Design, fabrication and testing of ceramic-matrix composite turbine blisk

-

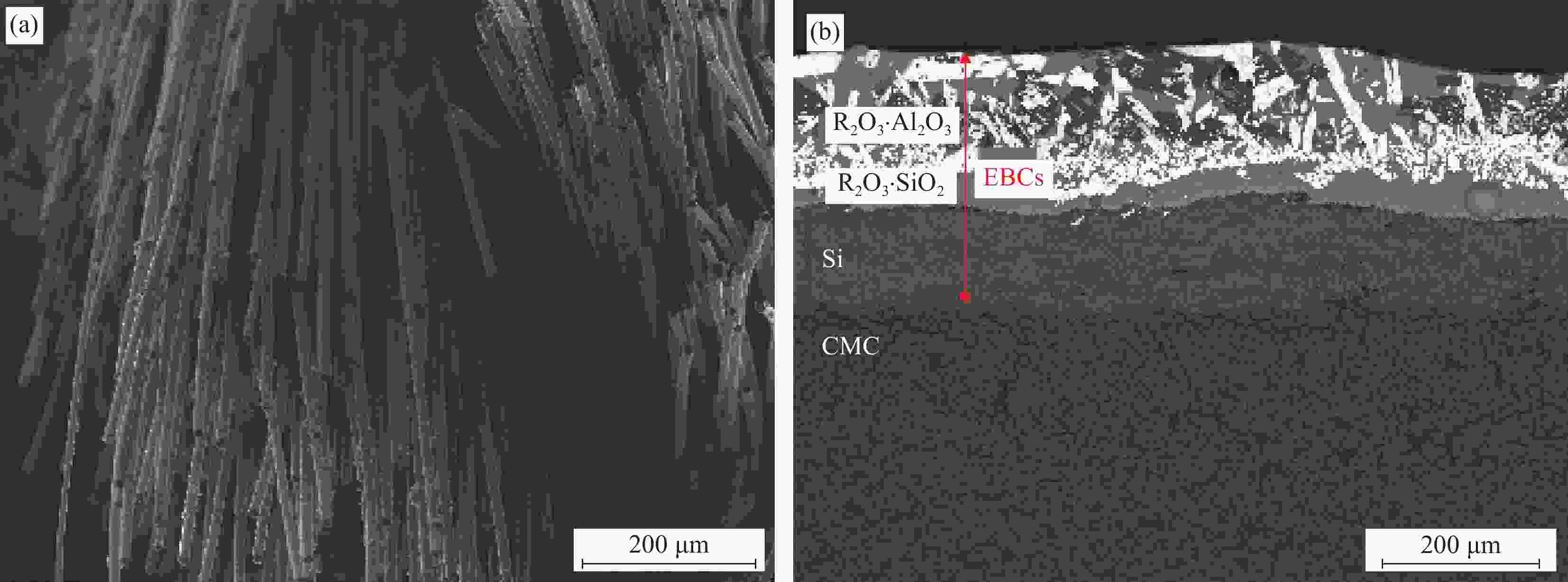

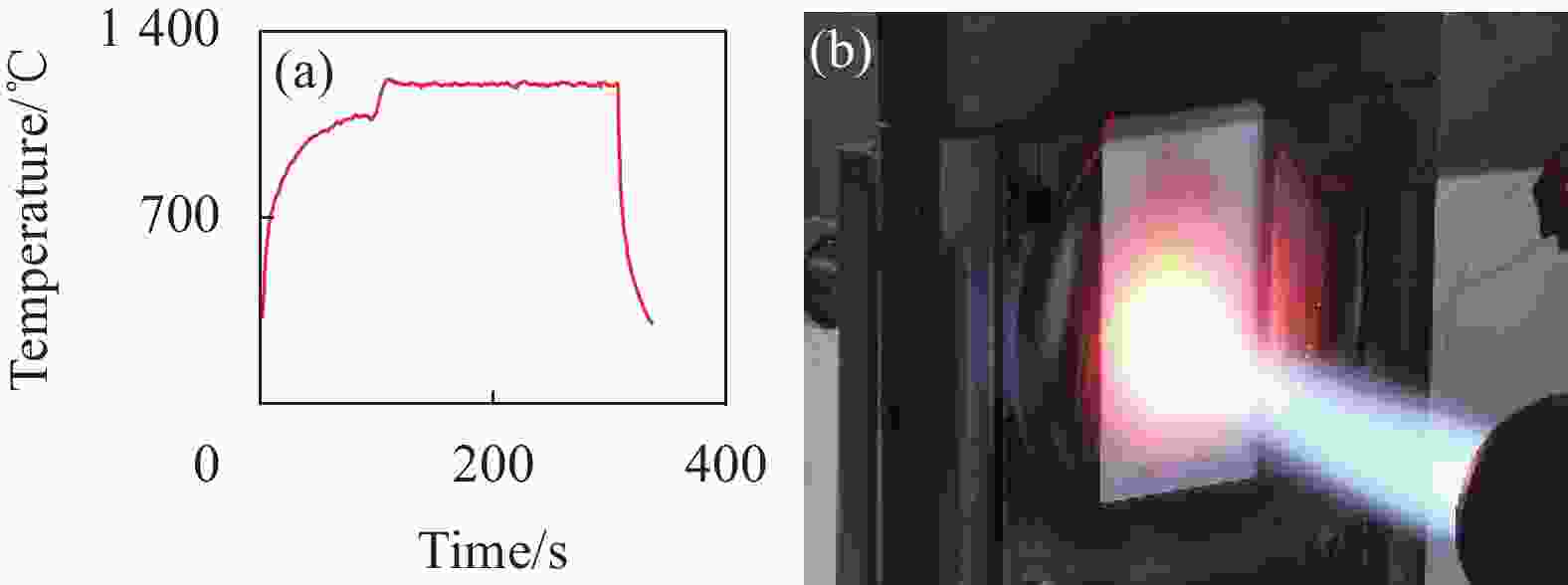

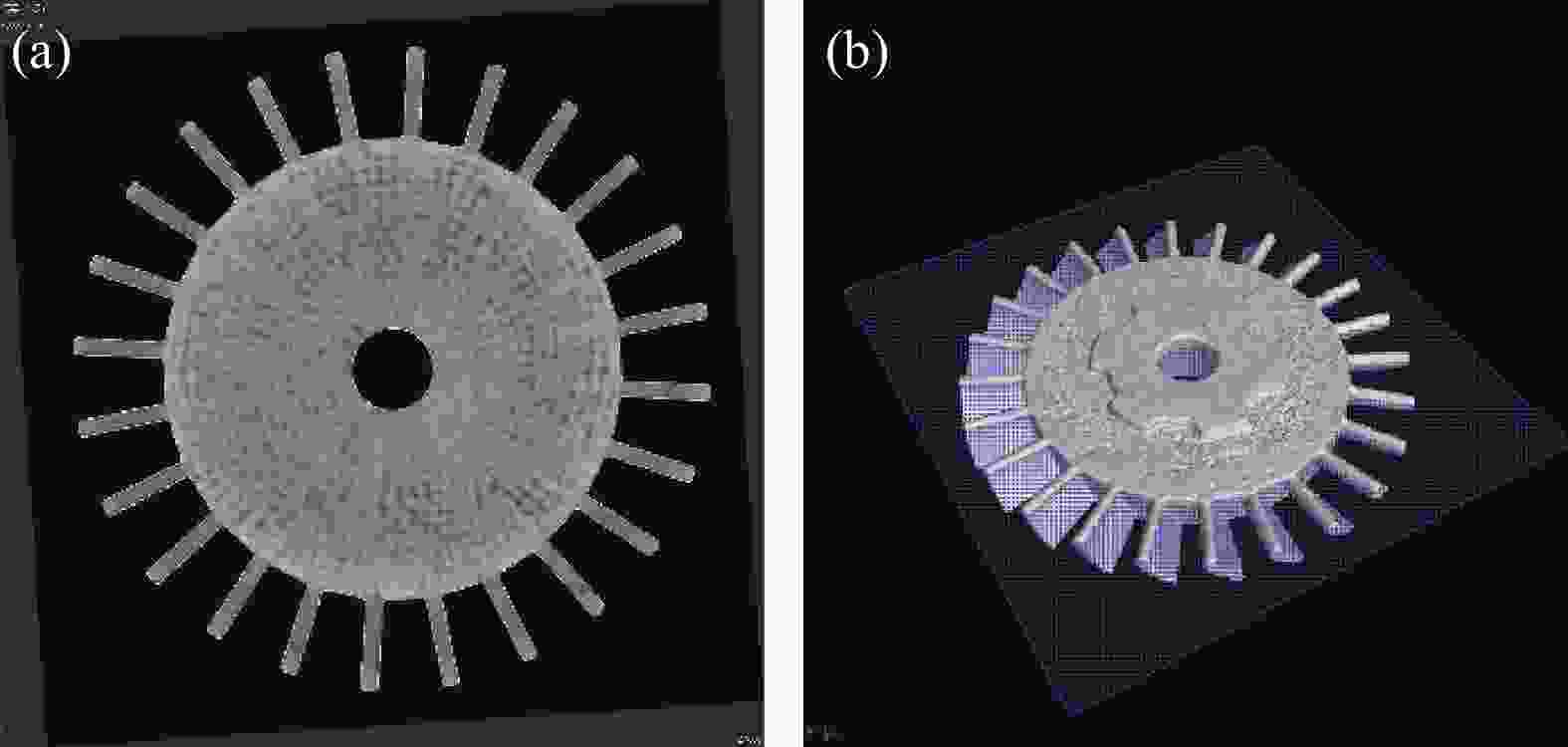

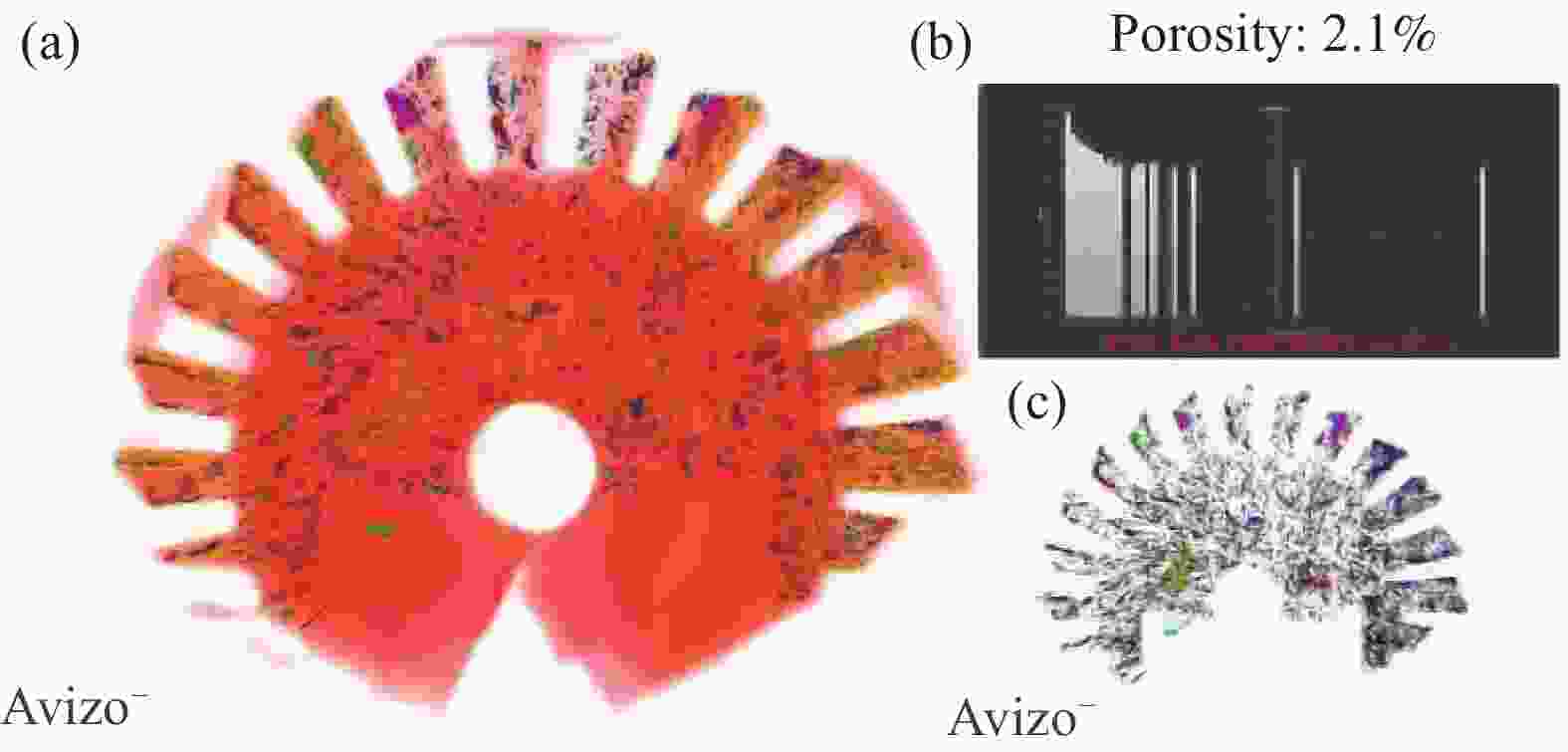

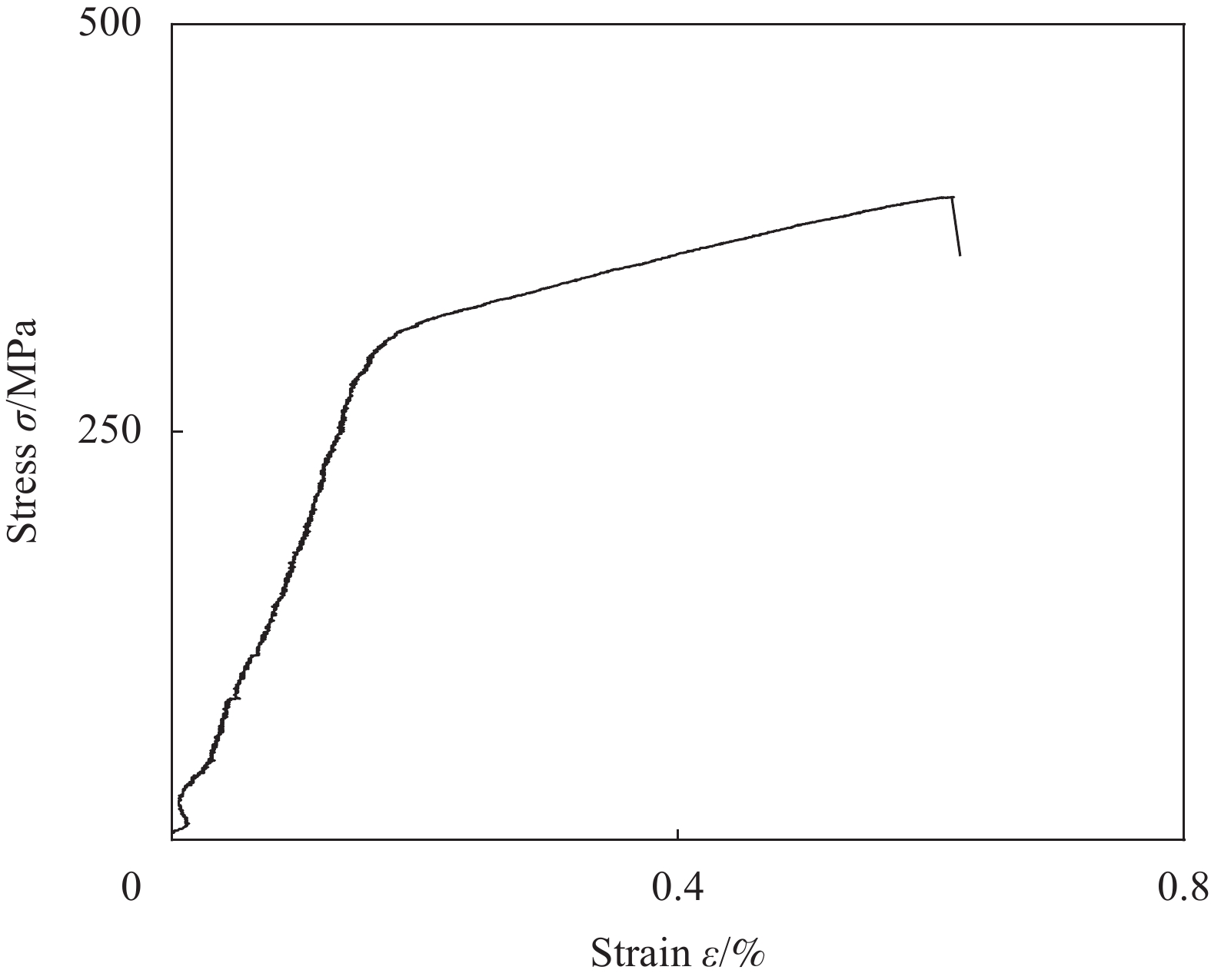

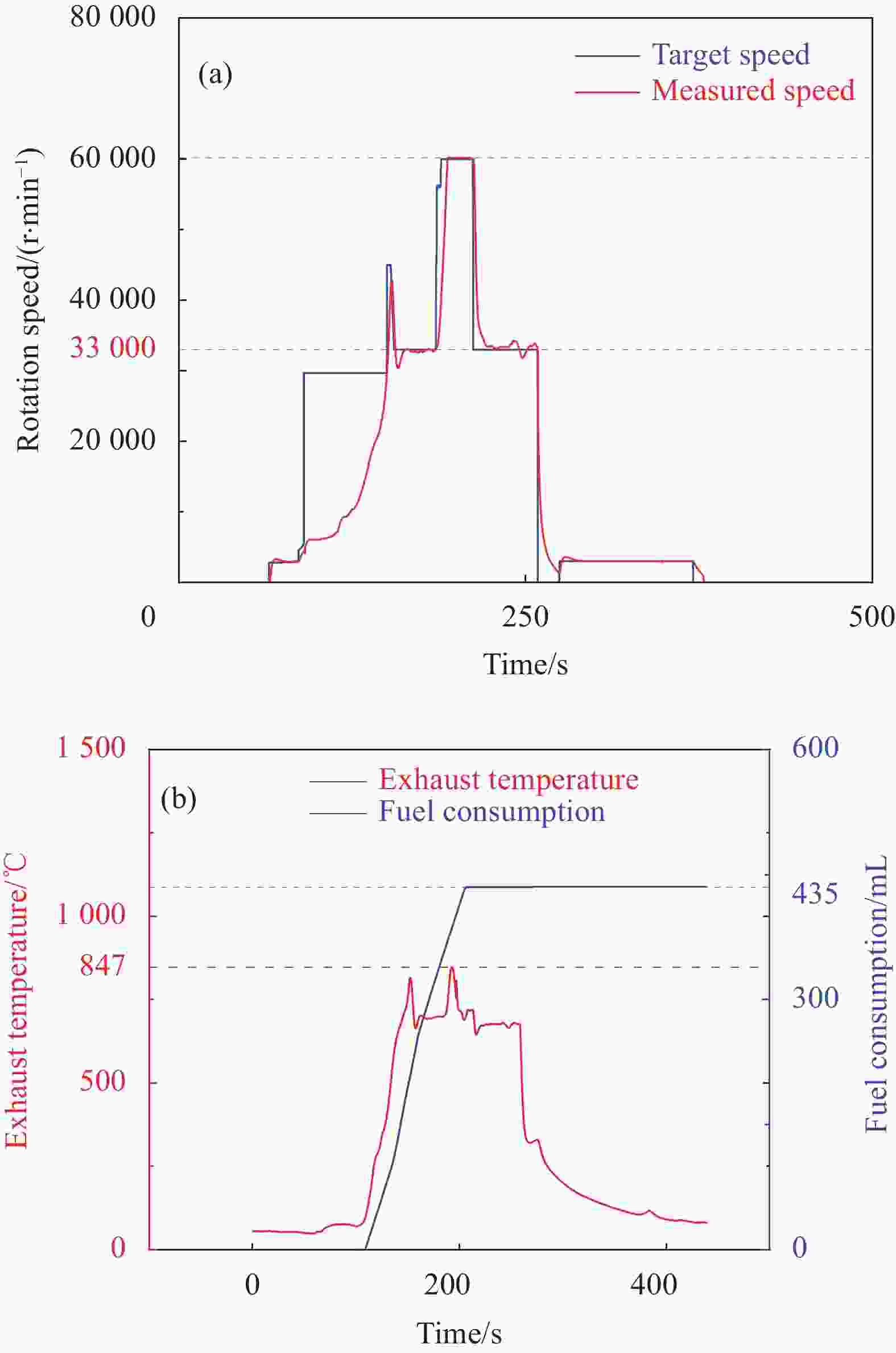

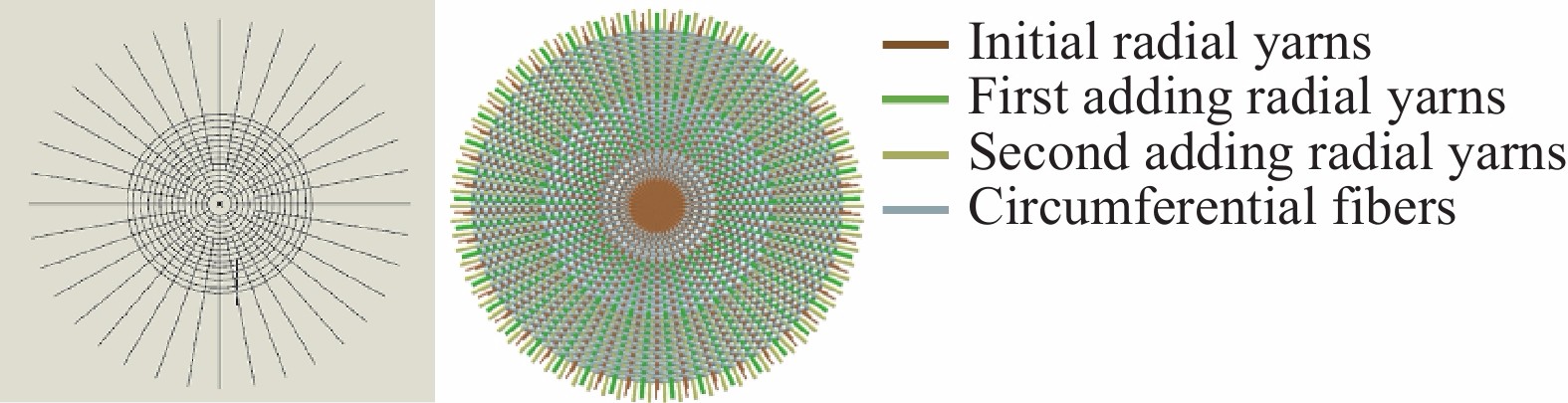

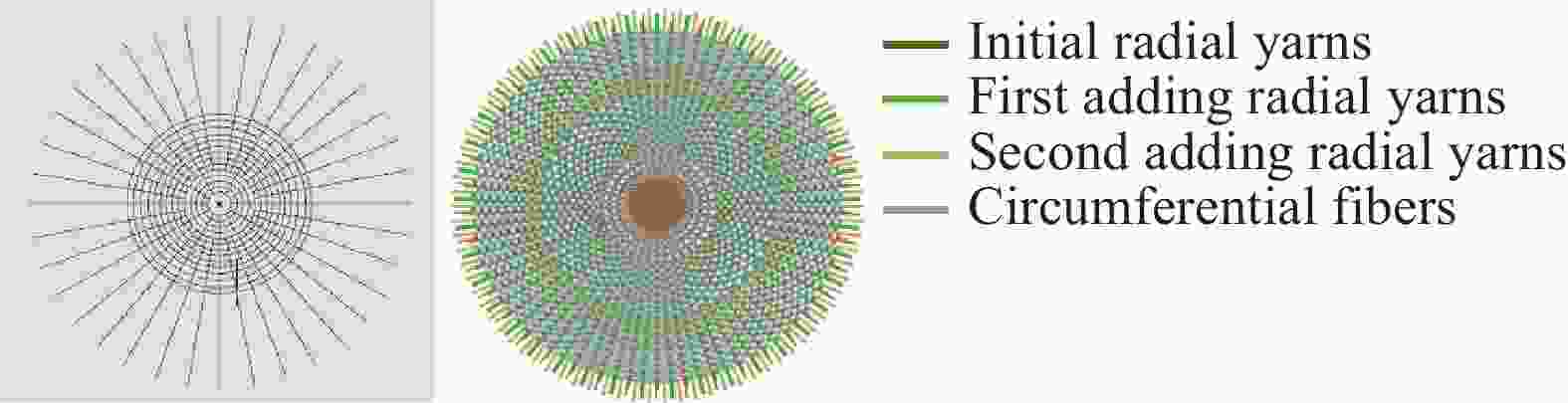

摘要: 涡轮转子是燃气涡轮发动机的核心部件。针对SiC/SiC涡轮叶盘设计、制备与考核验证开展研究,采用蛛网仿形(SWS)SiC纤维预制体作为涡轮叶盘的增强体,预制体表面分别沉积BN界面相与SiC基体,通“在线加工”方式对SiC/SiC涡轮叶盘分别进行粗加工和精加工,采用大气等离子喷涂方法制备环境障碍涂层,形成满足设计要求的涡轮叶盘。采用CT对SiC/SiC涡轮叶盘进行无损检测,表征叶盘内部缺陷分布。针对制备的SiC/SiC涡轮叶盘开展性能评价、超转试验、台架试验等考核验证,研究表明:SiC/SiC涡轮叶盘最大破坏强度达到300 MPa;在室温超转试验中,当转速达到n=104166 r/min时,叶片发生断裂,当转速达到n=108072 r/min时,轮体发生破裂;在发动机台架试验中,累积完成了N=994次最高转速nmax=60000 r/min的循环载荷及N=100次最高转速nmax=70000 r/min的循环载荷试车考核。2022年1月1日,SiC/SiC涡轮叶盘在株洲成功完成了首次飞行试验验证,这也是国内陶瓷基复合材料转子首次配装平台的空中飞行试验,验证了SiC/SiC涡轮转子在航空发动机上应用的可行性。Abstract: Turbine rotor is the key component of gas turbine engines. Design, fabrication, and experimental verification of SiC/SiC turbine blisk were investigated. The Spider Web Structure (SWS) SiC preform was used as the reinforcement in turbine blisk. The BN interphase and SiC matrix were deposited on the surface of the SWS SiC fiber preform, respectively. The SiC/SiC turbine blisk was machined by "on-line processing" to form a turbine bisk that meets the design requirements. The environmental barrier coatings (EBCs) were prepared on the surface of SiC/SiC turbine blisk using the atmospheric plasma spraying (APS) method. The CT scan was conducted to characterize the internal defects in SiC/SiC turbine blisk. The mechanical performance evaluation, over rotation test and engine bench test were performed, respectively. The maximum failure strength approached 300 MPa. During the over rotation test, when the rotating speed reached n=104166 r/min, the blade in the turbine blisk broke; and when the rotating speed reached n=108072 r/min, the disk in the turbine blisk broke. During the engine bench test, low cyclic fatigue of N=994 cyclic with maximum speed nmax=60000 r/min and N=100 cyclic with maximum speed nmax=70000 r/min were completed. On January 1, 2022, the SiC/SiC turbine blisk successfully completed the first flight test in Zhuzhou, which is also the first flight test of the domestic SiC/SiC rotor assembly platform and verified the feasibility of SiC/SiC turbine rotor application in gas turbine engines.

-

图 14 SiC/SiC涡轮叶盘性能评价方法:(a) 随炉圆环试样;(b) 缺口圆环试样;(c) 拉伸断裂测试;(d) 断裂试样;(e) 有限元仿真缺口圆环试样断裂;(f) 涡轮叶盘应力分布

Figure 14. Evaluation of SiC/SiC turbine blisk performance: (a) Circular specimen; (b) Notched circular specimen; (c) Tensile fracture test; (d) Fracture specimen; (e) Finite element simulation of notched circular specimen fracture; (f) Turbine blisk stress distribution

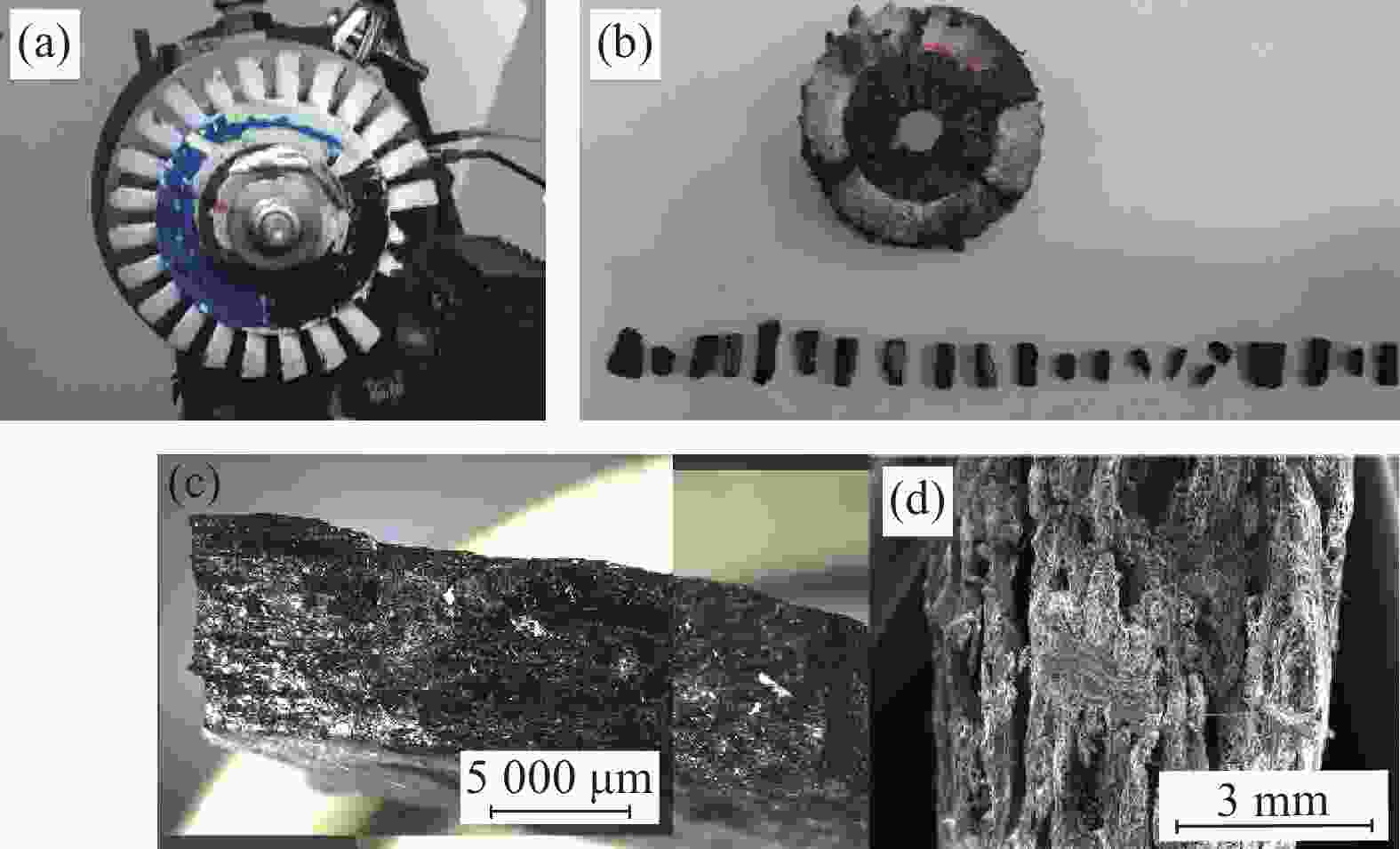

图 17 (a) 发动机试车台;(b) 安装在发动机内的SiC/SiC涡轮叶盘;(c) SiC/SiC原始涡轮叶盘;(d) EBCs-SiC/SiC涡轮叶盘;(e) N=994次n=60000 r/min试验后的轮盘表面状态;(f) 表面氧化形貌;((g)~(h)) 轮盘表面氧化产物形貌;(i) 叶片掉块;(j) CT切片;(k) CT切片

Figure 17. (a) Engine test bench; (b) SiC/SiC turbine blisk assembled in the test engine; (c) Original SiC/SiC turbine blisk; (d) EBCs-SiC/SiC turbine blisk; (e) EBC-SiC/SiC turbine blisk after N=994 tests at n=60000 r/min; (f) Surface morphology of SiC/SiC turbine blisk after test; ((g)-(h)) Surface morphology of oxidation products ; (i) Damage in the blade; (j) CT section; (k) CT section

表 1 叶片频率衰退范围统计表

Table 1. Statistical of blade frequency degradation range

Degradation range Number of blades 0.0%-0.5% 0 0.5%-1.0% 0 1.0%-1.5% 4 1.5%-2.0% 13 2.0%-2.5% 2 2.5%-3.0% 2 3.0%-3.5% 2 3.5%-4.0% 0 4.0%-4.5% 0 4.5%-5.0% 1 -

[1] 江和甫. 对涡轮盘材料的需求及展望[J]. 燃气涡轮试验与研究, 2002, 15(4):1-6. doi: 10.3969/j.issn.1672-2620.2002.04.001JIANG Hefu. Requirements and forecast of turbine disk materials[J]. Gas Turbine Experiment and Research,2002,15(4):1-6(in Chinese). doi: 10.3969/j.issn.1672-2620.2002.04.001 [2] 叶勇松, 黄璇璇, 郭双全, 等. 航空发动机碳化硅基复合材料环境性能评价研究进展[J]. 航空维修与工程, 2016(8):32-35. doi: 10.3969/j.issn.1672-0989.2016.11.007YE Yongsong, HUAGN Xuanxuan, GUO Shuangquan, et al. Progress of environmental property of ceramic matrix composite-SiC for aero-engine[J]. Aciation Maintenance & Engineering,2016(8):32-35(in Chinese). doi: 10.3969/j.issn.1672-0989.2016.11.007 [3] 刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料在航空发动机上的应用需求及挑战[J]. 材料工程, 2019, 47(2): 1-10.LIU Qiaomu, HUANG Shunzhou, HE Aijie. Application requirements and challenges of CMC-SiC composites on aero-engine[J]. Journal of Materials Engineering, 2019, 47(2): 1-10(in Chinese). [4] 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨[J]. 复合材料学报, 2007, 24(2):1-6. doi: 10.3321/j.issn:1000-3851.2007.02.001ZHANG Litong, CHENG Laifei. Discussion on strategies of sustainable development of continuous fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica,2007,24(2):1-6(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.02.001 [5] LI L B. Durability of ceramic matrix composites[M]. Oxford: Elsevier, 2020. [6] 朱思雨, 张巧君, 洪智亮, 等. 平纹编织SiCf/SiC复合材料的中温蠕变断裂时间及损伤机制[J]. 复合材料学报, 2023, 40(1): 464-471.ZHU Siyu, ZHANG Qiaojun, HONG Zhiliang, et al. Creep rupture time and damage mechanisms of a plain woven SiCf/SiC composite at intermediate temperature[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 464-471(in Chinese). [7] LI L B. Time-dependent mechanical behavior of ceramic-matrix composites at elevated temperatures[M]. Singapore: Springer Nature, 2020. [8] 胡晓安, 张宇, 阳海棠, 等. 三维编织SiC/SiC复合材料拉伸和弯曲损伤机制[J]. 复合材料学报, 2019, 36(8):1879-1885.HU Xiaoan, ZHANG Yu, YANG Haitang, et al. Tensile and bending damage mechanism of 3D braided SiC/SiC composites[J]. Acta Materiae Compositae Sinica,2019,36(8):1879-1885(in Chinese). [9] LI L B. High temperature mechanical behavior of ceramic-matrix composites[M]. Weinheim: Wiley-VCH, 2021. [10] 罗潇, 徐友良, 郭小军, 等. 涡轮发动机用陶瓷基复合材料涡轮转子研究进展[J]. 推进技术, 2021, 42(1):230-240.LUO Xiao, XU Youliang, GUO Xiaojun, et al. Research progress of ceramic matrix composites turbine rotors for turbine engines[J]. Journal of Propulsion Technology,2021,42(1):230-240(in Chinese). [11] 罗潇, 李坚, 李敏, 等. 蛛网式骨架增强陶瓷基复合材料涡轮叶盘设计及验证[J]. 航空动力, 2021(1): 54-56.LUO Xiao, LI Jian, LI Min, et al. Design and test of the CMC blisk reinforced by spider-web-like framework[J]. Aerospace Power, 2021(1): 54-56. [12] TENG X F, LYU S Q, HU X A, et al. Effect of off-axis angle on mesoscale deformation and failure behavior of plain-woven C/SiC composites with digital image correlation[J]. Journal of the European Ceramic Society, 2022, 42: 4712-4722. [13] WANG F, TENG X F, HU X A, et al. Damage and failure analysis of a SiCf/SiC ceramic matrix composite using digital image correlation and acoustic emission[J]. Ceramics International, 2022, 48: 4699-4709. [14] LI L B. Interfaces of ceramic-matrix composites: Design, characterization and damage effects[M]. Weinheim: Wiley-VCH, 2020. [15] 刘海韬, 程海峰, 王军, 等. SiC/SiC复合材料界面相研究进展[J]. 材料导报, 2010, 24:10-14.LIU Haitao, CHENG Haifeng, WANG Jun, et al. Study on the interphase of the continuous SiC fiber reinforced SiC composites[J]. Materials Review,2010,24:10-14(in Chinese). [16] NASLAIN R R. The design of the fiber-matrix interfacial zone in ceramic matrix composites[J]. Composites Part A: Applied Science & Manufacturing,1998,29:1145-1155. doi: 10.1016/S1359-835X(97)00128-0 [17] 张冰玉, 王岭, 焦健, 等. 界面层对SiC/SiC复合材料力学性能及氧化行为的影响[J]. 航空制造技术, 2017, 60(12): 78-83.ZHANG Bingyu, WANG Ling, JIAO Jian, et al. Effect of interface on mechanical property and oxidation behavior of SiC/SiC composites[J]. Aeronautical Manufacturing Technology, 2017, 60(12): 78-83(in Chinese). [18] 王章文, 张军, 方国东, 等. 界面层对纤维增韧陶瓷基复合材料力学性能影响的研究进展[J]. 装备环境工程, 2020, 17(1):77-89.WANG Zhangwen, ZHANG Jun, FANG Guodong, et al. Effect of interfacial layer on mechanical properties of fiber toughened ceramic matrix composites[J]. Equipment Environmental Engineering,2020,17(1):77-89(in Chinese). [19] 贾林涛, 王梦千, 徐海明, 等. SiC纤维表面(BN-SiC)n复合涂层的制备及单丝拉伸性能[J]. 复合材料学报, 2019, 36(8):1873-1878.JIA Lintao, WANG Mengqian, XU Haiming, et al. Preparation of (BN-SiC)n composite coatings on SiC fibers and tensile properties of monofilament[J]. Acta Materiae Compositae Sinica,2019,36(8):1873-1878(in Chinese). [20] LI L B. Matrix cracking of ceramic-matrix compo-sites[M]. Singapore: Springer Nature, 2022. [21] AN Q L, CHEN J, MING W W, et al. Machining of SiC ceramic matrix composites: A review[J]. Chinese Jour-nal of Aeronautics, 2021, 34(4): 540-567. [22] LI W N, ZHANG R H, LIU Y S, et al. Effect of different parameters on machining of SiC/SiC composites via pico-second laser[J]. Applied Surface Science,2016,364(28):378-387. [23] LI L B. Time-dependent deformation and fracture behavior of fiber-reinforced ceramic-matrix composites under stress-rupture loading at intermediate temperature[J]. Journal of Aerospace Engineering, 2021, 34(2): 04020111. [24] LI L B. A time-dependent tensile constitutive model for long-fiber-reinforced unidirectional ceramic-matrix minicomposites considering interface and fiber oxidation[J]. International Journal of Damage Mechanics,2020,29(7):1138-1166. doi: 10.1177/1056789520924103 [25] 刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料环境障涂层研究进展[J]. 材料工程, 2018, 46(10):1-8. doi: 10.11868/j.issn.1001-4381.2018.000230LIU Qiaomu, HUANG Shunzhou, HE Aijie. Research progress in environmental barrier coatings of SiC ceramic matrix composites[J]. Journal of Materials Engineering,2018,46(10):1-8(in Chinese). doi: 10.11868/j.issn.1001-4381.2018.000230 [26] NASIRI N A, PATRA N, PEZOLDT M, et al. Investigation of a single-layer EBC deposited on SiC/SiC CMCs: Processing and corrosion behavior in high-temperature steam[J]. Journal of the European Ceramic Society,2019,39(8):2703-2711. doi: 10.1016/j.jeurceramsoc.2018.12.019 [27] WANG F, TENG X F, HU X A, et al. Damage and failure analysis of a SiCf/SiC ceramic matrix composite using digital image correlation and acoustic emission[J]. Ceramics International,2022,48(4):4699-4709. doi: 10.1016/j.ceramint.2021.11.006 [28] GUO X J, WU J W, LI J, et al. Damage monitoring of 2D SiC/SiC composites under monotonic and cyclic loading/unloading using acoustic emission and natural frequency[J]. Ceramics-Silikaty,2021,65(2):125-131. [29] LIU X C, GUO X J, XU Y L, et al. Cyclic thermal shock damage behavior in CVI SiC/SiC high-pressure turbine twin guide vanes[J]. Materials,2021,14(20):6104. doi: 10.3390/ma14206104 [30] MORSCHER G N, SINGH M, KISER J D, et al. Modeling stress-dependent matrix cracking and stress-strain behavior in 2D woven SiC fiber reinforced CVI SiC composites[J]. Composites Science and Technology,2007,67(6):1009-1017. doi: 10.1016/j.compscitech.2006.06.007 [31] GOWAYED Y, OJARD G, SANTHOSH U, et al. Modeling of crack density in ceramic matrix composites[J]. Journal of Composite Materials,2015,49(18):2285-2294. doi: 10.1177/0021998314545188 [32] LI L B. Modeling matrix fracture in fiber-reinforced ceramic-matrix composites with different fiber preforms[J]. Textile Research Journal,2020,90(7-8):909-924. doi: 10.1177/0040517519883956 [33] LI L B. Nonlinear behavior of ceramic-matrix composites[M]. Oxford: Elsevier, 2021. [34] LI L B. Synergistic effects of fiber debonding and fracture on matrix cracking in fiber-reinforced ceramic-matrix composites[J]. Materials Science and Engineering A,2017,682:482-490. doi: 10.1016/j.msea.2016.11.077 [35] LI L B. Modeling for monotonic and cyclic tensile stress-strain behavior of 2D and 2.5D woven C/SiC ceramic-matrix composites[J]. Mechanics of Composite Materials,2018,54(2):165-178. doi: 10.1007/s11029-018-9729-5 [36] LI L B. Micromechanical modeling for tensile behavior of carbon fiber-reinforced ceramic-matrix composites[J]. Applied Composite Materials,2015,22:773-790. doi: 10.1007/s10443-014-9435-y [37] SANTHOSH U, AHMAD J, JOHN R, et al. Modeling of stress concentration in ceramic matrix composites[J]. Compo-sites Part B: Engineering,2013,45(1):1156-1163. doi: 10.1016/j.compositesb.2012.07.034 [38] LI L B. A time-dependent vibration damping model of fiber-reinforced ceramic-matrix composites at elevated temperature[J]. Ceramics International,2020,46(17):27031-27045. doi: 10.1016/j.ceramint.2020.07.180 [39] 单晓明, 黄金泉, 周文祥, 等, 涡轴发动机性能在线监测技术研究及试验验证[J]. 航空动力学报, 2013, 28(4): 721-729.SHAN Xiaoming, HUANG Jinquan, ZHOU Wenxiang, et al. Study and test validation of turboshaft engine online performance monitoring technology[J]. Journal of Aerospace Power, 2013, 28(4): 721-729(in Chinese). -

下载:

下载: