Scratch damage tolerance at the surface of CFRP-steel laminated composite structure

-

摘要: 碳纤维增强树脂复合材料(CFRP)-钢层状结构在实际运营过程中,脆性碳纤维层容易出现划痕等表面损伤,因此为了保障损伤后复合结构的安全运行,需要对其进行损伤容限研究。基于边界效应理论模型(Boundary effect model,BEM),建立了表面划痕损伤后的CFRP-钢层状结构三点弯曲断裂强度解析模型,并在CFRP表面分别预制了0.2 mm和0.4 mm深度的表面初始划痕缺陷,通过三点弯曲梁的成组试验验证了理论模型的可行性。研究结果表明:(1)利用金相显微镜观测了CFRP-钢层状结构三点弯曲极限荷载时的断裂特征,确定了表面划痕损伤后CFRP的结构特征参数Cch,代入解析模型获得了CFRP层的拉伸强度,并与CFRP直接拉伸试验测试的拉伸强度对比,两者偏差小于10%;(2)该解析模型为“断裂荷载=拉伸强度×等效面积”的线性方程形式,“等效面积”仅与CFRP-钢层状结构和表面裂纹的几何参数有关,因此,通过CFRP的直接拉伸强度可以预测表面损伤后CFRP-钢层状结构的断裂强度,实现损伤容限设计。

-

关键词:

- CFRP-钢层状结构 /

- 表面划痕 /

- 损伤容限 /

- 断裂强度 /

- 解析模型

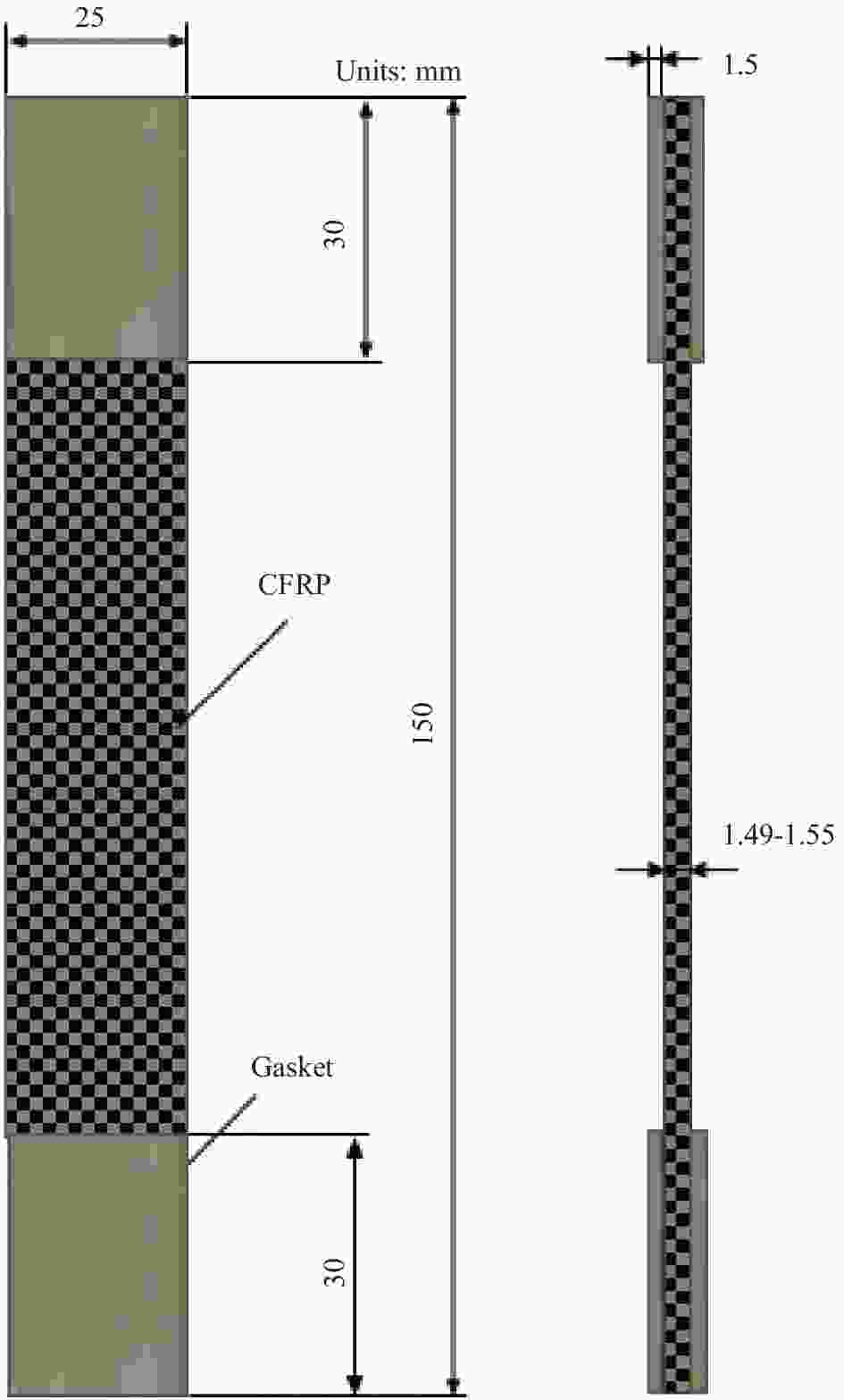

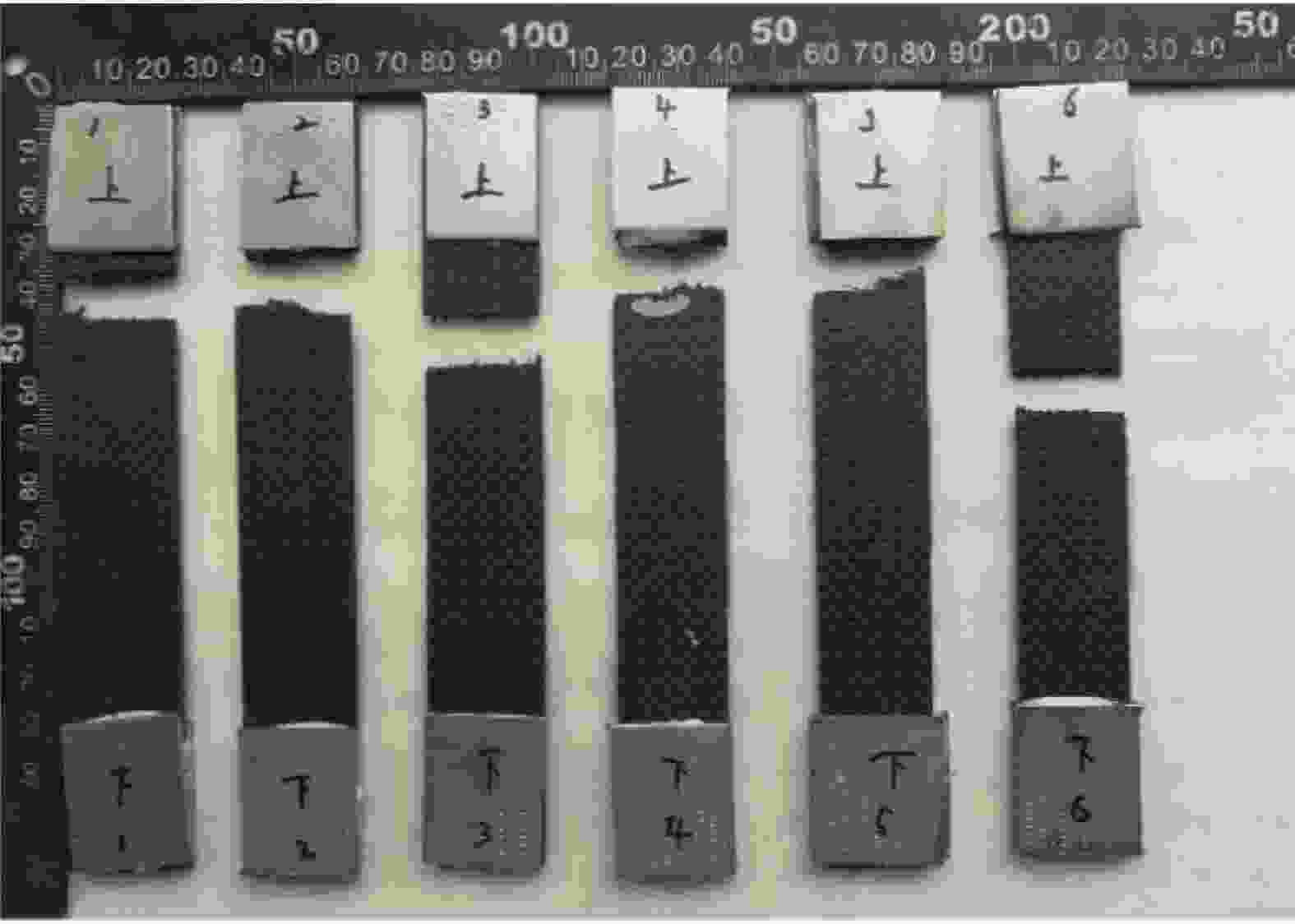

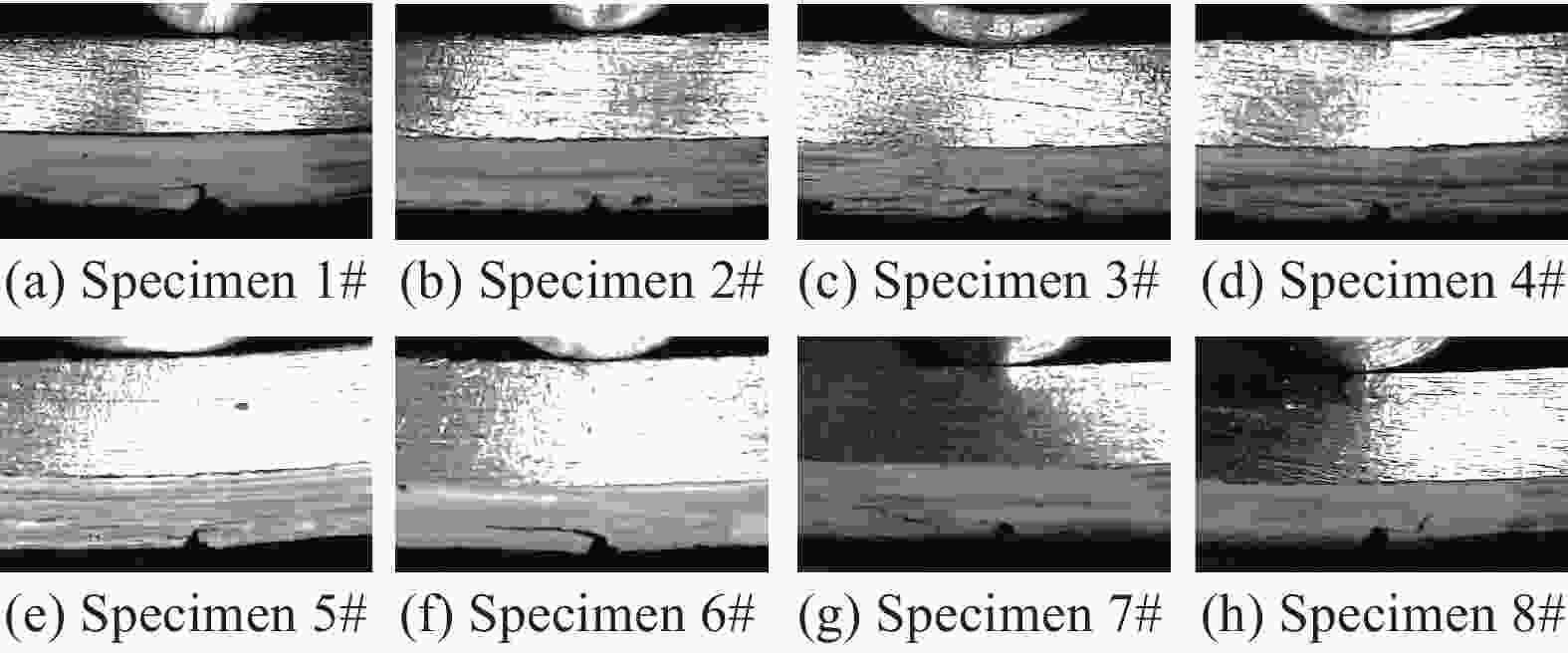

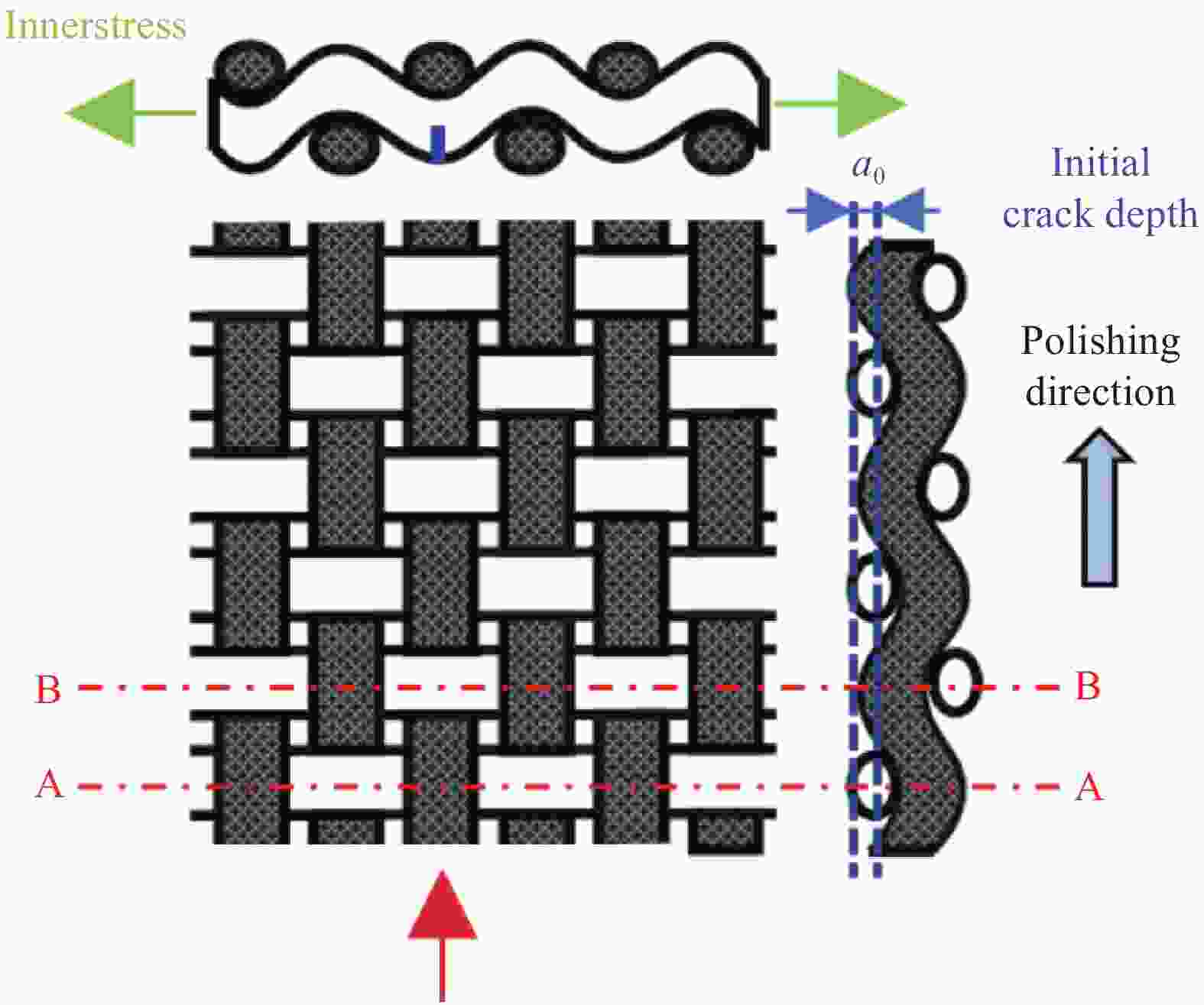

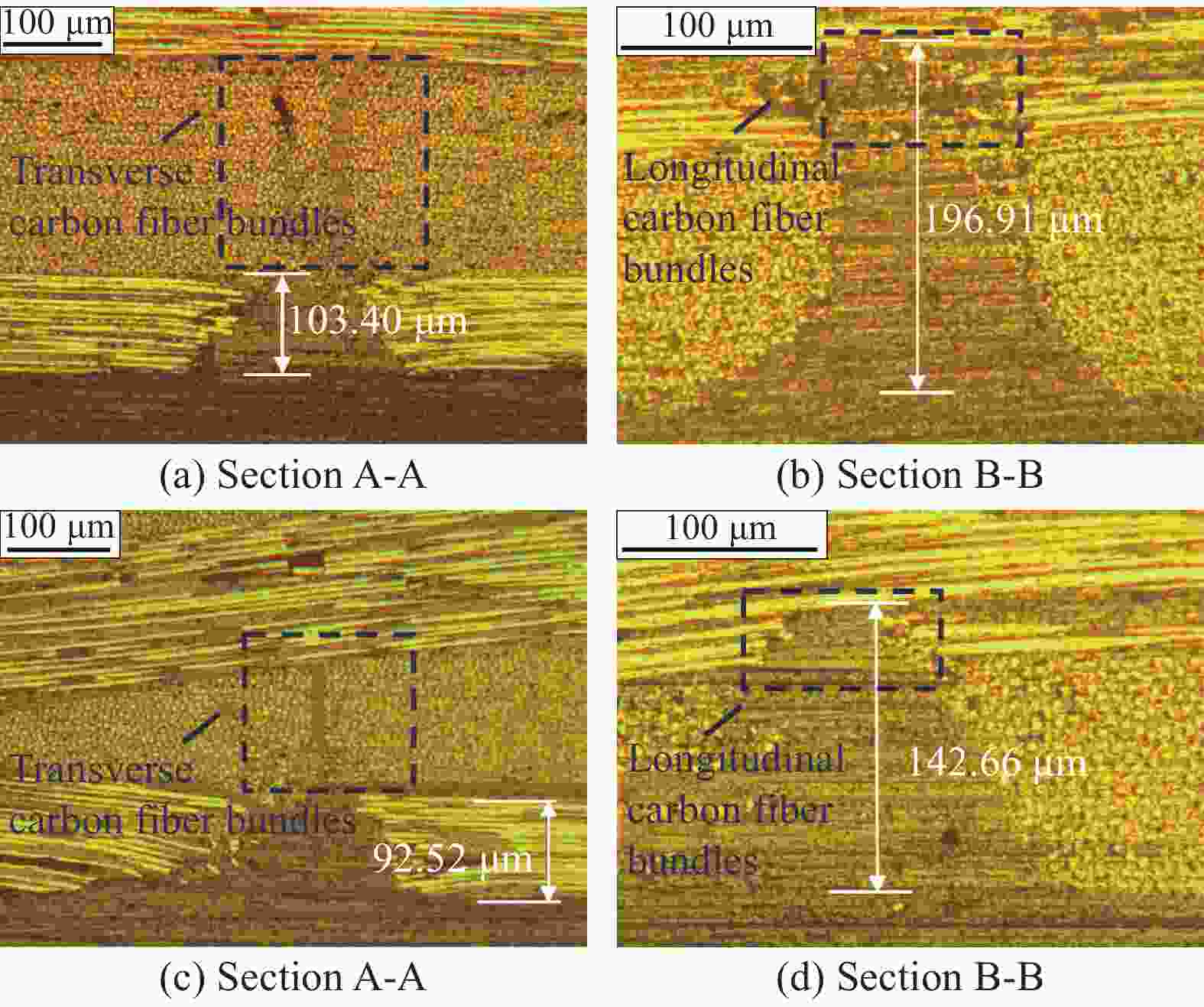

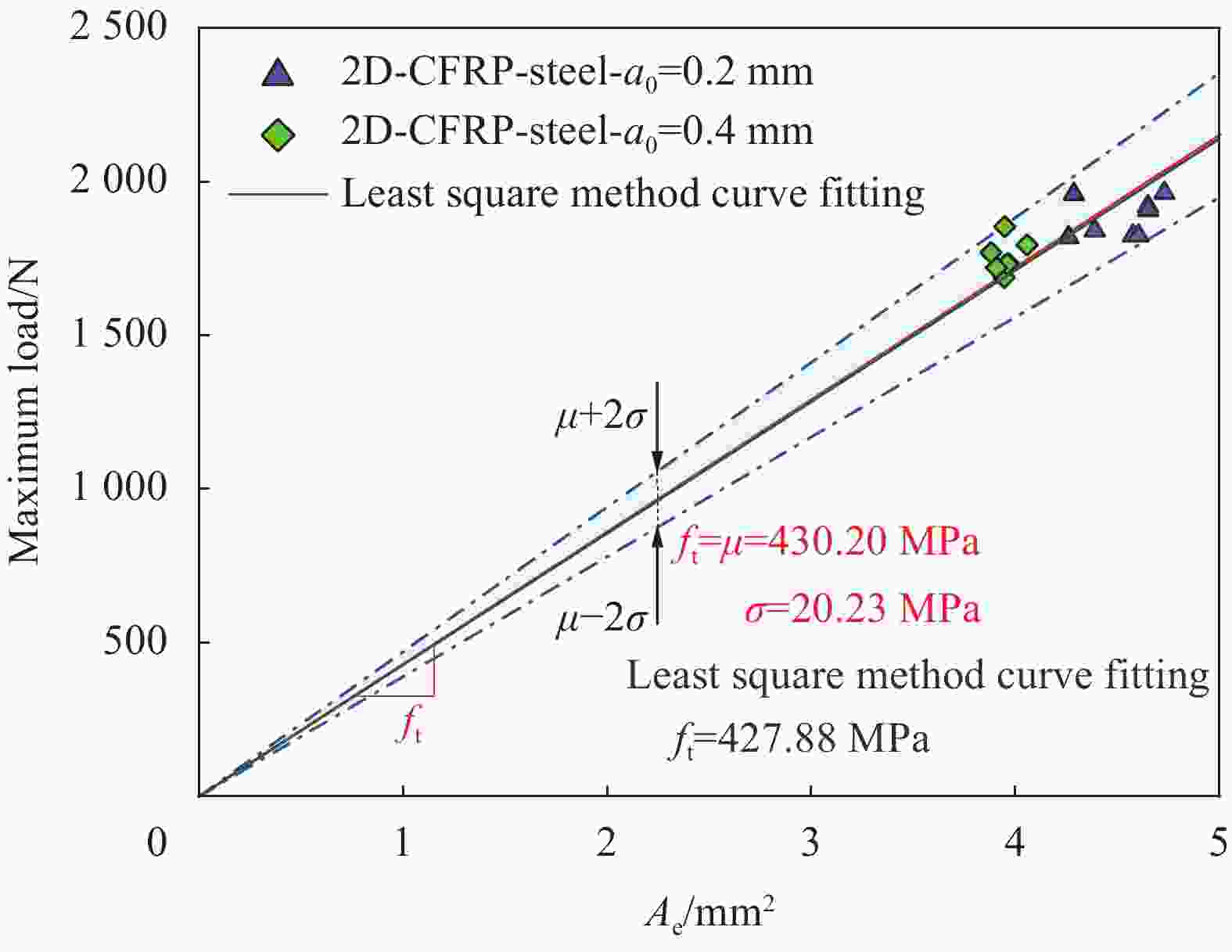

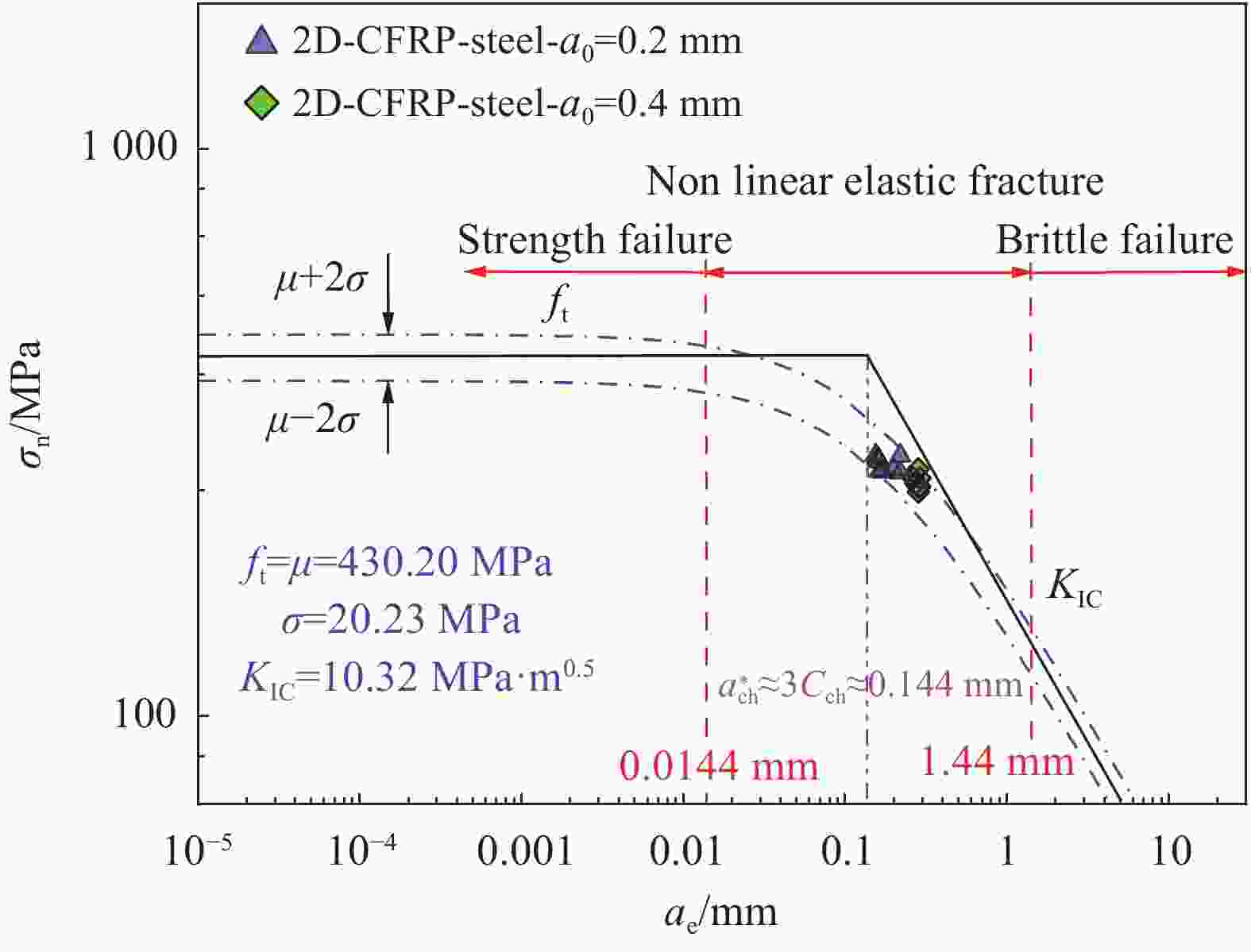

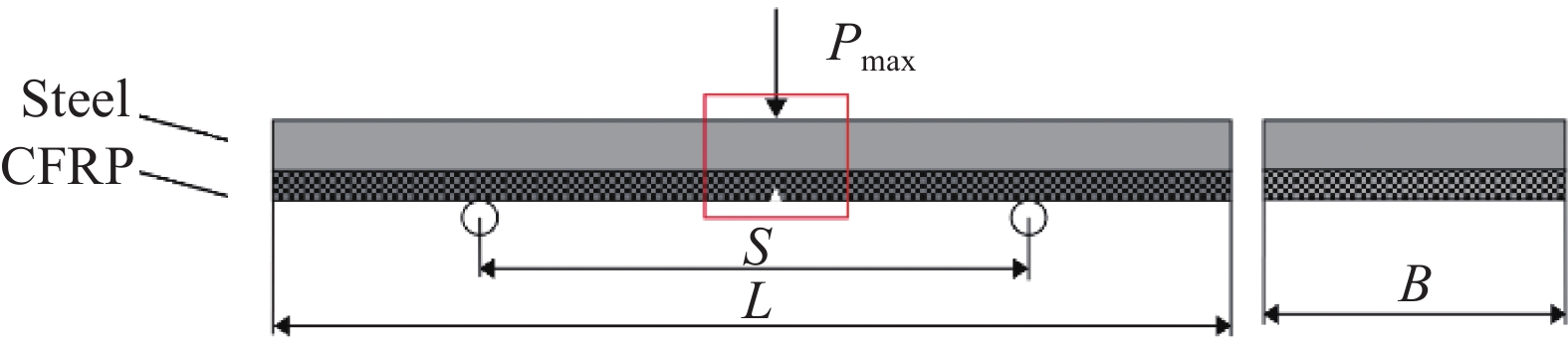

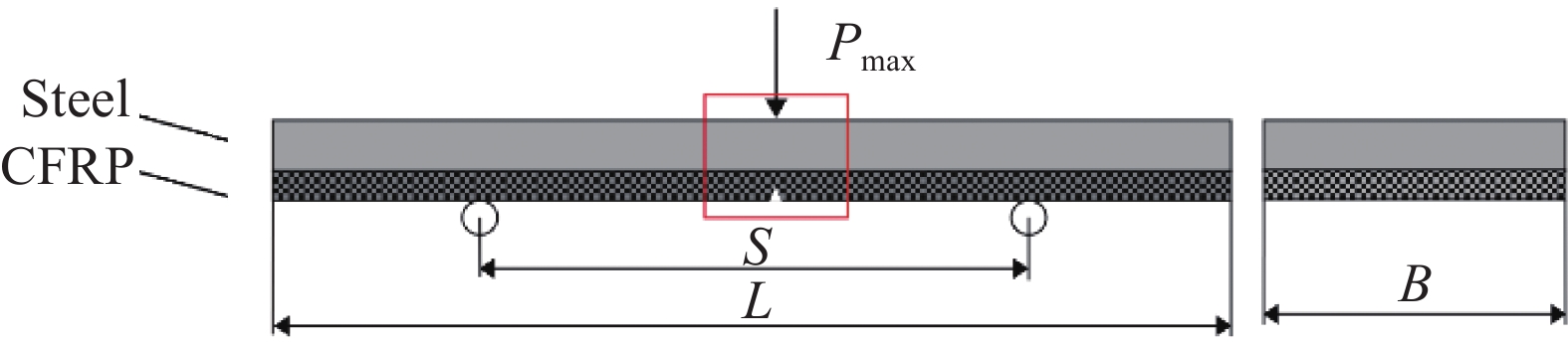

Abstract: In the actual operation process, the surface of brittle carbon fiber layer of carbon fiber reinforced polymer (CFRP)-steel layered structure suffered from scratch and other damage. Therefore, it is necessary to study the damage tolerance to ensure the safe operation of the damaged composite structure. An analytical model of fracture strength at the three-point bending (3-p-b) test for CFRP-steel laminated structure with surface scratch damage was established based on the boundary effect model (BEM). And the initial scratch defects of 0.2 mm and 0.4 mm depth were prefabricated on the surface of CFRP, respectively. The feasibility of this theoretical model was verified at the 3-p-b tests. The results indicate that: (1) The fracture characteristics of CFRP-steel laminated structure at the 3-p-b tests were observed by metallographic microscope, and the structural characteristic parameter Cch of CFRP after scratch damage was determined. The tensile strength of CFRP layer was carried out according to this analytical model, and the deviation is less than 10% compared with the tensile strength measured by CFRP direct tensile test. (2) The analytical model is a linear equation of “fracture load = tensile strength × equivalent area”. The “equivalent area” is only related to CFRP-steel laminated structure and the geometric parameters of surface crack. Therefore, the fracture strength of CFRP-steel laminated structure with surface damage can be predicted by the direct tensile strength of CFRP, and the damage tolerance design can be realized. -

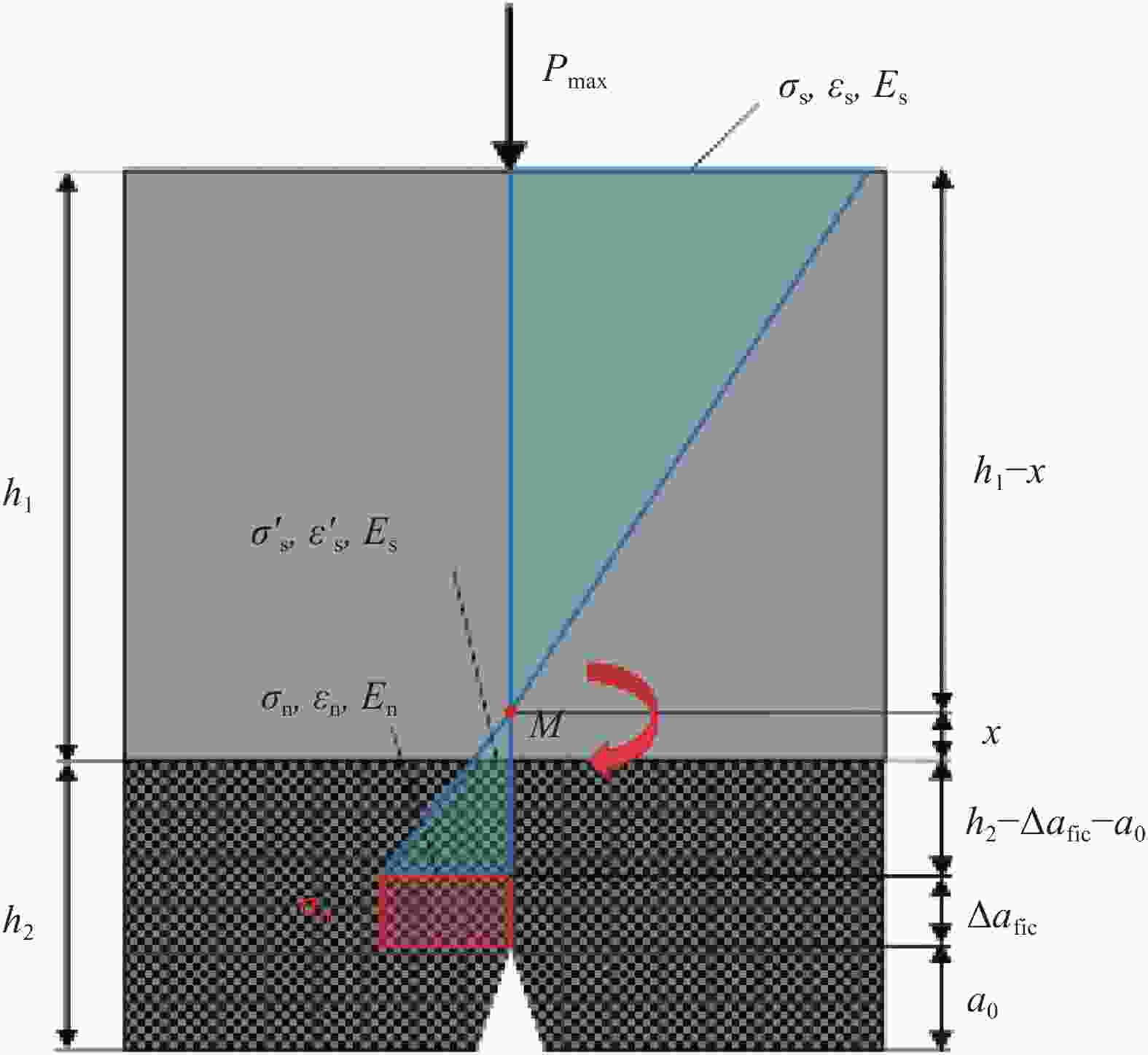

图 2 CFRP裂纹处截面的应力-应变图

Figure 2. Stress-strain diagram of CFRP crack section

h1—Thickness of steel plate; h2—Thickness of CFRP plate; Δafic—Crack tip damage zone/fictitious crack growth; σn—Nominal stress at crack tip damage zone; εn—Nominal stress at crack tip damage zone; σs—Stress at upper surface of steel plate; εs—Strain at upper surface of steel plate; Es—Elastic modulus of steel plate; σ’s—Stress at the interface between steel and CFRP on steel plate; ε’s—Strain at the interface between steel and CFRP; En—Equivalent elastic modulus of CFRP; a0—Initial crack depth; x—Distance from the neutral axis of CFRP/steel layered structure to the bonding interface between CFRP and steel; M—Moment in CFRP/steel layered structure

表 1 A-38/3K碳纤维丝材料性能

Table 1. Material properties of A-38/3K carbon fiber

Type Elastic modulus/GPa Yield strength/MPa Elongation/% A-38/3K 240 3800 1.6 表 2 环氧树脂胶粘剂材料性能

Table 2. Material properties of epoxy adhesive

Type Viscosity/(mPa·s) Hardness/shoreD Tensile strength/MPa Bending strength/MPa YT-CC302S 200-300 90 320 230 表 3 钢板的力学性能

Table 3. Mechanical properties of steel plate

Type Elastic modulus/GPa Yield strength/MPa Tensile strength/MPa Q235 206 235 420 表 4 CFRP板直接拉伸试验结果

Table 4. Direct tensile test results of CFRP plate

Specimen number Maximum tension/N Elastic modulus/GPa Tensile strength/MPa CFRP-1 24225.4 43 402.86 CFRP-2 24657.5 40 374.22 CFRP-3 26330.7 39 387.20 CFRP-4 29312.6 40 478.96 CFRP-5 30215.4 40 523.39 CFRP-6 22608.1 42 379.23 表 5 CFRP-钢层状复合结构三点弯曲试验数据

Table 5. Three point bending test datas of CFRP-steel laminated composite structure

Specimen type

(2D-CFRP-steel)a0/mm h1/mm h2/mm Pmax/N ft/MPa KIC/(MPa·m0.5) 0.2 mm-1 0.190 2.98 1.50 1919.9 412.85 9.91 0.2 mm-2 0.285 3.00 1.51 1959.1 457.04 10.97 0.2 mm-3 0.205 2.99 1.50 1824.3 398.56 9.57 0.2 mm-4 0.194 2.99 1.51 1906.8 409.92 9.84 0.2 mm-5 0.183 2.99 1.52 1963.1 414.96 9.96 0.2 mm-6 0.196 2.99 1.52 1824.3 396.25 9.51 0.2 mm-7 0.249 3.00 1.52 1840.8 419.31 10.06 0.2 mm-8 0.285 2.99 1.53 1818.5 426.80 10.24 0.4 mm-1 0.427 3.01 1.45 1728.2 437.50 10.50 0.4 mm-2 0.418 3.01 1.48 1853.5 469.37 11.26 0.4 mm-3 0.434 3.00 1.51 1769.5 455.93 10.94 0.4 mm-4 0.418 3.01 1.49 1688.2 427.90 10.27 0.4 mm-5 0.372 3.01 1.50 1794.5 442.24 10.61 0.4 mm-6 0.392 2.99 1.51 1733.5 437.09 10.49 0.4 mm-7 0.394 2.99 1.52 1731.8 437.28 10.49 0.4 mm-8 0.432 3.00 1.50 1720.2 440.27 10.57 Notes: a0—Initial crack depth; h1—Steel thickness; h2—CFRP thickness; Pmax—Limit load; ft—Tensile strength; KIC—Fracture toughness. 表 6 不同表面裂纹深度的CFRP-钢复合结构极限承载力Pmax预测值

Table 6. Pmax prediction of CFRP-steel composite structures with different surface crack depths

${a_0}$/mm Upper limit of ultimate load/N Lower limit of ultimate load /N Average of limit load/N Average decline/% 0 3274.11 2711.28 2992.74 − 0.001 3272.94 2710.31 2991.67 0.04 0.01 3163.20 2619.43 2891.36 3.39 0.1 2532.80 2097.40 2315.14 22.64 0.2 2017.21 1976.75 1996.98 33.27 0.4 1719.44 1678.98 1699.21 43.22 表 7 不同Cch值对CFRP-钢复合结构断裂性能的影响

Table 7. Effects of various Cch values on fracture properties of CFRP-steel composite structures

ft/MPa KIC/(MPa·m0.5) Cch/μm 33.6 48 62.4 33.6 48 62.4 Average µ 487.24 430.20 395.41 9.78 10.32 10.82 Standard deviation σ 26.96 20.23 16.20 0.54 0.49 0.44 Error/% 13.26 0 −8.08 −5.23 0 4.84 -

[1] 熊健, 李志彬, 刘惠彬, 等. 航空航天轻质复合材料壳体结构研究进展[J]. 复合材料学报, 2021, 38(6):1629-1650.XIONG Jian, LI Zhibin, LIU Huibin, et al. Advances in aerospace lightweight composite shell structure[J]. Acta Materiae Compositae Sinica,2021,38(6):1629-1650(in Chinese). [2] 肖何, 陈藩, 刘寒松, 等. 国产ZT7H碳纤维表面状态及其复合材料界面性能[J]. 复合材料学报, 2021, 38(8): 2554-2567.XIAO He, CHEN Fan, LIU Hansong, et al. Surface state of domestic ZT7H carbon fiber and interface property of composites[J]. Acta Materiae Compositae Sinica, 2021, 38(8): 2554-2567(in Chinese). [3] 李红, 刘旭升, 张宜生, 等. 新能源电动汽车异种材料连接技术的挑战、趋势和进展[J]. 材料导报, 2019, 33(23):3853-3861. doi: 10.11896/cldb.19020049LI Hong, LIU Xusheng, ZHANG Yisheng, et al. Challenges, trends and progress of dissimilar material bonding technology for new energy electric vehicles[J]. Material Guide,2019,33(23):3853-3861(in Chinese). doi: 10.11896/cldb.19020049 [4] 籍龙波, 朱学武, 丁建鹏, 等. 乘用车碳纤维复合材料研究及应用进展[J]. 汽车文摘, 2020(9):17-22.JI Longbo, ZHU Xuewu, DING Jianpeng, et al. Research and application progress of carbon fiber composites for passenger cars[J]. Automotive Digest,2020(9):17-22(in Chinese). [5] 杨桂英, 赵睿, 肖冰, 等. 碳纤维复合材料在汽车轻量化中的应用[J]. 当代石油石化, 2020, 28(10):24-28. doi: 10.3969/j.issn.1009-6809.2020.10.005YANG Guiying, ZHAO Rui, XIAO Bing, et al. Application of carbon fiber composite in automobile lightweight[J]. Petroleum & Petrochemical Today,2020,28(10):24-28(in Chinese). doi: 10.3969/j.issn.1009-6809.2020.10.005 [6] 王军照, 丁存光, 肖云健, 等. 车用碳纤维复合材料应用研究[J]. 中国新技术新产品, 2020(18):53-57. doi: 10.3969/j.issn.1673-9957.2020.18.027WANG Junzhao, DING Cunguang, XIAO Yunjian, et al. Research on the application of carbon fiber composites for vehicles[J]. New Technology and New Products in China,2020(18):53-57(in Chinese). doi: 10.3969/j.issn.1673-9957.2020.18.027 [7] 张莉, 董磊, 刘志远. 碳纤维复合材料在轨道交通车辆转向架上的应用[J]. 城市轨道交通研究, 2020, 23(8):190-193.ZHANG Li, DONG Lei, LIU Zhiyuan. Application of carbon fiber composite material in bogie of rail transit vehicle[J]. Urban Mass Transit,2020,23(8):190-193(in Chinese). [8] 梁云, 谌亮, 杨集友, 等. 碳纤维复合材料在轨道交通车辆转向架上的应用[J]. 城市轨道交通研究, 2020, 23(1):129-133.LIANG Yun, SHEN Liang, YANG Jiyou, et al. Application of carbon fiber composite material in bogie of rail transit vehicle[J]. Urban Mass Transit,2020,23(1):129-133(in Chinese). [9] 李荣翔. 海洋环境下CFRP复合桩水平承载特性研究[D]. 开封: 河南大学, 2019.LI Rongxiang. Study on horizontal bearing characteristics of CFRP composite pile in marine environment[D]. Kaifeng: Henan University, 2019(in Chinese). [10] 完海鹰, 李瑭颖. CFRP加固钢管柱极限承载力正交模拟与数值分析[J]. 安徽建筑, 2019, 26(9):110-112.WAN Haiying, LI Tangying. Orthogonal simulation and numerical analysis of ultimate bearing capacity of steel tubular columns strengthened with CFRP[J]. Anhui Architecture,2019,26(9):110-112(in Chinese). [11] 查晓玮. CFRP加固偏压H型钢柱承载力试验研究与数值模拟[D]. 合肥: 合肥工业大学, 2020.ZHA Xiaowei. Experimental study and numerical simulation of the bearing capacity of H-shaped steel column reinforced by CFRP[D]. Hefei: Hefei University of Technology, 2020(in Chinese). [12] WANG Y, LI J H, DENG J, et al. Bond behaviour of CFRP/steel strap joints exposed to overloading fatigue and wetting/drying cycles[J]. Engineering Structures,2018,172:1-12. doi: 10.1016/j.engstruct.2018.05.112 [13] 张彤彤, 吴健, 王纬波. CFRP加固损伤钢板的弯曲性能研究[J]. 复合材料科学与工程, 2020(12):26-30. doi: 10.3969/j.issn.1003-0999.2020.12.005ZHANG Tongtong, WU Jian, WANG Weibo. Bending behavior of damaged steel plate strengthened with CFRP[J]. Composite Materials Science and Engineering,2020(12):26-30(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.12.005 [14] LEPRETRE E, CHATAIGNER S, DIENG L, et al. Fatigue strengthening of cracked steel plates with CFRP laminates in the case of old steel material[J]. Construction and Building Materials,2018,174:421-432. doi: 10.1016/j.conbuildmat.2018.04.063 [15] CHEN T, YAO J X, LIU R Y, et al. Fatigue behavior of steel plates with multi-holes repaired by CFRP[J]. Composite Structures,2020,242:112163. doi: 10.1016/j.compstruct.2020.112163 [16] 李旭. CFRP布加固压弯钢构件极限承载力理论分析与试验研究[D]. 沈阳: 沈阳大学, 2018.LI Xu. Theoretical analysis and experimental study on ultimate bearing capacity of steel members strengthened with CFRP sheets [D]. Shenyang: Shenyang University, 2018(in Chinese). [17] 路志浩. 碳纤维在重型厂房钢吊车梁加固中的应用[J]. 上海建设科技, 2020, 238(2):13-17.LU Zhihao. Application of carbon fiber in reinforcement of steel crane beam of heavy workshop[J]. Shanghai Construction Science & Technology,2020,238(2):13-17(in Chinese). [18] HUO J S, ZHANG X F, YANG J, et al. Experimental study on dynamic behavior of CFRP-to-steel interface[J]. Structures,2019,20:465-475. doi: 10.1016/j.istruc.2019.05.007 [19] 郭奥, 杨勇新, 贾彬. 碳纤维布加固H型钢梁的抗弯性能及承载力计算[J]. 西南科技大学学报, 2019, 34(1):45-48. doi: 10.3969/j.issn.1671-8755.2019.01.008GUO Ao, YANG Yongxin, JIA Bin. Flexural behavior and bearing capacity calculation of H-beam strengthened with CFRP sheets[J]. Journal of Southwest University of Science and Technology,2019,34(1):45-48(in Chinese). doi: 10.3969/j.issn.1671-8755.2019.01.008 [20] TAFSIROJJAMAN T, FAWZIA S, THAMBIRATNAM D, et al. Behaviour of CFRP strengthened CHS members under monotonic and cyclic loading[J]. Composite Structures,2019,220:592-601. doi: 10.1016/j.compstruct.2019.04.029 [21] 王家栋. 纤维增强复合材料加固钢梁受力性能试验研究[D]. 成都: 西南交通大学, 2019.WANG Jiadong. Experimental study on mechanical behavior of steel beams strengthened with fiber reinforced composites [D]. Chengdu: Southwest Jiaotong University, 2019(in Chinese). [22] CAMINERO M A, RODRÍGUEZ G P, MUÑOZ V. Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates[J]. Composite Structures,2016,136:345-357. doi: 10.1016/j.compstruct.2015.10.019 [23] 施琪, 吴亚平, 王丽霞, 等. 碳纤维复合材料抗拉性能测试结果的影响因素分析[J]. 兰州交通大学学报, 2008(4):57-59.SHI Qi, WU Yaping, WANG Lixia, et al. Analysis of influence factors on tensile test results of carbon fiber composites[J]. Journal of Lanzhou Jiaotong University,2008(4):57-59(in Chinese). [24] YUAN B Y, HU Y S, HU X Z. Critical bending load of CFRP panel with shallow surface scratch determined by a tensile strength model[J]. Composites Science and Technology,2020,191:108072. doi: 10.1016/j.compscitech.2020.108072 [25] HU X Z, WITTMANN F. Size effect on toughness induced by crack close to free surface[J]. Engineering Fracture Mechanics,2000,65(2-3):209-221. doi: 10.1016/S0013-7944(99)00123-X [26] HU X Z, GUAN J F, WANG Y S, et al. Comparison of boundary and size effect models based on new developments[J]. Engineering Fracture Mechanics,2017,175:146-167. doi: 10.1016/j.engfracmech.2017.02.005 [27] WANG Y S, HU X Z. Determination of tensile strength and fracture toughness of granite using notched three-point-bend samples[J]. Rock Mechanics and Rock Engineering,2016,50(1):1-12. [28] ASTM international. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M [S]. West Conshohocken, United States: ASTM international, 2017. [29] WANG B H, BAI Y X, HU X Z, et al. Enhanced epoxy adhesion between steel plates by surface treatment and CNT/short-fibre reinforcement[J]. Composites Science and Technology,2016,127:149-157. doi: 10.1016/j.compscitech.2016.03.008 [30] WANG B H, HU X Z, LU P M. Improvement of adhesive bonding of grit-blasted steel substrates by using diluted resin as a primer[J]. International Journal of Adhesion & Adhesives,2017,73:92-99. [31] 管俊峰, 胡晓智, 王玉锁, 等. 用边界效应理论考虑断裂韧性和拉伸强度对破坏的影响[J]. 水利学报, 2016, 47(10):1298-1306.GUAN Junfeng, HU Xiaozhi, WANG Yusuo, et al. The influence of fracture toughness and tensile strength on failure is considered by boundary effect theory[J]. Journal of Hydraulic Engineering,2016,47(10):1298-1306(in Chinese). [32] 管俊峰, 胡晓智, 李庆斌, 等. 边界效应与尺寸效应模型的本质区别及相关设计应用[J]. 水利学报, 2017, 48(8):955-967.GUAN Junfeng, HU Xiaozhi, LI Qingbin, et al. Essential difference between boundary effect model and size effect model and related design application[J]. Journal of Hydraulic Engineering,2017,48(8):955-967(in Chinese). -

下载:

下载: