Low-velocity impact damage characterization of CFRP composite based on infrared thermography

-

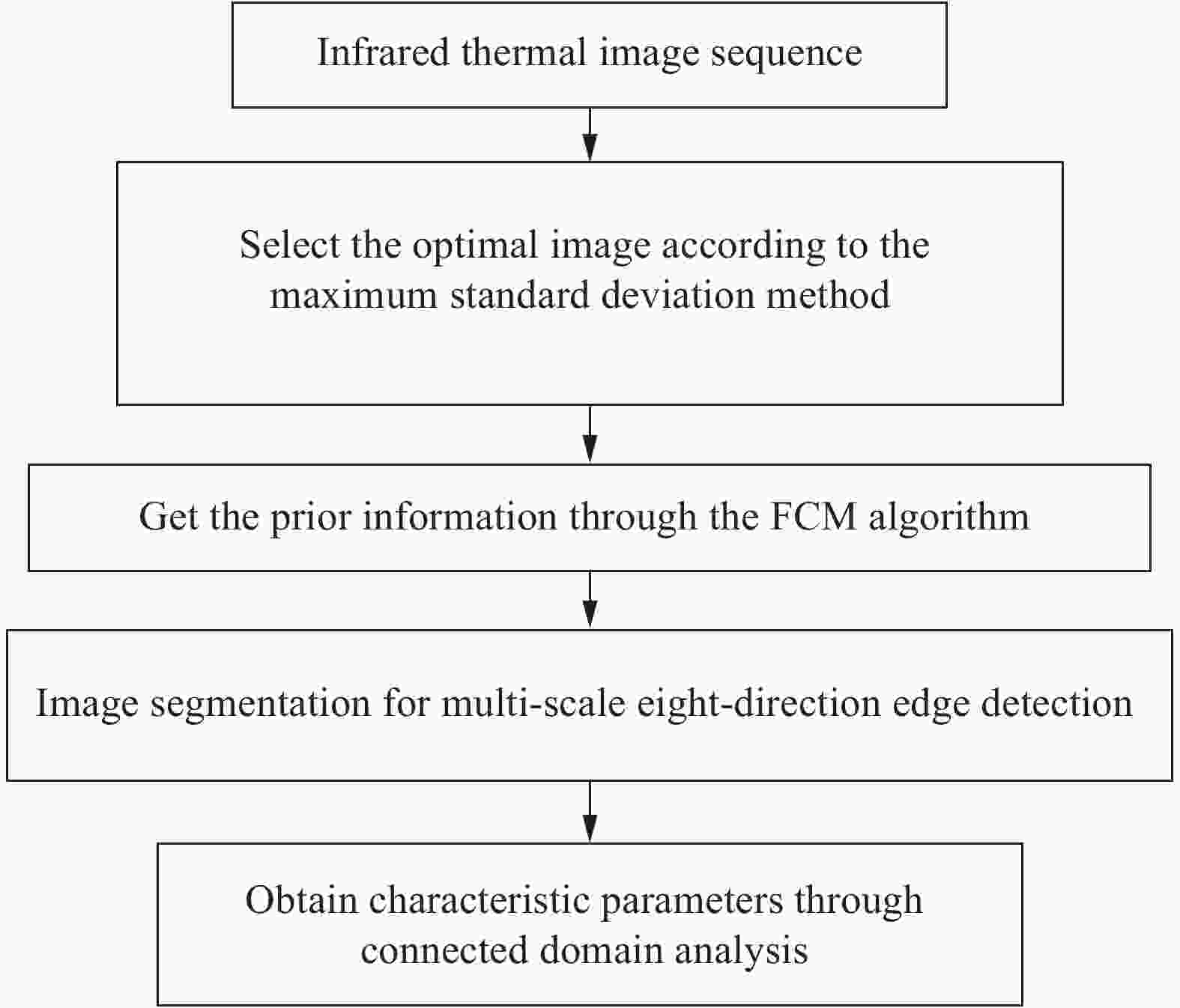

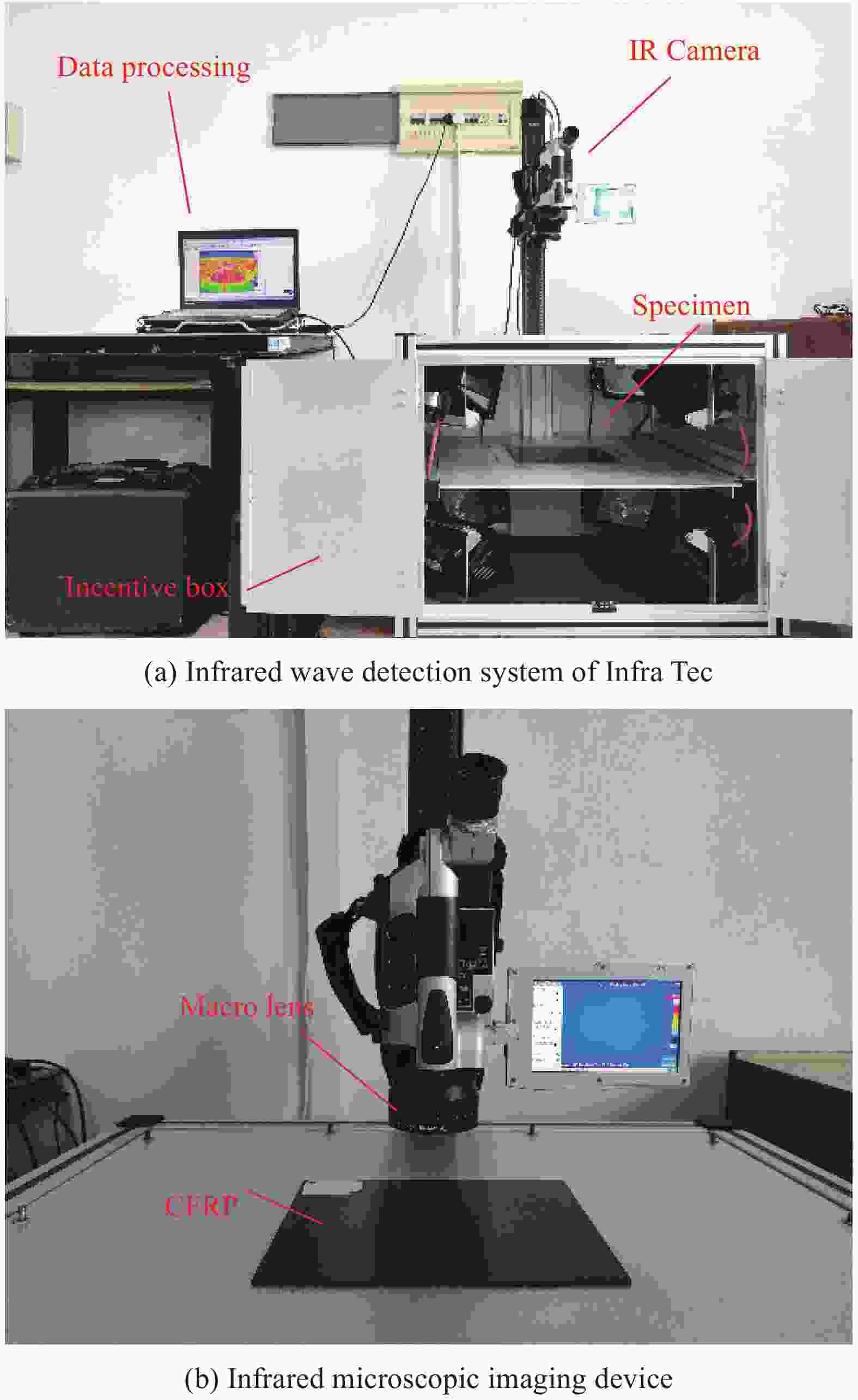

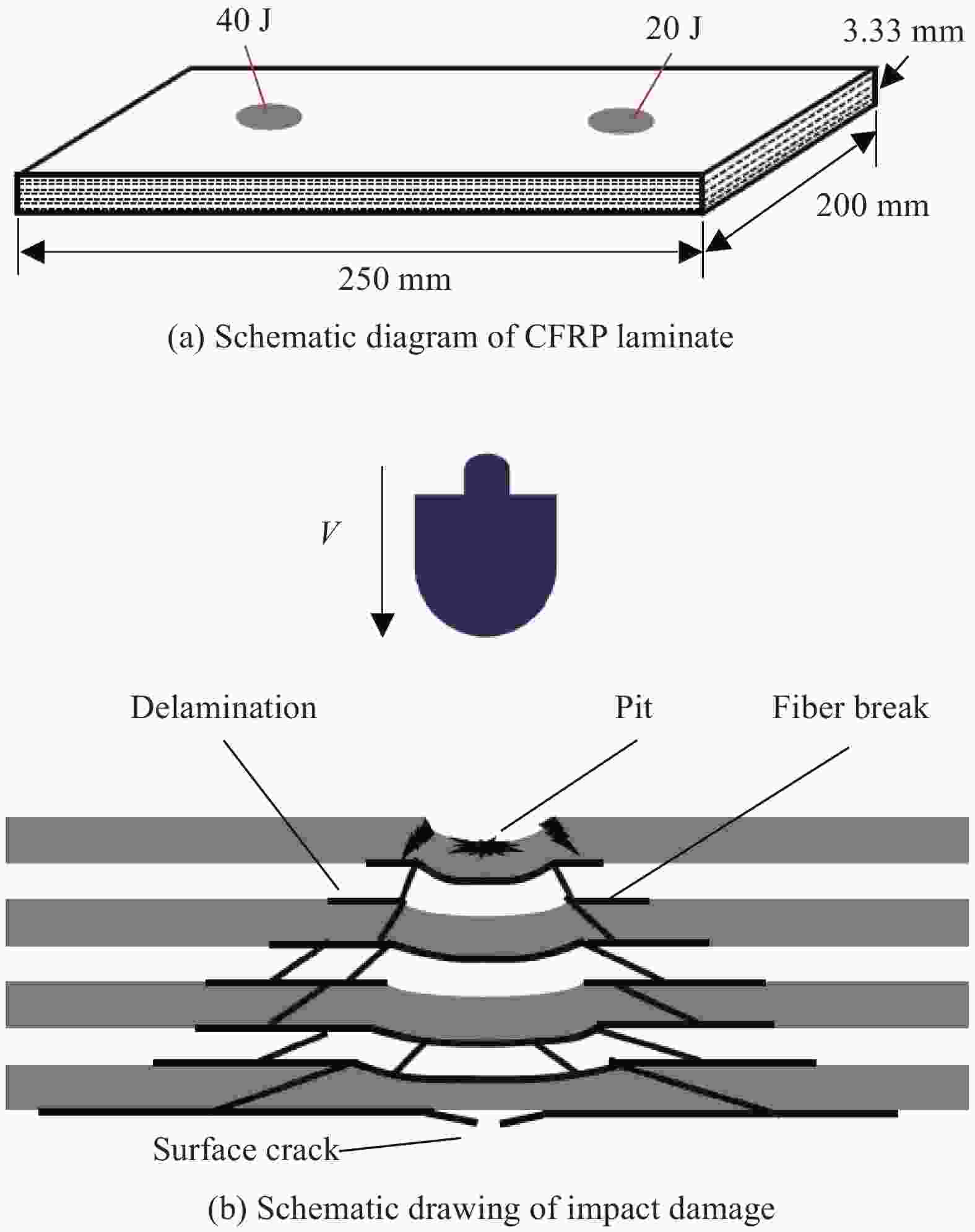

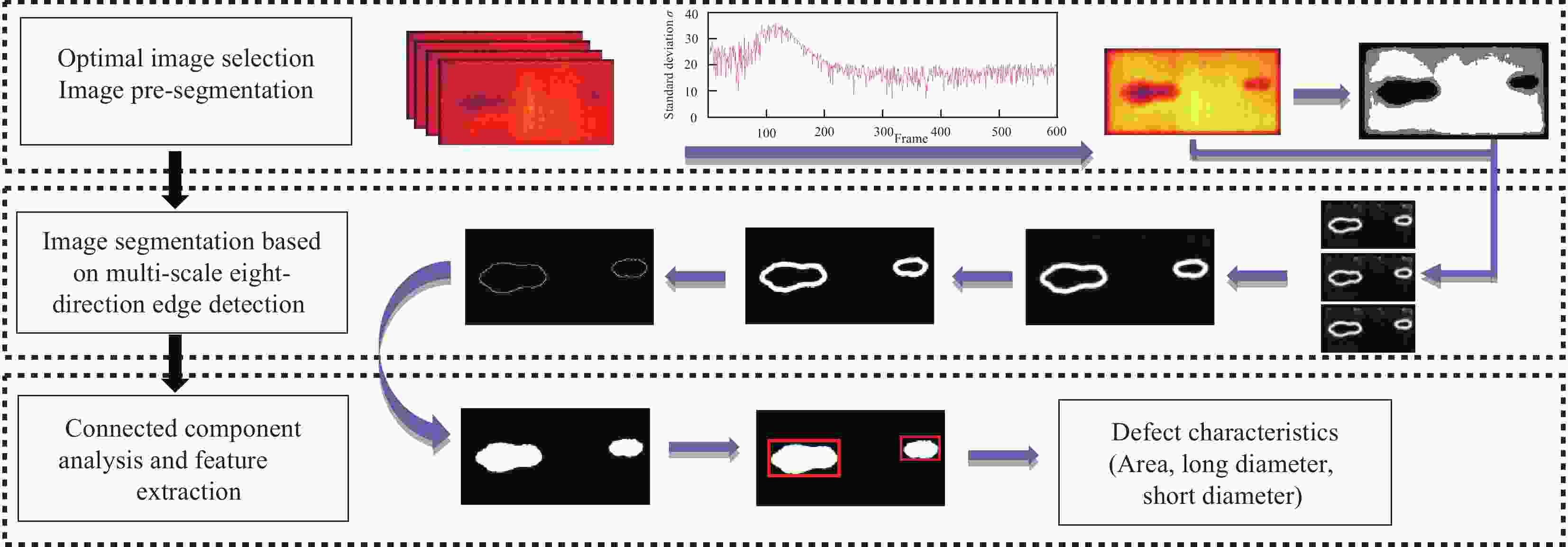

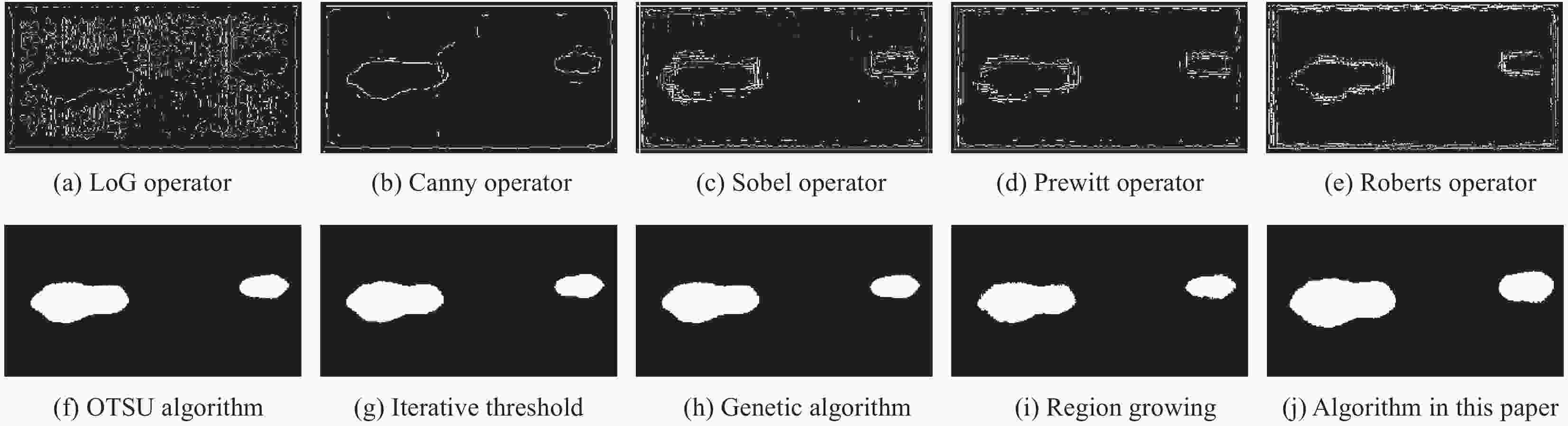

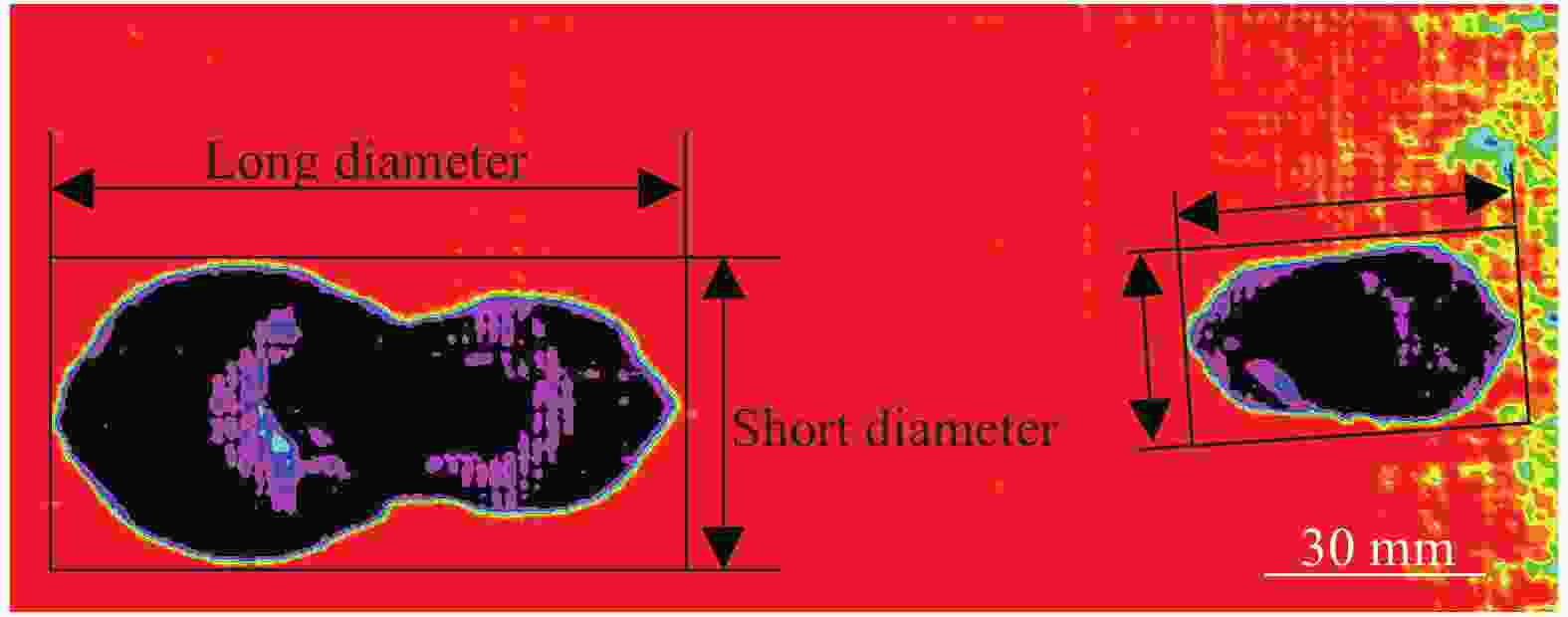

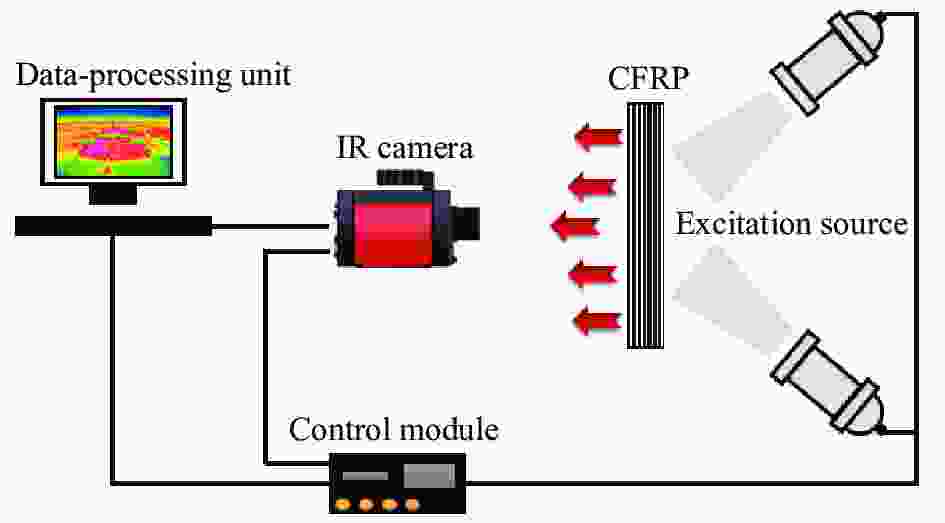

摘要: 采用红外热成像检测技术对20 J、40 J冲击载荷下的碳纤维增强树脂基(CFRP)复合材料层合板表面与内部损伤进行识别。针对内部缺陷定量提取不准确的问题,通过分析红外图像空域特征,提出一种多尺度八方向边缘检测图像分割算法。首先依据敏感区域最大标准差法选取最优图像并采用模糊C均值聚类算法对红外缺陷图像进行预分割获取先验信息,然后构建圆形卷积模板对红外图像进行多尺度八方向卷积运算,引入OTSU算法分割梯度图像,结合形态学运算得到缺陷边缘图,对目标区域进行连通域分析,实现缺陷特征的定量提取。研究结果表明,本文算法提高了损伤区域弱边缘的检测能力,保证了缺陷边缘的完整性与连通性,相较于传统图像分割方法在缺陷面积、长径、短径的检测精度上分别提升了20.41%、5.61%、9.77%以上。Abstract: The surface and internal damage of carbon fiber reinforced polymer (CFRP) laminates under 20 J and 40 J impact loads were identified by infrared thermography. Aiming at the inaccuracy of quantitative defect extraction, a multi-scale eight-direction edge detection image segmentation algorithm was proposed by analyzing the spatial characteristics of infrared images. Firstly, the optimal image was selected according to the maximum standard deviation of the sensitive area, and the fuzzy C-means clustering algorithm was used to presegment the defect image to obtain prior information. Then a circular convolution template was constructed to perform a multi-scale eight-direction convolution operation on the infrared image. The OTSU algorithm was introduced to segment the gradient image, combined with morphological operations to obtain the defect edge map, and the connected domain of the target area was analyzed to realize the quantitative extraction of defect features. The results show that the proposed algorithm improves the detection ability of weak edges in the damaged area and ensures the integrity and connectivity of defect edges. Compared with the traditional image segmentation algorithm, the detection accuracy of the defect area, long diameter and short diameter obtained by the proposed algorithm are improved by more than 20.41%, 5.61% and 9.77%, respectively.

-

表 1 CFRP缺陷特征定量提取结果

Table 1. Quantitative analysis results of defect characteristics of CFRP

Method Area/mm2 Long diameter/mm Short diameter/mm 20 J 40 J 20 J 40 J 20 J 40 J C-Scan 788.40 2356.23 43.70 83.60 23.94 40.30 OTSU 533.70 1657.92 38.14 73.94 19.36 31.69 Iterative threshold 530.63 1648.39 38.03 73.72 19.31 31.60 Genetic algorithm 539.19 1660.37 38.62 73.74 20.54 32.17 Region growing 492.31 1596.08 36.83 73.17 18.29 30.31 In this article 759.95 2141.47 41.07 79.20 22.88 37.55 表 2 不同算法处理结果的相对误差

Table 2. Relative errors of the results processed by different algorithms

Algorithms Relative error of area/% Relative error of long diameter/% Relative error of short diameter/% 20 J 40 J 20 J 40 J 20 J 40 J OTSU 32.31 29.64 12.72 11.56 19.13 21.36 Iterative threshold 32.70 30.04 12.97 11.82 19.34 21.59 Genetic algorithm 31.61 29.53 11.63 11.79 14.20 20.17 Region growing 37.56 32.26 15.72 12.48 23.60 24.79 In this article 3.61 9.11 6.02 5.26 4.43 6.82 -

[1] LI X, MA D Y, LIU H F, et al. Assessment of failure criteria and damage evolution methods for composite laminates under low-velocity impact[J]. Composite Structures,2019,207:727-739. doi: 10.1016/j.compstruct.2018.09.093 [2] 张辰, 饶云飞, 李倩倩, 等. 碳纤维-玻璃纤维混杂增强环氧树脂复合材料低速冲击性能及其模拟[J]. 复合材料学报, 2021, 38(1):165-176.ZHANG Chen, RAO Yunfei, LI Qianqian, et al. Low-velocity impact behavior and numerical simulation of carbon fiber-glass fiber hybrid reinforced epoxy composites[J]. Acta Materiae Compositae Sinica,2021,38(1):165-176(in Chinese). [3] RAUT N P, KOLEKAR A B, GOMBI S L. Methods of damage detection on composites under low velocity impact: Review[J]. Materials Today: Proceedings,2020,27(3):2823-2827. [4] MARZIO G, XU Y G, AMIT R, et al. Low-velocity impact behaviour of woven laminate plates with fire retardant resin[J]. Composites Part B: Engineering,2019,171:1-8. doi: 10.1016/j.compositesb.2019.04.023 [5] WANG Z, TIAN G, MEO M, et al. Image processing based quantitative damage evaluation in composites with long pulse thermography[J]. NDT & E International,2018,99:93-104. [6] HAUFFE A, HÄHNEL F, WOLF K. Comparison of algorithms to quantify the damaged area in CFRP ultrasonic scans[J]. Composite Structures,2020,235:111791. doi: 10.1016/j.compstruct.2019.111791 [7] 郑凯, 江海军, 陈力. 红外热波无损检测技术的研究现状与进展[J]. 红外技术, 2018, 40(5):401-411.ZHENG Kai, JIANG Haijun, CHEN Li. Infrared thermography NDT and its development[J]. Infrared Technology,2018,40(5):401-411(in Chinese). [8] 倪伟传, 许志明, 刘少江, 等. 复杂环境下的自适应红外目标分割算法[J]. 红外技术, 2019, 41(4):357-363.NI Weichuan, XU Zhiming, LIU Shaojiang, et al. Adaptive infrared target segmentation algorithm in complex envi-ronment[J]. Infrared Technology,2019,41(4):357-363(in Chinese). [9] 张莲, 李梦天, 余松林, 等. 基于改进Lazy Snapping算法的红外图像分割方法研究[J]. 红外技术, 2021, 43(4):372-377.ZHANG Lian, LI Mengtian, YU Songlin, et al. An infrared image segmentation method based on improved Lazy Snapping algorithm[J]. Infrared Technology,2021,43(4):372-377(in Chinese). [10] 王冬冬, 张炜, 金国锋, 等. 尖点突变理论在红外热波检测图像分割中的应用[J]. 红外与激光工程, 2014, 43(3):1009-1015.WANG Dongdong, ZHANG Wei, JIN Guofeng, et al. Appli-cation of cusp catastrophic theory in image segmentation of infrared thermal waving inspection[J]. Infrared and Laser Engineering,2014,43(3):1009-1015(in Chinese). [11] LI Y, YANG Z W, ZHU J T, et al. Investigation on the damage evolution in the impacted composite material based on active infrared thermography[J]. NDT & E International,2016,83:114-122. [12] 金国锋, 张炜, 杨正伟, 等. 界面贴合型缺陷的超声红外热波检测与识别[J]. 四川大学学报(工程科学版), 2013, 45(2):167-175.JIN Guofeng, ZHANG Wei, YANG Zhengwei, et al. Application of ultrasonic infrared thermal wave technique in detection and recognition of interface kissing damage[J]. Journal of Sichuan University (Engineering Science Edition),2013,45(2):167-175(in Chinese). [13] ZHENG K Y, YAO Y. Automatic defect detection based on segmentation of pulsed thermographic images[J]. Chemometrics and Intelligent Laboratory Systems,2017,162:35-43. doi: 10.1016/j.chemolab.2017.01.008 [14] FENG Q Z, GAO B, LU P, et al. Automatic seeded region growing for thermography debonding detection of CFRP[J]. NDT & E International,2018,99:36-49. [15] SREESHAN K, DINESH R, RENJI K. Enhancement of thermographic images of composite laminates for debond detection: An approach based on gabor filter and watershed[J]. NDT & E International,2019,103:68-76. [16] TANG Q J, GAO S S, LIU Y J, et al. Infrared image segmentation algorithm for defect detection based on FODPSO[J]. Infrared Physics & Technology,2019,102:103051. [17] YANG B, HUANG Y D, CHENG L. Defect detection and evaluation of ultrasonic infrared thermography for aerospace CFRP composites[J]. Infrared Physics & Technology,2013,60:166-173. [18] BU C W, TANG Q J, LIU J Y, et al. Inspection on CFRP sheet with subsurface defects using pulsed thermographic technique[J]. Infrared Physics & Technology,2014,65:117-121. [19] YUAN L H, ZHU X, SUN Q B, et al. Automatic extraction of material defect size by infrared image sequence[J]. Applied Sciences,2020,10(22):8248. doi: 10.3390/app10228248 [20] American Society for Testing and Materials. Standard practice for determination of the impact resistance of thermoplastic pipe and fitting by means of a tup (Falling weight): ASTM D2444-17[S]. West Conshohocken: International American Society for Testing and Materials, 2017. [21] ZHOU J W, LIAO B B, SHI Y Y, et al. Experimental investigation of the double impact position effect on the mechani-cal behavior of low-velocity impact in CFRP laminates[J]. Composites Part B: Engineering,2020,193:108020. doi: 10.1016/j.compositesb.2020.108020 [22] LIAO B B, WANG P D, ZHENG J Y, et al. Effect of double impact positions on the low velocity impact behaviors and damage interference mechanism for composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2020,136:105964. doi: 10.1016/j.compositesa.2020.105964 -

下载:

下载: