Preparation process optimization and performance of pre-impregnated yarn for dry winding

-

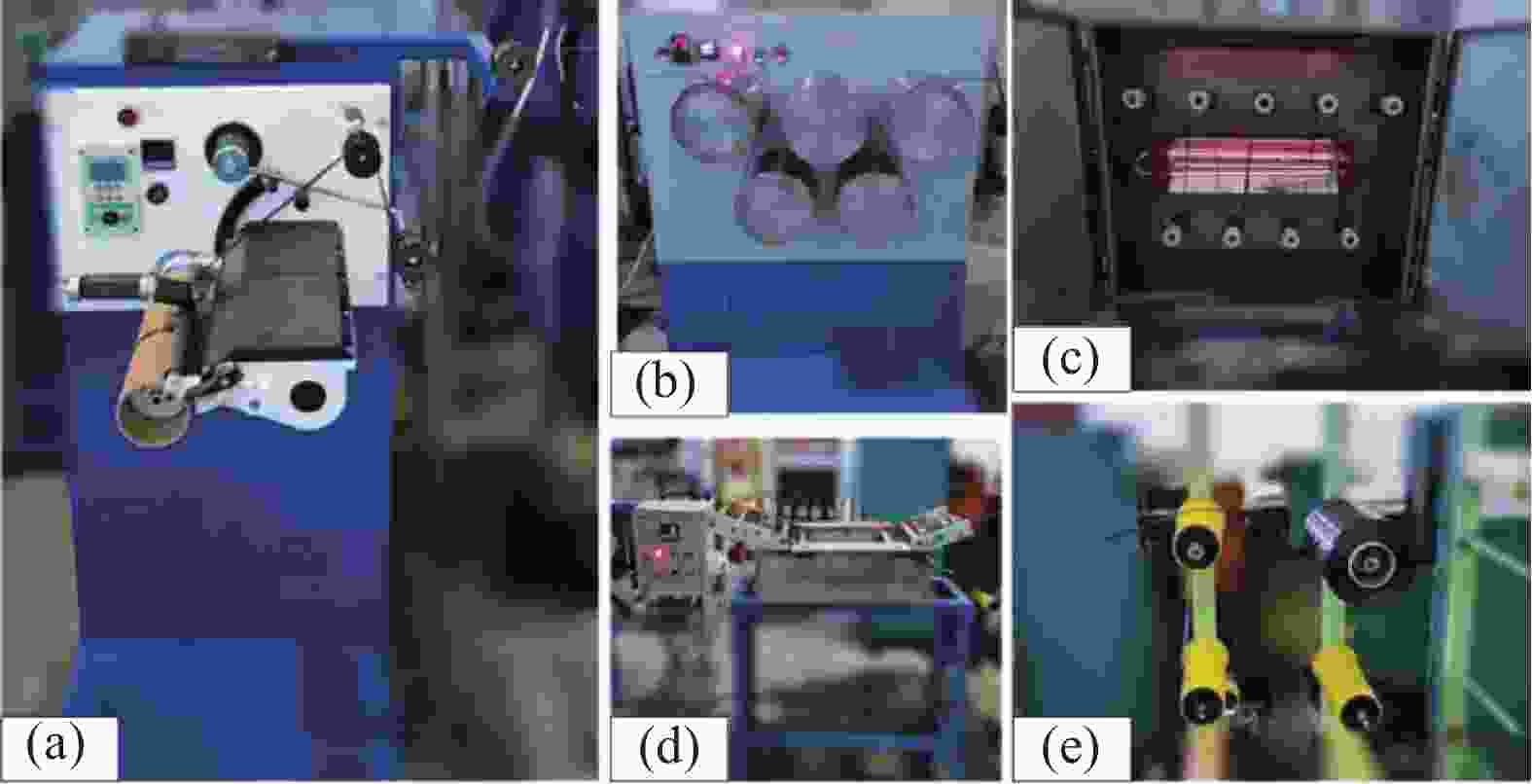

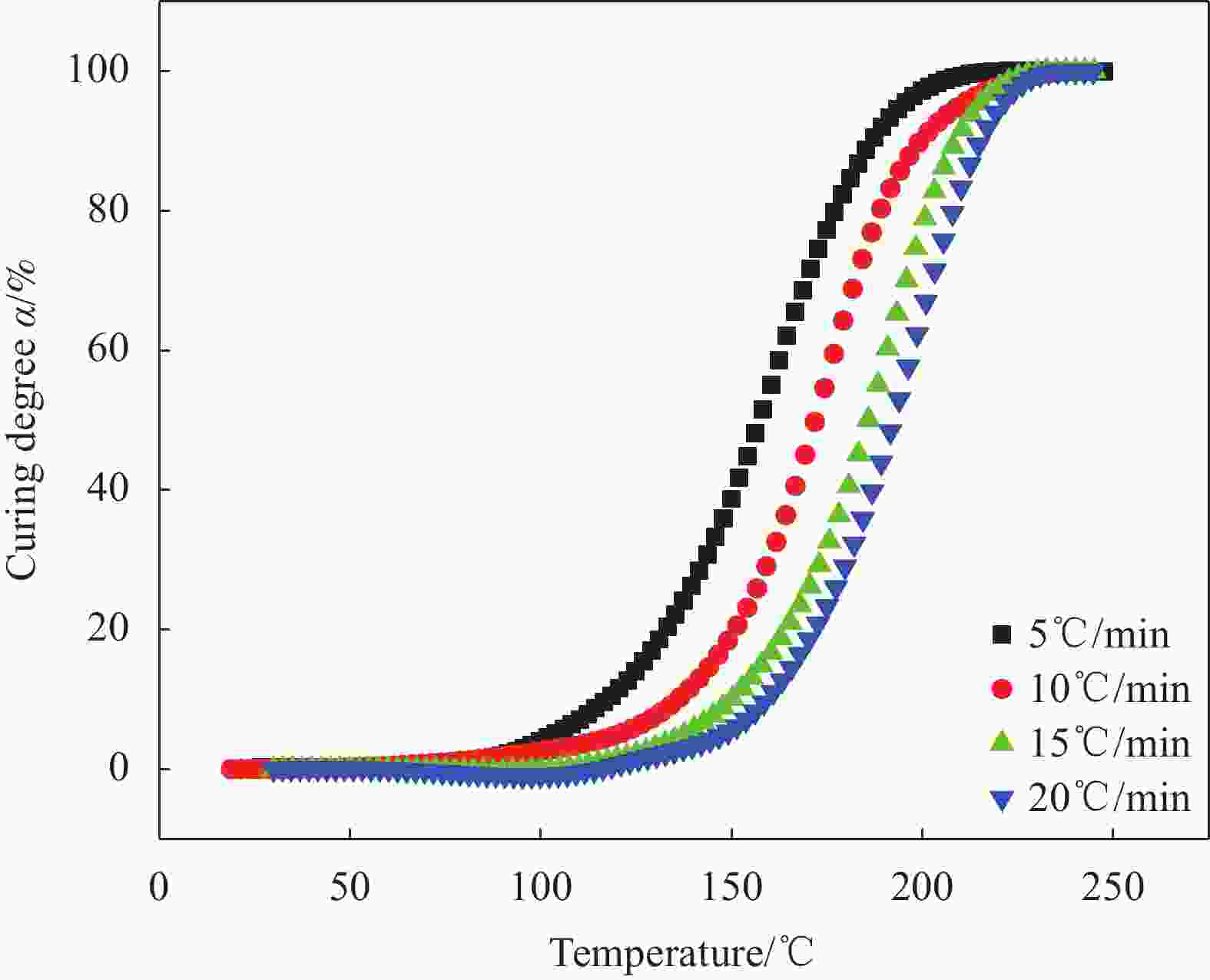

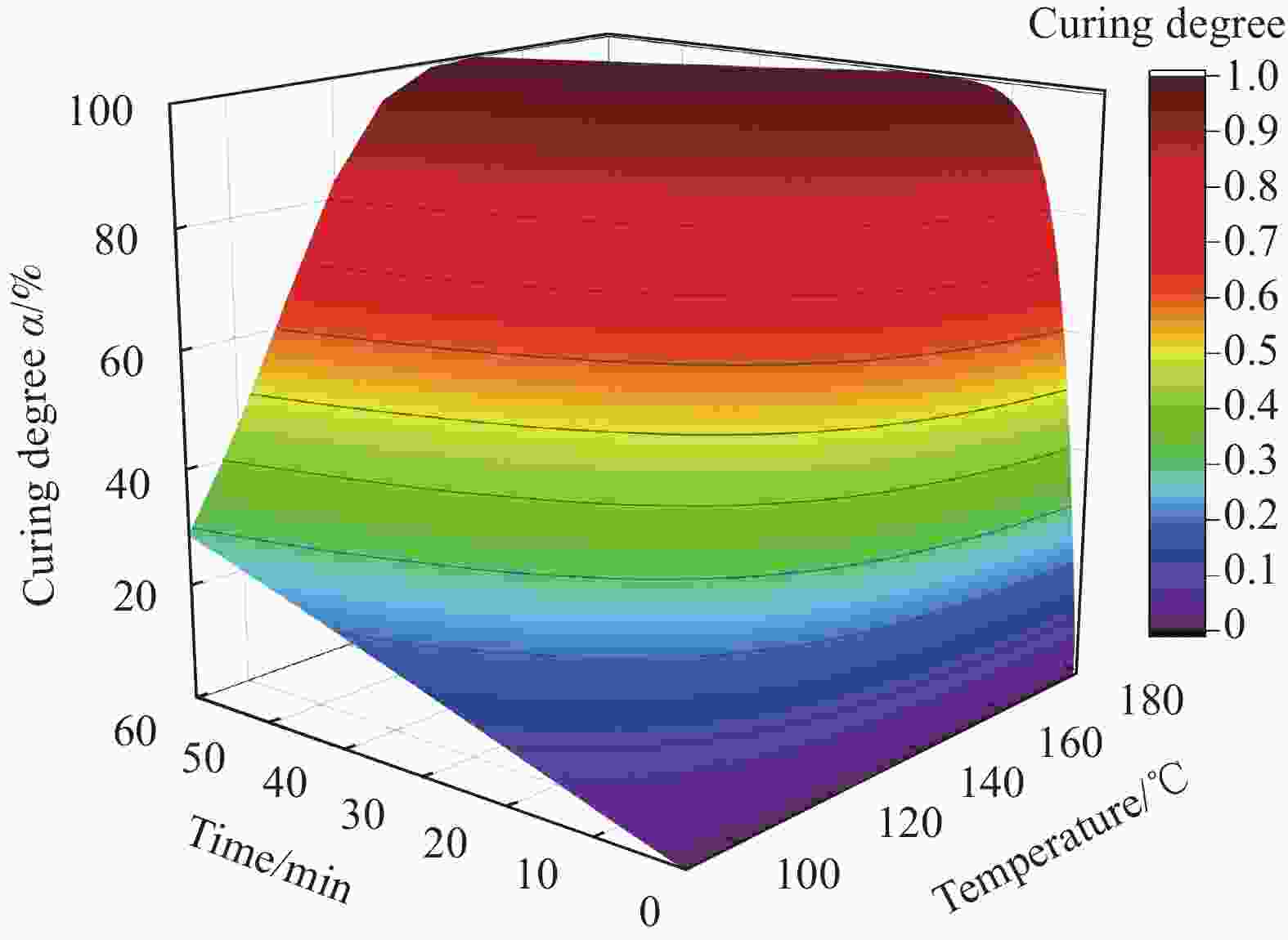

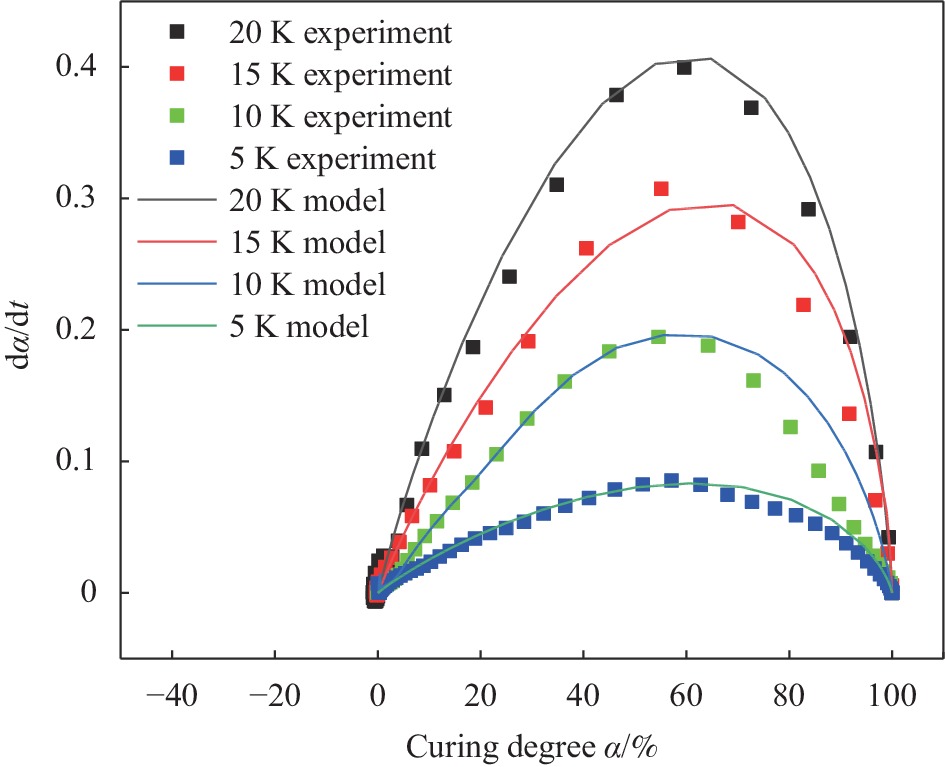

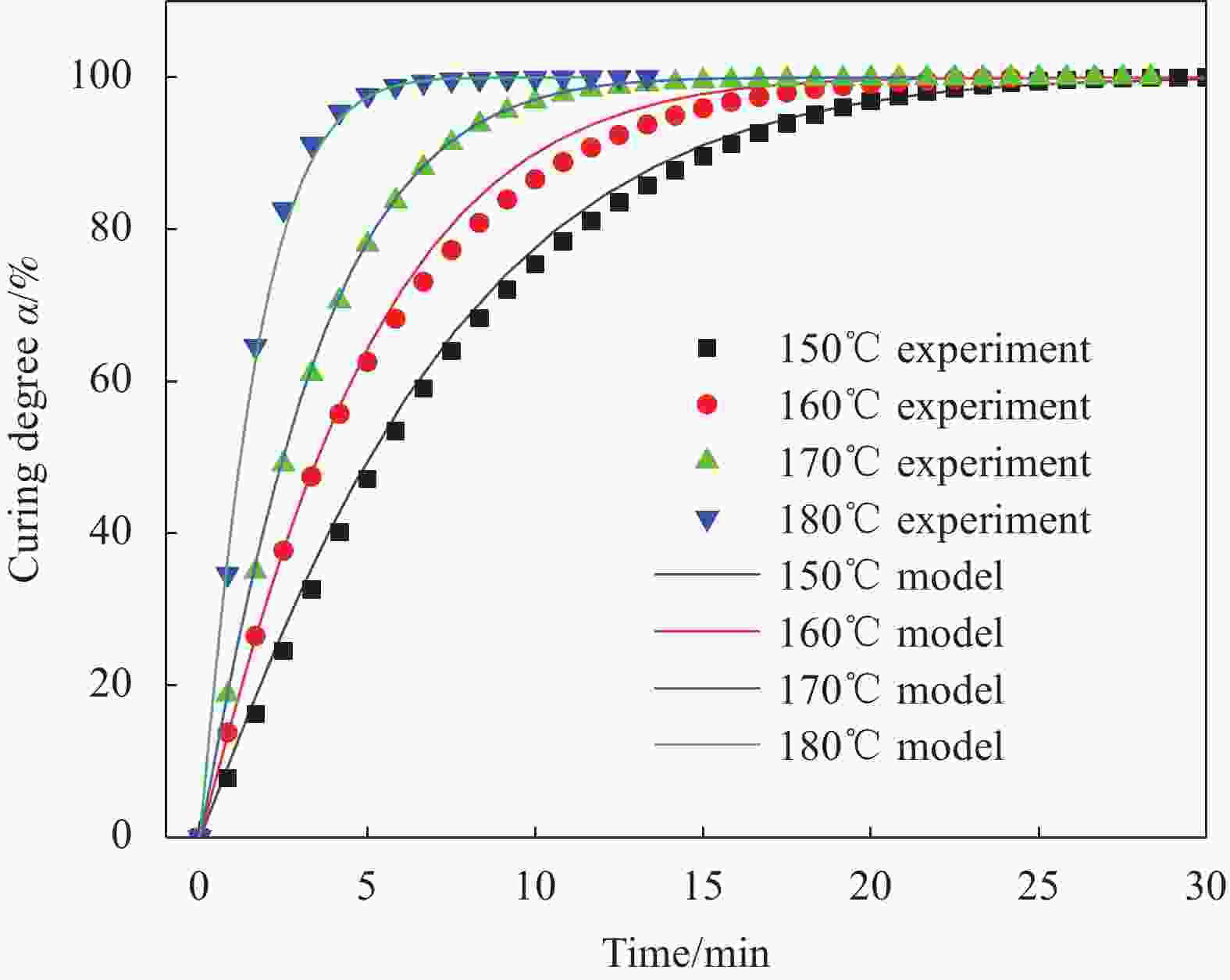

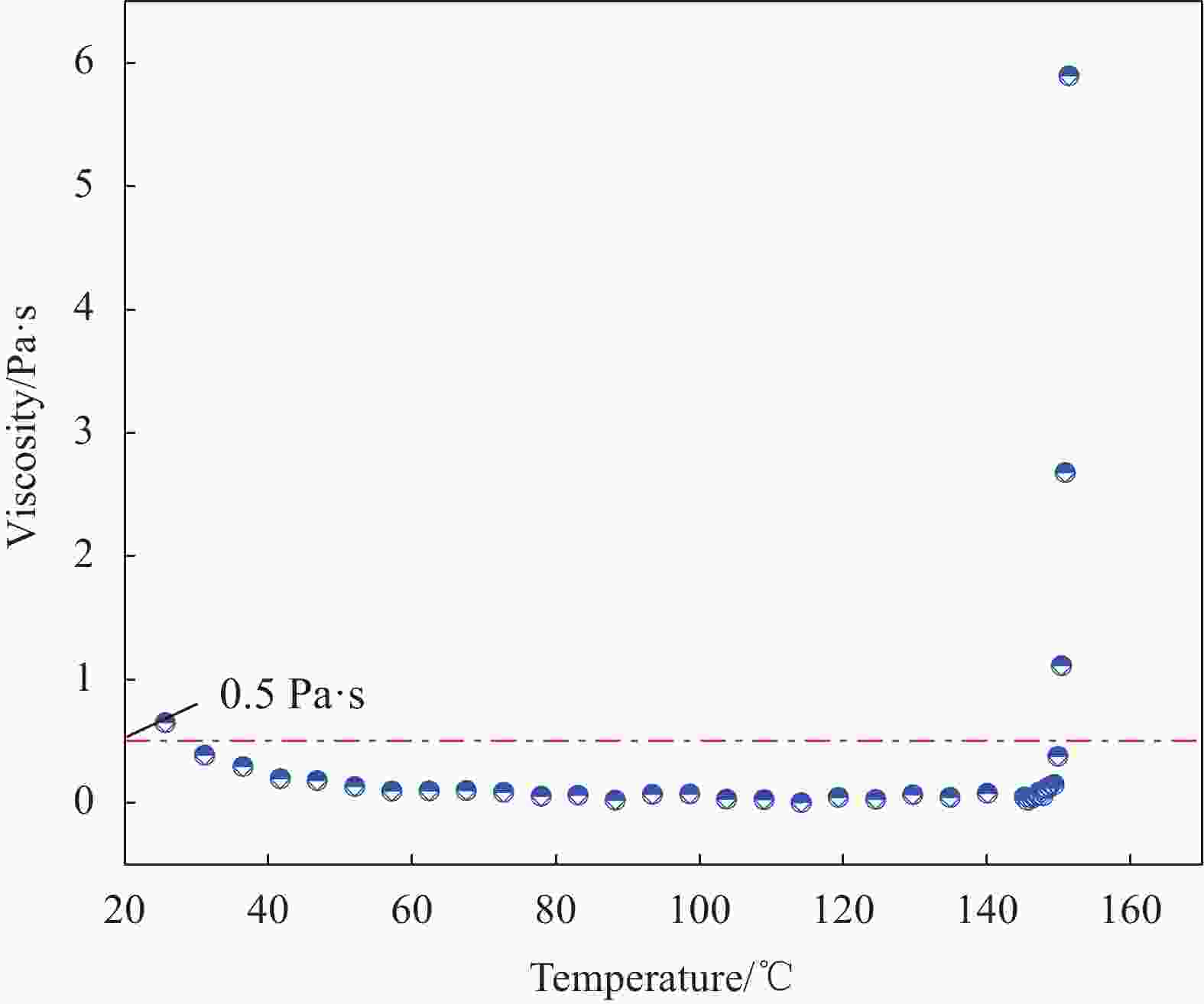

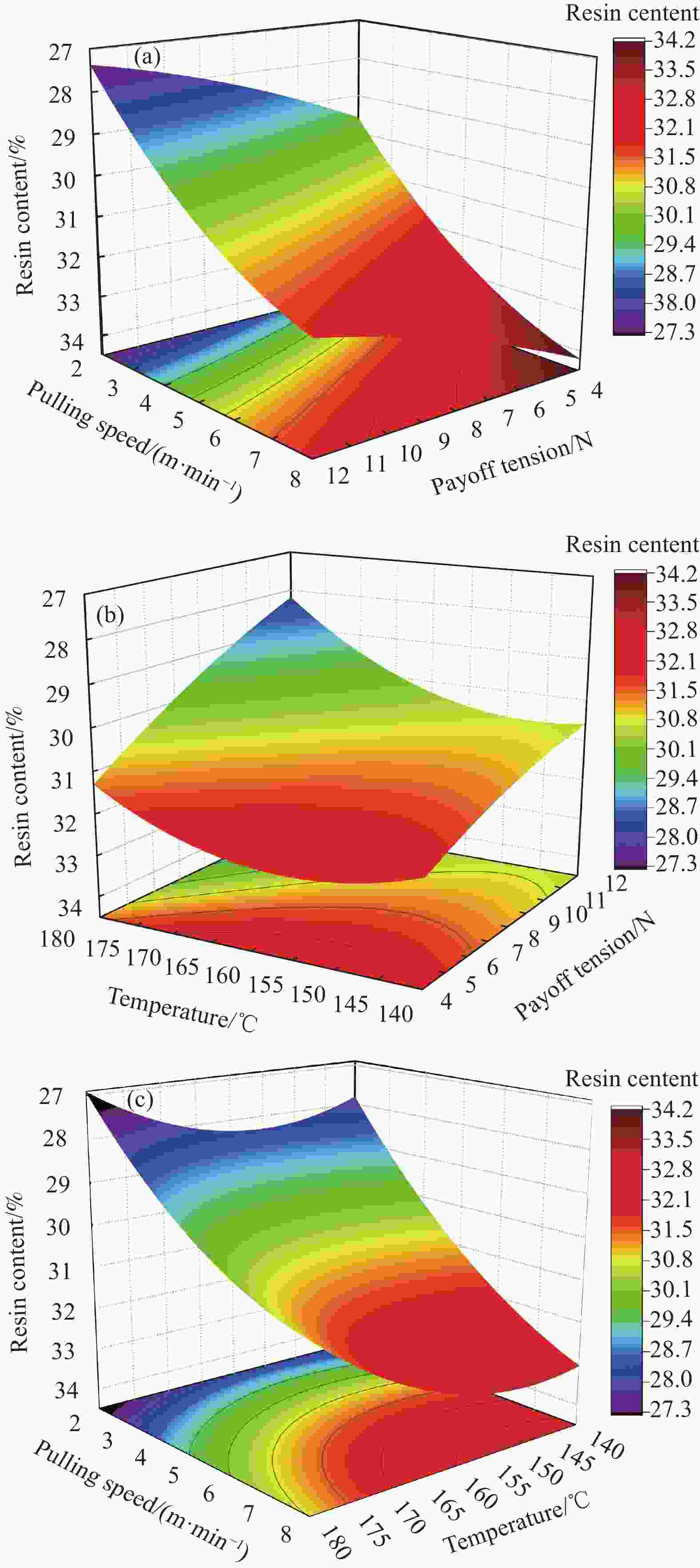

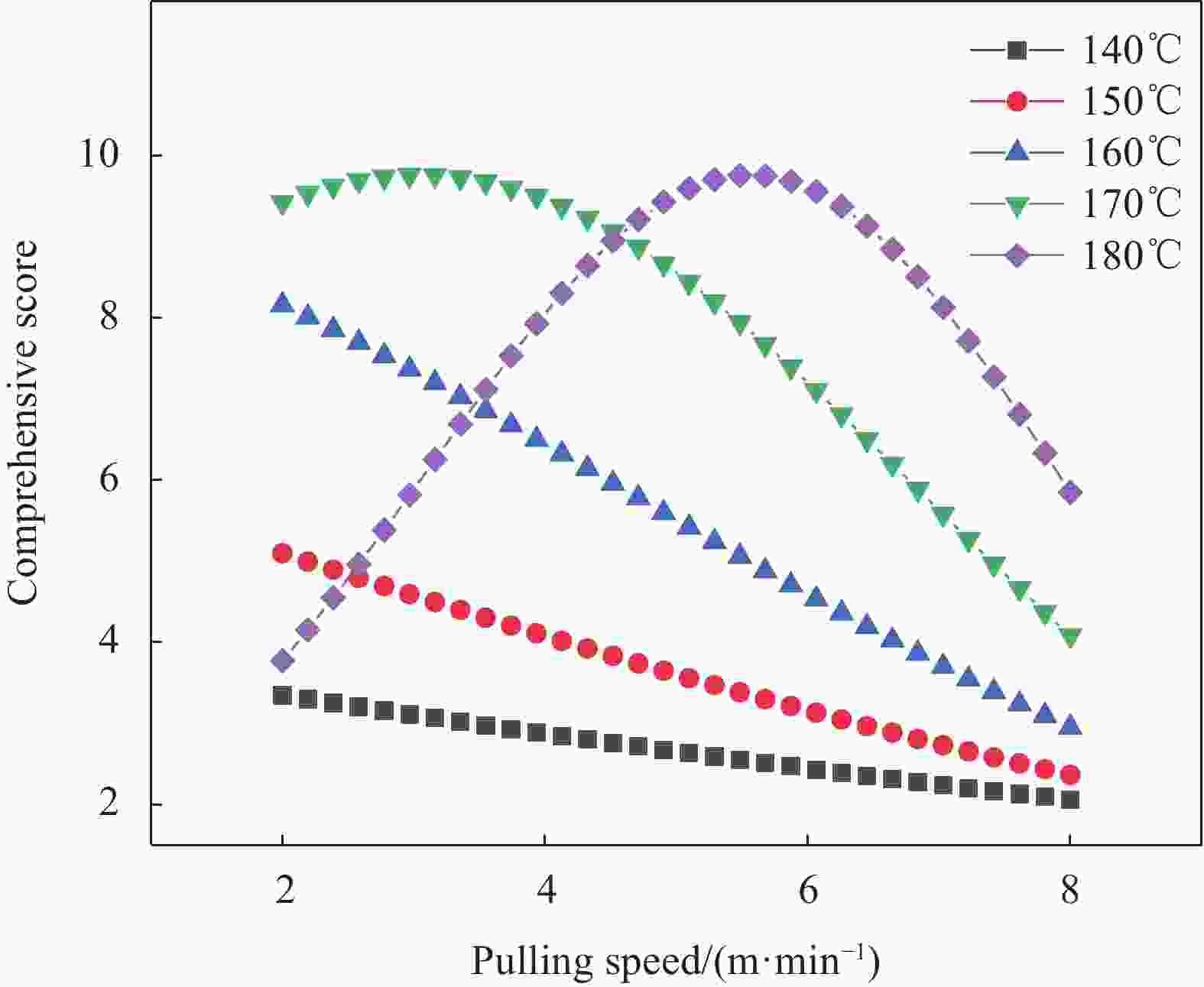

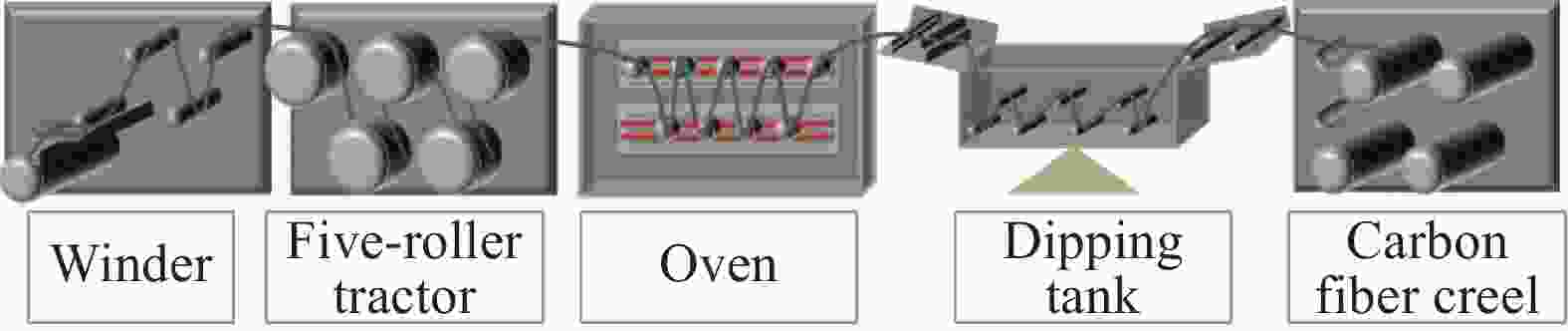

摘要: 干法缠绕是缠绕成型工艺的重要分支,其缠绕过程含胶量均匀、缠绕效率高、环境污染小,更容易实现工业自动化生产。开发具有良好加工性能的预浸纱,对干法缠绕的推广应用具有重要意义。通过动态DSC和恒温DSC,结合流变测试,研究了所用环氧树脂体系固化特性,基于自催化模型建立树脂固化反应动力学方程,并与实测固化度对比验证。搭建预浸纱制备平台,采用改进热熔法制备干法缠绕用预浸纱,分析制备过程中不同固化度对预浸纱表面质量的影响。在此基础上通过响应面法分析不同工艺参数(纱架张力、收卷速率、烘道温度)对预浸纱含胶量的影响。结果表明:自催化模型与实验结果基本吻合,适用于干法缠绕预浸纱最佳固化度范围为5%~10%,对含胶量影响最大的因子是收卷速率,其次是放纱张力,烘道温度影响最小。综合考虑各工艺参数影响规律,获得优化的制备工艺参数:烘道温度为180℃,收卷速率为8 m/min,放纱张力为6 N,此时树脂含胶量为30.1wt%。NOL环拉伸强度可达2536.1 MPa,拉伸模量为162.3 GPa,层间剪切强度为57.3 MPa。Abstract: Dry winding is an important branch of the winding forming process. The winding process has uniform glue content, high winding efficiency, low environmental pollution and easier industrial automation production. The development of prepreg yarn with good processing properties is of great significance to the promotion and application of dry winding. Through dynamic DSC and constant temperature DSC, combined with the viscosity test, the curing characteristics of the epoxy resin system used were studied. Based on the autocatalytic model, the resin curing reaction kinetic equation was established and verified by comparison with the measured curing degree. A prepreg yarn preparation platform was set up, an improved hot-melt method to prepare dry winding prepreg yarn was adopted, and the influence of different curing degrees on the surface quality of prepreg yarn during the preparation process was analyzed. On this basis, the response surface method was used to analyze the influence of different process parameters (creel tension, winding speed, drying tunnel temperature) on the glue content of the prepreg yarn. The results show that the autocatalytic model is basically consistent with the experimental results, and the best curing range for dry winding prepreg yarn is 5%-10%. The factor that has the greatest influence on the glue content is the winding rate, followed by the unwinding tension. The temperature of the drying tunnel has the least influence. Considering the influence law of various process parameters, the optimized preparation process parameters are obtained: The temperature of the drying tunnel is 180℃, the winding speed is 8 m/min, the yarn unwinding tension is 6 N, and the resin mass fraction is 30.1wt% at this time. The tensile strength of the NOL ring can reach 2536.1 MPa, the tensile modulus is 162.3 GPa, and the interlaminar shear strength is 57.3 MPa.

-

Key words:

- drying winding /

- prepreg yarn /

- hot-melt process /

- resin content /

- curing reaction kinetics

-

表 1 HY-230树脂不同升温速度下特征温度

Table 1. Parameters for the non-isothermal curing reaction thermogram of HY230

Heat rating β

/(℃·min−1)Tonset

/℃TP

/℃Tend

/℃5 123 162 199 10 129 185 214 15 141 189 227 20 149 197 235 Notes: Tonset—Temperature at onset point; TP—Temperature at peak point; Tend—Temperature at end point. 表 2 HY230环氧树脂体系多重线性回归参数

Table 2. Multiple linear regression parameters of HY230 epoxy resin system

Heat rating/(℃·min−1) m n lnA 5 1.03 0.09 14.01 10 0.95 0.05 14.14 15 0.74 0.10 14.40 20 0.84 0.06 14.48 表 3 HY230环氧树脂适用期

Table 3. HY230 epoxy resin pot life

Temperature/℃ Gel time/h Shelf life/d −18 8383.9 174.6 0 1257.8 26.2 25 131.9 2.7 表 4 不同固化度预浸纱制备实验方案

Table 4. Preparation experiment plan of prepregs with different curing degrees

Curing degree

/%Pulling speed

/(m·min−1)Temperature

/℃0 2 0 5 0.5 130 10 2 170 15 0.5 150 20 1 170 25 0.5 160 表 5 不同固化度预浸纱表面情况

Table 5. Surface quality of prepregs with different curing degrees

Curing degree

/%Wetness

indexGlutinosity 0 Serious Low 5 Slightly moist Slightly adhesive 10 Moderate Moderate 15 Slightly dry Relatively adhesive 20 Relatively drier Seriously adhesive 25 Tow curing Not sticky 表 6 预浸纱制备工艺参数

Table 6. Process parameters of prepreg yarn preparation

Parameter Payoff

tension/NPulling speed/

(m·min−1)Temperature/

℃Range 4-12 2-8 140-180 表 7 预浸纱制备工艺Box-Behnken实验设计因素与水平

Table 7. Levels of factors by Box-Behnken design of prepreg yarn preparation

Code Factor Level −1 0 1 A Payoff tension/N 4 8 12 B Pulling speed/(m·min−1) 2 5 8 C Temperature/℃ 140 160 180 Notes: −1—Code of minimum value of process parameter range; 0—Code of middle value of process parameter range; 1—Code of maximum value of process parameter range. 表 8 预浸纱制备工艺Box-Behnken实验结果

Table 8. Results of Box-Behnken experiment for prepreg yarn preparation

Number Payoff tension/N Pulling speed/

(m·min−1)Tempera-ture/℃ Resin content/% 1 0 0 0 30.62 2 1 0 1 27.77 3 0 0 0 32.08 4 −1 0 1 30.97 5 −1 0 −1 32.46 6 1 1 0 31.71 7 0 0 0 31.58 8 1 0 −1 30.92 9 1 −1 0 27.58 10 0 −1 1 27.10 11 0 0 0 30.75 12 0 1 −1 32.85 13 0 −1 −1 27.26 14 0 0 0 31.00 15 0 1 1 31.33 16 −1 1 0 33.98 17 −1 −1 0 29.73 表 9 T700/HY230含胶量模型方差分析

Table 9. Variance analysis of regression equation of T700/HY230 prepreg yarn

Source Sum of squares Df Mean square F-

valueP-

valueSignifi-

canceModel 63.70 9 7.08 17.29 0.0005 ** A 10.49 1 10.49 25.63 0.0015 ** B 41.41 1 41.41 101.17 <0.0001 *** C 4.99 1 4.99 12.20 0.0101 * AB 0.0036 1 0.0036 0.0087 0.9279 - AC 0.69 1 0.69 1.68 0.2356 - BC 0.46 1 0.46 1.13 0.3231 - A2 0.20 1 0.20 0.50 0.5041 - B2 1.92 1 1.92 4.69 0.0669 - C2 3.38 1 3.38 8.25 0.0239 * Residual 2.86 7 0.41 - - - Lack of fit 1.37 3 0.46 1.22 0.4118 - Pure error 1.50 4 0.37 - - - Cor total 66.56 16 - - - - Notes: Df—Degree freedom; F-value—Ratio of the mean square to the residual term; P-value—Influence degree value of each factor; ***—Significant in [−∞, 0.0001]; **—Significant in [0.0001, 0.01]; *—Significant in [0.01, 0.05]. 表 10 T700/H230预浸纱NOL环力学性能测试结果

Table 10. Interlaminar shear strength and tensile strength of T700/HY230 prepreg yarn NOL rings

Parameter Resin

content/

wt%Ring shear

strength/

GPaTensile

strength/

MPaTensile

modulus/

GPaAverage value 30.1 57.3 2536.1 162.3 Standard deviation 0.9 4.3 76.6 41.1 -

[1] PARK Y, HWANG T K, CHUNG S, et al. Recent research trends in carbon fiber tow prepreg for advanced compo-sites[J]. Journal of the Korean Society of Propulsion Engineers,2017,21(2):94-101. doi: 10.6108/KSPE.2017.21.2.094 [2] 谢飞. 热熔法制备自动铺丝预浸纱的展开技术研究[D]. 南京: 南京航空航天大学, 2015.XIE Fei. Research on spreading technology in preparation of prepreg for automated fiber placement by hot-melt method[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015(in Chinese). [3] VANHATTUM F, NUNES J P, BERNARDO C A. A theoretical and experimental study of new towpreg-based long fibre thermoplastic composites[J]. Composites Part A: Applied Science and Manufacturing,2005,36(1):25-32. doi: 10.1016/j.compositesa.2004.06.031 [4] POULADVAND A, MORTEZAEI M, JAHANI M. Carbon-epoxy towpreg: Challenges, advantages and disadvantages[C]. ISFAHAN: The 5th National Seminar on Polymer, 2019. [5] MIKITINSKIY A P, LOBOV B N, VALYUKEVICH Y A, et al. Selecting the engine power while the dry winding of the composite material[J]. Iop Conference Series: Materials Science and Engineering,2021,1029(1):12113. [6] 邱伟娟. M46J/QY8911-II复合材料预浸纱制备与缠绕技术研究[D]. 南京: 南京航空航天大学, 2002.QIU Weijuan. Study on preparation of prepreg strands and filament winding technology of M46J/QY8911-II compo-site materials[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2002(in Chinese). [7] 欧汉文. 阻燃改性环氧树脂的研究及其预浸纱的开发[D]. 上海: 东华大学, 2020.OU Hanwen. Research on the flame retardant modified epoxy resin and the prepreg yarn[D]. Shanghai: Donghua University, 2020(in Chinese). [8] 陈浩然. T700/PEEK预浸纱制备的浸渍机理及工艺优化[D]: 南京: 南京航空航天大学, 2018.CHEN Haoran. Impregnation mechanism and craft optimization of T700/PEEK prepreg processing[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018(in Chinese). [9] IRFAN M S, MACHAVARAM V, MAHENDRAN R S, et al. Lateral spreading of a fiber bundle via mechanical means[J]. Journal of Composite Materials,2011,46(3):311-330. [10] HOPMANN C, WILMS E, BESTE C, et al. Investigation of the influence of melt-impregnation parameters on the morphology of thermoplastic Ud-tapes and a method for quantifying the same[J]. Journal of Thermoplastic Composite Materials,2019, 34(9)::1299-1312. [11] 蔡志强, 肖军, 文立伟, 等. 基于预浸纱自动铺放缺陷的分割算法[J]. 航空材料学报, 2017, 37(2): 21-27.CAI Zhiqiang, XIAO Jun, WEN Liwei, et al. Lgorithm of defect segmentation for AFP based on prepregs [J]. Journal of Aeronautical Materials, 2017, 37(2): 21-27(in Chinese). [12] 文立伟, 王若舟, 谢飞. 通过调节工艺参数控制热熔法制备的自动铺丝预浸纱的展开质量[J]. 材料导报, 2019, 33(S2):599-603.WEN Liwei, WANG Ruozhou, XIE Fei. Improving lateral spreading quality by adjusting hot-melt process parameters applied in automated fiber placement[J]. Materials Reports,2019,33(S2):599-603(in Chinese). [13] 中国国家标准化管理委员会. 纤维缠绕增强塑料环形试样力学性能试验方法: GB/T 1458—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Test method for mechanical properties of ring of filament-winding reinforced plastics: GB/T 1458—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [14] 陶雷, 闵伟, 戚亮亮, 等. 增韧改性环氧树脂固化动力学研究及TTT图绘制[J]. 复合材料科学与工程, 2020, 321(10):21-29. doi: 10.3969/j.issn.1003-0999.2020.10.003TAO Lei, MIN Wei, QI Liangliang, et al. Study on curing kinetics of toughened modified epoxy resin and drawing of TTT diagram[J]. Composite Materials Science and Engineering,2020,321(10):21-29(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.10.003 [15] 胡建华. 含DOPO阻燃环氧树脂的固化动力学研究[D]. 广州: 华南理工大学, 2015.HU Jianhua. Curing kinetics of flame retardant epoxy resins with DOPO[D]. Guangzhou: South China University of Technology, 2015(in Chinese). [16] NEUNKIRCHEN S, SCHLEDJEWSKI R. Tack measurement of bindered rovings for the dry fiber winding process[J]. Polymer Composites, 2021: 42(9): 4607-4616. [17] 高腾龙, 余建虎, 许英杰. 碳纤维/环氧树脂预浸料固化动力学建模研究[J]. 机械科学与技术, 2022, 41(7): 1128-1137.GAO Tenglong, YU Jianhu, XU Yingjie. Dynamic modeling of curing process of carbon/epoxy prepreg [J]. Mechanical Science and Technology for Aerospace Engineering, 2022, 41(7): 1128-1137(in Chinese). [18] 毕全瑞. 特高压电气设备用环氧树脂/氧化铝复合绝缘材料的固化动力学研究[D]. 合肥: 合肥工业大学, 2020.BI Quanrui. Curing kinetics of epoxy resin/alumina insulation composites for ultra high voltage electrical equipment[D]. Hefei: Hefei University of Technology, 2020(in Chinese). [19] POULADVAND A R, MORTEZAEI M, FATTAHI H, et al. A novel custom-tailored epoxy prepreg formulation based on epoxy-amine dual-curable systems[J]. Composites Part A: Applied Science and Manufacturing,2020,132:105852. [20] POULADVAND A, MORTEZAEI M. Tack of prepreg: Effective factors, methods of measurement and failure mechanism[J]. Composites Science and Technology,2019,74(4):173-178. [21] 燕夏婧. 热塑性复合材料自动铺放设备工艺及曲面铺放研究[D]. 北京: 北京化工大学, 2019.YAN Xiajing. Research on automatic placement equipment and process and surface placement of thermoplastic composites[D]. Beijing: Beijing University of Chemical Technology, 2019(in Chinese). [22] 宋涛. 变刚度碳纤维/环氧树脂复合材料薄壁圆管轴向压溃响应与吸能特性研究[D]. 上海: 东华大学, 2021.SONG Tao. Axial compression response and energy absorption characteristics of thin-walled circular tubes containing variable stiffness carbon fiber/epoxy resin composite materials[D]. Shanghai: Donghua University, 2021(in Chinese). -

下载:

下载: