Preparation and properties of carbon fiber reinforced epoxy resin composites interlaminate-toughened by polyethersulfone ultrafine-fiber non-woven fabric

-

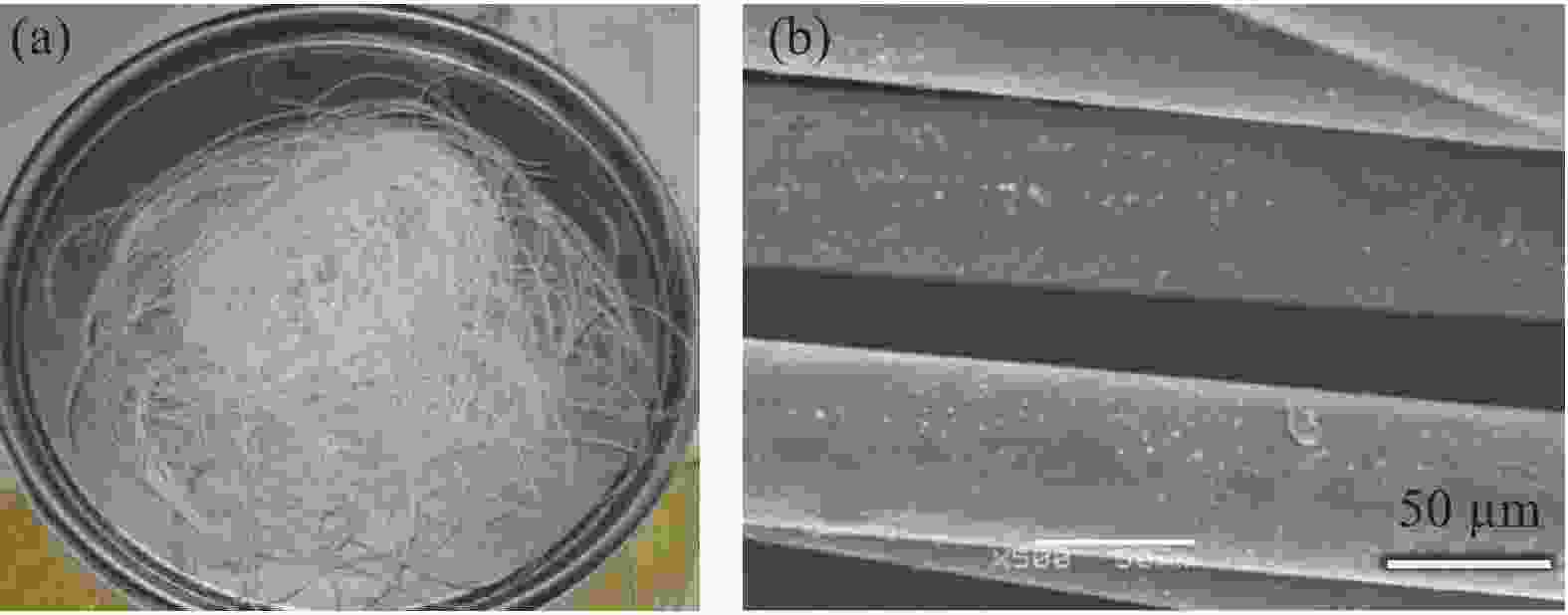

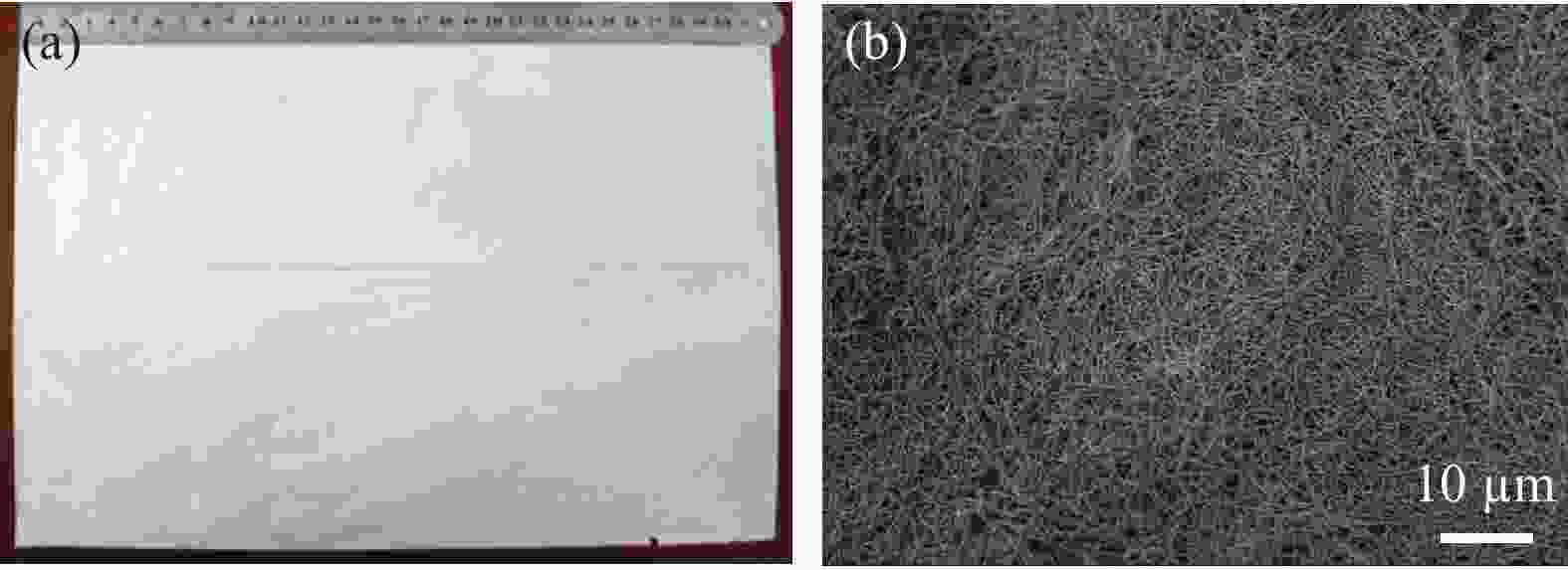

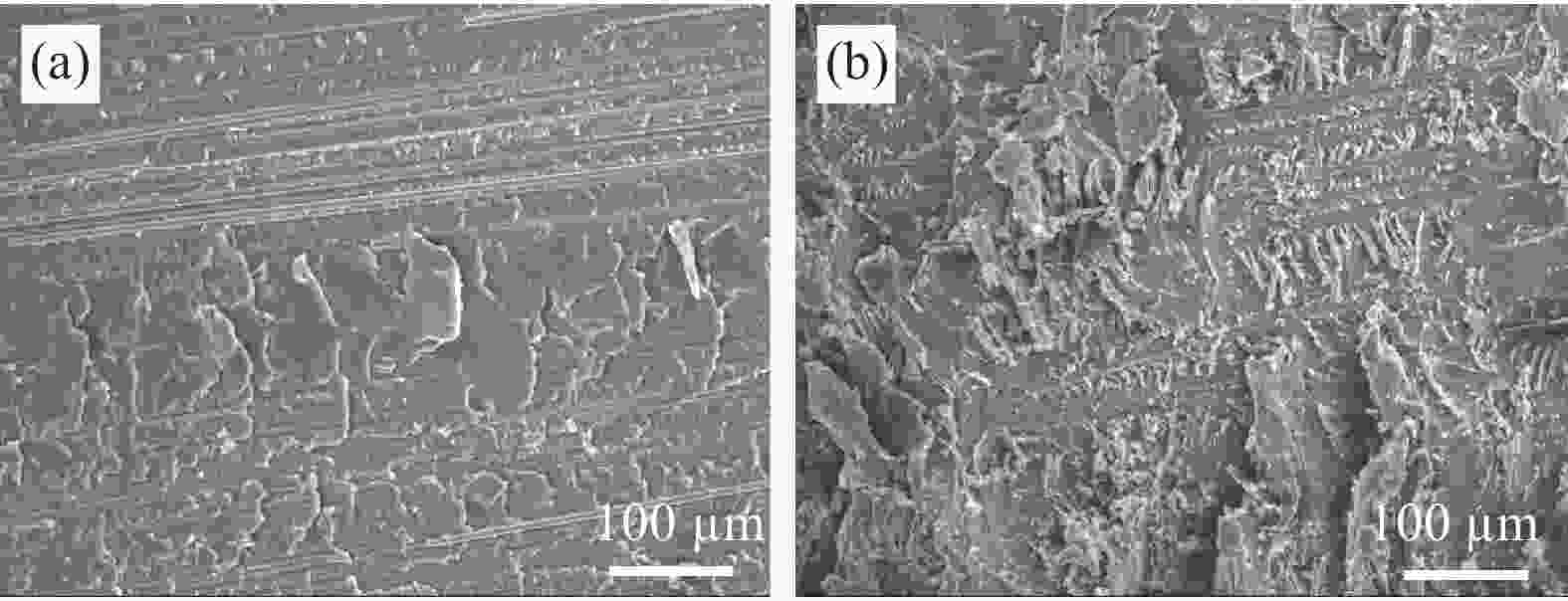

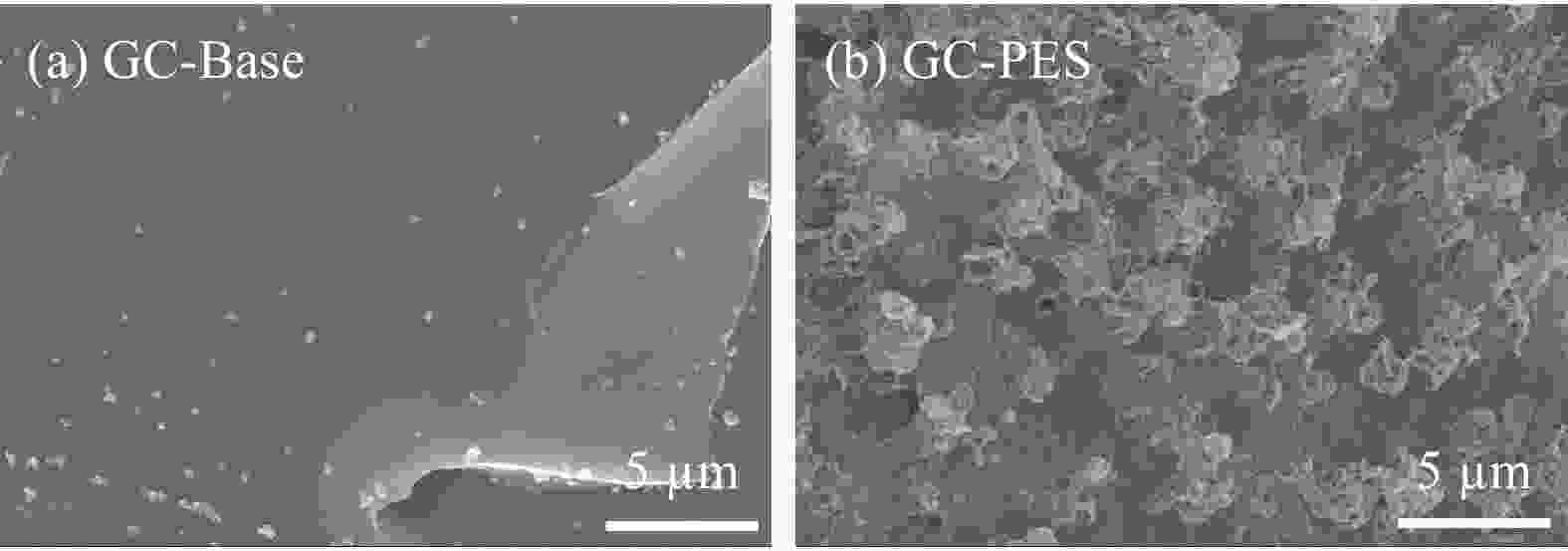

摘要: 为提高环氧树脂基复合材料的冲击后压缩强度,采用更适用于批量化制备的聚醚砜-尼龙6(PES-PA6)共混纺丝溶解剥离法制备PES超细纤维无纺布,并将该无纺布用于碳纤维增强环氧树脂基复合材料的层间增韧,通过测试复合材料增韧前后的I型层间断裂韧性(GIC)、II型层间断裂韧性(GIIC)和冲击后压缩强度(CAI),并表征复合材料层间断裂微观形貌,研究该无纺布对复合材料层间韧性的影响与复合材料超细纤维无纺布层间增韧机制。结果表明,采用无纺布层间增韧环氧树脂复合材料后,其GIC性能由增韧前的289 J/m2提升到增韧后的312 J/m2;GIIC性能由增韧前的1391 J/m2提升到增韧后的3649 J/m2。试样冲击后损伤面积由增韧前的1050 mm2降低到增韧后的204 mm2,相应的冲击后压缩强度由增韧前的228 MPa提升到增韧后307 MPa。Abstract: To improve the compression strength after impact of epoxy-based composites, polyethersulfone (PES) ultrafine-fiber non-woven fabric was fabricated from polyethersulfone-Nylon 6 (PES-PA6) blended fibers using solution-stripping method, which is more suitable for batch preparation. Then the obtained non-woven fabric was applied in the interlaminar toughing of carbon fiber reinforced epoxy resin-based composites. Interlaminar fracture toughness under mode I (GIC), interlaminar fracture toughness under mode II (GIIC), compressive strength after impact (CAI) and interlaminar fracture micro-morphology of composites were tested to research the influence of the non-woven fabric on the interlaminar toughness of composites and the corresponding mechanism of interla-minar toughing. The result indicates that after epoxy resin-based composites are interlaminate-toughened with the non-woven fabric, the GIC value is raised to 312 J/m2 from 289 J/m2 and GIIC value is improved to 3649 J/m2 from 1391 J/m2. Also, the post-impact damage area of tested specimens is reduced from 1050 mm2 to 204 mm2 after toughing treatment, and the corresponding post-impact compressive strength is increased from 228 MPa to 307 MPa.

-

Key words:

- epoxy resin /

- composites /

- carbon fiber /

- interlaminar toughing /

- blended spinning

-

表 1 碳纤维增强环氧树脂基复合材料层合板铺层方案

Table 1. Placement scheme of carbon fiber reinforced epoxy resin composite laminates

Sample Laying design Remarks GC-Base [0]22 and insert a 25 µm polytetrafluoroethylene (PTFE) film into the middle layer of the laminate as the initial delamination pre-crack Used to prepare GIC and GIIC samples GC-PES [0]11/PES-f/[0]11 and insert a 25 µm PTFE film into the middle layer of the laminate as the initial delamination pre-crack CAI-Base [45/0/–45/90]3s Used to prepare compressive strength after impact samples CAI-PES [45/0/–45/90]3s and insert a layer of PES-f non-woven fabric between each layer of prepreg Notes: GIC—Interlaminar fracture toughness under mode I; GIIC—Interlaminar fracture toughness under mode II; CAI—Compressive strength after impact; PES—Polyethersulfone; PES-f—PES ultrafine fiber; GC—Serial number. 表 2 PES-f无纺布层间增韧环氧树脂基复合材料层合板冲击后损伤投影面积及冲击后压缩强度(CAI)结果对比

Table 2. Damage area and compression after impact (CAI) results of PES-f non-woven interlayer toughened epoxy resin based composite laminates

Sample Damage area/mm2 Maximum force/kN CAI/MPa CAI-Base Average 1050 92.5 228 Standard deviation 70.34 8.23 19.6 CAI-PES Average 204 134 307 Standard deviation 32.96 9.07 17.7 -

[1] 陈祥宝, 张宝艳, 邢丽英. 先进树脂基复合材料技术发展及应用现状[J]. 中国材料进展, 2009, 28(6):2-12.CHEN Xiangbao, ZHANG Baoyan, XING Liying. Application and development of advanced polymer matrix composites[J]. Materials China,2009,28(6):2-12(in Chinese). [2] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [3] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322.MA Limin, ZHANG Jiazhen, YUE Guangquan, et al. Appli-cation of composites in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese). [4] ENDO M. Composites for aircraft and aerospace application[J]. Sen'I Gakkaishi,2014,70(9):508-511. doi: 10.2115/fiber.70.P-508 [5] 包建文, 钟翔屿, 张代军, 等. 国产高强中模碳纤维及其增强高韧性树脂基复合材料研究进展[J]. 材料工程, 2020, 48(8):33-48. doi: 10.11868/j.issn.1001-4381.2020.000208BAO Jianwen, ZHONG Xiangyu, ZHANG Daijun, et al. Progress in high strength intermediate modulus carbon fiber and its high toughness resin matrix composites in China[J]. Journal of Materials Engineering,2020,48(8):33-48(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000208 [6] 陈绍杰. 复合材料技术与大型飞机[J]. 航空学报, 2008, 29(3):605-610. doi: 10.3321/j.issn:1000-6893.2008.03.011CHEN Shaojie. Composite technology and large aircraft[J]. Acta Aeronautica et Astronautic Sinica,2008,29(3):605-610(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.011 [7] 刘代军, 陈亚莉. 先进树脂基复合材料在航空工业中的应用[J]. 材料工程, 2008(S1):194-198.LIU Daijun, CHEN Yali. Application of advanced polymer matrix composites in aviation industry[J]. Journal of Materials Engineering,2008(S1):194-198(in Chinese). [8] 乔海涛, 梁滨, 张军营, 等. 先进复合材料结构胶接体系的研发与应用[J]. 材料工程, 2018, 46(12):38-47. doi: 10.11868/j.issn.1001-4381.2018.000297QIAO Haitao, LIANG Bin, ZHANG Junying, et al. Development and application of adhesive materials for advanced composite bonding[J]. Journal of Materials Engineering,2018,46(12):38-47(in Chinese). doi: 10.11868/j.issn.1001-4381.2018.000297 [9] 张宗华, 刘刚, 张晖, 等. 纳米氧化铝颗粒对高性能环氧树脂玻璃化转变温度的影响[J]. 材料工程, 2014(9):39-44. doi: 10.11868/j.issn.1001-4381.2014.09.007ZHANG Zonghua, LIU Gang, ZHANG Hui, et al. Influence of nano-alumina particles on glass transition temperature of high-performance epoxy resin[J]. Journal of Materials Engineering,2014(9):39-44(in Chinese). doi: 10.11868/j.issn.1001-4381.2014.09.007 [10] 刘刚, 张代军, 张晖, 等. 纳米粒子改性环氧树脂及其复合材料力学性能研究[J]. 材料工程, 2010(1):47-53. doi: 10.3969/j.issn.1001-4381.2010.01.011LIU Gang, ZHANG Daijun, ZHANG Hui, et al. Mechanical properties of nanoparticles modified epoxy matrix and composites[J]. Journal of Materials Engineering,2010(1):47-53(in Chinese). doi: 10.3969/j.issn.1001-4381.2010.01.011 [11] 董慧民, 益小苏, 安学锋, 等. 纤维增强热固性聚合物基复合材料层间增韧研究进展[J]. 复合材料学报, 2014, 31(2):273-285.DONG Huimin, YI Xiaosu, AN Xuefeng, et al. Development of interleaved fibre-reinforced thermoset polymer matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(2):273-285(in Chinese). [12] 姚佳伟, 刘梦瑶, 牛一凡. PEK-C膜层间增韧碳纤维/环氧树脂复合材料的力学性能[J]. 复合材料学报, 2019, 36(5):1083-1091.YAO Jiawei, LIU Mengyao, NIU Yifan. Mechanical properties of PEK-C interlayer toughened carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2019,36(5):1083-1091(in Chinese). [13] 张朋, 刘刚, 胡晓兰, 等. 结构化增韧层增韧RTM复合材料性能[J]. 复合材料学报, 2012 , 29(4):1-9.ZHANG Peng, LIU Gang, HU Xiaolan, et al. Properties of toughened RTM composites by structural toughening layer[J]. Acta Materiae Compositae Sinica,2012 , 29(4):1-9(in Chinese). [14] 董慧民, 闫丽, 安学锋, 等. ESTM-fabric/3266复合材料低速冲击响应及冲击后压缩行为研究[J]. 材料工程, 2020, 48(1):41-47. doi: 10.11868/j.issn.1001-4381.2018.000960DONG Huimin, YAN Li, AN Xuefeng, et al. Low velocity impact response and post impact compression behaviour of ESTM-fabric/3266 composites[J]. Journal of Materials Engineering,2020,48(1):41-47(in Chinese). doi: 10.11868/j.issn.1001-4381.2018.000960 [15] BRUGO T, MINAK G, ZUCCHELLI A, et al. An investigation on the fatigue based delamination of woven carbon-epoxy composite laminates reinforced with polyamide nano-fibers[J]. Procedia Engineering,2015,109:65-72. doi: 10.1016/j.proeng.2015.06.208 [16] SHIVAKUMAR K, LINGAIAH S, CHEN H, et al. Polymer nanofabric interleaved composite laminates[J]. AIAA Journal,2009,47(7):1723-1729. [17] DAELEMANS L, SAM V, DE B I, et al. Nanofibre bridging as a toughening mechanism in carbon/epoxy composite lami-nates interleaved with electrospun polyamide nano-fibrous veils[J]. Composites Science and Technology,2015,117:244-256. doi: 10.1016/j.compscitech.2015.06.021 [18] American Society for Testing and Materials. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D 5528[S]. West Conshohocken: American Society for Testing and Materials International, 2009. [19] 中国航空工业总公司. 碳纤维复合材料层合板II型层间断裂韧性GIIC试验方法: HB 7403—96[S]. 北京: 中国航空工业总公司, 1997.Aviation Industry Corporation of China. Test method for mode II interlaminar fracture toughness of carbon fiber-reinforced polymer matrix composites: HB 7403—96[S]. Beijing: Aviation Industry Corporation of China, 1997(in Chinese). [20] American Society for Testing and Materials. Standard test for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D 7136[S]. West Conshohocken: American Society for Testing and Materials International, 2020. [21] American Society for Testing and Materials. Standard test method I for compressive residual strength properties of damaged polymer matrix composite plates: ASTM D 7137[S]. West Conshohocken: American Society for Testing and Materials International, 2017. [22] VOLKER A, DALE G, MICHAEL S, et al. Interlaminar crack growth in third-generation thermoset prepreg system[J]. Polymer,1993,34(4):907-909. doi: 10.1016/0032-3861(93)90379-O [23] RECKER H, ALTSTADT V, EBERLE W, et al. Toughened thermosets for damage tolerant carbon fiber reinforced composites[J]. SAMPE Journal, 1990, 26(2): 73-78. -

下载:

下载: