Simulation of microscopic fracture behavior of ODOPB epoxy resin based on molecular dynamics

-

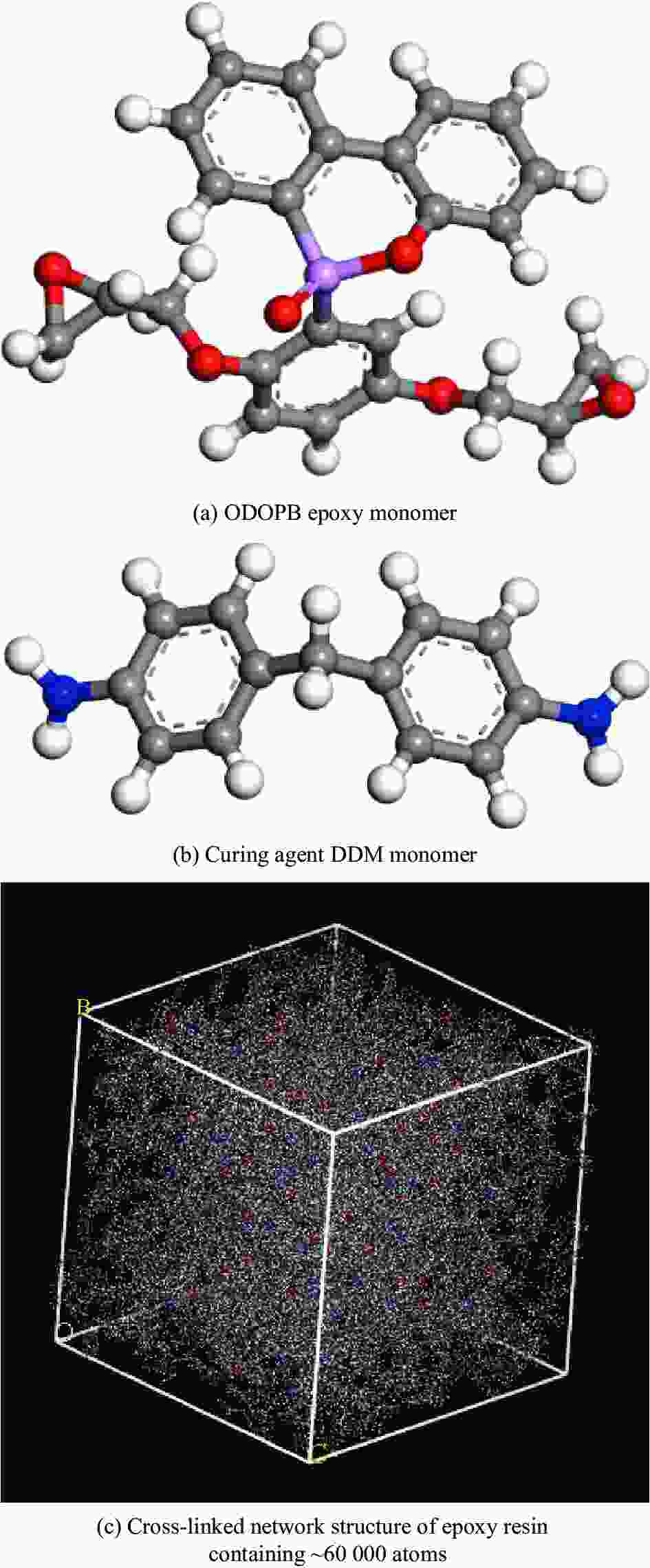

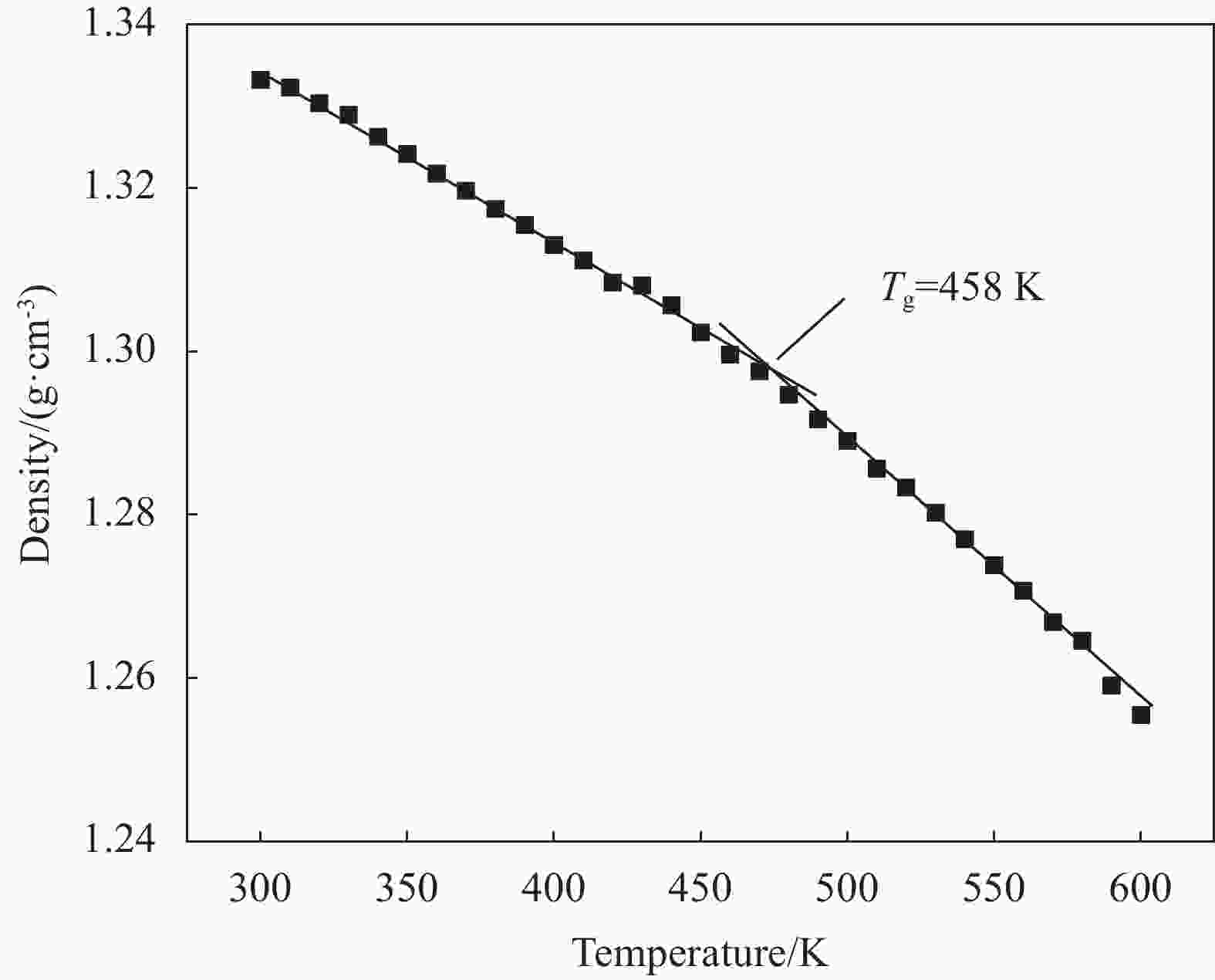

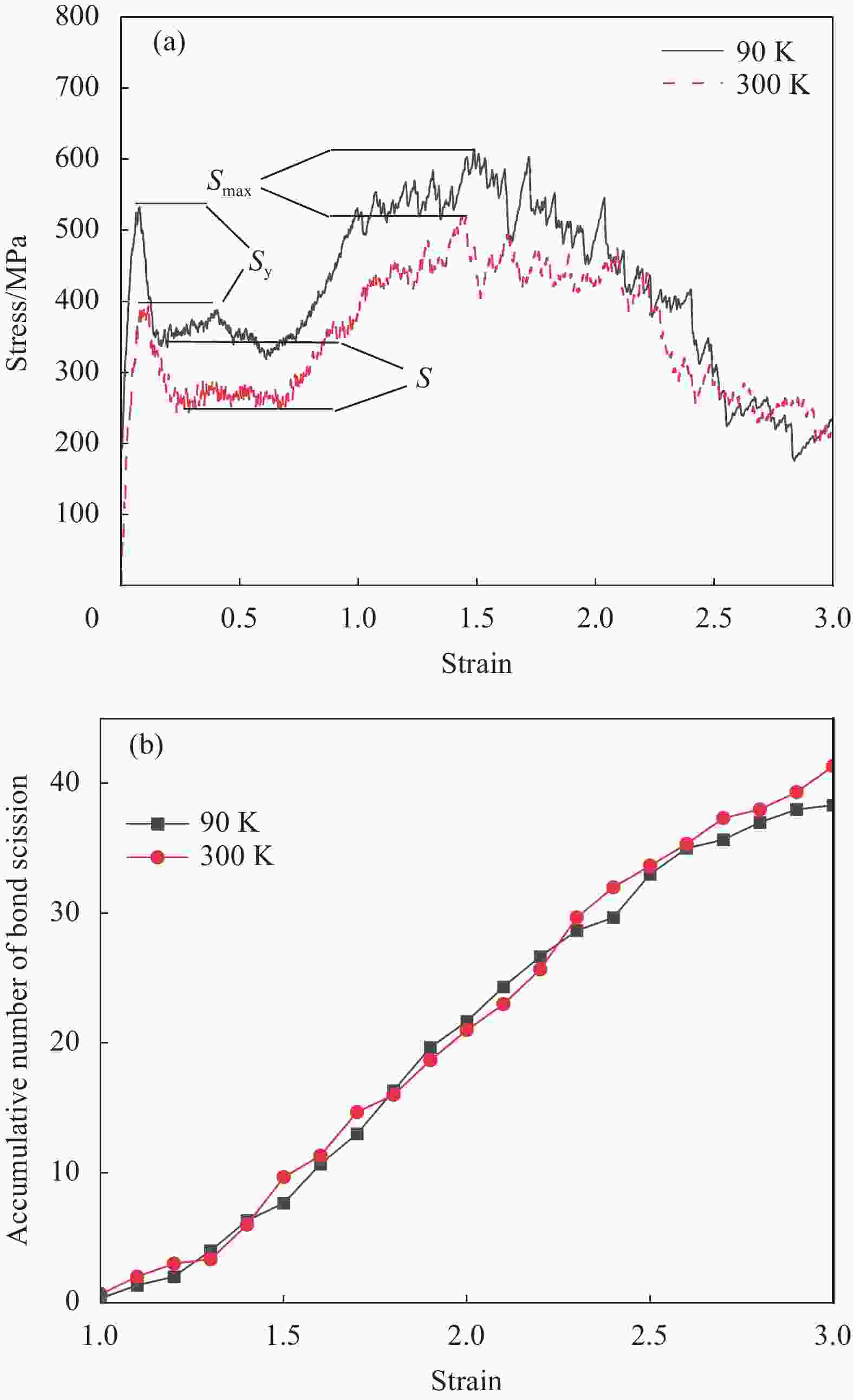

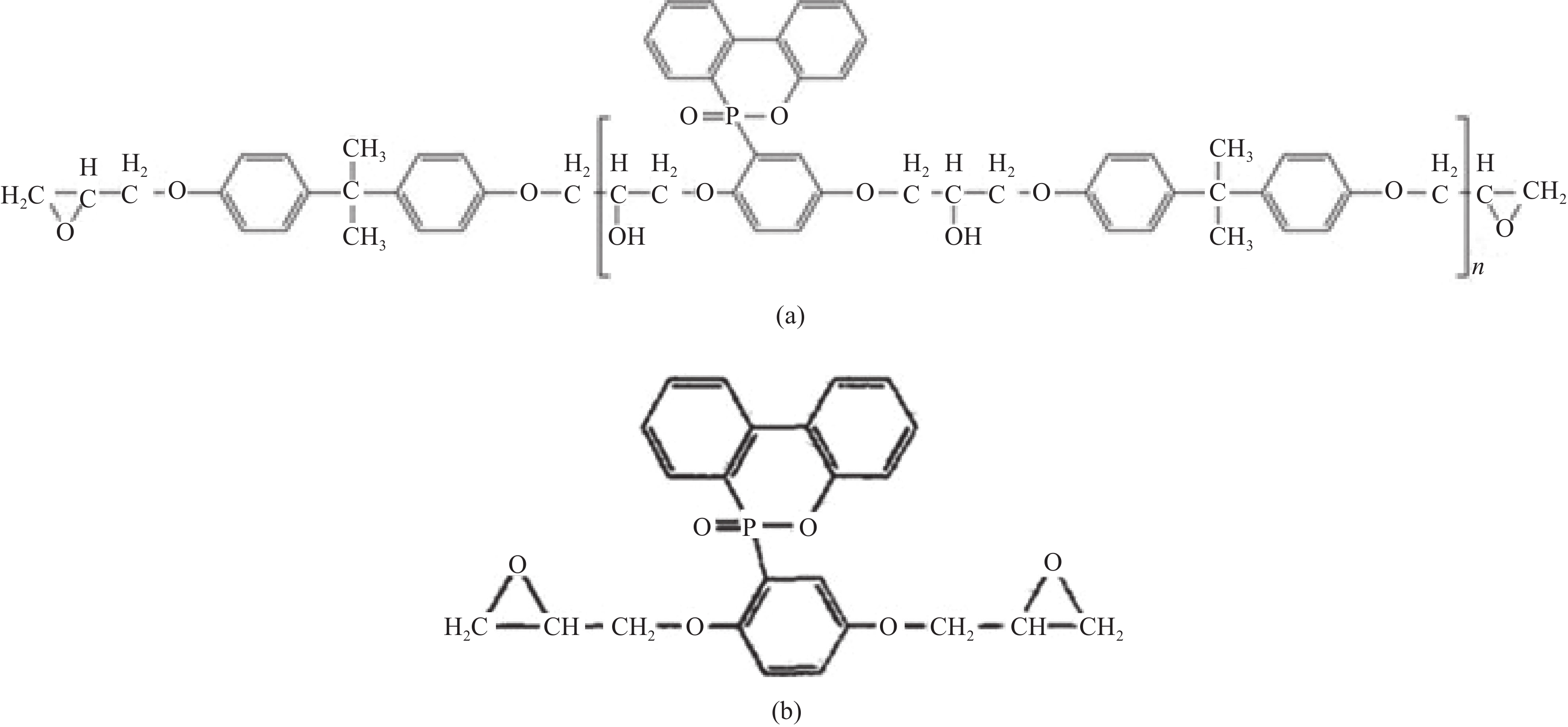

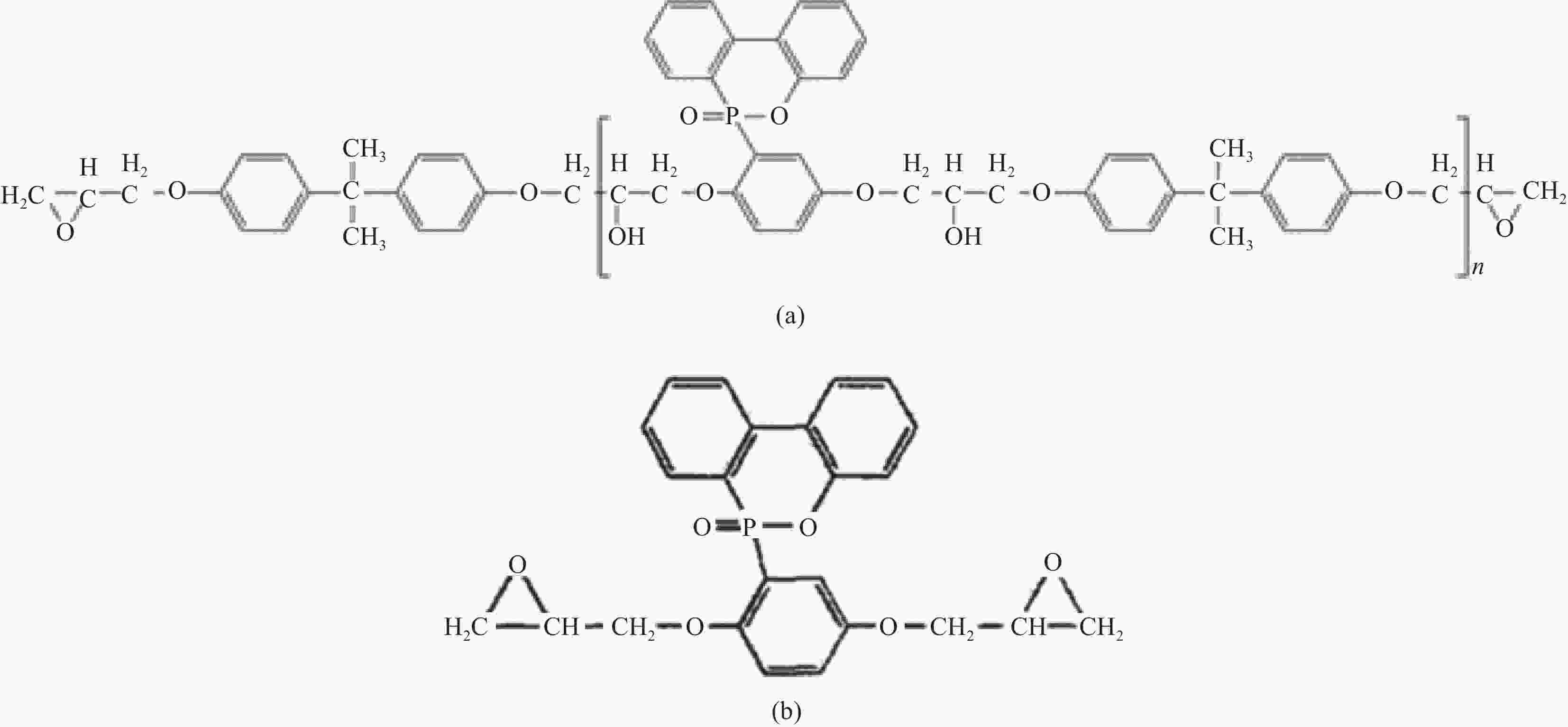

摘要: 将磷元素引入到环氧树脂体系可以有效改善其液氧相容性,但同时对其常低温力学性能的影响还有待研究。由于固化后的含磷环氧树脂体系具有复杂的无定形非晶交联网状结构,影响其力学性能的因素众多且相互关联,实验研究难以表征其微观破坏行为。本论文基于分子动力学(MD)研究,模拟出10-(2, 5-二羟基苯基)-10-氢-9-氧杂-10-磷杂菲-10-氧化物(ODOPB)与环氧氯丙烷反应得到的环氧树脂与固化剂4, 4'-二氨基二苯甲烷(DDM)的固化交联过程,计算了该树脂体系的热力学参数与微观破坏行为,揭示其断裂过程下的微观力学响应机制,并与2wt%含磷量下的ODOPB改性环氧树脂体系进行对比。分析结果为耐极端环境高性能环氧树脂与复合材料的设计与性能优化提供参考。Abstract: Adding phosphorus to the epoxy resin system could effectively improve its liquid oxygen compatibility. Anyway, the research about mechanical properties of such epoxy resin system containing phosphorus was absent. Since the cured phosphorus-containing epoxy resin system had a complex and amorphous interlaced network structure, and there were many interrelated factors affecting its mechanical properties, it was difficult to demonstrate the microscopic fracture behavior by experiments. In the present paper, based on molecular dynamics (MD) research, the curing and cross-linking process of epoxy resin containing phosphorus (synthesized from 10-(2, 5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide (ODOPB) and epichlorohydrin and 4, 4'-diaminodiphenylmethane (DDM) was simulated. The thermodynamic parameters and microscopic failure beha-vior of the resin system were calculated, and the micromechanical response mechanism under the fracture process was revealed. And the results were compared with another phosphorus containing epoxy resin system (ODOPB modified epoxy) with 2wt% phosphorus content. The analysis results provide a reference for the design and performance optimization of high-performance epoxy composites with extreme environment resistance.

-

Key words:

- molecular dynamics /

- epoxy resin /

- ODOPB /

- liquid oxygen compatibility /

- fracture behavior

-

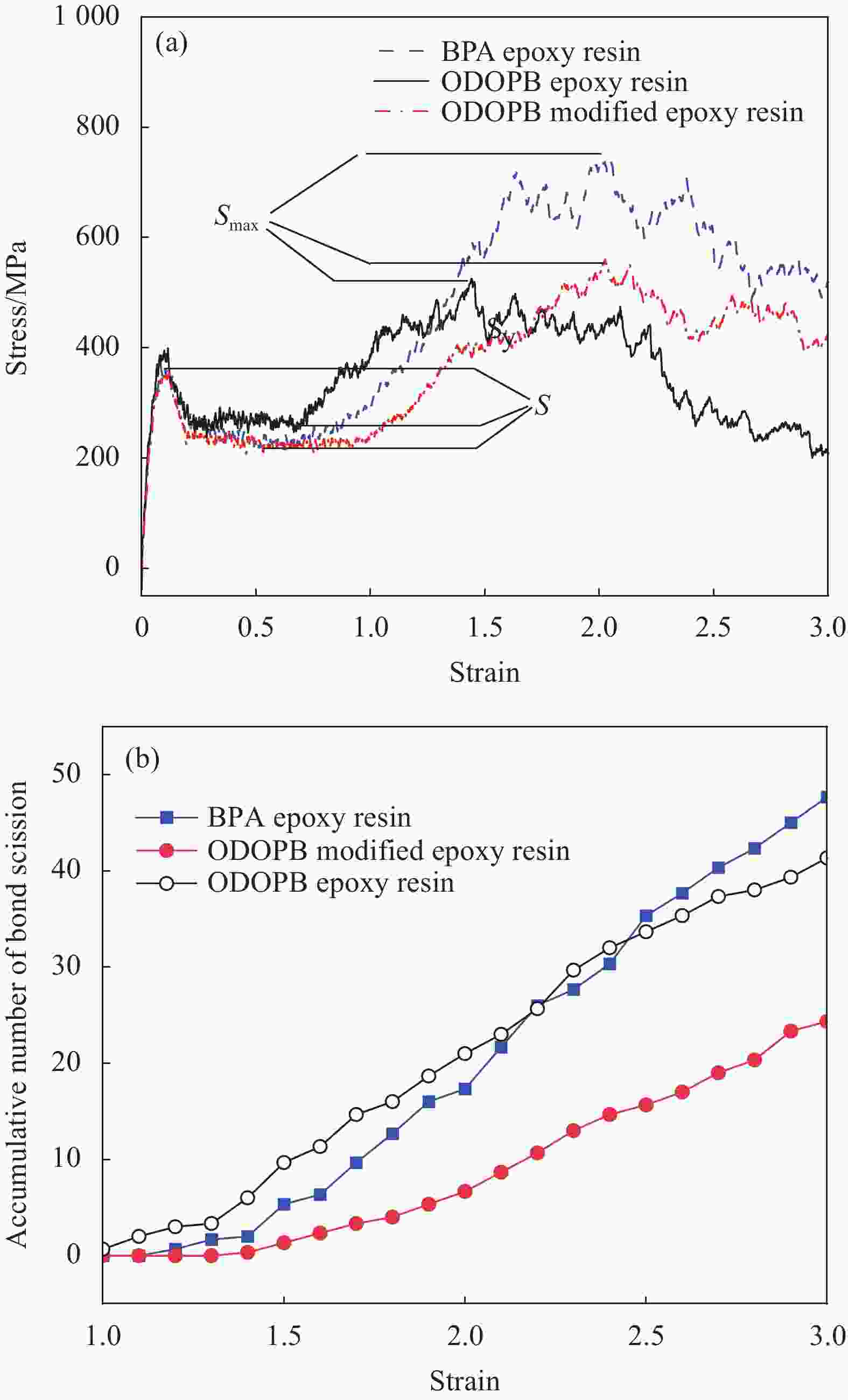

图 4 双酚A环氧树脂体系(BPA epoxy)、ODOPB改性环氧树脂体系(ODOPB modified)与ODOPB环氧树脂体系(ODOPB epoxy)的应力-应变曲线(a)和累计断键曲线(b)

Figure 4. Stress-strain curve (a) and cumulative broken bond number curves (b) of bisphenol A epoxy resin system (BPA epoxy), ODOPB modified epoxy resin system (ODOPB modified) and ODOPB epoxy resin system (ODOPB epoxy)

Smax—Maximum stress; S—Plateau stress

-

[1] 湛利华, 关成龙, 黄诚, 等. 航天低温复合材料贮箱国内外研究现状分析[J]. 航空制造技术, 2019, 62(16):79-87.ZHAN Lihua, GUAN Chenglong, HUANG Cheng, et al. Analysis of domestic and foreign research status of cryogenic composite storage tanks for aerospace[J]. Aviation Manufacturing Technology,2019,62(16):79-87(in Chinese). [2] 于斌, 刘志栋, 靳庆臣, 等. 国内外空间复合材料压力容器研究进展及发展趋势分析(一)[J]. 压力容器, 2012, 29(3):30-42. doi: 10.3969/j.issn.1001-4837.2012.03.007YU Bin, LIU Zhidong, JIN Qingchen, et al. Research progress and development trend analysis of space composite pressure vessels at home and abroad (1)[J]. Pressure Vessel,2012,29(3):30-42(in Chinese). doi: 10.3969/j.issn.1001-4837.2012.03.007 [3] 黄诚, 刘德博, 吴会强, 等. 我国航天运载器复合材料贮箱应用展望[J]. 沈阳航空航天大学学报, 2016, 33(2):27-35.HUANG Cheng, LIU Debo, WU Huiqiang, et al. Application prospects of composite storage tanks for space vehicles in my country[J]. Journal of Shenyang University of Aeronautics and Astronautics,2016,33(2):27-35(in Chinese). [4] WANG G, LI X D, YAN R. The study on compatibility of polymer matrix resins with liquid oxygen[J]. Materials Science & Engineering: B,2006,132(10):70-73. [5] BECHEL V, KIM R, DOMALDSON S. Composites containing barrier layers for reduced permeability at cryogenic temperature[C]//47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Newport, Rhode Island: AIAA, 2006: 2092. [6] 张辰威, 张博明. 复合材料贮箱在航天飞行器低温推进系统上的应用与关键技术[J]. 航空学报, 2014, 35(10):2747-2755.ZHANG Chenwei, ZHANG Boming. Application and key technology of composite material storage tank in cryogenic propulsion system of spacecraft[J]. Acta Aeronautica Sinica,2014,35(10):2747-2755(in Chinese). [7] ROBINSON M. Composite cryogenic propellant tank development[C]//35th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Hilton Head: AIAA, 1994: 1375. [8] 陈振国, 矫维成, 闫美玲, 等. 碳纤维增强树脂基复合材料低温贮箱抗渗漏性研究进展[J]. 玻璃钢/复合材料, 2018, 45(11):109-116.CHEN Zhen'guo, JIAO Weicheng, YAN Meiling, et al. Research progress on the leakage resistance of carbon fiber reinforced resin matrix composites in low temperature storage tanks[J]. Fiberglass/Composite Materials,2018,45(11):109-116(in Chinese). [9] ROBINSON M J. Composite cryogenic propellant tank development[J]. AIAA-94-1375-CP, 1994: 1375. [10] 李家亮. 环氧树脂液氧相容性与低温力学性能研究[D]. 大连: 大连理工大学, 2017.LI Jialiang. Study on liquid oxygen compatibility and low temperature mechanical properties of epoxy resin[D]. Dalian: Dalian University of Technology, 2017(in Chinese). [11] CHO C S, CHEN L W, CHIU Y S. Novel flame retardant epoxy resins[J]. Polymer Bulletin,1998,41:45-42. doi: 10.1007/s002890050331 [12] RAPAPORT D C. The art of molecular dynamics simulation[M]. Cambridge: Cambridge University Press, 2004: 146-149. [13] ALLEN M P. Introduction to molecular dynamics simulation[J]. Computational Soft Matter: From Synthetic Polymers to Proteins,2004,23(1):1-28. [14] TUCKERMAN M E, MARTYNA G J. Understanding modern molecular dynamics: Techniques and applications[J]. Journal of Physical Chemistry B,2000,104(2):159-178. doi: 10.1021/jp992433y [15] BINDER K. Monte carlo and molecular dynamics simulations in polymer science[M]. Oxford: Oxford University Press, 1995: 232. [16] 苗青. 改性SAPO-34催化性能的分子模拟研究[D]. 天津: 天津大学, 2009.MIAO Qing. Molecular simulation study on the catalytic performance of modified SAPO-34[D]. Tianjin: Tianjin University, 2009(in Chinese). [17] 张缨. 有机物系溶液结晶过程中形态学控制研究[D]. 天津: 天津大学, 2005.ZHANG Ying. Research on morphology control in the solution crystallization process of organic compounds[D]. Tianjin: Tianjin University, 2005(in Chinese). [18] LI C, STRACHAN A. Molecular simulations of crosslinking process of thermosetting polymers[J]. Polymer,2010,51:6058-6070. doi: 10.1016/j.polymer.2010.10.033 [19] 傅毅. 分子模拟及其在生物工程上的应用[D]. 无锡: 江南大学, 2010.FU Yi. Molecular simulation and its application in bioengineering[D]. Wuxi: Jiangnan University, 2010(in Chinese). [20] 王秀丽, 孙丽朋. 分子模拟在高分子材料研究中的应用[J]. 齐鲁石油化工, 2008, 36(4):331-333, 342. doi: 10.3969/j.issn.1009-9859.2008.04.018WANG Xiuli, SUN Lipeng. The application of molecular simulation in the research of polymer materials[J]. Qilu Petrochemical Industry,2008,36(4):331-333, 342(in Chinese). doi: 10.3969/j.issn.1009-9859.2008.04.018 [21] GRAZIANO G. Comment on “The mechanism of hydrophobic solvation depends on solute radius”[J]. The Journal of Physical Chemistry B, 2001, 105(10): 2079-2081. [22] 范世领, 张恒, 张冬菊. 分子模拟—理论与实验[M]. 北京: 化学工业出版社, 2016: 6-7.FAN Shiling, ZHANG Heng, ZHANG Dongju. Molecular simulation—Theory and experiment[M]. Beijing: Chemical Industry Press, 2016: 6-7(in Chinese). [23] SANDITOV D S, RAZUMOVSKAYA I V. New approach to justification of the Williams-Landel-Ferry equation[J]. Polymer Science: Series A, 2018: 60(2): 156-161. [24] D'ALMEIDA J R M, CELLA N. Analysis of the fracture behavior of epoxy resins under impact conditions[J]. Journal of Applied Polymer Science,2000,77(11):2486-2492. doi: 10.1002/1097-4628(20000912)77:11<2486::AID-APP18>3.0.CO;2-K [25] WILLEMS T F, RYCROFT C H, KAZI M, et al. Algorithms and tools for high-throughput geometry-based analysis of crystalline porous materials[J]. Microporous and Mesoporous Materials,2012,149(1):134-141. -

下载:

下载: