Effect of interfacial reaction products on the wettability and interfacial strength of B4C/Al composites

-

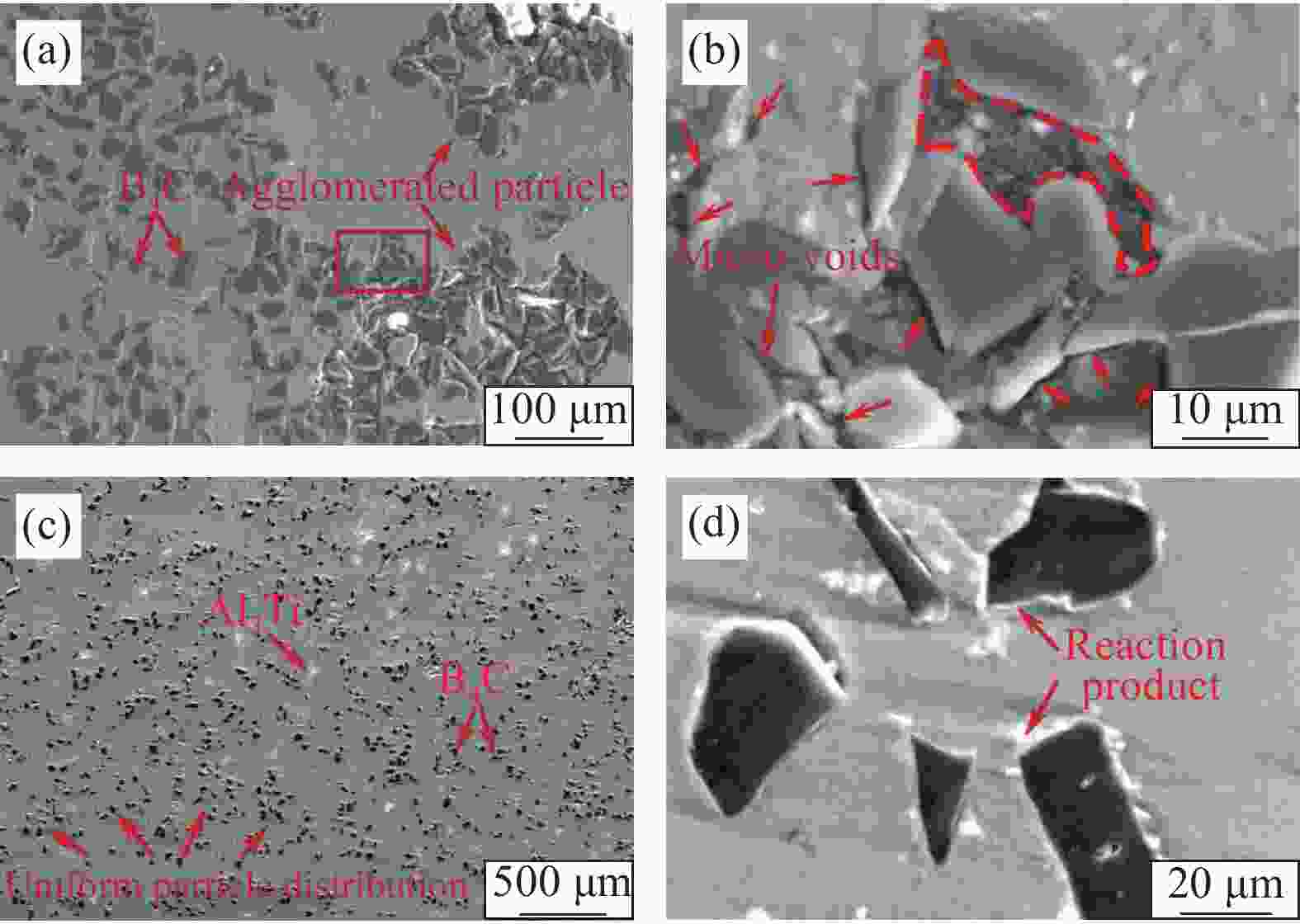

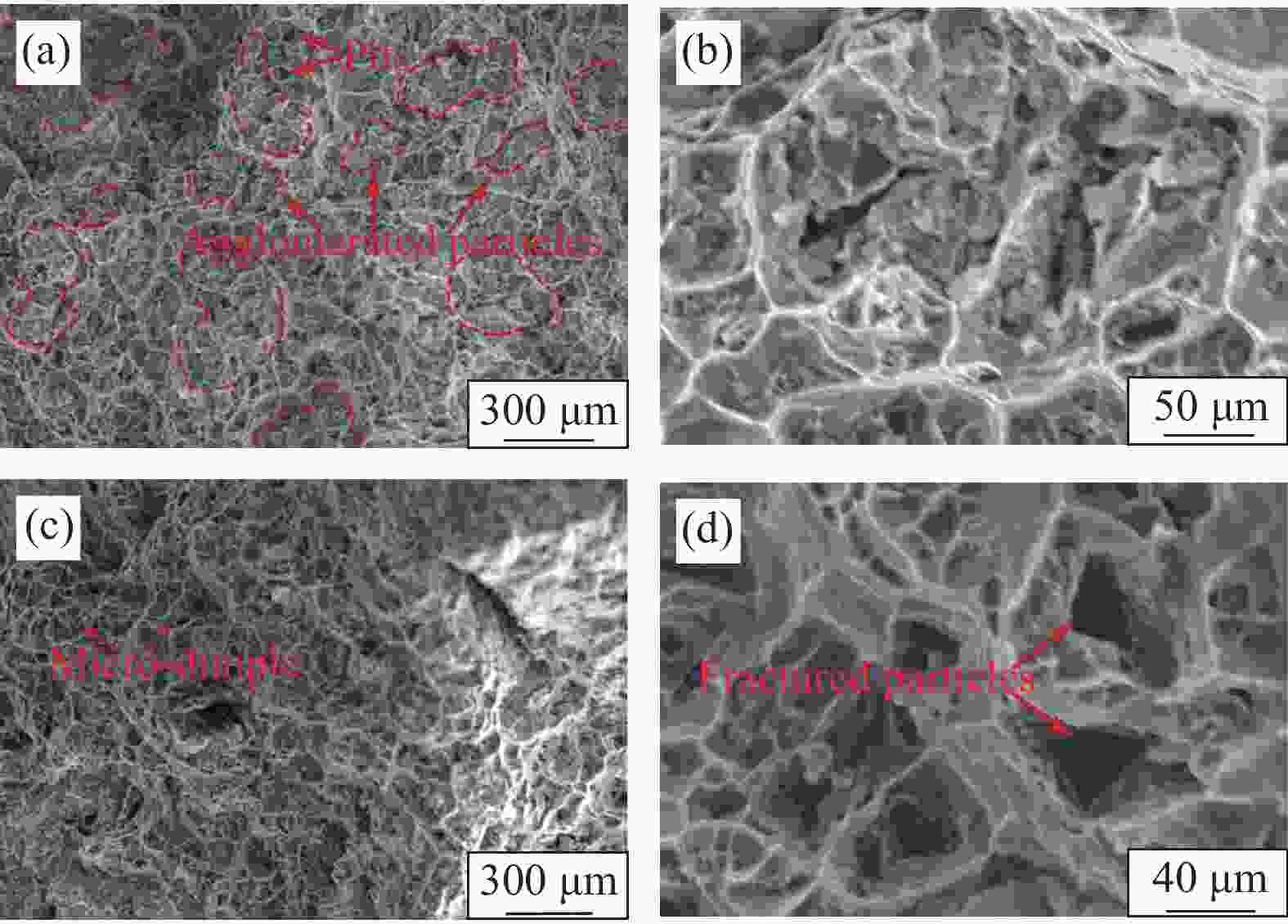

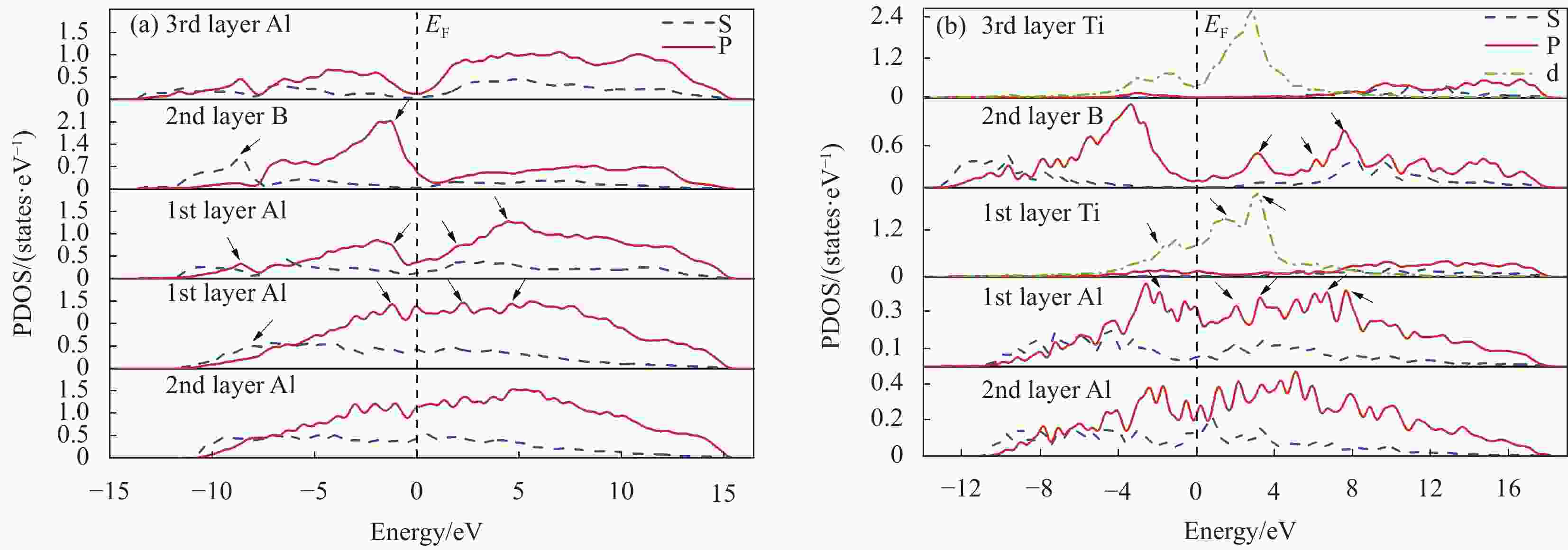

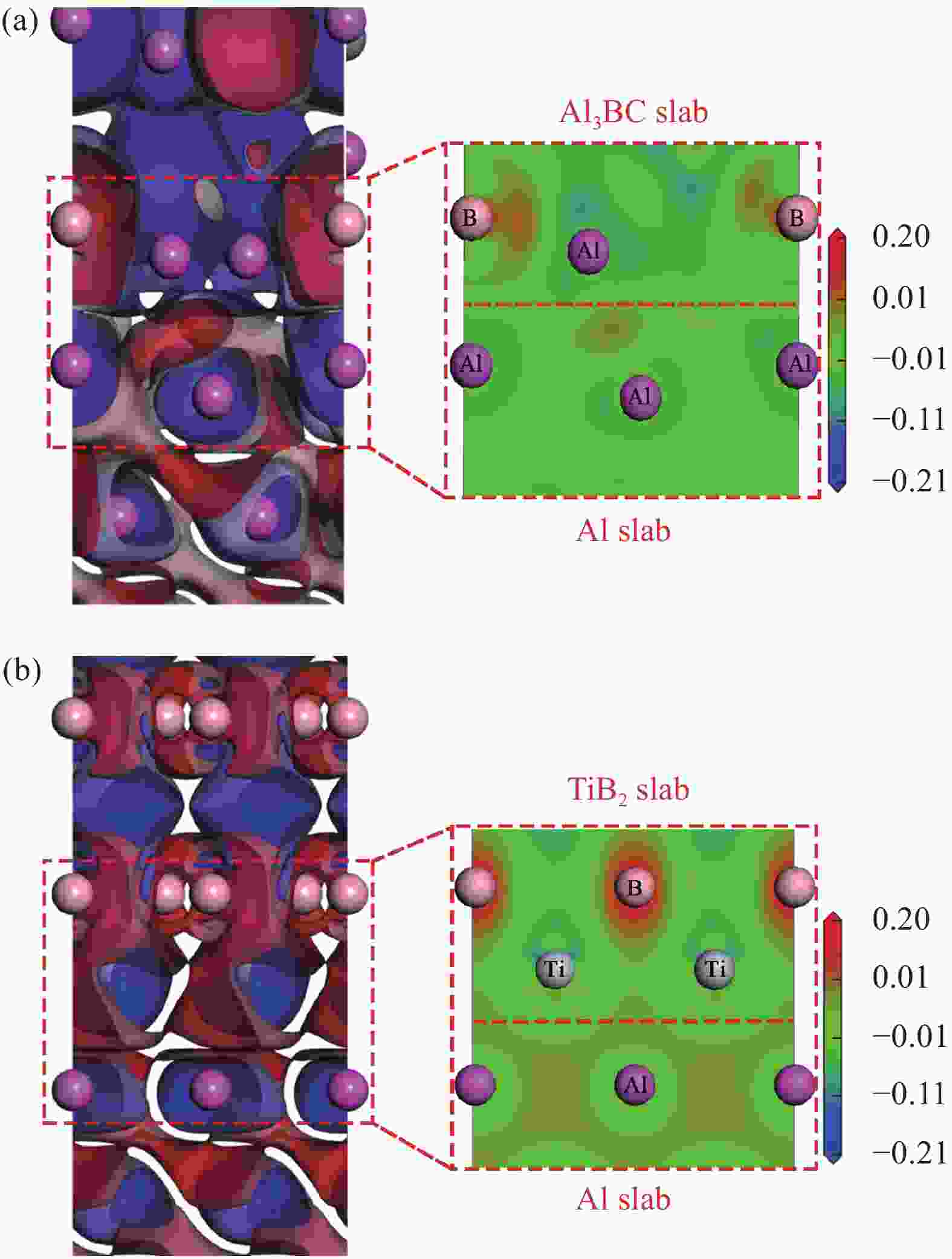

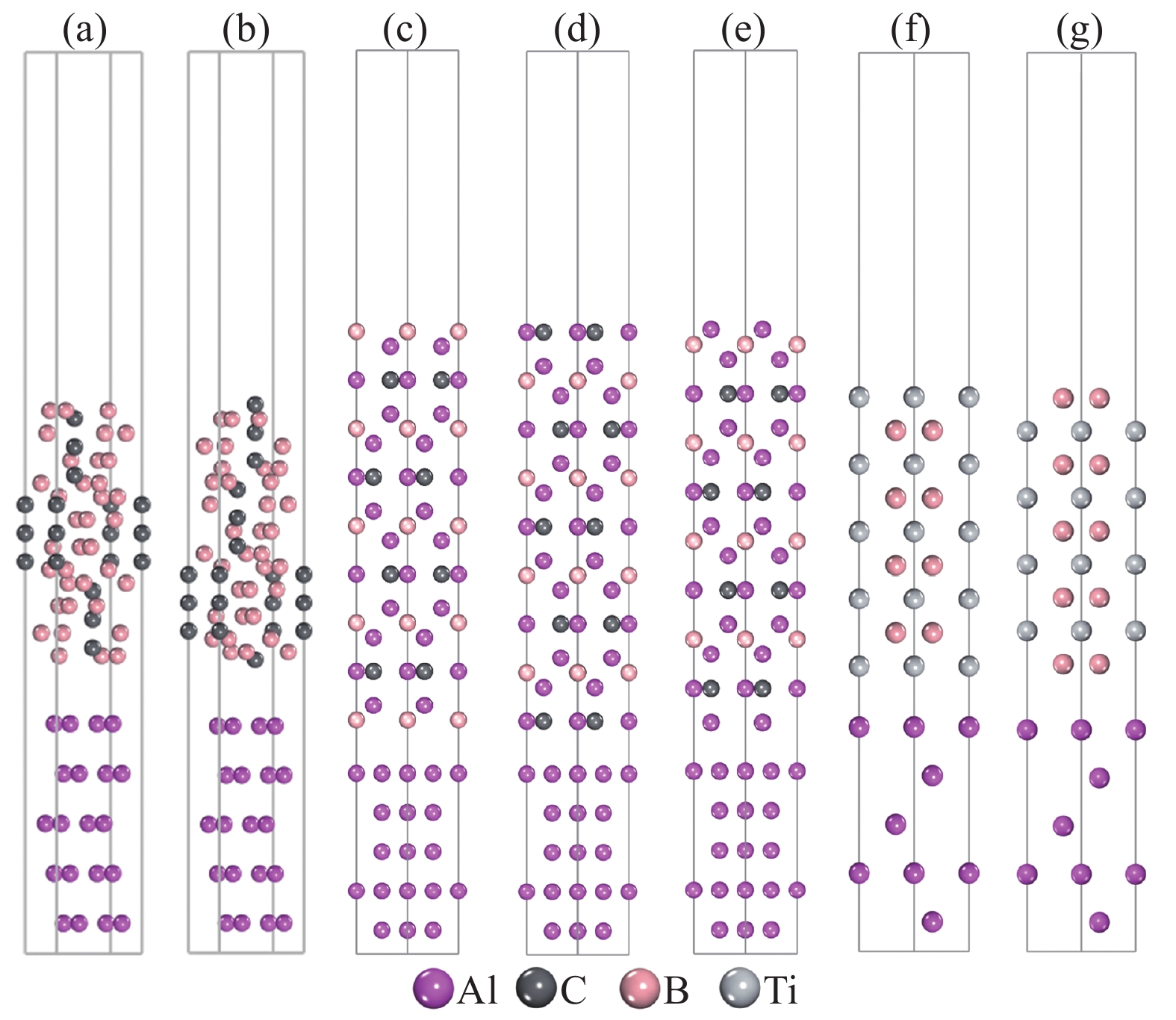

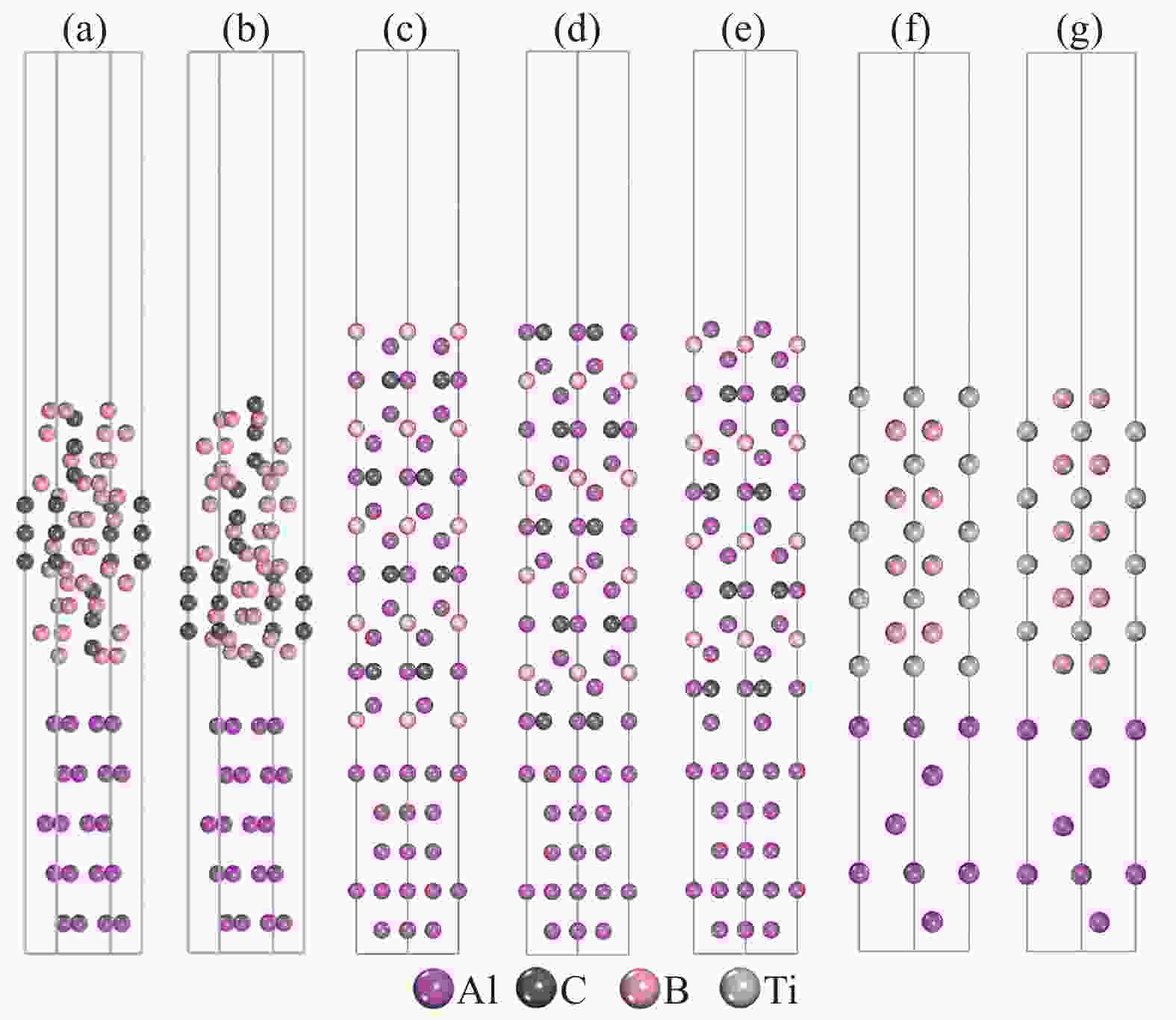

摘要: 采用搅拌铸造法制备了B4C/Al复合材料,利用实验分析结合第一性原理计算的方法,探讨了界面反应产物Al3BC和TiB2对B4C/Al复合材料颗粒润湿性及界面结合强度的影响机制。结果表明,界面反应产物为Al3BC时,B4C颗粒润湿性没有得到实质性改善,存在明显的颗粒团聚现象,界面结合强度较低且过度的界面反应使B4C颗粒分解损耗严重,导致B4C颗粒增强效果不明显;而通过添加Ti元素使界面反应产物为TiB2时,颗粒润湿性明显改善,B4C颗粒团聚现象显著减少,界面结合强度较高,力学性能得到显著提高。这主要是由于不同终端的Al(111)/TiB2(0001)界面黏附功均大于Al(111)/B4C(0001)的界面黏附功,表明界面反应产物TiB2可以提高B4C颗粒的润湿性,而界面反应产物Al3BC对提高B4C颗粒的润湿性非常有限;Al(111)/Al3BC(0001)和Al(111)/TiB2(0001)的界面上均形成了混合的共价键/金属键;Al(111)/TiB2(0001)的界面上的化学键作用力更大,相应地界面结合强度也更大。

-

关键词:

- B4C/Al复合材料 /

- 第一性原理 /

- 润湿性 /

- 力学性能 /

- 黏附功 /

- 偏态密度(PDOS)

Abstract: The B4C/Al composites were prepared by stirring casting method. The method of experimental analysis combined with first-principles calculations was used to explore the influence mechanism of the interfacial reaction products Al3BC and TiB2 on the wettability of B4C/Al composite particles and the interfacial bonding strength. The results show that when the interface reaction product is Al3BC, the wettability of B4C particles has not been substantially improved, particle agglomeration still exists, and the interface bonding is poor. Excessive interface reaction makes the decomposition and loss of B4C particles serious, resulting in insignificant strengthening effect of B4C particles. When the interface reaction product is TiB2 by adding Ti element, the particle wettability is significantly improved, the agglomeration of B4C particles is significantly reduced, the interface bonding strength is higher, and the mechanical properties are significantly improved. The Al(111)/TiB2(0001) interface adhesion work of different terminals is greater than that of Al(111)/B4C(0001), indicating that the interface reaction product TiB2 can improve the wettability of B4C particles. The interface reaction product Al3BC is very limited in improving the wettability of B4C particles. A mixed covalent/metallic bond is formed on the interface of Al(111)/Al3BC(0001) and Al(111)/TiB2(0001). The chemical bonding strength on the Al(111)/TiB2(0001) interface is greater, and the interface bonding strength is correspondingly greater. -

表 1 B4C/Al复合材料的力学性能

Table 1. Mechanical properties of B4C/Al composites

Sample Particle content/wt% Poriness/% Hardness/MPa Tensile strength/MPa Ductility/% Pure aluminium − − − 40±2.7 34.2±0.7 B4C/Al, Ti 0.0wt% 10 3.6±1.3 45.6±0.3 89±6.8 5.2±2.6 B4C/Al, Ti 3.5wt% 10 1.8±0.3 52.1±0.2 139±6.5 9.7±1.9 B4C/Al, Ti 1.5wt%a 15 − − 111.1±0.5 19.1±2.8 B4C/Al, Ti 1.5wt%b 15 − 34±0.9 100.9±0.4 23.1±1.5 Notes: a Ref. [22]; b Ref. [23]. 表 2 Al(111)/B4C(0001)、Al(111)/Al3BC(0001)和Al(111)/TiB2(0001)界面的黏附功Wad

Table 2. Adhesion work Wad of Al(111)/B4C(0001) interfaces, Al(111)/Al3BC(0001) interfaces and Al(111)/TiB2(0001) interfaces

Interface Termination Wad/(J·m−2) Al(111)/B4C(0001) B- 1.328 C- 1.853 Al(111)/Al3BC(0001) B- 1.976 AlC- 0.560 Al- 1.352 Al(111)/TiB2(0001) Ti- 3.085 B- 2.631 -

[1] 杨涛, 刘润爱, 王文先, 等. 热轧高含量B4C颗粒增强Al基复合材料的成形性能[J]. 复合材料学报, 2021, 38(7):2234-2243.YANG T, LIU R A, WANG W X, et al. Theformability of high content B4C particle reinforced Al matrix composites by hot rolling[J]. Acta Materiae Compositae Sinica,2021,38(7):2234-2243(in Chinese). [2] 童攀, 林立, 王全兆, 等. 颗粒尺寸对B4C增强铝基中子吸收材料界面反应与力学性能的影响[J]. 复合材料学报, 2019, 36(4):927-937.TONG P, LIN L. WANG Q Z, et al. Effects of particle size on interfacial reaction and mechanical properties of B4C reinforced aluminum matrix neutron absorber materials[J]. Acta Materiae Compositate Sinica,2019,36(4):927-937(in Chinese). [3] 靳涛, 王伟, 庞晓轩, 等. 热轧工艺对20% B4C/Al复合材料显微组织及缺陷的影响[J]. 材料导报, 2017, 31(S1):102-104.JIN Tao, WANG Wei, PANG Xiaoxuan, et al. Effect of hot rolling process on the microstructures and defects of 20wt% B4C/Al composites[J]. Materials Reports,2017,31(S1):102-104(in Chinese). [4] 周丽, 张鹏飞, 王全兆, 等. B4C/6061Al复合材料热压缩断裂行为的多尺度研究[J]. 金属学报, 2019, 55(7):911-918.ZHOU Li, ZHANG Pengfei, WANG Quanzhao, et al. Multi-scale study on the fracture behavior of hot compression B4C/6061Al composite[J]. Acta Metallurgica Sinica,2019,55(7):911-918(in Chinese). [5] KALAISELVAN K, MURUGAN N, PARAMESWARAN S. Production and characterization of AA6061–B4C stir cast composite[J]. Materials & Design,2011,32(7):4004-4009. [6] 邹爱华, 周贤良, 康志兵, 等. 不连续界面相Al4C3对SiC/Al复合材料界面结合影响的第一性原理及实验[J]. 复合材料学报, 2021, 38(3):824-831.ZOU Aihua, ZHOU Xianliang, KANG Zhibing, et al. Effect of discontinuous interfacial phase Al4C3 on interface bonding of SiC/Al composites: A first-principle and experiment[J]. Acta Materiae Compositae Sinica,2021,38(3):824-831(in Chinese). [7] GUO Hao, ZHANG Zhongwu, ZHANG Yang, et al. Improving the mechanical properties of B4C/Al composites by solidstate interfacial reaction[J]. Journal of Alloys and Compounds,2020,829:154521. doi: 10.1016/j.jallcom.2020.154521 [8] MO Zhuoqiang, LIU Yunzhong, GENG Jiangjiang, et al. The effects of temperatures on microstructure evolution and mechanical properties of B4C-AA2024 composite strips prepared by semi-solid powder rolling[J]. Materials Science & Engineering A,2016,652(15):305-314. [9] CHEN H S, WANG W X, LI Y L, et al. The design, microstructure and tensile properties of B4C particulate reinforced 6061Al neutron absorber composites[J]. Journal of Alloys and Compounds,2015,632:23-29. doi: 10.1016/j.jallcom.2015.01.048 [10] LI Yuli, WANG Wenxian, ZHOU Jun, et al. 10B areal density: A novel approach for design and fabrication of B4C/6061Al neutron absorbing materials[J]. Journal of Nuclear Mater-ials,2017,487:238-246. doi: 10.1016/j.jnucmat.2017.02.020 [11] ZHANG Z, FORTIN K, CHARETTE A, et al. Effect of titanium on microstructure and fluidity of Al-B4C composites[J]. Journal of Materials Ence,2011,46(9):3176-3185. [12] HU Qiyao, ZHAO Haidong, LI Fangdong et al. Effects of manufacturing processes on microstructure and properties of Al/A356-B4C composites[J]. Materials and Manufacturing Processes,2016,31(10):1292-1300. doi: 10.1080/10426914.2016.1151049 [13] 朱刚. SiCp/6061搅拌制备及铸造组织性能的研究[D]. 广州: 华南理工大学, 2015.ZHU Gang. Research on microstructure and mechanical properities of SiCp/6061 composites prepared by stirring technology[D]. Guangzhou: South China University of Technology, 2015(in Chinese). [14] PERDEW J P, BURKE K, ERNZERHOF M, et al. Generalized gradient approximation made simple[J]. Physical Review Letters,1996,77:3865. [15] LAASONEN K, PASQUARELLO A, CAR R, et al. Car-Parrinello molecular dynamics with Vanderbilt ultrasoft pseudopotentials[J]. Physical Review B Condensed Matter,1993,47(16):10142. doi: 10.1103/PhysRevB.47.10142 [16] FROYEN S. Brillouin-zone integration by Fourier quadra-ture: Special points for superlattice and supercell calculations[J]. Physical Review B Condensed Matter,1989,39(5):3168-3172. doi: 10.1103/PhysRevB.39.3168 [17] DENG Chao, XU Ben, WU Ping, et al. Stability of the Al/TiB2 interface and doping effects of Mg/Si[J]. Applied Surface Science,2017,425:639-645. doi: 10.1016/j.apsusc.2017.06.227 [18] XIAN Yajiang, QIU Ruizhi, WANG Xin, et al. Interfacial properties and electron structure of Al/B4C interface: A first-principles study[J]. Journal of Nuclear Materials,2016,478:227-235. doi: 10.1016/j.jnucmat.2016.06.015 [19] YANG Jian, HUANG Jihua, FAN Shuhai, et al. LaAlO3 as the heterogeneous nucleus of ferrite: Experimental investigation and theoretical calculation[J]. Journal of Alloys and Compounds,2016,683:357-369. doi: 10.1016/j.jallcom.2016.05.091 [20] HU Qiyao, ZHAO Haidong, GE Jilong, et al. Microstructure and mechanical properties of (B4C+Al3Ti)/Al hybrid composite fabricated by a two-step stir casting process[J]. Materials Science & Engineering A,2016,650:478-482. [21] ZHANG Jingjing, JUNG Moolee, YOUNG Heecho, et al. Effect of the Ti/B4C mole ratio on the reaction products and reaction mechanism in an Al-Ti-B4C powder mixture[J]. Materials Chemistry and Physics,2014,147(3):925-933. doi: 10.1016/j.matchemphys.2014.06.039 [22] RUAN Qing, JIA Yuzhen, ZHENG Jiyun et al. Improvement on mechanical property of B4C/Al composites by addition of Ti through interfacial reaction[J]. Rare Metal Materials and Engineering,2019,48(6):1777-1784. [23] LI Yu, LI Qinliu, LIU Wei, et al. Effect of Ti content and stirring time on microstructure and mechanical behavior of Al-B4C composites[J]. Journal of Alloys and Compounds,2016,684:496-503. doi: 10.1016/j.jallcom.2016.05.135 [24] ZHANG W, SMITH J R. Stoichiometry and adhesion of Nb/Al2O3[J]. Physical Review B,2000,61(24):16883-16889. [25] WANG Zhixuan, LI Qiulin, ZHENG Jiyuan, et al. Improving Al wettability on B4C by transition metal doping: A combined DFT and experiment study[J]. Rare Metal Materials and Engineering,2017,46(9):2345-2351. doi: 10.1016/S1875-5372(17)30195-9 -

下载:

下载: