Mechanical and thermal properties of pulp fiber/polylactic acid composite

-

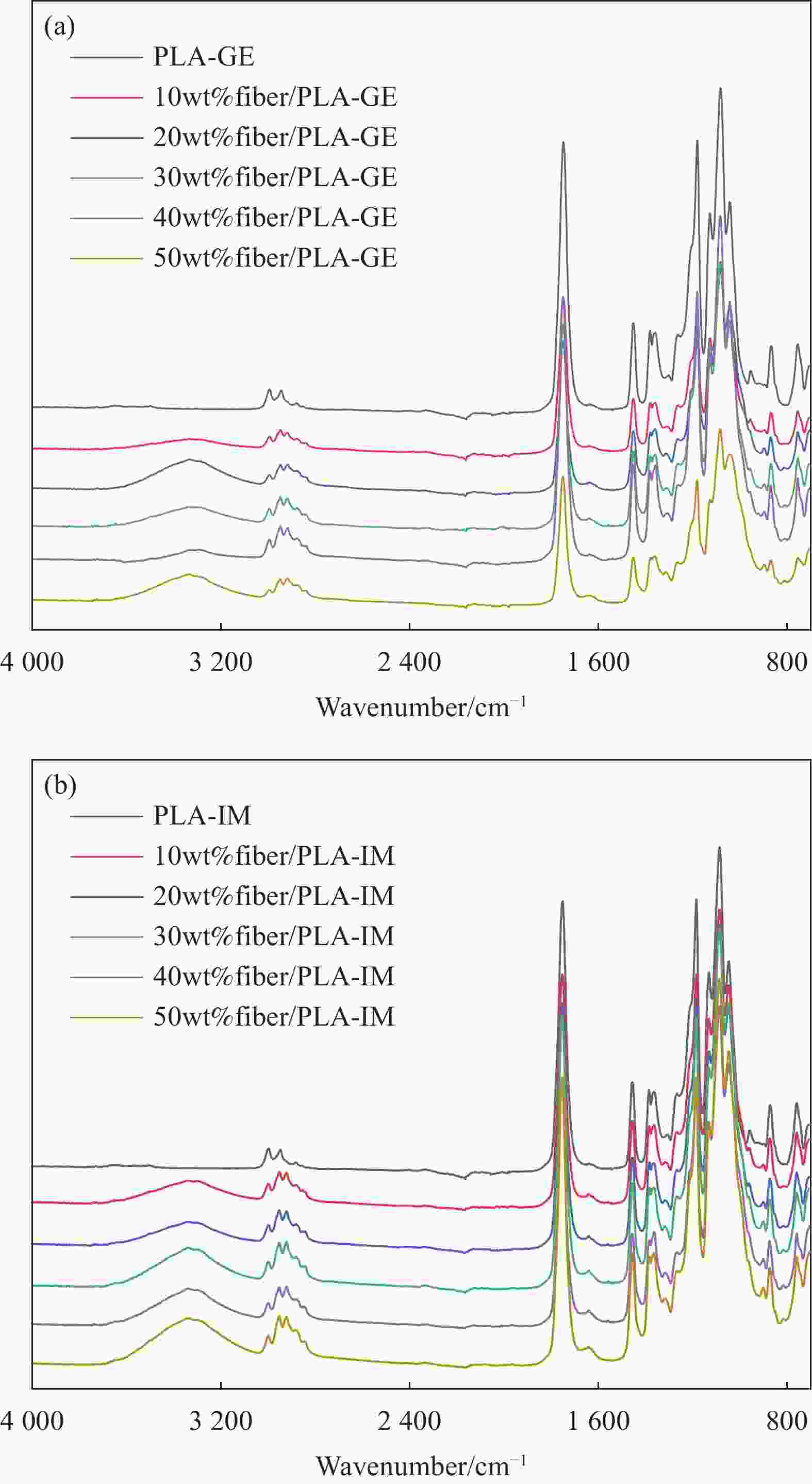

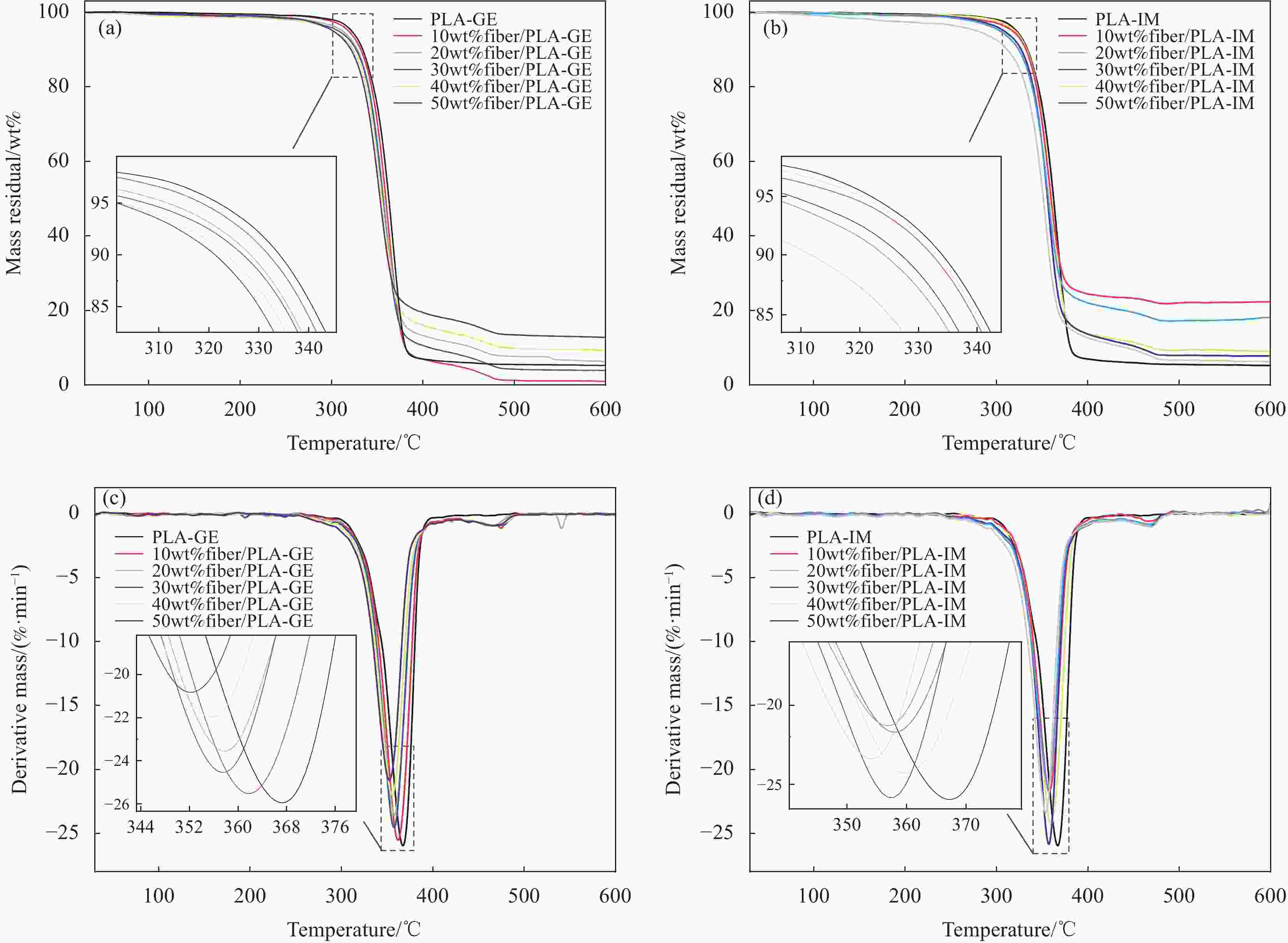

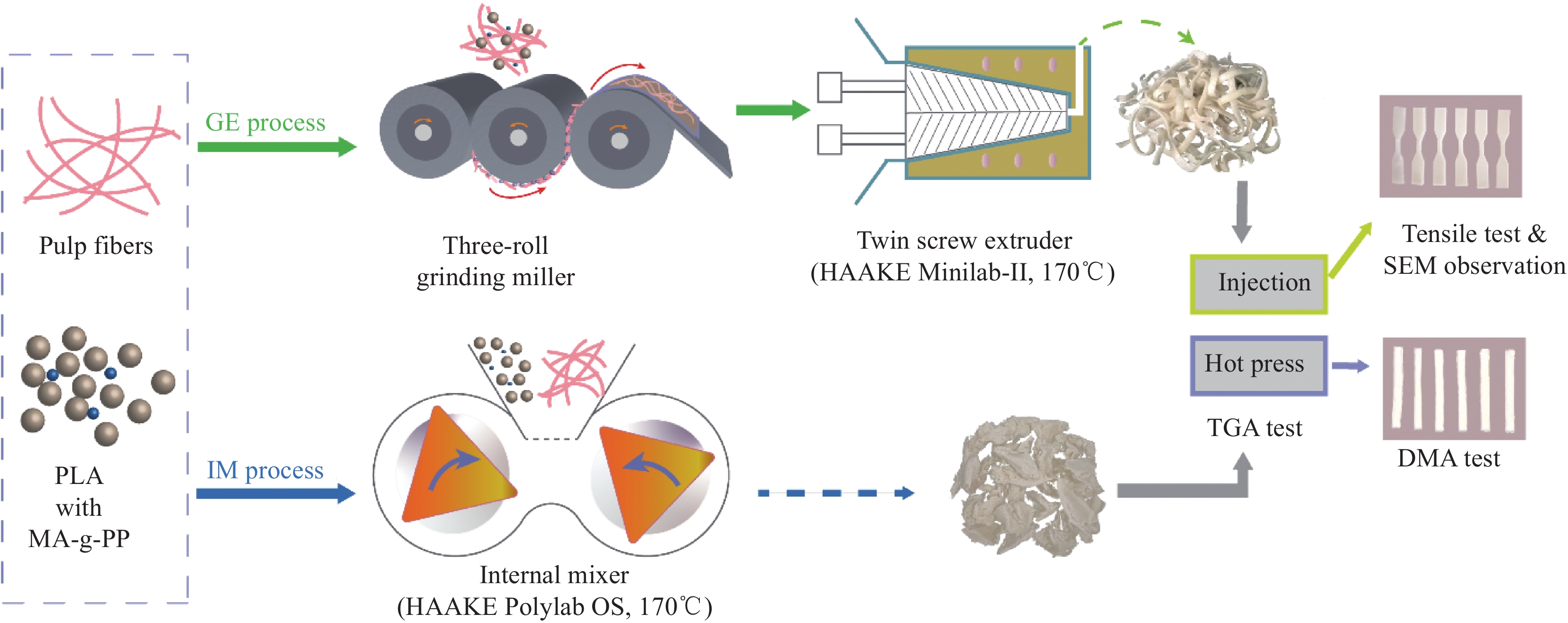

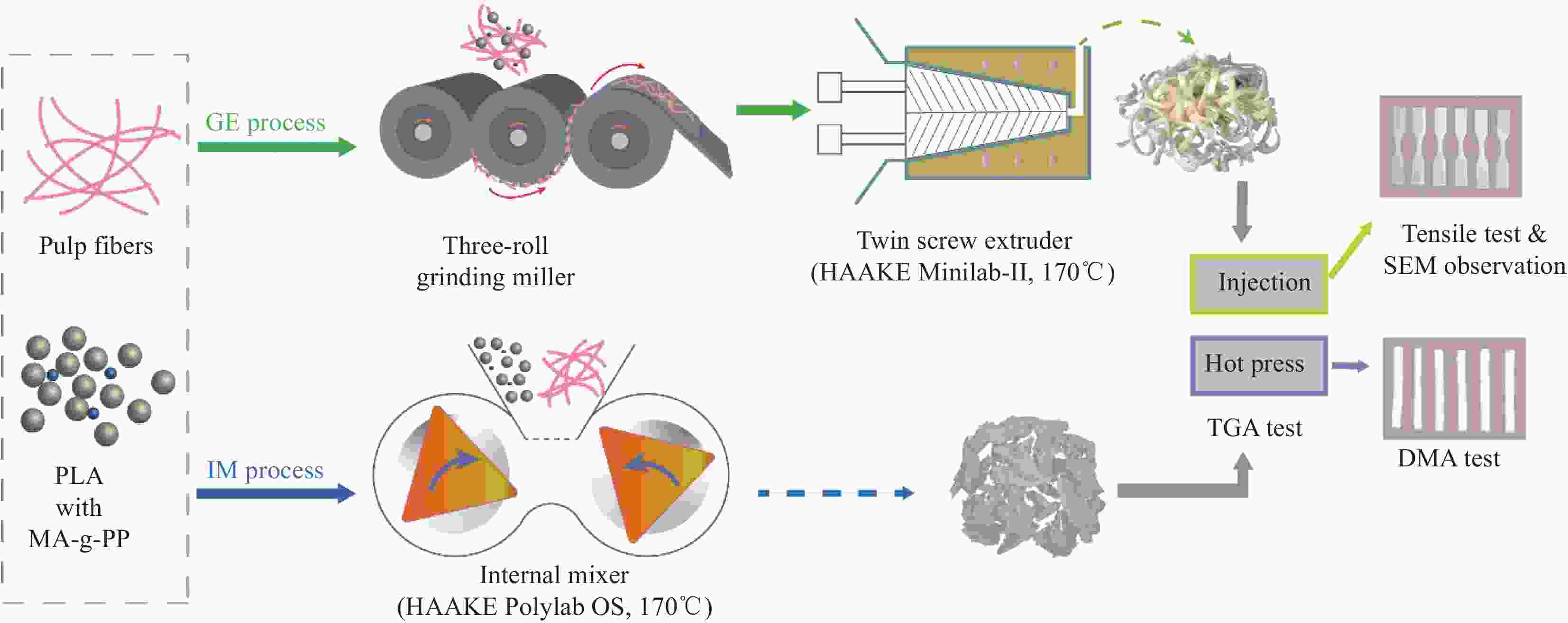

摘要: 生物质衍生填料增强的生物复合材料一直被认为是极具潜力的石油基产品的替代品。引入高含量漂白纸浆纤维(10wt%~50wt%),使用辊磨挤出法和密炼法两种预混工艺,采用马来酸酐接枝聚丙烯(MA-g-PP)为相容剂,制备了纸浆纤维/聚乳酸(PLA)复合材料。采用拉伸测试、SEM、FTIR、DMA和TGA表征,综合考察了制备工艺和纤维含量对复合材料的力学性能、热学性能和微观结构的影响。结果表明:密炼法比辊磨挤出法更有效地实现了纤维在基体中的良好分散(几乎定向排列)。50wt%纤维含量的密炼加工复合材料实现了最大的拉伸强度(50.49 MPa,略高于PLA)和最高的弹性模量值(2.56 GPa,比PLA高45.8%)。刚性填充的纸浆纤维降低了复合材料的阻尼性能,损耗因子tanδ峰值温度发生正迁移。纸浆纤维不会对热稳定性产生不利影响,复合材料的残留物含量提高。研究表明,漂白纸浆纤维增强改性PLA制造可生物降解的复合材料是可行的。Abstract: Biomass-derived fillers reinforced composites have always been considered as potential substitutes for petroleum-based products. In this work, high content of bleached pulp fibers (10wt% to 50wt%) were adopted to modify polylactic acid (PLA) with maleic anhydride grafted polypropylene (MA-g-PP) as the compatibilizer. Two pre-melting processes of fiber/PLA composites were tried, i.e., roll-grinding plus extruding as well as internal mixing process. Tensile test, SEM, FTIR、DMA and TGA were employed to comprehensively investigate the effects of processing methods and fiber content on the mechanical and thermal properties, and microstructure of fiber/PLA composites. The results showed that, internal mixing process (IM process) is more effective than grinding and extruding process (GE process) to achieve good dispersion and almost oriented-arrangement of the fibers in the matrix. IM-processed composites with fiber content up to 50wt% acquired the maximum tensile strength (50.49 MPa, slightly higher than PLA) and Young's modulus (2.56 GPa, 45.8% higher than PLA). Damping capacity and loss factor of composites are reduced by the rigid filled pulp fibers, while the peak temperature is positively migrated. Pulp fibers added have no adversely effect on thermal stability and improve the residues content of PLA composites. It can be concluded that bleached pulp fiber is an effective filler for PLA-based composites.

-

Key words:

- bleached pulp fiber /

- polylactic acid (PLA) /

- two-screw extrusion /

- internal mixing /

- biocomposite

-

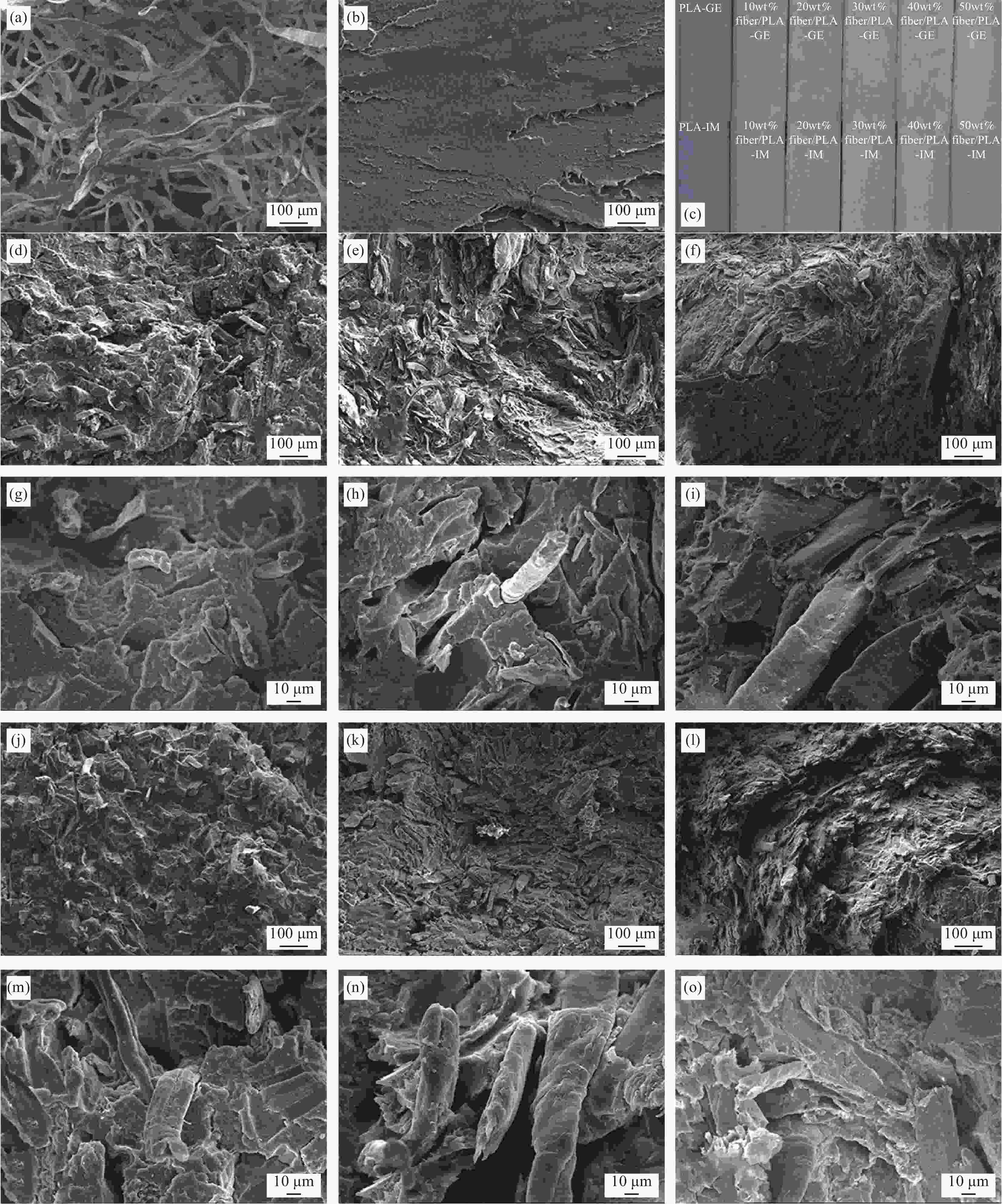

图 3 (a) 纸浆纤维; (b) PLA脆性断裂形貌;(c) 纸浆纤维/PLA试样表面(上层为辊磨挤出样品,下层为密炼样品);((d)~(o)) 纸浆纤维/PLA复合材料拉伸样品的微观断面形貌,样品分别选取了10wt%fiber/PLA-GE ((d)、(g))、40wt%fiber/PLA-GE ((e)、(h))、 50wt%fiber/PLA-GE ((f)、(i))、10wt%fiber/PLA-IM ((j)、(m))、40wt%fiber/PLA-IM ((k)、(n))、 50wt%fiber/PLA-IM ((l)、(o))

Figure 3. (a) Microscopic morphology of pulp fibers; (b) Brittle fracture morphology of pure PLA; (c) Specimen surface of pulp fiber/PLA (the upper layer represents GE samples, while the lower layer represents IM samples); ((d)-(o)) Cross-section morphologies of fractured specimen of pulp fiber/PLA composites, respectively, selected samples of 10wt%fiber/PLA-GE ((d), (g)), 40wt%fiber/PLA-GE ((e), (h)), 50wt%fiber/PLA-GE ((f), (i)), 10wt%fiber/PLA-IM ((j), (m)), 40wt%fiber/PLA-IM ((k), (n)), 50wt%fiber/PLA-IM ((l), (o))

图 5 辊磨挤出工艺 ((a)、(c)、(e)) 和密炼工艺 ((b)、(d)、(f)) 下纸浆纤维/PLA复合材料的动态黏弹性能:储能模量 ((a)、(b));损耗模量 ((c)、(d));损耗因子(tanδ) ((e)、(f))

Figure 5. Dynamic viscoelastic properties of pulp fiber/PLA composite under GE process ((a), (c), (e)) and IM process ((b), (d), (f)): Storage modulus ((a), (b)); Loss modulus ((c), (d)); Loss factor (tanδ) ((e), (f))

表 1 纸浆纤维/PLA复合材料的原料配比

Table 1. Formulations of pulp fiber/PLA composites

Pre-melting methods Sample code Fiber/wt% PLA/wt% MA-g-PP/wt% Grinding and extruding

process (GE process)PLA-GE 0 100 0 10wt%fiber/PLA-GE 10 86 4 20wt%fiber/PLA-GE 20 76 4 30wt%fiber/PLA-GE 30 66 4 40wt%fiber/PLA-GE 40 56 4 50wt%fiber/PLA-GE 50 46 4 Internal mixing

process (IM process)PLA-IM 0 100 0 10wt%fiber/PLA-IM 10 86 4 20wt%fiber/PLA-IM 20 76 4 30wt%fiber/PLA-IM 30 66 4 40wt%fiber/PLA-IM 40 56 4 50wt%fiber/PLA-IM 50 46 4 -

[1] 贾红兵, 宋晔, 王经逸. 高分子材料[M]. 南京: 南京大学出版社, 2019: 5-10.JIA Hongbing, SONG Ye, WANG Jingyi. Polymer materials[M]. Nanjing: Nanjing University Press, 2019: 5-10(in Chinese). [2] 魏泽昌, 蔡晨阳, 王兴, 等. 生物可降解高分子增韧聚乳酸的研究进展[J]. 材料工程, 2019, 47(5):34-42.WEI Zechang, CAI Chenyang, WANG Xing, et al. Research progress of biode gradable polymer toughened polylactic acid[J]. Journal of Materials Engineering,2019,47(5):34-42(in Chinese). [3] 陈鸣. 三螺杆挤出机制备PLA/PCL共混物及其性能研究[D]. 广州: 华南理工大学, 2020: 1-10.CHEN Ming. Preparation of PLA/PCL blends by three-screw extruder and its performance research[D]. Guangzhou: South China University of Technology, 2020: 1-10(in Chinese). [4] 黄晓兰, 李彩玲, 刘幸琪, 等. 绿色可降解生物高分子聚乳酸改性及应用研究进展[J]. 工程塑料应用, 2021, 49(7):162-166. doi: 10.3969/j.issn.1001-3539.2021.07.028HUANG Xiaolan, LI Cailing, LIU Xingqi, et al. Research progress on modification and application of green degradable biopolymer polylactic acid[J]. Engineering Plastics Application,2021,49(7):162-166(in Chinese). doi: 10.3969/j.issn.1001-3539.2021.07.028 [5] 丁诗娟, 朱西诗, 陈慧榕, 等. 生物质秸秆/聚乳酸材料的制备及成型研究进展[J]. 绿色包装, 2021(6):38-42.DING Shijuan, ZHU Xishi, CHEN Huirong, et al. Research progress on preparation and molding of biomass straw/polylactic acid materials[J]. Green Packaging,2021(6):38-42(in Chinese). [6] 孙东宝, 路琴, 陆鑫禹, 等. PLA/稻壳粉复合材料界面改性方法及性能研究[J]. 中国塑料, 2021, 35(6):80-84.SUN Dongbao, LU Qin, LU Xinyu, et al. Study on the interface modification methods and properties of PLA/rice husk powder composites[J]. China Plastics,2021,35(6):80-84(in Chinese). [7] 王璇. 纳米纤维素改性聚乳酸复合材料及增容机理研究[D]. 北京: 北京林业大学, 2016: 7-17.WANG Xuan. Nano-cellulose modified polylactic acid composite material and its compatibilization mechanism[D]. Beijing: Beijing Forestry University, 2016: 7-17(in Chinese). [8] 刘桦, 罗丙红, 陈睿鹏, 等. 纳米纤维素晶须增强增韧聚(L-乳酸)复合材料的制备与表征[J]. 复合材料学报, 2015, 32(6):1703-1713.LIU Hua, LUO Binghong, CHEN Ruipeng, et al. Preparation and characterization of nano-cellulose whisker reinforced and toughened poly(L-lactic acid) composites[J]. Acta Materiae Compositae Sinica,2015,32(6):1703-1713(in Chinese). [9] 应泽人. 聚乳酸/纤维素纳米纤维复合材料的结构与性能[D]. 扬州: 扬州大学, 2019: 15-18.YING Zeren. Structure and properties of polylactic acid/cellulose nanofiber composites[D]. Yangzhou: Yangzhou University, 2019: 15-18(in Chinese). [10] TEIJO R, HEIDI P, DAVID S Q. Foamability and viscosity behavior of extrusion foamed PLA-pulp fiber biocomposites[J]. Journal of Applied Polymer Science,2019,136(41):48202. [11] ESPINACH F X, BOUFI S, DELGADO-AGUILAR M, et al. Composites from poly(lactic acid) and bleached chemical fibres: Thermalproperties[J]. Composites Part B: Engineering,2018,134:169-176. doi: 10.1016/j.compositesb.2017.09.055 [12] CHOUDHARY P, MOHANTY S, NAYAK S K, et al. Poly (L-lactide)/polypropylene blends: Evaluation of mechanical, thermal, and morphological characteristics [J]. Journal of Applied Polymer Science, 2011, 121(6): 3223-3237. [13] 吴英柯, 马建中, 鲍艳. 聚合物基纳米复合材料的界面作用研究进展[J]. 材料导报, 2018, 32(3):434-442.WU Yingke, MA Jianzhong, BAO Yan. Research progress on the interface effect of polymer-based nanocomposites[J]. Materials Reports,2018,32(3):434-442(in Chinese). [14] MENARD K P. Dynamic mechanical analysis[M]. 3rd edition. Boca Raton: CRC Press, 2019. [15] SHOJAEIARANI J, HARTMAN K. Esterified cellulose nanocrystals as reinforcement in poly(lactic acid) nanocomposites[J]. Cellulose,2019,26(4):2349-2362. doi: 10.1007/s10570-018-02237-4 [16] 左迎峰, 李萍, 刘文杰, 等. 碱处理对竹纤维/聚乳酸可降解复合材料性能影响研究[J]. 功能材料, 2018, 49(2):2006-2012.ZUO Yingfeng, LI Ping, LIU Wenjie, et al. Study on the effect of alkali treatment on the properties of bamboo fiber/polylactic acid degradable composites[J]. Jorunal of Functional Materials,2018,49(2):2006-2012(in Chinese). [17] ZHAO X, LI K, WANG Y, et al. Bio-treatment of poplar via amino acid for interface control in biocomposites[J]. Composites Part B: Engineering,2020,199(6):108276. [18] ASTM Committee. Standard test methods for density and specific gravity (relative density) of plastics by displacement: ASTM D792—2013[S]. United States: American Society for Testing and Materials International, 2013. [19] ASTM Committee. Standard test method for melt flow rates of thermoplastics by extrusion plastometer: ASTM D1238—2013[S]. United States: American Society for Testing and Materials International, 2013. [20] ASTM Committee. Standard test method for tensile properties of plastics: ASTM D638—2014[S]. United States: American Society for Testing and Materials International, 2014 [21] 张庆法, 杨科研, 蔡红珍, 等. 稻壳/高密度聚乙烯复合材料与稻壳炭/高密度聚乙烯复合材料性能对比[J]. 复合材料学报, 2018, 35(11):3044-3050.ZHANG Qingfa, YANG keyan, CAI Hongzhen, et al. Performance comparison of rice husk/high density polyethylene composite and rice husk char/high density polyethylene composite[J]. Acta Materiae Compositae Sinica,2018,35(11):3044-3050(in Chinese). [22] 葛正浩, 邹辛祺, 陈威, 等. PLA/杨木粉木塑复合材料的配方优化与力学性能研究[J]. 陕西科技大学学报, 2020, 38(1):124-130, 163. doi: 10.3969/j.issn.1000-5811.2020.01.021GE Zhenghao, ZOU Xinqi, CHEN Wei, et al. Formulation optimization and mechanical properties of PLA/poplar wood powder wood-plastic composites[J]. Journal of Shaanxi University of Science and Technology,2020,38(1):124-130, 163(in Chinese). doi: 10.3969/j.issn.1000-5811.2020.01.021 [23] 滕健, 张亮青, 林胜强, 等. 多孔再生纤维素/聚乳酸复合材料的制备与性能[J]. 高分子材料科学与工程, 2017, 33(4):143-147.TENG Jian, ZHANG Liangqing, LIN Shengqiang, et al. Preparation and properties of porous regenerated cellulose/polylactic acid composites[J]. Polymeric Materials Science and Engineering,2017,33(4):143-147(in Chinese). [24] ZHANG J, KOUBAA A, XING D, et, al. Improving lignocellulose thermal stability by chemical modification with boricacid for incorporating into polyamide[J]. Materials and Design,2020,191:108589. doi: 10.1016/j.matdes.2020.108589 [25] AOU K, KANG S, HSU S L. Morphological study on thermal shrinkage and dimensional stability associated with oriented poly (lactic acid)[J]. Macromolecules,2005,38(18):7730-7735. doi: 10.1021/ma051022e [26] IGARASHI Y, SATO A, OKUMURA H, et al. Manufacturing process centered on dry-pulp direct kneading method opens a door for commercialization of cellulose nano fiber reinforced composites[J]. Chemical Engineering Journal,2018,354(8):563-568. [27] SUROV O V, VORONOVA M I, AFINEEVSKII A V, et al. Polyethylene oxide films reinforced by cellulose nanocrystals: Microstructure-properties relationship[J]. Carbohydrate Polymers, 2018, 181: 489-498. [28] KIM S, KIM E S, CHOI K, et al. Rheological and mechanical properties of polypropylene composites containing microfibrillated cellulose (MFC) with improved compatibility through surface silylation[J]. Cellulose,2019,26(2):1085-1097. doi: 10.1007/s10570-018-2122-7 [29] 杨潞霞, 付一政, 廖黎琼. PLA/PA11共混物的制备与分子动力学模拟[J]. 功能材料, 2018, 49(2):2024-2028, 2034.YANG Luxia, FU Yizheng, LIAO Liqiong. Preparation and molecular dynamics simulation of PLA/PA11 blends[J]. Journal of Functional Materials,2018,49(2):2024-2028, 2034(in Chinese). [30] 温慧颖, 孔维肖, 陈春霞. 拉伸冷结晶聚乳酸结构及性能研究[J]. 分子科学学报, 2019, 35(4):265-272.WEN Huiying, KONG Weixiao, CHEN Chunxia. Study on the structure and properties of stretched cold crystallized polylactic acid[J]. Journal of Molecular Science,2019,35(4):265-272(in Chinese). [31] 吴盾, 李会丽, 陆颖, 等. 不同相对分子质量聚乙二醇增塑聚乳酸共混物的制备与性能[J]. 高分子材料科学与工程, 2017, 33(5):164-169, 177.WU Dun, LI Huili, LU Ying, et al. Preparation and properties of polyethylene glycol plasticized polylactic acid blends with different molecular weights[J]. Polymeric Materials Science and Engineering,2017,33(5):164-169, 177(in Chinese). [32] 桑东英, 程丹, 于光华, 等. MCC对PLA/PPC复合材料力学性能与热稳定性的影响[J]. 中国塑料, 2018, 32(6):46-52.SANG Dongying, CHENG Dan, YU Guanghua, et al. The effect of MCC on the mechanical properties and thermal stability of PLA/PPC composites[J]. China Plastics,2018,32(6):46-52(in Chinese). [33] RIGOUSSEN A, VERGE P, RAQUEZ J, et al. Natural phenolic antioxidants as a source of biocompatibilizers for immiscible polymer blends[J]. ACS Sustainable Chemistry. Engineering,2018,6(10):13349-13357. doi: 10.1021/acssuschemeng.8b02999 [34] 刘志华, 聂率, 龚明山, 等. 木质素/木粉/聚乳酸复合材料的制备及其性能[J]. 塑料, 2019, 48(2):8-13.LIU Zhihua, NIE Lv, GONG Mingshan, et al. Preparation and properties of lignin/wood flour/polylactic acid composites[J]. Plastics,2019,48(2):8-13(in Chinese). [35] 余洁, 韩建, 朱斐超, 等. 可全生物降解PLA/PBAT/PHBV共混材料的结构与性能[J]. 复合材料学报, 2016, 33(8):1608-1614.YU Jie, HAN Jian, ZHU Feichao, et al. Structures and properties of fully biodegradable PLA/PBAT/PHBV blends[J]. Acta Materiae Compositae Sinica,2016,33(8):1608-1614(in Chinese). [36] PENG Y, GARDNER D J, HAN Y, et al. Influence of drying method on the material properties of nanocellulose I: Thermostability and crystallinity[J]. Cellulose,2013,20(5):2379-2392. doi: 10.1007/s10570-013-0019-z [37] 雷婉青. 废纸基纳米微晶纤维素/聚氨酯弹性体复合材料的制备及其性能研究[D]. 西安: 西安理工大学, 2019: 58-64.LEI W Q. Preparation and properties of waste paper-based nanocrystalline cellulose/polyurethane elastomer composite materials[D]. Xi'an: Xi'an University of Technology, 2019: 58-64(in Chinese). -

下载:

下载: