Tensile properties and failure mechanism of three-dimensional angle interlocking woven layup composites under tensile loading

-

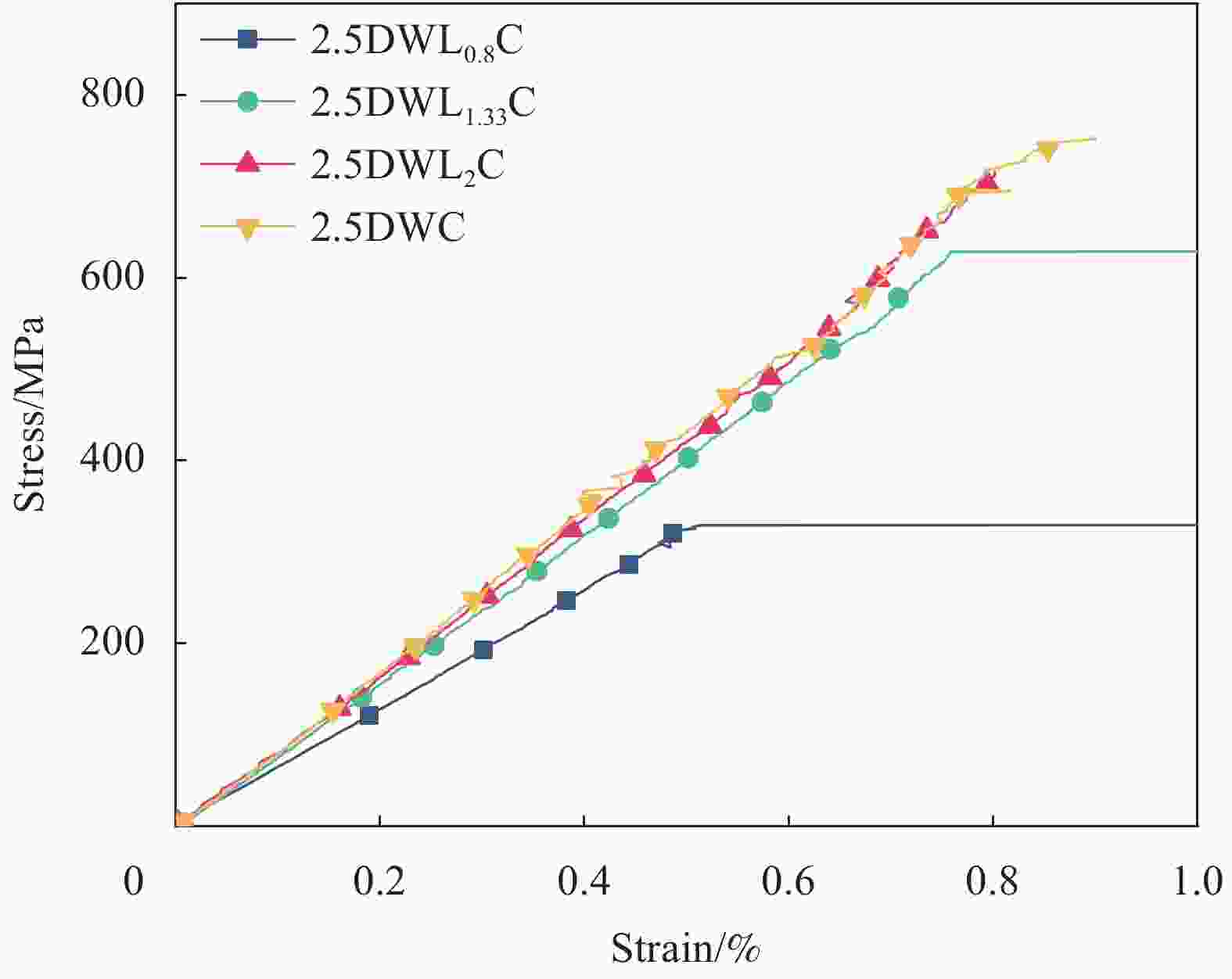

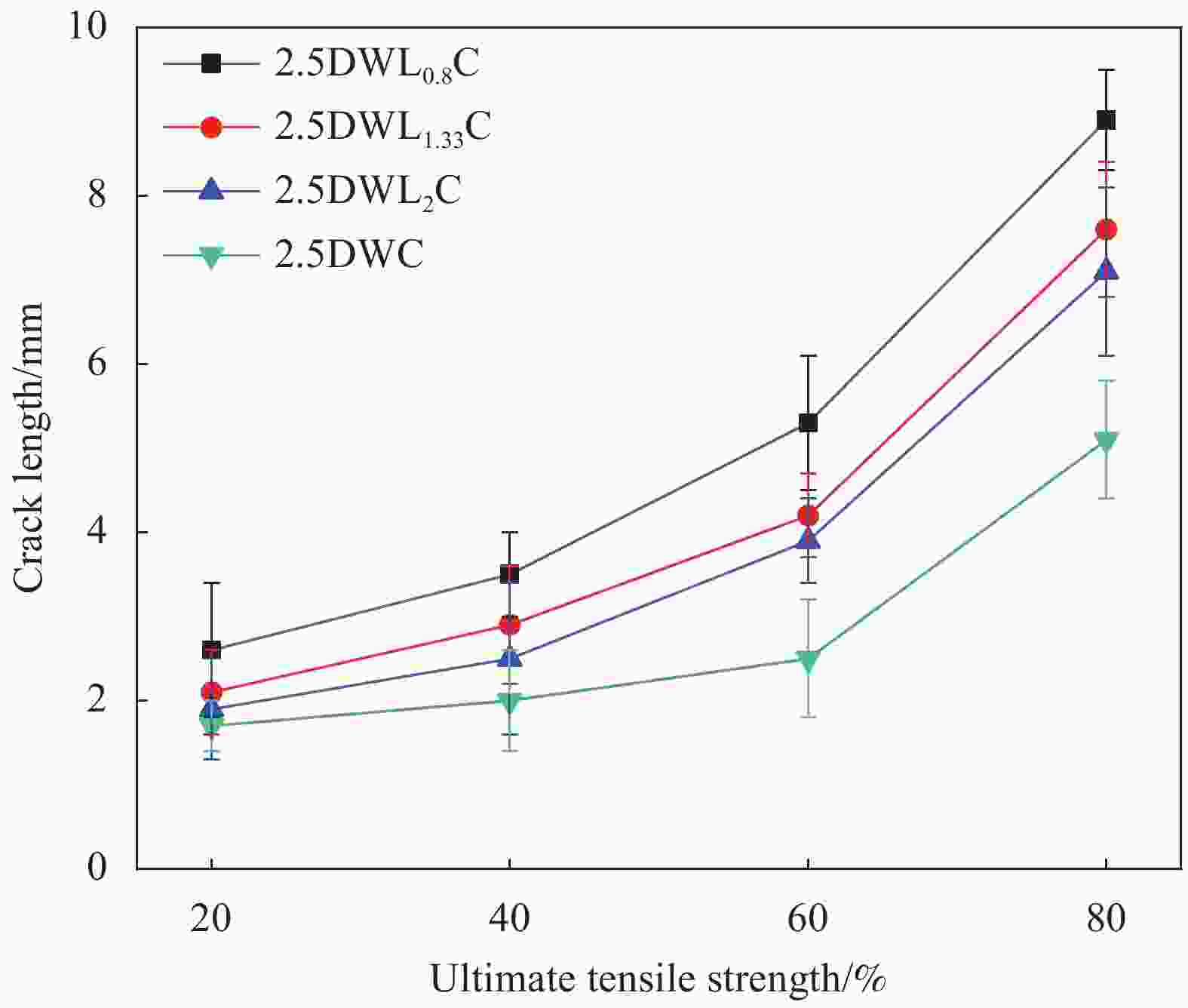

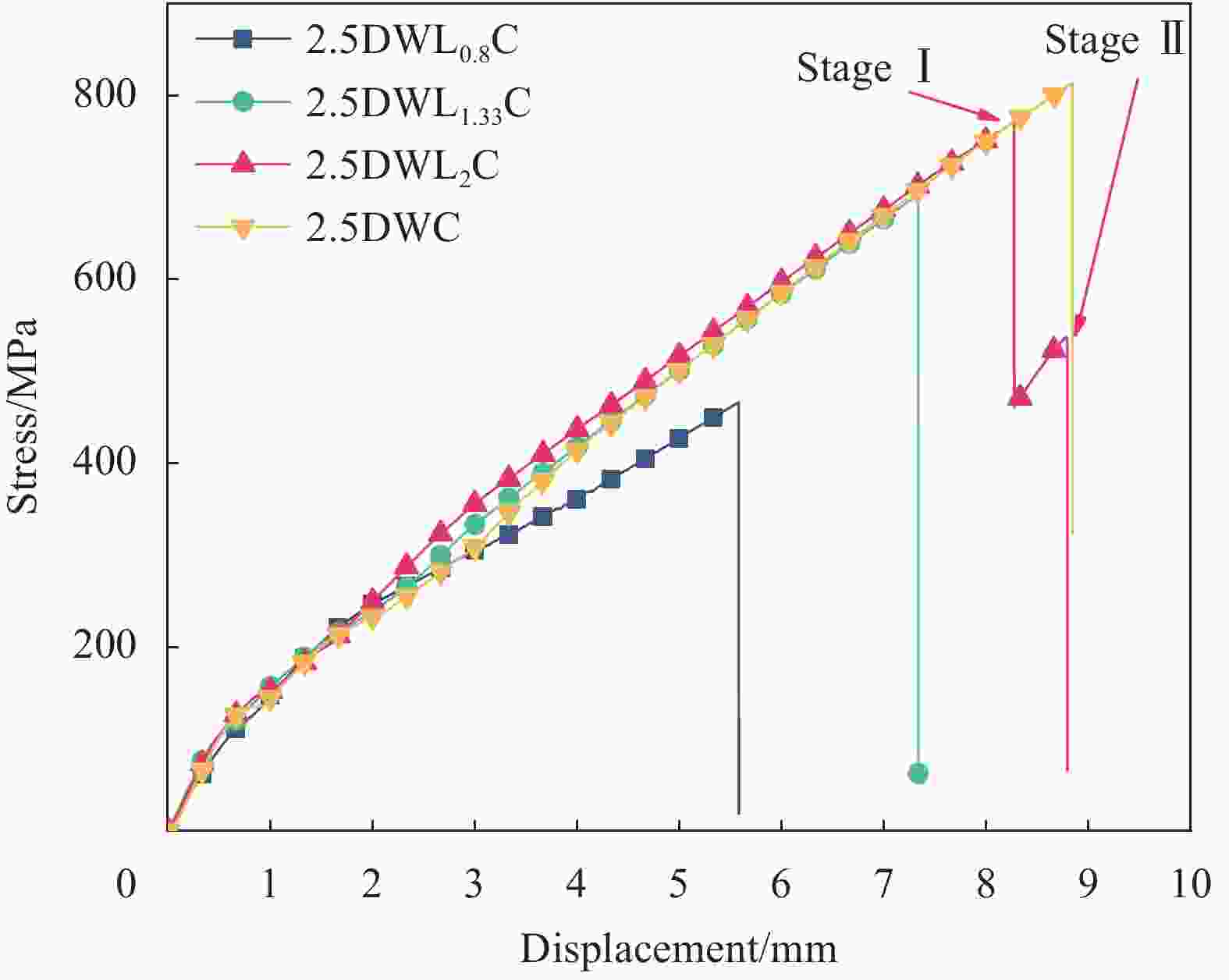

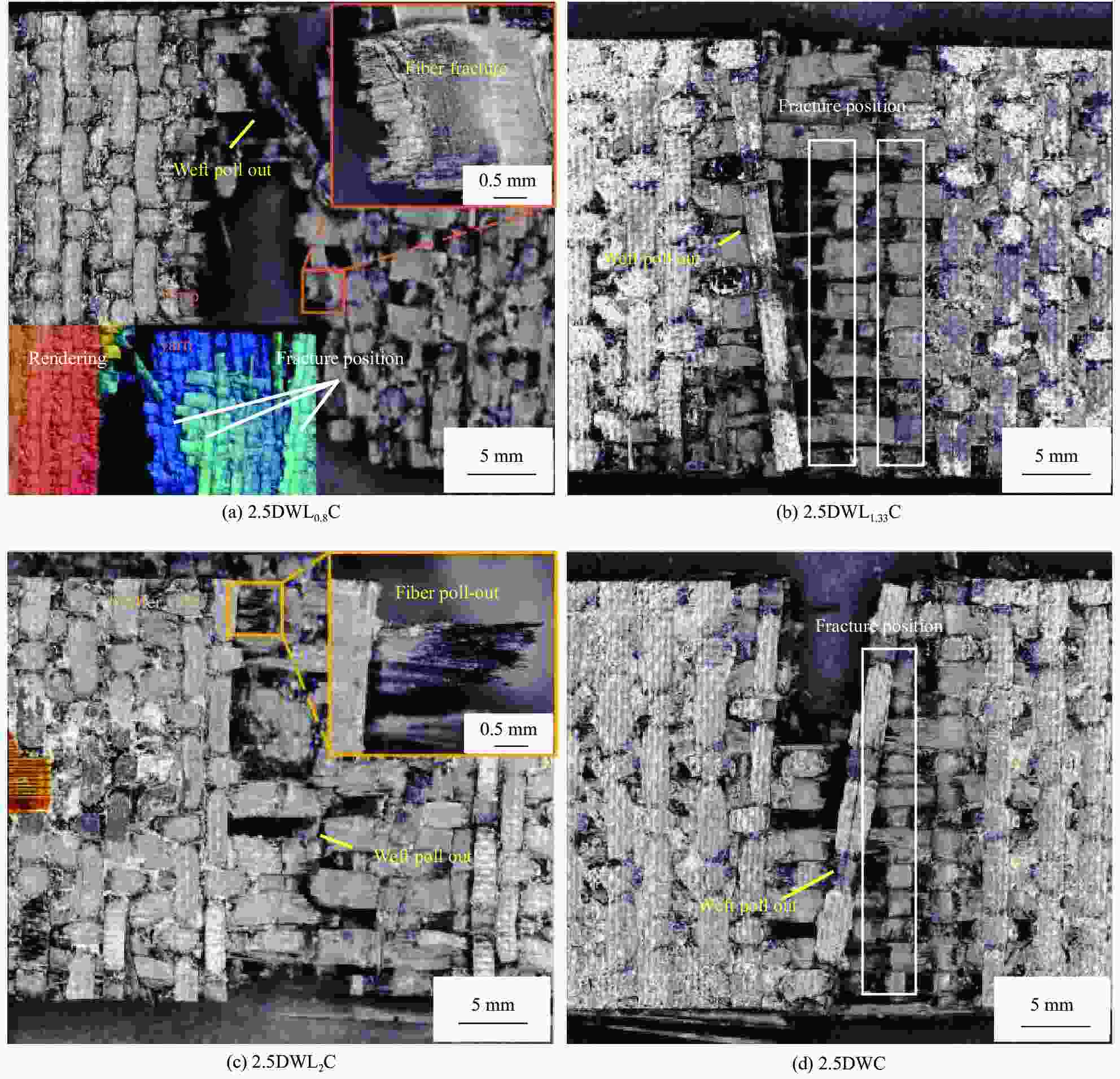

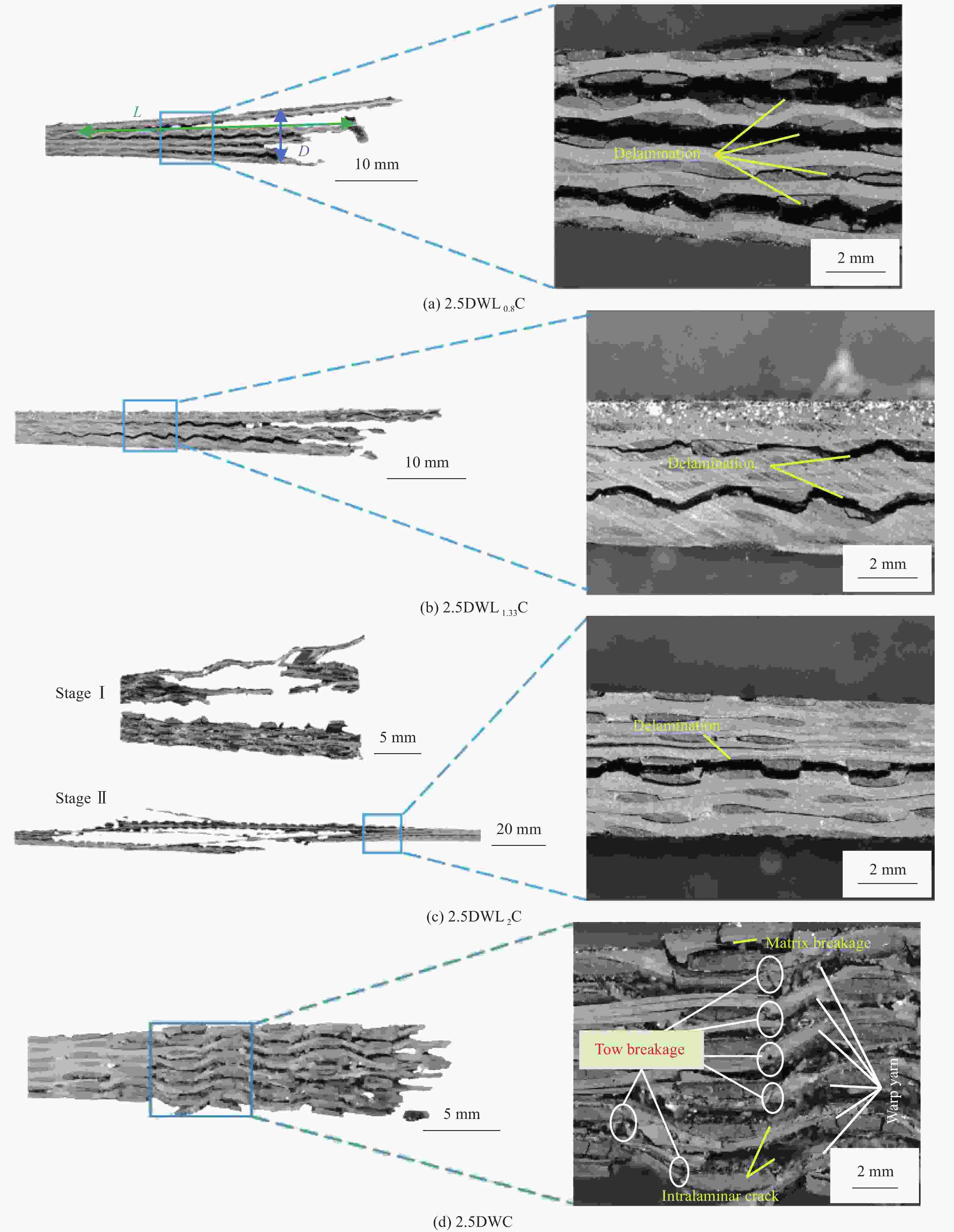

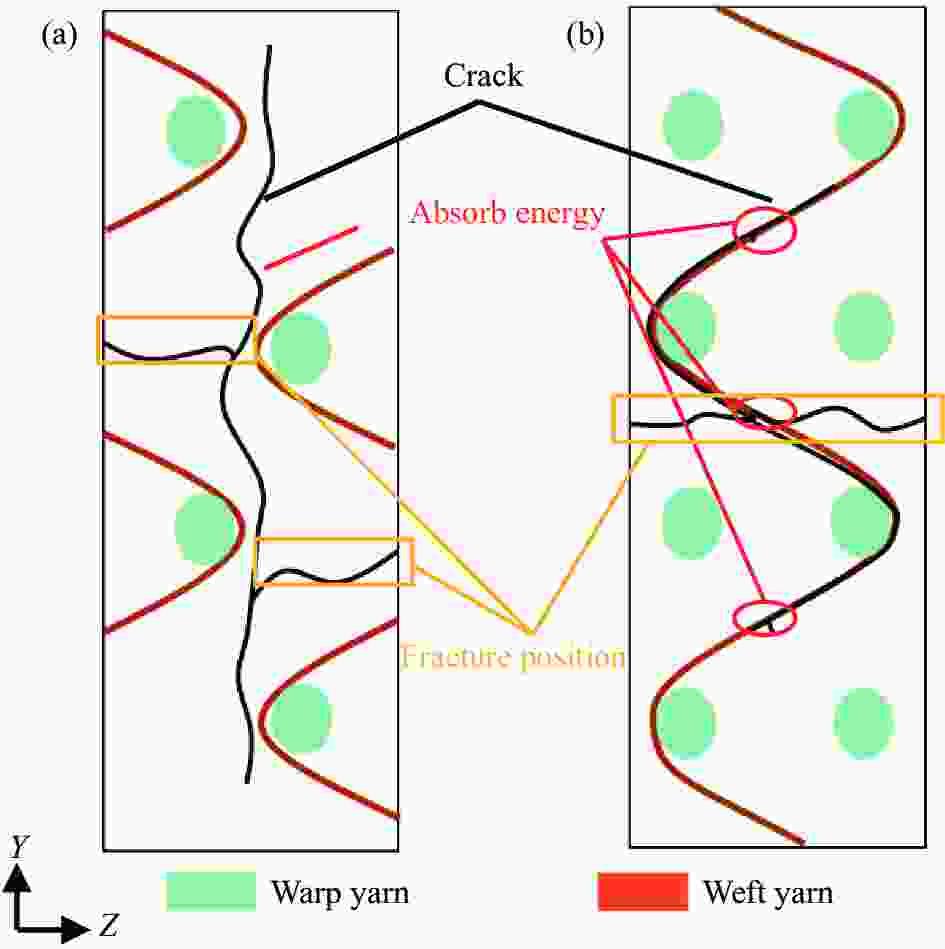

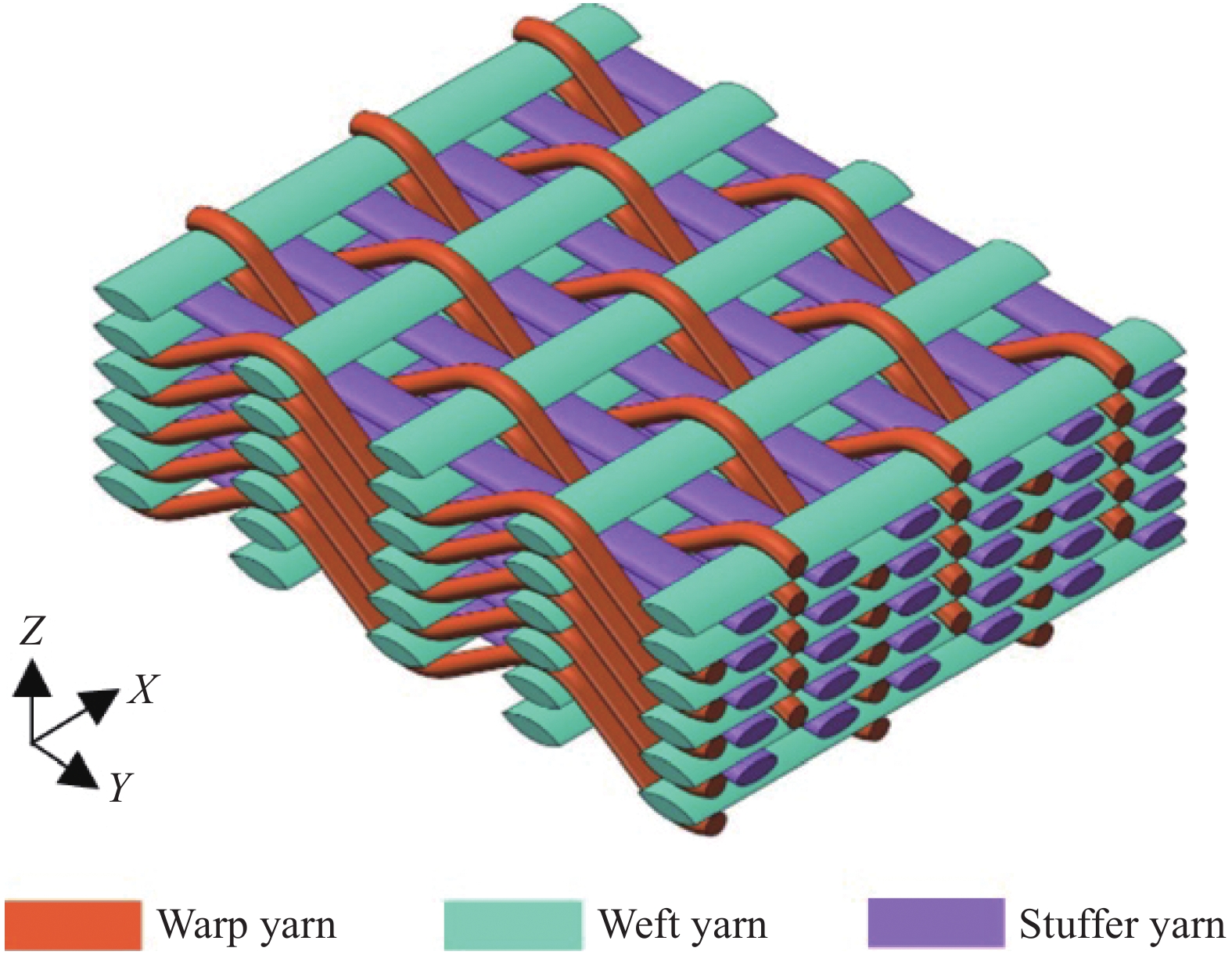

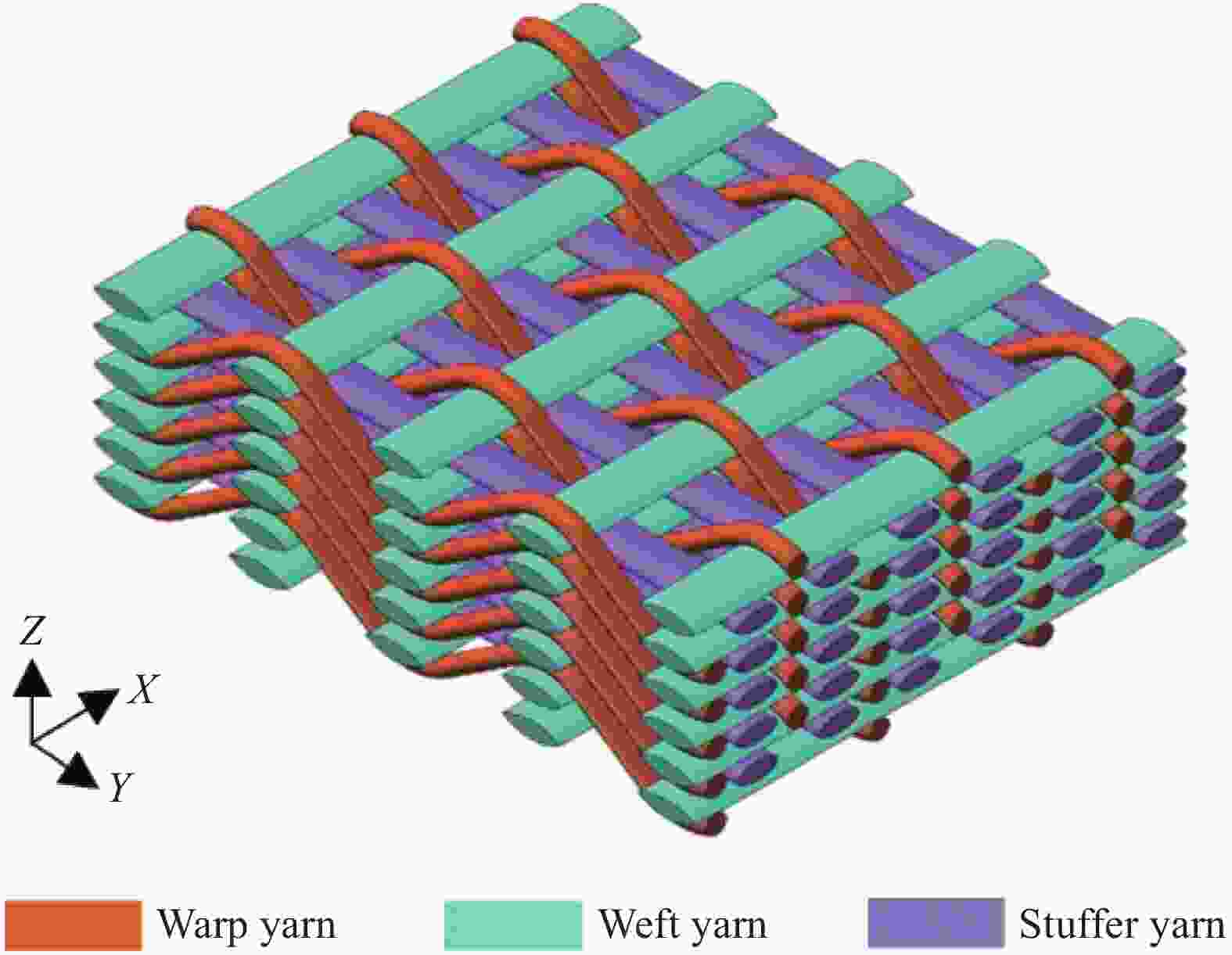

摘要: 采用树脂传递模塑 (Resin transfer molding,RTM)工艺方法制备了三维角联锁机织铺层复合材料,着重探讨了单层厚度对复合材料拉伸性能以及失效机制的影响。结果表明,复合材料的拉伸强度随着单层厚度的增大而显著增加,纤维体积含量相同时单层厚度对拉伸模量影响较小;在拉伸断裂过程中,各层断裂不同步,单层厚度的增加会加深各单层之间破坏应变的差异;失效试样分层现象显著,单层内未出现明显裂纹,经纱脆性断裂显著,层间伴随着大量基体碎屑,失效模式主要涵盖了纤维断裂和抽拔、界面脱黏、基体开裂以及分层。Abstract: The resin transfer molding (RTM) process was used to prepare the three-dimensional angle interlocking woven layup composites. The influence of the layer thickness on the tensile properties and failure mechanism was emphatically discussed. The results show that the tensile strength increases significantly with the enhancement of the layer thickness. In the case of similar fiber volume content, the layer thickness has little effect on the tensile modulus. In the process of tensile fracture, the break of each layer is not synchronized, and the augment of layer thickness deepens the diversity in failure strain between the individual layers. The failure samples have significant delamination, no obvious cracks appeared in the layer. The warp yarns show obvious brittle fracture and a large amount of resin chips appears in the interlamination. The failure modes mainly include fiber fracture and extraction, interface debonding, matrix cracking and delamination.

-

Key words:

- 3D woven /

- 2.5D /

- layer thickness /

- tensile property /

- failure mechanism

-

表 1 碳纤维参数

Table 1. Parameters of carbon fiber

Product type Density/(g·cm−3) Breakage elongation/% Tensile strength/$ {\rm{MPa}} $ Tensile modulus/$ {\rm{GPa}} $ TG800H-12K 1.79 2.28 5810 289 表 2 三维角联锁机织铺层复合材料(2.5DWLC)的结构参数

Table 2. Structural parameters of three-dimensional angle interlocking woven layup composites (2.5DWLC)

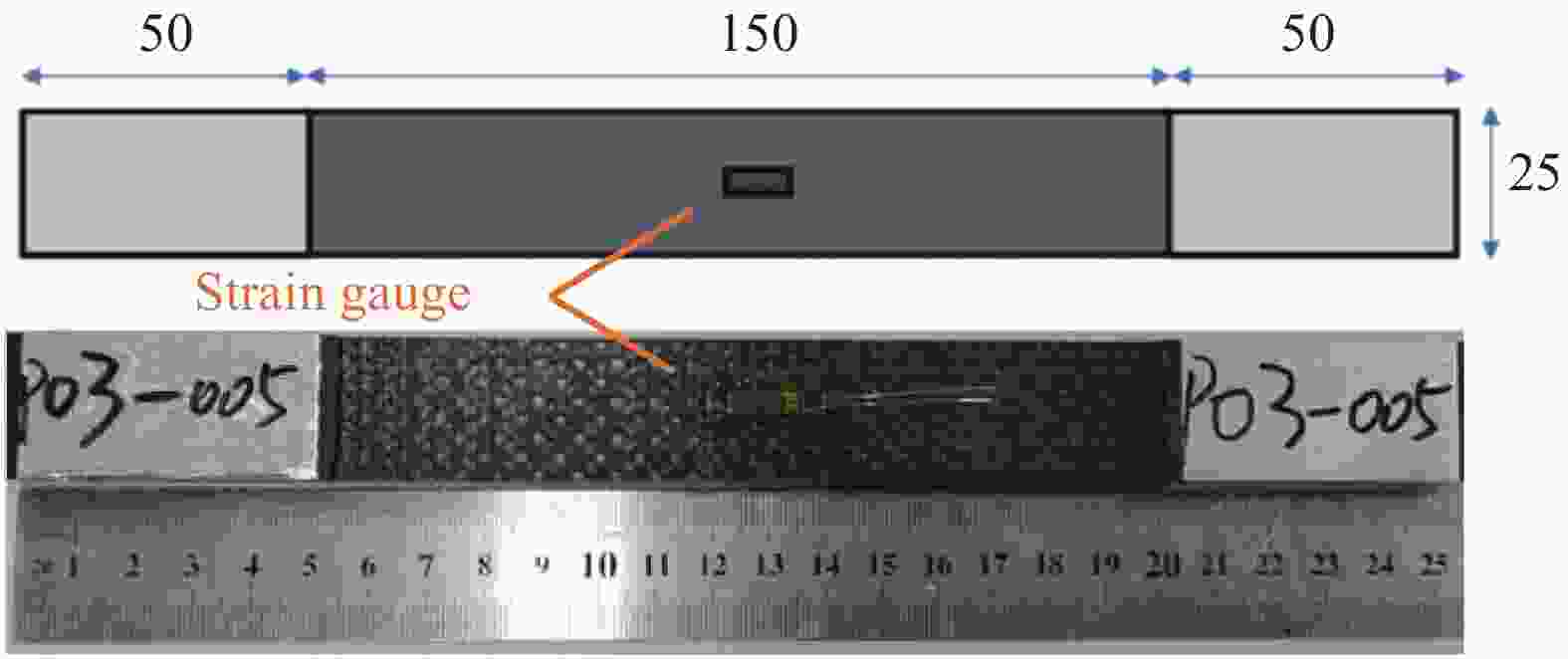

Structures Ply stacking sequence Layer thickness/mm Composite thickness/mm Fiber volume fraction/$ {\rm{vol\% }} $ 2.5DWL0.8C [(0)5/(0,90)] 0.80 4.02 47.9 2.5DWL1.33C [(0)3/(0,90)] 1.33 4.01 51.4 2.5DWL2C [(0)2/(0,90)] 2.00 4.00 51.2 2.5DWC — 4.00 4.01 50.8 Notes: Three types of 2.5DWLC are represented by 2.5DWLiC ($ i $=0.8, 1.33, 2), and “$ i $” represents the layer thickness. 表 3 2.5DWLC中经纱的局部偏离角度

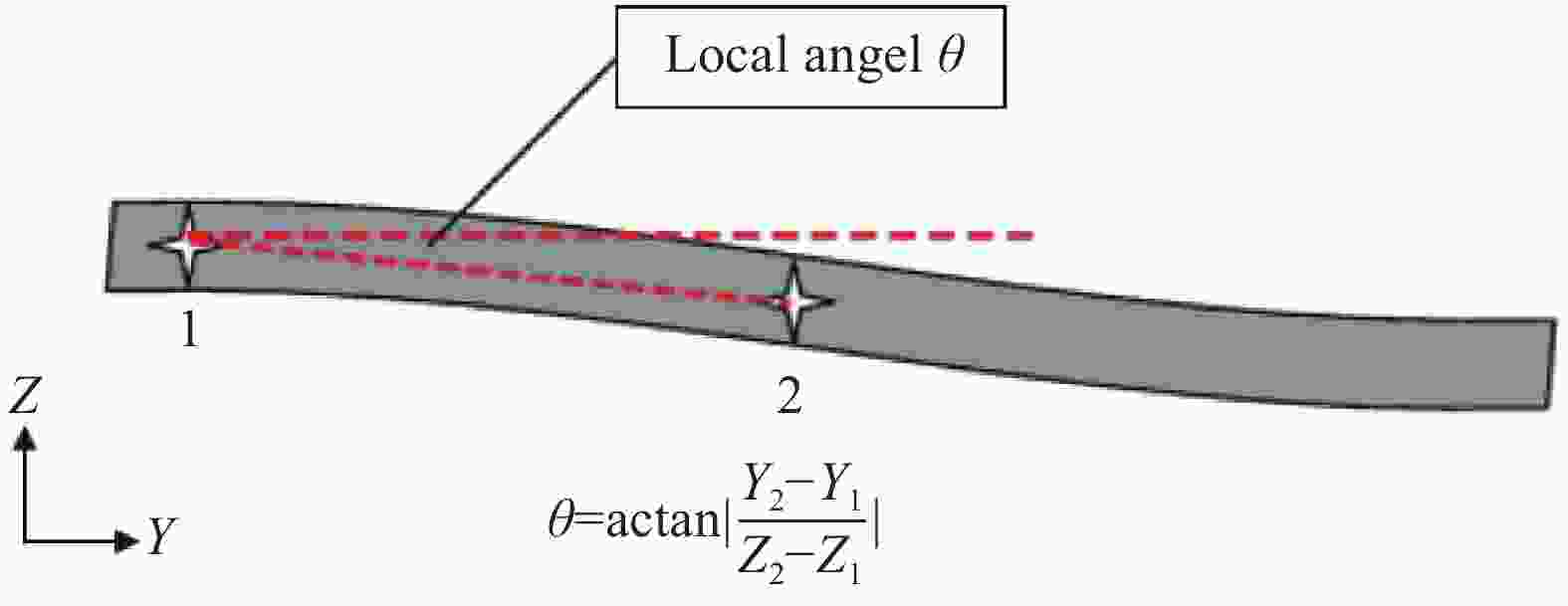

Table 3. Local angle of deviation of warp yarn in 2.5DWLC from a specified horizontal

Structure 2.5DWL0.8C 2.5DWL1.33C 2.5DWL2C 2.5DWC Local angle θ/(°) (CV) 12.34° (3.2%) 12.79° (2.6%) 12.64° (2.9%) 12.11° (2.1%) Notes: CV—Coefficient of variation. 表 4 2.5DWLC的拉伸强度和拉伸模量

Table 4. Tensile strength and tensile modulus of 2.5DWLC

Structure Tensile strength/

$ {\rm{MPa}} $ (CV)Tensile modulus/

$ {\rm{GPa}} $ (CV)2.5DWL0.8C 461.74 (7.22%) 63.17 (3.89%) 2.5DWL1.33C 688.75 (7.13%) 80.47 (1.94%) 2.5DWL2C 775.01 (7.32%) 81.97 (2.21%) 2.5DWC 803.13 (6.54%) 87.56 (1.62%) 表 5 2.5DWLC拉伸试样断口处的宽度(D)和裂纹扩展长度(L)

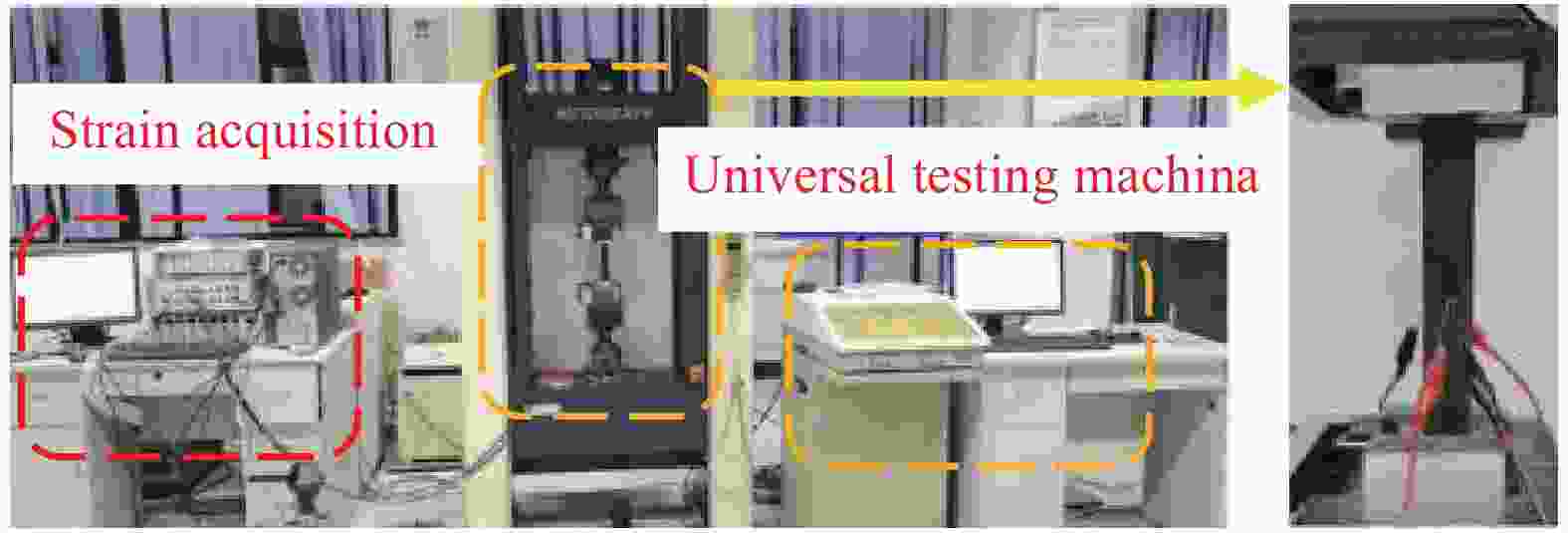

Table 5. Width(D) of 2.5DWLC tensile specimens and the crack propagation length(L)

Structure 2.5DWL0.8C 2.5DWL1.33C 2.5DWL2C 2.5DWC D/mm (CV) 9.44 (8.6%) 6.07 (7.1%) 8.98 (11.9%) 5.86 (5.9%) L/mm (CV) 44.45 (15.2%) 40.65 (14.7%) 73.08 (16.3%) 19.17 (19.1%) -

[1] ZHANG Y, GUO Q, CHEN X, et al. Effect of apertures on tensile property of warp-reinforced 2.5D woven composites notched plates[J]. Composite Structures,2020,252:112693. doi: 10.1016/j.compstruct.2020.112693 [2] DAI S, CUNNINGHAM P R, MARSHALL S, et al. Influence of fibre architecture on the tensile, compressive and flexu- ral behaviour of 3D woven composites[J]. Composites Part A: Applied Science and Manufacturing,2015,69:195-207. doi: 10.1016/j.compositesa.2014.11.012 [3] 郭瑞卿, 张一帆, 吕庆涛, 等. 多层多向层联三维机织复合材料的拉伸性能[J]. 复合材料学报, 2020, 37(10):2409-2417.GUO Ruiqing, ZHANG Yifan, LV Qingtao, et al. Tensile properties of multilayer multiaxial interlock 3D woven composites[J]. Acta Materiae Compositae Sinica,2020,37(10):2409-2417(in Chinese). [4] 王雅娜, 曾安民, 陈新文, 等. 2.5D机织石英纤维增强树脂复合材料不同方向力学性能测试与模量预测[J]. 复合材料学报, 2019, 36(6):1364-1373.WANG Yana, ZENG Anmin, CHEN Xinwen, et al. Mechanical properties testing for 2.5D quartz fiber reinforced resin composites in different and module prediction[J]. Acta Materiae Compositae Sinica,2019,36(6):1364-1373(in Chinese). [5] GU H, ZHILI Z. Tensile behavior of 3D woven composites by using different fabric structures[J]. Materials & Design,2002,23(7):671-674. [6] 关留祥, 李嘉禄, 焦亚男, 等. 航空发动机复合材料叶片用3D机织预制体研究进展[J]. 复合材料学报, 2018, 35(4):748-759.GUAN Liuxiang, LI Jialu, JIAO Yanan, et al. Review of 3D woven preforms for the composite blades of aero engine[J]. Acta Materiae Compositae Sinica,2018,35(4):748-759(in Chinese). [7] KUO W. The role of loops in 3D fabric composites[J]. Composites Science and Technology,2000,60(9):1835-1849. doi: 10.1016/S0266-3538(00)00075-0 [8] ZHOU W, QIN R, HAN K, et al. Progressive damage visualization and tensile failure analysis of three-dimensional braided composites by acoustic emission and micro-CT[J]. Polymer Testing,2020,93:106881. [9] LEE L, RUDOV-CLARK S, MOURITZ A P, et al. Effect of weaving damage on the tensile properties of three-dimensional woven composites[J]. Composite Structures,2002,57(1):405-413. [10] JIN L, NIU Z, JIN B C, et al. Comparisons of static bending and fatigue damage between 3D angle-interlock and 3D orthogonal woven composites[J]. Journal of Reinforced Plastics & Composites,2012,31(14):935-945. [11] LAPEYRONNIE P, LE GROGNEC P, BINÉTRUY C, et al. Homogenization of the elastic behavior of a layer-to-layer angle-inter-lock composite[J]. Composite Structures,2011,93(11):2795-2807. doi: 10.1016/j.compstruct.2011.05.025 [12] 王忠远, 蔡长春, 王振军, 等. 三维角联锁机织铝基复合材料面内拉伸力学行为与失效机制[J]. 复合材料学报, 2021, 38(9):2989-2999.WANG Zhongyuan, CAI Changchun, WANG Zhenjun, et al. Mechanical behavior and failure mechanism of the 3D angle interlocking woven reinforced aluminum matrix composites under in-plane tensile loading[J]. Acta Materiae Compositae Sinica,2021,38(9):2989-2999(in Chinese). [13] 吴宁, 韩美月, 焦亚男, 等. 高性能纤维的可织性研究进展[J]. 航空制造技术, 2020, 63(15):81-89.WU Ning, HAN Meiyue, JIAO Yanan, et al. Research progress on weavability of high-performance fibers[J]. Aeronautical Manufacturing Technology,2020,63(15):81-89(in Chinese). [14] MOHAMED M H, SALAMA M M. High speed three-dimensional weaving method and machine: United States Patent, US 6315007 B1[P]. 2001-06-23. [15] 王盼乐, 周光明. 2.5D与2D织物混杂铺设复合材料力学性能实验研究[J]. 科技信息, 2011(22):463-465. doi: 10.3969/j.issn.1001-9960.2011.22.391WANG Panle, ZHOU Guangming. Experimental study on mechanical properties of 2.5D and 2D hybrid fabric laid composites[J]. Science and Technology Information,2011(22):463-465(in Chinese). doi: 10.3969/j.issn.1001-9960.2011.22.391 [16] SONG L L, LI J L, ZHAO Y F, et al. Improvement of interlaminar shear strength of 2.5D fabric laminated composites with short-cut web interlayer[J]. Journal of polymer engineering,2017,37(3):261-269. doi: 10.1515/polyeng-2016-0029 [17] PANKOW M, JUSTUSSON B, RIOSBAAS M, et al. Effect of fiber architecture on tensile fracture of 3D woven textile composites[J]. Composite Structures,2019,225:111139. doi: 10.1016/j.compstruct.2019.111139 [18] LOMOV S V, BOGDANOVICH A E, IVANOV D S, et al. A comparative study of tensile proper-ties of non-crimp 3D orthogonal weave and multi-layer plain weave E-glass composites:Part 1— Materials, methods and principal results[J]. Composites Part A: Applied Science and Manufacturing,2009,40(8):1134-1143. doi: 10.1016/j.compositesa.2009.03.012 [19] 杨彩云, 李嘉禄, 田玲玲. 复合材料中纱束的几何形态[J]. 复合材料学报, 2007, 24(4):123-127. doi: 10.3321/j.issn:1000-3851.2007.04.022YANG Caiyun, LI Jialu, TIAN Lingling. Geometry configuration of yarn in composite materials[J]. Acta Materiae Compositae Sinica,2007,24(4):123-127(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.04.022 [20] 陆慧中, 孙颖, 焦亚男, 等. 典型多向2.5D机织预制体近净形编织结构设计[J]. 复合材料学报, 2021, 38(9):3109-3117.LU Huizhong, SUN Ying, JIAO Yanan, et al. Near net-shaped design on the architecture of typical multidirectional 2.5D woven preform[J]. Acta Materiae Com-positae Sinica,2021,38(9):3109-3117(in Chinese). [21] 杨连贺, 李姜. 三维机织复合材料纱线束截面变形研究[J]. 复合材料学报, 2008, 25(4):198-204. doi: 10.3321/j.issn:1000-3851.2008.04.035YANG Lianhe, LI Jiang. Study on tow cross-section deformation in three-dimensional woven composites[J]. Acta Materiae Compositae Sinica,2008,25(4):198-204(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.04.035 [22] American Society for Testing Materials. Standard test method for tensile properties of polymer matrix composite materials: ASTM-D3039/D3090M—2007[S]. United States: American Society for Testing Materials International, 2007-12-15. [23] JIAO W, CHEN L, XIE J, et al. Effect of weaving structures on the geometry variations and mechanical properties of 3D LTL woven composites[J]. Composite Structures,2020,252:112756. doi: 10.1016/j.compstruct.2020.112756 [24] 刘俊岭, 孙颖, 陈利. 含变异结构的三维机织复合材料的轴向拉伸性能[J]. 纺织学报, 2019, 40(12):162-168.LIU Junling, SUN Ying, CHEN Li. Axial tensile properties of three-dimensional woven compo-sites with variant structure[J]. Journal of Textile Research,2019,40(12):162-168(in Chinese). [25] COX B N, DADKHAH M S, MORRIS W L. On the tensile failure of 3D woven composites[J]. Composites Part A: Applied Science and Manufacturing,1996,27(6):447-458. doi: 10.1016/1359-835X(95)00053-5 [26] 赵丽滨, 龚愉, 张建宇. 纤维增强复合材料层合板分层扩展行为研究进展[J]. 航空学报, 2019, 40(1):171-199.ZHAO Libin, GONG Yu, ZHANG Jianyu. A survey on delamination growth behavior in fiber reinforced composite laminates[J]. Acta Aeronautica et Astronautica Sinica,2019,40(1):171-199(in Chinese). -

下载:

下载: