Effect of carbon nanotubes on mechanical and thermal stability of nitrile rubber O-ring

-

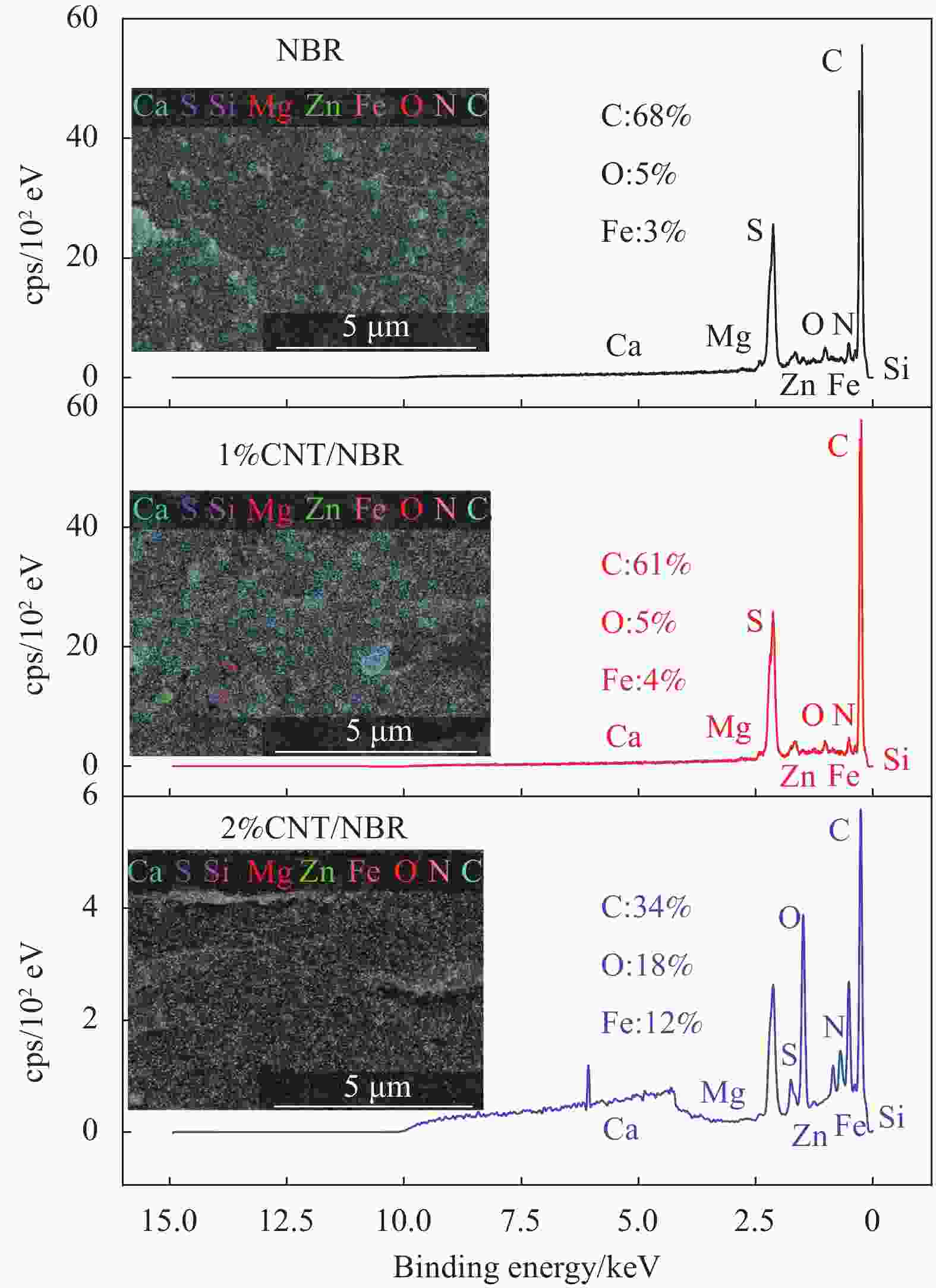

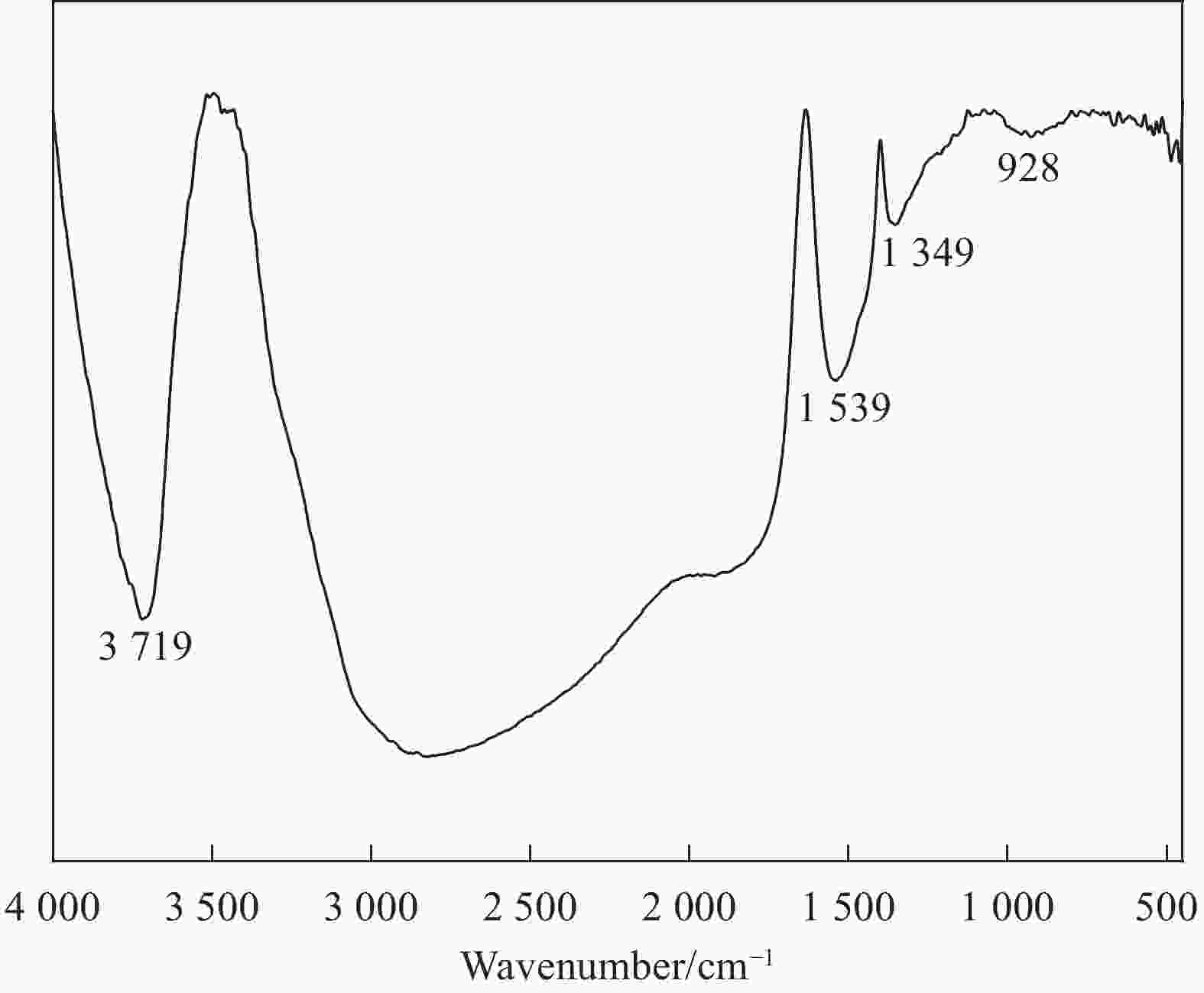

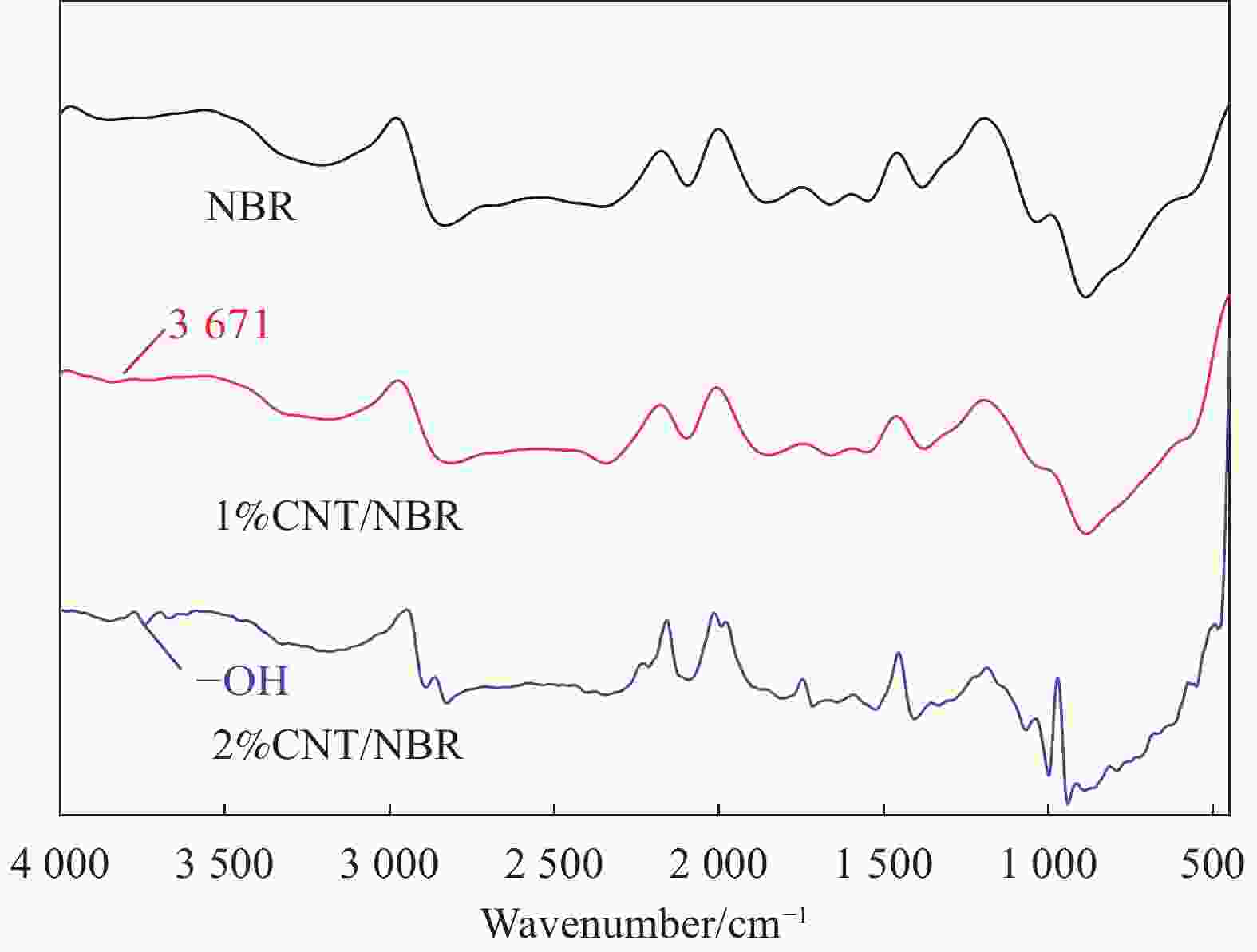

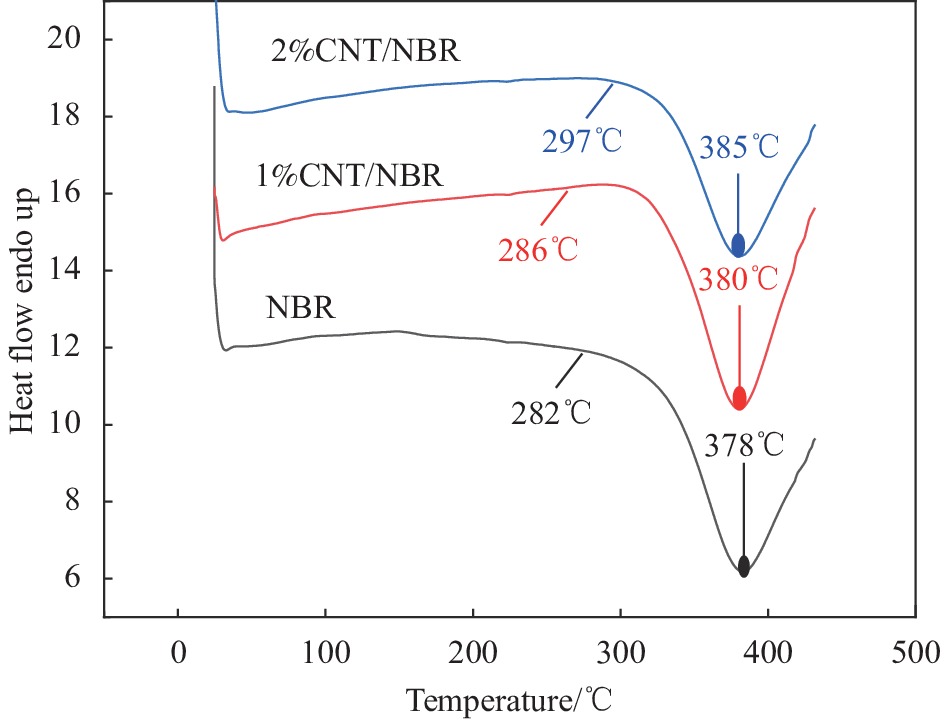

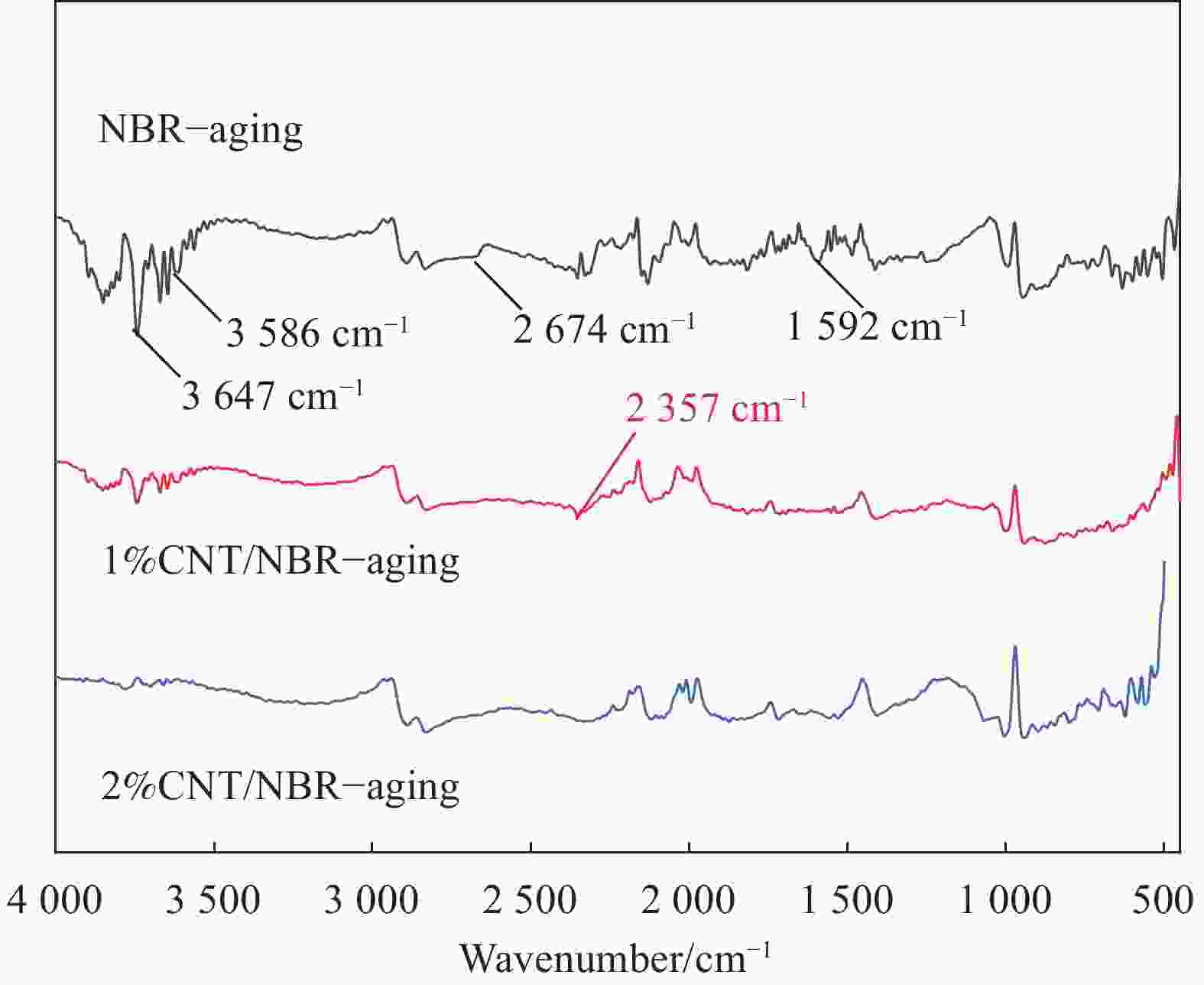

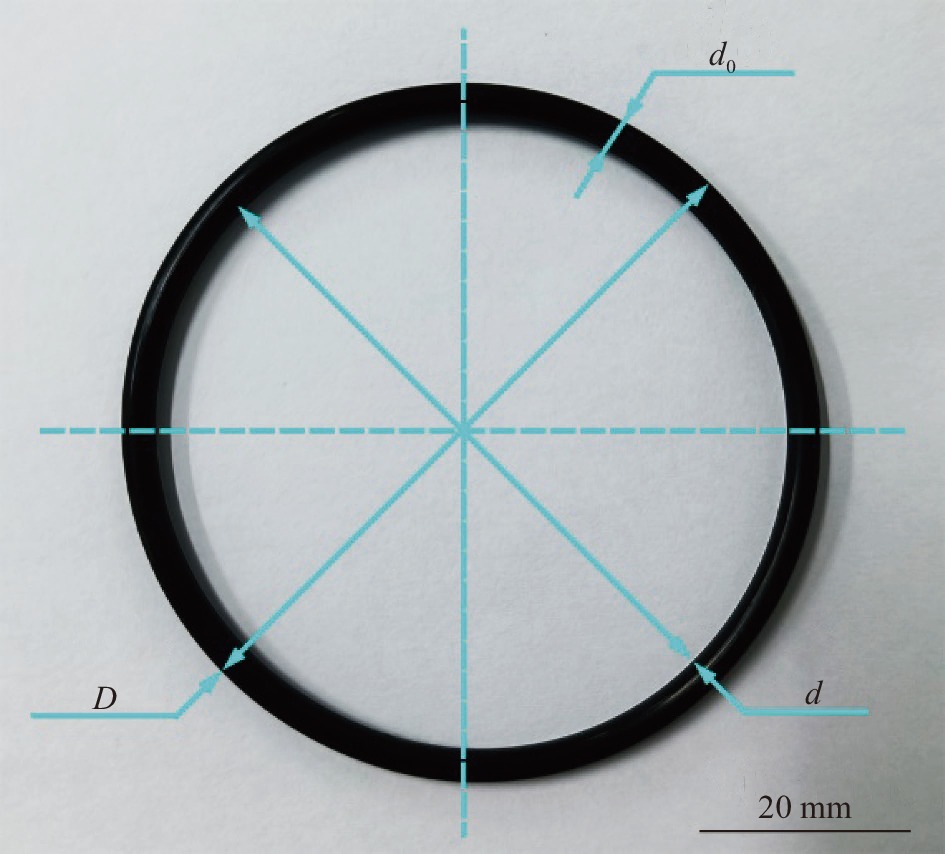

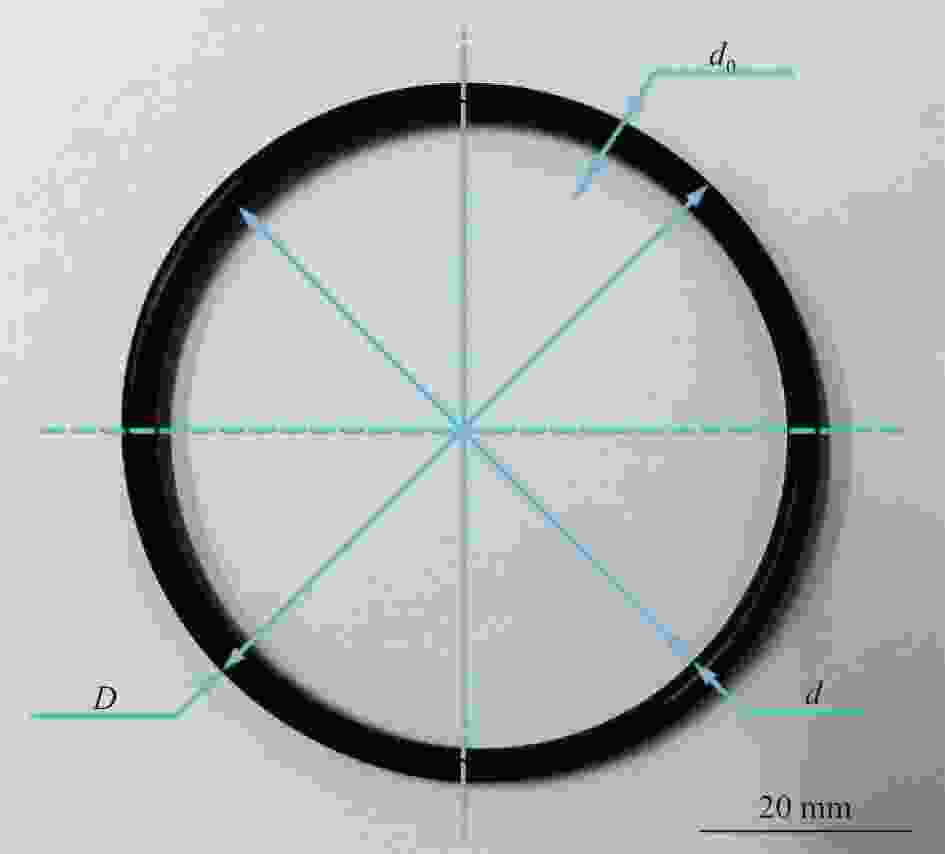

摘要: 为了研究碳纳米管(CNT)对丁腈橡胶(NBR) O型密封圈的力学及热稳定性能补强机制,利用机械共混法和热压成型法制备了1%CNT/NBR (CNT质量比)和2%CNT/NBR复合材料的O型密封圈,在表征CNT/NBR复合材料的截面SEM、EDS和FTIR基础上,测试了CNT/NBR复合材料O型密封圈的力学性能、热稳定性能和老化性能。研究结果表明,随着CNT含量的增加,CNT/NBR复合材质O型密封圈的弹性模量增大,刚性增强。1%CNT/NBR材质O型密封圈由于C—O键的形成,使其拉伸强度达到12.6 MPa。CNT在NBR基体中含量的增加可以提高CNT/NBR复合材质O型密封圈的热稳定性,2%CNT/NBR的相转变温度达到297℃。1%CNT/NBR复合材料具有优异的抗老化特性归因于CNT使NBR基体产生C≡N三键官能团。高性能CNT/NBR复合材料O型密封圈在航空密封件领域有一定的应用价值。Abstract: In order to study the reinforcing mechanism of carbon nanotubes (CNT) on the mechanical and thermal stability of nitrile rubber (NBR) O-ring, 1%CNT/NBR (mass ratio of CNT) and 2%CNT/NBR composite O-ring were prepared by mechanical blending and hot pressing. The mechanical properties of CNT/NBR composite O-ring were tested on the basis of SEM, EDS and FTIR. The results show that with the increase of CNT content, the elastic modulus and rigidity of CNT/NBR composite O-ring increase. The tensile strength of 1%CNT/NBR O-ring reaches 12.6 MPa due to the formation of C—O bond. The increase of CNT content in NBR matrix can improve the thermal stability of CNT/NBR composite O-ring, and the phase transition temperature of 2%CNT/NBR reaches 297℃. The excellent aging resistance of 1%CNT/NBR composites is attributed to the fact that CNT makes NBR matrix produce C≡N triple bond functional groups. High-performance CNT/NBR composite O-ring has certain application value in the field of aviation seals.

-

D/d/mm d0/mm d1/mm 65/60 $ {3.12}_{-0.10}^{+0.12} $ 59.5±0.40 Note: d1—Actual inner diameter. 表 2 不同CNT含量NBR复合材料O型密封圈的尺寸、硬度、拉伸强度及断裂伸长率

Table 2. Dimensions, hardness, tensile strength and elongation at break of NBR composite O-ring with different CNT content

d0/mm C0/mm S0/mm Shore A/HA T/MPa E/% NBR 3.12 186.3 69.4 76±1 12.1±0.7 210.8±31.5 1%CNT/NBR 3.12 186.8 69.4 78±1 12.6±1.1 187.2±21.4 2%CNT/NBR 3.14 187.4 69.4 80±1 9.8±1.8 131.0±15.6 Notes: C0—Inner circumference of O-ring; S0—Center distance of initial fixture; Shore A—Hardness. 表 3 不同CNT含量NBR复合材料O型密封圈老化后的尺寸、硬度、拉伸强度及断裂伸长率

Table 3. Dimensions, hardness, tensile strength and elongation at break of NBR composite O-ring with different CNT content after aging

d0/mm C0/mm S0/mm Shore A/HA T/MPa E/% NBR 3.10 184.6 69.4 82±1 13.2±0.5 218.0±15.2 1%CNT/NBR 3.08 186.2 69.4 83±2 17.3±0.4 199.8±7.4 2%CNT/NBR 3.06 185.9 69.4 84±1 10.2±0.9 114.6±13.1 表 4 不同CNT含量NBR复合材料O型密封圈的恒定压缩永久变形结果

Table 4. Permanent deformation results of NBR composite O-ring with different CNT content under constant compression

d1/

mmd2/

mmC1/

%$\overline C _{\textit{1} }$/% NBR 3.14 3.10 7 6.3 3.16 3.07 6 3.18 3.10 6 1%CNT/

NBR3.17 3.10 8 8.7 3.16 3.08 10 3.15 3.08 8 2%CNT/

NBR3.21 3.11 11 8.0 3.15 3.10 5 3.17 3.10 8 Notes: d1—Cross-sectional diameter of the O-ring before compression; d2—Cross-sectional diameter of the O-ring after compression recovery for 24 h; C1—Constant compression set; $\overline C _{{1} } $—Average constant compression set. -

[1] 唐黎明, 李云龙, 何恩球, 等. 分子模拟纳米ZnO/丁腈橡胶复合材料的摩擦学行为[J]. 复合材料学报, 2020, 37(3):690-695.TANG Liming, LI Yunlong, HE Enqiu, et al. Molecular simulation of tribologybehavior of nano ZnO/nitrile-butadienerubbercomposites[J]. Acta Materiae Compositae Sinica,2020,37(3):690-695(in Chinese). [2] 张志, 许勇, 岳耀, 等. 受阻酚AO-60/丁腈橡胶-环氧化天然橡胶-天然橡胶复合材料的制备及其阻尼性能[J]. 复合材料学报, 2019, 36(8):1796-1803.ZHANG Zhi, XU Yong, YUE Yao, et al. Preparation and damping properties of hindered phenol AO-60/nitrilebutadiene rubber-epoxidized natural rubber-natural rubbercomposites[J]. Acta Materiae Compositae Sinica,2019,36(8):1796-1803(in Chinese). [3] LIAO B P, SUN B, LI Y, et al. Sealing reliability modeling of aviation seal based on interval uncertainty method and multidimensional response surface[J]. Chinese Journal of Aeronautics,2019,32(9):2188-2198. doi: 10.1016/j.cja.2019.01.019 [4] ZHANG M T, FENG Y. Numerical model of mixed lubrication and experimental study of reciprocating seal based on inverse lubrication theory[J]. Lubricants,2022,10(7):153. doi: 10.3390/lubricants10070153 [5] ZENG D Z, DONG B J, QI Y D, et al. On how CO2 partial pressure on corrosion of HNBR rubber O-ring in CO2-H2S-CH4 environment[J]. International Journal of Hydrogen Energy,2021,46(11):8300-8316. doi: 10.1016/j.ijhydene.2020.11.264 [6] 王兴刚, 齐永新, 彭仁苹, 等. 我国丁腈橡胶产业发展现状及未来发展趋势[J]. 高分子通报, 2016(4):1-16.WANG Xinggang, QI Yongxin, PENG Renping, et al. The development status and future development trend of nitrile rubber industry in China[J]. Polymer Bulletin,2016(4):1-16(in Chinese). [7] 逄见光. 不同牌号氢化丁腈橡胶性能对比[J]. 特种橡胶制品, 2020, 41(2):31-35.YING Jianguang. Performance comparison of different grades of hydrogenated nitrile rubber[J]. Special Rubber Products,2020,41(2):31-35(in Chinese). [8] 钱伯章. Zeon公司扩大日本氢化丁腈橡胶产能[J]. 合成橡胶工业, 2022, 45(3):243.QIAN Bozhang. Zeon company expands the production capacity of hydrogenated nitrile rubber in Japan[J]. Synthetic Rubber Industry,2022,45(3):243(in Chinese). [9] HU G, MA J B, YUAN G J, et al. Effect of hard particles on the tribological properties of hydrogenated nitrile butadiene rubber under different lubricated conditions[J]. Tribology International,2022,169:107457. doi: 10.1016/j.triboint.2022.107457 [10] LENG D X, HUANG C, XU K, et al. Experimental mechanics and numerical prediction on stress relaxation and unrecoverable damage characteristics of rubber materials[J]. Polymer Testing,2021,98:107183. doi: 10.1016/j.polymertesting.2021.107183 [11] EL YAAGOUBI M, EL MAANAOUI H, MEIER J. Influence of operating temperature on the measured and predicted lifetime of carbon black-filled hydrogenated nitrile butadiene rubber[J]. Engineering Fracture Mechanics,2022,271:108633. doi: 10.1016/j.engfracmech.2022.108633 [12] NISHI T, YAMAGUCHI T, HOKKIRIGAWA K. Development of high slip-resistant footwear outsole using rubber surface filled with activated carbon/sodium chloride[J]. Scientific Reports,2022,12:267. doi: 10.1038/s41598-021-99269-x [13] ZHANG P, KONG X S, WANG Z, et al. High velocity projectile impact of a composite rubber/aluminium fluid-filled container[J]. International Journal of Lightweight Materials and Manufacture,2021,4(1):1-8. doi: 10.1016/j.ijlmm.2020.06.007 [14] LIU X S, ZHOU X C, KUANG F M, et al. Mechanical and tribological properties of nitrile rubber reinforced by nano-SiO2: Molecular dynamics simulation[J]. Tribology Letters,2021,69(2):1-11. [15] CUI J Z, ZHAO J, WANG S J, et al. A comparative study on enhancement of mechanical and tribological properties of nitrile rubber composites reinforced by different functionalized graphene sheets: Molecular dynamics simulations[J]. Polymer Composites,2021,42(1):205-219. doi: 10.1002/pc.25819 [16] AMMINENI S P, NAGARAJU C, LINGARAJU D. Thermal degradation of naturally aged NBR with time and temperature[J]. Materials Research Express,2022,9(6):065305. doi: 10.1088/2053-1591/ac7302 [17] MOHD NORIZAN N, ASYRAF M R M, KHALINA A, et al. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview[J]. Polymers,2021,13(7):1047. doi: 10.3390/polym13071047 [18] VENKATARAMAN A, AMADI E V, CHEN Y D, et al. Carbon nanotube assembly and integration for applications[J]. Nanoscale Research Letters,2019,14(1):1-47. doi: 10.1186/s11671-018-2843-4 [19] YANG Z F, TIAN J R, YIN Z F, et al. Carbon nanotube-and graphene-based nanomaterials and applications in high-voltage supercapacitor: A review[J]. Carbon,2019,141:467-480. doi: 10.1016/j.carbon.2018.10.010 [20] NORIZAN M N, MOKLIS M H, NGAH DEMON S Z, et al. Carbon nanotubes: Functionalisation and their application in chemical sensors[J]. RSC Advances,2020,10(71):43704-43732. doi: 10.1039/D0RA09438B [21] KITISAVETJIT W, NAKARAMONTRI Y, PICHAIYUT S, et al. Influences of carbon nanotubes and graphite hybrid filler on properties of natural rubber nanocomposites[J]. Polymer Testing,2021,93:106981. doi: 10.1016/j.polymertesting.2020.106981 [22] 唐黎明, 王新楠, 纪平, 等. 碳纳米管丁腈橡胶耐磨复合材料的摩擦与力学性能模拟[J]. 安徽大学学报(自然科学版), 2022, 46(5):83-88.TANG Liming, WANG Xinnan, JI Ping, et al. Simulation of frictionaland mechanical properties of CNTs/nitrile-butadienerubberwear-resistant composites[J]. Journal of Anhui University (Natural Science Edition),2022,46(5):83-88(in Chinese). [23] TZOUNIS L, PETOUSIS M, LIEBSCHER M, et al. Three-dimensional (3D) conductive network of CNT-modified short jute fiber-reinforced natural rubber: Hierarchical CNT-enabled thermoelectric and electrically conductive composite interfaces[J]. Materials,2020,13(11):2668. doi: 10.3390/ma13112668 [24] 国家标准计量局. O型橡胶密封圈尺寸系列: GB 1235—76[S]. 北京: 中国标准出版社, 1976.National Bureau of Standards and Metrology. Size series of O-type rubber sealing ring: GB 1235—76 [S]. Beijing: Standards Press of China, 1976(in Chinese). [25] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. O形橡胶密封圈实验方法: GB/T 5720—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, National Standardization Administration of China. Test method of O-shaped rubber sealing ring: GB/T 5720—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [26] 中华人民共和国国家质量监督检验检疫总局. 硫化橡胶或热塑性橡胶热空气加速老化和耐热实验: GB/T 3512—2001[S]. 北京: 中国标准出版社, 2001.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Hot air accelerated aging and heat resistance test of vulcanized rubber or thermoplastic rubber: GB/T 3512—2001[S]. Beijing: Standards Press of China, 2001(in Chinese). [27] 赵家琳, 高杜娟, 范国宁. 羧基丁腈橡胶中羧基含量测定方法的研究[J]. 合成材料老化与应用, 2018, 47(6):51-53.ZHAO Jialin, GAO Dujuan, FAN Guoning. Study on the method for determination of the content of carboxyl in carboxylated nitrile rubber[J]. Aging and Application of Synthetic Materials,2018,47(6):51-53(in Chinese). [28] 朱强强, 郭涛. 基于傅里叶变换红外光谱的航空丁腈橡胶鉴别方法[J]. 理化检验-物理分册, 2021, 57(3):19-22.ZHU Qiangqiang, GUO Tao. Identification method of aviation nitrile rubber based on Fourier transform infrared spectroscopy[J]. Physical and Chemical Inspection-Physical Volume,2021,57(3):19-22(in Chinese). -

下载:

下载: