Dynamic response of composite materials designed by 3D printing imitation conch shell pearl shell hybrid design

-

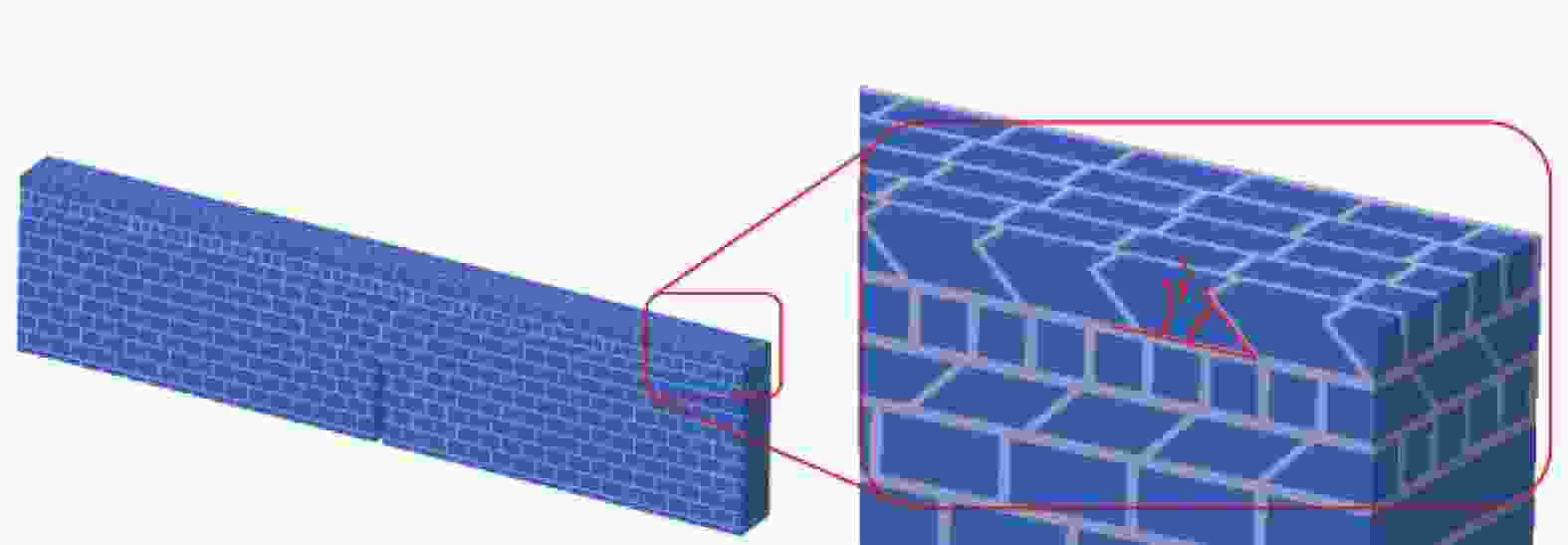

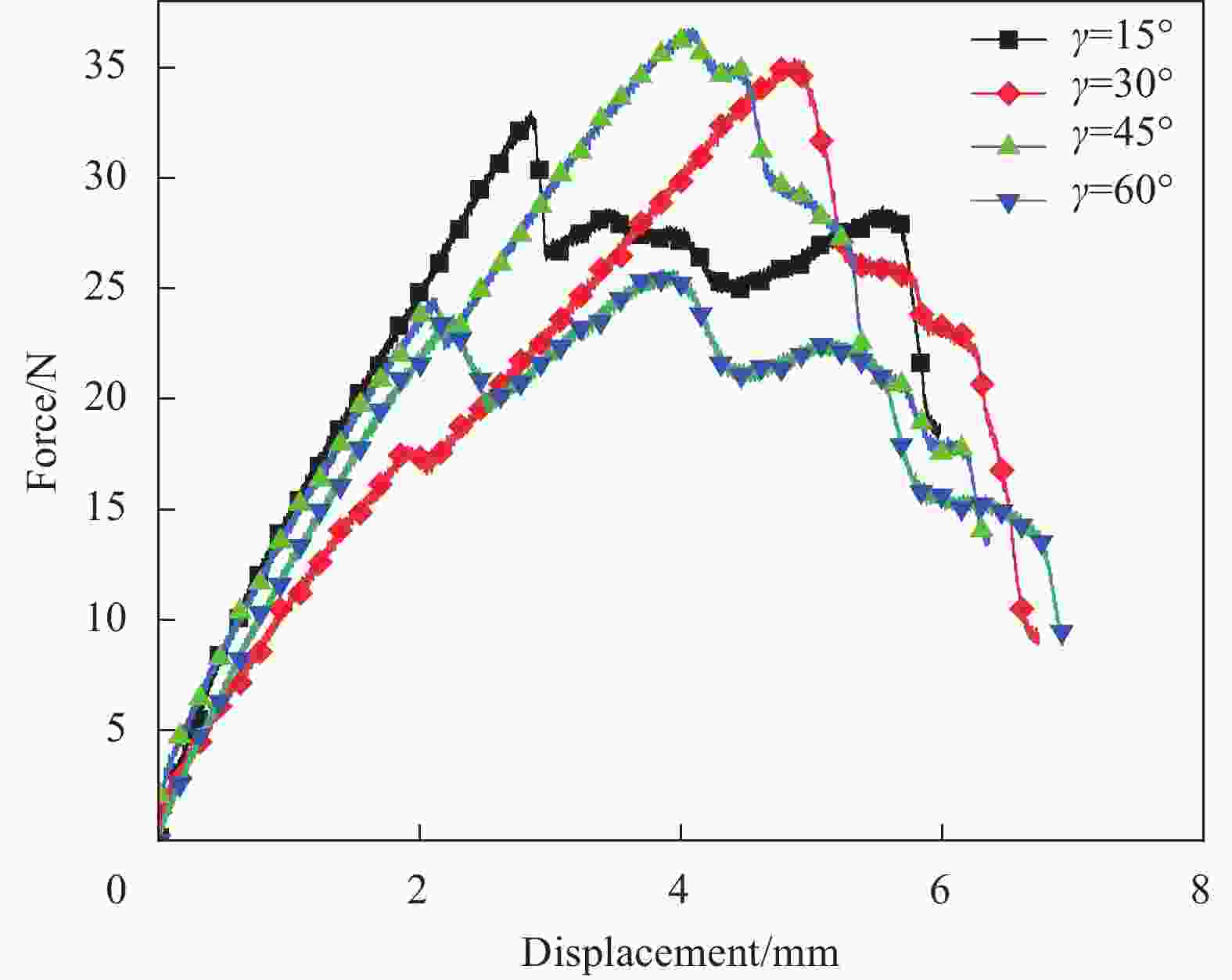

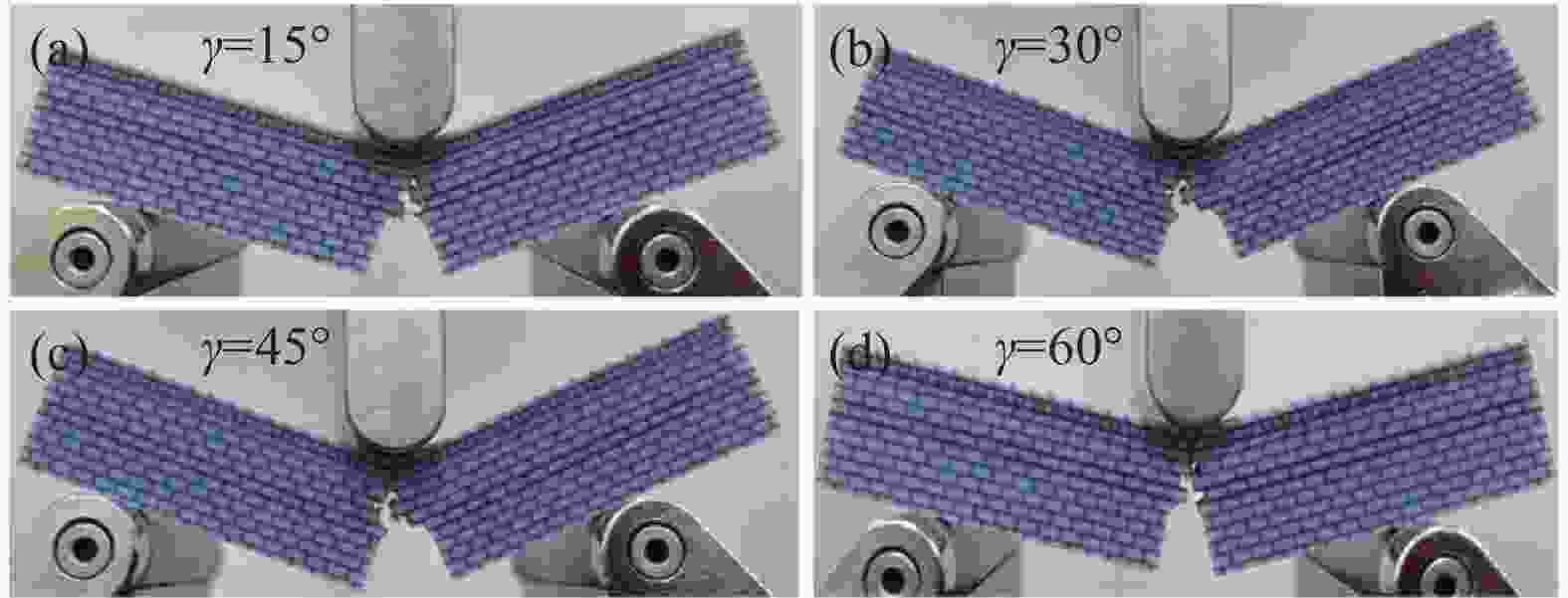

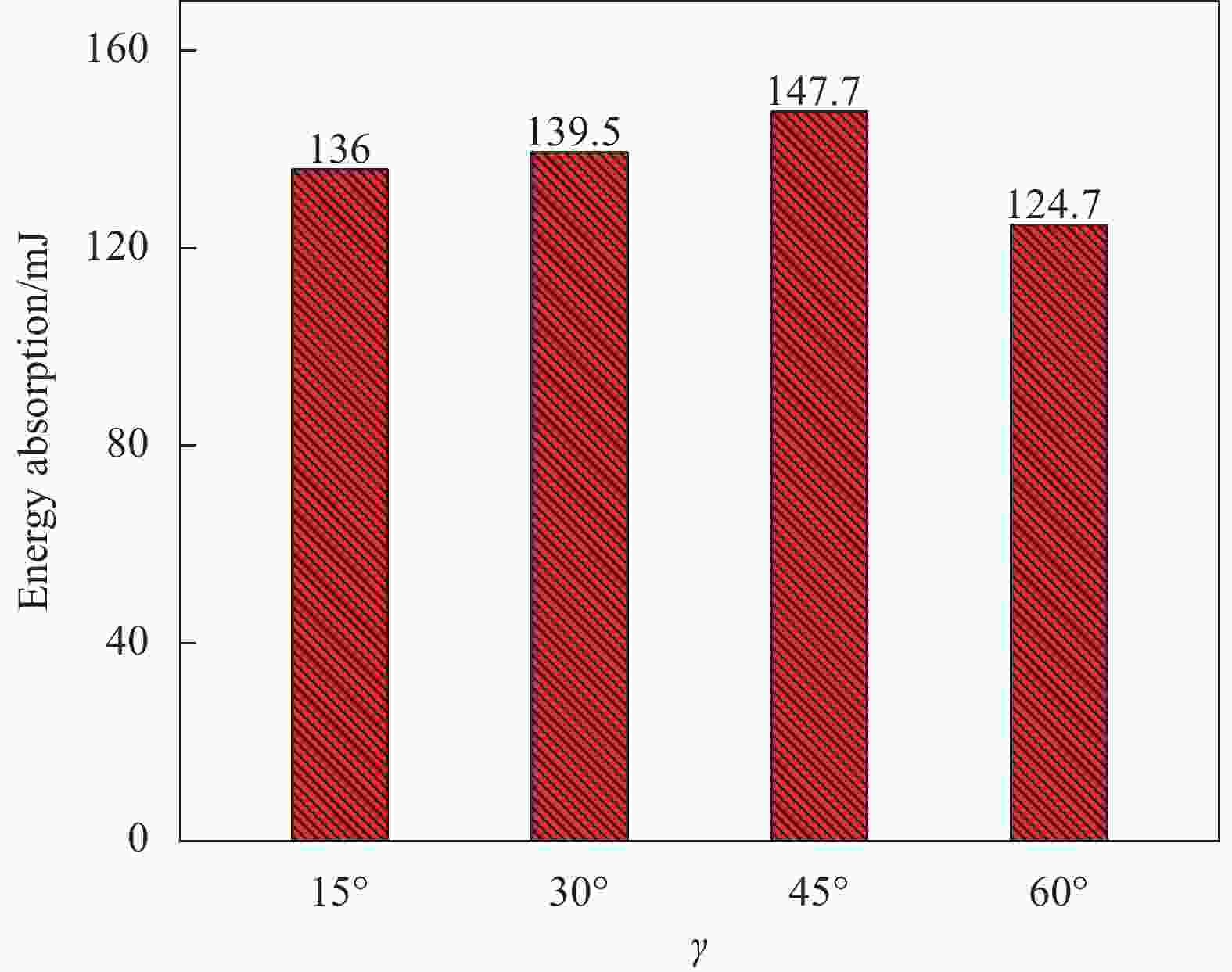

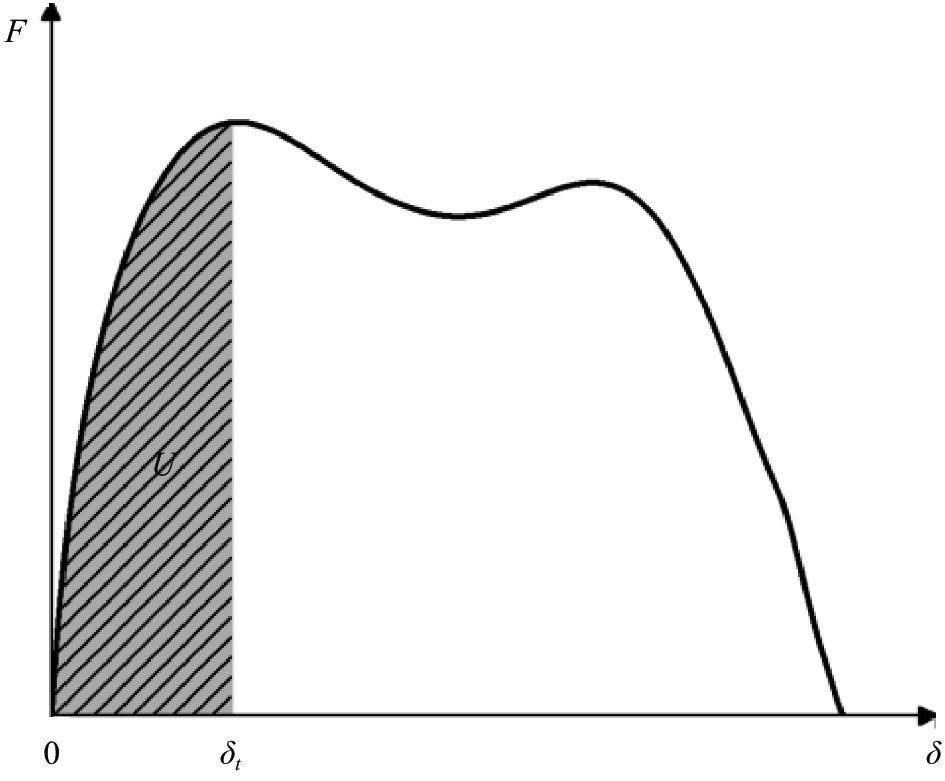

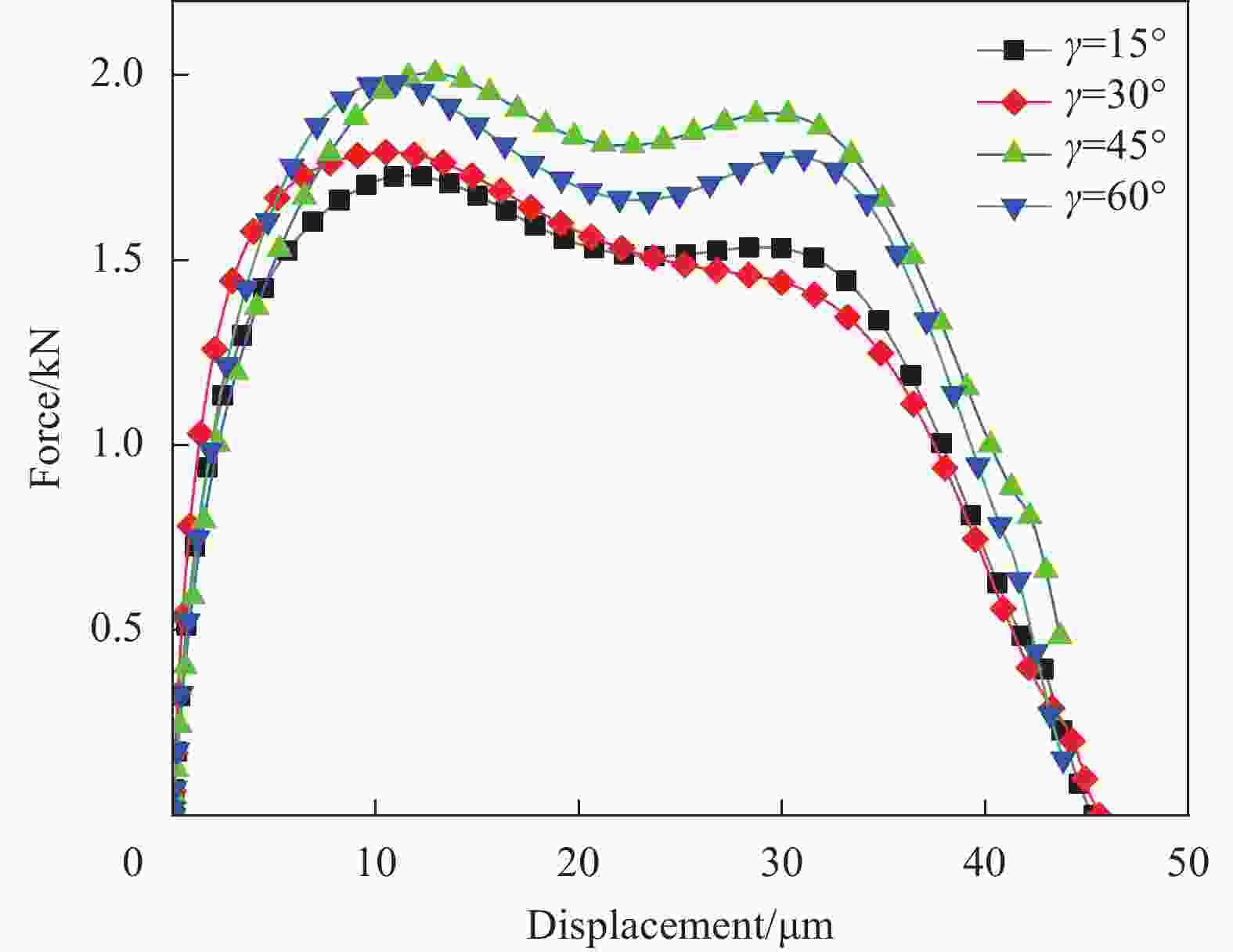

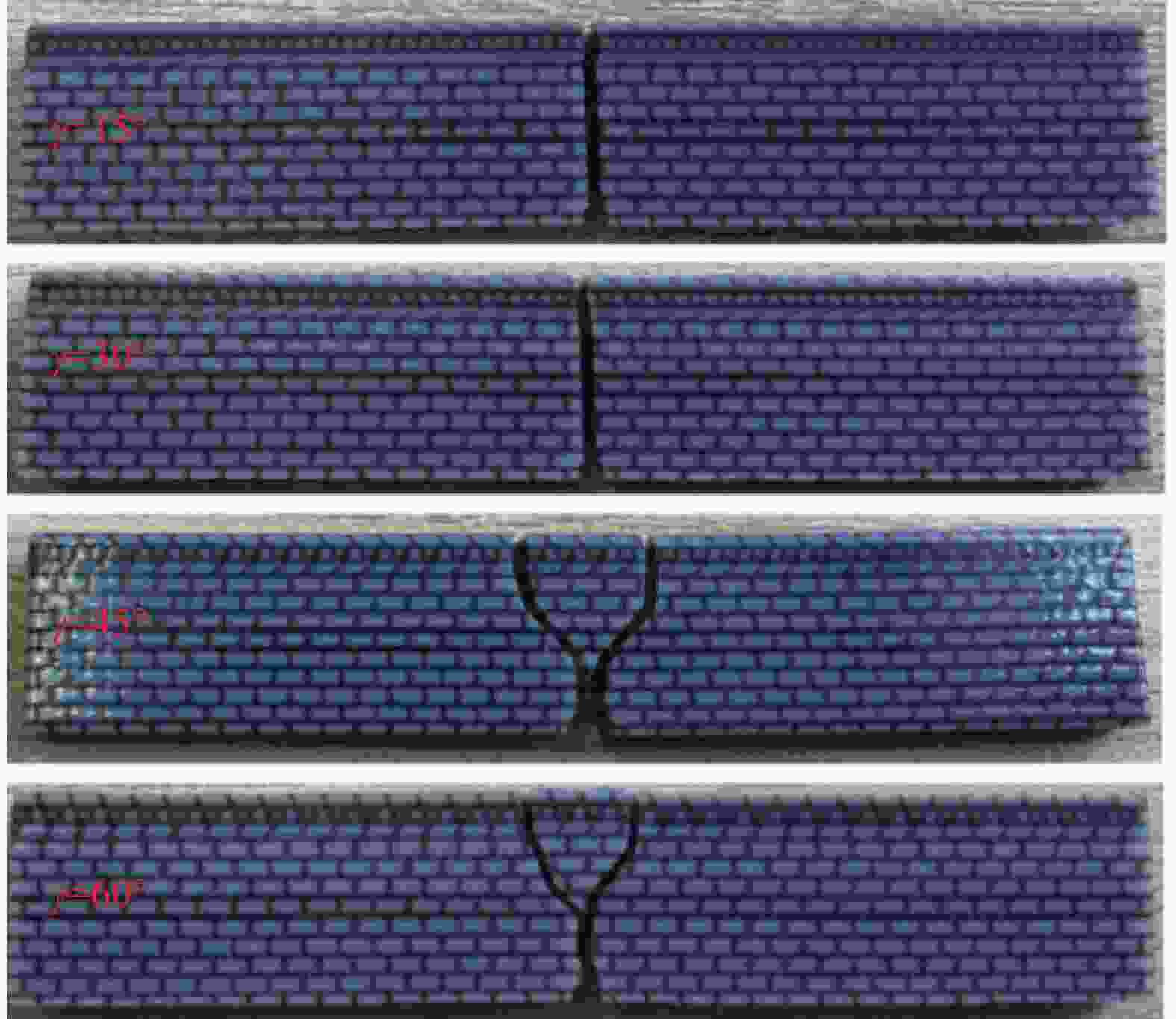

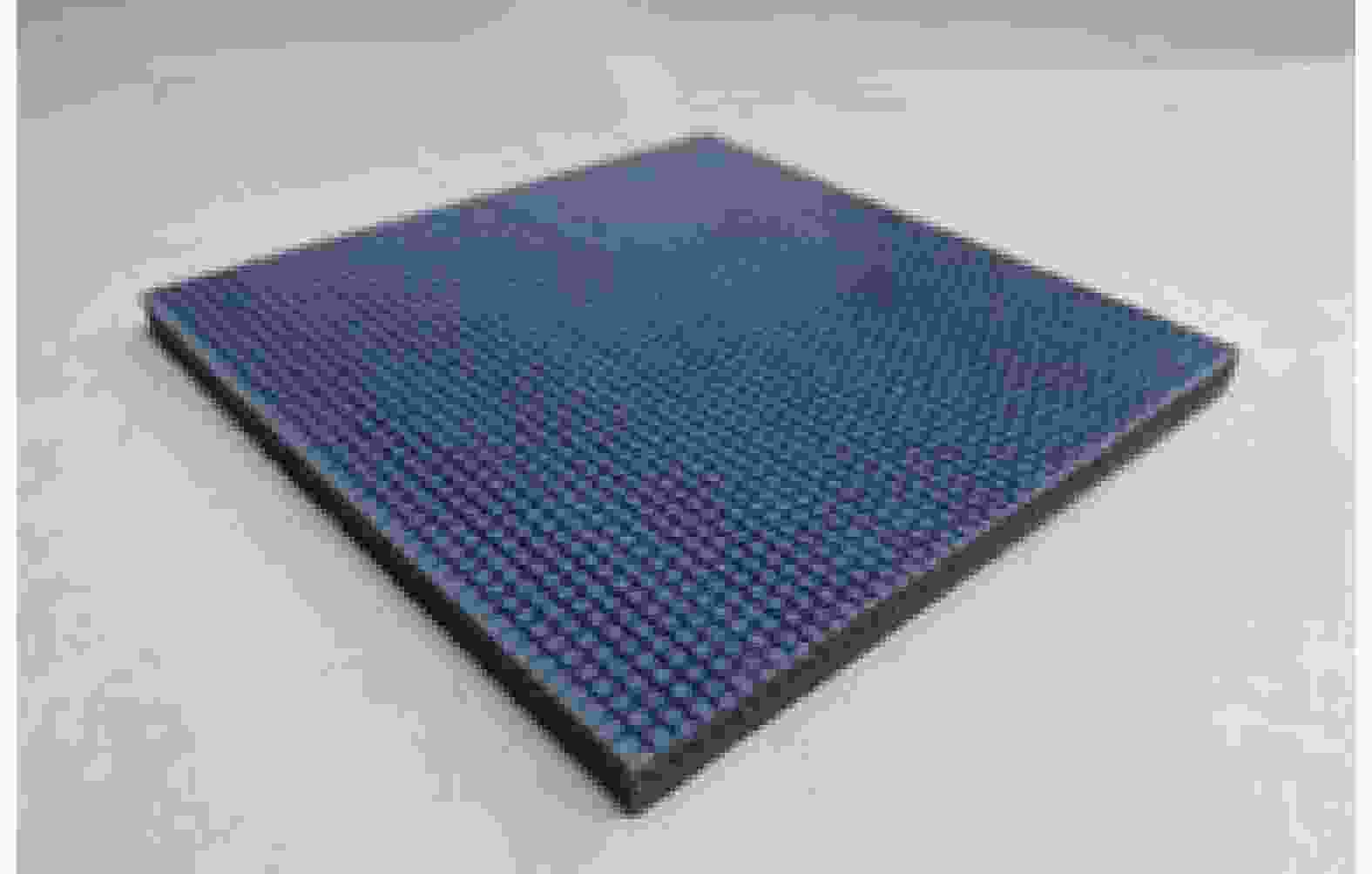

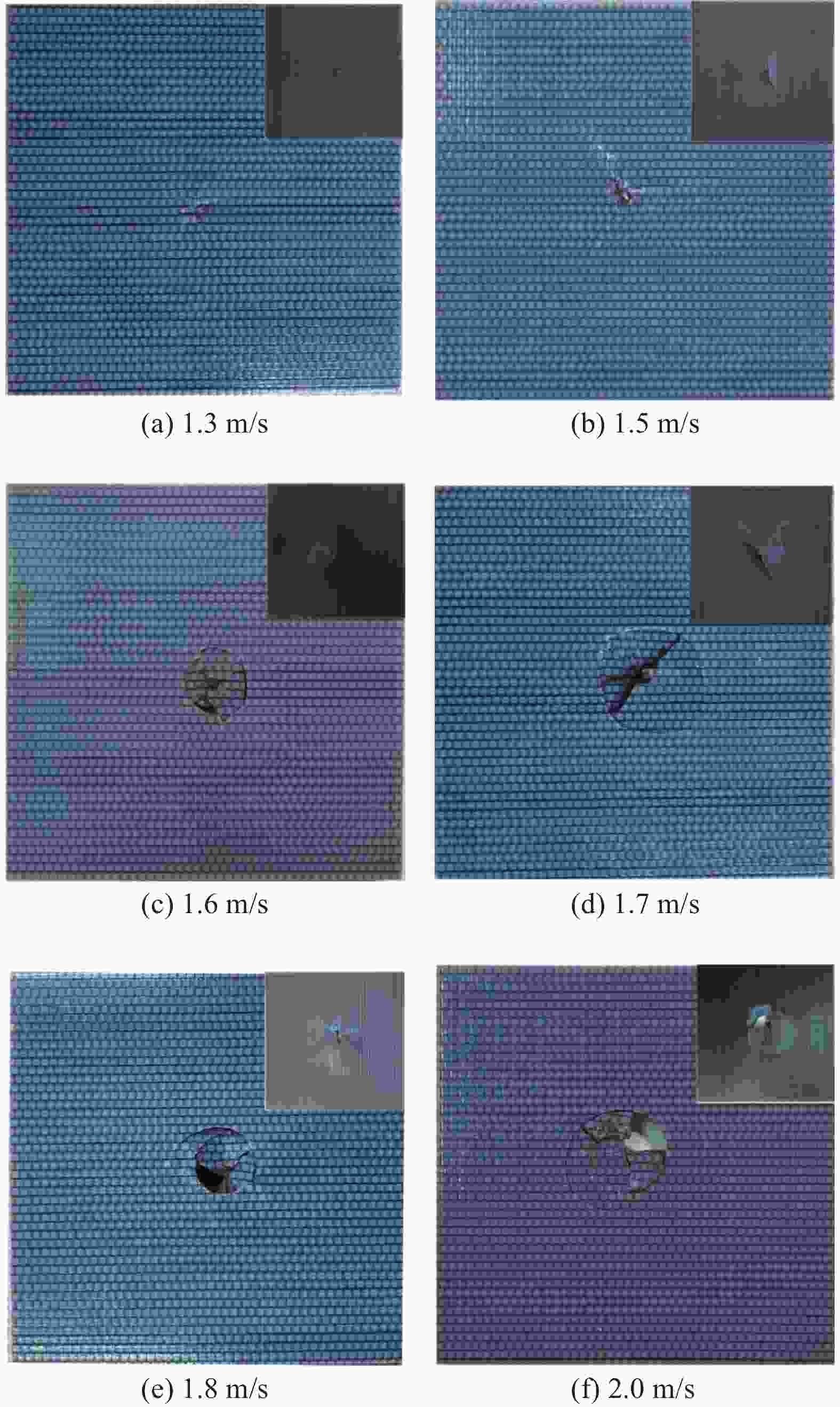

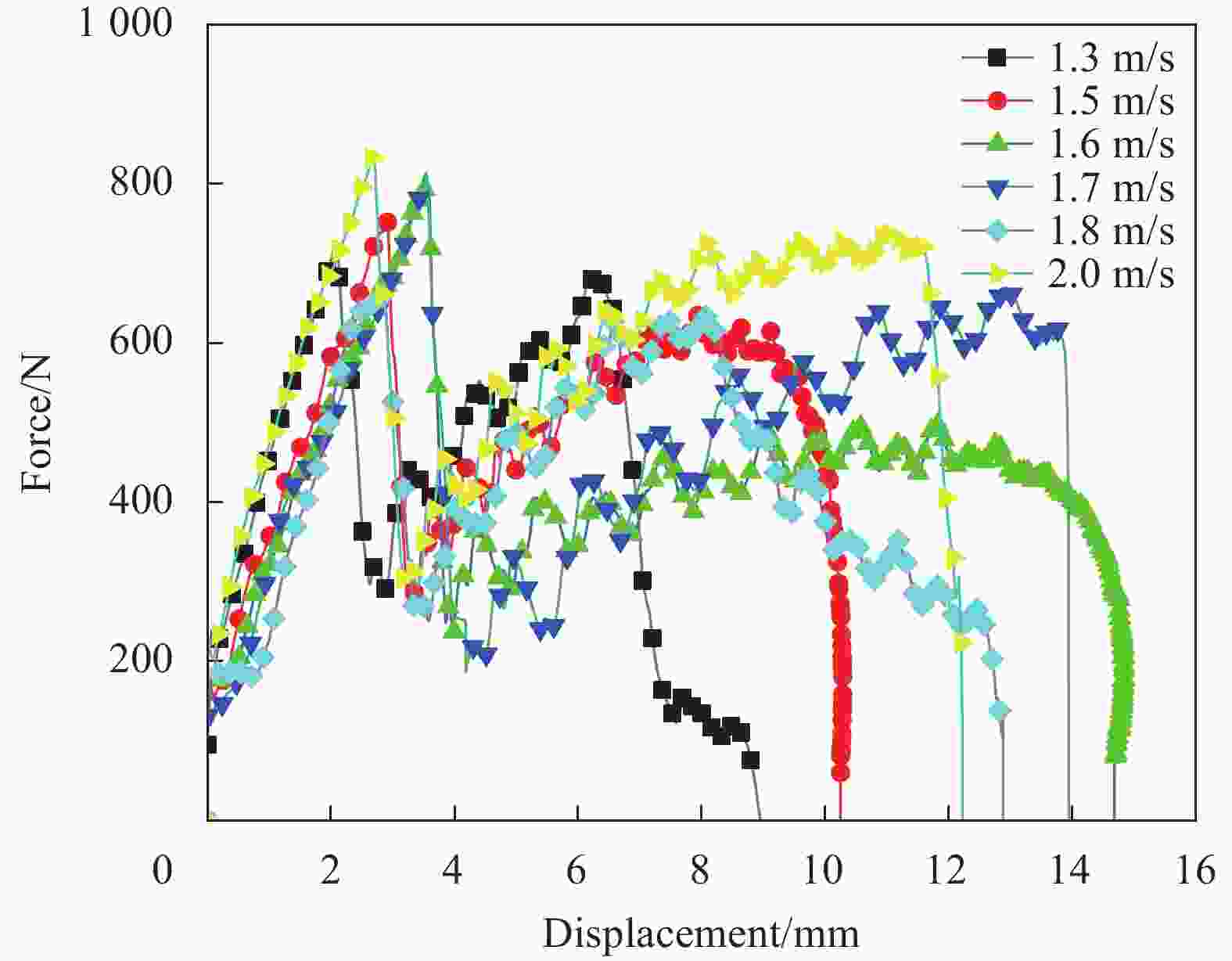

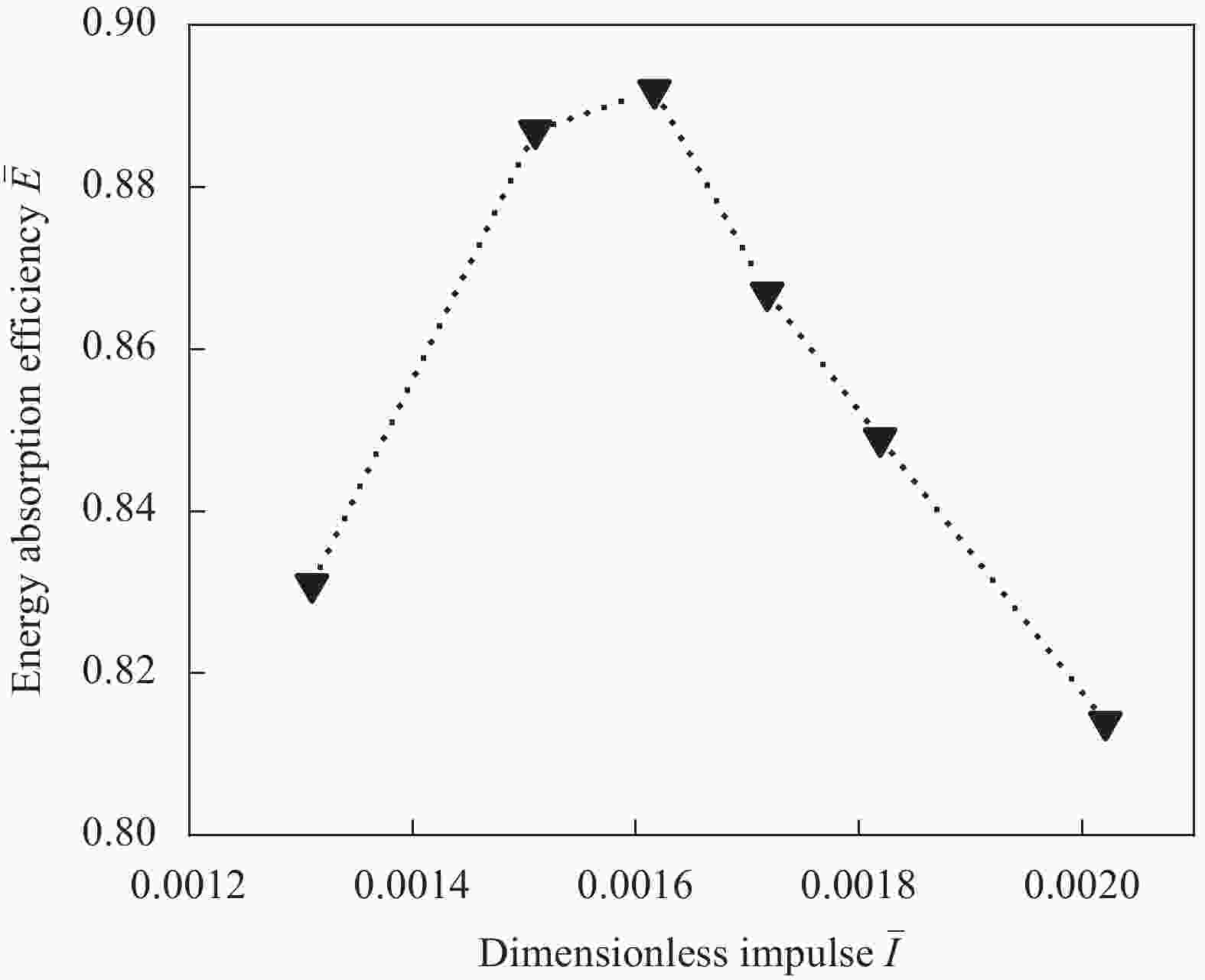

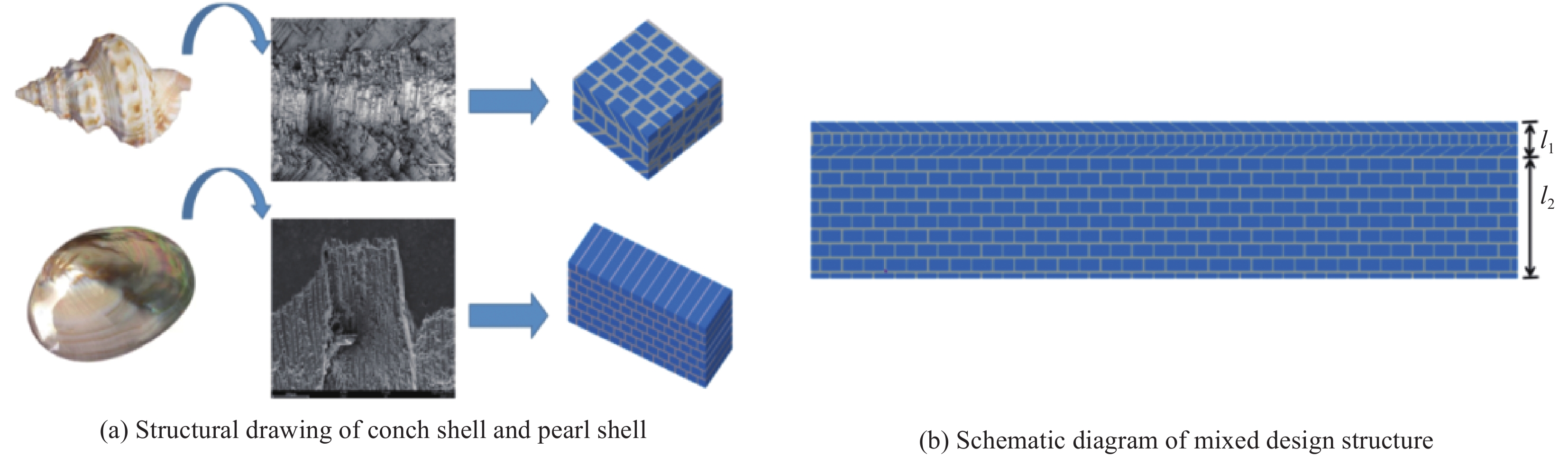

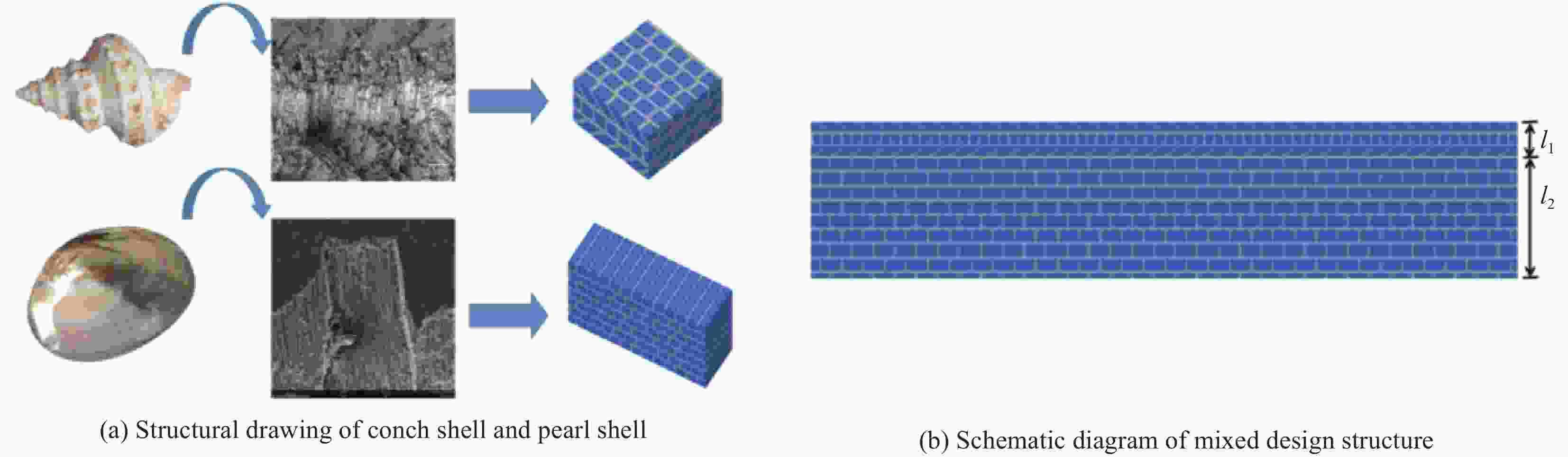

摘要: 通过静态三点弯和动态三点弯实验,研究了基于海螺壳和珍珠贝壳层的仿生混合设计复合材料在不同应变率下海螺壳单元倾斜角度对试样断裂行为的影响。使用软相和硬相两种基体材料通过3D打印技术制备4组试样,基于准静态和动态三点弯冲击实验,得到了4组试样的载荷-位移曲线和起裂功等参数。结果表明:不同应变率下结构发生不同的裂纹偏转路径,在较低的应变率下,45°样品强度高,吸能效果好,30°样品断裂韧性较好;在较高应变率下,45°样品强度与韧性较好。最后,通过落锤实验,研究了不同冲击速度对混合设计结构板破坏的影响,得到了临界破坏速度及两种破坏模式。落锤实验表明,当冲击速度达到1.8 m/s时,继续增加冲击速度至2.0 m/s对仿海螺壳-珍珠贝壳结构的动态响应无明显影响。结构起裂前吸收的能量和起裂后吸收的能量在总吸能中的占比趋于稳定。Abstract: Based on the static three-point bending and dynamic three-point bending experiments, the influence of the inclined angle of the conch shell element on the fracture behavior of the specimen under different strain rates was studied. Four groups of samples were prepared by 3D printing using two kinds of matrix materials, soft phase and hard phase. Based on quasi-static and dynamic three-point bending impact experiments, the load-displacement curves and initiation work of four groups of samples were obtained. The results show that the structure has different crack deflection paths under different strain rates. At lower strain rates, the 45° sample has higher strength, better energy absorption effect and better fracture toughness; At higher strain rate, the strength and toughness of 45° samples are better. Finally, through the drop weight experiment, the influence of different impact speeds on the failure of the mixed design structural plate was studied, and the critical failure speed and two failure modes were obtained. The drop weight experiment shows that when the impact velocity reaches 1.8 m/s, further increasing the impact velocity to 2.0 m/s has no obvious effect on the dynamic response of the structure. The proportion of the energy absorbed before the crack initiation and the energy absorbed after the crack initiation in the total energy absorption tends to be stable.

-

表 1 不同冲击速度下海螺壳结构基本单元倾斜角度为45°的仿海螺壳-珍珠贝壳复合结构(Design-1)和单一设计的珍珠贝壳层砖泥结构(Design-2)落锤测试结果

Table 1. Drop hammer test results of the sea snail shell like pearl shell composite structure (Design-1) and the single designed pearl shell layer brick mud structure (Design-2) with the basic unit inclination angle of 45° under different impact velocities

Number Composite type Impact velocity/

(m·s−1)Max load/

kNMax deflection/

mmResidual velocity/

(m·s−1)Perforated? Critical impact

energy/JDesign-1

1.3 0.752±0.1 8.9±0.4 0.0 No — 1.5 0.776±0.1 10.2±0.5 0.0 No — 1.6 0.794±0.1 14.6±1.5 0.08±0.1 Yes 6.1 1.7 0.825±0.1 13.9±1.1 0.25±0.1 Yes — 1.8 0.822±0.2 12.8±1.3 0.42±0.1 Yes — 2.0 0.836±0.1 12.2±0.8 0.55±0.2 Yes — Design-2

1.3 0.741±0.1 9.8±0.3 0.0 No — 1.5 0.762±0.1 10.9±0.4 0.09±0.1 Yes 5.4 2.0 0.818±0.1 8.9±0.5 0.61±0.3 Yes — -

[1] ZHOU B L. The biomimetic study of composite materials[J]. JOM,1994,46(2):57-62. doi: 10.1007/BF03222561 [2] ZHANG P, HEYNE M A, TO A C. Biomimetic staggered composites with highly enhanced energy dissipation: Modeling, 3D printing, and testing[J]. Journal of the Mechanics and Physics of Solids,2015,83:285-300. doi: 10.1016/j.jmps.2015.06.015 [3] 王振兴, 原梅妮, 李立州, 等. 贝壳珍珠母增韧机理研究进展[J]. 材料导报, 2015, 29(15): 98-102.WANG Zhenxing, YUAN Meini, LI Lizhou, et al. Research progress of toughening mechanisms of nacre shell[J]. Materials Review, 2015, 29(15): 98-102(in Chinese). [4] 马骁勇, 梁海弋, 王联凤. 三维打印贝壳仿生结构的力学性能[J]. 科学通报, 2016(7): 728-734.MA Xiaoyong, LIANG Haiyi, WANG Lianfeng. Multi-materials 3D printing application of shell biomimctic structure[J]. Chinese Science Bulletin, 2016, 61(7): 728-734(in Chinese). [5] 邵浩彬, 朱军, 周琦, 等. 三角帆蚌贝壳的微结构及尺寸变化特征[J]. 复合材料学报, 2019, 36(10):2398-2406.SHAO Haobin, ZHU Jun, ZHOU Qi, et al. Characteristics of microstructure and size change of the shellof Hyriopsis cumingii[J]. Acta Materiae Compositae Sinica,2019,36(10):2398-2406(in Chinese). [6] LI H Z, SHEN J H, WEI Q M, et al. Dynamic self-strengthening of a bio-nanostructured armor-conch shell[J]. Materials Science and Engineering: C,2019,103:109820. doi: 10.1016/j.msec.2019.109820 [7] HOU D F, ZHOU G S, ZHENG M. Conch shell structure and its effect on mechanical behaviors[J]. Biomaterials,2004,25(4):751-756. doi: 10.1016/S0142-9612(03)00555-6 [8] VAN L T, GHAZLAN A, NGO T, et al. Performance of a bio-mimetic 3D printed conch-like structure under quasi-static loading[J]. Composite Structures,2020,246:112433. doi: 10.1016/j.compstruct.2020.112433 [9] MENIG R, MEYERS M H, MEYERS M A, et al. Quasi-static and dynamic mechanical response of Strombus gigas (conch) shells[J]. Materials Science and Engineering: A,2001,297(1-2):203-211. doi: 10.1016/S0921-5093(00)01228-4 [10] KAMAT S, SU X, BALLARINI R, et al. Structural basis for the fracture toughness of the shell of the conch Strombus gigas[J]. Nature,2000,405(6790):1036-1040. doi: 10.1038/35016535 [11] KUHN-SPEARING L T, KESSLER H, CHATEAU E, et al. Fracture mechanisms of the Strombus gigas conch shell: Implications for the design of brittle laminates[J]. Journal of Materials Science,1996,31(24):6583-6594. doi: 10.1007/BF00356266 [12] GU G X, TAKAFFOLI M, HSIEH A J, et al. Biomimetic additive manufactured polymer composites for improved impact resistance[J]. Extreme Mechanics Letters,2016,9:317-323. doi: 10.1016/j.eml.2016.09.006 [13] GU G X, TAKAFFOLI M, BUEHLER M J. Hierarchically enhanced impact resistance of bioinspired composites[J]. Advanced Materials,2017,29(28):1700060. doi: 10.1002/adma.201700060 [14] JIA Z A, YU Y, HOU S Y, et al. Biomimetic architected materials with improved dynamic performance[J]. Journal of the Mechanics and Physics of Solids,2019,125:178-197. doi: 10.1016/j.jmps.2018.12.015 [15] JIA Z A, YU Y, WANG L F. Learning from nature: Use material architecture to break the performance tradeoffs[J]. Materials & Design,2019,168:107650. [16] BARTHELAT F, TANG H, ZAVATTIERI P D, et al. On the mechanics of mother-of-pearl: A key feature in the material hierarchical structure[J]. Journal of the Mechanics and Physics of Solids,2007,55(2):306-337. doi: 10.1016/j.jmps.2006.07.007 [17] BRUET B J F, SONG J H, BOYCE M C, et al. Materials design principles of ancient fish armour[J]. Nature Materials,2008,7(9):748-756. doi: 10.1038/nmat2231 [18] WEAVER J C, MILLIRON G W, MISEREZ A, et al. The stomatopod dactyl club: A formidable damage-tolerant biological hammer[J]. Science,2012,336(6086):1275-1280. doi: 10.1126/science.1218764 [19] WANG B, YANG W, SHERMAN V R, et al. Pangolin armor: Overlapping, structure, and mechanical properties of the keratinous scales[J]. Acta Biomaterialia,2016,41:60-74. doi: 10.1016/j.actbio.2016.05.028 [20] WU X D, MENG X S, ZHANG H G. An experimental investigation of the dynamic fracture behavior of 3D printed nacre-like composites[J]. Journal of the Mechanical Behavior of Biomedical Materials,2020,112:104068. doi: 10.1016/j.jmbbm.2020.104068 [21] ŁODYGOWSKI T, RUSINEK A. Constitutive relations under impact loadings[M]. Udine: CISM International Centre for Mechanical Sciences, 2014. [22] 马小敏, 李世强, 李鑫, 等. 编织Kevlar/Epoxy复合材料层合板在冲击荷载下的动态响应[J]. 爆炸与冲击, 2016, 36(2):170-176. doi: 10.11883/1001-1455(2016)02-0170-07MA Xiaomin, LI Shiqiang, LI Xin, et al. Dynamic response of woven Kevlar/Epoxy composite laminates under impact loading[J]. Explosion and Shock Waves,2016,36(2):170-176(in Chinese). doi: 10.11883/1001-1455(2016)02-0170-07 -

下载:

下载: