Forming characteristics of Mg/Al laminated composite based on lattice severe deformation rolling

-

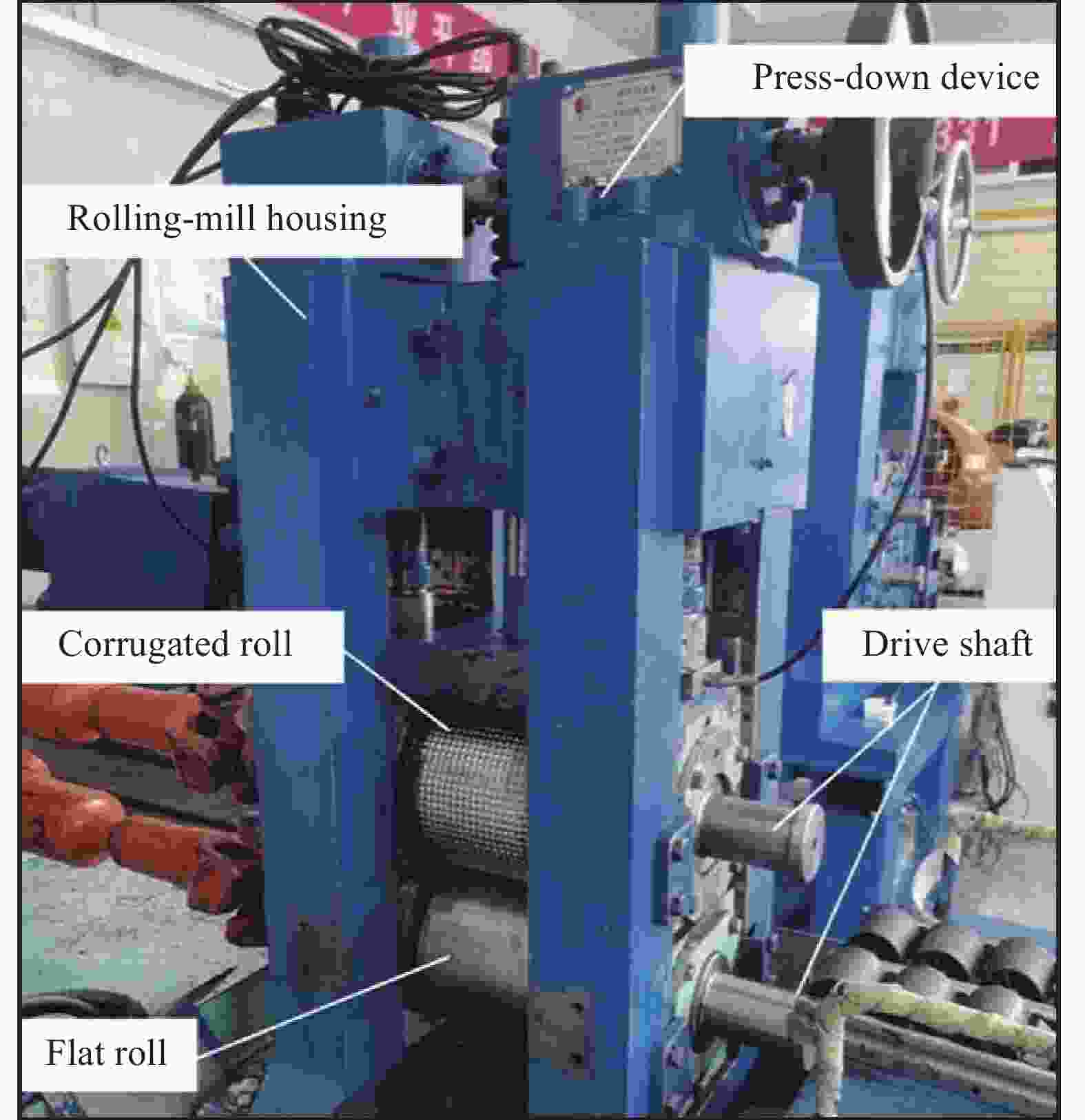

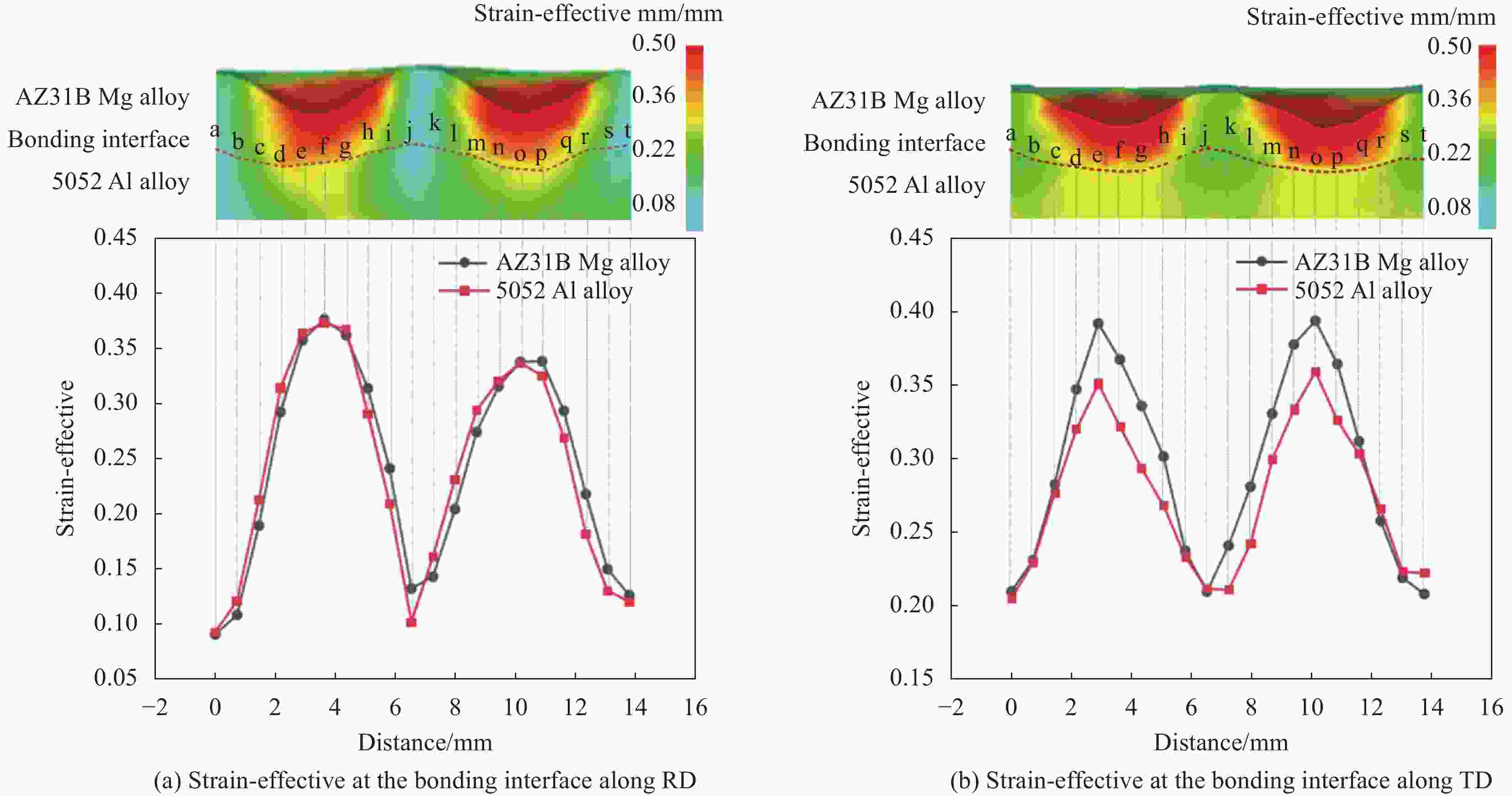

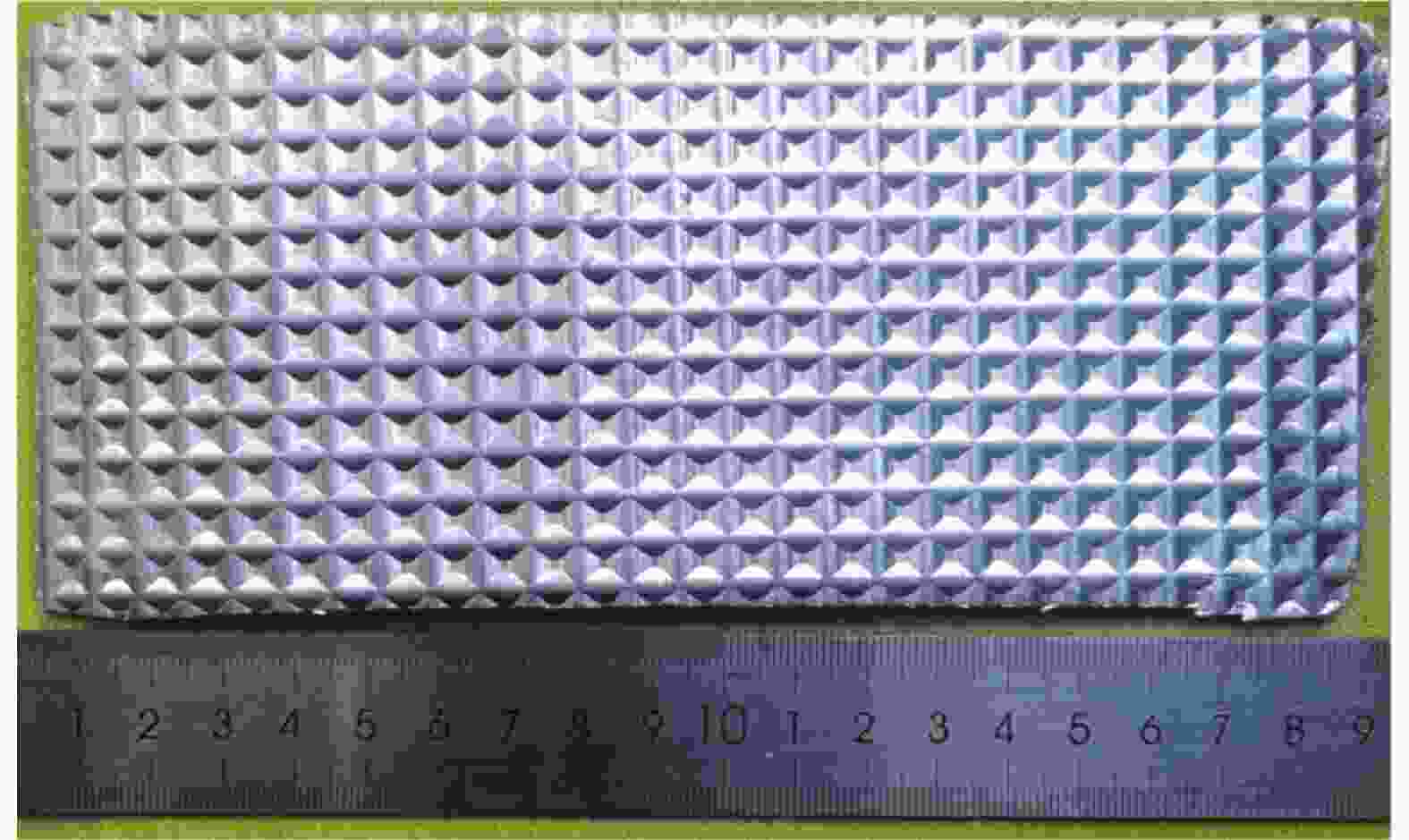

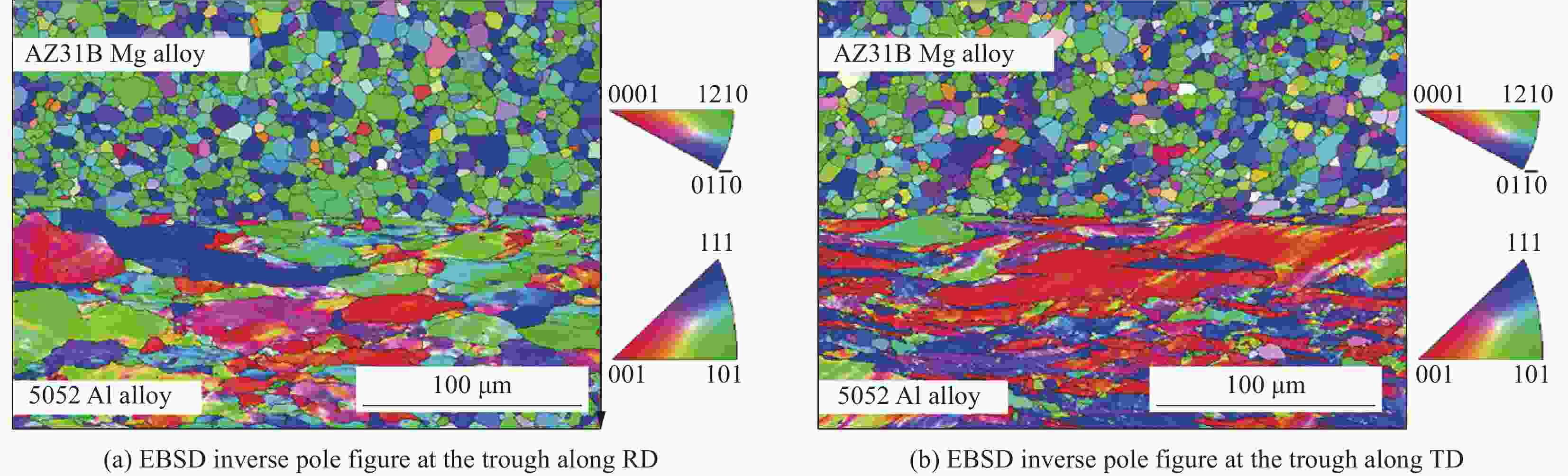

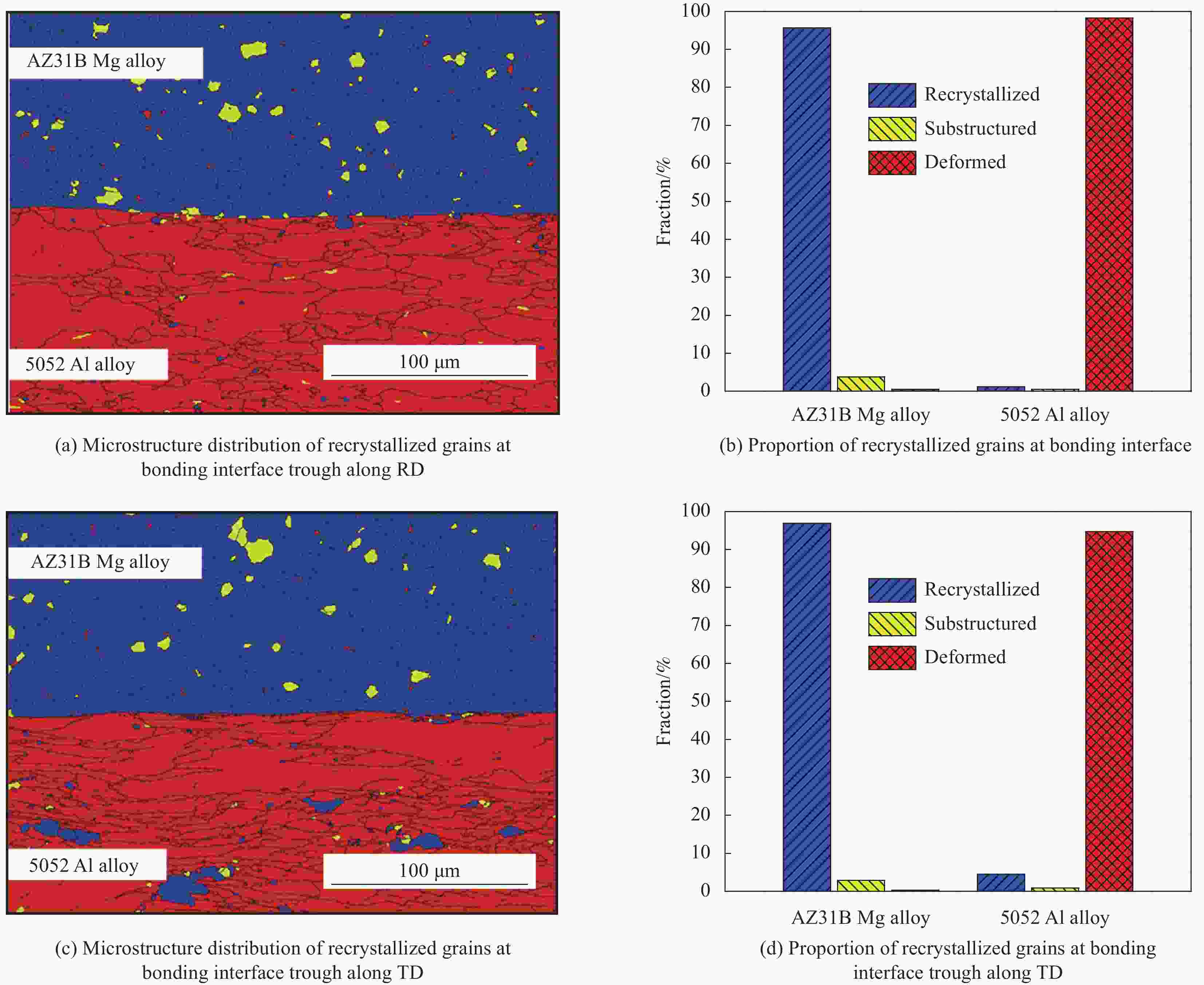

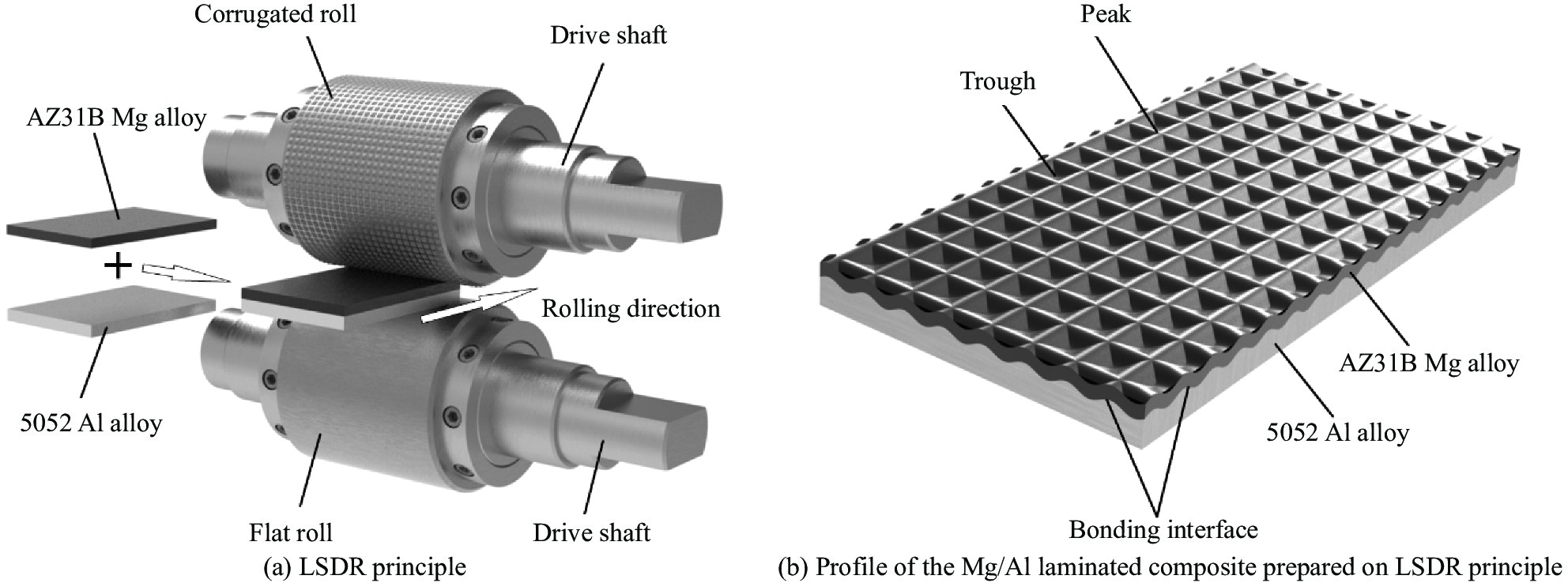

摘要: 针对镁/铝层合板轧制过程中存在结合强度低、翘曲和边裂严重等技术难题,研究了基于点阵强变形轧制(Lattice severe deformation rolling,LSDR)原理以波纹辊对其一道次轧制成形。借助有限元数值计算分析了金属板材在复杂辊缝下的塑性流动规律和成形特点,并进行了轧制实验。结果表明:LSDR原理轧制镁/铝层合板时,波纹辊能够对难变形的镁合金及结合界面处产生点阵状分布的局部强非均匀变形作用,增强镁合金沿轧向(Rolling direction,RD)和横向(Transverse direction,TD)的塑性流动,并在结合界面处产生更大的剪切应力。相较于传统平轧,LSDR原理轧制所得镁/铝层合板的抗拉强度、拉剪强度和抗弯强度均有提高,其中拉剪强度最大增幅达77%;并且结合界面均匀可靠,产生约5 μm厚的扩散层。研究内容为高质量镁/铝层合板的制备提供了有价值的参考。Abstract: Aiming at the technical problems such as low bonding strength, serious warpage and edge cracks in the rolling process of Mg/Al laminated composite, one rolling pass forming with a corrugated roll was studied based on lattice severe deformation rolling (LSDR) principle. The plastic flow law and forming characteristics of the metal plates at complex roll gap were analyzed by finite element numerical calculation, and the rolling experiment was performed. The results show that a series of local strong non-uniform deformation effects distributed as a lattice structure can be applied on the magnesium alloy plate and at the bonding interface by the corrugated roll, and the plastic flow along both rolling direction (RD) and transverse direction (TD) has been strengthened when the LSDR principle is used. Additionally, larger shearing stress can be produced at the bonding interface. Compared with the traditional rolling using flat rolls, the tensile strength, tensile-shear strength and bending strength of the laminated composite prepared on the LSDR principle are significantly improved, and the maximum increase rate of tensile-shear strength obtained reaches 77%. Meanwhile, the bonding interface is uniform and reliable. The diffusion layer is about 5 μm thick. This study provides a valuable reference for the preparation of high-quality Mg/Al laminated composite.

-

表 1 AZ31B镁合金与5052铝合金的化学成分

Table 1. Chemical composition of AZ31B Mg alloy and 5052 Al alloy

wt% Material Mg Cu Ca Mn Si Al Zn Cr Fe AZ31B Mg alloy Others 0.01 0.04 0.8 0.07 3.2 1.2 – – 5052 Al alloy 2.2-2.8 0.1 – 0.1 0.25 Others 0.1 0.15-0.35 0.4 -

[1] 陈连生, 张鑫磊, 郑小平, 等. 轧制双金属复合板材的研究现状[J]. 稀有金属材料与工程, 2018, 47(10):3243-3250.CHEN Liansheng, ZHANG Xinlei, ZHENG Xiaoping, et al. Research status of bimetal laminated composite plate prepared by rolling process[J]. Rare Metal Materials and Engineering,2018,47(10):3243-3250(in Chinese). [2] KUZ'MIN E V, LYSAK V I, KUZ'MIN S V, et al. Influence of structure formation and properties of bimetal produced by ultrasound-assisted explosive welding[J]. Journal of Manu-facturing Processes,2021,71:734-742. [3] 彭治力, 颜家维, 唐靖钊, 等. 电流辅助累积叠轧镁/铝层状复合板的微观形貌及力学性能[J]. 机械工程材料, 2019, 43(12):1-6. doi: 10.11973/jxgccl201912001PENG Zhili, YAN Jiawei, TANG Jingzhao, et al. Microstructure and mechanical properties of Mg/Al multilayered composite sheet by electrically-assisted accumulative roll bonding[J]. Materials for Mechanical Engineering,2019,43(12):1-6(in Chinese). doi: 10.11973/jxgccl201912001 [4] WANG T, LIU W L, LIU Y M, et al. Formation mechanism of dynamic multi-neutral points and cross shear zones in corrugated rolling of Cu/Al laminated composite[J]. Journal of Materials Processing Technology,2021,295:117157. doi: 10.1016/j.jmatprotec.2021.117157 [5] WU Y, FENG B, XIN Y C, et al. Microstructure and mecha-nical behavior of a Mg AZ31/Al 7050 laminate composite fabricated by extrusion[J]. Materials Science and Engi-neering: A,2015,640:454-459. doi: 10.1016/j.msea.2015.05.094 [6] 赵博文, 周存龙, 赵广辉, 等. 轧制工艺制备镁铝层合板的研究现状[J]. 重型机械, 2020(5):1-8. doi: 10.3969/j.issn.1001-196X.2020.05.001ZHAO Bowen, ZHOU Cunlong, ZHAO Guanghui, et al. Research status of Mg-Al laminate prepared by rolling process[J]. Heavy Machinery,2020(5):1-8(in Chinese). doi: 10.3969/j.issn.1001-196X.2020.05.001 [7] ZHU Y C, WEI Z J, RONG S F, et al. Formation mechanism of bimetal composite layer between LCS and HCCI[J]. China Foundry,2016,13(6):396-401. [8] PENG B, JIE J C, WANG M F, et al. Microstructure characteristics and deformation behavior of tin bronze/1010 steel bimetal layered composite by continuous solid/liquid bonding[J]. Materials Science and Engineering: A,2022,844:143155. [9] 王涛, 齐艳阳, 刘江林, 等. 金属层合板轧制复合工艺国内外研究进展[J]. 哈尔滨工业大学学报, 2020, 52(6):42-56. doi: 10.11918/202003114WANG Tao, QI Yanyang, LIU Jianglin, et al. Research progress of metal laminates roll bonding process at home and abroad[J]. Journal of Harbin Institute of Technology,2020,52(6):42-56(in Chinese). doi: 10.11918/202003114 [10] HUO P D, LI F, WANG Y, et al. Formability and interface structure of Al/Mg/Al composite sheet rolled by hard-plate rolling (HPR)[J]. The International Journal of Advanced Manufacturing Technology,2022,118(1-2):55-65. doi: 10.1007/s00170-021-07178-0 [11] 范金辉, 李鹏飞, 梁晓军, 等. 镍-不锈钢复合板轧制过程中界面的结合机制[J]. 材料研究学报, 2021, 35(7):493-500.FAN Jinhui, LI Pengfei, LINAG Xiaojun, et al. Interface evolution during rolling of Ni-clad stainless steel plate[J]. Chinese Journal of Materials Research,2021,35(7):493-500(in Chinese). [12] WANG S, HUANG L J, LIU B X, et al. Microstructure and mechanical properties of Ti6Al4V based laminated compo-sites at various rolling reductions[J]. Composites Communications,2022,33:101212. doi: 10.1016/j.coco.2022.101212 [13] ZHANG X P, YANG T H, CASTAGNE S, et al. Microstructure, bonding strength and thickness ratio of Al/Mg/Al alloy laminated composites prepared by hot rolling[J]. Materials Science and Engineering A,2011,528(4-5):1954-1960. doi: 10.1016/j.msea.2010.10.105 [14] CHEN Z J, LIU Q, WANG G J, et al. Deformation inhomogeneities of Mg-Al laminated metal composites fabricated by accumulative roll bonding[J]. Materials Research Innovations,2015,19(S4):147-151. [15] 谢红飙, 郑阳, 郭允畅, 等. 轧制制备铝/镁复合板数值模拟和翘曲变形控制[J]. 精密成形工程, 2021, 13(6):42-48. doi: 10.3969/j.issn.1674-6457.2021.06.005XIE Hongbiao, ZHENG Yang, GUO Yunchang, et al. Numerical simulation and warpage deformation control of rolled aluminum/magnesium composite plate[J]. Journal of Netshape Forming Engineering,2021,13(6):42-48(in Chinese). doi: 10.3969/j.issn.1674-6457.2021.06.005 [16] NIE H H, LIANG W, CHI C Z, et al. Effect of annealing on microstructure and tensile properties of 5052/AZ31/5052 clad sheets[J]. The Journal of the Minerals, Metals & Materials Society (TMS),2016,68(5):1282-1292. [17] 常东旭, 王平, 赵莹莹. 铜/铝异步轧制复合带的界面反应与强化机制[J]. 东北大学学报(自然科学版), 2019, 40(11):1574-1578, 1583. doi: 10.12068/j.issn.1005-3026.2019.11.010CHANG Dongxu, WANG Ping, ZHAO Yingying. Interfacial reaction and strengthening mechanism of Cu/Al compo-site strip produced by asymmetrical rolling[J]. Journal of Northeastern University (Natural Science),2019,40(11):1574-1578, 1583(in Chinese). doi: 10.12068/j.issn.1005-3026.2019.11.010 [18] DHINWAL S S, ERNOULD C, BEAUSIR B. Facilitating the occurrence of dynamic recrystallization in plain extra low-carbon steel by warm asymmetric rolling[J]. Materials Characterization,2022,189:111942. doi: 10.1016/j.matchar.2022.111942 [19] 祖国胤, 李小兵, 丁明明, 等. 异步轧制铜/铝双金属复合板变形行为的研究[J]. 东北大学学报(自然科学版), 2011, 32(5): 675-678.ZU Guoying, LI Xiaobing, DING Mingming, et al. Investigating deformation behavior of asymmetrically rolled Cu/Al bimetal clad sheets[J]. Journal of Northeastern University (Natural Science), 2011, 32(5):675-678(in Chinese). [20] 刘子健, 赵红阳, 胡小东, 等. 轧制温度和轧制方式对镁铝复合板组织性能的影响[J]. 轻金属, 2015(10):55-58.LIU Zijian, ZHAO Hongyang, HU Xiaodong, et al. Effects of rolling temperature and method on the microstructure and performance of Mg-Al clad sheets[J]. Light Metals,2015(10):55-58(in Chinese). [21] 魏伟, 史庆南. 铜/钢双金属板异步轧制复合机理研究[J]. 稀有金属, 2001, 25(4):307-311. doi: 10.3969/j.issn.0258-7076.2001.04.016WEI Wei, SHI Qingnan. Bonding mechanism of Cu/steel clad sheet in asymmetrical rolling of bimetal[J]. Rare Metals,2001,25(4):307-311(in Chinese). doi: 10.3969/j.issn.0258-7076.2001.04.016 [22] FENG G, WANG L, GAO H J. Lattice severe deformation rolling (LSDR) for bimetal laminated composite preparation[J]. Materials and Manufacturing Processes, 2023, 38(4): 409 − 415. [23] XU J J, FU J Y, LI S J, et al. Effect of annealing and cold rolling on interface microstructure and properties of Ti/Al/Cu clad sheet fabricated by horizontal twin-roll casting[J]. Journal of Materials Research and Technology,2022,16:530-543. doi: 10.1016/j.jmrt.2021.12.017 [24] 潘复生, 蒋斌. 镁合金塑性加工技术发展及应用[J]. 金属学报, 2021, 57(11):1362-1379. doi: 10.11900/0412.1961.2021.00349PAN Fusheng, JIANG Bin. Development and application of plastic processing technologies of magnesium alloys[J]. Acta Metallurgica Sinica,2021,57(11):1362-1379(in Chinese). doi: 10.11900/0412.1961.2021.00349 [25] PEKGULERYUZ M, CELIKIN M, HOSEINI M, et al. Study on edge cracking and texture evolution during 150°C rolling of magnesium alloys: The effects of axial ratio and grain size[J]. Journal of Alloys and Compounds,2012,510(1):15-25. doi: 10.1016/j.jallcom.2011.08.093 [26] 张柏瑞, 周存龙, 赵广辉, 等. 双温段热轧态镁铝层合板性能分析[J]. 塑性工程学报, 2022, 29(5):79-85. doi: 10.3969/j.issn.1007-2012.2022.05.010ZHANG Borui, ZHOU Cunlong, ZHAO Guanghui, et al. Property analysis of hot rolled Mg-Al laminates at double-temperature section[J]. Journal of Plasticity Engineering,2022,29(5):79-85(in Chinese). doi: 10.3969/j.issn.1007-2012.2022.05.010 [27] ZHAO G X, LANG Y J, HAO J, et al. Nb/NiTi laminate composite with high pseudoelastic energy dissipation capacity[J]. Materials Today Nano,2022,19:100238. doi: 10.1016/j.mtnano.2022.100238 [28] MA X G, ZHAO J W, DU W, et al. Quantification of texture-induced ridging in ferritic stainless steels 430 and 430LR during tensile deformation[J]. Journal of Materials Research and Technology,2019,8(2):2041-2051. doi: 10.1016/j.jmrt.2018.12.019 [29] 宋广胜, 姜敬前, 陈帅峰, 等. 非对称轧制AZ31镁合金板材组织与性能[J]. 稀有金属材料与工程, 2017, 46(11):3512-3517.SONG Guangsheng, JIANG Jingqian, CHEN Shuaifeng, et al. Microstructure and mechanical properties of AZ31 magnesium alloy sheet processed by asymmetry rolling[J]. Rare Metal Materials and Engineering,2017,46(11):3512-3517(in Chinese). [30] NIE J, LIU M, WANG F, et al. Fabrication of Al/Mg/Al composites via accumulative roll bonding and their mechanical properties[J]. Materials,2016,9(11):951. doi: 10.3390/ma9110951 [31] FAN J, DAI X, XIE R, et al. Surface ferrite grain refinement and mechanical properties of low carbon steel plates[J]. Journal of Iron and Steel Research,2006,13(4):35-39. doi: 10.1016/S1006-706X(06)60074-5 [32] 梅瑞斌, 史现利, 包立, 等. 多道次热辊轧制Al/Mg 层状复合板材结合面特性[J]. 复合材料学报, 2022, 39(7):3485-3497.MEI Ruibin, SHI Xianli, BAO Li, et al. Interface characteristics study of Al/Mg laminated composite sheets by multi-passes RHR[J]. Acta Materiae Compositae Sinica,2022,39(7):3485-3497(in Chinese). [33] 蔡正旭. 热轧变形Mg-1.5 Zn-(0.2~1.0)Gd合金再结晶组织及织构演变规律研究[J]. 稀有金属, 2022, 46(5):581-588.CAI Zhengxu. Recrystallization and texture mechanism of hot rolled Mg-1.5 Zn-(0.2-1.0)Gd alloy[J]. Chinese Journal of Rare Metals,2022,46(5):581-588(in Chinese). [34] LI Q K, YAN H, LIU H H, et al. Dynamic recrystallization mechanism and near-isotropic mechanical properties of WE43 magnesium alloy sheets rolled at different tempera-tures[J]. Materials Characterization,2022,193:112259. doi: 10.1016/j.matchar.2022.112259 [35] WANG T, LI S, NIU H, et al. EBSD research on the interfacial microstructure of the corrugated Mg/Al laminated material[J]. Journal of Materials Research and Technology,2020,9(3):5840-5847. doi: 10.1016/j.jmrt.2020.03.111 -

下载:

下载: