Preparation and process optimization of superhydrophobic surface on 7075 Al alloy based on picosecond laser

-

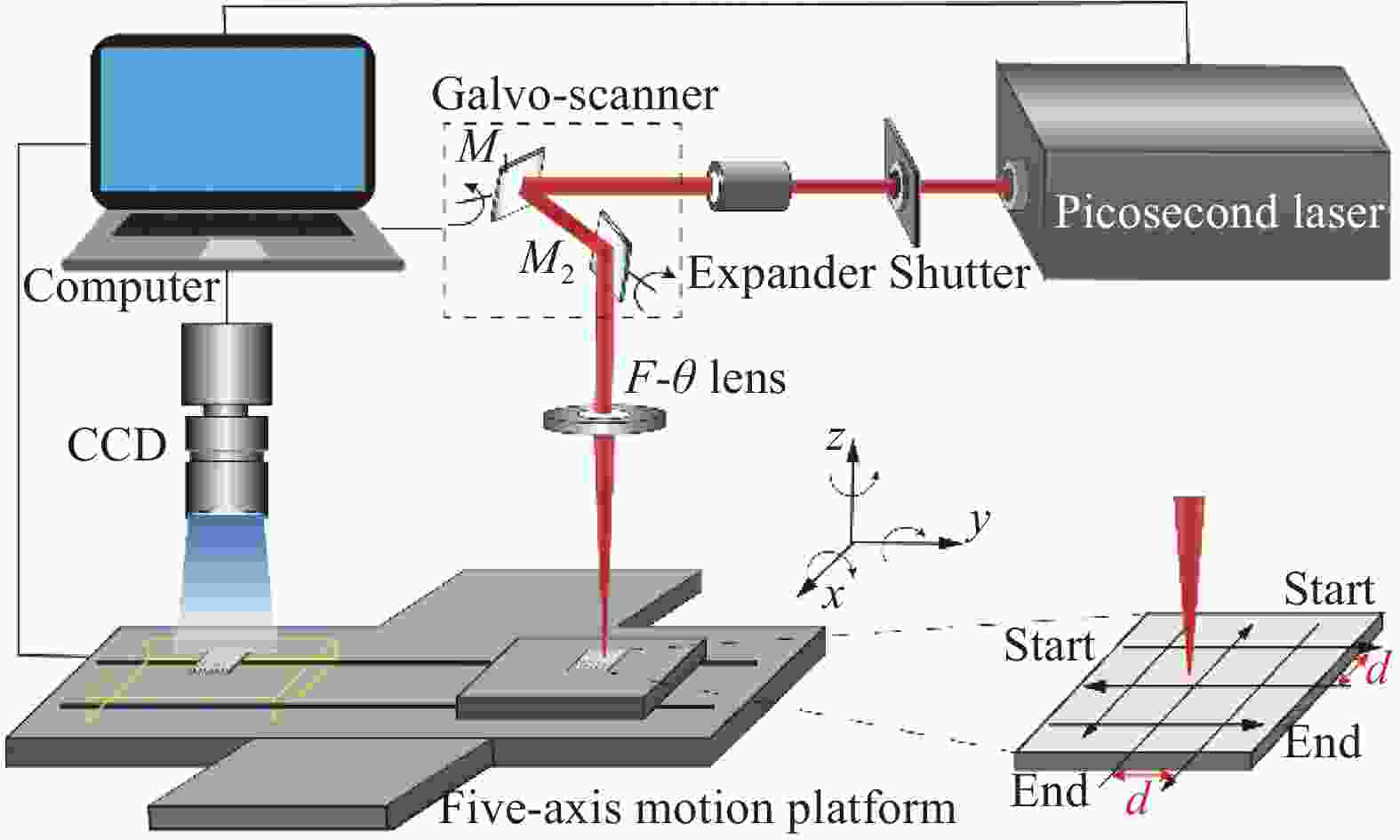

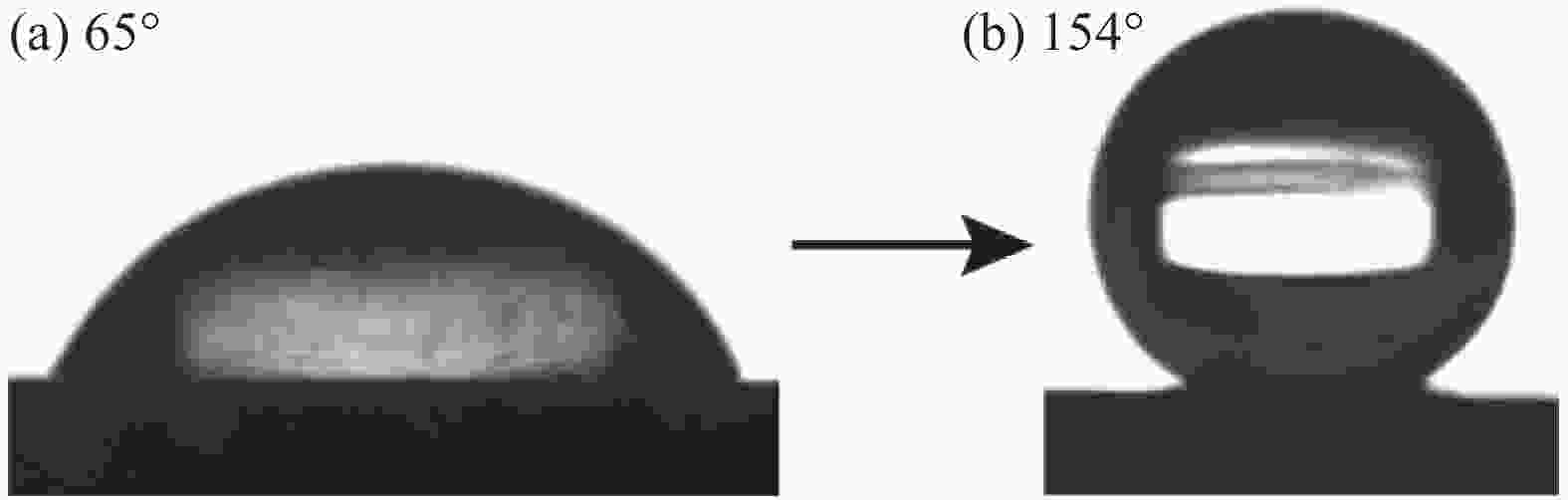

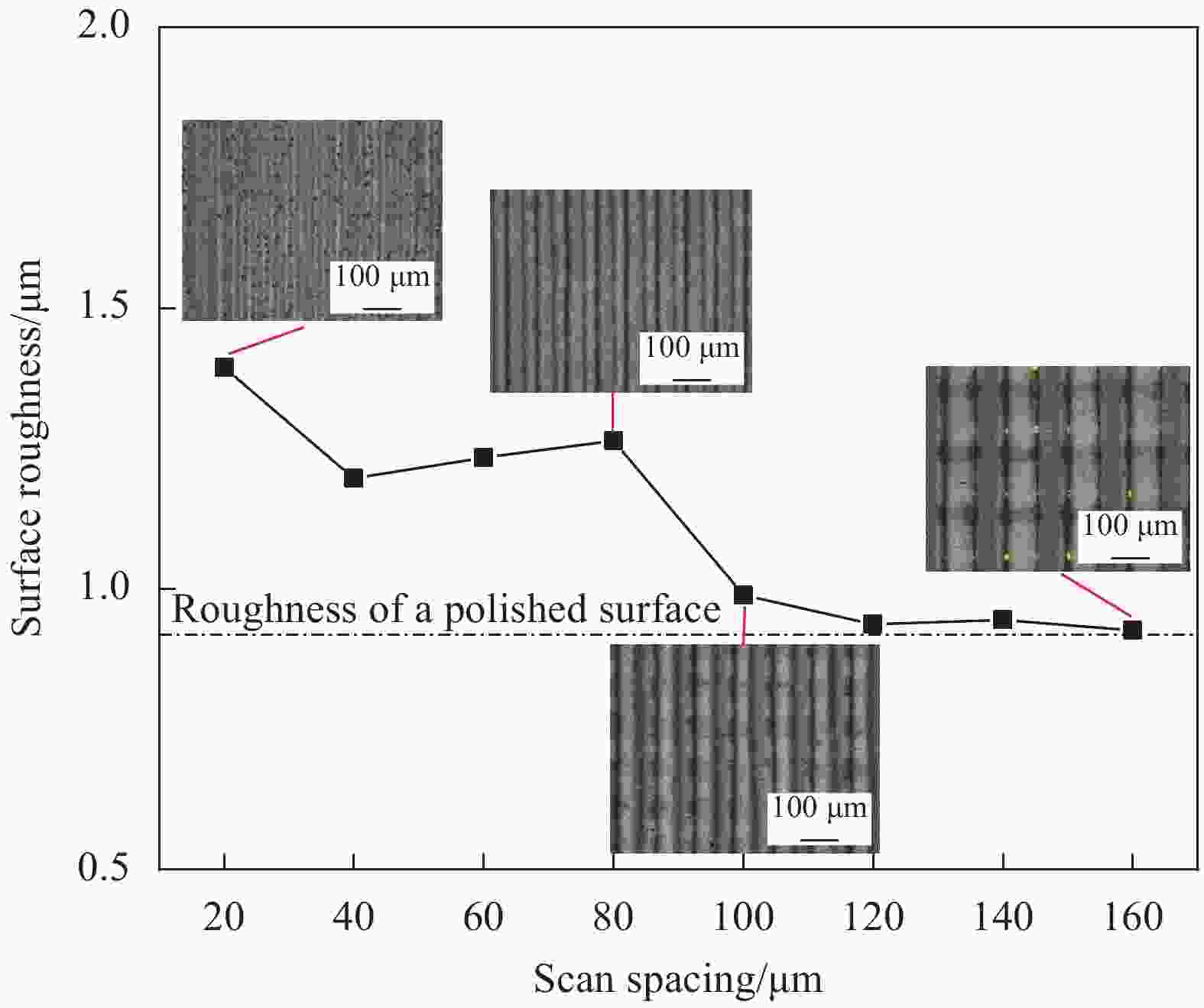

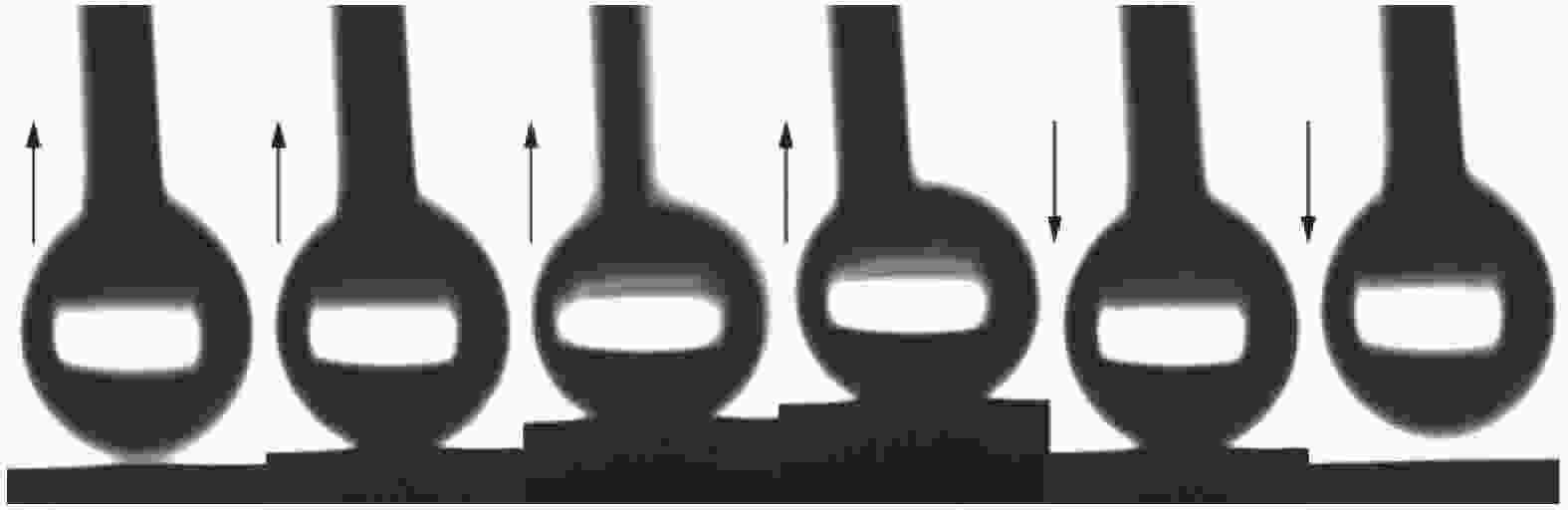

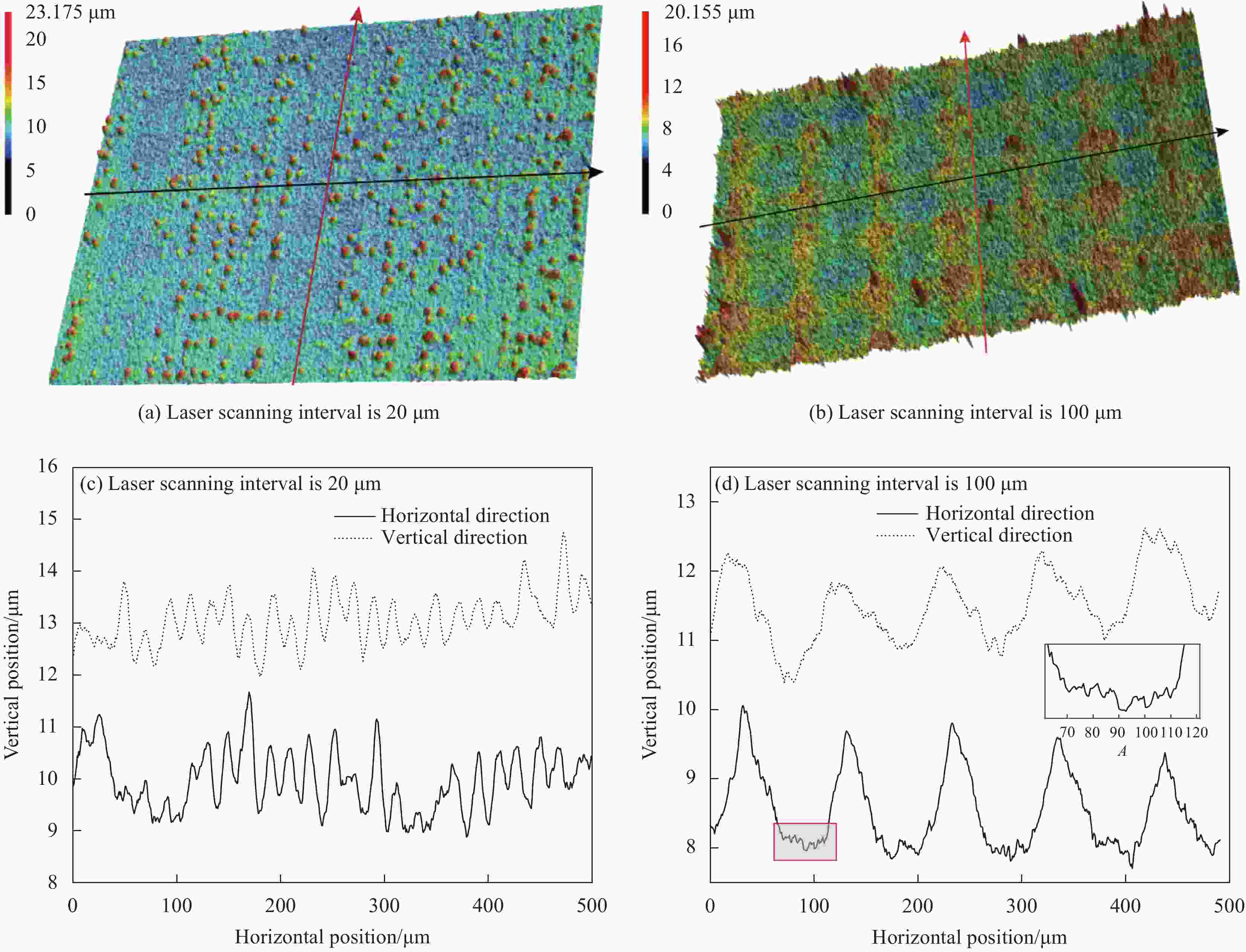

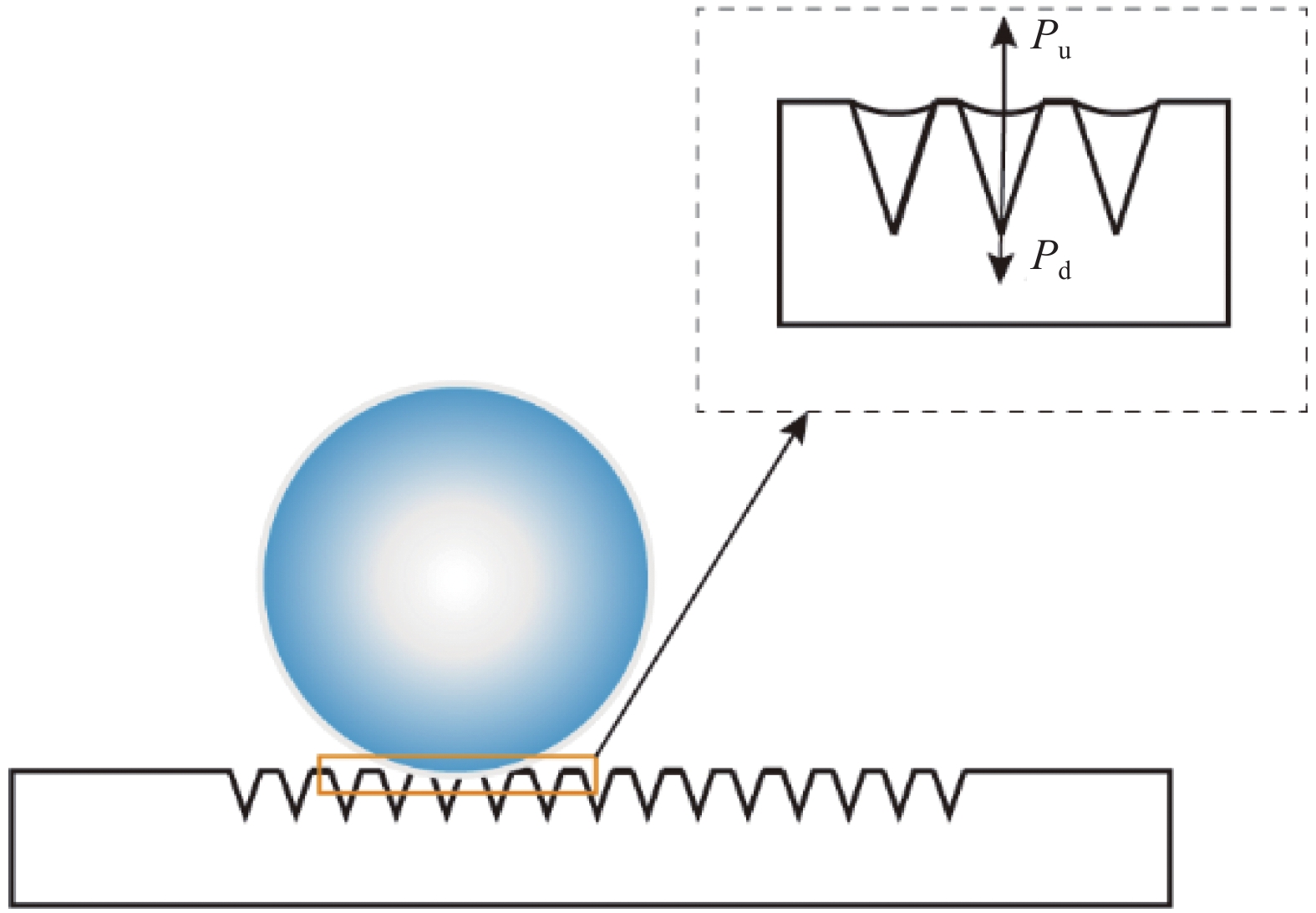

摘要: 为在Al合金表面获得稳定的超疏水性能,进一步拓宽Al合金材料在工业领域的应用范围,研究了一种简单、灵活、可靠的超疏水表面制备方法。首先,基于超疏水表面结构特征,采用单因素控制变量法和响应面法对激光加工参数进行了选取和优化。后采用皮秒激光刻蚀和硬脂酸处理相结合的方式获得了(超)疏水表面。通过控制激光扫描间距间接操控表面形貌的方式研究了微纳结构对表面润湿性的影响。利用接触角测量仪、SEM、共聚焦显微镜、FTIR等分析了样品的表面润湿性、形貌及化学成分。结果表明:最佳激光刻蚀参数为:扫描次数2次,扫描速度460 mm/s,频率835 kHz,平均功率21 W;扫描间距为20~80 μm的表面具有超疏水性,扫描间距为100~160 μm的表面具有疏水性。当扫描间距为20、80 μm时,接触角最大为154°,且表面黏附性很低。本文对在金属表面快速获得稳定超疏水性具有指导意义。Abstract: In order to obtain stable superhydrophobic properties on Al alloy surface and further expand the industrial application of Al alloy material, a simple, flexible and reliable preparation method of superhydrophobic surface was studied. Firstly, based on the structural characteristics of superhydrophobic surface, single factor control variable method and response surface method were used to select and optimize the laser machining parameters. The (super) hydrophobic surface was obtained by picosecond laser etching and stearic acid treatment. The influence of micro-nano structure on surface wettability was studied by controlling laser scanning distance to indirectly control surface topography. The surface wettability, morphology and chemical composition of the samples were analyzed by contact angle measuring instrument, SEM, confocal microscope and FTIR. The results show that the optimal laser etching parameters are as follows: Number of scanning is 2 times, scanning speed is 460 mm/s, frequency is 835 kHz, average power is 21 W; The surface with scanning interval of 20-80 μm exists superhydrophobicity, and the surface with scanning interval of 100-160 μm exists hydrophobicity. The maximum contact angle is 154° when the scanning interval is 20 μm and 80 μm, and the surface has low adhesion. This paper has guiding significance for obtaining stable superhydrophobicity on metal surface quickly.

-

Key words:

- 7075 Al alloy /

- picosecond laser /

- wettability /

- the response surface method /

- stearic acid

-

表 1 7075 Al合金成分表

Table 1. Chemical composition of 7075 Al alloy

Element Si Fe Cu Mn Mg Cr Zn Ti Al Mass fraction/wt% ≤0.4 ≤0.5 1.2-2.0 ≤0.3 2.1-2.9 0.18-0.28 5.1-6.1 ≤0.2 Bal 表 2 单因素控制变量法试验方案

Table 2. Test scheme of single factor control variable method

A/n B/(mm·s−1) C/μm D/kHz E/W 1-8 500 4 500 21 4 200-900 4 500 21 4 500 0-14 500 21 4 500 4 200-900 21 4 500 4 500 9-30 Notes: A—Number of scanning; B—Scanning speed; C—Feed distance; D—Laser frequency; E—Average power. 表 3 因素水平表

Table 3. Factor levels table

Factors Factor levels Low value (−1) Median value (0) High value (1) A/n 2 3 4 B/(mm·s−1) 400 500 600 C/μm 0 4 8 D/kHz 700 800 900 E/W 21 24 27 表 4 正交试验方案及结果

Table 4. Scheme and results of orthogonal test

Experimental group A/n B/(mm·s−1) C/μm D/kHz E/W L/μm D/μm 1 3 500 0 700 24 107.38 6.23 2 3 500 4 800 24 102.17 5.65 3 3 600 8 800 24 101.31 5.99 4 4 500 8 800 24 97.88 7.51 5 4 400 4 800 24 107.45 8.33 6 3 500 4 800 24 103.03 7.54 7 3 400 0 800 24 104.16 7.85 8 3 500 0 800 27 104.07 7.74 9 2 500 4 800 21 96.58 5.29 10 3 500 4 700 21 106.31 7.55 11 3 500 4 900 27 97.40 7.06 12 3 500 0 800 21 99.28 6.55 13 3 500 8 800 27 104.04 7.48 14 3 600 4 800 27 101.45 6.45 15 3 400 8 800 24 100.73 6.80 16 3 500 4 800 24 103.92 7.29 17 3 400 4 800 27 99.11 7.54 18 3 600 4 900 24 102.23 6.58 19 4 500 4 800 21 105.66 7.54 20 3 500 4 900 21 95.65 6.60 21 3 500 4 800 24 99.02 6.89 22 3 500 8 700 24 104.06 7.25 23 4 500 0 800 24 101.41 8.49 24 3 400 4 700 24 106.74 8.11 25 2 500 4 900 24 94.54 5.62 26 2 500 8 800 24 97.24 5.71 27 4 600 4 800 24 103.49 7.51 28 2 500 4 700 24 106.90 6.16 29 4 500 4 800 27 102.23 7.89 30 3 500 4 700 27 105.72 6.88 31 3 500 8 800 21 100.14 6.25 32 3 500 4 800 24 96.10 6.64 33 3 600 0 800 24 99.16 6.03 34 3 600 4 700 24 103.16 6.59 35 3 500 4 800 24 99.92 6.36 36 4 500 4 700 24 109.18 8.16 37 3 400 4 800 21 100.14 6.82 38 3 600 4 800 21 99.54 6.19 39 3 400 4 900 24 98.52 6.83 40 2 500 4 800 27 96.62 4.38 41 2 600 4 800 24 94.09 4.83 42 3 500 0 900 24 96.22 6.60 43 3 500 8 900 24 94.53 5.60 44 2 500 0 800 24 95.60 5.21 45 2 400 4 800 24 96.82 5.52 46 4 500 4 900 24 98.64 8.28 Notes: L—Width; D—Depth. 表 5 微槽宽度和深度二次多项式模型的方差分析(ANOVA)

Table 5. Analysis of variance (ANOVA) of quadratic polynomial model for the depth and width of the microgroove

Source Sum of squares df Mean square F-value P-value Width Model 1 539.03 20 26.95 3.85 0.0009 Significant Residual 175.07 25 7.00 Lack of fit 132.56 20 6.63 0.7796 0.6898 Not significant Pure error 42.51 5 8.50 Cor total 714.10 45 — Depth Model 2 36.48 20 1.82 7.06 <0.0001 Significant Residual 6.46 25 0.2584 Lack of fit 4.15 20 0.2075 0.4493 0.9082 Not significant Pure error 2.31 5 0.4618 Cor total 42.94 45 — Notes: df—Degree of freedom; F—Statistical value of F-test; P—Assumed value. 表 6 试验与预测结果对比表

Table 6. Comparison table of experimental and predicted results

No. Width/μm Relative error rate/% Depth/μm Relative error rate/% Test results Predictive value Test results Predictive value 1 93.85 93.39 0.49 5.30 5.39 1.67 2 96.26 3.07 5.15 4.45 3 92.43 1.03 5.12 5.00 -

[1] LYNCH F T, KHODADOUST A. Effects of ice accretions on aircraft aerodynamics[J]. Progress in Aerospace Sciences,2001,37(8):669-767. doi: 10.1016/S0376-0421(01)00018-5 [2] GAO X B. Condensation and subsequent freezing delays as a result of using femtosecond laser functionalized surfaces[J]. Journal of Laser Applications,2018,30(1):011501. doi: 10.2351/1.4986058 [3] 徐达, 肖振, 余新泉, 等. 多功能疏水/超疏水复合涂层的制备及其防覆冰性[J]. 复合材料学报, 2022, 39(3):1102-1109. doi: 10.13801/j.cnki.fhclxb.20210513.004XU Da, XIAO Zhen, YU Xinquan, et al. Preparation and anti-icing characteristics of multifunctional hydrophobic/superhydrophobic composite coating[J]. Acta Materiae Compositae Sinica,2022,39(3):1102-1109(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210513.004 [4] YUAN G, LIU Y W, NGO C V, et al. Rapid fabrication of anti-corrosion and self-healing superhydrophobic aluminum surfaces through environmentally friendly femtosecond laser processing[J]. Optics Express,2020,28(24):35636-35650. doi: 10.1364/OE.400804 [5] MAURER J A, MILLER M J, BARTOLUCCI S F. Self-cleaning superhydrophobic nanocomposite surfaces generated by laser pulse heating[J]. Journal of Colloid & Interface Science,2018,524:204-208. [6] WANG M, GU X H, MA P S, et al. Microstructured superhydrophobic anti-reflection films for performance improvement of photovoltaic devices[J]. Materials Research Bulletin,2017,91:208-213. doi: 10.1016/j.materresbull.2017.03.019 [7] YIN Y S, LIU T, CHEN S G, et al. Structure stability and corrosion inhibition of super-hydrophobic film on aluminum in seawater[J]. Applied Surface Science,2008,255(5):2978-2984. doi: 10.1016/j.apsusc.2008.08.088 [8] FAN Q H, JI X, LAN Q, et al. An anti-icing copper-based superhydrophobic layer prepared by one-step electrodeposition in both cathode and anode[J]. Colloids & Surfaces A: Physicochemical and Engineering Aspects,2022,637:128220. [9] WU Y L, WANG Z D, YANG J Y, et al. Designing superhydrophobic robotic surfaces: Self-cleaning, high-grip impact, and bacterial repelling[J]. Colloids & Surfaces A Physicochemical and Engineering Aspects,2021,629:127444. [10] LIU S H, LIU X J, LATTHE S S, et al. Self-cleaning transparent superhydrophobic coatings through simple sol-gel processing of fluoroalkylsilane[J]. Applied Surface Science,2015,351:897-903. doi: 10.1016/j.apsusc.2015.06.016 [11] QI Y, CUI Z, LIANG B, et al. A fast method to fabricate superhydrophobic surfaces on zinc substrate with ion assisted chemical etching[J]. Applied Surface Science,2014,305(1):716-724. [12] CHOI H J, SHIN J H, CHOO S, et al. Fabrication of superhydrophobic and oleophobic Al surfaces by chemical etching and surface fluorination[J]. Thin Solid Films,2015,585:76-80. doi: 10.1016/j.tsf.2015.03.046 [13] JISR R M, SCHLENOFF J B, RMAILE H H. Hydrophobic and ultrahydrophobic multilayer thin films from perfluorinated polyelectrolytes[J]. Angewandte Chemie International Edition,2005,44(5):782-785. doi: 10.1002/anie.200461645 [14] LI K K, YAO W, XIE Y X, et al. A strongly hydrophobic and serum-repelling surface composed of CrN films deposited on laser-patterned microstructures that was optimized with an orthogonal experiment[J]. Surface & Coatings Technology,2020,391:125708. [15] SUN K, YANG H, XUE W, et al. Tunable bubble assembling on a hybrid superhydrophobic-philic surface fabricated by selective laser texturing[J]. Langmuir,2018,34(44):13203-13209. doi: 10.1021/acs.langmuir.8b02879 [16] XING W, LI Z, YANG H O, et al. Anti-icing aluminum alloy surface with multi-level micro-nano textures constructed by picosecond laser[J]. Materials & Design,2019,183:108156. [17] ZHANG Z B, HUA Y Q, YE Y X, et al. Fabrication of superhydrophobic nickel-aluminum bronze alloy surfaces based on picosecond laser pulses[J]. Chinese Journal of Lasers,2019,46(3):0302013. doi: 10.3788/CJL201946.0302013 [18] GUO X L, GUO Z G. Superhydrophobic plant leaves with micro-line structures: An optimal biomimetic objective in bionic engineering[J]. Journal of Bionic Engineering,2018,15(5):851-858. doi: 10.1007/s42235-018-0072-2 [19] BARTHLOTT W, MAIL M, BHUSHAN B, et al. Plant surfaces: Structures and functions for biomimetic innovations[J]. Nano-Micro Letters,2017,9(2):116-155. [20] YANG Z, LIU X P, TIAN Y L. Insights into the wettability transition of nanosecond laser ablated surface under ambient air exposure[J]. Journal of Colloid & Interface Science,2019,533:268-277. doi: 10.1016/j.jcis.2018.08.082 [21] LONG J Y, ZHONG M L, ZHANG H J, et al. Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air[J]. Journal of Colloid & Interface Science,2015,441:1-9. [22] JAGDHEESH R, DIAZ M, MARIMUTHU S, et al. Robust fabrication of μ-patterns with tunable and durable wetting properties: hydrophilic to ultrahydrophobic via a vacuum process[J]. Journal of Materials Chemistry A,2017,5(15):7125-7136. doi: 10.1039/C7TA01385J [23] 杨统林, 赵中华, 肖建军, 等. 硬脂酸改性纳米氧化铝的工艺[J]. 南昌大学学报(工科版), 2018, 40(1):8-12. doi: 10.13764/j.cnki.ncdg.2018.01.002YANG Tonglin, ZHAO Zhonghua, XIAO Jianjun, et al. Surface modification process of nano-Al2O3 with stearic acid[J]. Journal of Nanchang University,2018,40(1):8-12(in Chinese). doi: 10.13764/j.cnki.ncdg.2018.01.002 -

下载:

下载: