Preparation and properties of polydopamine modified nano-silica reinforced trans-1, 4-polyisoprene shape memory polymers

-

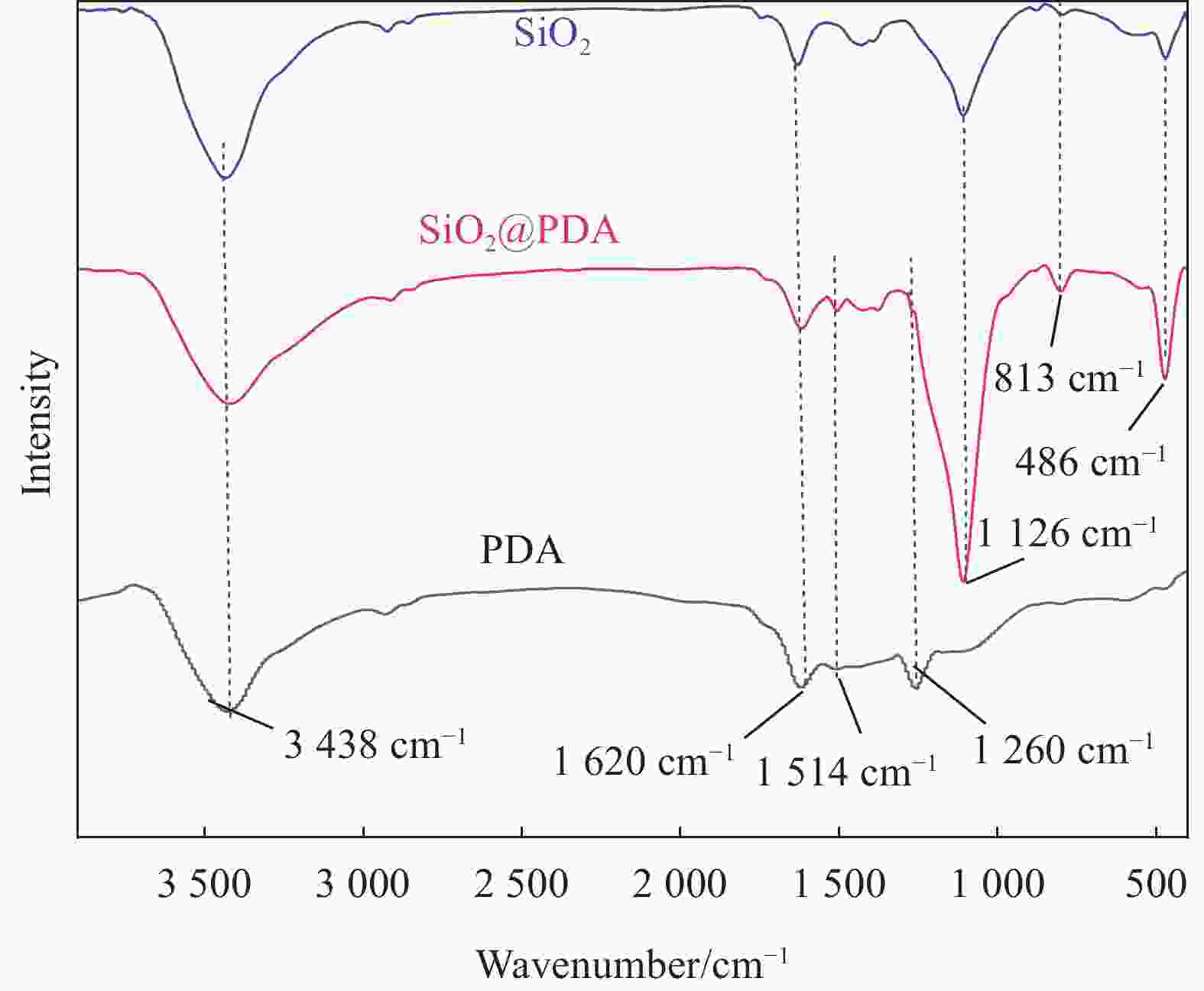

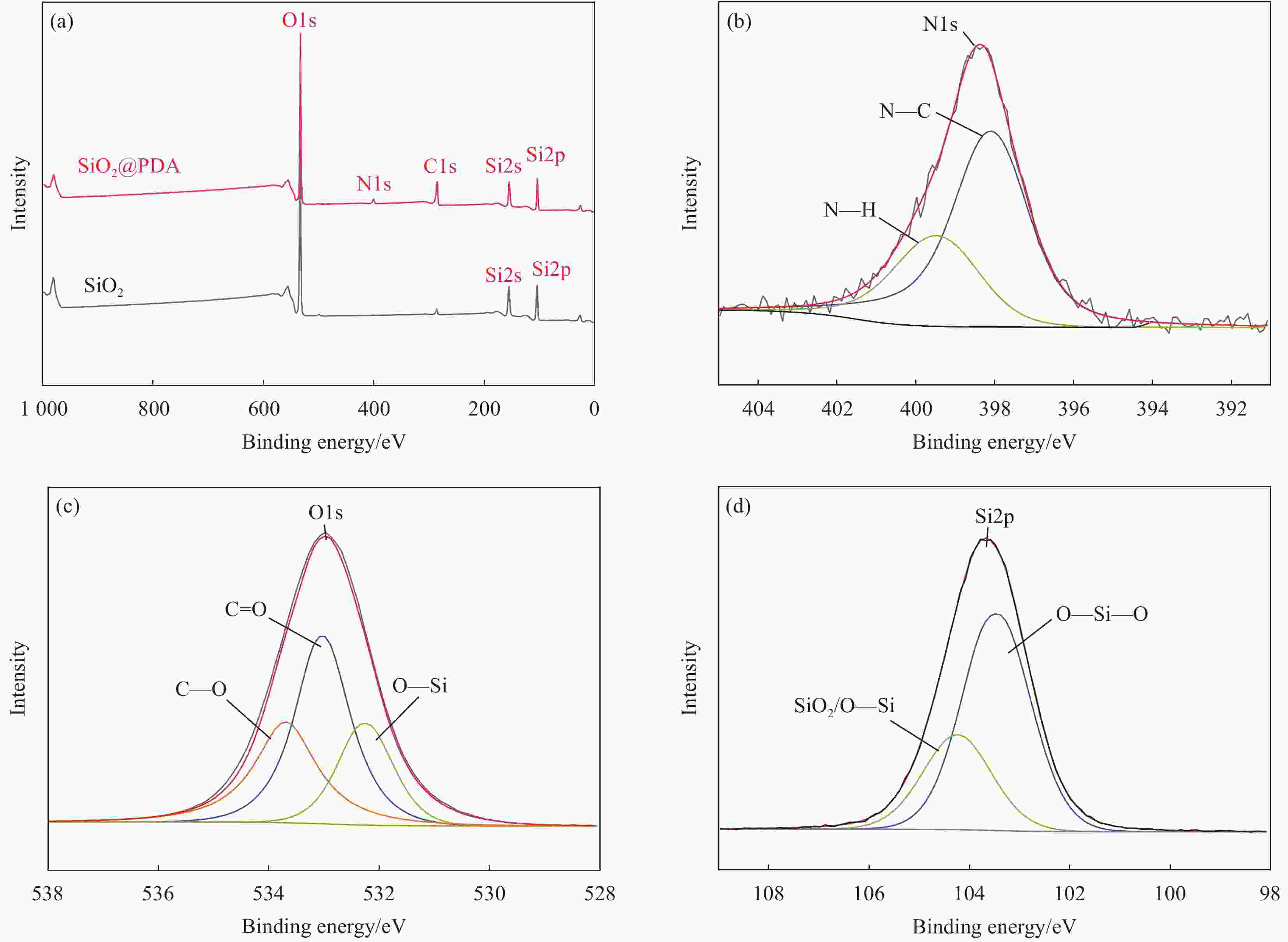

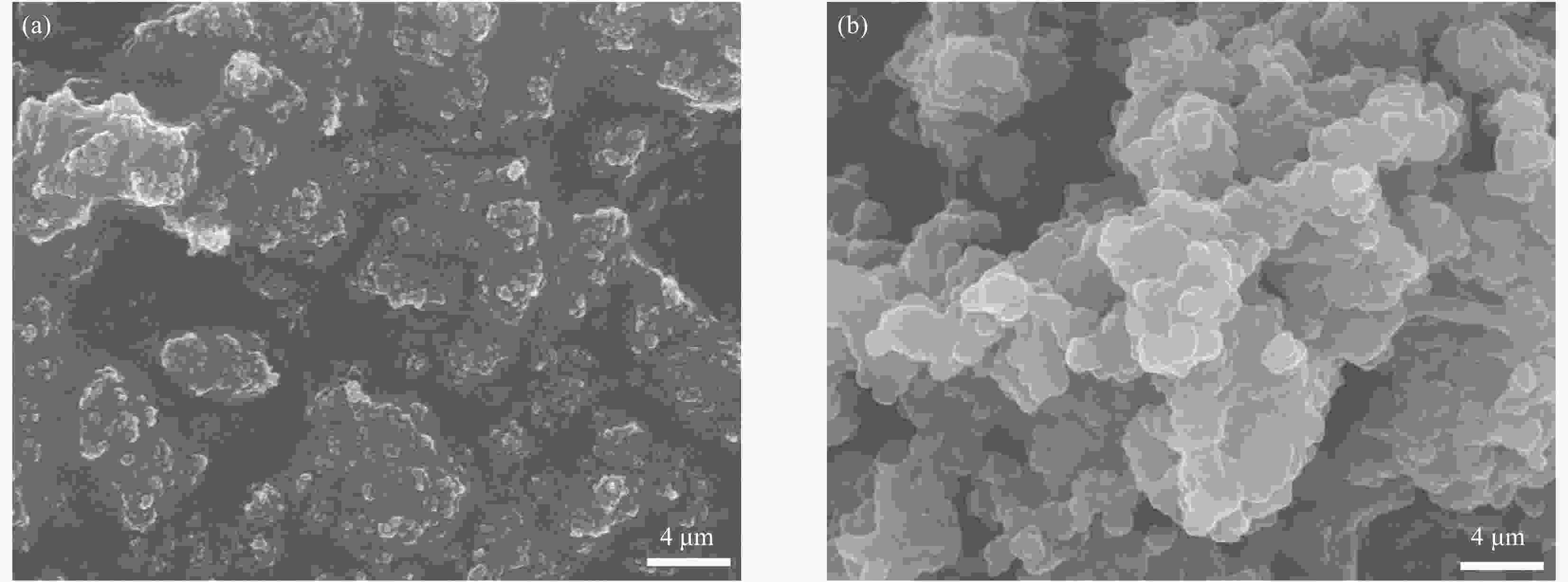

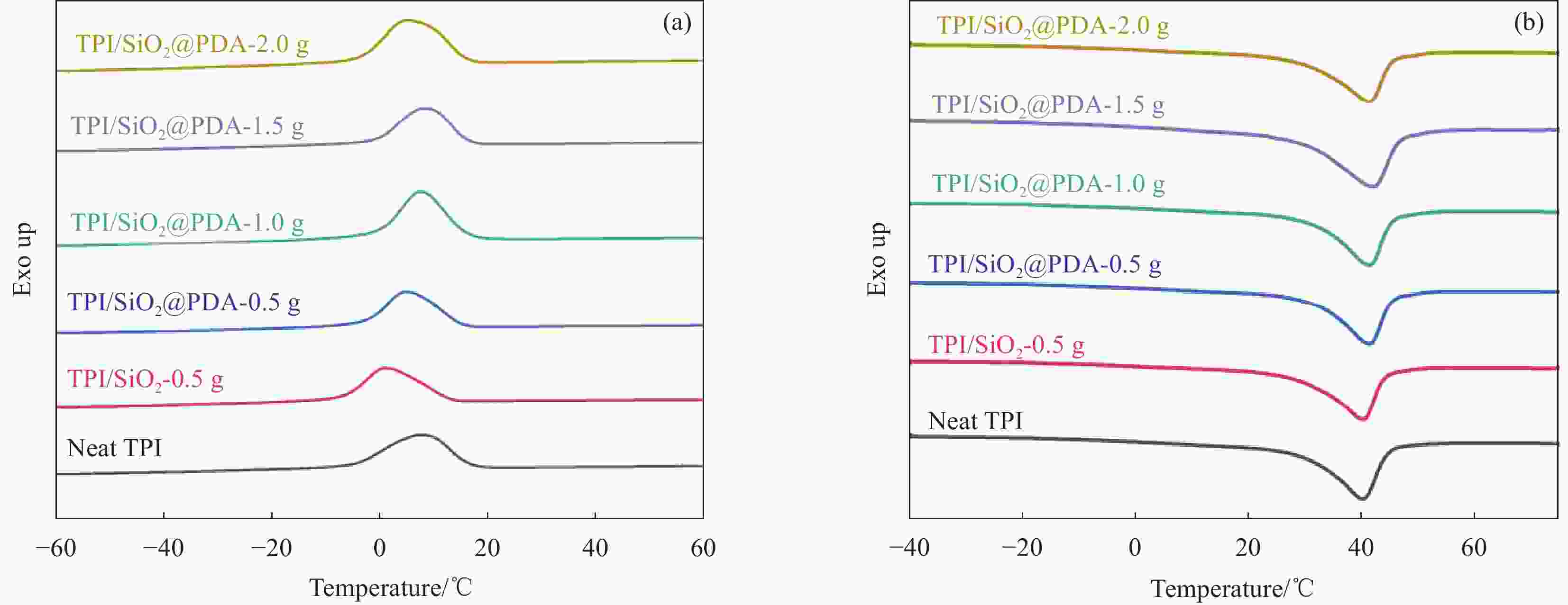

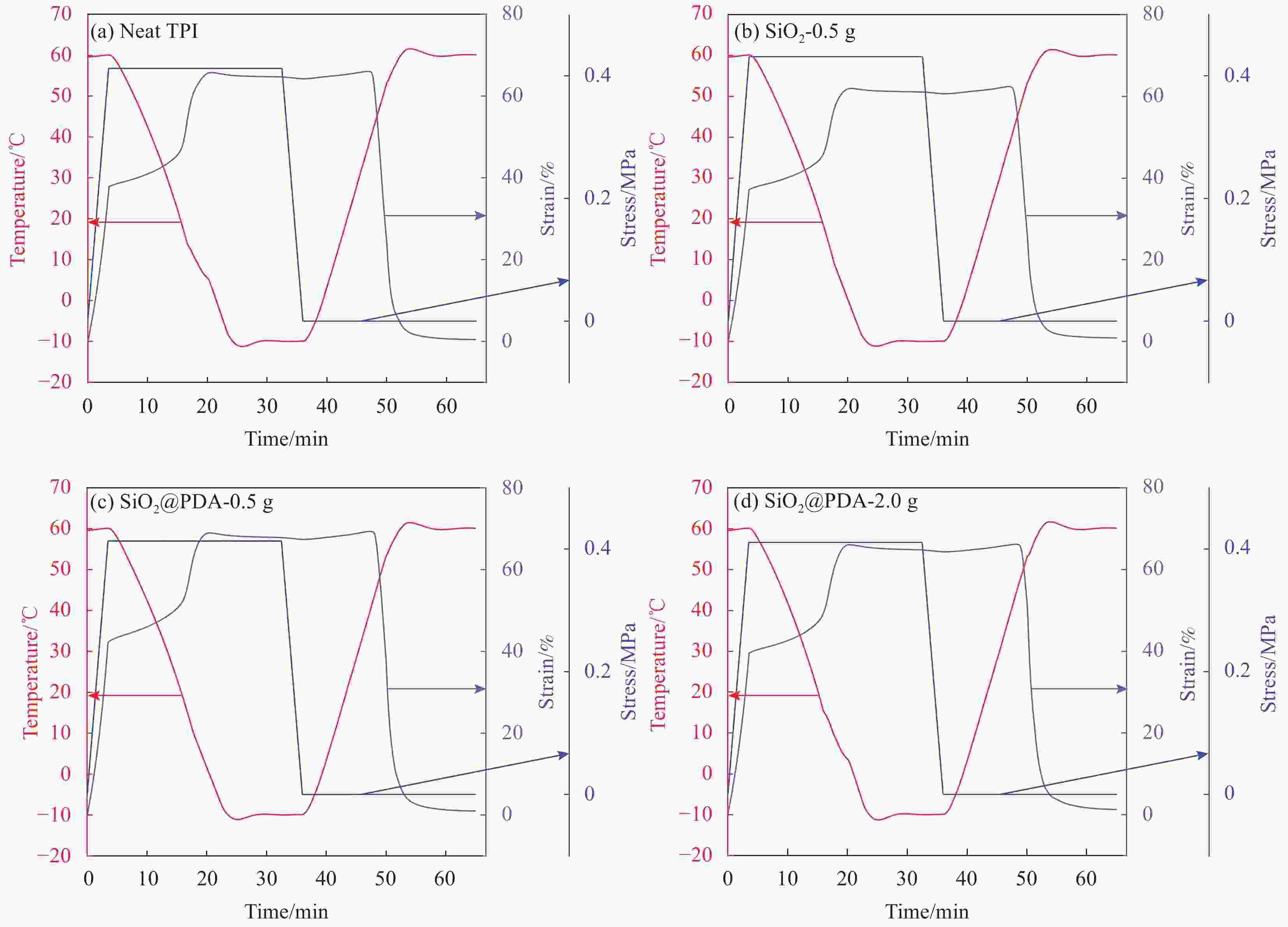

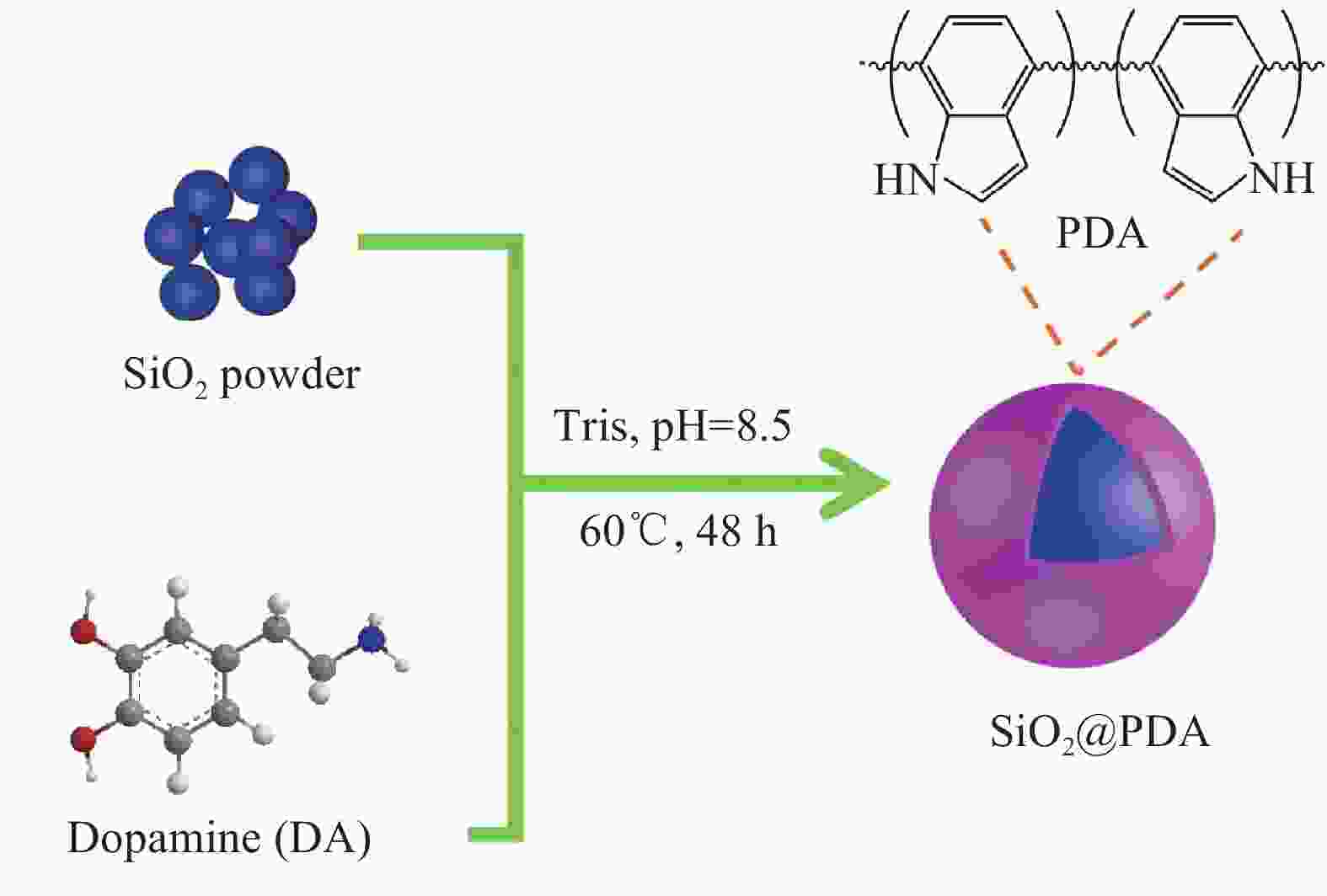

摘要: 由于形状记忆聚合物(SMP)较低的力学强度,不足以满足现今大多数商用复合材料的使用标准,严重限制了其在许多高级应用中的使用。因此,为制备高性能SMP复合材料,利用聚多巴胺(PDA)对纳米SiO2进行表面改性,制备了一种新型纳米填料SiO2@PDA,并通过SEM、XPS和FTIR对其结构和性能进行了表征。将SiO2和SiO2@PDA作为纳米填料填充到反式-1, 4-聚异戊二烯(TPI)中,制备了TPI形状记忆复合材料,系统的研究了TPI/SiO2和TPI/SiO2@PDA复合材料的热稳定性、力学性能和形状记忆性能。结果表明:PDA修饰增强了SiO2在TPI基体中的分散性和界面相互作用,从而使TPI/SiO2@PDA复合材料的热稳定性、力学性能得到提升的同时仍能够保持良好的形状记忆性能。当SiO2@PDA含量为1.5% (以TPI的质量为基准,下同)时,TPI复合材料的冲击强度和拉伸强度达到最大值,分别比纯TPI提高了43.5%和25%。此外,复合材料固定率(Rf)和回复率(Rr)均超过97%。

-

关键词:

- 反式-1, 4-聚异戊二烯 /

- 聚多巴胺 /

- 纳米二氧化硅 /

- 力学性能 /

- 形状记忆

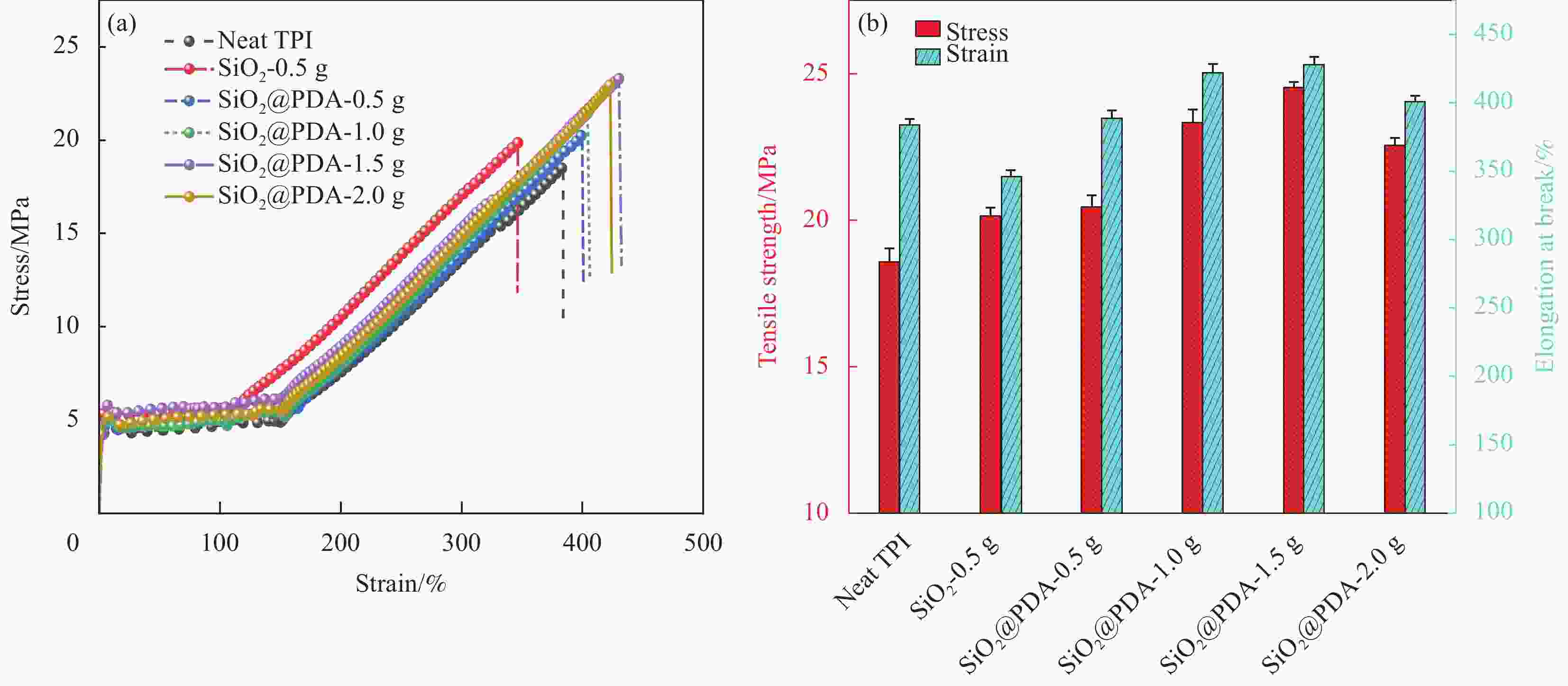

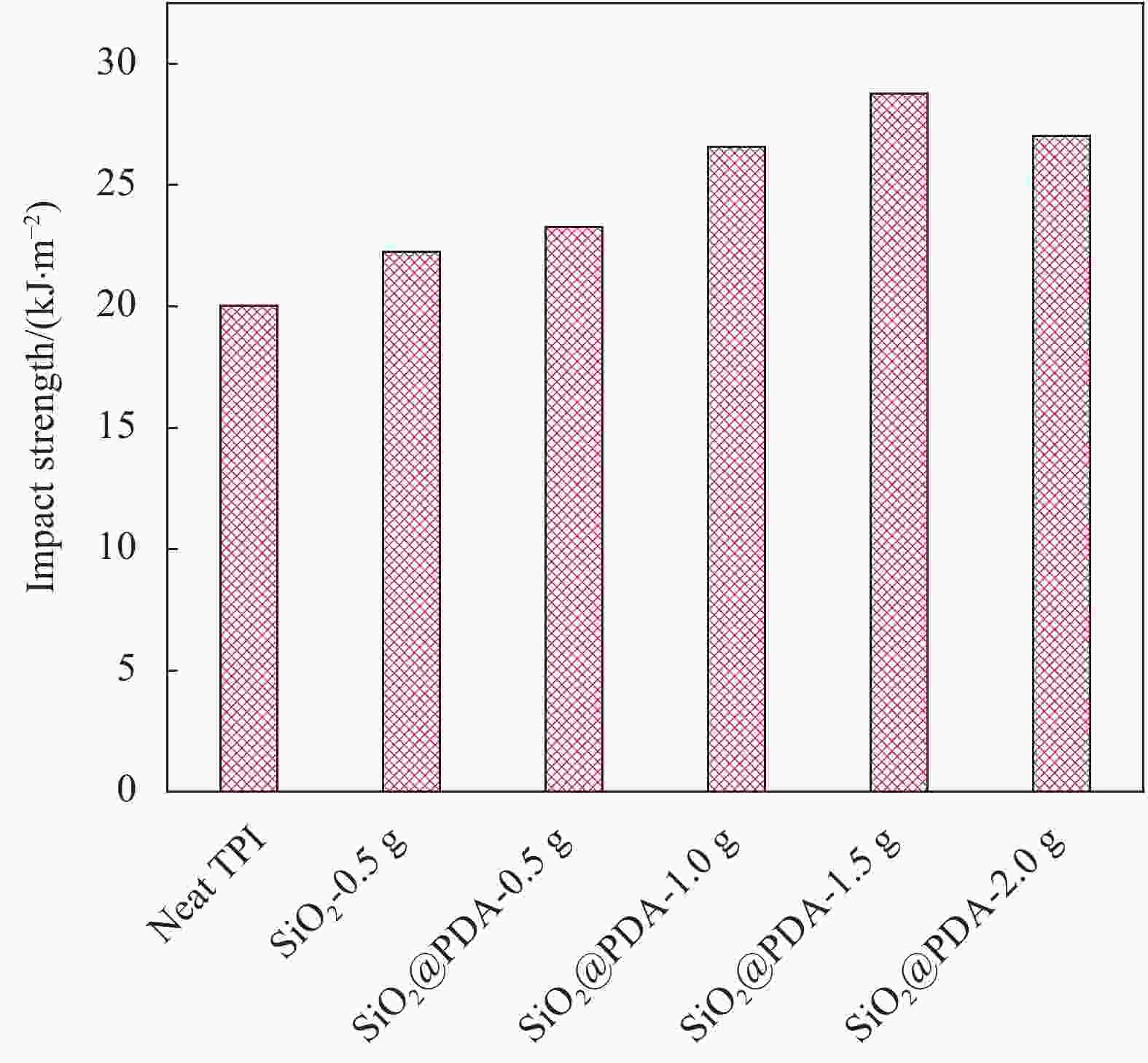

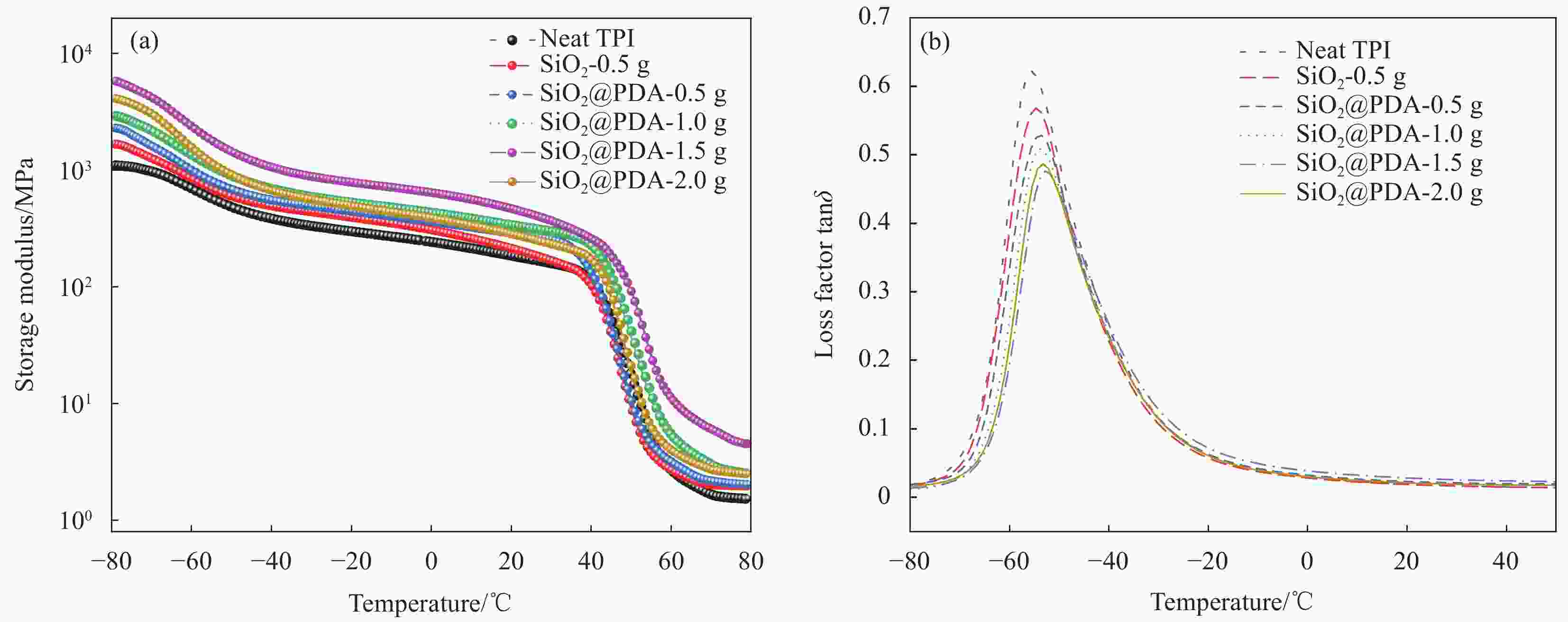

Abstract: The low mechanical strength of shape memory polymers (SMP) are insufficient to meet the standards of most commercial composites today, severely limiting their use in many advanced applications. Therefore, in order to prepare high-performance SMP composite materials, a novel nano-filler SiO2@PDA was prepared by surface modification of nano-silica (SiO2) with polydopamine (PDA), its structure and properties were characterized by SEM, XPS and FTIR, respectively. Shape memory composites based on trans-1,4-polyisoprene (TPI) were prepared by filling SiO2 and SiO2@PDA into TPI as nano-fillers. The thermal stability, comprehensive mechanical properties and shape memory properties of TPI/SiO2 and TPI/SiO2@PDA composites were systematically studied. The results show that PDA modification enhances the dispersion and interfacial interaction of SiO2 in the TPI matrix, so that the thermal stability and mechanical properties of the TPI/SiO2@PDA composites can be improved, while maintaining good shape memory performance. The impact strength and tensile strength of the composite reach the maximum values when the SiO2@PDA content is 1.5% (based on the mass of TPI, the same below), which are 43.5% and 25% higher than that of the neat TPI, respectively. Moreover, shape fixation rate (Rf) and shape recovery rate (Rr) of the composites are over 97%.-

Key words:

- trans-1, 4-polyisoprene /

- polydopamine /

- nano-silica /

- mechanical properties /

- shape memory

-

表 1 反式-1, 4-聚异戊二烯(TPI)复合材料的命名

Table 1. Naming of trans-1, 4-polyisoprene (TPI) composites

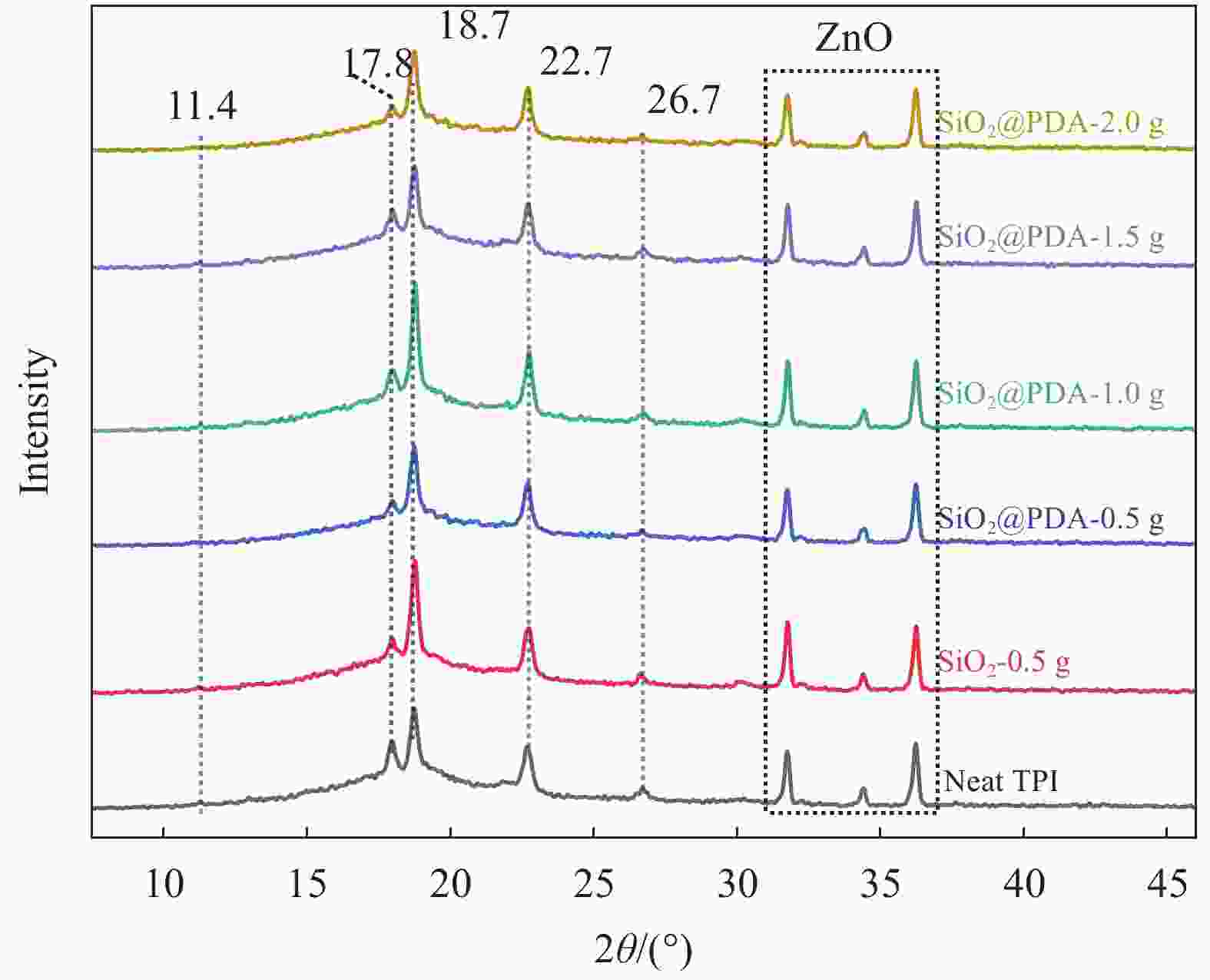

Sample TPI/g SiO2/g SiO2@PDA/g Neat TPI 100 − − TPI/SiO2-0.5 g 100 0.5 − TPI/SiO2@PDA-0.5 g 100 − 0.5 TPI/SiO2@PDA-1.0 g 100 − 1.0 TPI/SiO2@PDA-1.5 g 100 − 1.5 TPI/SiO2@PDA-2.0 g 100 − 2.0 表 2 TPI复合材料的DSC测试数据

Table 2. DSC test data of TPI composites

Sample Xc/% Tm/℃ Tc/℃ ∆Hm/(J·g-1) Neat TPI 14.03 40.08 7.62 26.21 TPI/SiO2-0.5 g 13.77 40.33 1.06 25.72 TPI/SiO2@PDA-0.5 g 14.76 41.18 5.27 27.58 TPI/SiO2@PDA-1.0 g 15.28 41.68 7.32 28.55 TPI/SiO2@PDA-1.5 g 15.80 42.36 8.89 29.53 TPI/SiO2@PDA-2.0 g 15.20 41.46 5.53 28.40 Note: Xc, Tm, Tc and ∆Hm—Crystallinity, crystallization temperature, melting temperature and melting enthalpy of TPI shape memory composites, respectively. 表 3 TPI形状记忆复合材料的TG测试数据

Table 3. TG test data for TPI shape memory composites

Sample T5%/℃ Tmax/℃ W600/wt% Neat TPI 277.13 371.21 2.39 TPI/SiO2-0.5 g 310.36 372.53 4.62 TPI/SiO2@PDA-0.5 g 318.93 373.68 5.52 TPI/SiO2@PDA-1.0 g 323.88 375.38 5.75 TPI/SiO2@PDA-1.5 g 326.46 379.06 9.12 TPI/SiO2@PDA-2.0 g 320.95 376.45 6.39 Notes: T5% and Tmax—Initial degradation temperature and maximum degradation temperature of TPI shape memory composites; W600—Mass fraction of residual carbon at 600℃. 表 4 TPI形状记忆复合材料的形状记忆测试数据

Table 4. Shape memory test data for TPI shape memory composites

Sample Rf/% Rr/% Neat TPI 98.7 98.8 TPI/SiO2-0.5 g 98.3 98.1 TPI/SiO2@PDA-0.5 g 98.6 98.5 TPI/SiO2@PDA-2.0 g 98.5 97.9 Note: Rf and Rr—Shape fixation rate and shape recovery rate of TPI shape memory composites, respectively. -

[1] CHAN B Q, LOW Z W, HENG S J, et al. Recent advances in shape memory soft materials for biomedical applications[J]. ACS Applied Materials & Interfaces, 2016, 8(16): 10070-10087. [2] XIA Y, HE Y, ZHANG F, et al. A review of shape memory polymers and composites: Mechanisms, materials, and applications[J]. Advanced Materials,2021,33(6):2000713. doi: 10.1002/adma.202000713 [3] 赵先锋, 汤朋飞, 史红艳. 4D打印复合软材料力学性能预测研究进展[J]. 复合材料学报, 2021, 38(6):1651-1668.ZHAO Xianfeng, TANG Pengfei, SHI Hongyan. Research progress on prediction of mechanical properties of 4D printing soft composite[J]. Acta Materiae Compositae Sinica,2021,38(6):1651-1668(in Chinese). [4] 李文兵, 魏婉婷, 李金嵘, 等. 形状记忆聚合物纤维及增强复合材料的研究进展[J]. 复合材料学报, 2022, 39(1):77-96. doi: 10.13801/j.cnki.fhclxb.20210729.005LI Wenbing, WEI Wanting, LI Jinrong, et al. Research progress of shape memory polymer fibers and reinforced composites[J]. Acta Materiae Compositae Sinica,2022,39(1):77-96(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210729.005 [5] TIAN M, GAO W, HU J, et al. Multidirectional triple-shape-memory polymer by tunable cross-linking and crystallization[J]. ACS Applied Materials & Interfaces, 2020, 12(5): 6426-6435. [6] JIA X, SHEN B, ZHANG L, et al. Construction of shape-memory carbon foam composites for adjustable EMI shielding under self-fixable mechanical deformation[J]. Chemical Engineering Journal, 2021, 405: 126927. [7] WANG E, DONG Y, ISLAM Z, et al. Technology, effect of graphene oxide-carbon nanotube hybrid filler on the mechanical property and thermal response speed of shape memory epoxy composites[J]. Composites Science and Technology,2019,169(5):209-216. [8] LIU Y, GUO Y, ZHAO J, et al. Technology, carbon fiber reinforced shape memory epoxy composites with superior mechanical performances[J]. Composites Science and Technology,2019,177(16):49-56. [9] JIAN W, WANG X, LU H, et al. Molecular dynamics simulations of thermodynamics and shape memory effect in CNT-epoxy nanocomposites[J]. Composites Science and Technology,2021,211(4):108849. [10] XU L, FU Y, DU M. Investigation on structures and properties of shape memory polyurethane/silica nanocompo-sites[J]. Chinese Journal of Chemistry,2011,29(4):703-710. doi: 10.1002/cjoc.201190144 [11] SHARMA A, SINGHOLI A. Effect of nanosilica on shape memory and mechanical characterization of polylactic acid wood composite[J]. Polymer Composites,2021,42(5):2502-2510. doi: 10.1002/pc.25995 [12] FU Y W, ZHANG Y Q, SUN W F, et al. Functionalization of silica nanoparticles to improve crosslinking degree, insulation performance and space charge characteristics of UV-initiated XLPE[J]. Molecules,2020,25(17):3794. doi: 10.3390/molecules25173794 [13] LI X T, WANG H T, ZHANG Z W, et al. Preparation and mechanical properties of poly(γ-benzyl-glutamate) modified nano-silica reinforced polyurea composites[J]. Polymers for Advanced Technologies,2021,33(1):270-279. [14] ZHANG C, LI L, XIN Y, et al. Development of trans-1, 4-polyisoprene shape-memory polymer composites reinforced with carbon nanotubes modified by polydopamine[J]. Polymers,2022,14(1):110. [15] TENG J, WANG Z, LIU J, et al. Thermodynamic and shape memory properties of TPI/HDPE hybrid shape memory polymer[J]. Polymer Testing,2019,81:106257. [16] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People's Republic of China. Determination of tensile stress-strain properties of vulcanized or thermoplastic rubber: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [17] 中国国家标准化管理委员会. 塑料悬臂梁冲击强度的测定: GB/T 1843—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Plastics-determination of izod impact strength: GB/T 1843—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [18] CHEN Q T, YANG B, DING M Y, et al. Enhanced physical, mechanical and protein adsorption properties of PVDF composite films prepared via thermally-induced phase separation (TIPS): Effect of SiO2@PDA nanoparticles[J]. European Polymer Journal,2020,140:110039. doi: 10.1016/j.eurpolymj.2020.110039 [19] QIU Z, WANG J, YANG K, et al. Simultaneous enhancements of mechanical properties and hydrophilic properties of polypropylene via nano: Silicon dioxide modified by polydopamine[J]. Journal of Applied Polymer Science,2017,134(26):45004. [20] YANG H, PI P H, YANG Z R, et al. Design of a superhydrophobic and superoleophilic film using cured fluoropolymer@silica hybrid[J]. Applied Surface Science,2016,388:268-273. doi: 10.1016/j.apsusc.2016.01.099 [21] QIAN Y R, FENG J H, FAN D W, et al. A sandwich-type photoelectrochemical immunosensor for NT-pro BNP detection based on F-Bi2WO6/Ag2S and GO/PDA for signal amplification[J]. Biosensors and Bioelectronics,2019,131:299-306. doi: 10.1016/j.bios.2019.02.029 [22] ZHU L, LU Y, WANG Y, et al. Preparation and characterization of dopamine-decorated hydrophilic carbon black[J]. Applied Surface Science,2012,258(14):5387-5393. doi: 10.1016/j.apsusc.2012.02.016 [23] WU Y L, LU J, LIN X Y, et al. Bioinspired synthesis of SiO2/PDA-based nanocomposite-imprinted membranes with sol-gel imprinted layers for selective adsorption and separation applications[J]. Physical Chemistry Chemical Physics,2018,20(23):15775-15783. doi: 10.1039/C8CP02068J [24] WANG Z, REN R, SONG H, et al. Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives[J]. Applied Surface Science,2018,428(15):630-639. [25] ZHANG J, XUE Z. A comparative study on the properties of eucommia ulmoides gum and synthetic trans-1, 4-polyisoprene[J]. Polymer Testing,2011,30(7):753-759. doi: 10.1016/j.polymertesting.2011.06.010 [26] KRÓL A, POMASTOWSKI P, RAFIŃSKA K, et al. Zinc oxide nanoparticles: Synthesis, antiseptic activity and toxicity mechanism[J]. Advances in Colloid and Interface Science,2017,249:37-55. doi: 10.1016/j.cis.2017.07.033 -

下载:

下载: