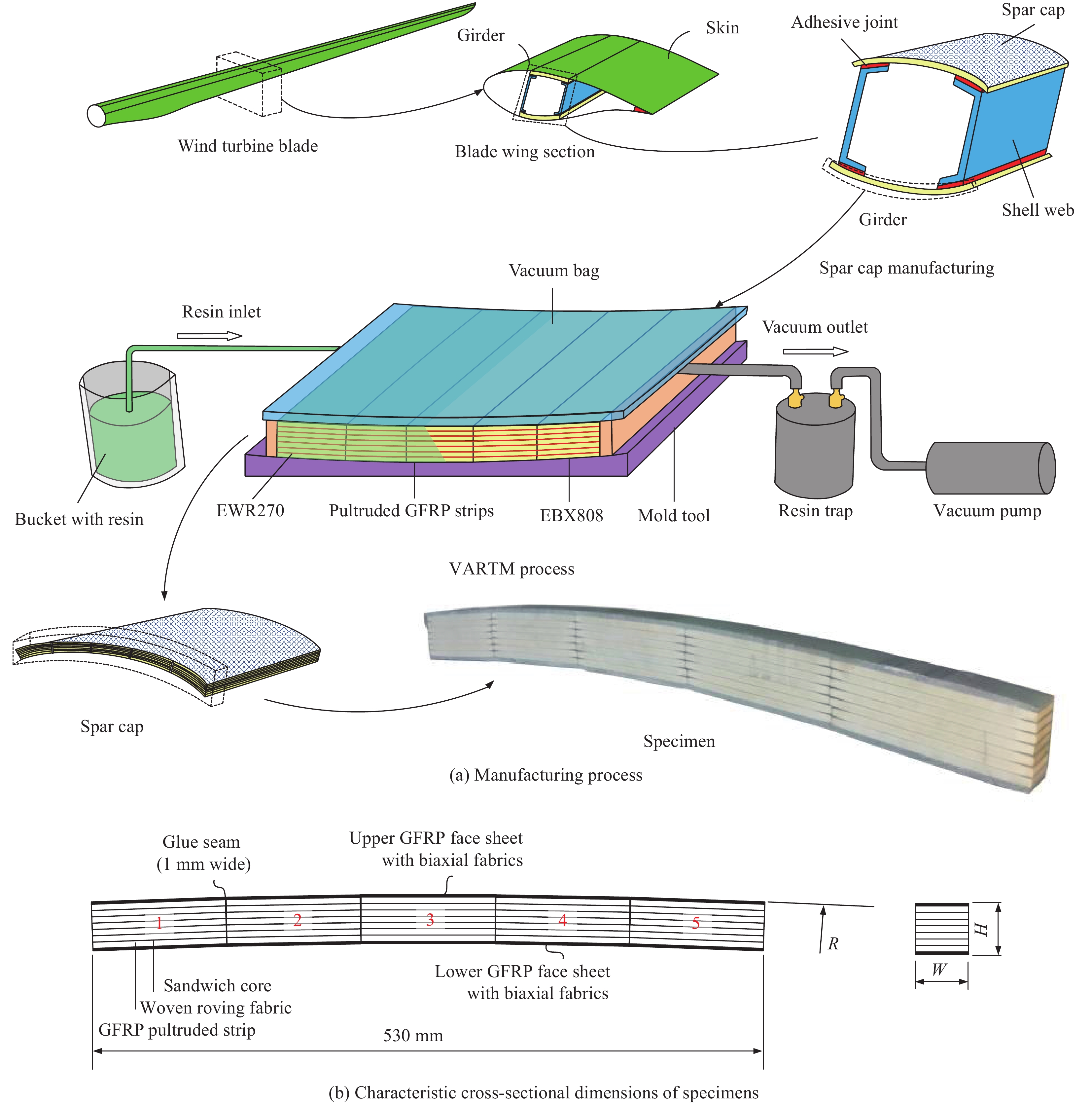

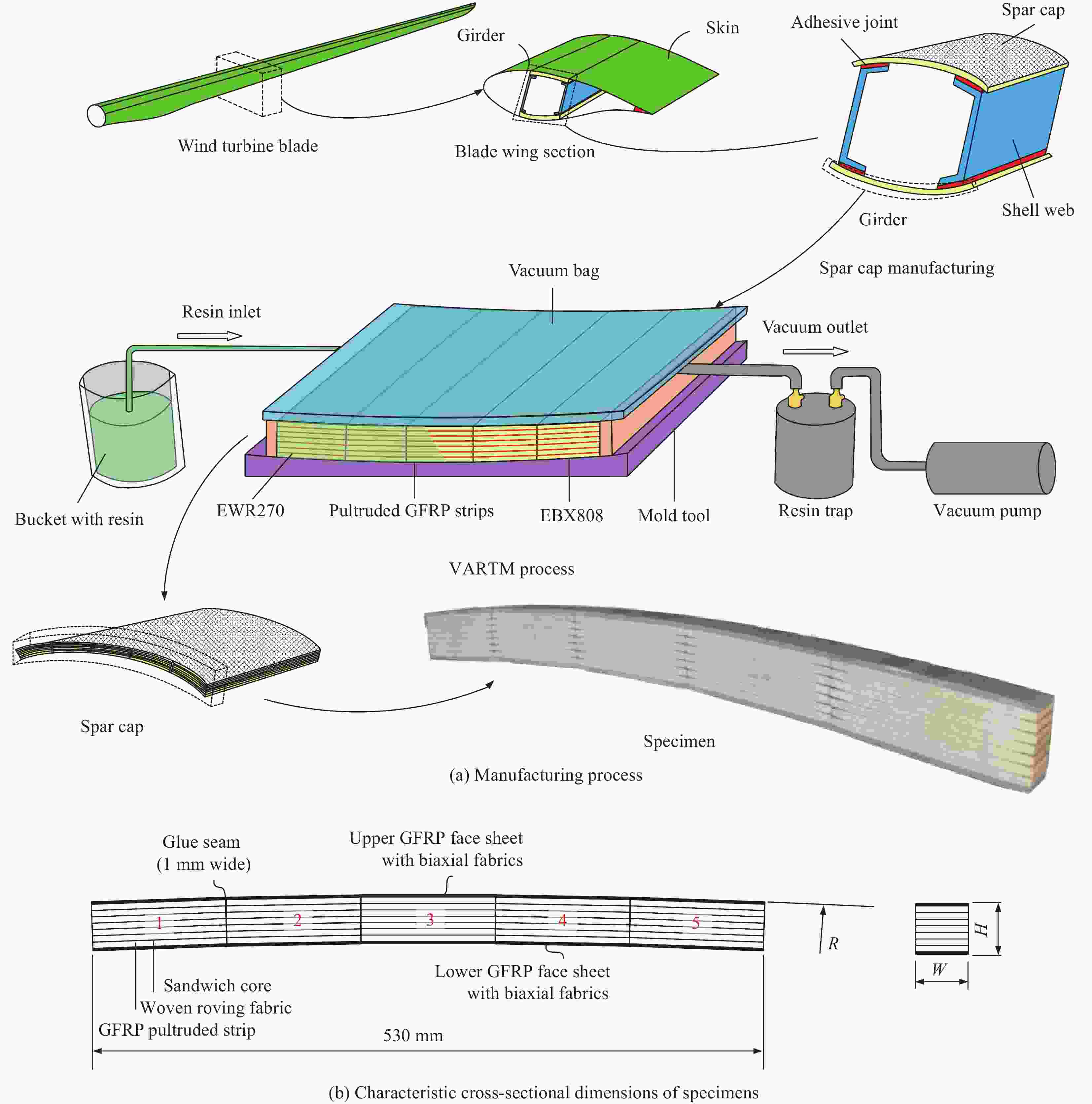

图 1 风电叶片拉挤夹芯梁帽足尺试件

VARTM—Vacuum assisted resin transfer molding; GFRP—Glass fiber-reinforced polymer; EWR270—E-glass woven roving EWR270 (0/90) with an area weight of 270 g/m2; EBX808—E-glass biaxial fabric EBX808 (+45/-45) with an area weight of 808 g/m2; R—Radius of curvature of upper layer (mm); W—Width of midspan section (mm); H—Height of midspan section (mm)

Figure 1. Full-scale specimen of pultruded sandwich spar cap cut from wind turbine blade

表 1 GFRP拉挤夹芯梁帽试件材料基本力学性能

Table 1. Material properties of pultruded GFRP sandwich spar cap specimens

Material property GFRP(EBX808) (±45°) GFRP(EWR270) (0°/90°) Pultruded GFRP strip Epoxy resin Density/(kg·m−3) 1930 1810 2030 1200 Ex/MPa 12500 20000 57000 2700 Ey/MPa 12500 20000 13500 2700 Ez/MPa 8000 12000 13500 2700 νxy 0.60 0.14 0.27 0.30 Gxy/MPa 4000 8750 4000 1039 Gyz/MPa 4000 8750 4000 1039 Gzx/MPa 4000 8750 4000 1039 Xt/MPa 230 – 1100 65 Xc/MPa 230 – 850 65 Yt/MPa – – 65 20 Yc/MPa – – 130 20 S/MPa 56 – 40 25 Notes: Ex—Longitudinal elastic modulus; Ey, Ez—Transverse elastic modulus; νxy—Poisson's ratio; Gxy, Gyz and Gzx—Shear modulus; Xt—Longitudinal tensile strength; Xc—Longitudinal compressive strength; Yt—Transverse tensile strength; Yc—Transverse compressive strength; S—Shear strength. 表 2 GFRP拉挤夹芯梁帽试件基本参数

Table 2. Pultruded GFRP sandwich spar cap specimen geometries

Specimen Radius of curvature

of upper layer/mmWidth of midspan section/mm Height of midspan section/mm Span length of

pure bending l/mmEBX8080-1 965 32.02 37.81 216 EBX8081-1 1715 25.63 37.80 106 EBX8081-2 1779 24.91 37.79 216 EBX8081-3 1739 25.26 38.13 318 EBX8083-1 1762 26.65 40.14 106 EBX8083-2 1768 26.73 40.06 216 EBX8083-3 1768 25.83 40.06 318 EBX8085-1 1834 24.65 43.12 106 EBX8085-2 1854 25.23 42.98 216 EBX8085-3 1739 27.14 43.30 318 Note: EBX8080-1 means the specimen 1 in the group where the number of face sheet piles (with the biaxial fabric EBX808 material) is 0. 表 3 GFRP拉挤夹芯梁帽试件特征荷载及破坏模式

Table 3. Characteristic loads and failure modes of pultruded GFRP sandwich spar cap specimens

Specimen Initial stiffness/

(kN·mm−1)Initial cracking

load/kNMaximum point Load after

failure/kNCrack propagation

of glue seamFinal failure position

of specimenFailure

modeLoad/kN Deflection

/mmEBX8080−1 1.18 3.79 4.49 3.90 0.09 Pultruded strip near L2 L2 1 EBX8081−1 1.05 3.21 3.62 4.20 0.55 L2, R1

simultaneouslyL2 2 EBX8081−2 1.27 3.25 5.32 4.69 0.28 R1→L2 R1 2 EBX8081−3 1.58 7.78 8.54 5.50 0.00 R1→L2→L1, R2 simultaneously R2 2 EBX8083−1 1.61 4.02 6.10 4.43 3.44 R1→L2 L2 3 EBX8083−2 1.62 5.40 9.03 6.07 5.48 R1 R1 3 EBX8083−3 1.81 10.65 16.21 9.31 8.96 L1→R1→R2→L2 R2 3 EBX8085−1 1.61 6.05 7.47 5.34 5.25 L2→R1 R1 3 EBX8085−2 1.71 9.62 10.53 6.59 8.64 R1→L2 L2 3 EBX8085−3 1.89 14.89 19.17 10.58 16.54 L1→R2→R1 R2 3 -

[1] 寇海霞. 复合材料风电叶片刚度退化模型研究[D]. 兰州: 兰州理工大学, 2019.KOU Haixia. Research on stiffness degradation model of composite wind turbine blades[D]. Lanzhou: Lanzhou University of Technology, 2019(in Chinese). [2] SAHU B K. Wind energy developments and policies in China: A short review[J]. Renewable and Sustainable Energy Reviews,2018,81(1):1393-1405. [3] 唐荆. 大型风电复合材料叶片主承力部件结构失效研究[D]. 北京: 中国科学院大学, 2019.TANG Jing. Structural failure of the primary load-carrying component of large composite wind turbine blades[D]. Beijing: University of Chinese Academy of Science, 2019(in Chinese). [4] HEGLER S, PLETTEMEIER D. Simulative investigation of the radar cross section of wind turbines[J]. Applied Sciences,2019,9(19):4024. doi: 10.3390/app9194024 [5] 国家能源局. 2020年度全国可再生能源电力发展监测评价报告[EB/OL]. (2021-06-20) [2022-04-30]. http://zfxxgk.nea.gov.cn/2021-07/02/c_1310039970.htm.National Energy Administration. Monitoring and evaluation report of national renewable energy and electric power development in 2020[EB/OL].(2021-06-20)[2022-04-30]. http://zfxxgk.nea.gov.cn/2021-07/02/c_1310039970.htm. [6] 蔡新, 潘盼, 朱杰, 等. 风力发电机叶片[M]. 北京: 中国水利水电出版社, 2014: 8.CAI Xin, PAN Pan, ZHU Jie, et al. Wind turbine blade[M]. Beijing: China Water Power Press, 2014: 8(in Chinese). [7] MUTKULE S K, GORAD P P, RAUT S R, et al. Optimum and reliable material for wind turbine blade[J]. International Journal of Engineering Research & Technology,2015,4(2):624-627. [8] 许经纬. 碳纤维/玻璃纤维混杂增强复合材料力学性能研究及风电叶片应用[D]. 苏州: 苏州大学, 2019.XU Jingwei. Study on mechanical properties of carbon/glass hybridized fabric reinforced composites and applications for wind turbine blades[D]. Suzhou: Soochow University, 2019(in Chinese). [9] STEWART R. Wind turbine blade production-New products keep pace as scale increases[J]. Reinforced Plastics,2012,56(1):18-25. doi: 10.1016/S0034-3617(12)70033-4 [10] BRØNDSTED P, HOLMES J W, SØRENSEN B F. Wind rotor blade materials technology[J]. European Sustainable Energy Review,2008(2):36-41. [11] 李成良, 王继辉, 薛忠民, 等. 大型风机叶片材料的应用和发展[J]. 玻璃钢/复合材料, 2008(4):49-52.LI Chengliang, WANG Jihui, XUE Zhongmin, et al. Application and development of materials of large-scale wind turbine blades[J]. Fiber Reinforced Plastics/Composites,2008(4):49-52(in Chinese). [12] BAI Y, KELLER T, WU C. Pre-buckling and post-buckling failure at web-flange junction of pultruded GFRP beams[J]. Materials and Structures,2013,46(7):1143-1154. doi: 10.1617/s11527-012-9960-9 [13] CHEN G M, TENG J G, CHEN J F, et al. Finite element modeling of debonding failures in FRP-strengthened RC beams: A dynamic approach[J]. Computers & Structures,2015,158:167-183. [14] FENG P, LI Z Y, WANG J, et al. Novel joint for pultruded FRP beams and concrete-filled FRP columns: Conceptual and experimental investigations[J]. Composite Structures,2022,287:115339. doi: 10.1016/j.compstruct.2022.115339 [15] MARTIN R W, SABATO A, SCHOENBERG A, et al. Comparison of nondestructive testing techniques for the inspection of wind turbine blades' spar caps[J]. Wind Energy,2018,21(11):980-996. doi: 10.1002/we.2208 [16] 马志勇. 大型风电叶片结构设计方法研究[D]. 北京: 华北电力大学, 2011.MA Zhiyong. Research on large-scale wind turbine blade structure design method[D]. Beijing: North China Electric Power University, 2011(in Chinese). [17] GRIFFIN D, MALKIN M. Lessons learned from recent blade failures: Primary causes and risk-reducing technologies[C]//49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition. Orlando: American Institute of Aeronautics and Astronautics, 2011, 259: 1-9. [18] MISHNAEVSKY L, BRANNER K, PETERSEN H N, et al. Materials for wind turbine blades: An overview[J]. Materials,2017,10(11):1285. doi: 10.3390/ma10111285 [19] 冯鹏. 新型FRP空心桥面板的设计开发与受力性能研究[D]. 北京: 清华大学, 2004.FENG Peng. Development and study on an innovative FRP bridge deck[D]. Beijing: Tsinghua University, 2004(in Chinese). [20] 齐玉军, 熊伟, 刘伟庆, 等. 新型FRP拉挤夹芯型材及其结构应用初探[J]. 玻璃钢/复合材料, 2014(12):25-30.QI Yujun, XIONG Wei, LIU Weiqing, et al. A review on innovative pultruded FRP composite sandwich profiles and structural utilization[J]. Fiber Reinforced Plastics/Composites,2014(12):25-30(in Chinese). [21] LIU T Q, FENG P, WU Y W, et al. Developing an innovative curved-pultruded large-scale GFRP arch beam[J]. Composite Structures,2021,256:113111. doi: 10.1016/j.compstruct.2020.113111 [22] ZHAO D H, LIU T Q, LU X F, et al. Experimental and numerical analysis of a novel curved sandwich panel with pultruded GFRP strip core[J]. Composite Structures,2022,288:115404. doi: 10.1016/j.compstruct.2022.115404 [23] WU C, TIAN J, DING Y, et al. Axial compression behavior of pultruded GFRP channel sections[J]. Composite Structures,2022,289:115438. doi: 10.1016/j.compstruct.2022.115438 [24] 何东晓, 黄力刚, 杨松, 等. 我国复合材料风机叶片的几种制造工艺与发展前景[J]. 纤维复合材料, 2007(2): 12-14.HE Dongxiao, HUANG Ligang, YANG Song, et al. The outlook and manufacturing process of composite turbine rotor blades[J]. Fiber Composites, 2007(2): 12-14(in Chinese). [25] YARBROUGH A A, GEIGER S B, CARUSO C D. Methods for manufacturing a spar cap for a wind turbine rotor blade: US, 14/552 518[P]. 2016-05-26. [26] GIROLAMO D, KRISTENSEN J J Ø, NOERLEM M. Pultruded fibrous composite strips having corrugated profiles for wind turbine blade spar caps: US, 16/218 631[P]. 2019-06-27. [27] VEDERNIKOV A, SAFONOV A, TUCCI F, et al. Pultruded materials and structures: A review[J]. Journal of Compo-site Materials,2020,54(26):4081-4117. doi: 10.1177/0021998320922894 [28] RAO B V. A study towards the optimization of pultrusion processes: Process-microstructure-property correlation[D]. Enschede: University of Twente, 2021. [29] 柴红梅, 袁凌, 李颖, 等. 复合材料风电叶片先进制造技术研究现状[J]. 玻璃钢/复合材料, 2019(2):102-107.CHAI Hongmei, YUAN Ling, LI Ying, et al. Present research situation of advanced technology in composite wind blade[J]. Fiber Reinforced Plastics/Composites,2019(2):102-107(in Chinese). [30] ERTURK E. Preliminary analysis of a concept wind turbine blade with piecewise constant chord and constant twist angle using BEM method[J]. International Journal of Renewable Energy Research (IJRER),2018,8(4):1890-1902. [31] 张为军, 田野, 覃兆平, 等. 桥梁用大截面FRP拉挤型材的结构设计与试验研究[J]. 玻璃钢/复合材料, 2013(9):55-60.ZHANG Weijun, TIAN Ye, QIN Zhaoping, et al. The research of large cross-section FRP pultrusion profiles structural design and type testing in bridge[J]. Fiber Reinforced Plastics/Composites,2013(9):55-60(in Chinese). -

下载:

下载: