Protective performance of PASGT combat helmet under pistol bullet impact

-

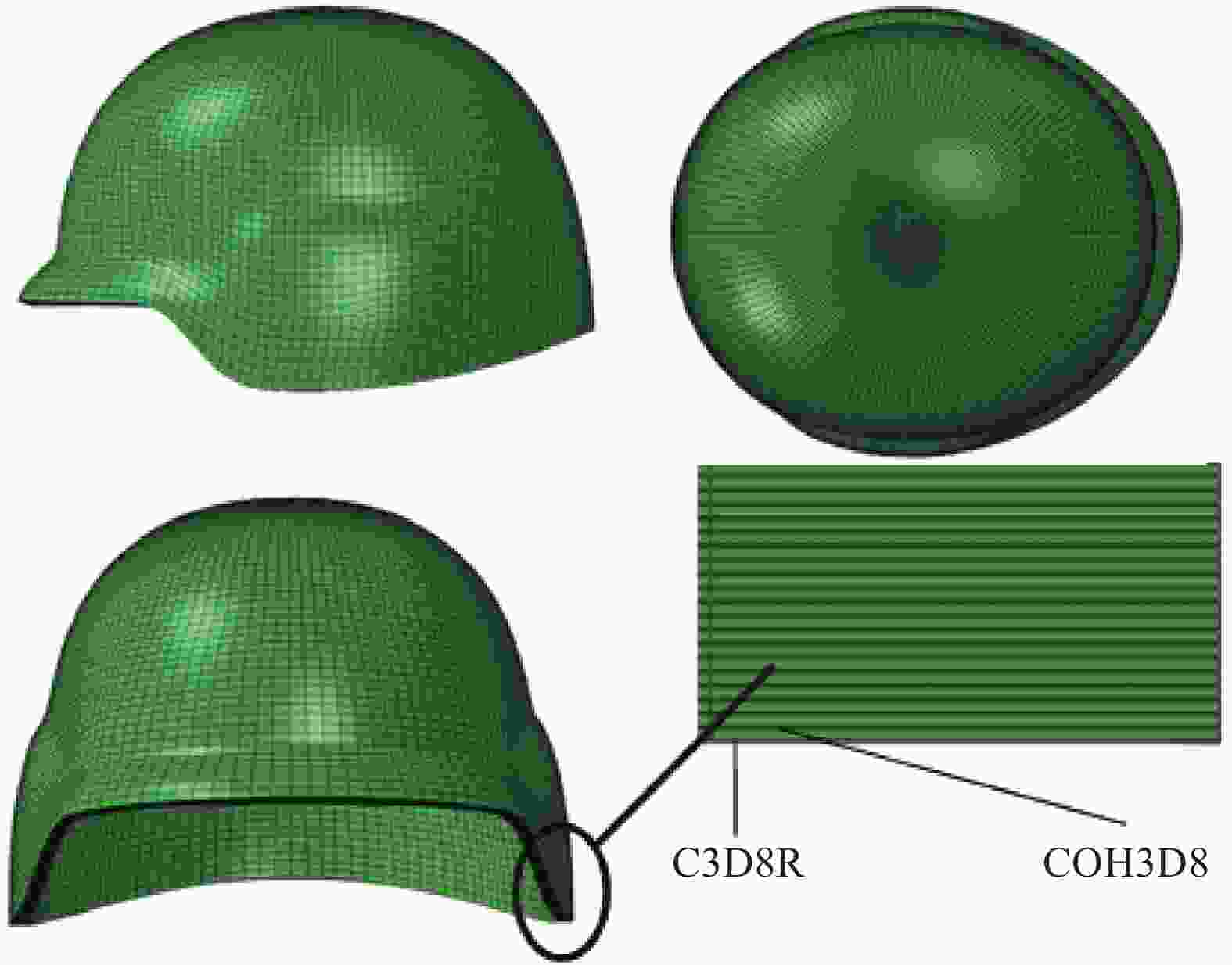

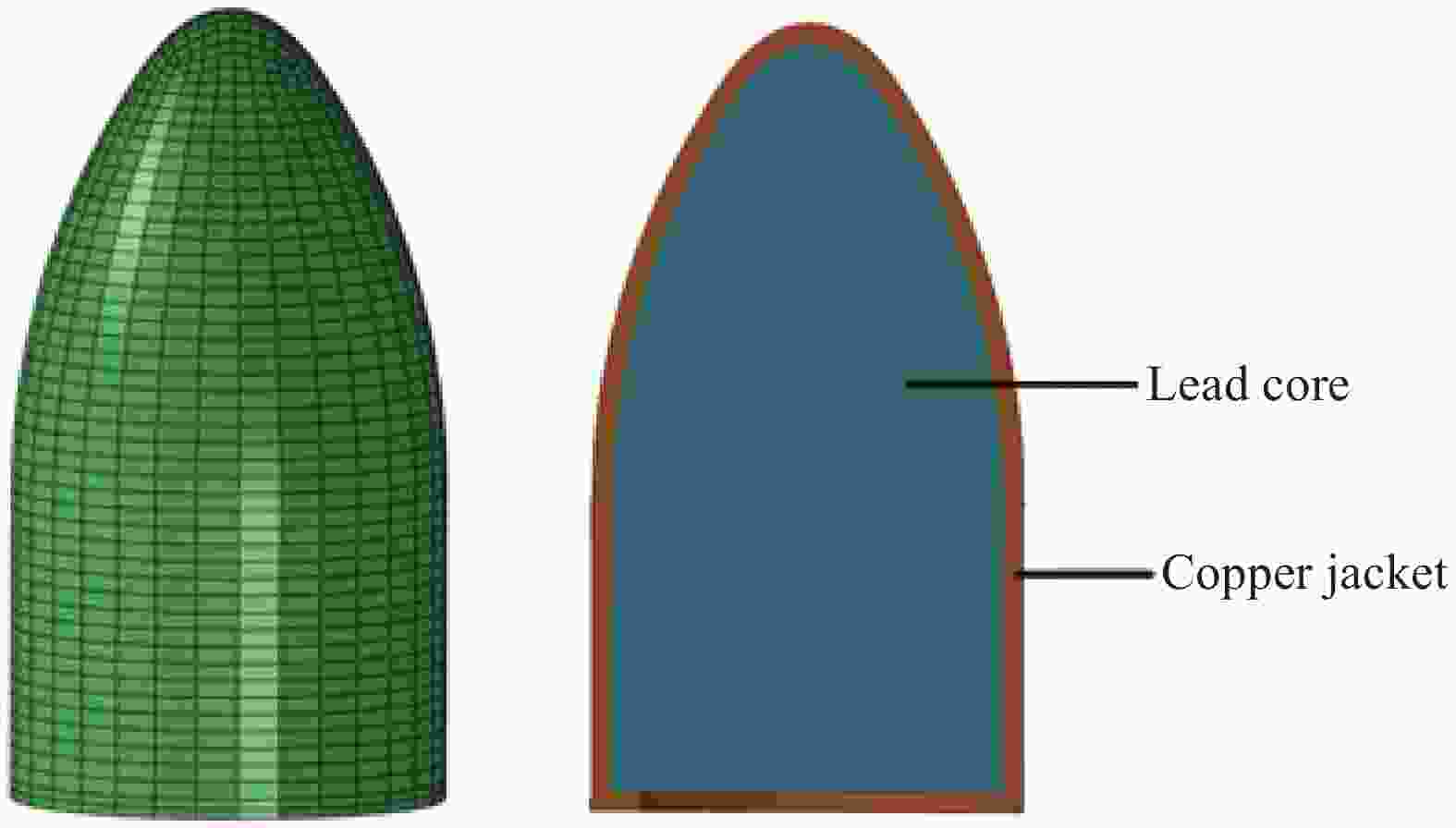

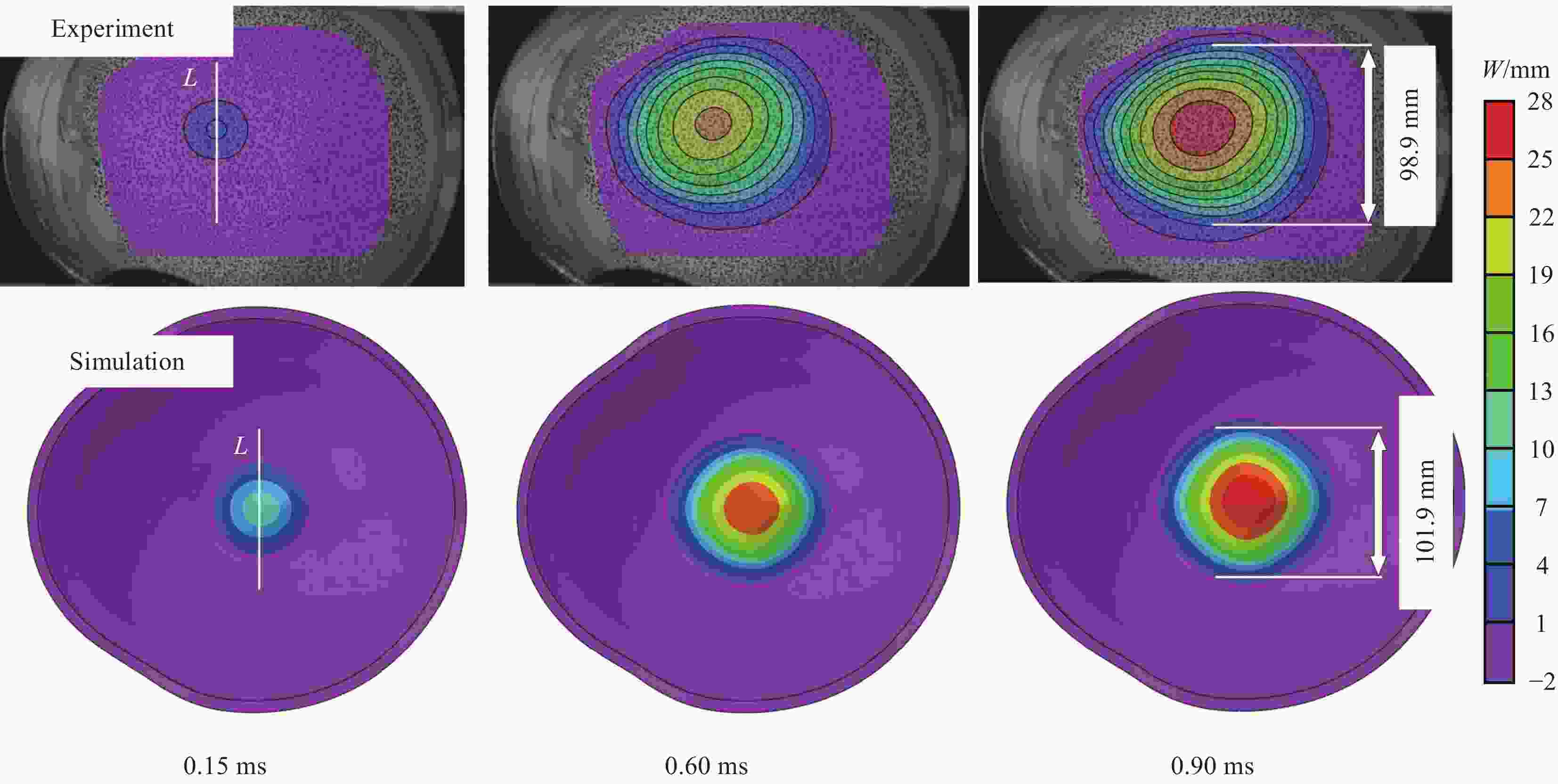

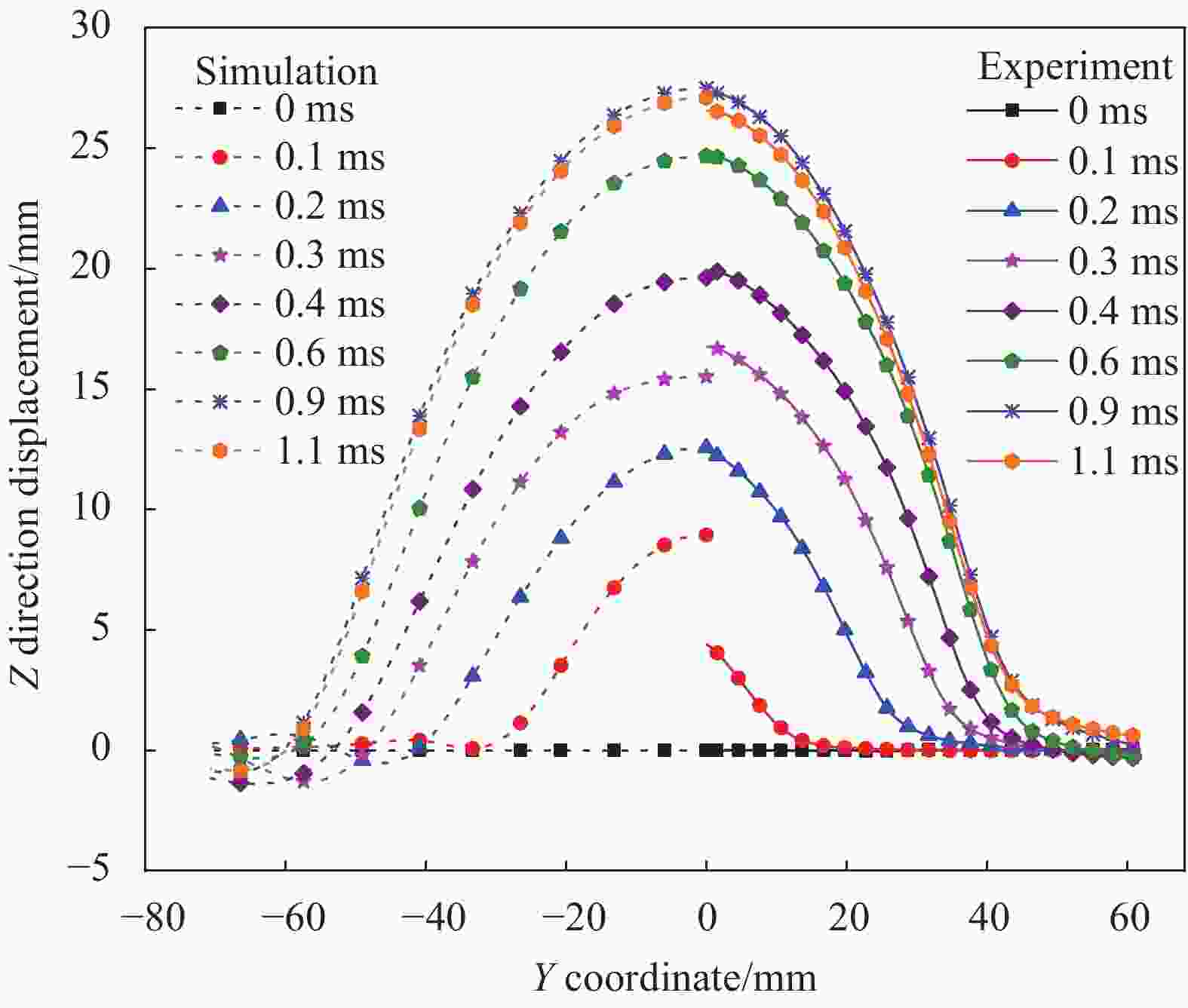

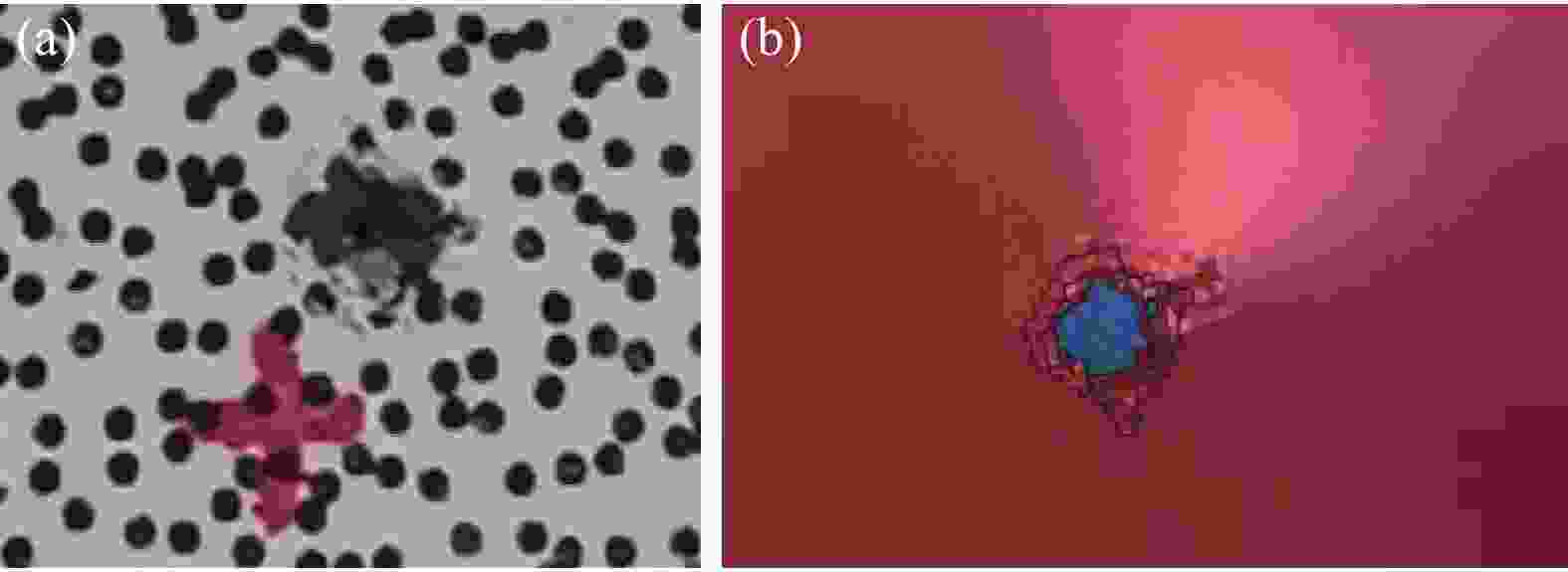

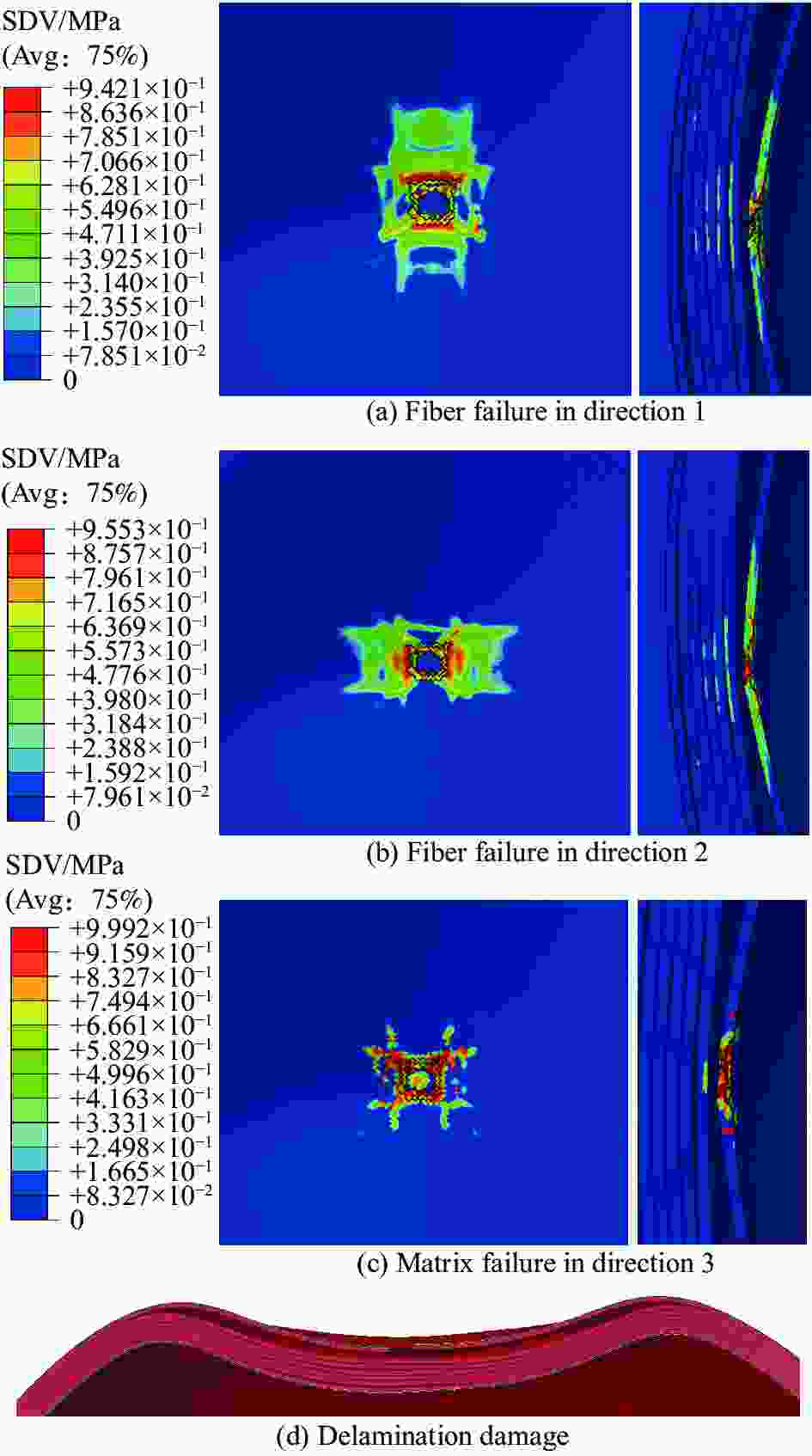

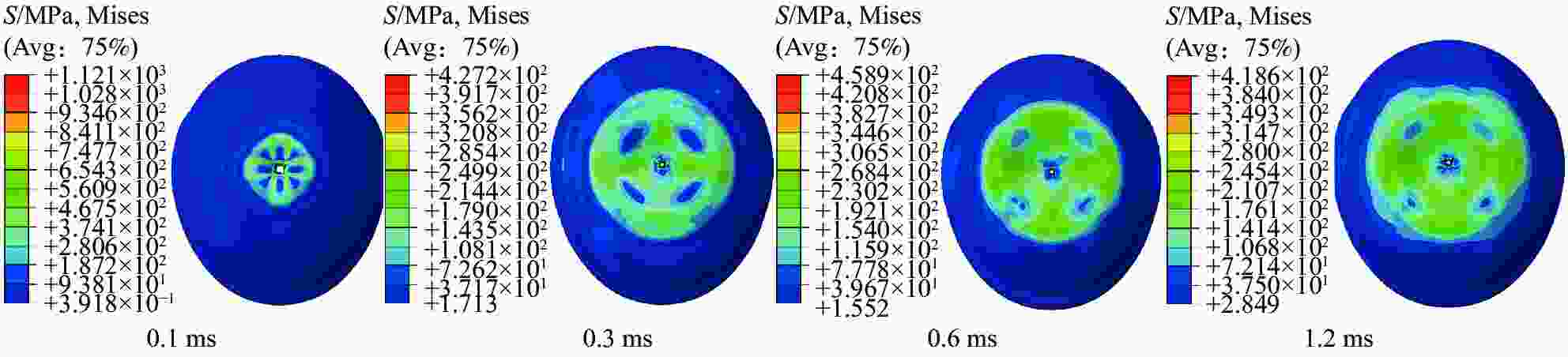

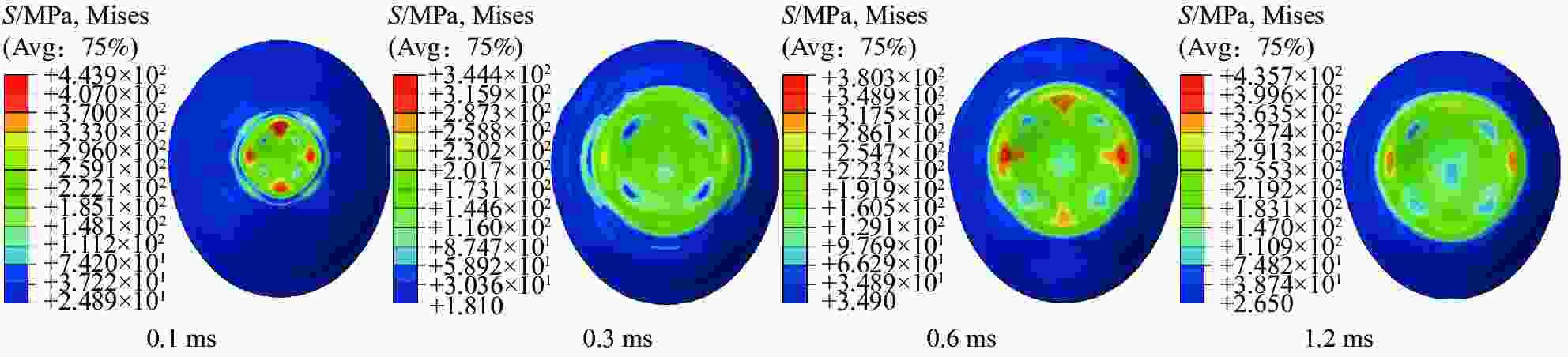

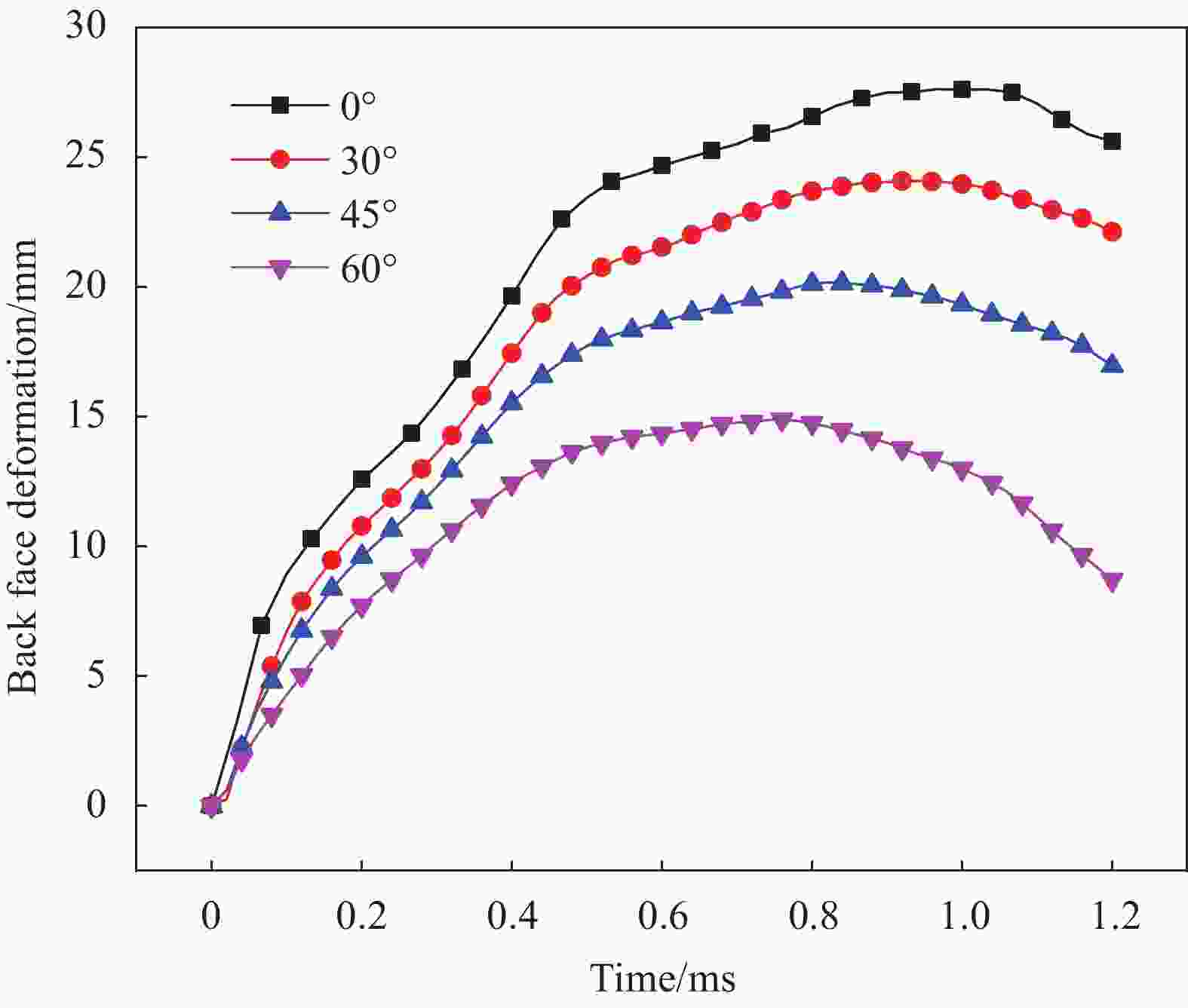

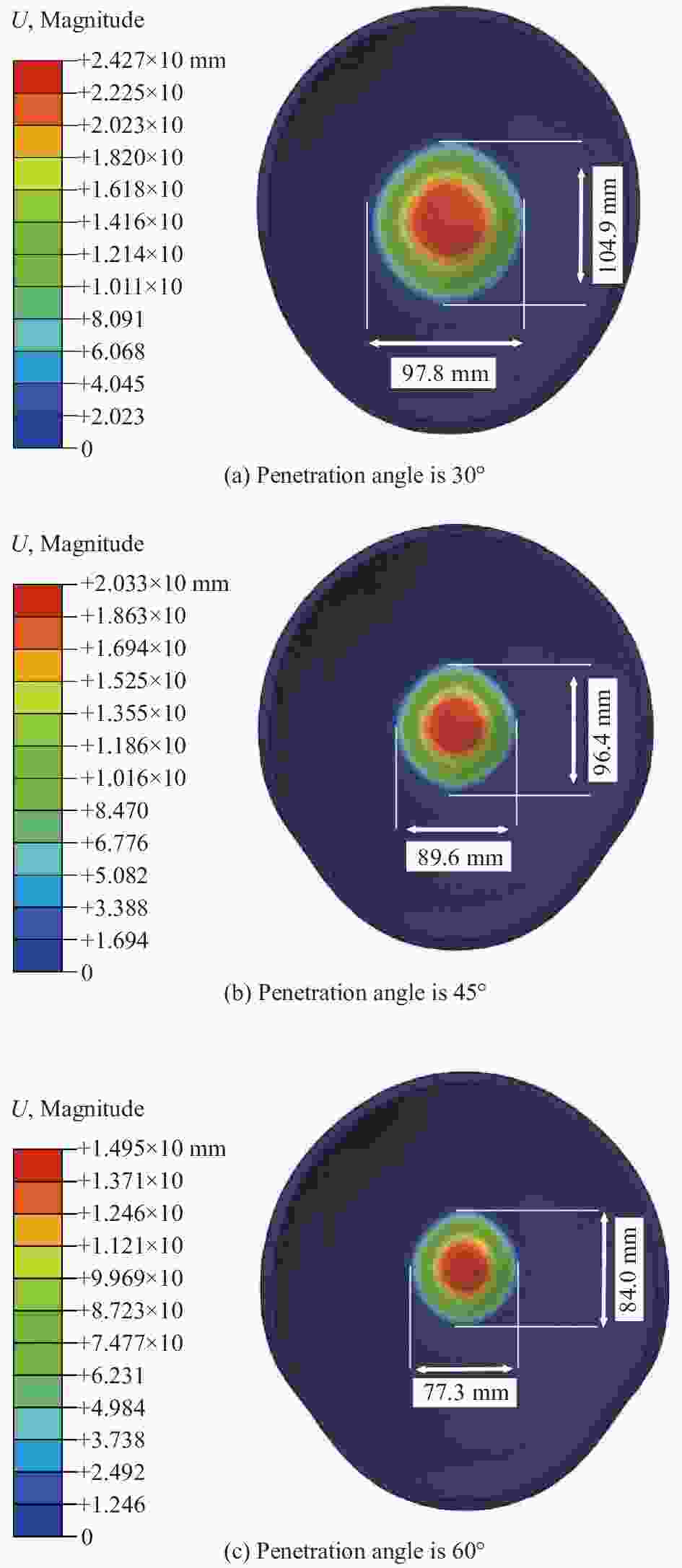

摘要: 新型防弹头盔虽然能有效减少手枪弹穿透性损伤,但头盔内表面变形(Back face deformation,BFD)仍有可能对人体头部造成损伤。为准确模拟防弹头盔受到子弹冲击时的瞬态力学响应,基于Abaqus的用户材料子程序VUMAT编写了适用于模拟复合材料防弹头盔力学性能的渐进损伤本构模型,建立了9 mm铅芯手枪弹以343 m/s侵彻PASGT芳纶防弹头盔的有限元模型,从头盔BFD曲线和内表面鼓包形态两方面验证了数值模拟的准确性。防弹头盔失效模式表明,头盔主要发生纤维拉伸、基体压缩和分层失效;子弹侵彻防弹头盔的过程中,头盔上的应力云图在初期呈现较为规则的菱形,然后再慢慢向四周扩散演化为圆形;子弹以三种不同入射角(30°、45°、60°)冲击头盔顶部时均出现了跳弹,反跳后的速度分别为72.9 m/s、165.5 m/s和240.1 m/s。最后采用钝性准则对头盔内表面变形可能造成的颅骨骨折概率进行了估算。Abstract: Although the new combat helmet can effectively reduce the pistol bullet penetrating damage, the back face deformation (BFD) of helmet may cause head injury. In order to accurately simulate the transient mechanical response of combat helmet under bullet impact, a progressive damage constitutive model for simulating the mechanical properties of composite combat helmet was developed based on the user material subroutine VUMAT of Abaqus. The finite element model of 9 mm lead core pistol bullet penetrating PASGT aramid combat helmet with impacting velocity 343 m/s was established. The accuracy of the numerical simulation was verified by the helmet BFD curve and the bulge shape of the inner surface. The failure mode of combat helmet shows that the helmet mainly occurs fiber tension, matrix compression and delamination failure. During the penetrating process, the stress contours on the helmet presents a regular diamond shape at the initial stage, and then slowly diffuses around and evolves into a circle. At three different angles of incidence (30°, 45°, 60°), the velocity of rebound is 72.9 m/s, 165.5 m/s and 240.1 m/s, respectively. Finally, the probability of skull fracture caused by the BFD of the helmet was estimated using the blunt criterion.

-

Key words:

- combat helmet /

- bullet /

- finite element model /

- penetration /

- back face deformation (BFD)

-

ρ/

(g·cm−3)E1/

GPaE2/

GPaE3/

GPa${v_{12}}$ ${v_{13}}$ ${v_{23}}$ G12/

MPaG13/

MPaG23/

MPaXt/

MPaXc/

MPaYt/

MPaYc/

MPaZt/

MPaZc/

MPaS12/

MPaS13/

MPaS23/

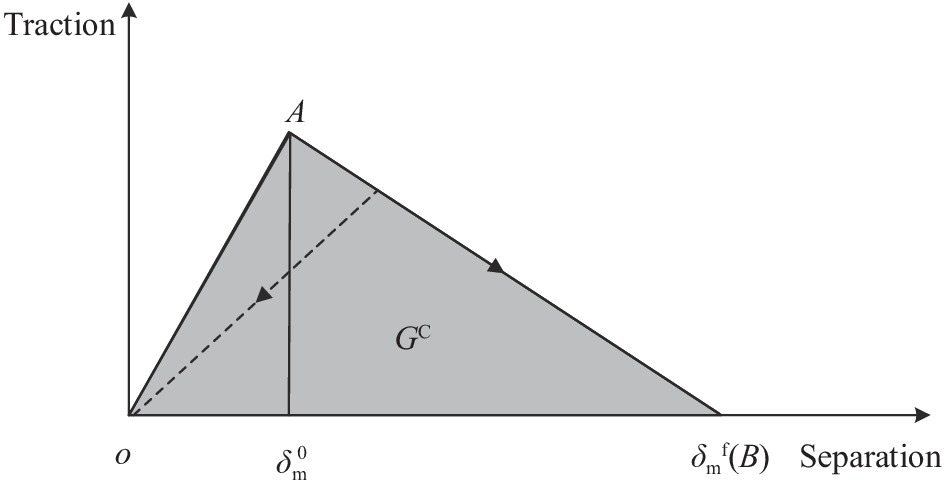

MPa1.23 22 22 9 0.25 0.33 0.33 770 2715 2715 800 80 800 80 1200 1200 77 898 898 Notes:ρ—Density; ${E_1}$, ${E_2}$, ${E_3}$—The elastic modulus in X, Y, and Z directions; ${v_{12}}$, ${v_{13}}$, ${v_{23}}$—Poisson's ratios; ${G_{12}}$, ${G_{23}}$, ${G_{13}}$—Shear modulus; Xc, Xt, Yc, Yt, Zc, Zt—Compressive and tensile strength in X, Y, Z directions; S12, S23, S13—Shear strength. ρ/(g·cm−3) ${K_{{\rm{nn}}}}$/MPa ${K_{{\rm{ss}}}}$/MPa ${K_{{\rm{tt}}}}$/MPa $t_{\rm{n}}^0$/MPa $t_{\rm{s}}^0$/MPa $t_{\rm{t}}^0$/MPa $G_{\rm{n}}^{\rm{C}}$/(J·mm−2) $G_{\rm{s}}^{\rm{C}}$/(J·mm−2) $G_{\rm{t}}^{\rm{C}}$/(J·mm−2) 2 4830 4830 4830 34.5 9 9 0.24 0.47 0.47 Notes: ρ—Density; ${K_{{\rm{nn}}}}$, ${K_{{\rm{ss}}}}$, ${K_{{\rm{tt}}}}$—Elastic modulus; $t_{\rm{n}}^0$, $t_{\rm{s}}^0$, $t_{\rm{t}}^0$—Normal and tangential strength; $G_{\rm{n}}^{\rm{C}}$, $G_{\rm{s}}^{\rm{C}}$, $G_{\rm{t}}^{\rm{C}}$—Critical energy release rates in mode I, mode II and mode III. ρ/(g·cm−3) G/GPa A/MPa B/MPa N C M Tm Tr D1 D2-D5 Lead core 11.34 7 14 18 0.685 0.035 1.68 600 294.0 1.0 0 Copper jacket 8.45 46 90 292 0.01 0.025 1.09 1356 300.15 0.8 0 Notes:G—Shear modulus; A—Initial yield stress; B—Hardening constant; N—Hardening exponent; C—Strain rate constant; M—Thermal softening exponent; Tm—Melting temperature; Tr—Room temperature; D1-D5—Damage constants. 表 4 PASGT防弹头盔钝击评估结果

Table 4. Blunt impact assessment results of PASGT helmet

Angle of

incidence/(°)VBC Probability of

fracture/%0 1.27 23.4 30 0.93 8.2 45 0.49 2.0 60 –0.93 0 Notes: VBC—Blunt criterion parameter used to predict injury risk. -

[1] 杨莹雪, 张秀芹, 杨丹, 等. 纤维增强复合材料防弹头盔壳体的研究进展[J]. 北京服装学院学报(自然科学版), 2019, 39(3):93-100.YANG Yingxue, ZHANG Xiuqing, YANG Dan, et al. Research progress of fiber reinforced composite bulletproof helmet shell[J]. Journal of Beijing Institute of Fashion Technology (Natural Sicence Edition),2019,39(3):93-100(in Chinese). [2] 高晓清, 黄献聪, 周宏, 等. 防弹头盔防非贯穿性损伤性能测试技术研究[J]. 警察技术, 2013(4):66-69. doi: 10.3969/j.issn.1009-9875.2013.04.019GAO Xiaoqing, HUANG Xiancong, ZHOU Hong, et al. Research on test technology of non penetrating damage resistance of bulletproof helmet[J]. Police Technology,2013(4):66-69(in Chinese). doi: 10.3969/j.issn.1009-9875.2013.04.019 [3] RODRÍGUEZ-MILLÁN M, ITO T, LOYA J A, et al. Development of numerical model for ballistic resistance evaluation of combat helmet and experimental validation[J]. Materials & Design,2016,110:391-403. [4] 王昕昇. 头盔钝击过程中能量耗散规律研究[D].南京: 南京理工大学, 2018.WANG Xinsheng. Study on energy dissipation law of helmet blunt impact[D]. Nanjing: Nanjing University of Science and Technology, 2018(in Chinese). [5] 黄艺峰. 手枪弹击中防弹头盔致颅脑损伤特点及机理的实验研究[D].重庆: 第三军医大学, 2012.HUANG Yifeng. Experimental study on characteristics and mechanism of craniocerebral injury caused by pistol bullet hitting bulletproof helmet[D]. Chongqing: Third Military Medical University, 2012(in Chinese). [6] 蔡志华, 包正, 王威, 等. 枪弹冲击防弹头盔致头部非贯穿性损伤的数值模拟研究[J]. 兵工学报, 2017, 38(6):1097-1105. doi: 10.3969/j.issn.1000-1093.2017.06.008CAI Zhihua, BAO Zheng, WANG Wei, et al. Study numerical simulation of non penetrating head damage caused by bullet impact on bullet helmet[J]. Acta Armamentarii,2017,38(6):1097-1105(in Chinese). doi: 10.3969/j.issn.1000-1093.2017.06.008 [7] 李泽民. 子弹冲击防弹头盔动力学响应及防护性能仿真研究[D].湘潭: 湖南科技大学, 2016.LI Zeming. Simulation study on dynamic response and protective performance of bullet impact bulletproof helmet[D]. Xiangtan: Hunan University of Science and Technology, 2016 (in Chinese). [8] 王威, 毛征宇, 李桂兵, 等. 枪弹冲击下新型防弹头盔质量对颈椎损伤影响[J]. 医用生物力学, 2019, 34(4):339-345.WANG Wei, MAO Zhengyu, LI Guibing, et al. Effect of new bullet proof helmet mass on cervical spine injury under bullet impact[J]. Journal of Medical Biomechanics,2019,34(4):339-345(in Chinese). [9] LI Y Q, LI X G, GAO X L. Modeling of advanced combat helmet under ballistic impact[J]. Journal of Applied Mechanics,2015,82(11):111004. [10] JAZI M S, REZAEI A, KARAMI G, et al. A computational study of influence of helmet padding materials on the human brain under ballistic impacts[J]. Computer Methods in Biomechanics and Biomedical Engineering,2014,17(12):1368-1382. [11] LEE H P, GONG S W. Finite element analysis for the evaluation of protective functions of helmets against ballistic impact[J]. Computer Methods in Biomechanics and Biomedical Engineering,2010,13(5):537-550. [12] THAM C Y, TAN V B C, LEE H P. Ballistic impact of a KEVLAR ® helmet: Experiment and simulations[J]. International Journal of Impact Engineering,2007,35(5):304-318. [13] CARLOS M G, IGNACIO R, JACOBO A M, et al. Evaluation of combat helmet behavior under blunt impact[J]. Applied Sciences,2020,10(23):8470. [14] CAI Z, HUANG X Y, XIA Y, et al. Study on behind helmet blunt trauma caused by high-speed bullet[J]. Applied Bionics and Biomechanics,2020(7):1-12. [15] CAÇOILO A, MOURÃO R, TEIXEIRA D F, et al. Modelling ballistic impact on military helmets: The relevance of projectile plasticity[J]. Defence Technology,2020,17(5):1699-1711. [16] LI X G, GAO X L, KLEIVEN S. Behind helmet blunt trauma induced by ballistic impact: A computational model[J]. International Journal of Impact Engineering,2016,91:56-67. [17] PALOMAR M, LOZANO-MÍNGUEZ E, RODRÍGUEZ-MILLÁ M, et al. Relevant factors in the design of composite ballistic helmets[J]. Composite Structures,2018,201:49-61. [18] TAN L B, TSE K M, LEE H P, et al. Performance of an advanced combat helmet with different interior cushioning systems in ballistic impact: Experiments and finite element simulations[J]. International Journal of Impact Engineering,2012,50:99-112. [19] RUBIO I, RODRÍGUEZ-MILLÁN M, MARCO M, et al. Ballistic performance of aramid composite combat helmet for protection against small projectiles[J]. Composite Structures,2019,226:111153. [20] 王涛. 基于多尺度方法的平纹机织复合材料低速冲击损伤研究[D]. 郑州: 郑州大学, 2020.WANG Tao. Research on low velocity impact damage of plane woven composites based on multi-scale method[D]. Zhengzhou: Zhengzhou University, 2020(in Chinese). [21] 罗小豪, 温垚珂, 闫文敏, 等. 基于ABAQUS二次开发的球形破片侵彻UHMWPE软质防弹衣数值模拟[J]. 复合材料学报, 2021, 38(10): 3373-3386.LUO Xiaohao, WEN Yaoke, YAN Wenmin, et al. Numerical simulation of spherical fragment penetrating UHMWPE soft body armor based on ABAQUS[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3373-3386(in Chinese). [22] 程之遥, 张健. 基于内聚力模型的层合板屈曲行为分析[J]. 西安理工大学学报, 2020, 36(04): 581-586.CHENG Zhiyao, ZHANG Jian. Buckling behavior analysis of laminated plates based on cohesive force model[J]. Journal of Xi’an University of Technology, 2020, 36(04): 581-586(in Chinese). [23] CAMANHO P P, DAVILA C G, DE MOURA M F. Numerical simulation of mixed-mode progressive delamination in composite materials[J]. Journal of Composite Materials, 2003, 37(16): 1415-1438. [24] JOHNSON G R, COOK W H. Constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[J]. Engineering Fracture Mechanics,1983,21:541−548. [25] 舒畅, 程礼, 许煜. Johnson-Cook本构模型参数估计研究[J]. 中国有色金属学报, 2020, 30(5):1073-1083.SHU Chang, CHENG Li, XU Yu. Parameter estimation of Johnson cook constitutive model[J]. The Chinese Journal of Nonferrous Metals,2020,30(5):1073-1083(in Chinese). [26] 孙非, 马力, 朱一辉, 等. 手枪弹对带UHMWPE软防护明胶靶标冲击效应的数值分析[J]. 振动与冲击, 2018, 37(13):20-26.SUN Fei, MA Li, ZHU Yihui, et al. Numerical analysis of impact effect of pistol projectile on gelatin target with UHMWPE soft protection[J]. Journal of Vibration and Shock,2018,37(13):20-26(in Chinese). [27] 崔广宇. 枪弹对带防弹头盔的人体模拟靶标钝击效应研究[D].南京: 南京理工大学, 2019.CUI Guangyu. Blunt impact effect of bullet on human simulated target with bulletproof helmet[D]. Nanjing: Nanjing University of Science and Technology, 2019(in Chinese). [28] LARRY M S, DAVID C V, HOWARD R C. Analysis of injury criteria to assess chest and abdominal injury risks in blunt and ballistic impacts[J]. Journal of Trauma,2004,56(3):651-663. doi: 10.1097/01.TA.0000074108.36517.D4 [29] HISLEY D M, GURGANUS C, DRYSDALE A W. Experimental methodology using digital image correlation to assess ballistic helmet blunt trauma[J]. Journal of Applied Mechanics,2011,78(5):051022. [30] RAYMOND D, EE C V, CRAWFORD G, et al. Tolerance of the skull to blunt ballistic temporo-parietal impact[J]. Biomech,2009,42(15):2479-2485. doi: 10.1016/j.jbiomech.2009.07.018 -

下载:

下载: