Synthesis and characterization of the barium titanate-potassium sodium niobate relaxor ferroelectric energy storage ceramics

-

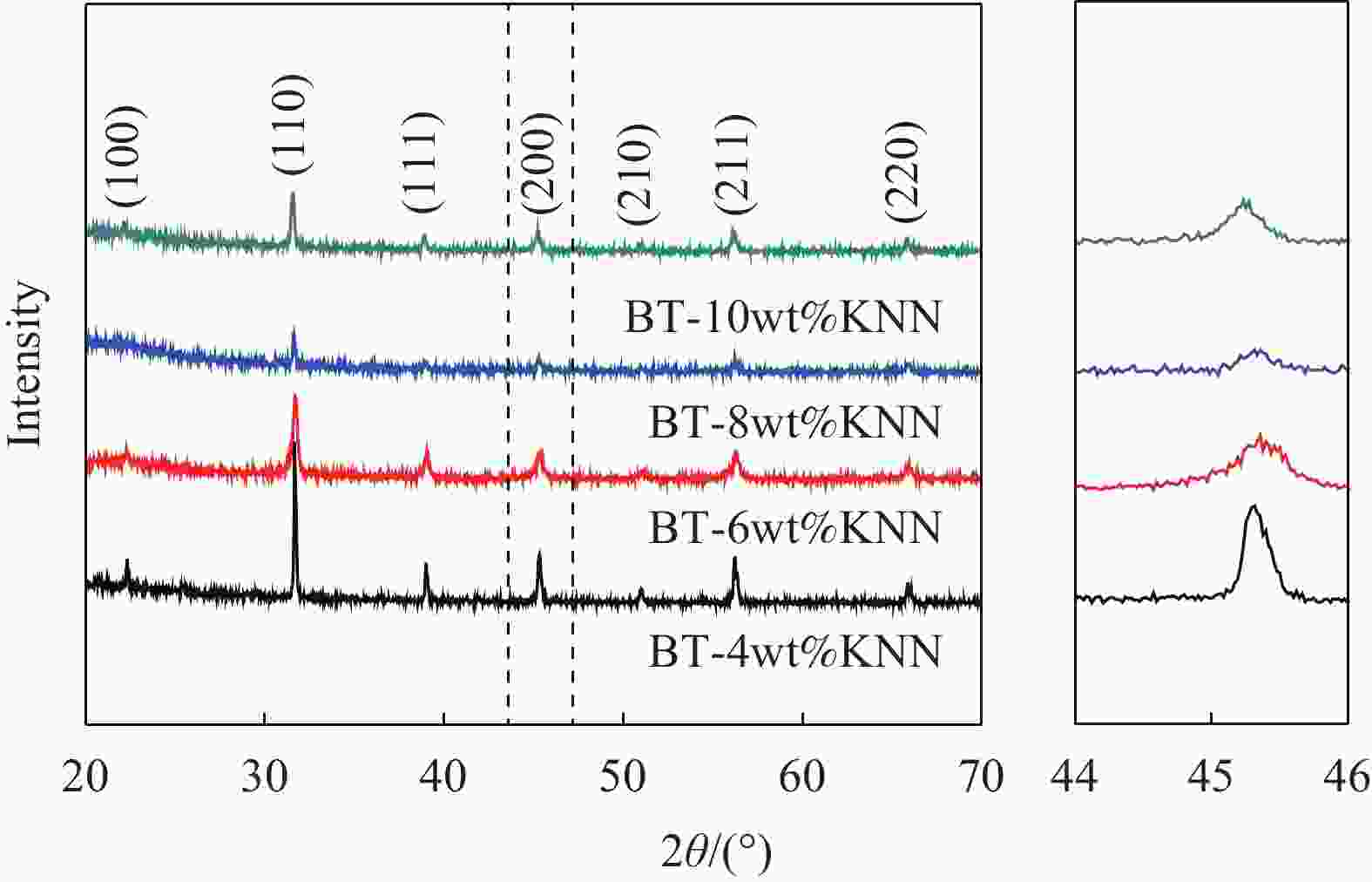

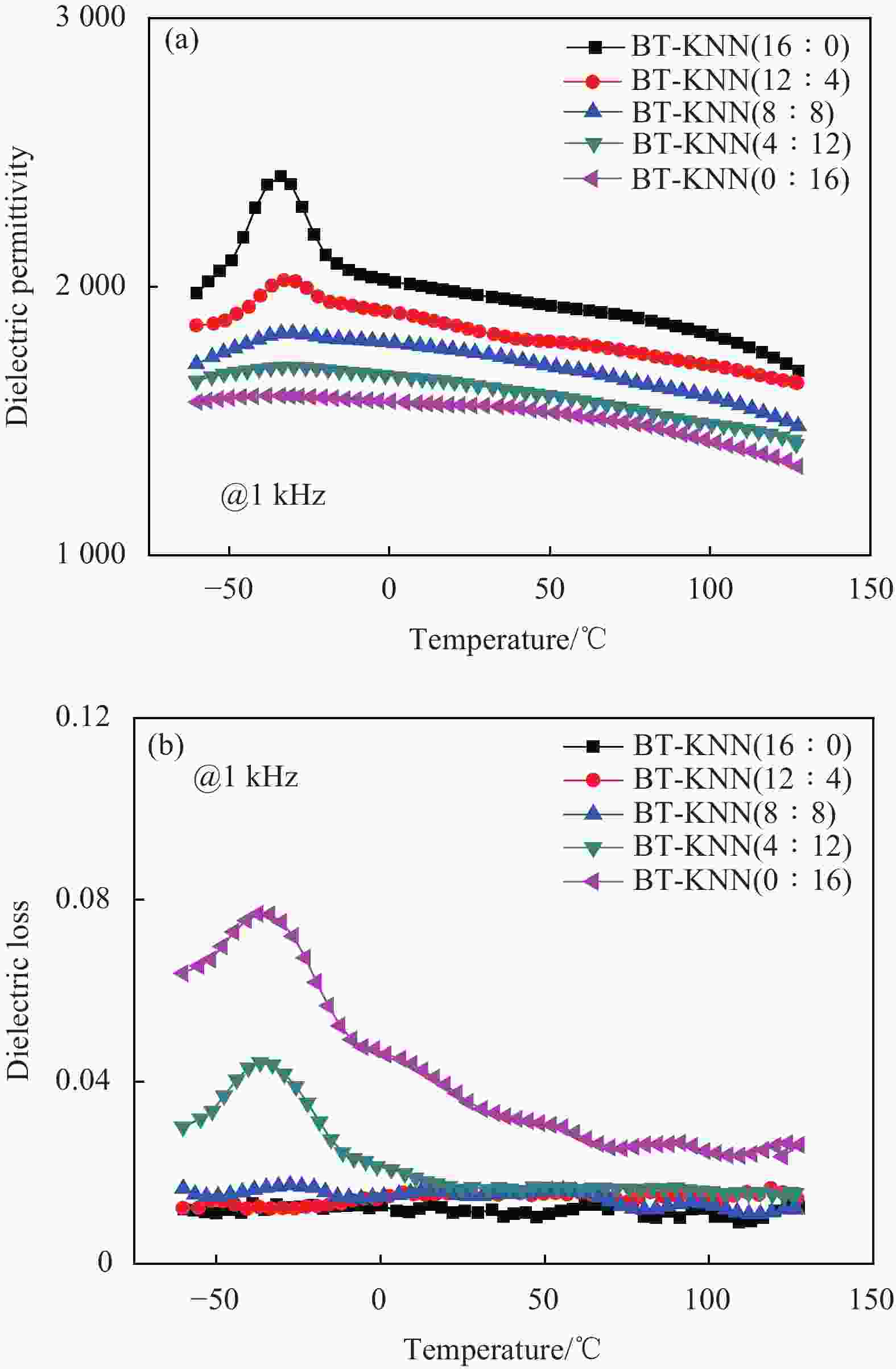

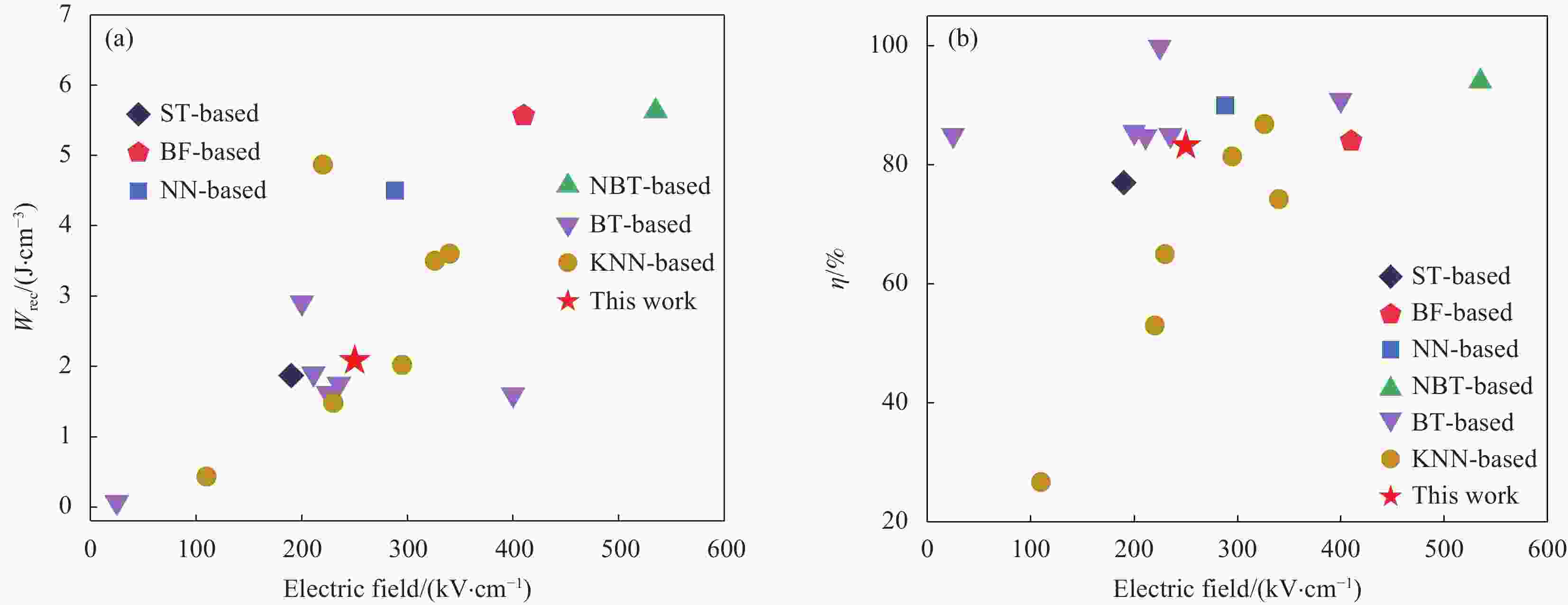

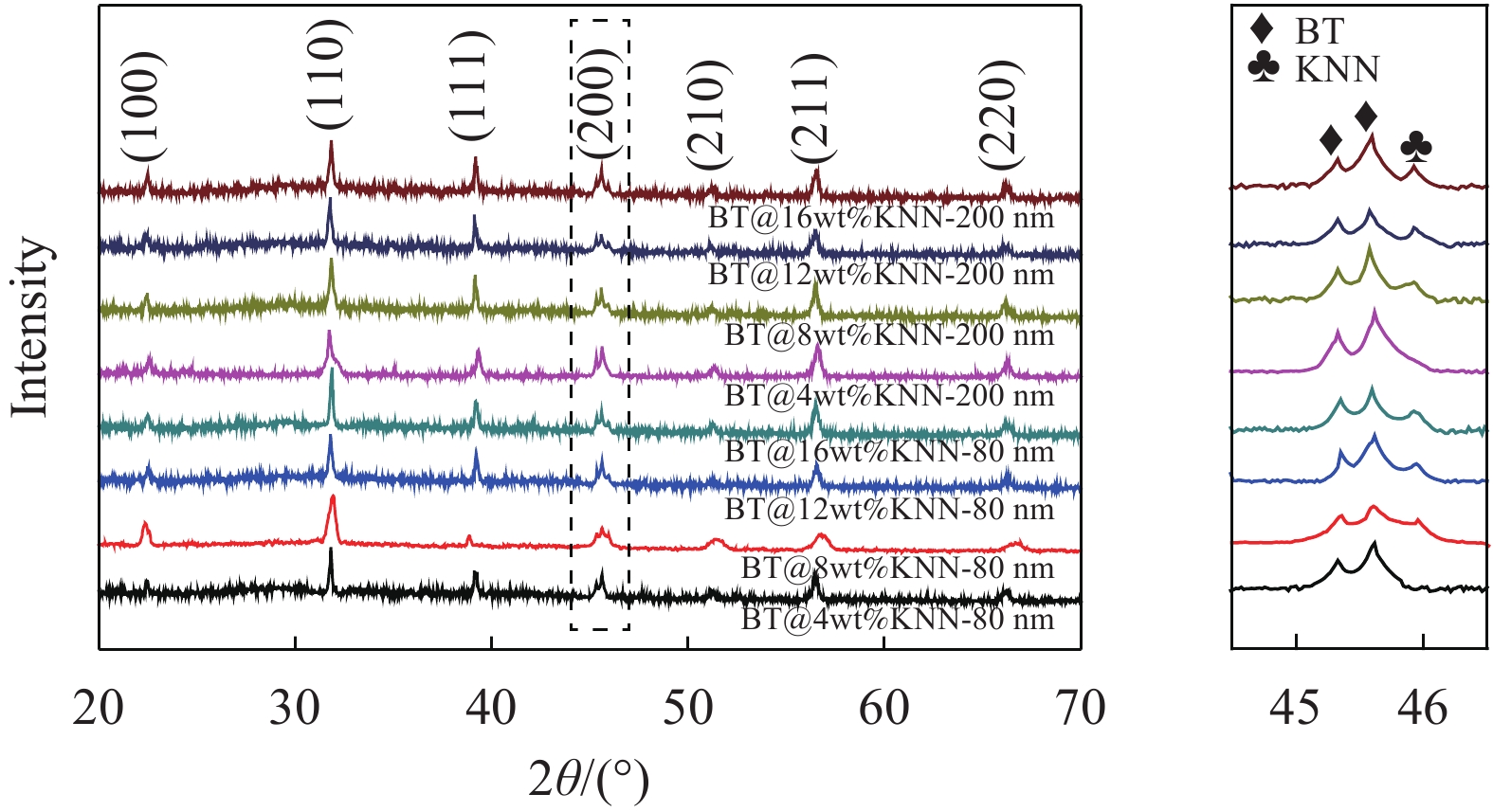

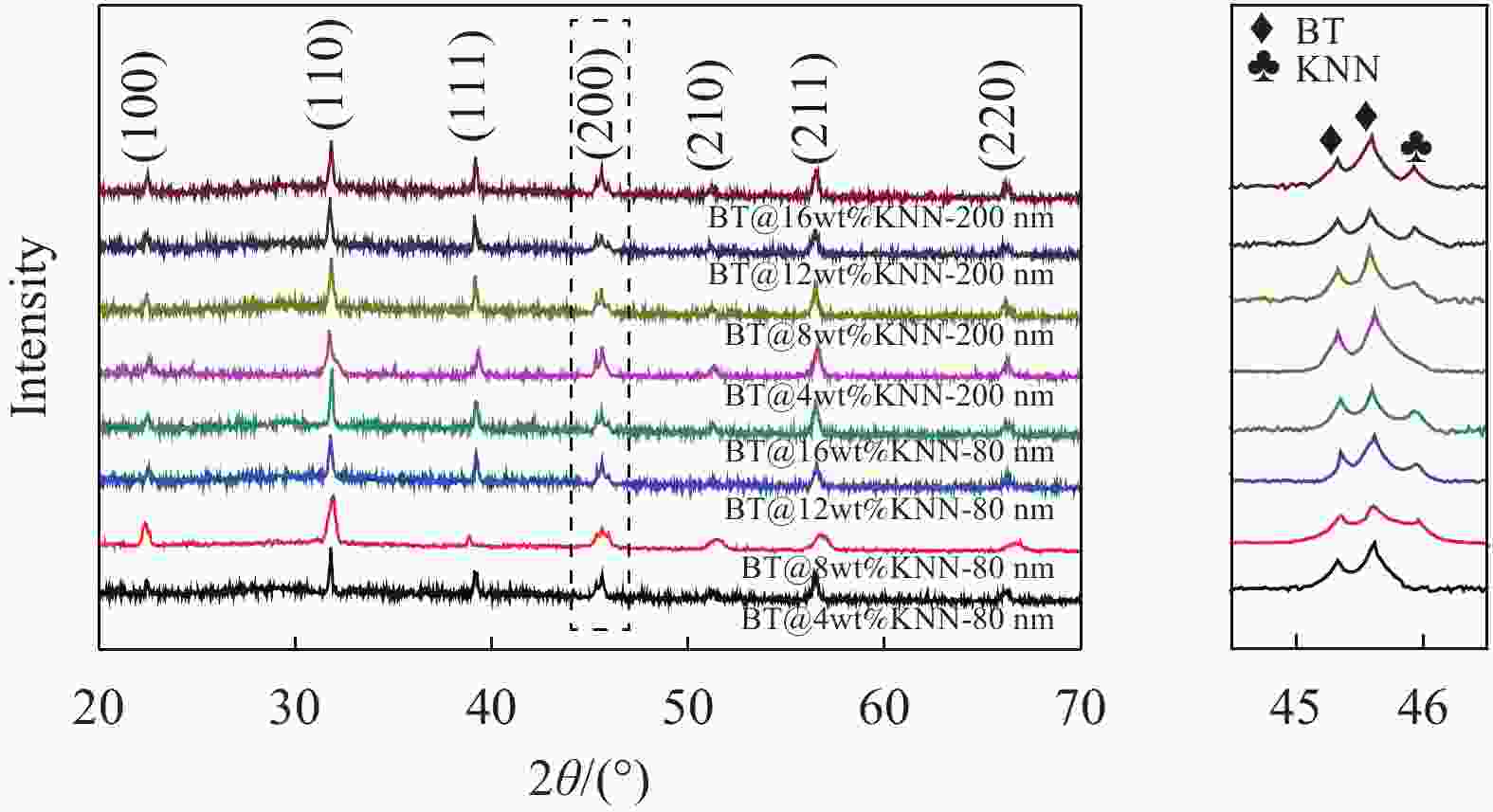

摘要: 综合储能性能(充电能量密度、放电能量密度和储能效率)较低是储能陶瓷领域亟待解决的关键科学问题。同时提高陶瓷的极化差(ΔP)和击穿场强(BDS),是提高陶瓷综合储能性能的重要方法。以BaTiO3(BT)为主晶相,K0.5Na0.5NbO3(KNN)为包覆剂、助烧剂和添加剂,合成了晶粒尺寸为100 nm和200 nm的BT-KNN陶瓷。结果表明:BT-KNN陶瓷具有明显的纳米畴、弛豫行为和介电温度稳定性,且兼具高ΔP和高BDS。相比晶粒尺寸为100 nm的BT-KNN陶瓷,晶粒尺寸为200 nm的BT-KNN陶瓷具有更加优异的综合储能性能,包括较高的充电能量密度W (2.50 J·cm−3)、放电能量密度Wrec (2.08 J·cm−3)和储能效率η (83.2%)。该研究可为高综合储能性能陶瓷的合成提供一定的理论依据。Abstract: The low comprehensive energy storage performance, such as the charging energy density, discharging energy density, and energy storage efficiency, is a key scientific problem to be solved urgently in the energy storage ceramics field. Both improving the polarization difference (∆P) and breakdown field strength (BDS) of the ceramics are the key to enhance their comprehensive energy storage performance. With the main crystal phase BaTiO3 (BT), utilizing the K0.5Na0.5NbO3 (KNN) as the coating agent, sintering aid and additives, the BT-KNN ceramics with the grain sizes of 100 nm and 200 nm was synthesized, respectively. The BT-KNN ceramics has obvious nanodomains, relaxation behaviors and dielectric temperature stability, and with a high ∆P and high BDS. Compared with the BT-KNN ceramics with the grain size of 100 nm, the BT-KNN ceramics with the grain size of 200 nm has a better comprehensive energy storage properties, including high charging energy density W (2.50 J·cm−3), recoverable energy density Wrec (2.08 J·cm−3) and energy storage efficiency η (83.2%). This research may provide a theoretical basis for preparing high comprehensive energy storage performance ceramics.

-

图 2 粉体的TEM图像:(a) BT@4wt%KNN-80 nm;(b) BT@8wt%KNN-80 nm;(c) BT@12wt%KNN-80 nm;(d) BT@16wt%KNN-80 nm;(e) BT@4wt%KNN-200 nm;(f) BT@8wt%KNN-200 nm;(g) BT@12wt%KNN-200 nm;(h) BT@16wt%KNN-200 nm

Figure 2. TEM images of the powders: (a) BT@4wt%KNN-80 nm; (b) BT@8wt%KNN-80 nm; (c) BT@12wt%KNN-80 nm; (d) BT@16wt%KNN-80 nm; (e) BT@4wt%KNN-200 nm; (f) BT@8wt%KNN-200 nm; (g) BT@12wt%KNN-200 nm; (h) BT@16wt%KNN-200 nm

图 3 BT@8wt%KNN-200 nm ((a)、(b)、(b1)~(b6))和BT@8wt%KNN-80 nm ((c)、(d)、(d1)~(d6))的高角度环形暗场像(HAADF)和EDS图像 (((a)、(c)) HAADF图像;((b)、(d)) EDS各元素叠加图像;((b1)~(b6)、(d1)~(d6)) 各元素的EDS图像)

Figure 3. High-angle annular dark field (HAADF) and EDS images of the BT@8wt%KNN-200 nm ((a), (b), (b1)-(b6)) and the BT@8wt%KNN-80 nm ((c), (d), (d1)-(d6))(((a), (c)) HAADF images; ((b), (d)) Superimposed EDS images of each elements; ((b1)-(b6), (d1)-(d6)) EDS images of each elements)

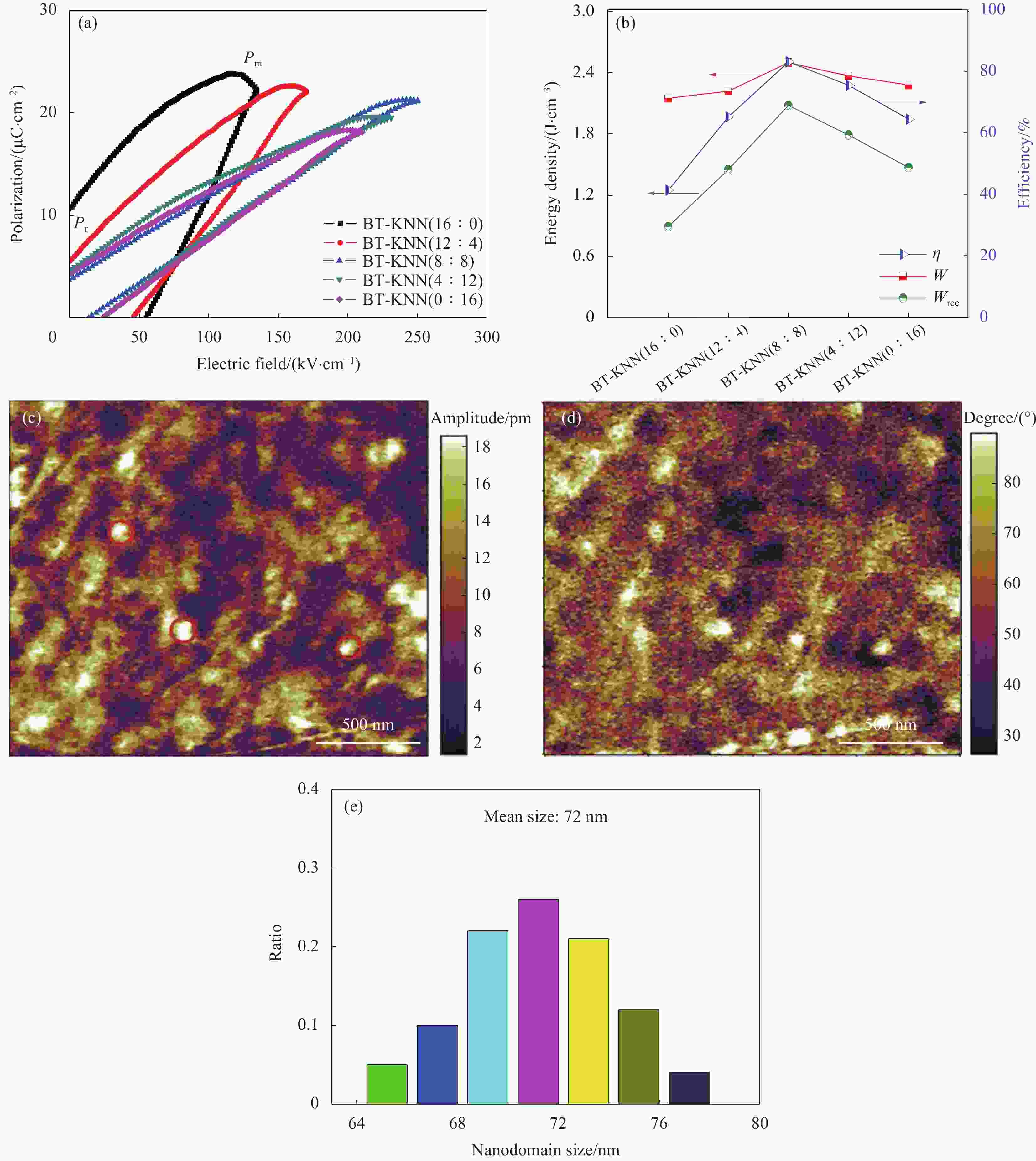

图 7 (a) 陶瓷的电滞回线;(b) 陶瓷的储能性能对比;BT-8wt% KNN的压电响应力显微镜(PFM)图像(c)、相位图像(d)和纳米畴尺寸分布(e)

Figure 7. (a) Polarization-electric field (P-E) hysteresis loops of the ceramics; (b) Energy storage performance comparison diagram of the ceramics; Piezoresponse scanning force microscopy (PFM) (c), phase (d) and nanodomain size distribution (e) of the BT-8wt%KNN

W—Energy storage density; Wrec—Recoverable energy storage density; η—Ratio of Wrec to W; Pm—Maximum polarization

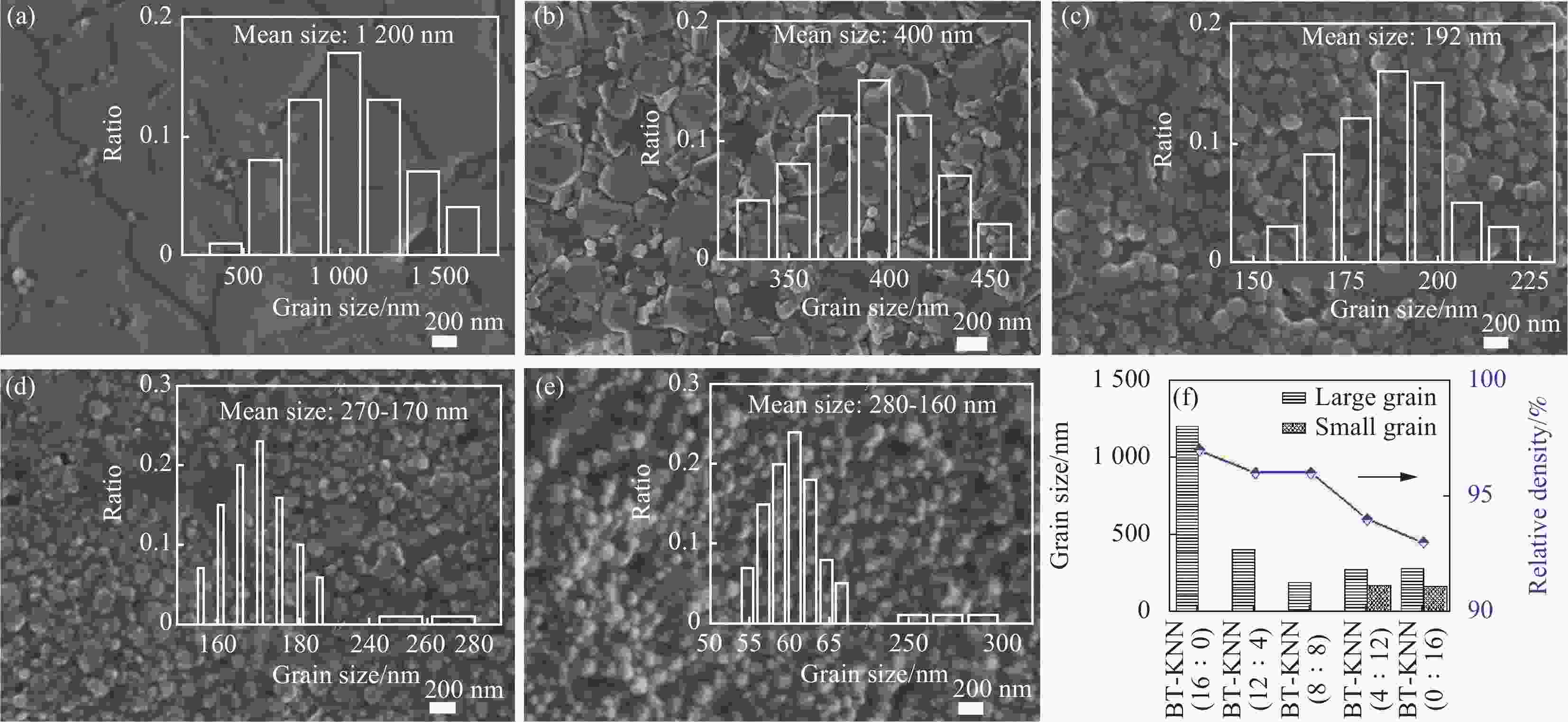

图 9 BT-KNN陶瓷的SEM图像(内插图为粒径分布):(a) BT-KNN(16∶0);(b) BT-KNN(12∶4);(c) BT-KNN(8∶8);(d) BT-KNN(4∶12);(e) BT-KNN(0∶16);(f) BT@KNN陶瓷晶粒尺寸和相对密度变化趋势图

Figure 9. SEM images of the BT-KNN ceramics (Inset: Particle size distribution): (a) BT-KNN(16∶0); (b) BT-KNN(12∶4); (c) BT-KNN(8∶8); (d) BT-KNN(4∶12); (e) BT-KNN(0∶16); (f) Trend of grain size and relative density of BT@KNN ceramics

表 1 80 nm和200 nm BaTiO3(BT)@K0.5Na0.5NbO3(KNN)粉体编号、包覆量和尺寸

Table 1. Abbreviation, coating amounts and sizes of the 80 nm and 200 nm BT@KNN powders

Powder sample KNN coating

amount/wt%Diameter/nm BT@4wt%KNN-80 nm 4 80 BT@8wt%KNN-80 nm 8 80 BT@12wt%KNN-80 nm 12 80 BT@16wt%KNN-80 nm 16 80 BT@4wt%KNN-200 nm 4 200 BT@8wt%KNN-200 nm 8 200 BT@12wt%KNN-200 nm 12 200 BT@16wt%KNN-200 nm 16 200 表 2 BT-KNN陶瓷编号和掺杂量

Table 2. Abbreviation and doping amount of the BT-KNN ceramics

Ceramic sample BT-KNN content/wt% BT-4wt%KNN 4 BT-6wt%KNN 6 BT-8wt%KNN 8 BT-10wt%KNN 10 表 3 粉体的组合方式

Table 3. Combination methods of the powders

Combination methods KNN coating amount of the 200 nm BT@KNN powders/wt% KNN coating amount of the 80 nm BT@KNN powders/wt% BT-KNN(16∶0) 16 0 BT-KNN(12∶4) 12 4 BT-KNN(8∶8) 8 8 BT-KNN(4∶12) 4 12 BT-KNN(0∶16) 0 16 表 4 KNN干凝胶粉不同用量所得陶瓷参数汇总(1 kHz)

Table 4. Summary of parameters of the ceramics by the KNN xerogel powders with different amounts (1 kHz)

Ceramics samples Average grain size/nm Relative density

/%εmax εr tanδ BT-4wt%KNN 292 97 2252 1 952 0.013 BT-6wt%KNN 216 96 1753 1645 0.015 BT-8wt%KNN 93 95 1088 1038 0.018 BT-10wt%KNN 172 93 1342 1299 0.082 Notes: εmax—Maximum dielectric permittivity; εr—Dielectric permittivity at room temperature; tanδ—Dielectric loss. 表 5 陶瓷储能参数汇总

Table 5. Energy storage parameters of the ceramics

Ceramics sample ∆P/(µC·cm−2) BDS/(kV·cm−1) W/(J·cm−3) Wrec/(J·cm−3) η/% BT-4wt%KNN 15.42 180 2.45 1.39 56.7 BT-6wt%KNN 14.62 210 2.71 1.54 56.8 BT-8wt%KNN 11.21 295 2.13 1.65 77.5 BT-10wt%KNN 7.92 175 2.11 0.69 32.7 Notes: ∆P—Polarization difference (ΔP=Pm−Pr, Pm—Maximum polarization, Pr—Remanent polarization); BDS—Breakdown field strength. 表 6 BT-KNN陶瓷的参数(1 kHz)

Table 6. Parameters of the BT-KNN ceramics (1 kHz)

Ceramics

sampleAverage grain size/nm Relative density/% εmax εr tanδ BT-KNN(16∶0) 1200 97 2410 1 974 0.013 BT-KNN(12∶4) 400 96 2 023 1 843 0.015 BT-KNN(8∶8) 192 96 1 827 1760 0.017 BT-KNN(4∶12) 270·170 94 1701 1639 0.044 BT-KNN(0∶16) 280·160 93 1593 1557 0.077 Notes: The average grain size of 270·170 means that there is a bimodal distribution of the grain size, whose peaks are 270 nm and 170 nm; The average grain size 280·160 means that there is a bimodal distribution of the grain size, whose peaks are 280 nm and 160 nm. 表 7 BT-KNN陶瓷储能性能

Table 7. Energy storage parameters of the BT-KNN ceramics

Ceramics sample ∆P/(µC·cm−2) BDS/(kV·cm−1) W/(J·cm−3) Wrec/(J·cm−3) η/% BT-KNN(16∶0) 13.21 134 2.15 0.89 41.4 BT-KNN(12∶4) 17.10 170 2.22 1.45 65.3 BT-KNN(8∶8) 18.20 250 2.50 2.08 83.2 BT-KNN(4∶12) 15.50 231 2.37 1.79 75.5 BT-KNN(0∶16) 14.02 210 2.28 1.47 64.5 表 8 本工作与其他无铅陶瓷在最大施加电场下储能性能的对比

Table 8. Comparison of the energy storage performances between this work and the other lead-free ceramics at the maximum applied electric field

Composition BDS/(kV·cm−1) Wrec/(J·cm−3) η

/%Ref. 0.5ST-0.5(BNT-BAN) 190 1.87 77 [1] 0.88BFBT-0.12NBN 410 5.57 84 [2] 0.8NN-0.2BST 288 4.50 90 [3] BNST-0.08 535 5.63 94 [4] 0.88BST-0.12BZN 225 1.62 99.8 [5] BST@SiO2-8 400 1.60 90.9 [6] 0.95KNN-0.05BZN 220 4.87 53 [29] BaTiO3@Na0.5K0.5NbO3

(8wt%)211 1.90 84.8 [30] KNNC-12.75SZ 230 1.48 65 [31] KNN 110 0.43 26.7 [32] 0.85KNN-0.15BZZ 326 3.50 86.8 [33] 0.975KNN-0.025LB 340 3.60 74.2 [34] 0.8KNN-0.2SSN 295 2.02 81.4 [35] Ba0.6Sr0.34Ce0.04TiO3 235 1.75 85 [36] BaTi0.89Sn0.11O3 25 0.07 85 [37] 0.7(BT-BMN)-0.3NBT 200 2.91 85.5 [38] BT-KNN-S3 250 2.08 83.2 This work Notes:0.5ST-0.5(BNT-BAN)—0.5SrTiO3-0.5(0.95Bi0.5Na0.5TiO3-0.05BaAl0.5Nb0.5O3); 0.88BFBT-0.12NBN—0.88(0.67BiFeO3-0.33BaTiO3)-0.12Na0.73Bi0.09NbO3; 0.8NN-0.2BST—0.8NaNbO3-0.2Sr0.7Bi0.2TiO3; BNST-0.08—0.75Bi0.58Na0.42TiO3-0.25SrTiO3; 0.88BST-0.12BZN—0.88(Ba0.8Sr0.2)TiO3-0.12Bi(Zn2/3Nb1/3)O3; BST@SiO2-8—Ba0.4Sr0.6TiO3@SiO2(8mol%); 0.95KNN-0.05BZN—0.95K0.5Na0.5NbO3-0.05Ba(Zn1/3-Nb2/3)O3; KNNC-12.75SZ—0.8725K0.5Na0.5NbO3-0.1275SrZrO3; 0.85KNN-0.15BZZ—0.8K0.5Na0.5NbO3-0.15Bi(Zn0.5Zr0.5)O3; 0.975KNN-0.025LB—0.975K0.5Na0.5NbO3-0.025LaBiO3; 0.8KNN-0.2SSN—0.8K0.5Na0.5NbO33-0.2Sr(Sc0.5Nb0.5)O3; BT-BMN-NBT—0.7[0.85BaTiO3-0.15Bi(Mg2/3Nb1/3)O3]-0.3Na0.5Bi0.5TiO3. -

[1] YAN F, YANG H B, LIN Y, et al. Dielectric and ferroelectric properties of SrTiO3-Bi0.5Na0.5TiO3-BaAl0.5Nb0.5O3 lead-free ceramics for high-energy-storage applications[J]. Inorganic Chemistry,2017,56(21):13510-13516. doi: 10.1021/acs.inorgchem.7b02181 [2] YAN F, SHI Y J, ZHOU X F, et al. Optimization of polarization and electric field of bismuth ferrite-based ceramics for capacitor applications[J]. Chemical Engineering Journal,2020,417(1):127945. [3] WEI T, LIU K, FAN P Y, et al. Novel NaNbO3-Sr0.7Bi0.2TiO3 lead-free dielectric ceramics with excellent energy storage properties[J]. Ceramics International,2021,47(3):3713-3719. doi: 10.1016/j.ceramint.2020.09.228 [4] YAN F, HUANG K W, JIANG T, et al. Significantly enhanced energy storage density and efficiency of BNT-based perovskite ceramics via A-site defect engineering[J]. Energy Storage Materials,2020,30:392-400. doi: 10.1016/j.ensm.2020.05.026 [5] ZHANG L, PANG L X, LI W B, et al. Extreme high energy storage efficiency in perovskite structured (1-x)(Ba0.8Sr0.2)TiO3-xBi(Zn2/3Nb1/3)O3 (0.04≤x≤0.16) ceramics[J]. Journal of the European Ceramic Society,2020,40(8):3343-3347. doi: 10.1016/j.jeurceramsoc.2020.03.015 [6] HUANG Y H, WU Y J, LIU B, et al. From core-shell Ba0.4Sr0.6TiO3@SiO2 particles to dense ceramics with high energy storage performance by spark plasma sintering[J]. Journal of Materials Chemistry A,2018,6(10):4477-4484. doi: 10.1039/C7TA10821D [7] CAI Z M, WANG X H, HONG W, et al. Grain-size-dependent dielectric properties in nanograin ferroelectrics[J]. Journal of the American Ceramic Society,2018,101(12):5487-5496. doi: 10.1111/jace.15803 [8] LIU B B, WANG X H, ZHANG R X, et al. Grain size effect and microstructure influence on the energy storage properties of fine-grained BaTiO3-based ceramics[J]. Journal of the American Ceramic Society,2017,100(8):3599-3607. doi: 10.1111/jace.14802 [9] ZHANG C, CHEN Y, ZHOU M X, et al. Achieving ultrahigh dielectric breakdown strength in MgO-based ceramics by composite structure design[J]. Journal of Materials Chemistry C,2019,7(26):8120-8130. doi: 10.1039/C9TC02197C [10] LI Y, SUN N N, LI X W, et al. Multiple electrical response and enhanced energy storage induced by unusual coexistent-phase structure in relaxor ferroelectric ceramics[J]. Acta Materialia,2018,146:202-210. doi: 10.1016/j.actamat.2017.12.048 [11] GAO P, LIU Z H, ZHANG N, et al. New antiferroelectric perovskite system with ultrahigh energy storage performance at low electric field[J]. Chemistry of Materials,2019,31(3):979-990. doi: 10.1021/acs.chemmater.8b04470 [12] YE J M, WANG G S, ZHOU M X, et al. Excellent comprehensive energy storage properties in novel lead-free NaNbO3-based ceramics for dielectric capacitor applications[J]. Journal of Materials Chemistry C,2019,7(19):5639-5645. doi: 10.1039/C9TC01414D [13] WANG G, LI J L, ZHANG X, et al. Ultrahigh energy storage density lead-free multilayers by controlled electrical homogeneity[J]. Energy & Environmental Science,2019,12(2):582-588. [14] QI H, XIE A W, TIAN A, et al. Superior energy-storage capacitors with simultaneously giant energy density and effciency using nanodomain engineered BiFeO3-BaTiO3-NaNbO3 lead-free bulk ferroelectrics[J]. Advanced Energy Materials,2020,10(6):1903338. [15] YAN Z N, ZHANG D, ZHOU X F, et al. Silver niobate based lead-free ceramics with high energy storage density[J]. Journal of Materials Chemistry A,2019,7(17):10702-10711. doi: 10.1039/C9TA00995G [16] LIU G, LI Y, SHI M Q, et al. An investigation of the dielectric energy storage performance of Bi(Mg2/3Nb1/3)O3-modifed BaTiO3 Pb-free bulk ceramics with improved temperature/frequency stability[J]. Ceramics International,2019,45(15):19189-19196. doi: 10.1016/j.ceramint.2019.06.166 [17] LI Q, LI M Y, WANG C, et al. Enhanced temperature stable dielectric properties and energy-storage density of BaSnO3-modifed (Bi0.5Na0.5)0.94Ba0.06TiO3 lead-free ceramics[J]. Ceramics International,2019,45(16):19822-19828. doi: 10.1016/j.ceramint.2019.06.237 [18] PAN H, LI F, LIU Y, et al. Ultrahigh-energy density lead-free dielectric films via polymorphic nanodomain design[J]. Science,2019,365(6453):578-582. doi: 10.1126/science.aaw8109 [19] PAN H, MA J, MA J, et al. Giant energy density and high efficiency achieved in bismuth ferrite-based film capacitors via domain engineering[J]. Nature Communications,2018,9:1813. [20] SUN Z X, MA C R, LIU M, et al. Ultrahigh energy storage performance of lead-free oxide multilayer film capacitors via interface engineering[J]. Advanced Materials,2017,29(5):1604427. [21] LI F, LIN D B, CHEN Z B, et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design[J]. Nature Materials,2018,17:349-354. doi: 10.1038/s41563-018-0034-4 [22] SHVARTSMAN V V, LUPASCU D C. Lead-free relaxor ferroelectrics[J]. Journal of the American Ceramic Society,2012,95(1):1-26. doi: 10.1111/j.1551-2916.2011.04952.x [23] JO W, SCHAAB S, SAPPER E, et al. On the phase identity and its thermal evolution of lead free (Bi1/2Na1/2)TiO3-6mol% BaTiO3[J]. Journal of Applied Physics,2011,110:74106. [24] HIRATA Y, FUJITA H, SHIMONOSONO T. Compressive mechanical properties of partially sintered porous alumina of bimodal particle size system[J]. Ceramics International,2017,43(2):1895-1903. doi: 10.1016/j.ceramint.2016.10.149 [25] OH J W, SEONG Y J, SHIN D S, et al. Investigation and two-stage modeling of sintering behavior of nano/micro-bimodal powders[J]. Powder Technology,2019,352(15):42-52. [26] XU H Y, ZOU J, WANG W M, et al. Densification mechanism and microstructure characteristics of nano- and micro- crystalline alumina by high-pressure and low temperature sintering[J]. Journal of the European Ceramic Society,2021,41(1):635-645. doi: 10.1016/j.jeurceramsoc.2020.08.018 [27] ZHAI X Y, CHEN Y J, MA Y Q, et al. A new strategy of binary-size particles model for fabricating fine grain, high density and low resistivity ITO target[J]. Ceramics International,2020,46(9):13660-13668. doi: 10.1016/j.ceramint.2020.02.152 [28] YANG Y, JI Y, FANG M X, et al. Morphotropic relaxor boundary in a relaxor system showing enhancement of electrostrain and dielectric permittivit[J]. Physical Review Letters,2019,123(13):137601. [29] CHEN B, TIAN Y, LU J B, et al. Ultrahigh storage density achieved with (1-x)KNN-xBZN ceramics[J]. Journal of the European Ceramic Society,2020,40(8):2936-2944. doi: 10.1016/j.jeurceramsoc.2020.03.003 [30] JIN Q, ZHAO L L, CUI B, et al. Enhanced energy storage properties in lead-free BaTiO3@Na0.5K0.5NbO3 nano-ceramics with nanodomains via a core-shell structural design[J]. Journal of Materials Chemistry C,2020,8(15):5248-5258. doi: 10.1039/D0TC00179A [31] HUI K Z, CHEN L L, CEN Z Y, et al. KNN based high dielectric constant X9 R ceramics with fine grain structure and energy storage ability[J]. Journal of the American Ceramic Society,2021,104(11):5815-5825. doi: 10.1111/jace.17970 [32] CHEN B, LIANG P F, WU D, et al. High-efficiency synthesis of high-performance K0.5Na0.5NbO3 ceramics[J]. Powder Technology,2019,346(15):248-255. [33] ZHANG M, YANG H B, LI D, et al. Giant energy storage efficiency and high recoverable energy storage density achieved in K0.5Na0.5NbO3-Bi(Zn0.5Zr0.5)O3 ceramics[J]. Journal of Materials Chemistry C,2020,8(26):8777-8785. doi: 10.1039/D0TC01711F [34] XING J, HUANG Y L, XU Q, et al. Realizing high comprehensive energy storage and ultrahigh hardness in lead-free ceramics[J]. ACS Applied Materials & Interfaces,2021,13(24):28472-28483. [35] QU B Y, DU H L, YANG Z T. Lead-free relaxor ferroelectric ceramics with high optical transparency and energy storage ability[J]. Journal of Materials Chemistry C,2016,4(9):1795-1803. doi: 10.1039/C5TC04005A [36] LI Y M, BIAN J J. Effects of reoxidation on the dielectric and energy storage properties of Ce-doped (Ba, Sr)TiO3 ceramics prepared by hot-pressed sintering[J]. Journal of the European Ceramic Society,2020,40(15):5441-5449. doi: 10.1016/j.jeurceramsoc.2020.06.076 [37] MERSELMIZ S, HANANI Z, MEZZANE D, et al. High energy storage efficiency and large electrocaloric effect in lead-free BaTi0.89Sn0.11O3 ceramic[J]. Ceramics International,2020,46(15):23867-23876. doi: 10.1016/j.ceramint.2020.06.163 [38] WANG T, LIU J Q, KONG L, et al. Evolution of the structure, dielectric and ferroelectric properties of Na0.5Bi0.5TiO3-added BaTiO3-Bi(Mg2/3Nb1/3)O3 ceramics[J]. Ceramics International,2020,46(16):25392-25398. doi: 10.1016/j.ceramint.2020.07.007 [39] YANG Z T, DU H L, QU S B, et al. Significantly enhanced recoverable energy storage density in potassium-sodium niobate-based lead free ceramics[J]. Journal of Materials Chemistry A,2016,4(36):13778-13785. doi: 10.1039/C6TA04107H [40] YANG Z T, GAO F, DU H L, et al. Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties[J]. Nano Energy,2019,58:768-777. doi: 10.1016/j.nanoen.2019.02.003 [41] YAN X D, ZHENG M P, GAO X, et al. High-performance lead-free ferroelectric BZT-BCT and its application in energy fields[J]. Journal of Materials Chemistry C,2020,8(39):13530-13556. doi: 10.1039/D0TC03461D -

下载:

下载: