Constitutive relation of uniaxial compression of hybrid fiber reinforced mortar after high temperature

-

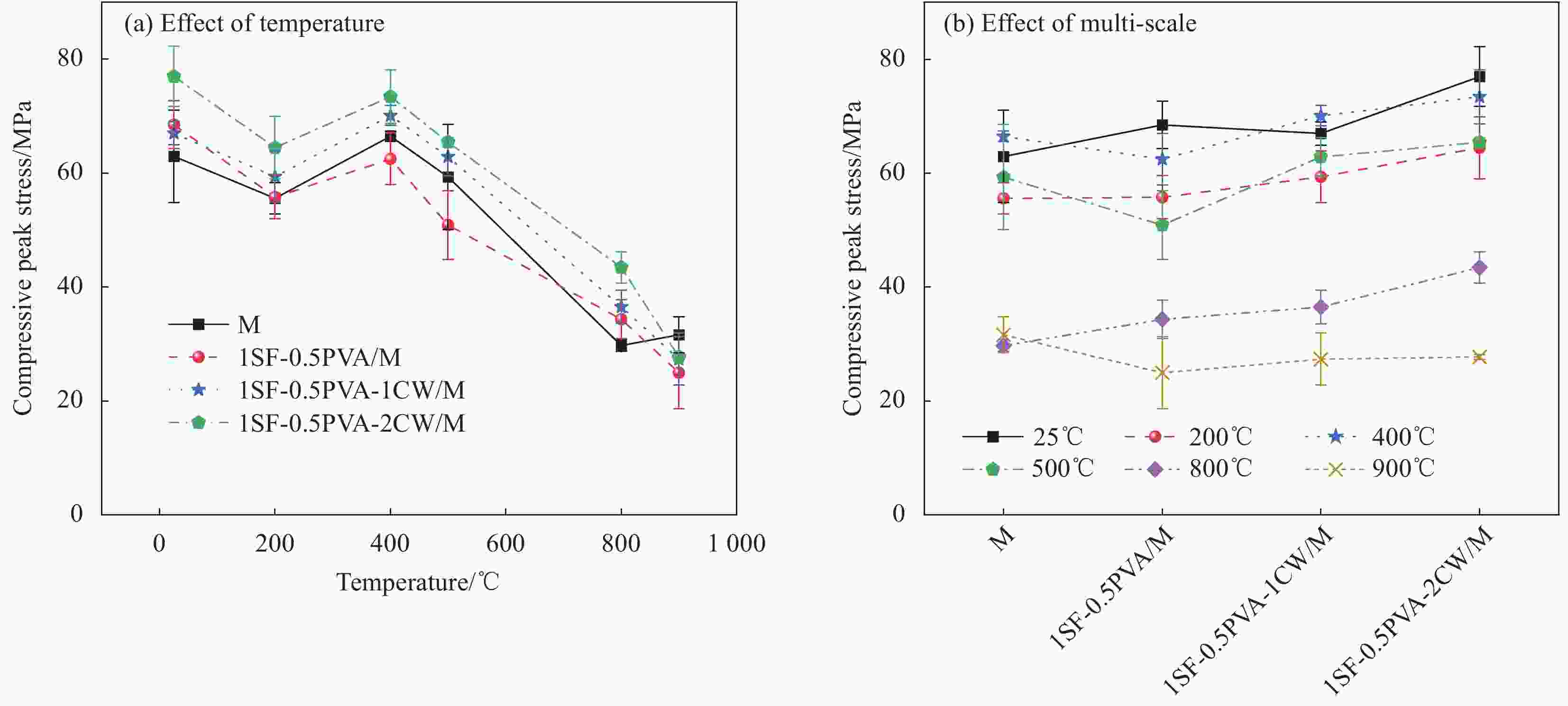

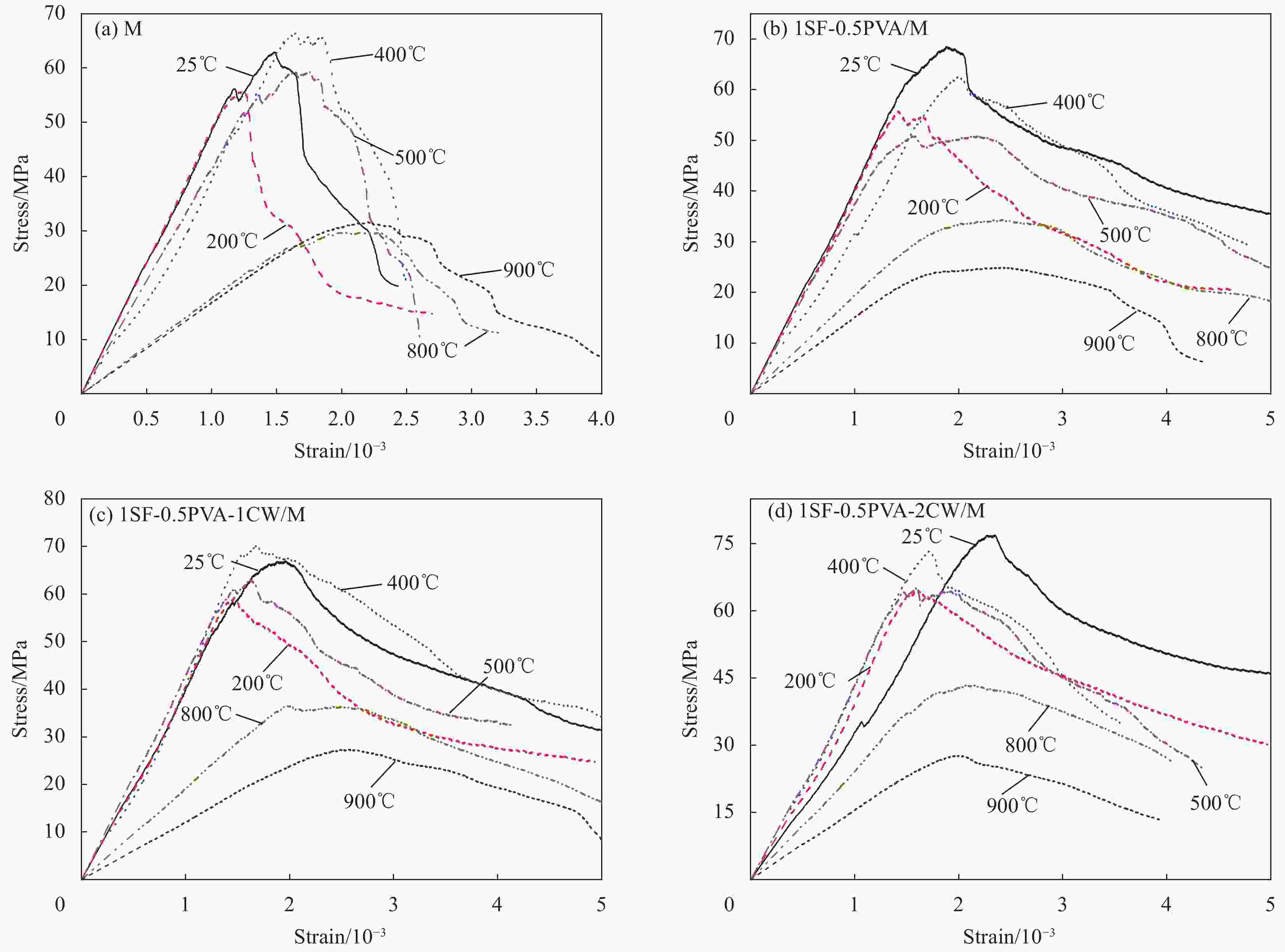

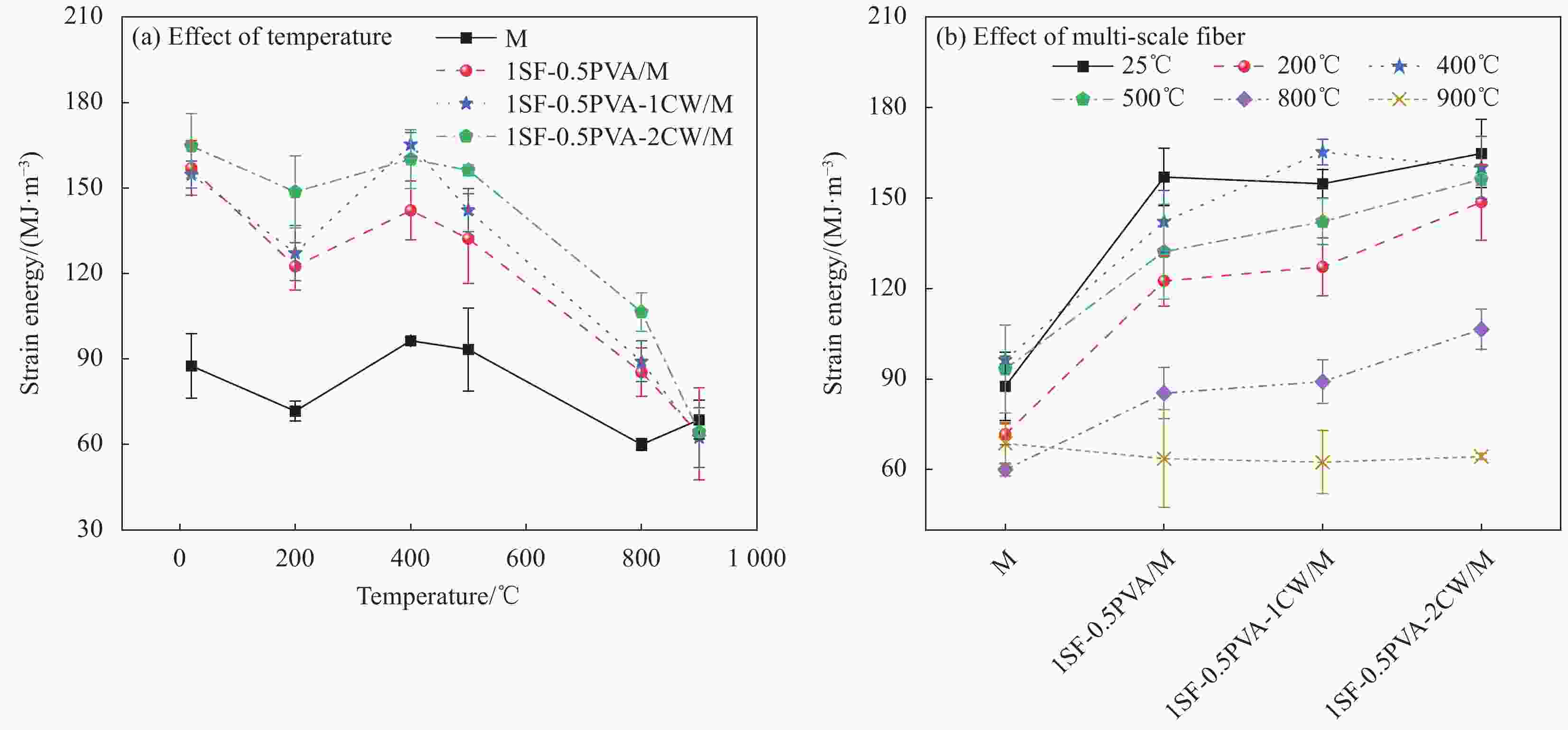

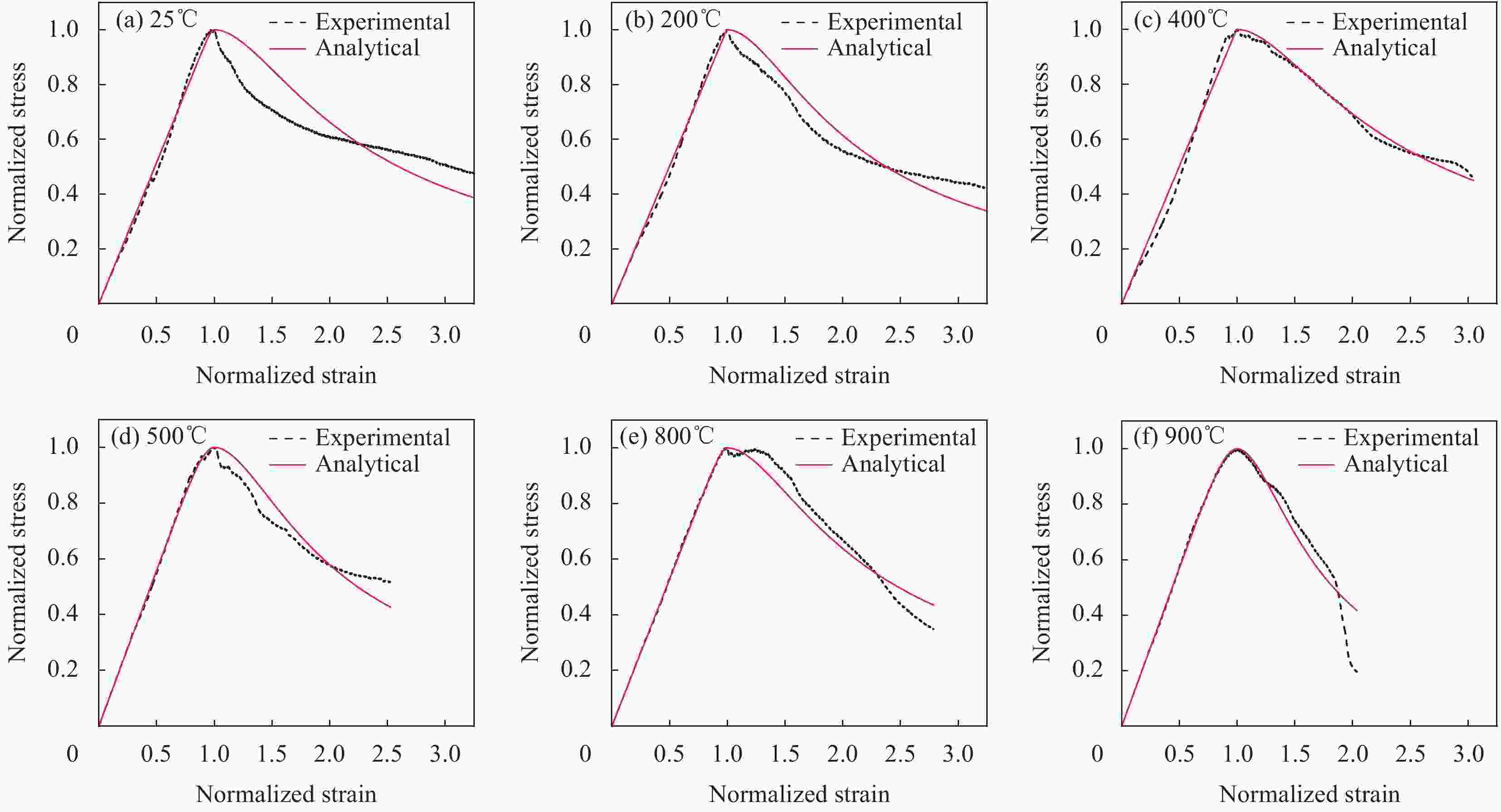

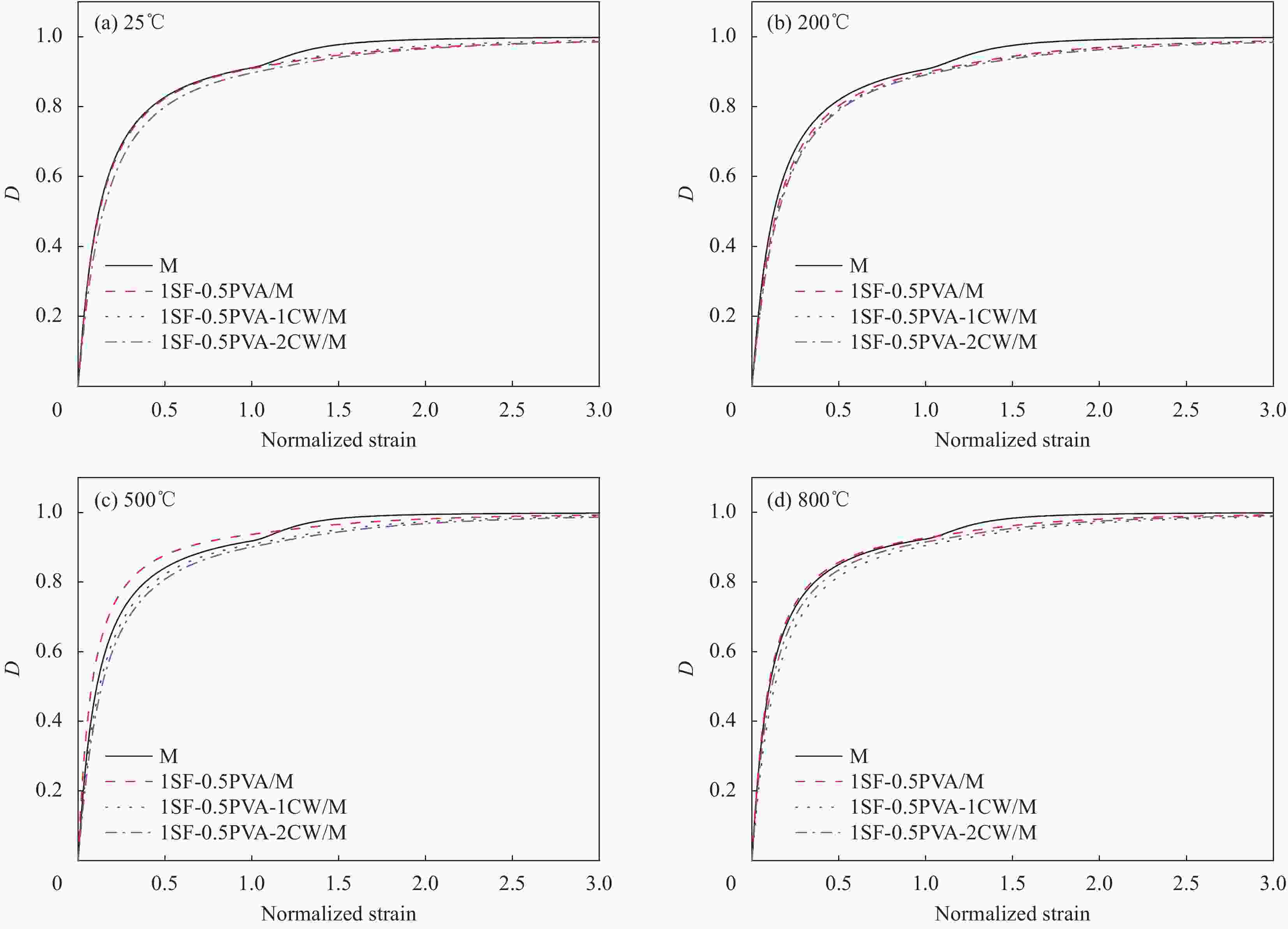

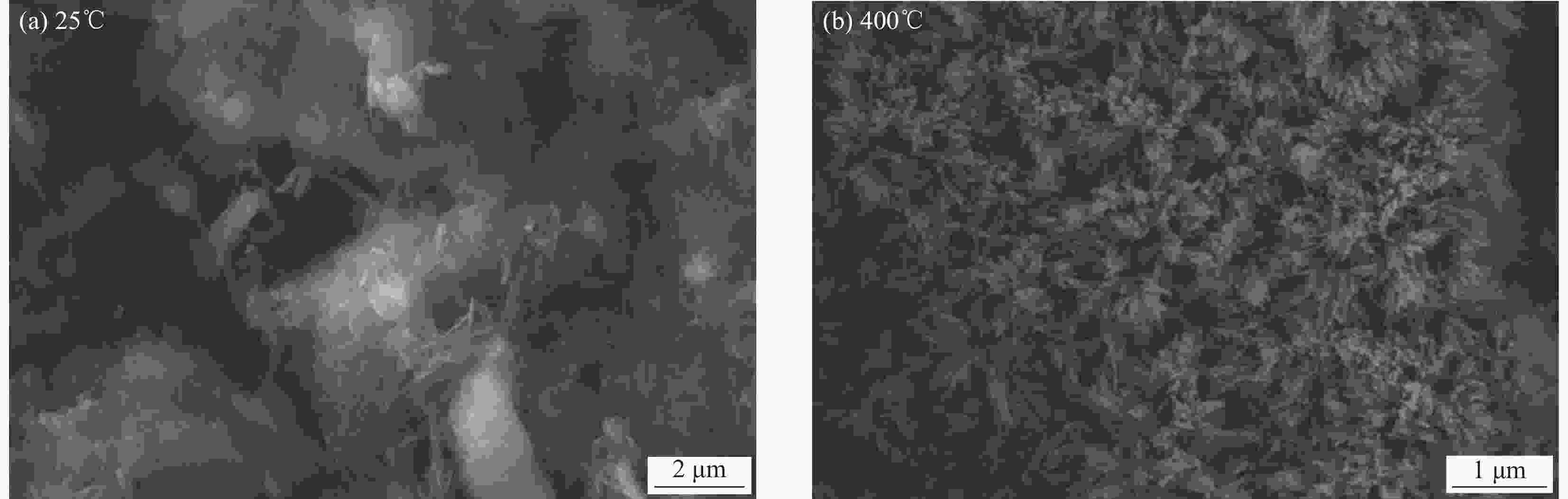

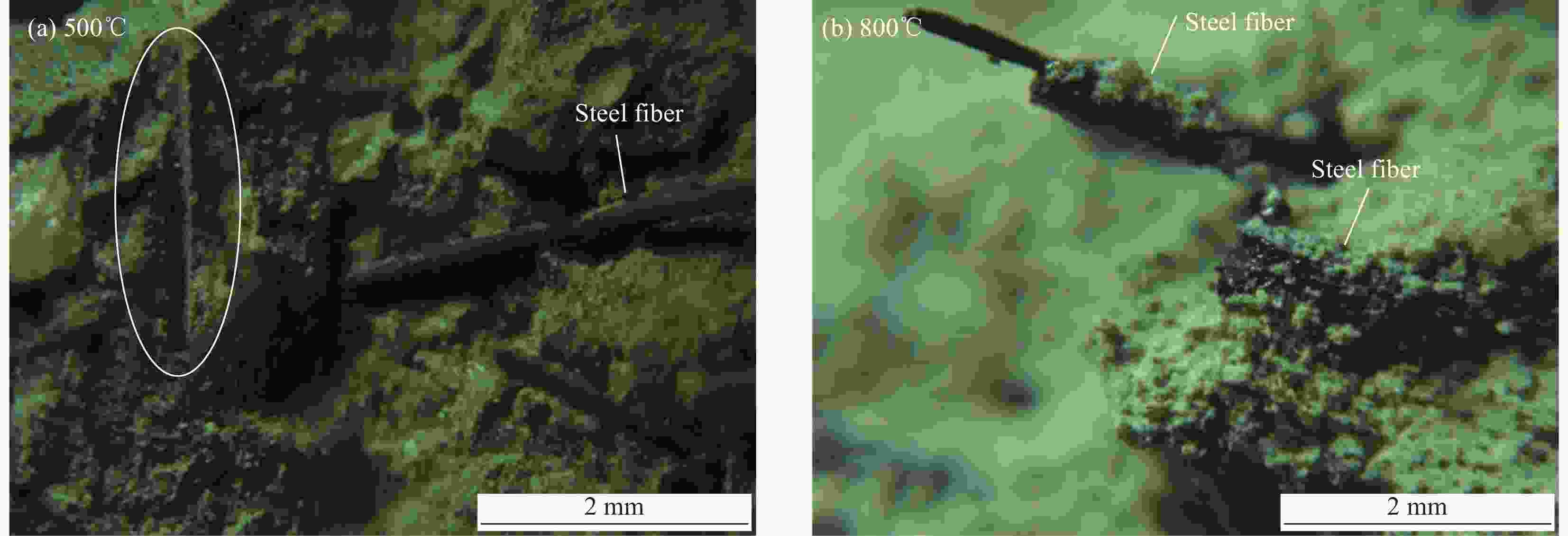

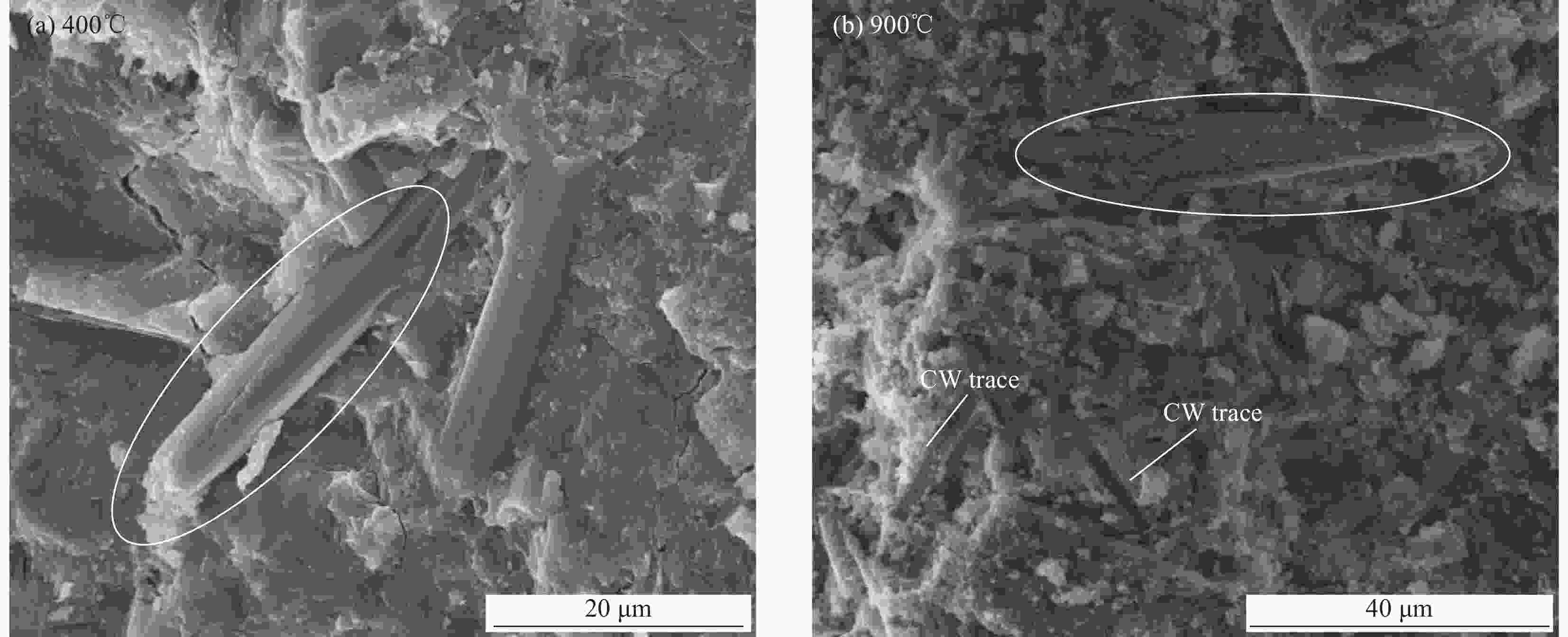

摘要: 为建立高温和CaCO3晶须(CW)影响下混杂纤维增强砂浆(HyFRM)的单轴受压本构关系,对不同CW掺量的钢-聚乙烯醇(PVA) HyFRM开展25℃、200℃、400℃、500℃、800℃、900℃六个温度水平的单轴受压性能试验。结果表明:随钢-PVA混杂纤维的引入,高温后砂浆的轴压峰值应力显著提高;随CW的引入,轴压峰值应力进一步提高:800℃以下,1.5vol%钢纤维+0.5vol%PVA纤维+2vol%CW的HyFRM轴压峰值应力均为最优。随温度升高,轴压应力-应变曲线由陡峭趋于扁平,HyFRM轴压峰值应力、弹性模量、应变能总体下降。但500℃以下下降缓慢,甚至还有所提高,以1.5vol%钢纤维+0.5vol%PVA纤维+2vol%CW的HyFRM提高最为明显;800℃及以上,受压性能则急剧劣化。建立了考虑温度和CW掺量的HyFRM受压应力-应变损伤本构模型。损伤本构模型和损伤变量不仅可以较好地体现出多尺度纤维体系在砂浆单轴受压破坏的不同阶段多尺度阻裂、延缓砂浆损伤扩展的作用,而且可以反映高温对砂浆初始损伤的影响。光学显微镜和SEM观测揭示了高温对HyFRM轴压性能的影响机制。Abstract: In order to establish the uniaxial compressive constitutive relation of hybrid fiber reinforced mortar (HyFRM) under the influence of high temperature and CaCO3 whisker (CW), uniaxial compressive tests were carried out on steel-polyvinyl alcohol (PVA) HyFRM with different dosages of CW at six temperature levels of 25℃, 200℃, 400℃, 500℃, 800℃ and 900℃. The results show that with the introduction of steel-PVA hybrid fiber, the peak axial compressive stress of mortar is increased significantly. With the introduction of CW, the peak axial compressive stress of HyFRM is further increased before and after high temperature: Below 800℃, the peak axial compressive stress of 1.5vol%steel fiber+0.5vol%PVA fiber+2vol%CW is the best. With the increase of the high treatment temperature, the axial compressive stress-strain curve becomes flat from steep, and the peak axial compressive stress, elastic modulus and strain energy of HyFRM generally decrease. However, below 500℃, they decrease slowly and even increase, and the increases are most obvious when 1.5vol%steel fiber+0.5vol%PVA fiber+2vol%CW. At 800℃ and above, the compressive performance deteriorates sharply. A stress-strain damage constitutive model for HyFRM under compression considering the effects of high temperature treatment temperature and CW content was established. The damage constitutive model and damage variable can’t only preferably reflect the multi-scale fiber system in the different stages of uniaxial compression crack inhibition and retardation of mortar damage propagation, but also reflect the effect of high temperature on the initial damage of mortar. The observations by optical microscope and SEM reveal the influence mechanism of high temperature on the axial compression of HyFRM.

-

Key words:

- mortar /

- hybrid fiber /

- multi-scale /

- high temperature /

- constitutive model

-

表 1 混杂纤维增强砂浆(HyFRM)原材料的基本性能

Table 1. Properties of raw materials of hybrid fiber reinforced mortar (HyFRM)

Raw

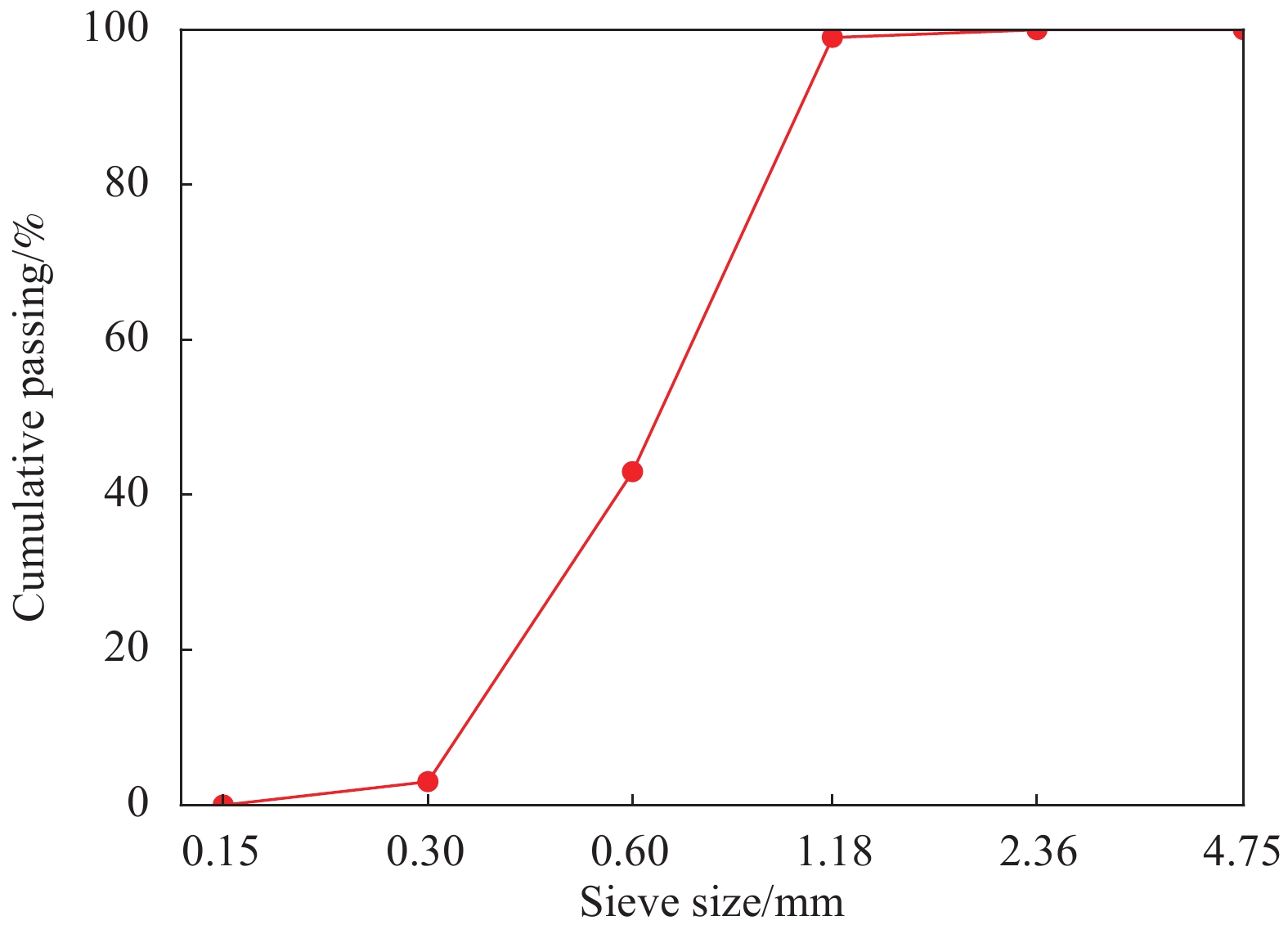

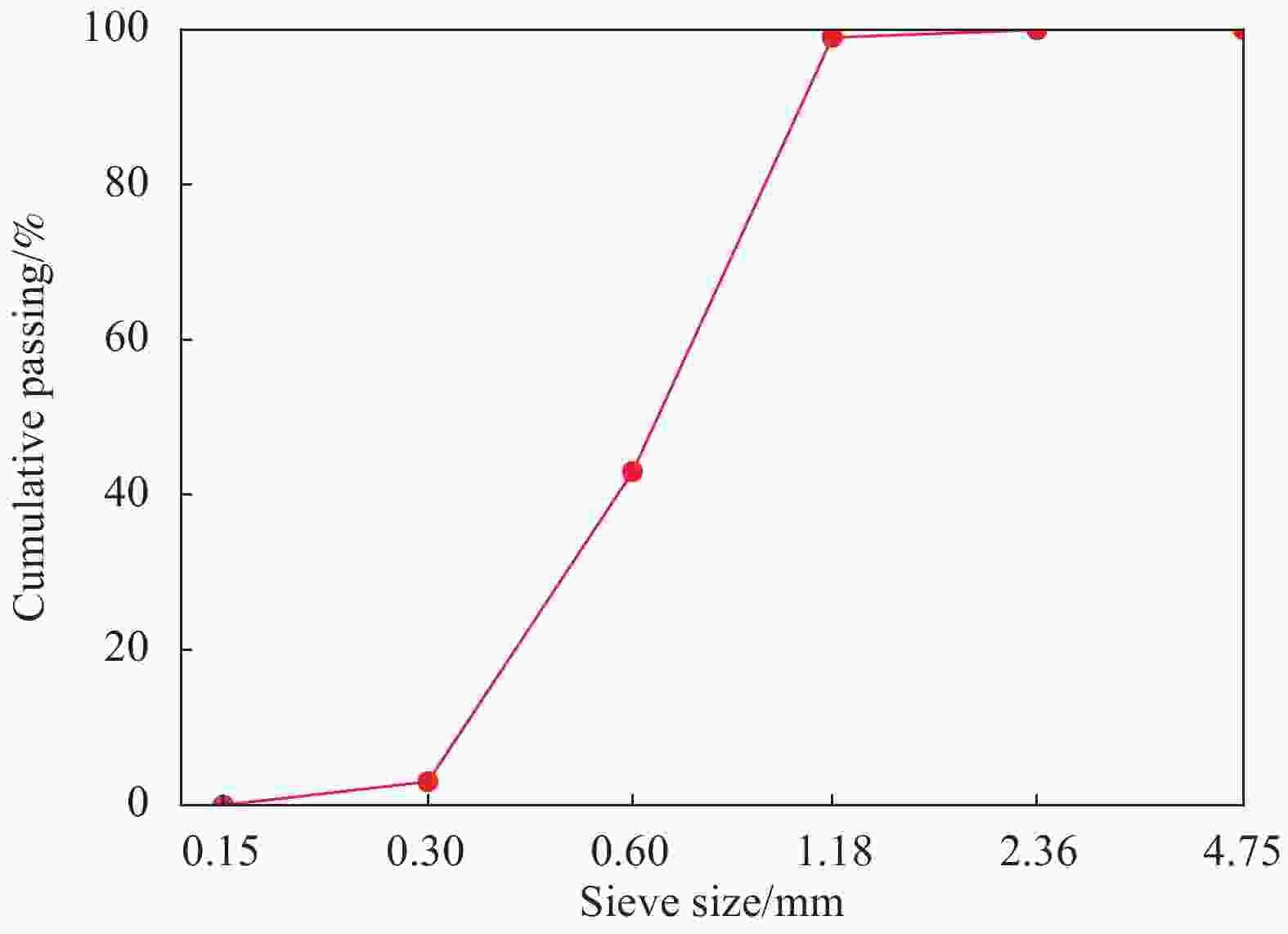

materialsSize Mechanical property Cement Specific surface

area 356 m2/kg28 days cement mortar strength 46.5 MPa Fly ash 45 μm sieve residue 23.72wt% — Silica sand Fineness modulus

1.9 media sandMoh’s hardness 7 Steel fiber Length 13 mm

Diameter 200 μmTensile strength ≥2 GPa

Elastic modulus 200-210 GPaPVA fiber Length 6 mm

Diameter 31 μmTensile strength 1.1 GPa

Elastic modulus 41 GPaCW Length 20-30 μm

Diameter 0.5-2 μmTensile strength 3-6 GPa

Elastic modulus 410–710 GPaNotes: PVA—Polyvinyl alcohol; CW—CaCO3 whisker. 表 2 HyFRM的配合比

Table 2. Mix ratios of HyFRM

kg/m3 Group Steel fiber PVA fiber CW Binder Water Sand M 0 0.00 0.0 1220 366 610 1SF-0.5PVA/M 117 6.45 0.0 1196 359 598 1SF-0.5PVA-1CW/M 117 6.45 28.6 1183 355 592 1SF-0.5PVA-2CW/M 117 6.45 57.2 1171 351 586 Notes: M—Mortar; SF—Steel fiber. 表 3 高温后HyFRM的孔隙率

Table 3. Porosity of HyFRM after high temperatures

Group Temperature/℃ Porosity 2-5000 nm/% Porosity <50 nm/% Porosity ≥50 nm/% 1SF-0.5PVA/M 25 15.30 10.32 4.98 1SF-0.5PVA-2CW/M 25 16.59 12.48 4.11 1SF-0.5PVA-2CW/M 200 17.10 11.66 5.34 1SF-0.5PVA-2CW/M 400 16.86 11.61 5.25 1SF-0.5PVA-2CW/M 900 24.92 4.99 19.93 -

[1] 肖建庄, 刘良林, 董毓利, 等. 高性能混凝土高温爆裂研究进展[J]. 建筑科学与工程学报, 2019, 36(3):1-15. doi: 10.3969/j.issn.1673-2049.2019.03.001XIAO Jianzhuang, LIU Lianglin, DONG Yuli, et al. Progress of study on explosive spalling of high performance concrete at elevated temperatures[J]. Journal of Architecture and Civil Engineering,2019,36(3):1-15(in Chinese). doi: 10.3969/j.issn.1673-2049.2019.03.001 [2] POON C S, SHUI Z H, LAM L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures[J]. Cement and Concrete Research,2004,34(12):2215-2222. doi: 10.1016/j.cemconres.2004.02.011 [3] XU L, HUANG L, CHI Y, et al. Tensile behavior of steel-polypropylene hybrid fiber-reinforced concrete[J]. ACI Materials Journal,2016,113(2):219-229. [4] PENG G, YANG W, ZHAO J, et al. Explosive spalling and residual mechanical properties of fiber-toughened high-performance concrete subjected to high temperatures[J]. Cement and Concrete Research,2006,36(4):723-727. doi: 10.1016/j.cemconres.2005.12.014 [5] 李黎, 曹明莉. 纤维增强水泥基复合材料的纤维混杂效应研究进展[J]. 应用基础与工程科学学报, 2018, 26(4):843-853.LI Li, CAO Mingli. Research progress on fiber hybrid effect in fiber reinforced cementitious composite[J]. Journal of Basic Science and Engineering,2018,26(4):843-853(in Chinese). [6] ABADEL A, ABBAS H, ALMUSALLAM T, et al. Mechanical properties of hybrid fibre-reinforced concrete—Analytical modelling and experimental behaviour[J]. Magazine of Concrete Research,2016,68(16):823-843. doi: 10.1680/jmacr.15.00276 [7] DING Y, ZHANG C, CAO M, et al. Influence of different fibers on the change of pore pressure of self-consolidating concrete exposed to fire[J]. Construction and Building Materials,2016,113:456-469. doi: 10.1016/j.conbuildmat.2016.03.070 [8] BANTHIA N, SOLEIMANI S M. Flexural response of hybrid fiber-reinforced cementitious composites[J]. ACI Materials Journal,2005,6(102):382-389. [9] CAO M, XU L, ZHANG C. Rheology, fiber distribution and mechanical properties of calcium carbonate (CaCO3) whisker reinforced cement mortar[J]. Composites Part A: Applied Science and Manufacturing,2016,90:662-669. doi: 10.1016/j.compositesa.2016.08.033 [10] LI L, GAO D, LI Z, et al. Effect of high temperature on morphologies of fibers and mechanical properties of multi-scale fiber reinforced cement-based composites[J]. Construction and Building Materials,2020,261:120487. doi: 10.1016/j.conbuildmat.2020.120487 [11] CAO M, XIE C, GUAN J. Fracture behavior of cement mortar reinforced by hybrid composite fiber consisting of CaCO3 whiskers and PVA-steel hybrid fibers[J]. Compo-sites Part A: Applied Science and Manufacturing,2019,120:172-187. doi: 10.1016/j.compositesa.2019.03.002 [12] LI L, CAO M, MING X, et al. Microstructure of calcium carbonate whisker reinforced cement paste after elevated temperature exposure[J]. Construction and Building Materials,2019,227:116609. doi: 10.1016/j.conbuildmat.2019.07.335 [13] 高丹盈, 赵亮平, 陈刚. 高温中纤维纳米混凝土单轴受压应力-应变关系[J]. 土木工程学报, 2017, 50(9):46-58.GAO Danying, ZHAO Liangping, CHEN Gang. Compres-sive stress-strain relationship of fiber and nanosized material reinforced concrete in high temperature[J]. China Civil Engineering Journal,2017,50(9):46-58(in Chinese). [14] 张文华, 张仔祥, 刘鹏宇, 等. 多尺度纤维增强超高性能混凝土的轴心抗拉和抗压行为[J]. 硅酸盐学报, 2020, 48(8):1-13.ZHANG Wenhua, ZHANG Zixiang, LIU Pengyu, et al. Uniaxial tensile and compressive stress-strain behavior of multi-scale fiber-reinforced ultra-high performance concrete[J]. Journal of the Chinese Ceramic Society,2020,48(8):1-13(in Chinese). [15] 曹明莉, 李黎, 李志文, 等. CaCO3晶须对钢-聚乙烯醇混杂纤维增强水泥基复合材料板弯曲性能的影响[J]. 复合材料学报, 2017, 34(11):2614-2623.CAO Mingli, LI Li, LI Zhiwen, et al. Influence of CaCO3 whisker on flexural behavior of steel-polyvinyl alcohol hybrid fiber reinforced cement matrix composite slabs[J]. Acta Materiae Compositae Sinica,2017,34(11):2614-2623(in Chinese). [16] CAO M, ZHANG C, LI Y, et al. Using calcium carbonate whisker in hybrid fiber-reinforced cementitious compo-sites[J]. ASCE Journal of Materials in Civil Engineering,2015,27(4):4014139. doi: 10.1061/(ASCE)MT.1943-5533.0001041 [17] American Society of Testing Materials. Standard test method for static modulus of elasticity and poisson's ratio of concrete in compression: ASTM C469/C469M-14[S]. West Conshohocken: American Society of Testing Materials, 2014. [18] 高丹盈, 李晗, 杨帆. 聚丙烯-钢纤维增强高强混凝土高温性能[J]. 复合材料学报, 2013, 30(1): 187-193.GAO Danying, LI Han, YANG Fan. Performance of polypropylene-steel hybrid fiber reinforced concrete after being exposed to high temperature[J]. Acta Materiae Compositae Sinica, 2013, 30(1): 187-193(in Chinese). [19] ZHENG W, LI H, WANG Y. Compressive behaviour of hybrid fiber-reinforced reactive powder concrete after high temperature[J]. Materials & Design,2012,41:403-409. [20] LI L, CAO M, YIN H. Comparative roles between aragonite and calcite calcium carbonate whiskers in the hydration and strength of cement paste[J]. Cement and Concrete Composites,2019,104:103350. doi: 10.1016/j.cemconcomp.2019.103350 [21] 宁喜亮, 丁一宁. 钢纤维对混凝土单轴受压损伤本构模型的影响[J]. 建筑材料学报, 2015, 18(2):214-220. doi: 10.3969/j.issn.1007-9629.2015.02.006NING Xiliang, DING Yining. Effect of steel fiber on the damage constitutive model of concrete under uniaxial compression[J]. Journal of Building Materials,2015,18(2):214-220(in Chinese). doi: 10.3969/j.issn.1007-9629.2015.02.006 [22] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB/T 50010—2010[S]. Beijing: China Building Industry Press, 2010(in Chinese). [23] 郭晓宇, 亢景付, 朱劲松. 超高性能混凝土单轴受压本构关系[J]. 东南大学学报(自然科学版), 2017, 47(2):369-376. doi: 10.3969/j.issn.1001-0505.2017.02.028GUO Xiaoyu, KANG Jingfu, ZHU Jinsong. Constitutive relationship of ultrahigh performance concrete under uniaxial compression[J]. Journal of Southeast University (Natural Science Edition),2017,47(2):369-376(in Chinese). doi: 10.3969/j.issn.1001-0505.2017.02.028 [24] 焦楚杰, 孙伟, 秦鸿根, 等. 钢纤维高强混凝土单轴受压本构方程[J]. 东南大学学报(自然科学版), 2004, 34(3):366-369.JIAO Chujie, SUN Wei, QIN Honggen, et al. Constitutive equation of SFRHSC under uniaxial compression[J]. Journal of Southeast University (Natural Science Edition),2004,34(3):366-369(in Chinese). [25] LI L, GUAN J, XIE Y, et al. Characterization of bending performance of reinforced cementitious composites beams with hybrid fibers after exposure to high temperatures[J]. Structural Concrete,2022,23(1):395-411. doi: 10.1002/suco.202100078 [26] LI L, LI Z, CAO M, et al. Nanoindentation and porosity fractal dimension of calcium carbonate whisker reinforced cement paste after elevated temperatures (up to 900℃)[J]. Fractals,2021,29(2):2140001. doi: 10.1142/S0218348X21400016 -

下载:

下载: