Preparation and properties of bacterial cellulose/phenolic resin composite transparent film

-

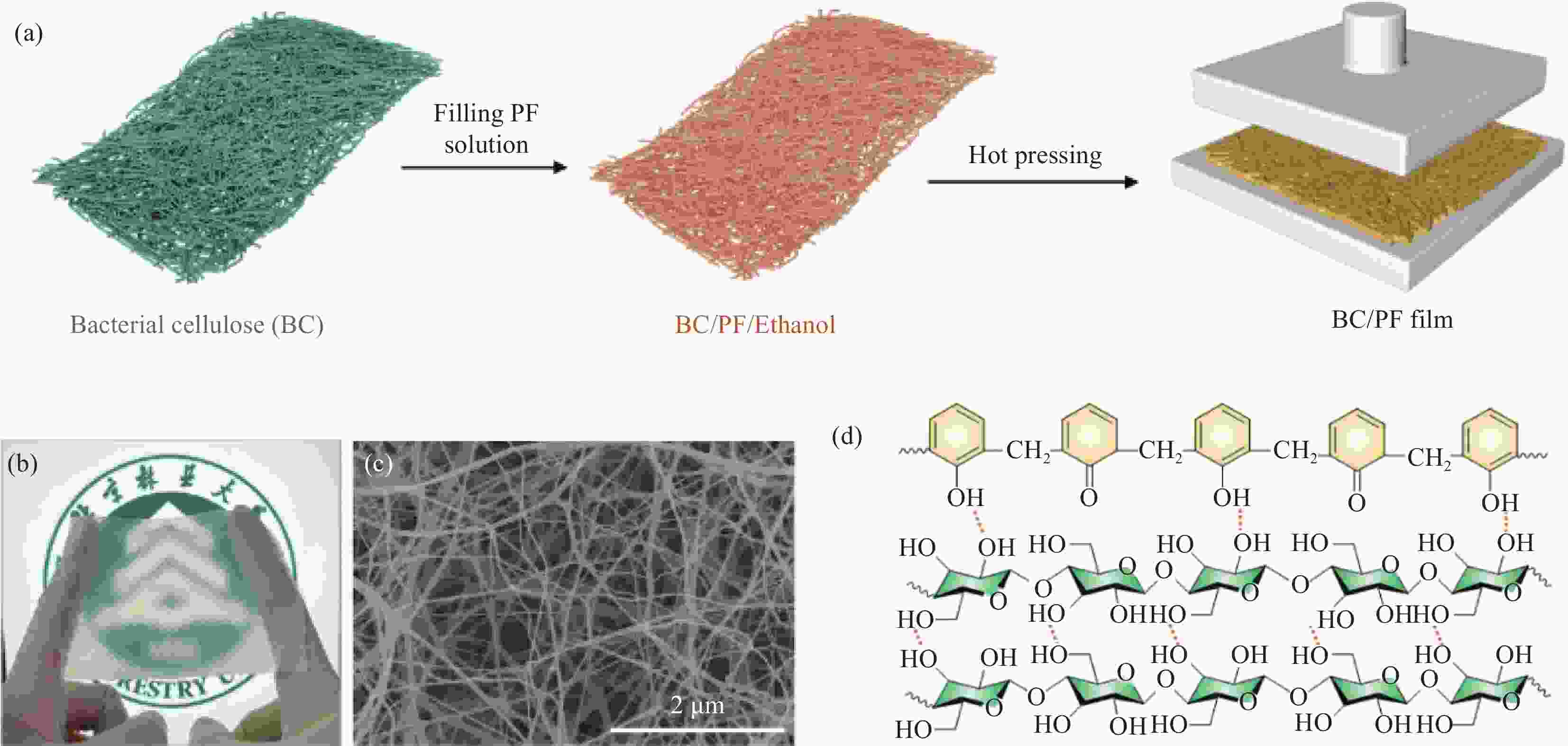

摘要: 近年来石油基高分子透明薄膜的大量使用导致塑料污染问题日益严重,基于绿色环保材料制备综合性能优异的复合透明薄膜具有重要现实意义。纤维素因其绿色、环保、可再生、可持续的优点成为制备柔性复合透明材料的理想原料。本文将细菌纤维素(BC)浸渍于酚醛树脂(PF)溶液中,通过热压成型技术制备得到BC/PF复合透明薄膜,探究了酚醛树脂浓度和热压温度对BC/PF复合透明薄膜微观结构、光学性能、热稳定性、力学性能和浸润性能的影响规律。结果表明,相比于BC薄膜,BC/PF复合薄膜具有更致密的结构和更光滑的表面,透射率可达88%,力学强度、热稳定性、防水性能得到显著提高,BC/PF复合薄膜的干强度和湿强度分别是BC薄膜的2.2倍和3.4倍。本研究对于缓解塑料透明薄膜的污染和探究绿色透明薄膜的快速制备具有科学指导意义。Abstract: In recent years, the plastics pollution is becoming more and more serious due to the overuse of fossil-derived transparent films. It is significant to prepare the composite transparent film with excellent comprehensive properties based on green environment-friendly materials. Cellulose is an ideal raw material for the preparation of flexible composite transparent materials because of its advantages of environmental friendliness, renewability and sustainability. In this study, bacterial cellulose (BC) was immersed in phenolic resin (PF) solution, and BC/PF composite transparent film was prepared by hot pressing technology. The effects of phenolic resin concentration and hot-pressing temperature on the microstructure, optical properties, thermal stability, mechanical properties and wettability of BC/PF composite transparent film were investigated. The results show that the BC/PF composite film has a more compact structure and smooth surface when compared with BC film, and its transmittance as high as 88%. The mechanical strength, thermal stability, and waterproof performance of the BC/PF composite film are also significantly improved. The dry strength and wet strength of BC/PF composite film are 2.2 times and 3.4 times higher than that of BC film. This study has scientific guiding significance for alleviating pollution of plastic transparent film and exploring the rapid preparation of green transparent film.

-

Key words:

- bacterial cellulose /

- phenolic resin /

- hot press /

- transparent film /

- transmittance

-

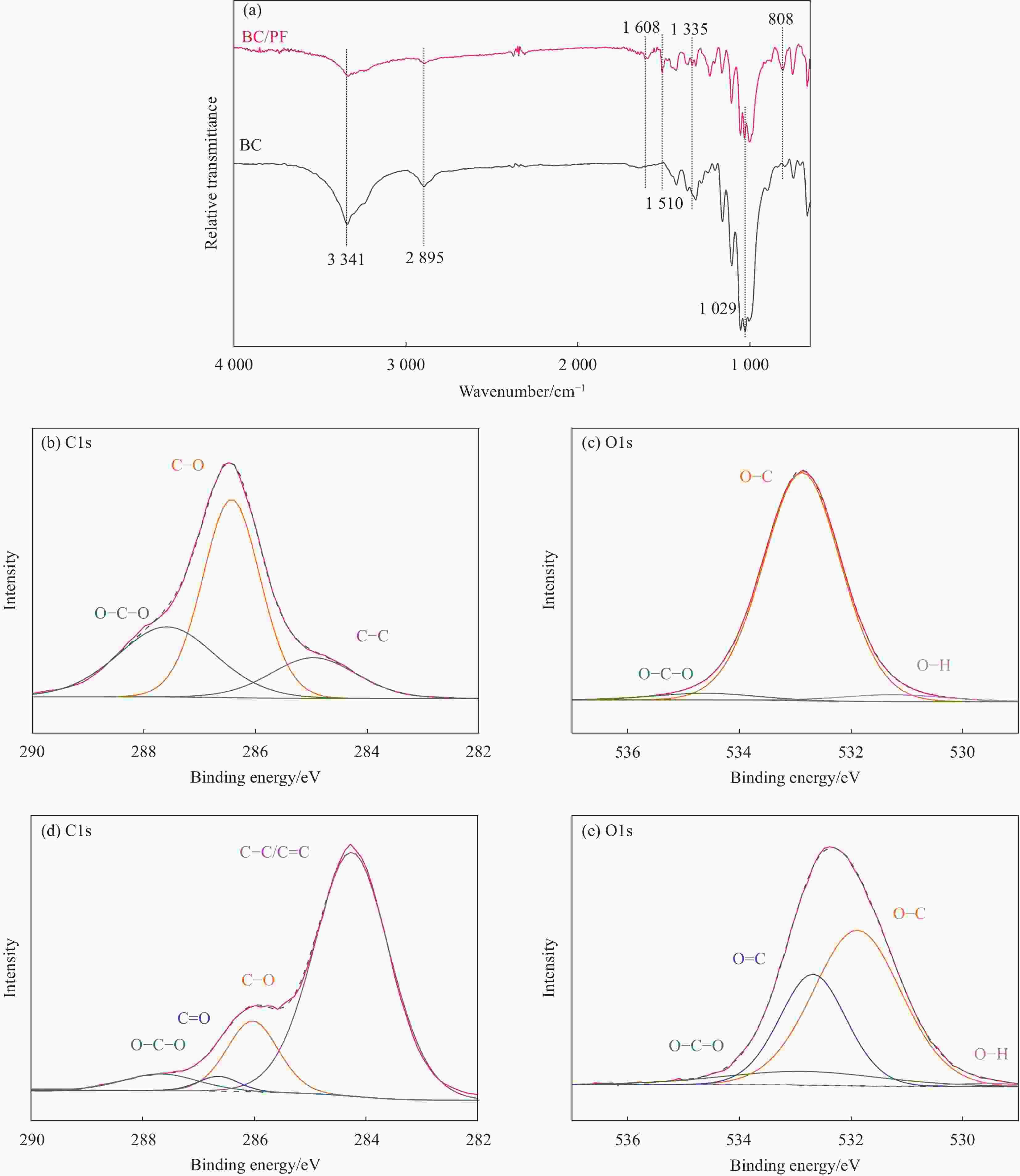

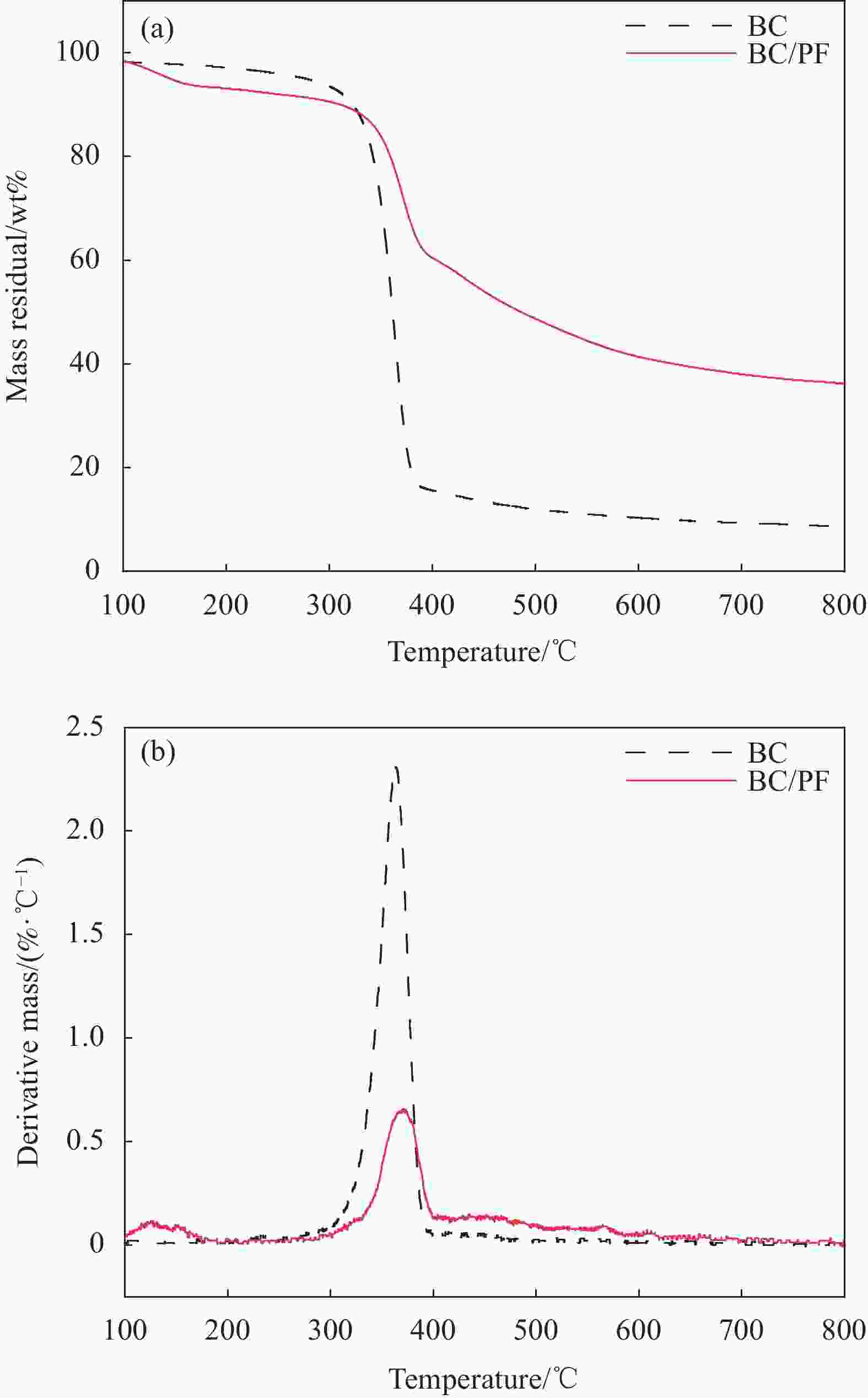

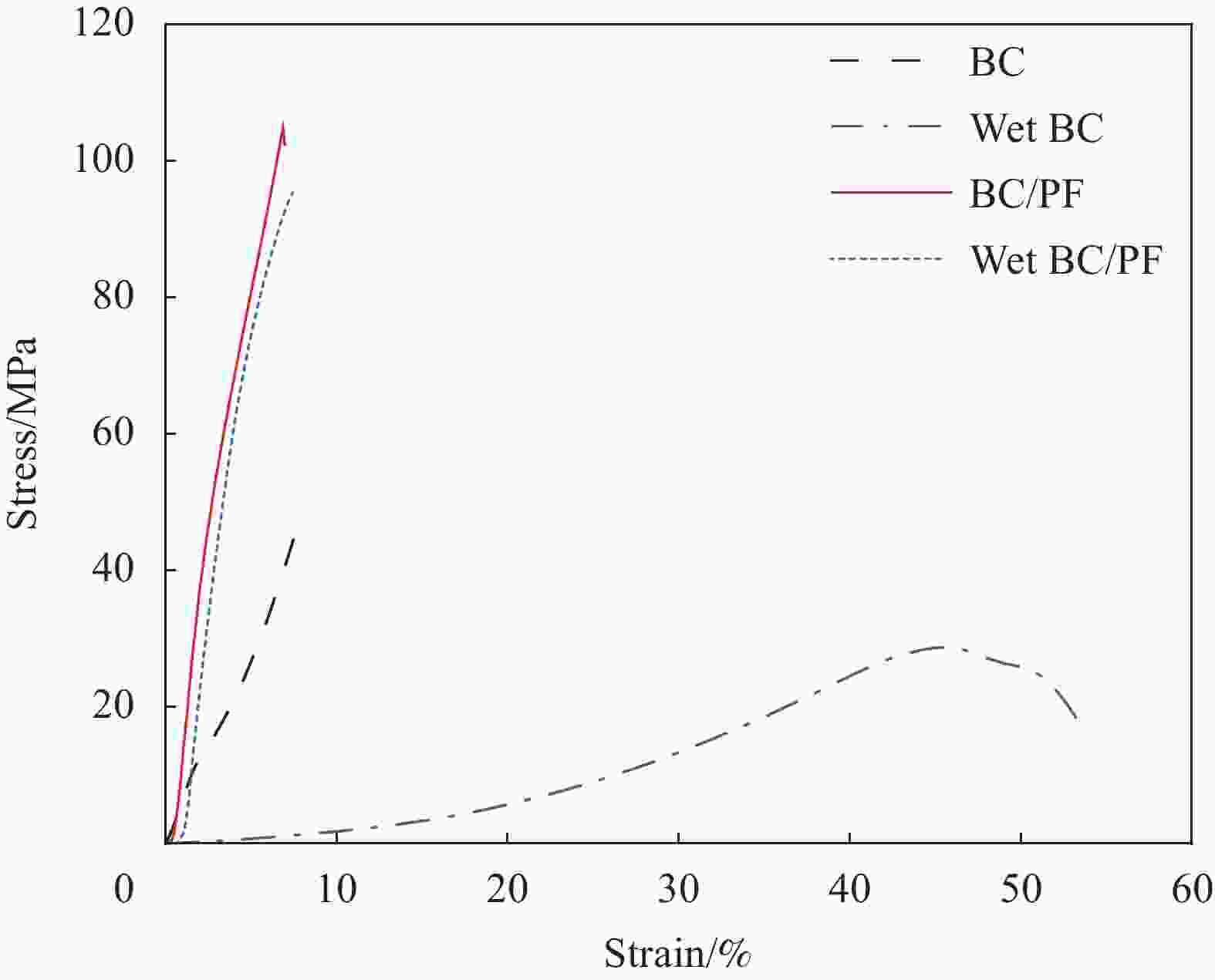

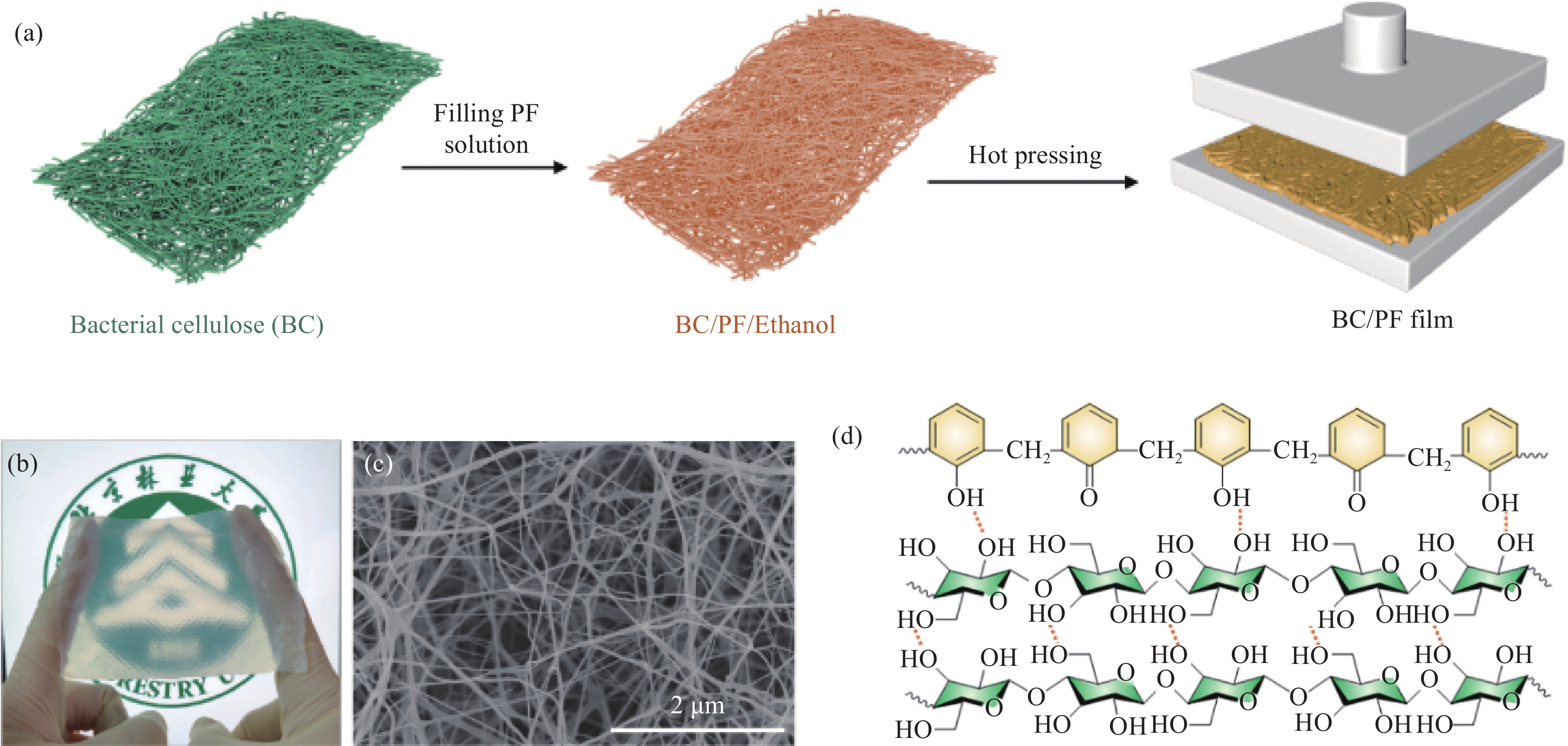

图 1 (a) 细菌纤维素/酚醛树脂(BC/PF)复合透明薄膜制备流程;(b) BC薄膜湿润状态下的光学照片;(c) BC的SEM图像;(d) 复合透明薄膜中纤维素与PF树脂的氢键相互作用示意图

Figure 1. (a) Preparation process of bacterial cellulose/phenolic resin (BC/PF) composite transparent film; (b) Optical photograph of BC film in wet state; (c) SEM image of BC; (d) Schematic diagram of hydrogen bond interaction between cellulose and PF in composite transparent film

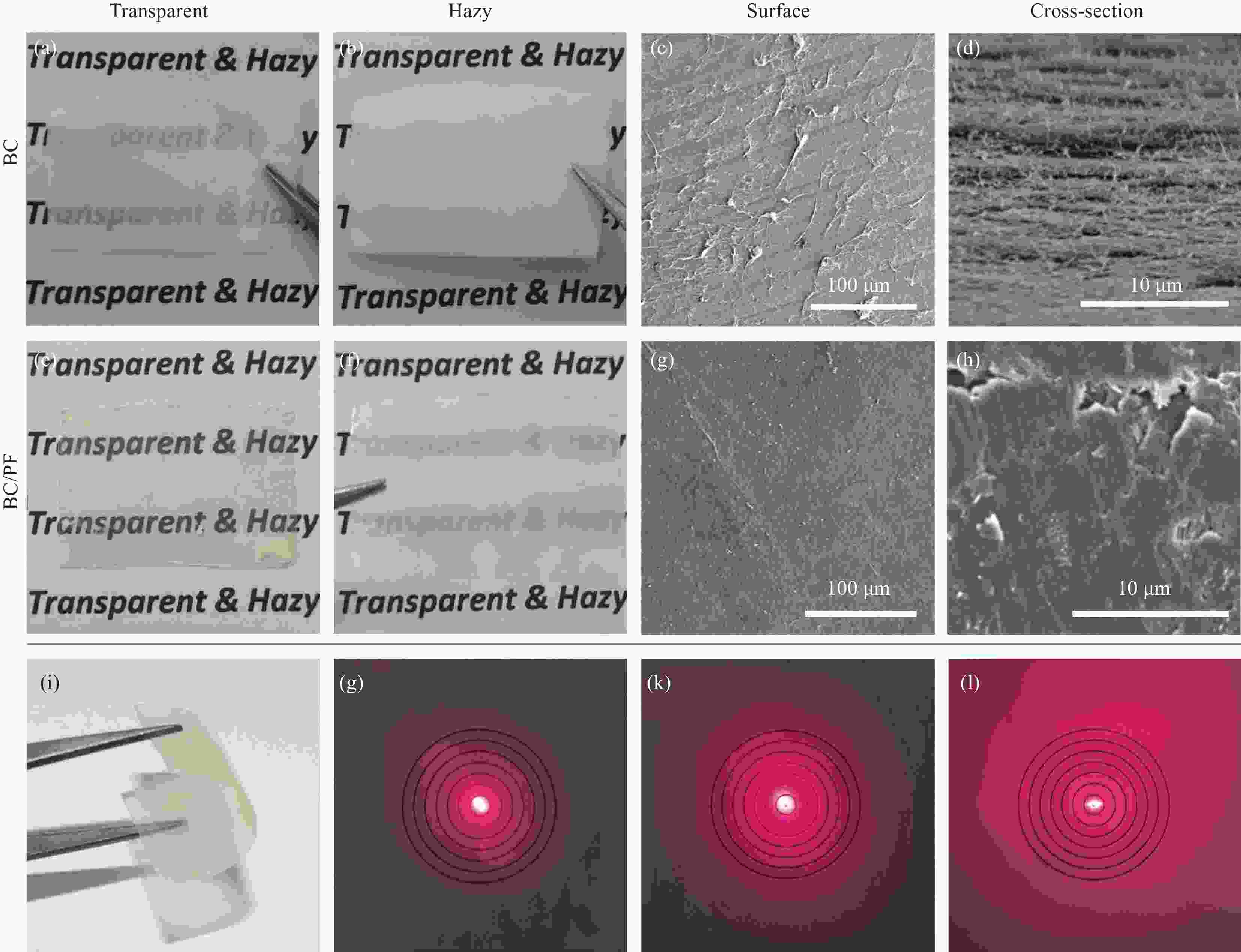

图 2 ((a)~(h)) 致密化BC薄膜与BC/PF复合透明薄膜的光学照片与SEM图像;(i) 复合透明薄膜弯曲状态下的光学照片;激光透过玻璃 (j)、BC/PF复合透明薄膜 (k) 和致密化BC薄膜 (l) 后的光学照片

Figure 2. ((a)-(h)) Optical photographs and SEM images of densified BC film and BC/PF composite transparent film; (i) Optical photograph of the composite transparent film in its bending state; Optical photographs of laser through glass (j), BC/PF composite transparent film (k) and densified BC film (l)

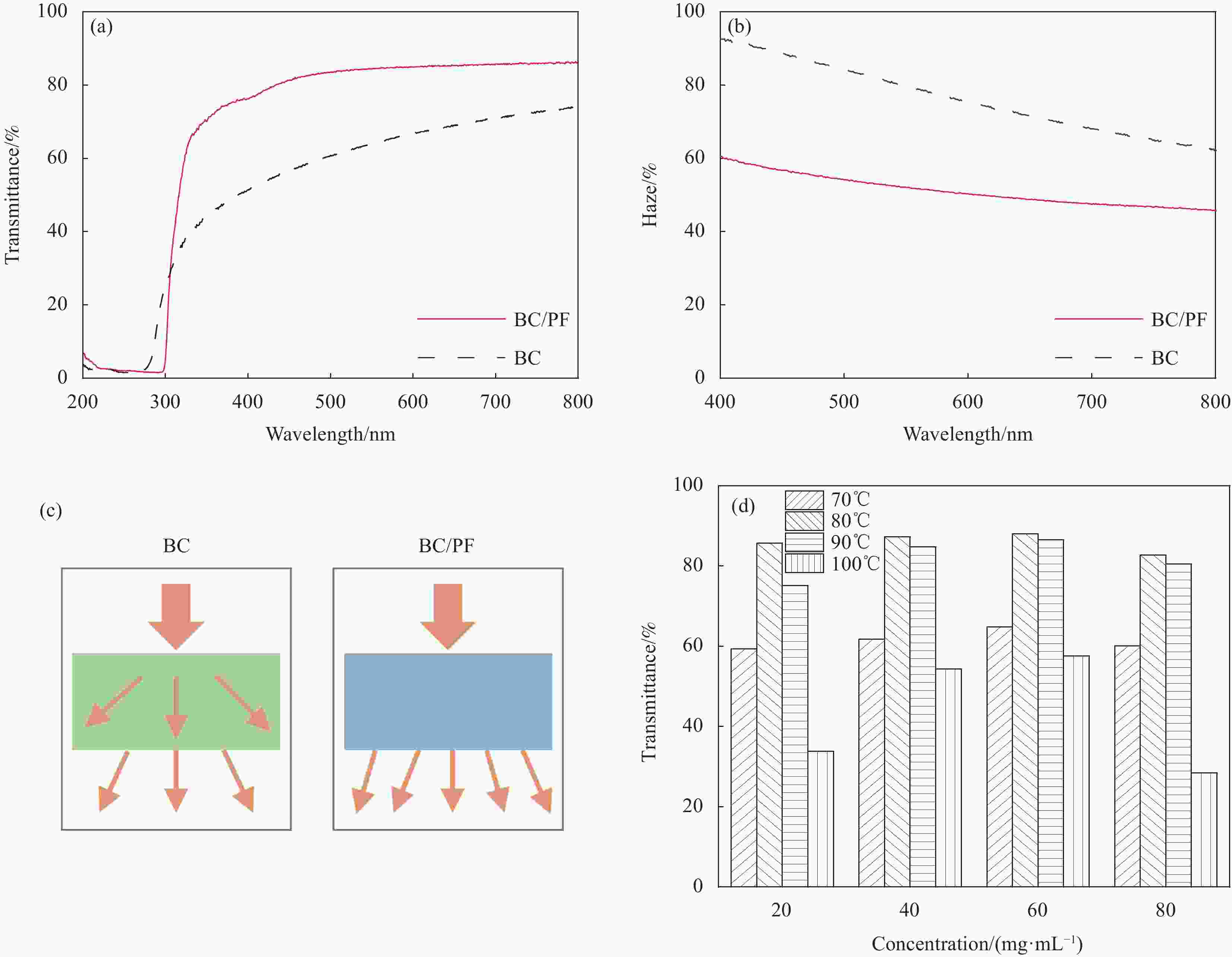

图 3 致密化BC薄膜与BC/PF复合透明薄膜的透射率曲线 (a)、雾度曲线 (b) 和光线分布示意图 (c);(d) PF树脂溶液浓度与热压温度对BC/PF复合透明薄膜透射率的影响

Figure 3. Transmission curves (a), haze curves (b) and light distribution diagram (c) of densified BC film and BC/PF composite transparent film; (d) Influence of PF solution concentration and hot-pressing temperature on the transmittance of BC/PF composite transparent film

表 1 同种类型透明材料透射率和拉伸应力的比较

Table 1. Comparison of the transmittance and tensile stress of the same type of transparent materials

-

[1] JEHANNO C, SARDON H. A step towards truly recyclable plastics[J]. Nature,2019,568(7753):467-468. doi: 10.1038/d41586-019-01209-3 [2] 黄菊洪. 纸张透明化和透明化剂[J]. 纸和造纸, 1993(1):8-9.HUANG Juhong. Paper transparency and transparency agent[J]. Paper and Paper Making,1993(1):8-9(in Chinese). [3] 邱格, 贺莹莹, 陈港. 基于纳米纤维素涂层的高阻隔透明纸的制备及性能研究[J]. 造纸科学与技术, 2022, 41(1):12-17, 23.QIU Ge, HE Yingying, CHEN Gang. Preparation and properties of high barrier transparent paper based on nanocellulose coating[J]. Paper Science and Technology,2022,41(1):12-17, 23(in Chinese). [4] 宁逗逗. 纳米纤维素薄膜的增强增韧及其机理研究[D]. 西安: 陕西科技大学, 2021.NING Doudou. Study on strengthening and toughening of nanocellulose film and its mechanism[D]. Xi'an: Shaanxi University of Science and Technology, 2021(in Chinese). [5] 霍丹, 张希鹏, 孙悦凯, 等. 纳米纤维素吸附材料的制备及在工业废水处理中的应用[J]. 中国造纸, 2021, 40(11):90-97. doi: 10.11980/j.issn.0254-508X.2021.11.011HUO Dan, ZHANG Xipeng, SUN Yuekai, et al. Preparation of nanocellulose adsorption material and its application in industrial wastewater treatment[J]. China Pulp and Paper,2021,40(11):90-97(in Chinese). doi: 10.11980/j.issn.0254-508X.2021.11.011 [6] 李元成, 王瑞. 纳米纤维素及其在纺织行业上的研究现状[J]. 黑龙江纺织, 2013, 132(2):4-6.LI Yuancheng, WANG Rui. Nanocellulose and its research status in textile industry[J]. Heilongjiang Textile,2013,132(2):4-6(in Chinese). [7] 于亚童, 王晓映, 王文波, 等. 氨基纳米纤维素的制备及其抗菌应用研究进展[J]. 中国造纸, 2021, 40(11):118-125. doi: 10.11980/j.issn.0254-508X.2021.11.014YU Yatong, WANG Xiaoying, WANG Wenbo, et al. Research progress on the preparation and antibacterial application of amino nanocellulose[J]. China Pulp and Paper,2021,40(11):118-125(in Chinese). doi: 10.11980/j.issn.0254-508X.2021.11.014 [8] 赵冬梅, 初小宇, 魏丽娜, 等. 纳米纤维素在食品包装材料中的应用研究进展[J]. 高分子通报, 2021, 271(11):11-20.ZHAO Dongmei, CHU Xiaoyu, WEI Lina, et al. Research progress on the application of nanocellulose in food packaging materials[J]. Polymer bulletin,2021,271(11):11-20(in Chinese). [9] KLOCHKO N P, BARBASH V A, KLEPIKOVA K S, et al. Biodegradable flexible transparent films with copper iodide and biomass-derived nanocellulose for ultraviolet and high-energy visible light protection[J]. Solar Energy,2021,220:852-863. doi: 10.1016/j.solener.2021.04.014 [10] NIU X, HUAN S, LI H, et al. Transparent films by ionic liquid welding of cellulose nanofibers and polylactide: Enhanced biodegradability in marine environments[J]. Journal of Hazardous Materials,2021,402:124073. doi: 10.1016/j.jhazmat.2020.124073 [11] WU C N, CHENG K C. Strong, thermal-stable, flexible, and transparent films by self-assembled TEMPO-oxidized bacterial cellulose nanofibers[J]. Cellulose,2017,24(1):269-283. doi: 10.1007/s10570-016-1114-8 [12] 陈港, 胡稳, 朱朋辉, 等. 高透明羧甲基纤维素/纤维素纤维复合薄膜的制备及其力学性能[J]. 复合材料学报, 2018, 35(6):1574-1581.CHEN Gang, HU Wen, ZHU Penghui, et al. Preparation and mechanical properties of high transparent carboxymethyl cellulose/cellulose fiber composite films[J]. Acta Materiae Composiae Sinica,2018,35(6):1574-1581(in Chinese). [13] HE X, MENG H, SONG H, et al. Novel bacterial cellulose membrane biosynthesized by a new and highly efficient producer Komagataeibacter rhaeticus TJPU03[J]. Carbohydrate Research, 2020, 493: 108030. [14] 谭玉静, 洪枫, 邵志宇. 细菌纤维素在生物医学材料中的应用[J]. 中国生物工程杂志, 2007, 181(4):126-131.TAN Yujing, HONG Feng, SHAO Zhiyu. Application of bacterial cellulose in biomedical materials[J]. China Biotechnology,2007,181(4):126-131(in Chinese). [15] YANG W S, JIAO L, MIN D Y, et al. Effects of preparation approaches on optical properties of self-assembled cellulose nanopapers[J]. RSC Advances,2017,7(17):10463-10468. doi: 10.1039/C6RA27529J [16] YANG W S, JIAO L, LIU W, et al. Morphology control for tunable optical properties of cellulose nanofibrils films[J]. Cellulose,2018,25(10):5909-5918. doi: 10.1007/s10570-018-1974-1 [17] SUN H D, LIU Y, GUO X F, et al. Strong, robust cellulose composite film for efficient light management in energy efficient building[J]. Chemical Engineering Journal,2021,425:131469. doi: 10.1016/j.cej.2021.131469 [18] ZHU H L, FANG Z Q, WANG Z, et al. Extreme light management in mesoporous wood cellulose paper for optoelectronics[J]. ACS Nano,2016,10(1):1369-1377. doi: 10.1021/acsnano.5b06781 [19] JIA C, LI T, CHEN C J, et al. Scalable, anisotropic transparent paper directly from wood for light management in solar cells[J]. Nano Energy,2017,36:366-373. doi: 10.1016/j.nanoen.2017.04.059 [20] 中国国家标准化管理委员会. 透明塑料透光率和雾度的测定: GB/T 2410—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of China. Determination of transmittance and haze of transparent plastics: GB/T 2410—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [21] KLEMM D, KRAMER F, MORITZ S, et al. Nanocelluloses: A new family of nature-based materials[J]. Angewandte Chemie International Edition,2011,50(24):5438-5466. doi: 10.1002/anie.201001273 [22] KLEMM D, CRANSTON E D, FISCHER D, et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today's state[J]. Materials Today,2018,21(7):720-748. doi: 10.1016/j.mattod.2018.02.001 [23] 王晓静, 李寅, 梁欢, 等. 基于原位红外光谱的热固性酚醛树脂固化过程研究[J]. 宇航材料工艺, 2018, 48(6):72-77.WANG Xiaojing, LI Yin, LIANG Huan, et al. The curing process of thermosetting phenolic resin based on in-situ infrared spectroscopy[J]. Aerospace Material and Technology,2018,48(6):72-77(in Chinese). [24] DI FILIPPO M F, DOLCI L S, LICCARDO L, et al. Cellulose derivatives-snail slime films: New disposable eco-friendly materials for food packaging[J]. Food Hydrocolloids,2021,111:106247. doi: 10.1016/j.foodhyd.2020.106247 [25] WEI X, HUANG T, YANG J H, et al. Green synthesis of hybrid graphene oxide/microcrystalline cellulose aerogels and their use as superabsorbents[J]. Journal of Hazardous Materials,2017,335:28-38. doi: 10.1016/j.jhazmat.2017.04.030 [26] ZHOU G, YIN L C, WANG D W, et al. Fibrous hybrid of graphene and sulfur nanocrystals for high-performance lithium-sulfur batteries[J]. ACS Nano,2013,7(6):5367-5375. doi: 10.1021/nn401228t [27] SMITH M, SCUDIERO L, ESPINAL J, et al. Improving the deconvolution and interpretation of XPS spectra from chars by ab initio calculations[J]. Carbon,2016,110:155-171. doi: 10.1016/j.carbon.2016.09.012 [28] KIM H, OKUBO K, FUJII T, et al. Influence of fiber extraction and surface modification on mechanical properties of green composites with bamboo fiber[J]. Journal of Adhesion Science and Technology,2013,27(12):1348-1358. doi: 10.1080/01694243.2012.697363 [29] WANG B X, LI D G. Strong and optically transparent biocomposites reinforced with cellulose nanofibers isolated from peanut shell[J]. Composites Part A-Applied Science and Manufacturing,2015,79:1-7. doi: 10.1016/j.compositesa.2015.08.029 [30] PARK S Y, YOOK S, GOO S, et al. Preparation of transparent and thick CNF/epoxy composites by controlling the properties of cellulose nanofibrils[J]. Nanomaterials, 2020, 10(4): 625. [31] ZHANG Z, WANG H Y, LI S Y, et al. Transparent and flexible cellulose nanoflbers/silver nanowires/acrylic resin composite electrode[J]. Composites Part A-Applied Science and Manufacturing,2015,76:309-315. doi: 10.1016/j.compositesa.2015.06.010 [32] LIAO H Q, WU Y Q, WU M Y, et al. Aligned electrospun cellulose fibers reinforced epoxy resin composite films with high visible light transmittance[J]. Cellulose,2012,19(1):111-119. doi: 10.1007/s10570-011-9604-1 [33] 邓巧云, 李大纲, 邵旭, 等. 光学透明、低热膨胀性的甲壳素纳米纤维/聚醚砜复合薄膜[J]. 科技导报, 2014, 32(Z1):45-50.DENG Qiaoyun, LI Dagang, SHAO Xu, et al. Chitin nanofiber/polyethersulfone composite films with optical transparency and low thermal expansion[J]. Science & Technology Review,2014,32(Z1):45-50(in Chinese). -

下载:

下载: