Effect of conductive carbon black Super-P on concrete properties

-

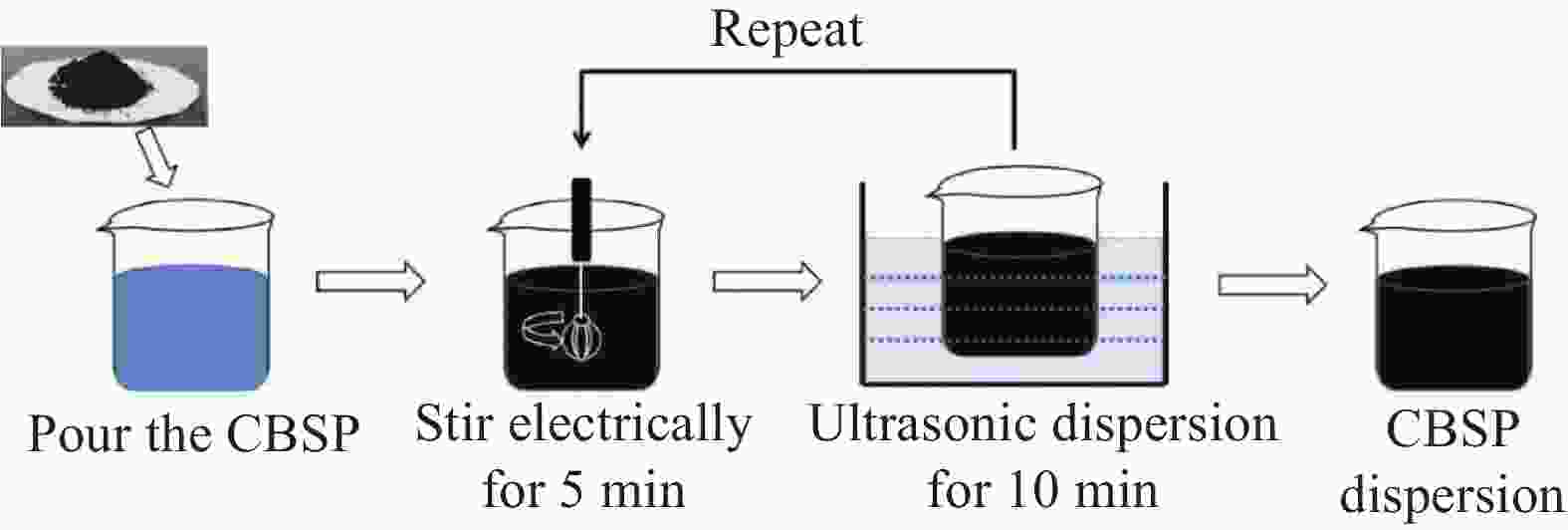

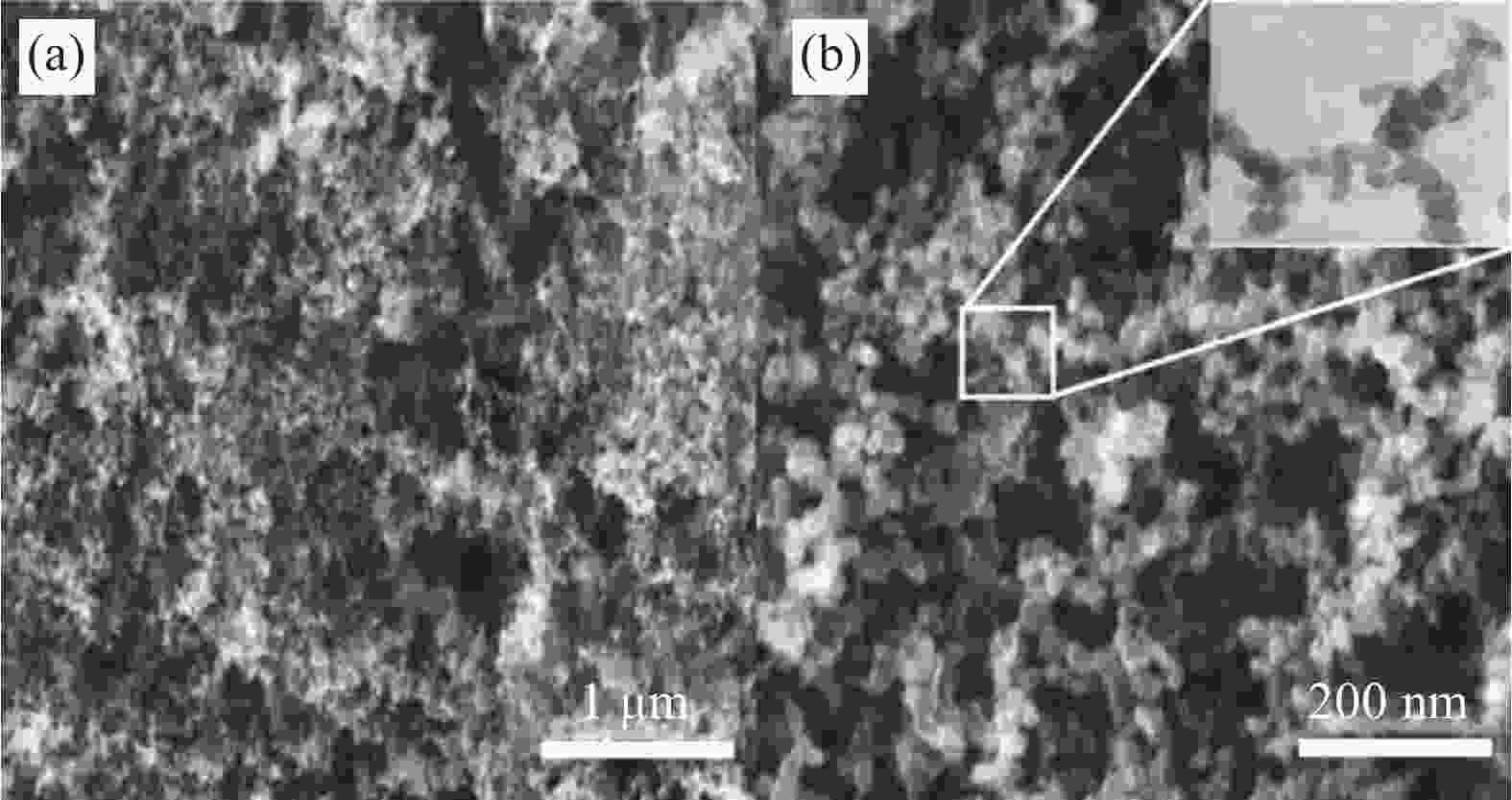

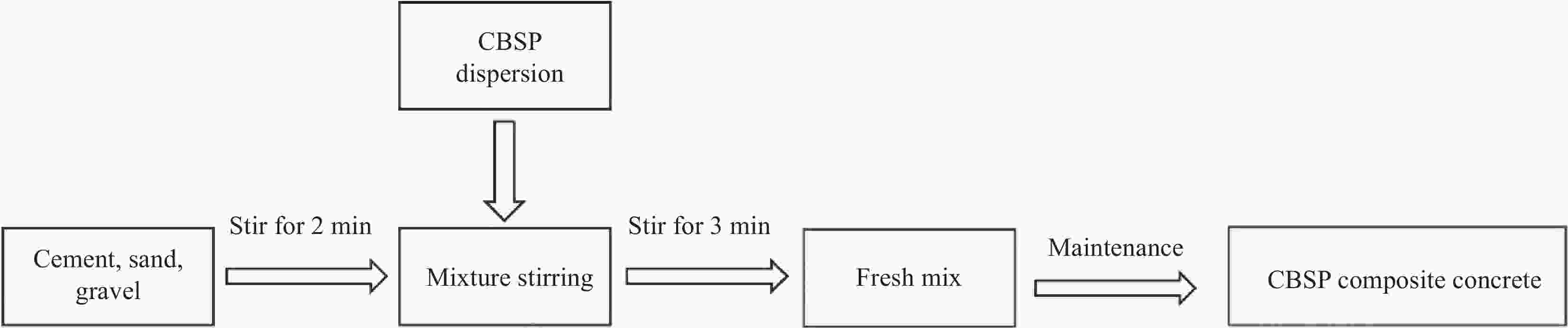

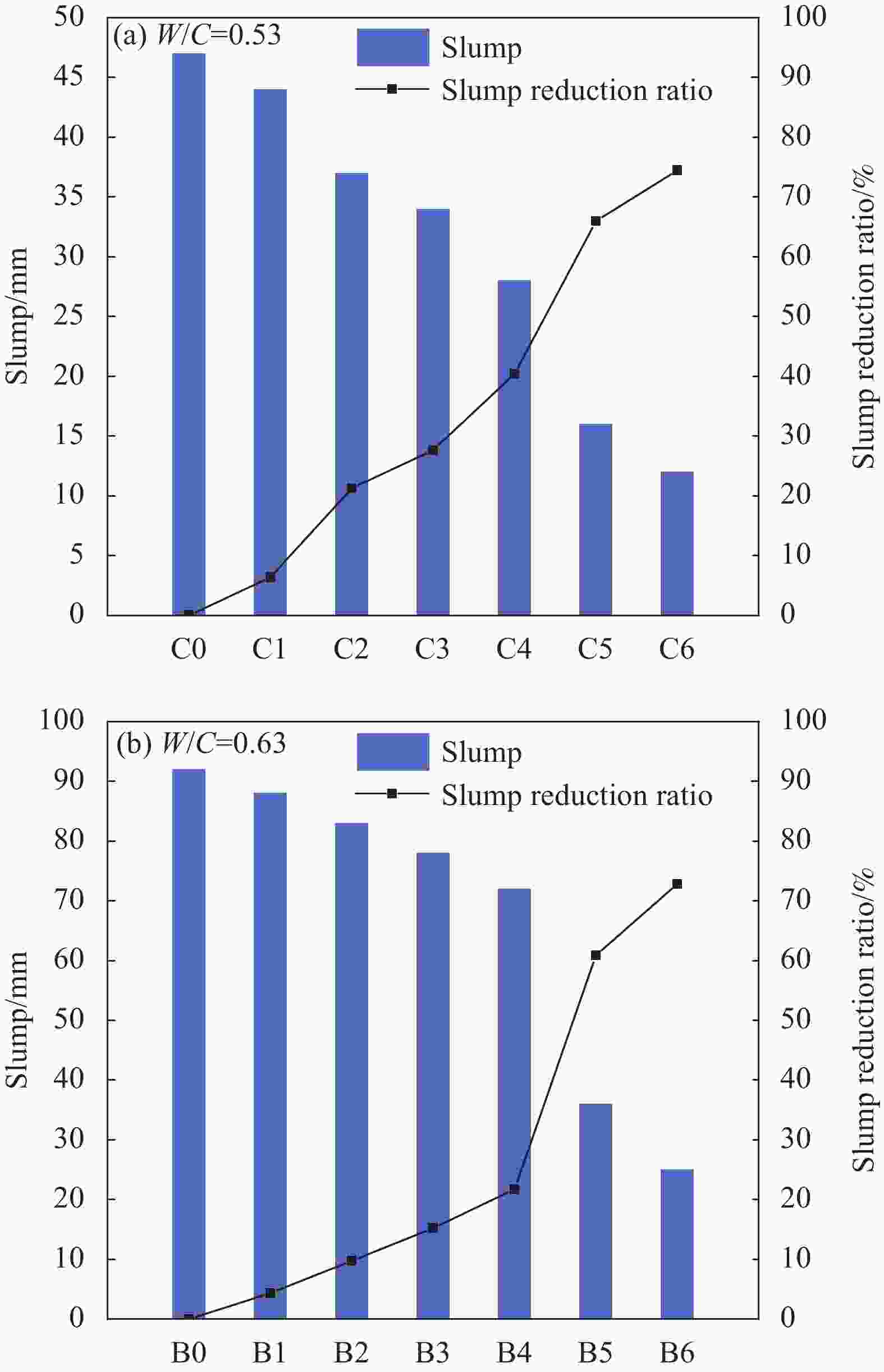

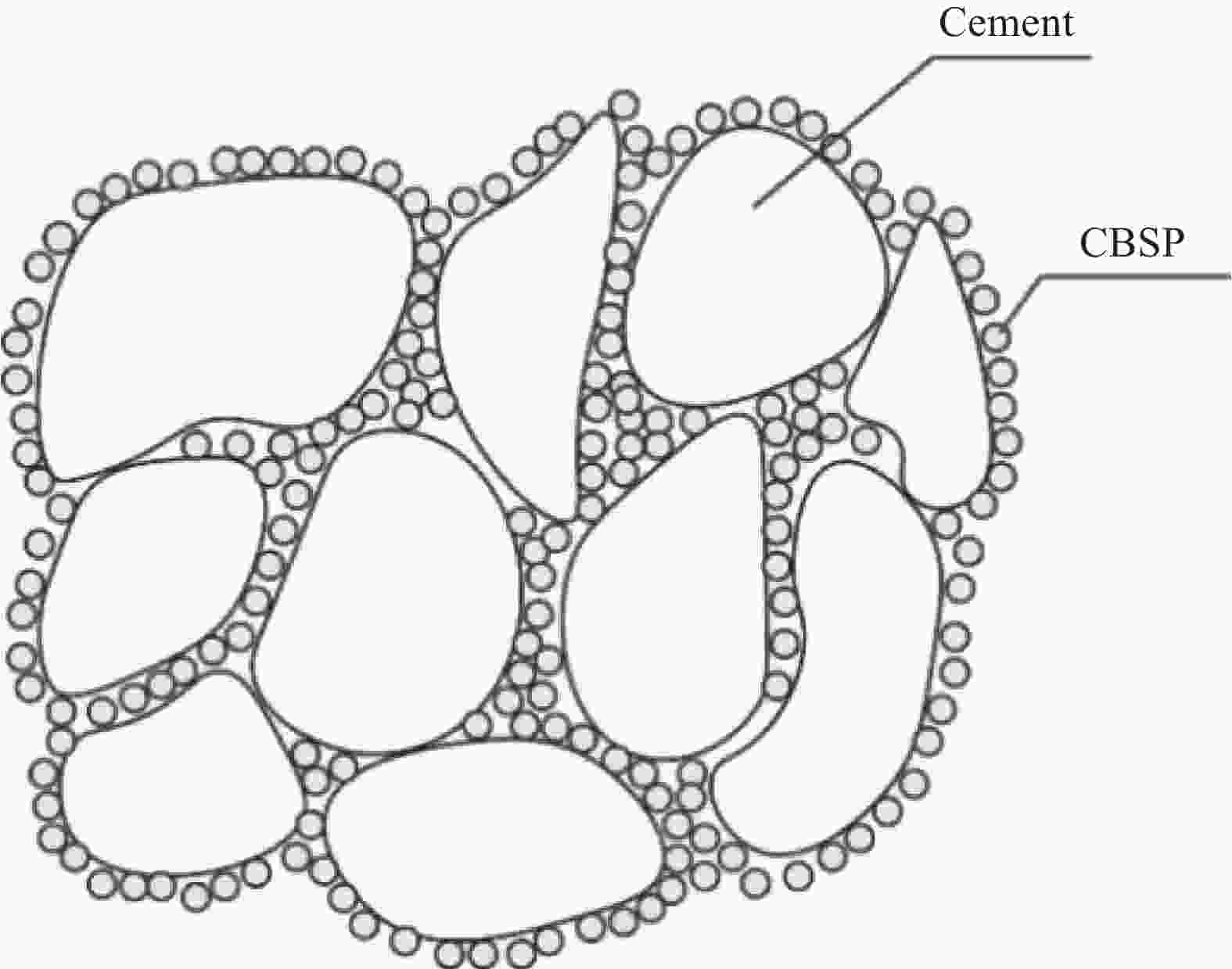

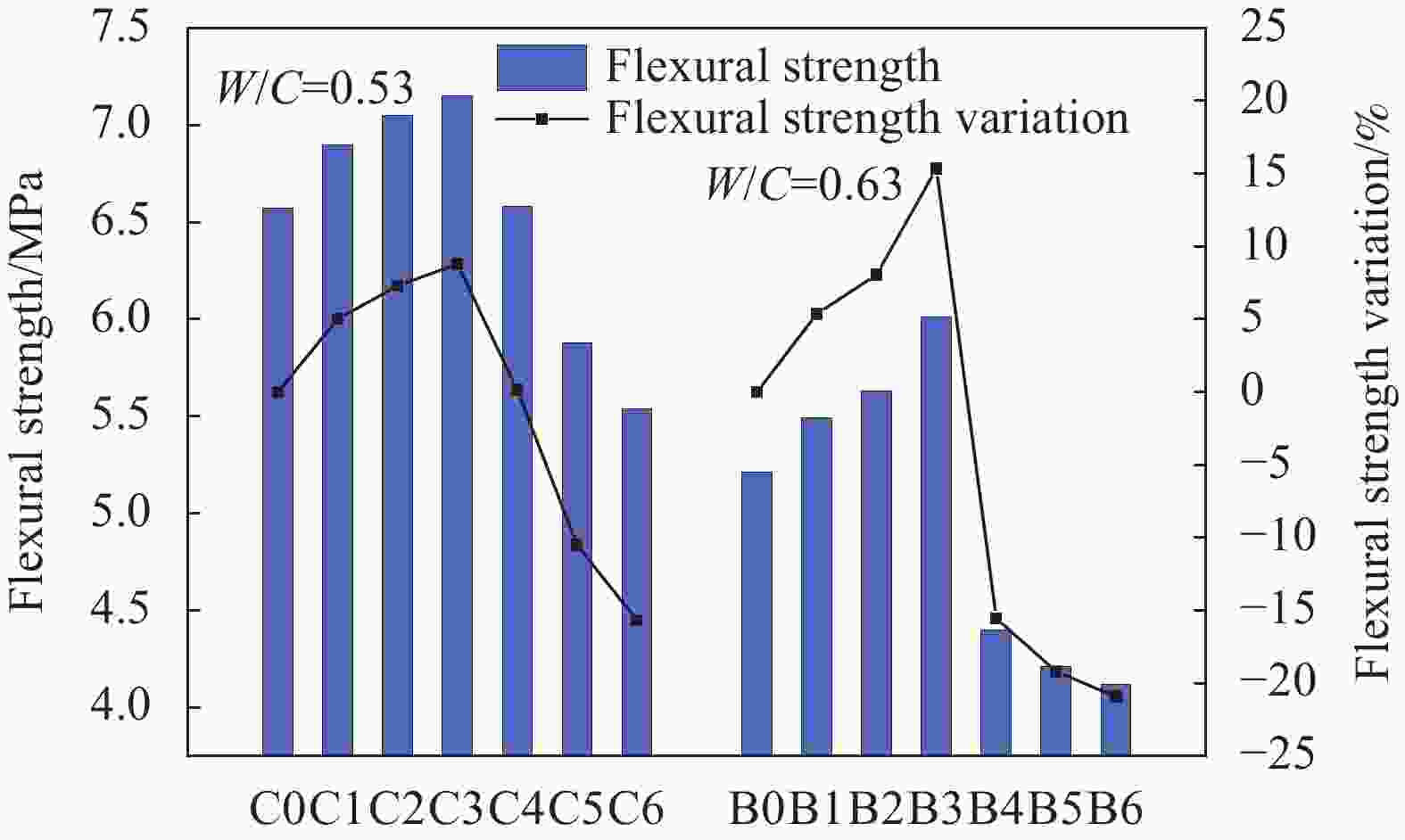

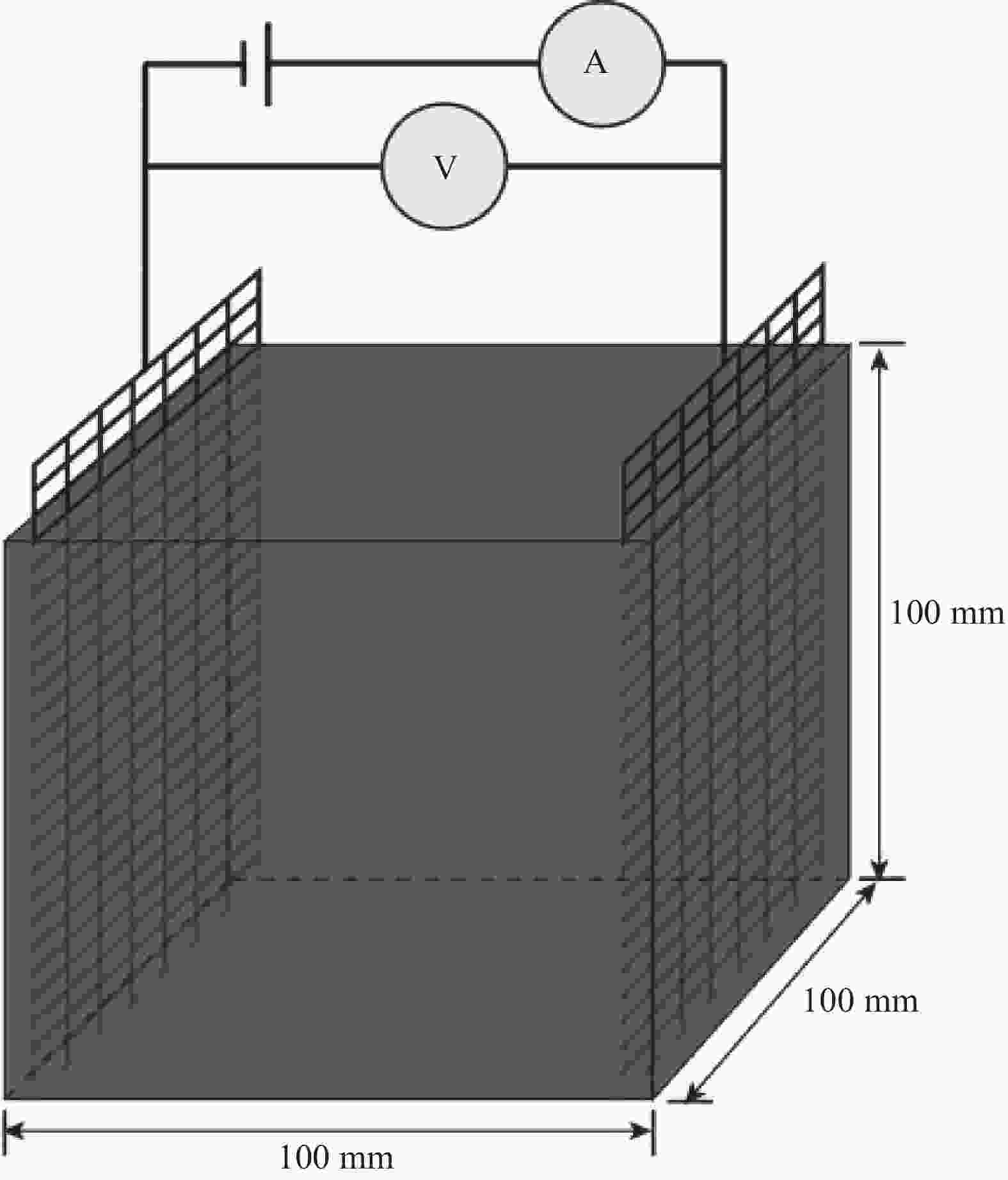

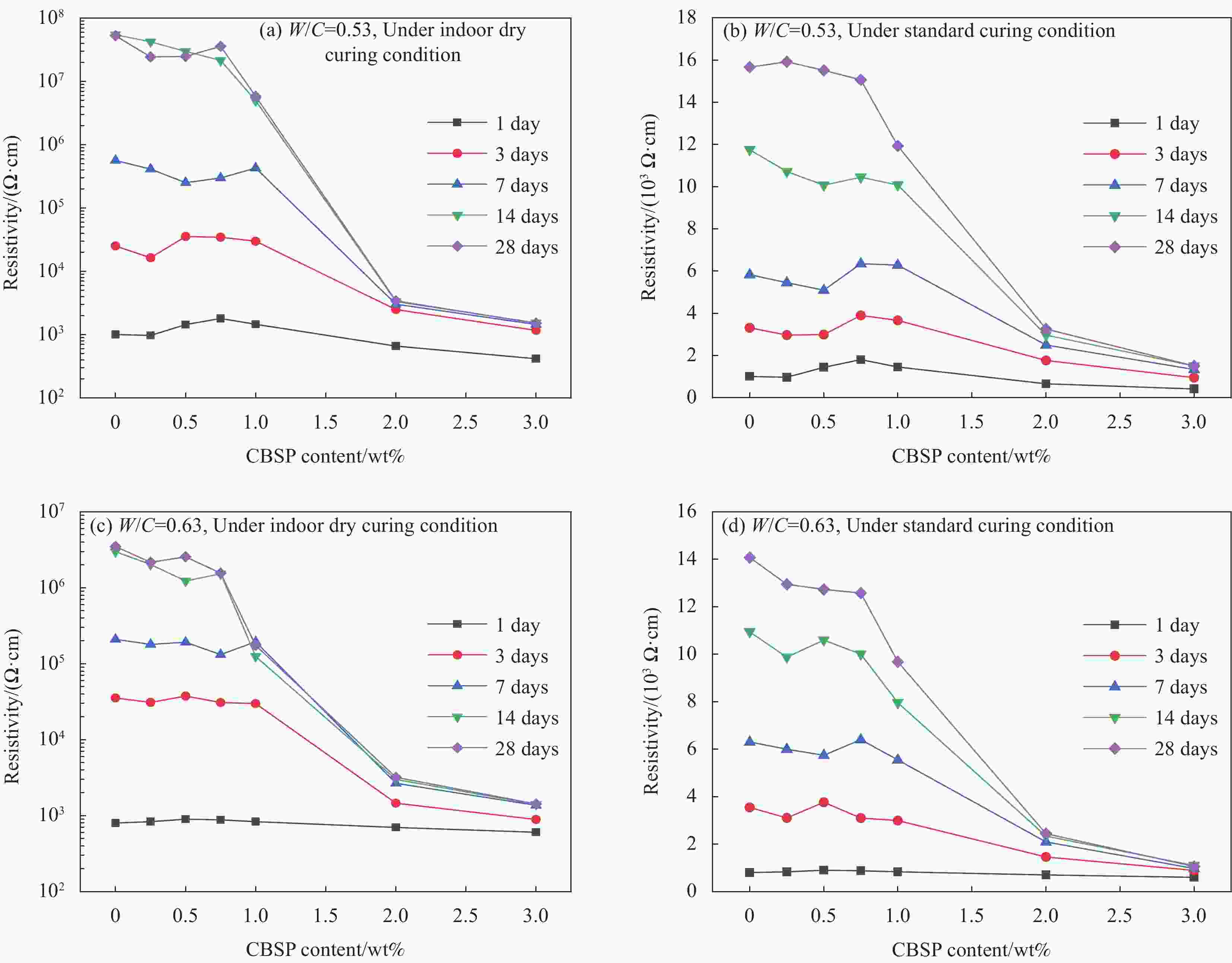

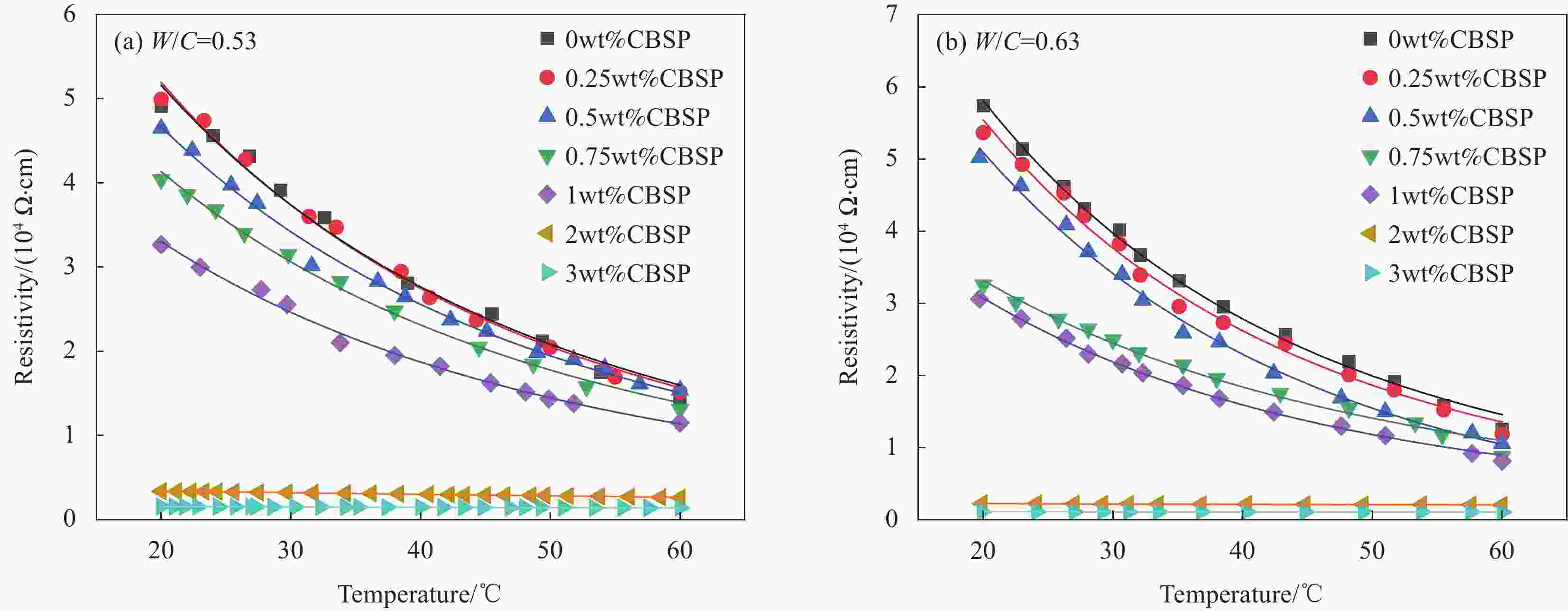

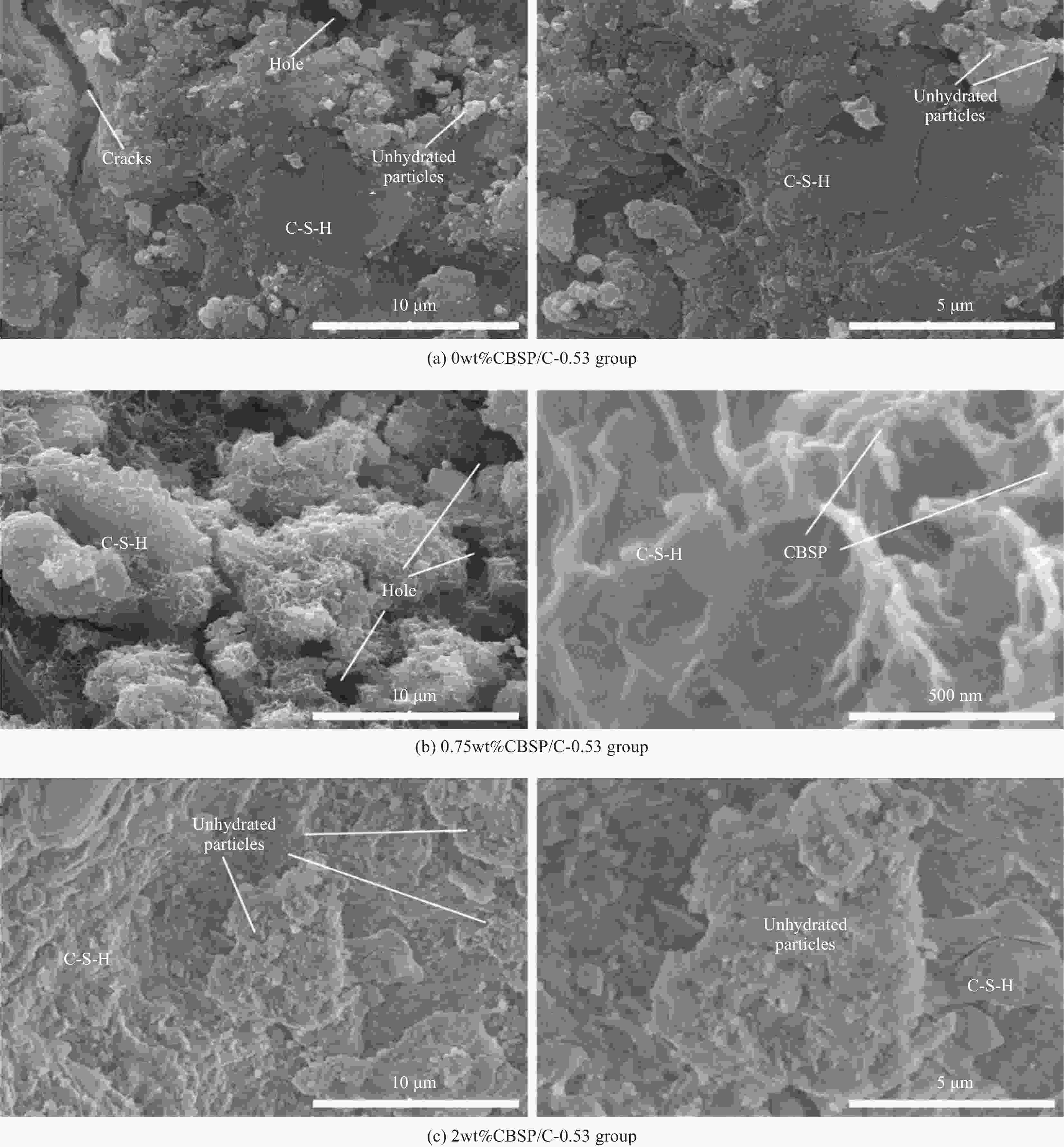

摘要: 采用低成本和高稳定性的纳米导电炭黑Super-P (CBSP)作为水泥混凝土的添加剂。通过设置不同的水灰比和不同的CBSP掺量,研究了CBSP的加入对混凝土各方面性能的影响(即坍落度、力学性能、抗渗性能、导电性能和温敏性能)。通过SEM对混凝土微观形貌进行分析。实验结果显示,掺入纳米材料CBSP使混凝土坍落度不断降低。随着CBSP的掺入量不断增大,混凝土的力学性能先提升后降低且各龄期变化趋势相似,当CBSP的掺入量为0.75wt%时力学性能达到最大。同时混凝土的力学性能随水灰比的增加而降低。混凝土的抗渗性能随着CBSP掺量的增加而先提高后降低,且当水灰比较大时抗渗性能有所降低。当CBSP掺入量为0.75wt%~2wt%时,混凝土电阻率迅速降低。标准养护条件比室内干燥养护的混凝土电阻率低。不同水灰比混凝土之间电阻率相差较小。SEM显示了CBSP的填充孔隙和隧道导电作用。通过实验证明CBSP的加入可以改善混凝土的各项性能。Abstract: Nano conductive carbon black Super-P (CBSP) with low cost and high stability was used as additive of cement concrete. By setting different water-cement ratios and different CBSP contents, the effects of CBSP addition on various properties of concrete (slump, mechanical properties, impermeability, electrical conductivity and temperature sensitivity) were studied. The microstructure of concrete was analyzed by SEM. The experimental results show that the slump of concrete decreases with the addition of CBSP. With the increase of CBSP content, the mechanical properties of concrete improve first and then decrease, and the change trend of each age is similar. When the CBSP content is 0.75wt%, the mechanical properties reach the maximum. Meanwhile, the mechanical properties of concrete decrease with the increase of water cement ratio. The impermeability of concrete increases first and then decreases with the increase of CBSP content and decreases when the water-cement ratio is large. When CBSP content is 0.75wt%-2wt%, the resistivity of concrete decreases rapidly. The resistivity of concrete cured by standard curing condition is lower than that cured by indoor drying. The resistivity of concrete with different water cement ratios has little difference. SEM shows that CBSP fills pores and conducts electricity in tunnels. Experiments show that the addition of CBSP can improve the performance of concrete.

-

表 1 P∙O 42.5水泥的化学成分组成

Table 1. Chemical composition of P∙O 42.5 cement

wt% SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O (eq) f-CaO Cl− 21.47 7.17 3.11 60.04 2.90 2.77 0.11 0.57 0.024 Notes: eq—Equipoise; f-CaO—Free calcium oxide. 表 2 P∙O 42.5水泥的物理性能检测结果

Table 2. Physical performance test results of P∙O 42.5 cement

Density/

(g·cm−3)Degree of powder Setting time Stability Flexural

strength/MPaCompressive

strength/MPaSpecific surface

area/(m2·kg−1)80 μm/% Normal

consistency/%Initial

set/minFinal

set/minRay type

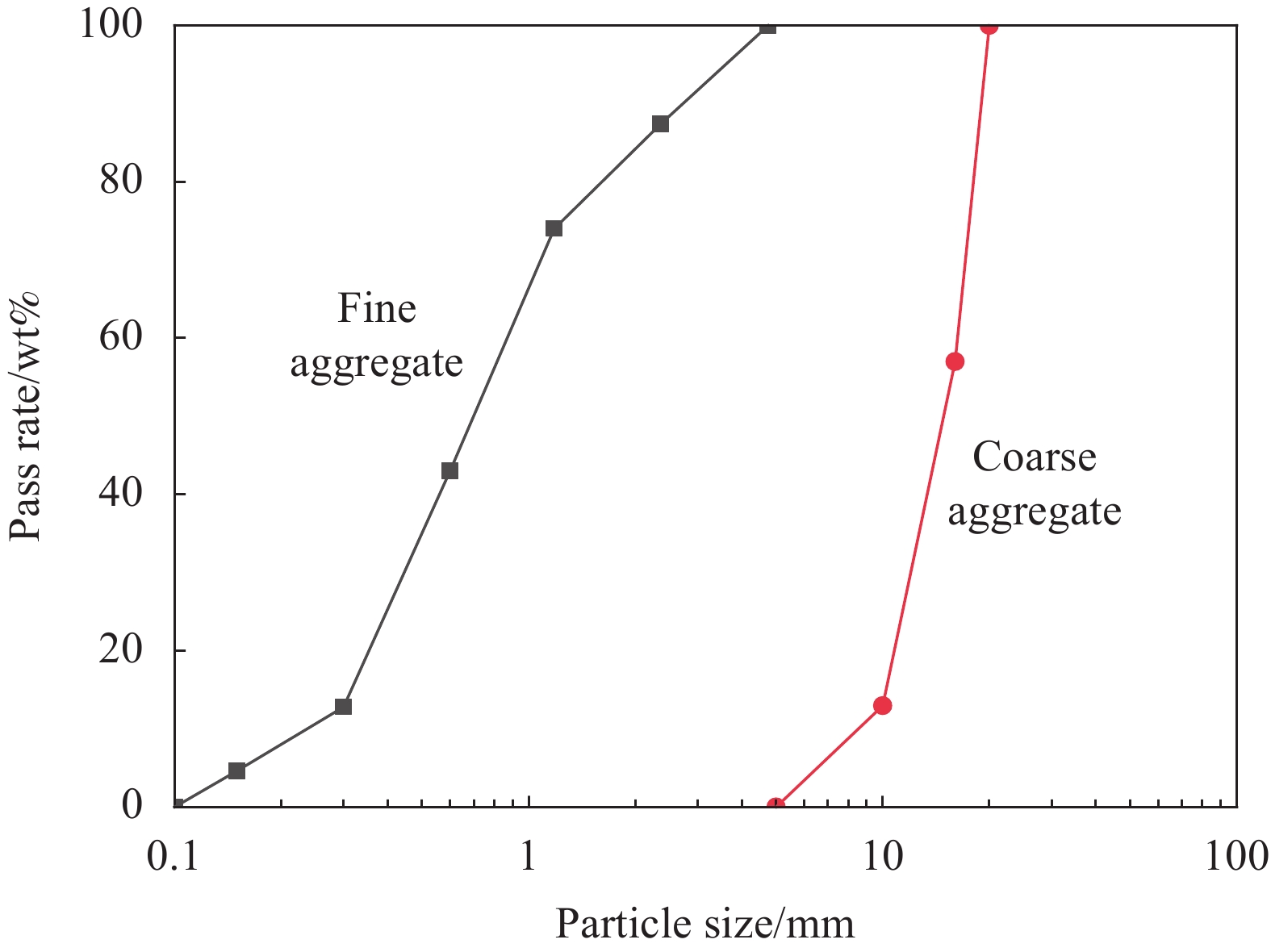

method/mm3 days 28 days 3 days 28 days 3.06 351 0.28 28.0 170 235 0.50 5.6 8.9 29.0 57.3 表 3 砂的筛分析结果

Table 3. Sieve analysis results of sand

Sieve pore/mm Proportion/wt% Cumulative proportion/wt% 9.50 — — 4.75 0.0 0.0 2.36 12.6 12.6 1.18 13.4 26.0 0.60 31.0 57.0 0.30 30.2 87.2 0.15 8.2 95.4 表 4 纳米导电炭黑Super-P (CBSP)的性能参数

Table 4. Performance parameters of conductive carbon black Super-P (CBSP)

Type Mean grain

size/nmSpecific

area/(m2·g−1)DBP

valueCarbon

content/wt%Volatile con-tent/vol% Ash

content/wt%Density/

(kg·m−3)pH Specific

resistance/(Ω·cm)Super-P 40 62 290 ≥99.5 ≤0.15 ≤0.05 125 8 0.15-0.25 Note: DBP—Carbon black oil absorption. 表 5 CBSP混凝土试件编号

Table 5. Serial numbers of CBSP concretes

Serial number Abbreviation Cement/(kg·m−3) Sand/(kg·m−3) Stone/(kg·m−3) Water/(kg·m−3) W/C CBSP/wt% 0.00wt%CBSP/C-0.53 C0 387 683 1115 205 0.53 0.00 0.25wt%CBSP/C-0.53 C1 387 683 1115 205 0.53 0.25 0.50wt%CBSP/C-0.53 C2 387 683 1115 205 0.53 0.50 0.75wt%CBSP/C-0.53 C3 387 683 1115 205 0.53 0.75 1.00wt%CBSP/C-0.53 C4 387 683 1115 205 0.53 1.00 2.00wt%CBSP/C-0.53 C5 387 683 1115 205 0.53 2.00 3.00wt%CBSP/C-0.53 C6 387 683 1115 205 0.53 3.00 0.00wt%CBSP/C-0.63 B0 387 683 1115 244 0.63 0.00 0.25wt%CBSP/C-0.63 B1 387 683 1115 244 0.63 0.25 0.50wt%CBSP/C-0.63 B2 387 683 1115 244 0.63 0.50 0.75wt%CBSP/C-0.63 B3 387 683 1115 244 0.63 0.75 1.00wt%CBSP/C-0.63 B4 387 683 1115 244 0.63 1.00 2.00wt%CBSP/C-0.63 B5 387 683 1115 244 0.63 2.00 3.00wt%CBSP/C-0.63 B6 387 683 1115 244 0.63 3.00 Notes: 0.00wt%CBSP/C-0.53—Concrete with water cement ratio of 0.53 and CBSP content of 0.00wt%; W/C—Water cement mass ratio. 表 6 W/C=0.53 CBSP混凝土温敏性曲线拟合参数

Table 6. Fitting parameters of CBSP concrete temperature sensitivity curve with W/C=0.53

Parameter A B R2 0.00wt%CBSP/C-0.53 −0.55081 3 377.85960 0.99597 0.25wt%CBSP/C-0.53 −0.81745 3 442.25644 0.99120 0.50wt%CBSP/C-0.53 −101.31949 313 277.24880 0.99483 0.75wt%CBSP/C-0.53 1.17462 2 707.85747 0.98732 1.00wt%CBSP/C-0.53 0.03326 3 019.87428 0.99705 2.00wt%CBSP/C-0.53 7.01614 204.24485 0.95776 3.00wt%CBSP/C-0.53 6.63551 109.41760 0.97458 Notes: A,B—Fit the curve parameters; R—Coefficient of determination. 表 7 W/C=0.63 CBSP混凝土温敏性曲线拟合参数

Table 7. Fitting parameters of CBSP concrete temperature sensitivity curve with W/C=0.63

Parameter A B R2 0.00wt%CBSP/B-0.63 1.08724 2 862.18204 0.98602 0.25wt%CBSP/B-0.63 0.87482 2 926.42100 0.99256 0.50wt%CBSP/B-0.63 1.33534 2 759.96766 0.99416 0.75wt%CBSP/B-0.63 1.53696 2 665.37278 0.99559 1.00wt%CBSP/B-0.63 1.51155 2 607.06713 0.99333 2.00wt%CBSP/B-0.63 6.08571 600.09686 0.98262 3.00wt%CBSP/B-0.63 6.43309 267.29325 0.98163 -

[1] DAHLAN A S. Impact of nanotechnology on high performance cement and concrete[J]. Journal of Molecular Structure,2020,1223:128896. doi: 10.1016/j.molstruc.2020.128896 [2] LIU D J, CHEN M J, XUE L, et al. The effect of the carbon fiber on concrete compressive strength[J]. Advanced Materials Research,2018,1145:106-111. doi: 10.4028/www.scientific.net/AMR.1145.106 [3] JANG S H, HOCHSTEIN D P, KAWASHIMA S, et al. Experiments and micromechanical modeling of electrical conductivity of carbon nanotube/cement composites with moisture[J]. Cement and Concrete Composites,2017,77:49-59. doi: 10.1016/j.cemconcomp.2016.12.003 [4] DIMOV D, AMIT I, GORRIE O, et al. Ultrahigh performance nanoengineered graphene-concrete composites for multifunctional applications[J]. Advanced Functional Materials,2018,28(23):1705183. doi: 10.1002/adfm.201705183 [5] PAN Z, HE L, QIU L, et al. Mechanical properties and microstructure of a graphene oxide-cement composite[J]. Cement and Concrete Composites,2015,58:140-147. doi: 10.1016/j.cemconcomp.2015.02.001 [6] CHUAH S, ZHU P, SANJAYAN J G, et al. Nano reinforced cement and concrete composites and new perspective from graphene oxide[J]. Construction and Building Materials,2014,73:113-124. doi: 10.1016/j.conbuildmat.2014.09.040 [7] WANG B M, HAN Y, PAN B F, et al. Mechanical and morphological properties of highly dispersed carbon nanotubes reinforced cement based materials[J]. Journal of Wuhan University of Technology (Materials Science Edition),2013,28(1):82-87. doi: 10.1007/s11595-013-0645-1 [8] CHAIPANICH A, NOCHAYA T, WONGKEO W, et al. Compressive strength and microstructure of carbon nanotubes-fly ash cement composites[J]. Materials Science and Engineering: A,2010,527(4-5):1063-1067. doi: 10.1016/j.msea.2009.09.039 [9] BODNAROVA L, JAROLIM T. Study the effect of carbon nanoparticles in concrete[C]//International Conference on Construmat. Bristol: Institute of Physics, 2018: 13-15. [10] RU H Z, ZHAO R R. Research on electrical double percolation of carbon black-filled cement-based composites[J]. Advanced Materials Research,2011,311-313:201-204. doi: 10.4028/www.scientific.net/AMR.311-313.201 [11] ELKADY H, HASSAN A. Assessment of high thermal effects on carbon nanotube (CNT)-reinforced concrete[J]. Scientific Reports,2018,8:11243. doi: 10.1038/s41598-018-29663-5 [12] LIM M J, LEE H K, NAM I W, et al. Carbon nanotube/cement composites for crack monitoring of concrete structures[J]. Composite Structures,2017,180:741-750. doi: 10.1016/j.compstruct.2017.08.042 [13] DING Y, HAN Z, ZHANG Y, et al. Concrete with triphasic conductive materials for self-monitoring of cracking development subjected to flexure[J]. Composite Structures,2015,138:184-191. doi: 10.1016/j.compstruct.2015.11.051 [14] TUAN C Y, YEHIA S. Evaluation of electrically conductive concrete containing carbon products for deicing[J]. Materials Journal,2004,101(4):287-293. [15] KHALID T, ALBASHA L, QADDOUMI N, et al. Feasibility study of using electrically conductive concrete for electromagnetic shielding applications as a substitute for carbon-laced polyurethane absorbers in anechoic chambers[J]. IEEE Transactions on Antennas & Propagation,2017,65(5):2428-2435. [16] 徐令娜, 赵庆新, 李炜, 等. 碳纤维炭黑导电混凝土的接地特性研究[J]. 硅酸盐通报, 2014, 33(12):3366-3370.XU Lingna, ZHAO Qingxin, LI Wei, et al. Grounding characteristics of carbon fiber carbon black conductive concrete[J]. Bulletin of the Chinese Ceramic Society,2014,33(12):3366-3370(in Chinese). [17] PACHECO-TORGAL F, JALALI S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials[J]. Construction and Building Materials,2011,25(2):582-590. doi: 10.1016/j.conbuildmat.2010.07.009 [18] WANG Y F, ZHAO Y, ZHAO X H, et al. Mechanical and strain-sensing properties of cement-matrix composite containing nano-sized carbon black[J]. Key Engineering Materials,2019,815:203-209. doi: 10.4028/www.scientific.net/KEM.815.203 [19] REZANIA M, PANAHANDEH M, RAZAVI M J, et al. Experimental study of the simultaneous effect of nano-silica and nano-carbon black on permeability and mechanical properties of the concrete[J]. Theoretical and Applied Fracture Mechanics,2019,104:102391. doi: 10.1016/j.tafmec.2019.102391 [20] WANG J W, ZHANG W K, JIAO C, et al. Activated carbon based supercapacitors with a reduced graphene oxide additive: Preparation and properties[J]. Journal of Nanoscience and Nanotechnology,2020,20(7):4073-4083. doi: 10.1166/jnn.2020.17688 [21] GNANAMUTHU R, LEE C W. Electrochemical properties of Super P carbon black as an anode active material for lithium-ion batteries[J]. Materials Chemistry & Physics,2011,130(3):831-834. [22] HONGWEN C, HAIXIN Z, TIAN Z, et al. Nanostructured Nb2O5 cathode for high-performance lithium-ion battery with Super-P and graphene compound conductive agents[J]. Journal of Electroanalytical Chemistry,2018,827:112-119. doi: 10.1016/j.jelechem.2018.08.037 [23] MARINARO M, MANCINI M, NOBILI F, et al. A newly designed Cu/Super-P composite for the improvement of low-temperature performances of graphite anodes for lithium-ion batteries[J]. Journal of Power Sources,2013,222:66-71. doi: 10.1016/j.jpowsour.2012.08.065 [24] KIM H K, NAM I W, LEE H K. Enhanced effect of carbon nanotube on mechanical and electrical properties of cement composites by incorporation of silica fume[J]. Composite Structures,2014,107:60-69. doi: 10.1016/j.compstruct.2013.07.042 [25] 朱洪波, 王培铭, 李晨, 等. 多壁碳纳米管在水泥浆中的分散性[J]. 硅酸盐学报, 2012, 40(10):1431-1436. doi: 10.14062/j.issn.0454-5648.2012.10.021ZHU Hongbo, WANG Peiming, LI Chen, et al. Dispersion of multi-walled carbon nanotubes in cement slurries[J]. Journal of the Chinese Ceramic Society,2012,40(10):1431-1436(in Chinese). doi: 10.14062/j.issn.0454-5648.2012.10.021 [26] 檀付瑞, 李红波, 桂慧, 等. 超声分散对单壁碳纳米管分离的影响[J]. 物理化学学报, 2012, 28(7):1790-1796. doi: 10.3866/PKU.WHXB201204174TAN Furui, LI Hongbo, GUI Hui, et al. Effect of ultrasonic dispersion on the separation of SWCNTs[J]. Acta Physico-Chimica Sinica,2012,28(7):1790-1796(in Chinese). doi: 10.3866/PKU.WHXB201204174 [27] WU J M, LIU J G, YANG F. Three-phase composite conductive concrete for pavement deicing[J]. Construction and Building Materials,2015,75:129-135. doi: 10.1016/j.conbuildmat.2014.11.004 [28] 中国国家标准化管理委员会. 普通混凝土拌合物性能试验方法标准: GB/T 50080—2016[S]. 北京: 中国建筑工业出版社, 2016.Standardization Administration of China. Standard for test method of performance on ordinary fresh concrete: GB/T 50080—2016[S]. Beijing: China Architecture & Building Press , 2016(in Chinese). [29] 中国国家标准化管理委员会. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2002.Standardization Administration of China. Standard for test method of mechanical properties on ordinary concrete: GB/T 50081—2002[S]. Beijing: China Architecture & Building Press , 2002(in Chinese). [30] 中国国家标准化管理委员会. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009.Standardization Administration of China. Standard for test methods of long-term performance and durability of ordinary concrete: GB/T 50082—2009[S]. Beijing: China Architecture & Building Press, 2009(in Chinese). [31] NORHASRI M S M, HAMIDAH M S, FADZIL A M. Applications of using nano material in concrete: A review[J]. Construction and Building Materials,2017,133:91-97. doi: 10.1016/j.conbuildmat.2016.12.005 [32] SUROVIKIN Y V, SHAITANOV A G, RESANOV I V, et al. The properties of nanodispersed carbon black particles after thermal treatment[J]. Procedia Engineering,2015,113:519-524. doi: 10.1016/j.proeng.2015.07.345 [33] 柳逸凡. 炭黑本征性能与其填充聚乙烯复合材料导电性能的研究[D]. 北京: 北京化工大学, 2016.LIU Yifan. Study on the intrinsic properties of carbon black and its electrical conductivity of polyethylene composites[D]. Beijing: Beijing University of Chemical Technology, 2016(in Chinese). [34] NALON G H, RIBEIRO J C L, DE ARAÚJO E N D, et al. Effects of different kinds of carbon black nanoparticles on the piezoresistive and mechanical properties of cement-based composites[J]. Journal of Building Engineering,2020,32:101724. doi: 10.1016/j.jobe.2020.101724 [35] 王琴, 李时雨, 王健, 等. 氧化石墨烯对水泥水化进程及其主要水化产物的影响[J]. 硅酸盐学报, 2018, 46(2):163-172. doi: 10.14062/j.issn.0454-5648.2018.02.10WANG Qin, LI Shiyu, WANG Jian, et al. Effect of graphene oxide on hydration process and main hydration products of cement[J]. Journal of the Chinese Ceramic Society,2018,46(2):163-172(in Chinese). doi: 10.14062/j.issn.0454-5648.2018.02.10 [36] WANG S, MA S, CAO L, et al. Conductive vitrimer nanocomposites enable advanced and recyclable thermo-sensitive materials[J]. Journal of Materials Chemistry C,2020,8(34):11681-11686. doi: 10.1039/D0TC02821E [37] SUN W Z, LI X, YANG Q, et al. Resistivity-temperature characteristics of conductive asphalt concrete[J]. Journal of Wuhan University of Technology (Materials Science),2016,31(2):367-371. doi: 10.1007/s11595-016-1377-9 -

下载:

下载: