Mechanical performance of basalt fiber reinforced foam concrete subjected to quasi-static tensile and compressive tests

-

摘要: 为研究玄武岩纤维增强泡沫混凝土的力学性能,共设计了52组试件,讨论了玄武岩纤维体积掺量和纤维长度对各密度试件的拉伸和压缩性能的影响。结果表明:玄武岩纤维可显著提高试件的抗拉峰值应力(最大提升达到737%)和峰值应变(最大提升达到833%),可有效改善中高密度试件的受拉失效模式,使其出现伪应变硬化现象,提升了试件的抗拉承载能力和变形能力。试件抗拉峰值应力和峰值应变随纤维体积掺量增大而增大,随纤维长度增长先增大后降低;另一方面,玄武岩纤维能改变试件的受压破坏模式,使其从纵向劈裂破坏转变为斜向剪切破坏和横向压溃破坏,显著提高了中低密度试件的抗压承载力和吸能能力(最大提升达到328%)。试件的吸能能力随纤维体积掺量增大而增强,随纤维长度增长先提升后降低。

-

关键词:

- 玄武岩纤维泡沫混凝土 /

- 单轴拉伸 /

- 应变硬化 /

- 准静态压缩 /

- 能量吸收

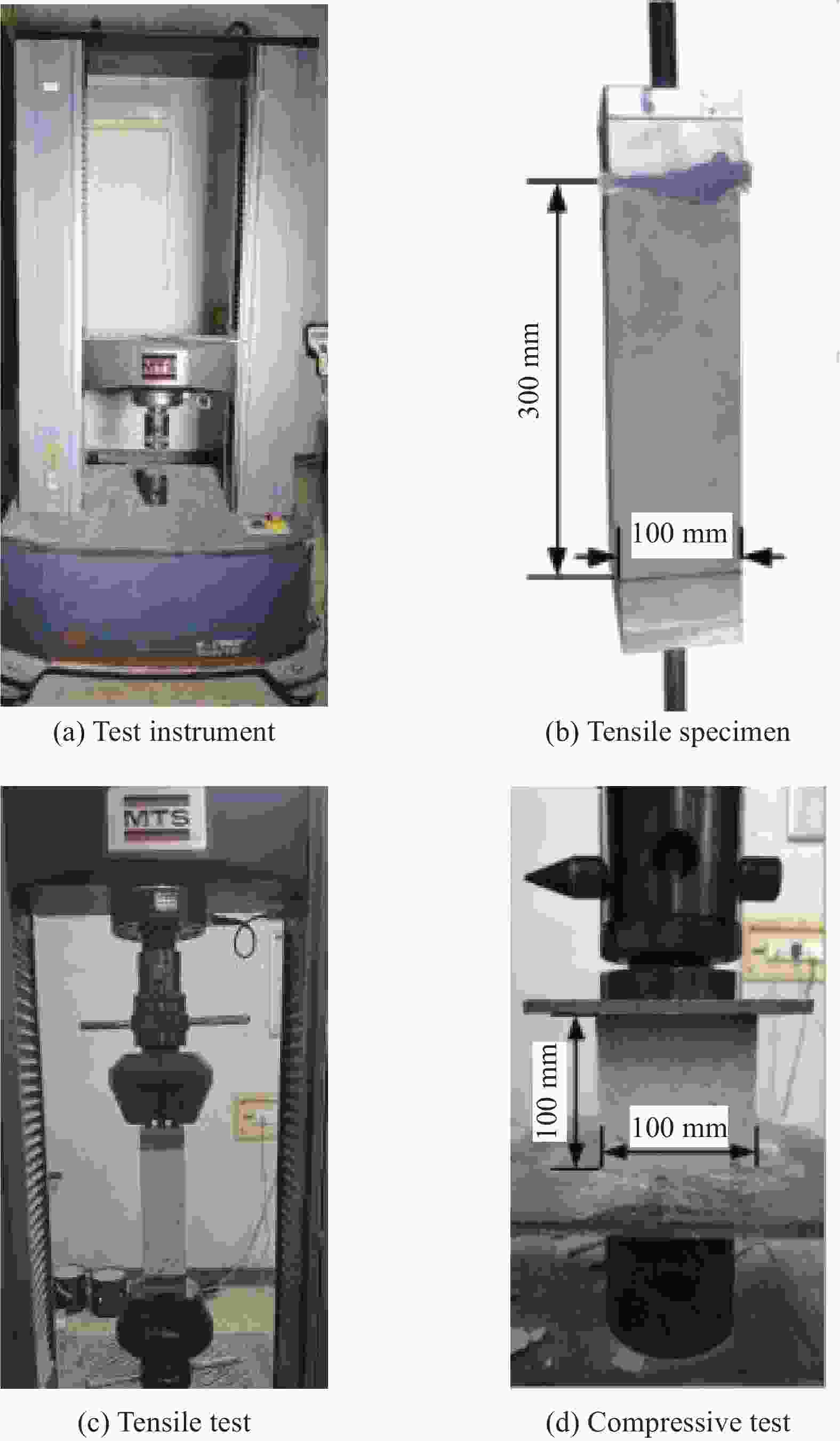

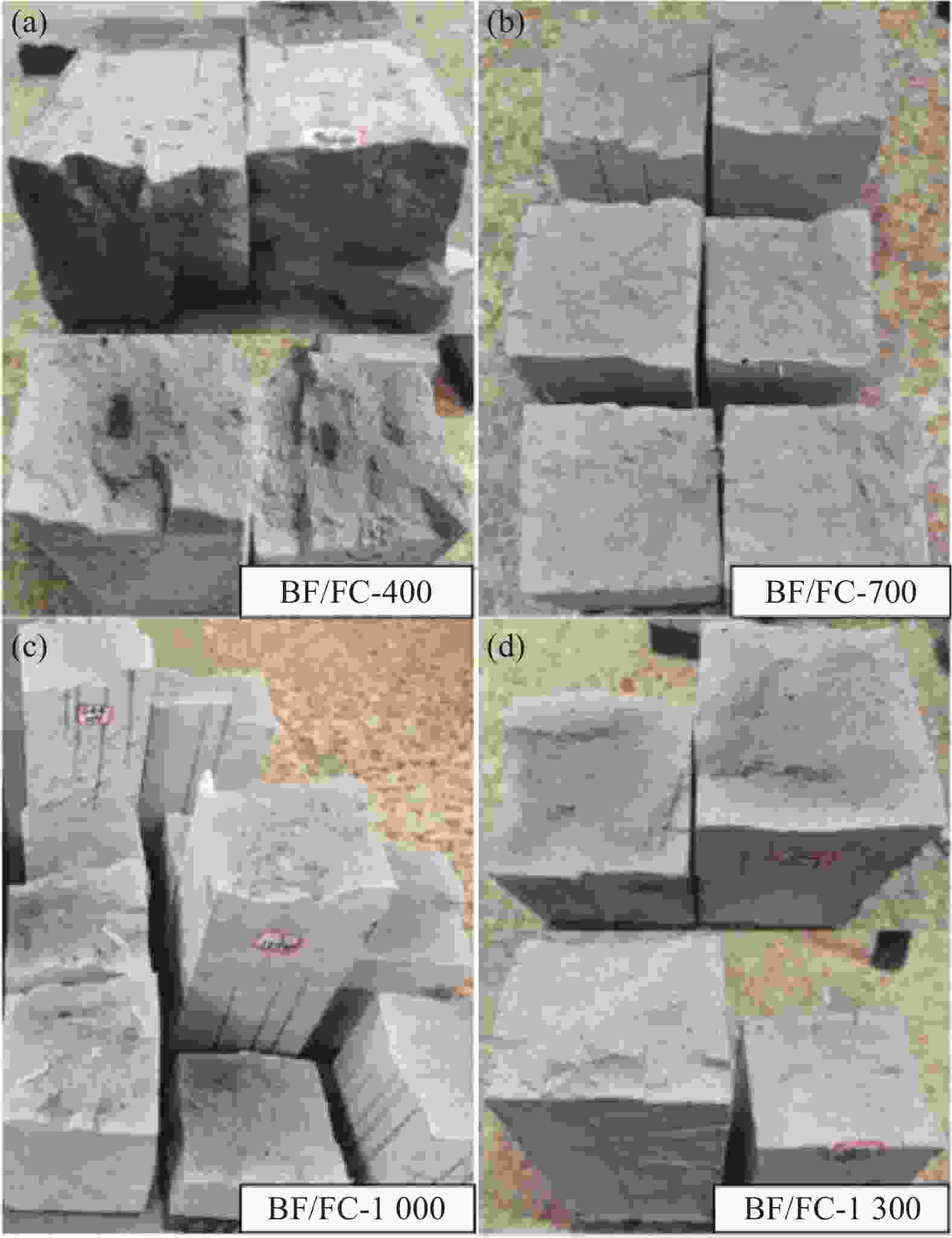

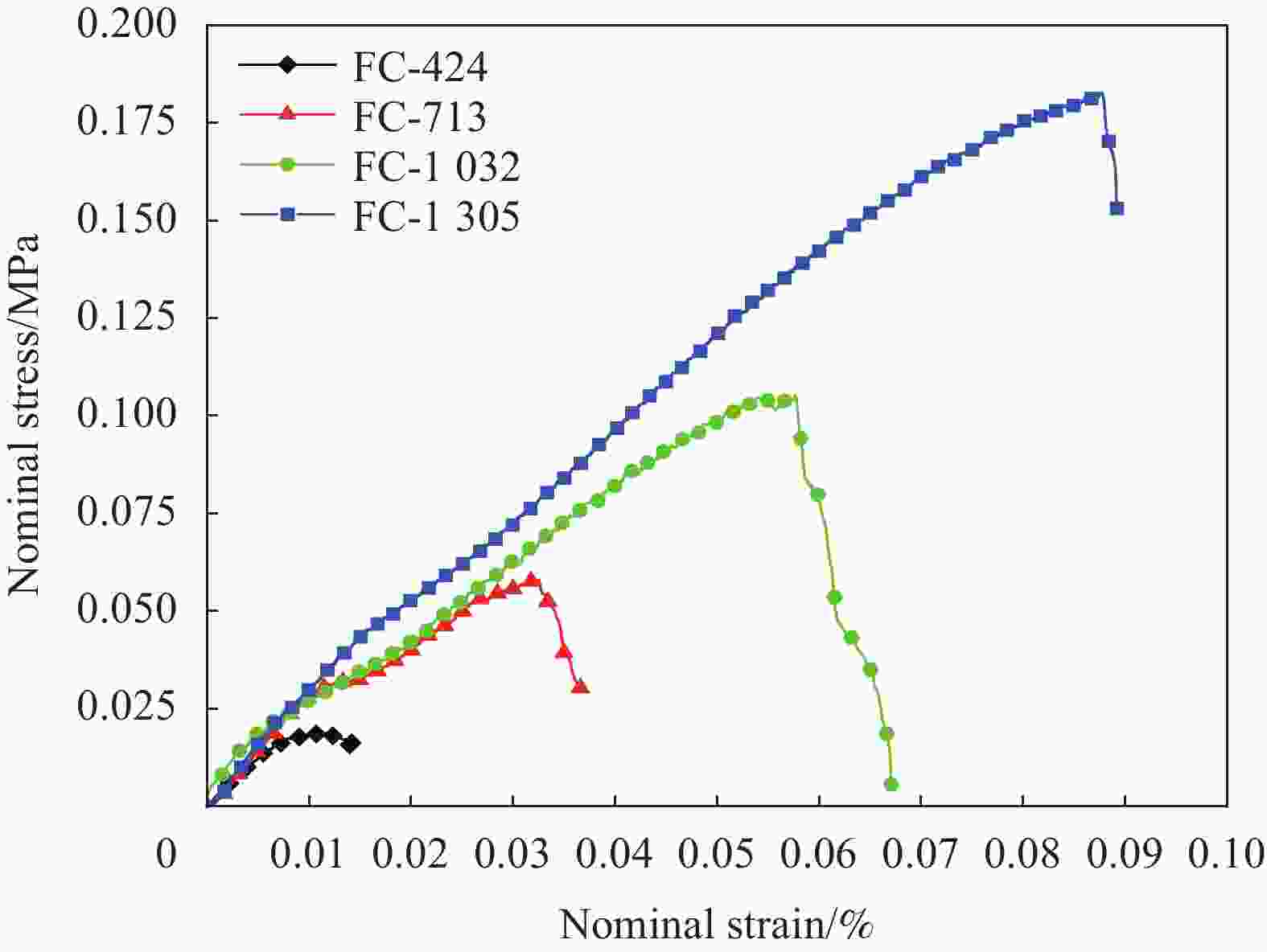

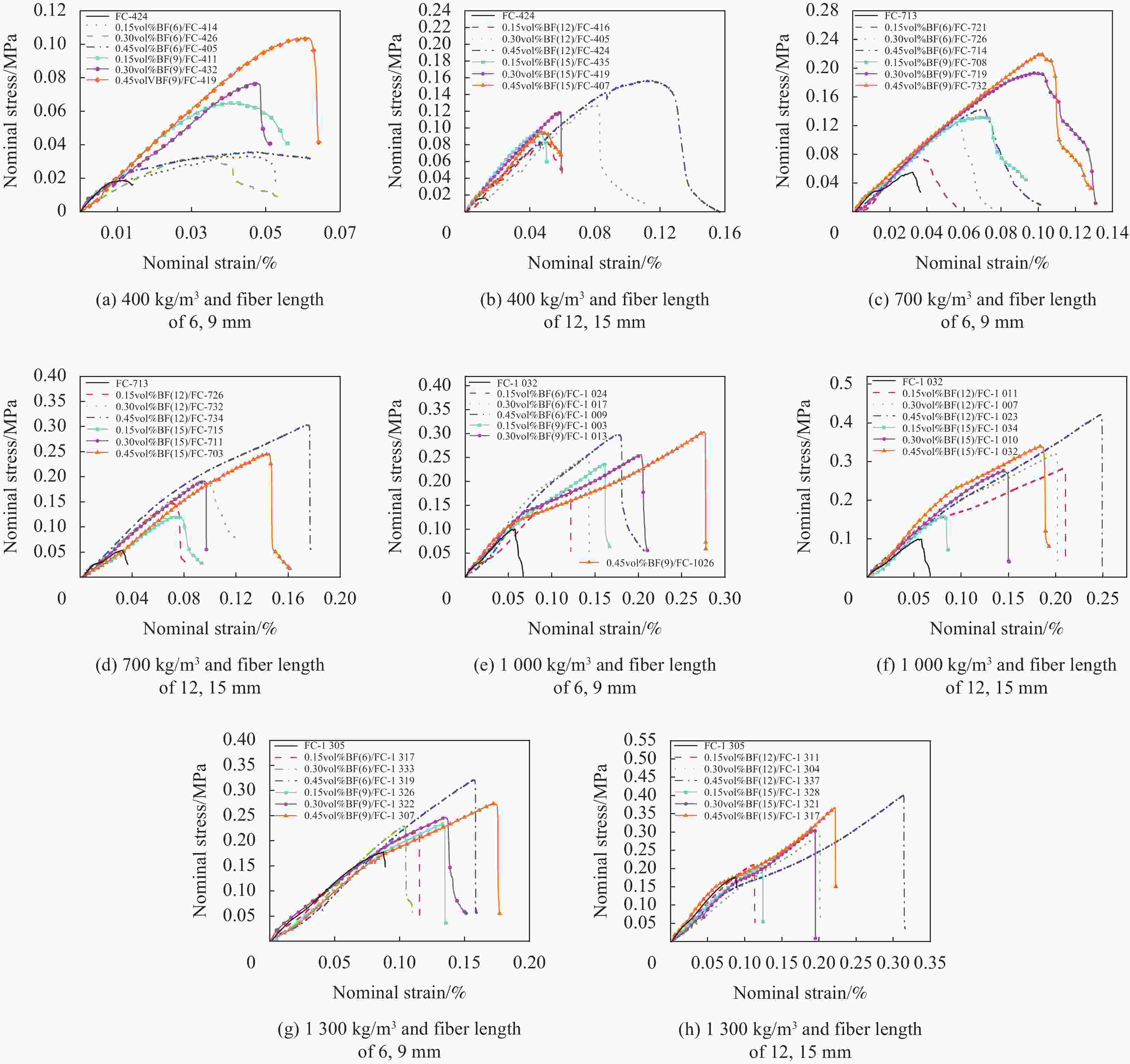

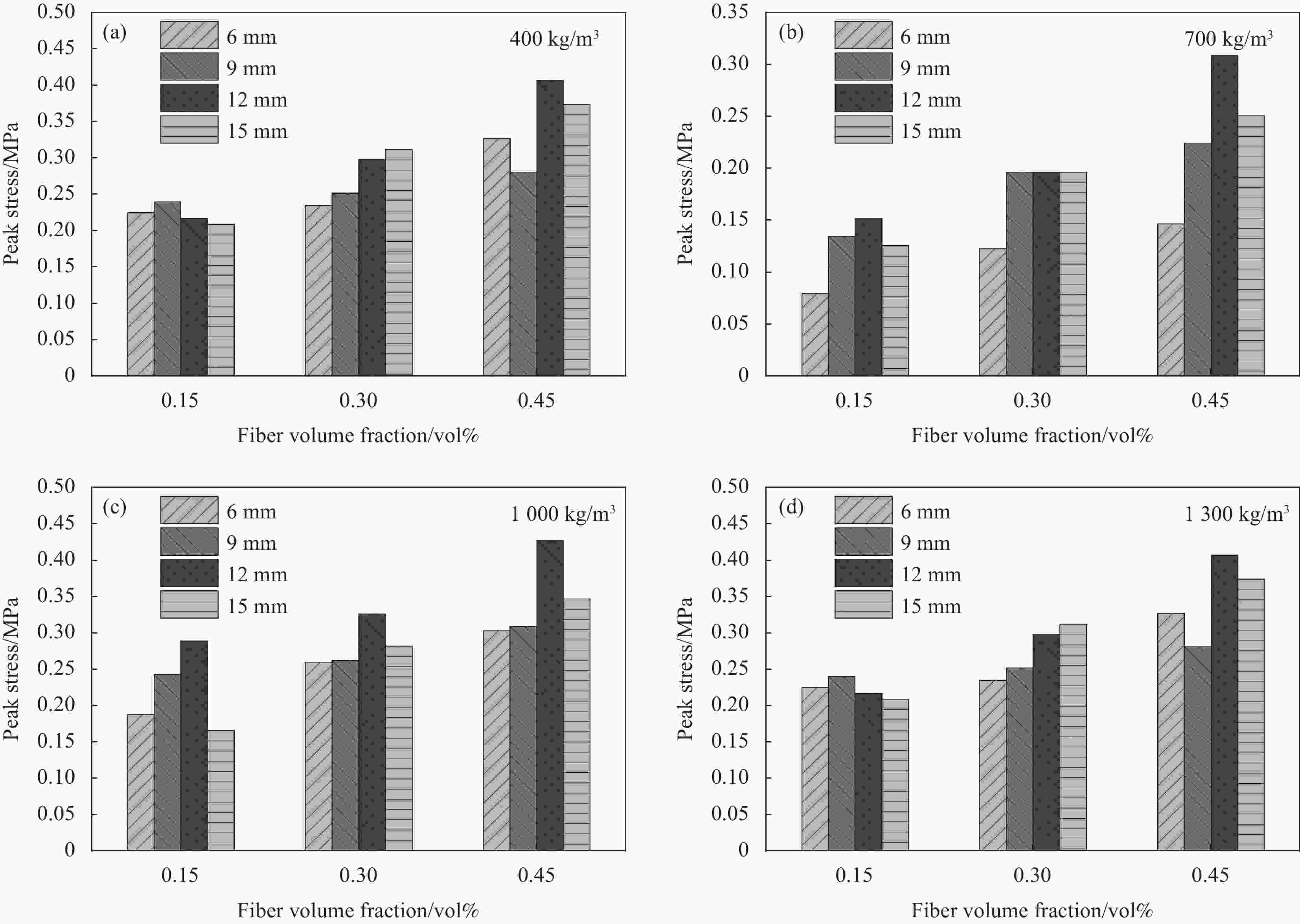

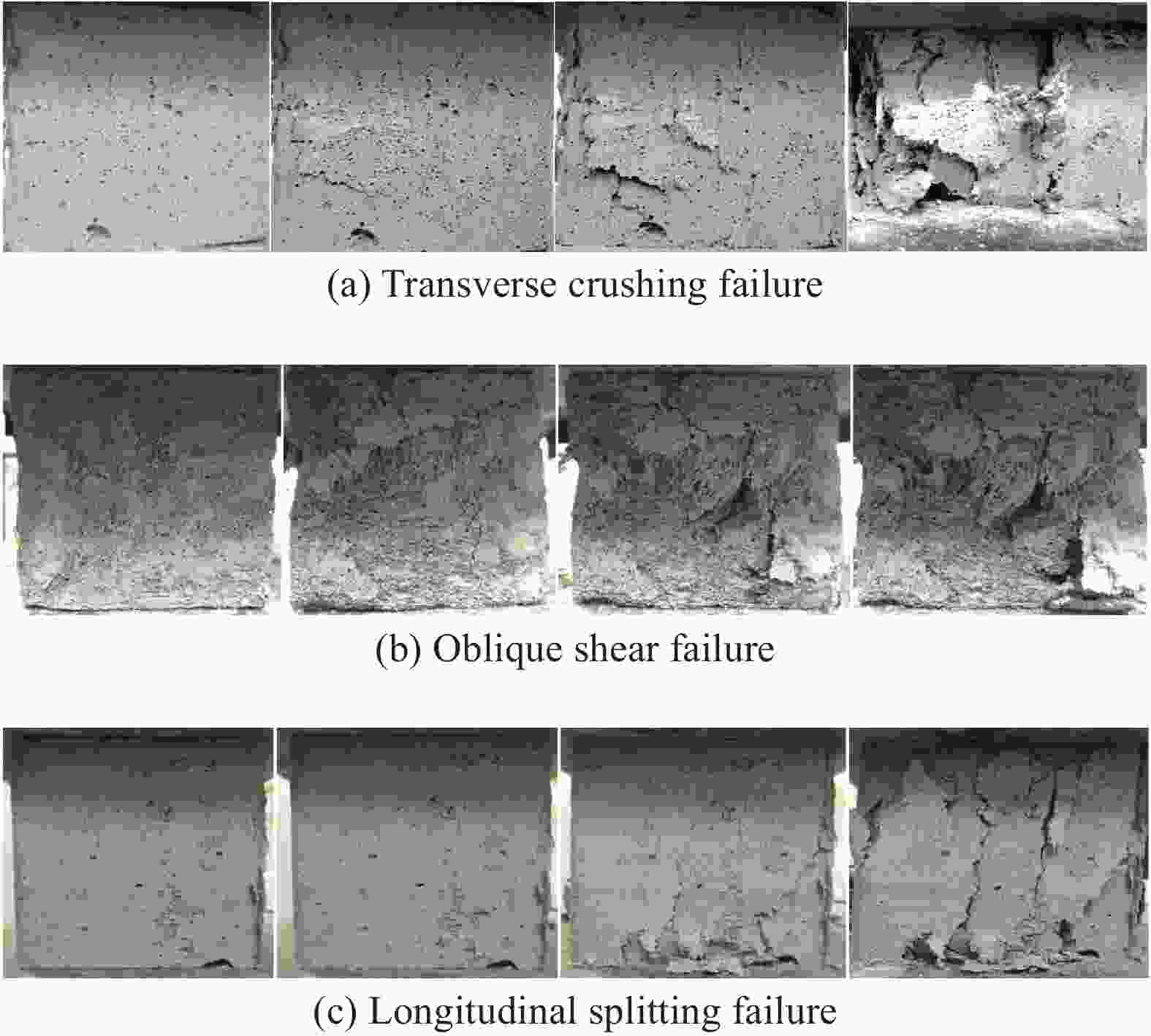

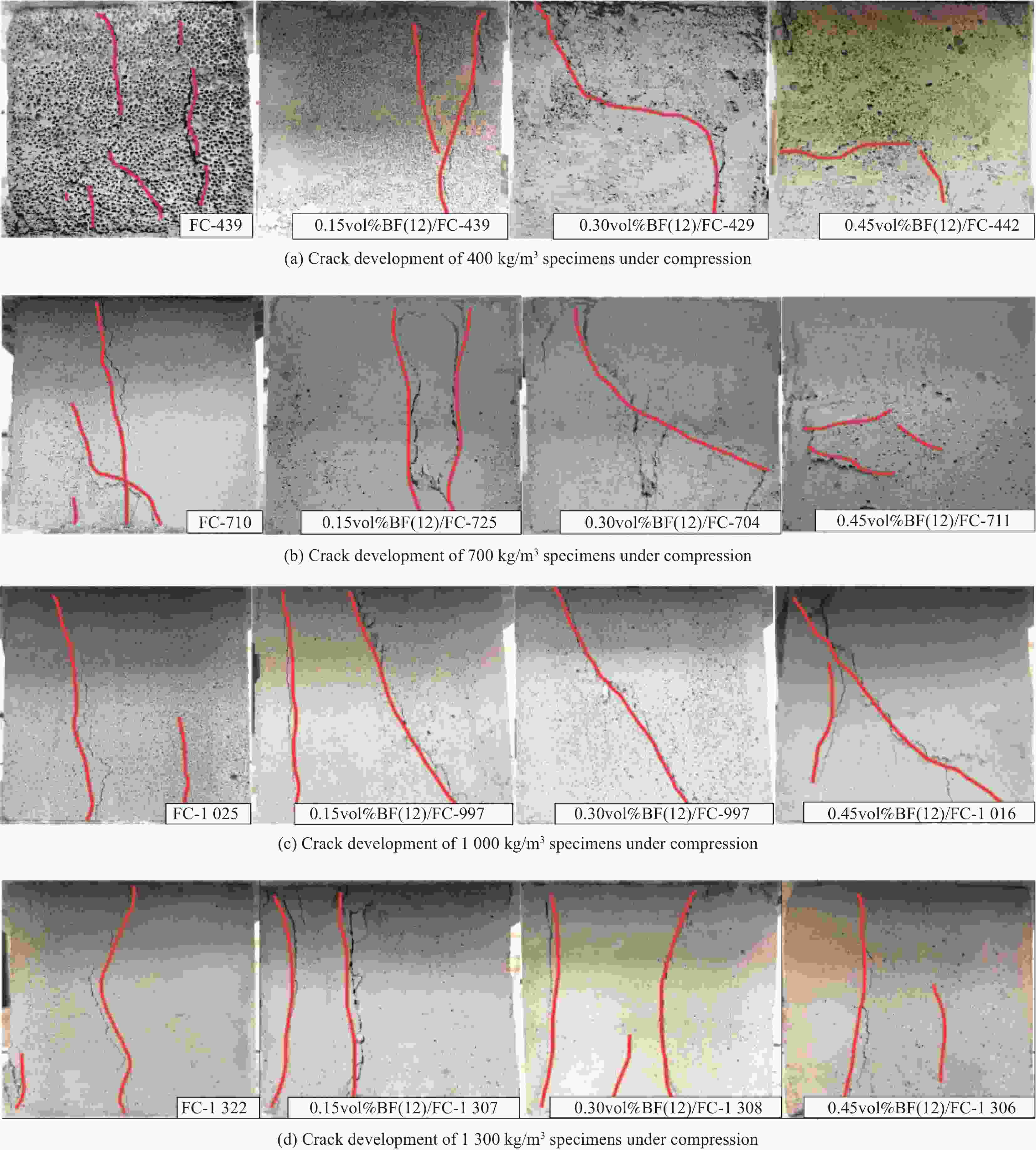

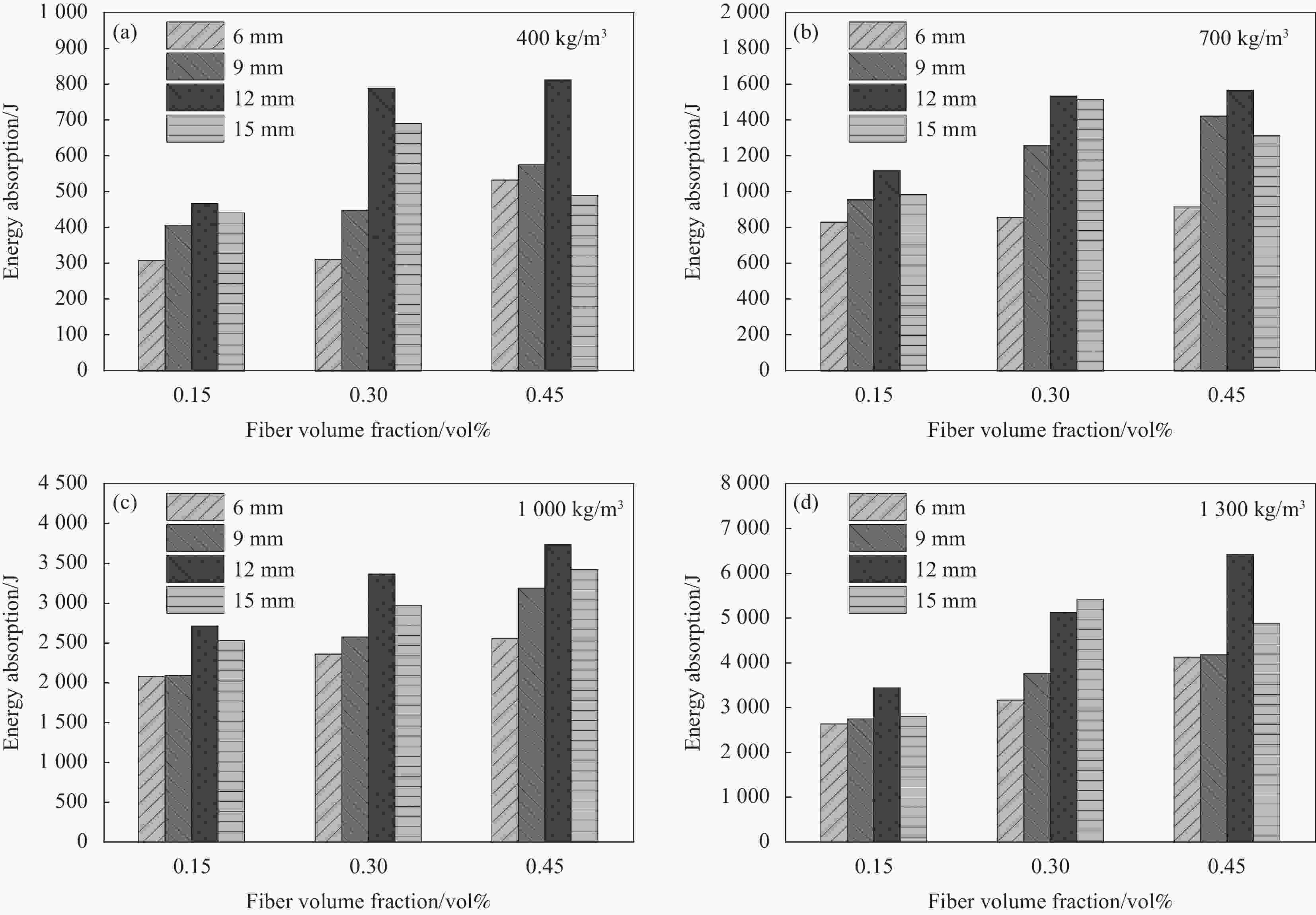

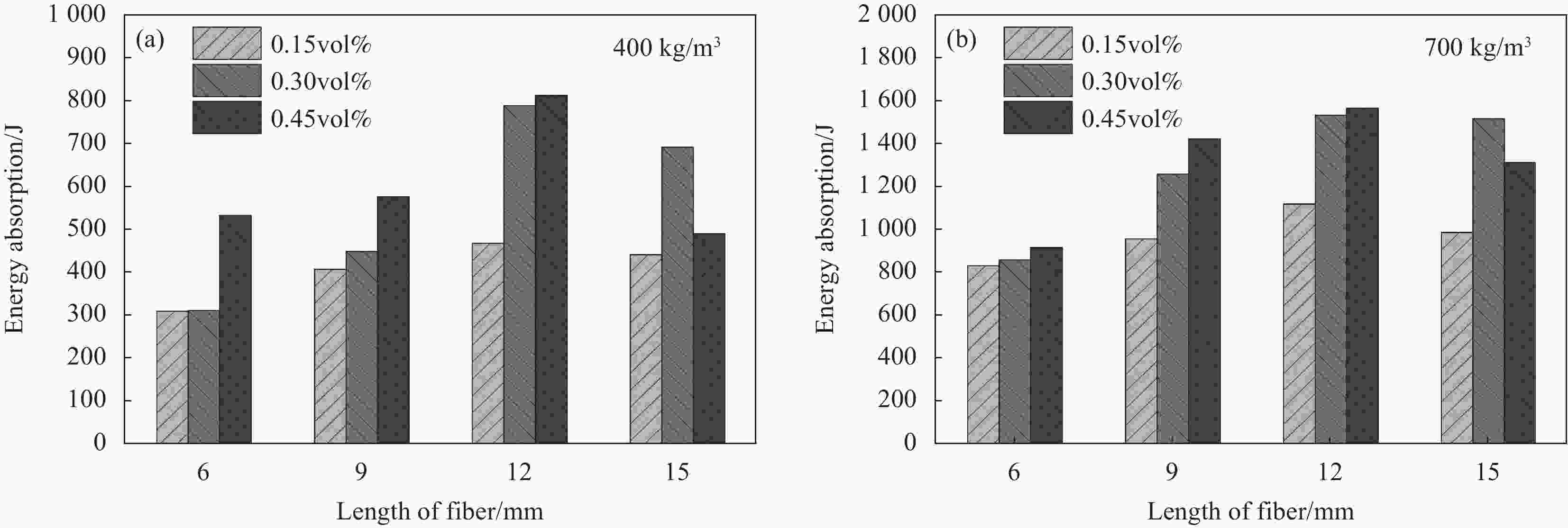

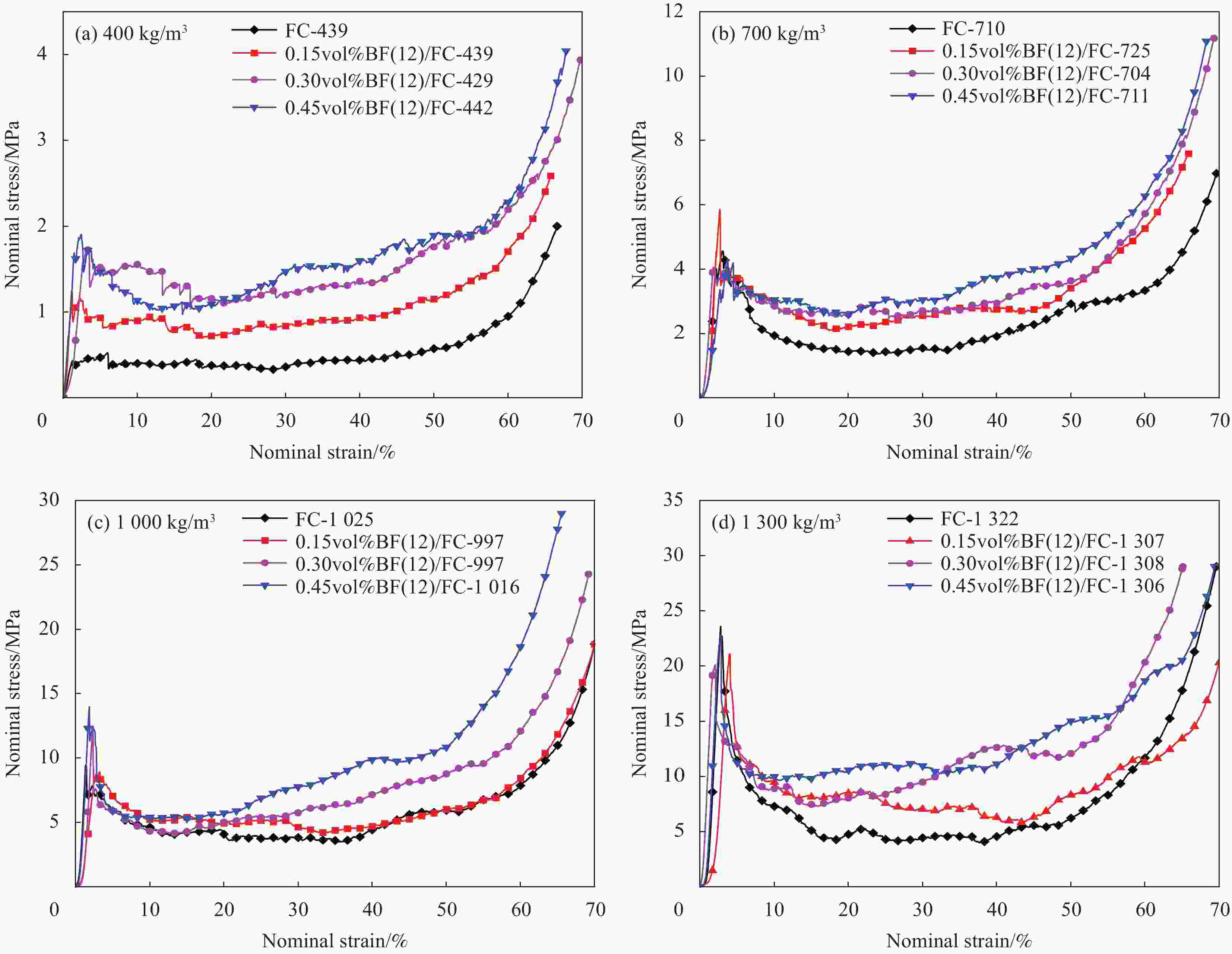

Abstract: To investigate the mechanical properties of basalt fiber reinforced foam concrete, the quasi-static tensile and compressive tests were carried out on the prepared 52 groups of specimens, and the effects of basalt fiber volume fraction and fiber length on the tensile and compressive properties of specimens with different densities were experimentally studied. The test results show that the basalt fiber could significantly improve the tensile peak stress (maximum improvement of 737%) and peak strain (maximum improvement of 833%) of specimens. Due to the appearance of pseudo strain hardening phenomenon, the basalt fiber could effectively improve the tensile failure mode of the medium and high density specimens, so as to improve the tensile bearing capacity and deformation ability of specimens. It is found that tensile peak stress and peak strain increase with increasing the fiber volume fraction, and increase first and then decrease with increasing the fiber length. Furthermore, basalt fiber could change the compression failure mode of specimens with the observed trend from longitudinal splitting failure to oblique shear failure and transverse crushing failure, resulting in significant improvement of the compressive bearing capacity and energy absorption ability of low and medium density specimens. In addition, it is observed that increasing the fiber volume content will lead to an increase in the energy absorption (maximum improvement of 328%) of the specimen, which increases first and then decreases with increasing the fiber length. -

表 1 水泥基本参数

Table 1. Basic parameters of cement

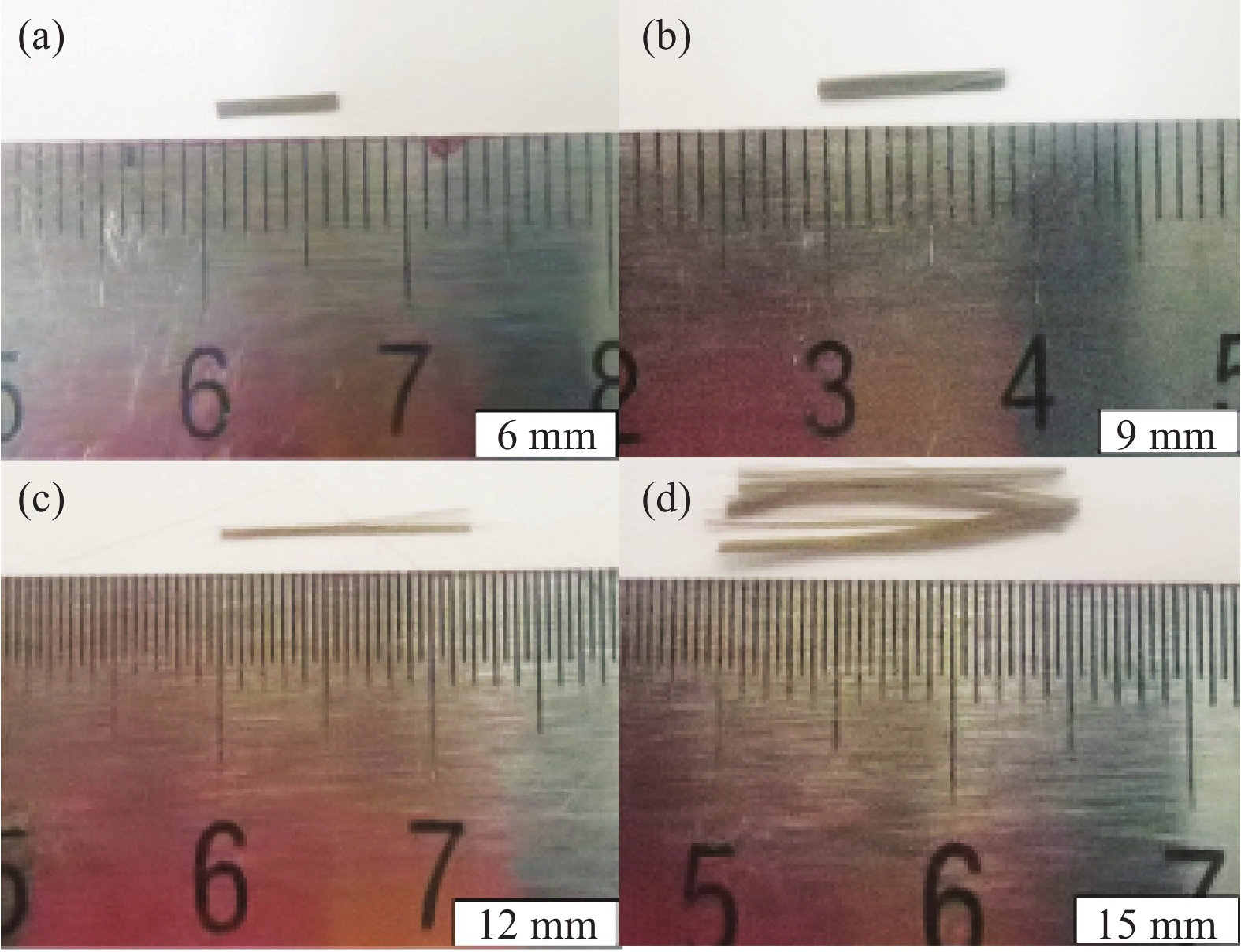

Cement Specific surface area/(m2·kg−1) Setting time/min Flexural strength/MPa Compressive strength/MPa Initial Final 3 days 28 days 3 days 28 days P.O 42.5 340 70 270 6 8.5 35 48 表 2 BF的主要性能指标

Table 2. Main properties of BF

Diameter/μm Tensile strength/MPa Elastic modulus/GPa Elongation/% Density/(kg·m-3) 13 4150-4750 95-115 3.1 2650 表 3 玄武岩纤维增强泡沫混凝土(BF/FC)配合比

Table 3. Mix proportion of basalt fiber reinforced foam concrete (BF/FC)

Target density of foam concrete/(kg·m−3) Cement/

(kg·m−3)Water/

(kg·m−3)Foam/

(kg·m−3)Length of

fiber/mmFiber volume

fraction/vol%Mass of fiber/

(kg·m−3)400 230.98 115.49 56.56 0/6/12/15 0/0.15/0.3/0.45 0/3.98/7.96/11.94 700 439.22 219.61 44.38 0/6/12/15 0/0.15/0.3/0.45 0/3.98/7.96/11.94 1000 647.45 323.73 32.27 0/6/12/15 0/0.15/0.3/0.45 0/3.98/7.96/11.94 1300 855.67 427.84 20.09 0/6/12/15 0/0.15/0.3/0.45 0/3.98/7.96/11.94 表 4 BF/FC试件汇总

Table 4. Summary of BF/FC specimens

Tensile specimen Compressive specimen FC-424 FC-439 0.15vol%BF(6)/FC-414 0.15vol%BF(6)/FC-438 0.30vol%BF(6)/FC-426 0.30vol%BF(6)/FC-440 0.45vol%BF(6)/FC-405 0.45vol%BF(6)/FC-428 0.15vol%BF(9)/FC-411 0.15vol%BF(9)/FC-444 0.30vol%BF(9)/FC-432 0.30vol%BF(9)/FC-440 0.45vol%BF(9)/FC-419 0.45vol%BF(9)/FC-423 0.15vol%BF(12)/FC-416 0.15vol%BF(12)/FC-439 0.30vol%BF(12)/FC-405 0.30vol%BF(12)/FC-429 0.45vol%BF(12)/FC-424 0.45vol%BF(12)/FC-442 0.15vol%BF(15)/FC-435 0.15vol%BF(15)/FC-419 0.30vol%BF(15)/FC-419 0.30vol%BF(15)/FC-415 0.45vol%BF(15)/FC-407 0.45vol%BF(15)/FC-404 FC-713 FC-710 0.15vol%BF(6)/FC-721 0.15vol%BF(6)/FC-736 0.30vol%BF(6)/FC-726 0.30vol%BF(6)/FC-713 0.45vol%BF(6)/FC-714 0.45vol%BF(6)/FC-730 0.15vol%BF(9)/FC-708 0.15vol%BF(9)/FC-740 0.30vol%BF(9)/FC-719 0.30vol%BF(9)/FC-702 0.45vol%BF(9)/FC-732 0.45vol%BF(9)/FC-720 0.15vol%BF(12)/FC-726 0.15vol%BF(12)/FC-725 0.30vol%BF(12)/FC-732 0.30vol%BF(12)/FC-704 0.45vol%BF(12)/FC-734 0.45vol%BF(12)/FC-711 0.15vol%BF(15)/FC-715 0.15vol%BF(15)/FC-715 0.30vol%BF(15)/FC-711 0.30vol%BF(15)/FC-725 0.45vol%BF(15)/FC-703 0.45vol%BF(15)/FC-696 FC-1032 FC-1025 0.15vol%BF(6)/FC-1024 0.15vol%BF(6)/FC-1026 0.30vol%BF(6)/FC-1017 0.30vol%BF(6)/FC-1044 0.45vol%BF(6)/FC-1009 0.45vol%BF(6)/FC-1016 0.15vol%BF(9)/FC-1003 0.15vol%BF(9)/FC-1011 0.30vol%BF(9)/FC-1013 0.30vol%BF(9)/FC-1003 0.45vol%BF(9)/FC-1026 0.45vol%BF(9)/FC-992 0.15vol%BF(12)/FC-1011 0.15vol%BF(12)/FC-997 0.30vol%BF(12)/FC-1007 0.30vol%BF(12)/FC-997 0.45vol%BF(12)/FC-1023 0.45vol%BF(12)/FC-1016 0.15vol%BF(15)/FC-1034 0.15vol%BF(15)/FC-1001 0.30vol%BF(15)/FC-1010 0.30vol%BF(15)/FC-1000 0.45vol%BF(15)/FC-1032 0.45vol%BF(15)/FC-1041 FC-1305 FC-1322 0.15vol%BF(6)/FC-1317 0.15vol%BF(6)/FC-1331 0.30vol%BF(6)/FC-1333 0.30vol%BF(6)/FC-1332 0.45vol%BF(6)/FC-1319 0.45vol%BF(6)/FC-1308 0.15vol%BF(9)/FC-1326 0.15vol%BF(9)/FC-1320 0.30vol%BF(9)/FC-1322 0.30vol%BF(9)/FC-1326 0.45vol%BF(9)/FC-1307 0.45vol%BF(9)/FC-1293 0.15vol%BF(12)/FC-1311 0.15vol%BF(12)/FC-1307 0.30vol%BF(12)/FC-1304 0.30vol%BF(12)/FC-1308 0.45vol%BF(12)/FC-1337 0.45vol%BF(12)/FC-1306 0.15vol%BF(15)/FC-1328 0.15vol%BF(15)/FC-1302 0.30vol%BF(15)/FC-1321 0.30vol%BF(15)/FC-1310 0.45vol%BF(15)/FC-1317 0.45vol%BF(15)/FC-1296 Note: Three number in the materials name indicate the volume fraction of the fiber, the length of the fiber, and the density of the specimen, respectively. 表 5 BF/FC单轴拉伸试件的特征点

Table 5. Characteristics of BF/FC specimen subjected to uniaxial tension

Specimen index Peak stress/MPa Improvement rate/% Peak strain Improvement rate/% FM FC-424 0.019 - 0.012 - Ⅰ 0.15vol%BF(6)/FC-414 0.033 74 0.049 308 Ⅰ 0.30vol%BF(6)/FC-426 0.033 74 0.037 208 Ⅰ 0.45vol%BF(6)/FC-405 0.036 90 0.048 300 Ⅰ 0.15vol%BF(9)/FC-411 0.065 242 0.039 225 Ⅰ 0.30vol%BF(9)/FC-432 0.077 305 0.047 292 Ⅰ 0.45vol%BF(9)/FC-419 0.104 447 0.059 392 Ⅰ 0.15vol%BF(12)/FC-416 0.087 358 0.050 317 Ⅰ 0.30vol%BF(12)/FC-405 0.130 584 0.080 567 Ⅰ 0.45vol%BF(12)/FC-424 0.159 737 0.112 833 Ⅰ 0.15vol%BF(15)/FC-435 0.098 416 0.046 283 Ⅰ 0.30vol%BF(15)/FC-419 0.121 537 0.059 392 Ⅰ 0.45vol%BF(15)/FC-407 0.099 421 0.047 292 Ⅰ FC-713 0.058 - 0.032 - Ⅰ 0.15vol%BF(6)/FC-721 0.079 37 0.035 10 Ⅰ 0.30vol%BF(6)/FC-726 0.122 110 0.054 69 Ⅰ 0.45vol%BF(6)/FC-714 0.146 152 0.070 119 Ⅰ 0.15vol%BF(9)/FC-708 0.134 131 0.067 109 Ⅰ 0.30vol%BF(9)/FC-719 0.196 238 0.098 206 Ⅰ 0.45vol%BF(9)/FC-732 0.224 286 0.101 216 Ⅰ 0.15vol%BF(12)/FC-726 0.151 160 0.072 125 Ⅰ 0.30vol%BF(12)/FC-732 0.196 238 0.092 188 Ⅰ 0.45vol%BF(12)/FC-734 0.308 431 0.175 447 Ⅰ 0.15vol%BF(15)/FC-715 0.125 116 0.072 125 Ⅰ 0.30vol%BF(15)/FC-711 0.196 238 0.095 198 Ⅰ 0.45vol%BF(15)/FC-703 0.250 331 0.145 353 Ⅰ FC-1032 0.105 - 0.058 - Ⅰ 0.15vol%BF(6)/FC-1024 0.187 78 0.120 107 Ⅰ 0.30vol%BF(6)/FC-1017 0.259 147 0.141 143 Ⅰ 0.45vol%BF(6)/FC-1009 0.302 188 0.177 205 Ⅰ 0.15vol%BF(9)/FC-1003 0.242 131 0.159 174 Ⅰ 0.30vol%BF(9)/FC-1013 0.261 149 0.203 250 Ⅱ 0.45vol%BF(9)/FC-1026 0.308 193 0.275 374 Ⅱ 0.15vol%BF(12)/FC-1011 0.288 174 0.208 259 Ⅱ 0.30vol%BF(12)/FC-1007 0.325 210 0.200 245 Ⅱ 0.45vol%BF(12)/FC-1023 0.426 306 0.247 326 Ⅱ 0.15vol%BF(15)/FC-1034 0.165 57 0.082 41 Ⅰ 0.30vol%BF(15)/FC-1010 0.281 168 0.144 148 Ⅰ 0.45vol%BF(15)/FC-1032 0.346 137 0.184 217 Ⅱ FC-1305 0.183 - 0.088 - Ⅰ 0.15vol%BF(6)/FC-1317 0.224 22 0.115 31 Ⅰ 0.30vol%BF(6)/FC-1333 0.234 28 0.103 17 Ⅰ 0.45vol%BF(6)/FC-1319 0.326 78 0.158 80 Ⅰ 0.15vol%BF(9)/FC-1326 0.239 31 0.133 51 Ⅰ 0.30vol%BF(9)/FC-1322 0.251 37 0.135 53 Ⅰ 0.45vol%BF(9)/FC-1307 0.280 53 0.173 97 Ⅱ 0.15vol%BF(12)/FC-1311 0.216 18 0.112 27 Ⅰ 0.30vol%BF(12)/FC-1304 0.297 62 0.167 90 Ⅰ 0.45vol%BF(12)/FC-1337 0.406 122 0.314 257 Ⅱ 0.15vol%BF(15)/FC-1328 0.208 14 0.121 38 Ⅰ 0.30vol%BF(15)/FC-1321 0.311 70 0.193 119 Ⅱ 0.45vol%BF(15)/FC-1317 0.373 104 0.221 151 Ⅱ Note: FM—Failure mode. 表 6 BF/FC准静态压缩能量吸收指标

Table 6. Energy absorption characteristics of BF/FC under quasi-static compression

Specimen index Peak and plateau stress/MPa ${\varepsilon _{\text{D}}}$ ${E_{\text{a}}}$/J and ${E_{{\text{SA}}}}$/(J·g-1) FC-439 0.525/0.411 0.47 190.0/0.433 0.15vol%BF(6)/FC-438 0.995/0.696 0.42 309.5/0.707 0.30vol%BF(6)/FC-440 1.259/0.636 0.43 311.2/0.707 0.45vol%BF(6)/FC-428 1.589/1.050 0.51 532.9/1.245 0.15vol%BF(9)/FC-444 1.246/0.724 0.52 407.1/0.917 0.30vol%BF(9)/FC-440 1.229/0.881 0.52 448.7/1.020 0.45vol%BF(9)/FC-423 1.772/1.250 0.43 576.2/1.362 0.15vol%BF(12)/FC-439 1.254/0.923 0.52 468.0/1.066 0.30vol%BF(12)/FC-429 1.755/1.427 0.57 789.4/1.840 0.45vol%BF(12)/FC-442 1.910/1.570 0.56 813.1/1.840 0.15vol%BF(15)/FC-419 1.390/0.784 0.53 441.2/1.053 0.30vol%BF(15)/FC-415 1.696/1.399 0.51 692.0/1.668 0.45vol%BF(15)/FC-404 1.443/0.846 0.59 490.2/1.213 FC-710 4.561/1.459 0.33 614.8/0.866 0.15vol%BF(6)/FC-736 4.220/1.430 0.53 831.6/1.130 0.30vol%BF(6)/FC-713 4.137/1.848 0.39 857.7/1.203 0.45vol%BF(6)/FC-730 4.470/1.386 0.57 916.7/1.256 0.15vol%BF(9)/FC-740 5.072/1.718 0.44 955.6/1.291 0.30vol%BF(9)/FC-702 3.553/2.636 0.49 1258.0/1.792 0.45vol%BF(9)/FC-720 5.070/3.249 0.44 1423.4/1.977 0.15vol%BF(12)/FC-725 5.723/2.440 0.45 1118.3/1.542 0.30vol%BF(12)/FC-704 4.063/2.994 0.52 1534.3/2.179 0.45vol%BF(12)/FC-711 4.305/3.413 0.50 1566.7/2.204 0.15vol%BF(15)/FC-715 5.250/2.338 0.37 985.8/1.379 0.30vol%BF(15)/FC-725 4.648/3.292 0.47 1516.5/2.092 0.45vol%BF(15)/FC-696 5.064/2.719 0.49 1313.5/1.887 FC-1025 9.459/3.760 0.36 1587.9/1.549 0.15vol%BF(6)/FC-1026 11.707/3.758 0.46 2086.0/2.033 0.30vol%BF(6)/FC-1044 13.488/4.327 0.49 2365.9/2.266 0.45vol%BF(6)/FC-1016 12.417/5.047 0.48 2558.2/2.518 0.15vol%BF(9)/FC-1011 11.565/4.933 0.37 2096.2/2.073 0.30vol%BF(9)/FC-1003 12.319/5.536 0.47 2580.7/2.573 0.45vol%BF(9)/FC-992 11.471/6.739 0.51 3193.3/3.219 0.15vol%BF(12)/FC-997 8.913/5.017 0.52 2716.4/2.725 0.30vol%BF(12)/FC-997 12.503/6.959 0.55 3374.7/3.385 0.45vol%BF(12)/FC-1016 14.011/8.529 0.50 3739.2/3.680 0.15vol%BF(15)/FC-1001 9.984/4.969 0.51 2536.6/2.534 0.30vol%BF(15)/FC-1000 11.940/5.390 0.53 2981.3/2.981 0.45vol%BF(15)/FC-1041 12.538/6.911 0.51 3430.7/3.296 FC-1322 23.601/4.547 0.38 2351.2/1.779 0.15vol%BF(6)/FC-1331 24.556/5.920 0.37 2646.3/1.988 0.30vol%BF(6)/FC-1332 23.282/5.990 0.43 3180.0/2.377 0.45vol%BF(6)/FC-1308 20.178/8.669 0.49 4136.7/3.163 0.15vol%BF(9)/FC-1320 23.643/6.124 0.37 2759.1/2.090 0.30vol%BF(9)/FC-1326 24.580/6.502 0.50 3776.5/2.848 0.45vol%BF(9)/FC-1293 25.920/9.083 0.47 4189.5/3.240 0.15vol%BF(12)/FC-1307 21.120/7.136 0.44 3452.7/2.642 0.30vol%BF(12)/FC-1308 20.126/10.708 0.50 5135.4/3.926 0.45vol%BF(12)/FC-1306 22.800/12.194 0.56 6433.7/4.926 0.15vol%BF(15)/FC-1302 24.311/5.397 0.39 2816.0/2.163 0.30vol%BF(15)/FC-1310 23.903/11.051 0.52 5432.6/4.147 0.45vol%BF(15)/FC-1296 20.191/9.794 0.52 4884.6/3.769 Notes: ${\varepsilon _{\text{D}}}$—Densification strain; ${E_{\text{a}}}$and ${E_{{\text{SA}}}}$—Energy absorption and specific energy absorption. -

[1] 崔玉理, 贺鸿珠. 温度对泡沫混凝土性能影响[J]. 建筑材料学报, 2015, 18(5):836-839, 846. doi: 10.3969/j.issn.1007-9629.2015.05.021CUI Yuli, HE Hongzhu. Influence of temperature on performances of foam concrete[J]. Journal of Building Materials,2015,18(5):836-839, 846(in Chinese). doi: 10.3969/j.issn.1007-9629.2015.05.021 [2] 李从波, 文梓芸, 殷素红. 大型承重保温夹芯复合墙体的材料选型及模拟[J]. 建筑材料学报, 2013, 16(6):1012-1016.LI Congbo, WEN Ziyun, YIN Suhong. Material selection and simulation research of large bearing insulation sandwich composite wall[J]. Journal of Building Materials,2013,16(6):1012-1016(in Chinese). [3] 张亚梅, 孙超, 王申, 等. 不同密度等级泡沫混凝土的性能和孔结构[J]. 重庆大学学报, 2020, 43(8):54-63.ZHANG Yamei, SUN Chao, WANG Shen, et al. Properties and pore structure of foam concrete with different density[J]. Journal of Chongqing University,2020,43(8):54-63(in Chinese). [4] 宋强, 张鹏, 鲍玖文, 等. 泡沫混凝土的研究进展与应用[J]. 硅酸盐学报, 2021, 49(2):398-410.SONG Qiang, ZHANG Peng, BAO Jiuwen, et al. Research progress and application of foam concrete[J]. Journal of the Chinese Ceramic Society,2021,49(2):398-410(in Chinese). [5] 李升涛, 陈徐东, 张锦华, 等. 不同密度等级泡沫混凝土的单轴压缩破坏特征[J]. 建筑材料学报, 2021, 24(6):1146-1153.LI Shengtao, CHEN Xudong, ZHANG Jinhua, et al. Failure characteristics of foam conrete with different density under uniaxial compression[J]. Journal of Building Materials,2021,24(6):1146-1153(in Chinese). [6] 王武祥. 泡沫混凝土绝干密度与抗压强度的相关性研究[J]. 混凝土世界, 2010(6):50-53.WANG Wuxiang. Correlation between absolute dry density and compressive strength of foam concrete[J]. China Concrete,2010(6):50-53(in Chinese). [7] 袁璞, 马芹永, 张海东. 轻质泡沫混凝土SHPB试验与分析[J]. 振动与冲击, 2014, 33(17):116-119.YUAN Pu, MA Qinyong, ZHANG Haidong. SHPB tests for light weight foam concrete[J]. Journal of Vibration and Shock,2014,33(17):116-119(in Chinese). [8] 刘海燕, 李然. 泡沫混凝土吸能机理试验研究[J]. 成都大学学报(自然科学版), 2010, 29(2):166-167,180.LIU Haiyan, LI Ran. Experimental study on energy absorbing mechanism of foam concrete[J]. Journal of Chengdu University (Natural Science),2010,29(2):166-167,180(in Chinese). [9] 刘军, 齐玮, 刘润清, 等. 粉煤灰对泡沫混凝土物理力学性能的影响[J]. 材料导报, 2015, 29(16):111-114.LIU Jun, QI Wei, LIU Runqing, et al. Effect of fly ash on physical and mechanical properties of foam concrete[J]. Materials Reports,2015,29(16):111-114(in Chinese). [10] 王小娟, 刘路, 贾昆程, 等. 陶粒泡沫混凝土的力学性能及吸能特性[J]. 建筑材料学报, 2021, 24(1): 207-215.WANG Xiaojuan, LIU Lu, JIA Kuncheng, et al. Mechanical properties and energy absorption characteristics of ceramsite foam concrete[J]. Journal of Building Materials, 2021, 24(1): 207-215(in Chinese). [11] 詹炳根, 郭建雷, 林兴胜. 玻璃纤维增强泡沫混凝土性能试验研究[J]. 合肥工业大学学报(自然科学版), 2009, 32(2):226-229.ZHAN Binggen, GUO Jianlei, LIN Xingsheng. Properties of foamed concrete with fibre glass reinforcement[J]. Jour-nal of Hefei University of Technology (Natural Science),2009,32(2):226-229(in Chinese). [12] 王静文, 王伟. 玄武岩纤维增强泡沫混凝土响应面多目标优化[J]. 材料导报, 2019, 33(24):4092-4097.WANG Jingwen, WANG Wei. Response surface based multi-objective optimization of basalt fiber reinforced foamed concrete[J]. Materials Reports,2019,33(24):4092-4097(in Chinese). [13] 杨瑞环, 霍冀川, 赵星. 玄武岩纤维掺量对泡沫混凝土性能的影响[J]. 西南科技大学学报, 2014, 29(2):29-32, 65. doi: 10.3969/j.issn.1671-8755.2014.02.007YANG Ruihuan, HUO Jichuan, ZHAO Xing. The effect of basalt fibre dosage on the properties of foam concrete[J]. Journal of Southwest University of Science and Technology,2014,29(2):29-32, 65(in Chinese). doi: 10.3969/j.issn.1671-8755.2014.02.007 [14] 范然森, 程新, 詹炳根. 玄武岩纤维泡沫混凝土性能研究及抗裂评价[J]. 合肥工业大学学报(自然科学版), 2020, 43(9):1223-1228.FAN Ransen, CHENG Xin, ZHAN Binggen. Performance study and crack resistance evaluation of basalt fibre foam concrete[J]. Journal of Hefei University of Technology (Natural Science),2020,43(9):1223-1228(in Chinese). [15] 江旋, 季韬, 徐维, 等. 聚丙烯纤维掺量对碱矿渣泡沫混凝土砌块性能影响的研究[J]. 新型建筑材料, 2021, 48(4): 95-98, 114.JIANG Xuan, JI Tao, XU Wei, et al. Effect of polypropylene fibre content on behavior of alkali-activated slag foamed concrete block[J]. New Building Materials, 2021, 48(4): 95-98, 114(in Chinese). [16] 杨小芳, 于水军, 高岩, 等. 泡沫混凝土和混凝土耐火极限的比较研究[J]. 火灾科学, 2012, 21(2):78-83. doi: 10.3969/j.issn.1004-5309.2012.02.005YANG Xiaofang, YU Shuijun, GAO Yan, et al. Comparison of the fire resistance limits of foamed concrete and concrete[J]. Fire Safety Science,2012,21(2):78-83(in Chinese). doi: 10.3969/j.issn.1004-5309.2012.02.005 [17] 周宏元, 于鸿鑫, 王小娟, 等. 玄武岩纤维平纹织物约束建筑固体废弃物颗粒力学性能及吸能特性[J]. 复合材料学报, 2022, 39(2):695-706.ZHOU Hongyuan, YU Hongxin, WANG Xiaojuan, et al. Mechanical properties and energy absorption characteristics of basalt fiber plain woven fabric constrained building solid waste particles[J]. Acta Materiae Compositae Sinica,2022,39(2):695-706(in Chinese). [18] 刘霞, 李峰, 佘殷鹏. 玄武岩纤维增强聚合物筋增强珊瑚礁砂混凝土柱轴压试验[J]. 复合材料学报, 2020, 37(10):2428-2438.LIU Xia, LI Feng, SHE Yinpeng. Axial compression test of basalt fiber reinforced polymer reinforced coral reef and sand aggregate concrete column[J]. Acta Materiae Compositae Sinica,2020,37(10):2428-2438(in Chinese). [19] LI H N, LIU P F, LI C, et al. Experimental research on dynamic mechanical properties of metal tailings porous concrete[J]. Construction and Building Materials,2019,213:20-31. [20] 高淑玲, 王文昌. 应变硬化水泥基复合材料性能与应用研究进展[J]. 材料导报, 2019, 33(21):3620-3629. doi: 10.11896/cldb.18110175GAO Shuling, WANG Wenchang. A review on performance and application of strain hardening cementitious compo-sites[J]. Materials Reports,2019,33(21):3620-3629(in Chinese). doi: 10.11896/cldb.18110175 [21] 董志芳, 邓明科, 张聪. 纤维织物增强高延性混凝土单轴拉伸性能试验研究[J]. 土木工程学报, 2020, 53(10): 13-25.DONG Zhifang, DENG Mingke, ZHANG Cong. Experimental investigation on uniaxial tension behavior of textile-reinforced highly ductile concrete[J]. China Civil Engineering Journal, 2020, 53(10): 13-25(in Chinese). [22] 罗洪林, 杨鼎宜, 周兴宇, 等. 不同长径比聚丙烯纤维增强混凝土的力学特性[J]. 复合材料学报, 2019, 36(8):1935-1948.LUO Honglin, YANG Dingyi, ZHOU Xingyu, et al. Mecha-nical properties of polypropylene fiber reinforced concrete with different aspect ratios[J]. Acta Materiae Compositae Sinica,2019,36(8):1935-1948(in Chinese). [23] 周浩, 贾彬, 黄辉. 玄武岩纤维混凝土受拉性能试验研究与分析[J]. 建筑结构, 2020, 50(24):104-109.ZHOU Hao, JIA Bin, HUANG Hui. Experimental study and analysis on tensile performance of basalt fiber concrete[J]. Building Structure,2020,50(24):104-109(in Chinese). [24] MILTZ J, GRUENBAUM G. Evaluation of cushioning pro-perties of plastic foams from compressive measurements[J]. Polymer Engineering & Science,1981,21(15):1010-1014. [25] TAN P J, HARRIGAN J J, REID S R. Inertia effects in uniaxial dynamic compression of a closed cell aluminium alloy foam[J]. Materials Science and Technology,2002,18(5):480-488. [26] 张文武, 张丹, 王珊珊, 等. 吸能材料缓冲性能评价方法综述[J]. 包装工程, 2022, 43(5):143-151.ZHANG Wenwu, ZHANG Dan, WANG Shanshan, et al. Review of evaluation methods of cushioning performance of energy absorbing materials[J]. Packaging Engineering,2022,43(5):143-151(in Chinese). [27] BATOOL F, BINDIGANAVILE V. Microstructural parameters of fiber reinforced cement-based foam and influence on compressive and thermal properties[J]. Journal of Building Engineering,2020,31:101320. doi: 10.1016/j.jobe.2020.101320 [28] 陈峰宾, 许斌, 焦华喆, 等. 玄武岩纤维混凝土纤维分布及孔隙结构表征[J]. 中国矿业大学学报, 2021, 50(2):273-280.CHEN Fengbin, XU Bin, JIAO Huazhe, et al. Fiber distribution and pore structure characterization of basalt fiber reinforced concrete[J]. Journal of China University of Mining & Technology,2021,50(2):273-280(in Chinese). -

下载:

下载: