A simulation method of forming wrinkle defects in thermoplastic woven fabric prepregs in a wide temperature range based on non-orthogonal constitutive model

-

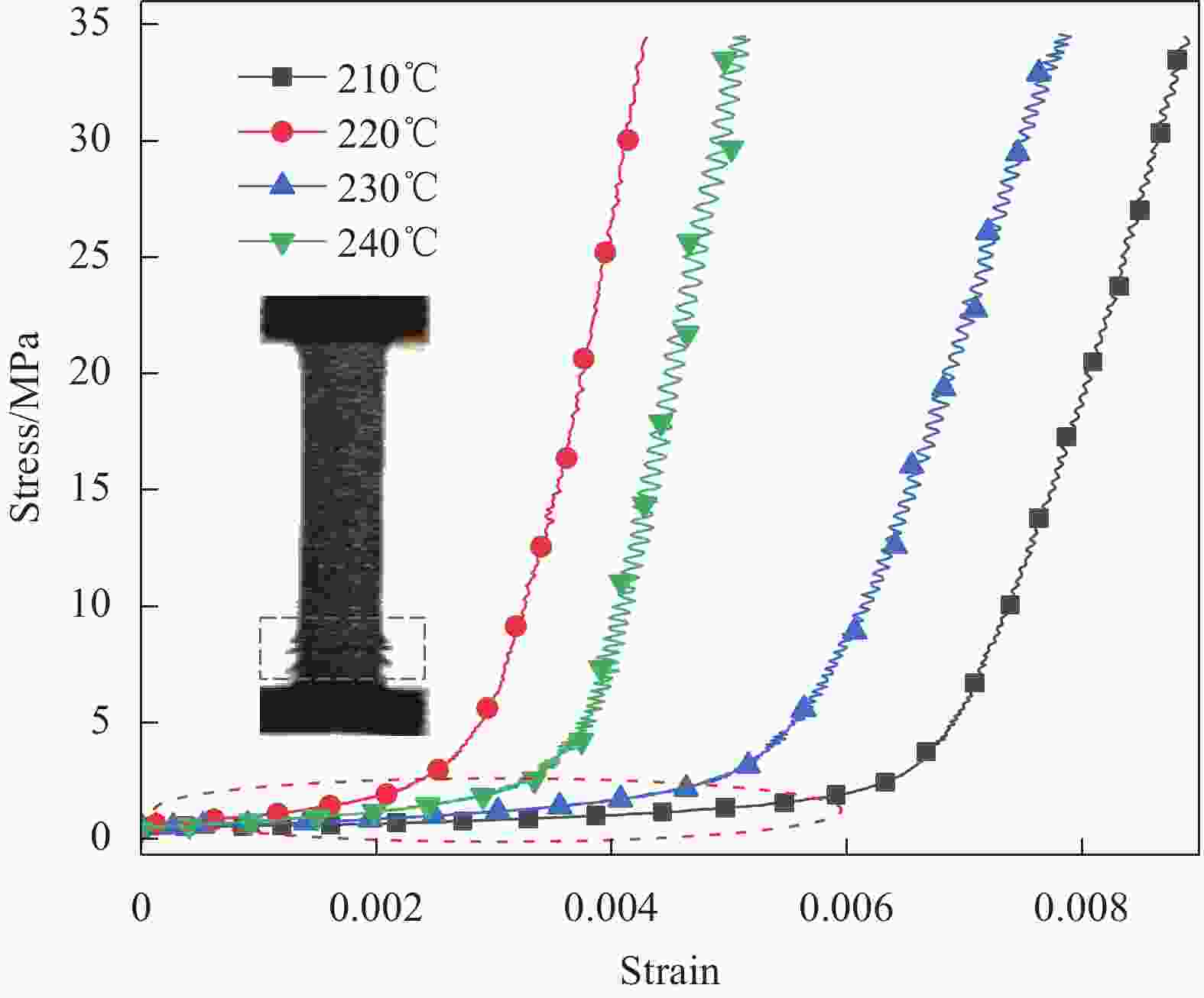

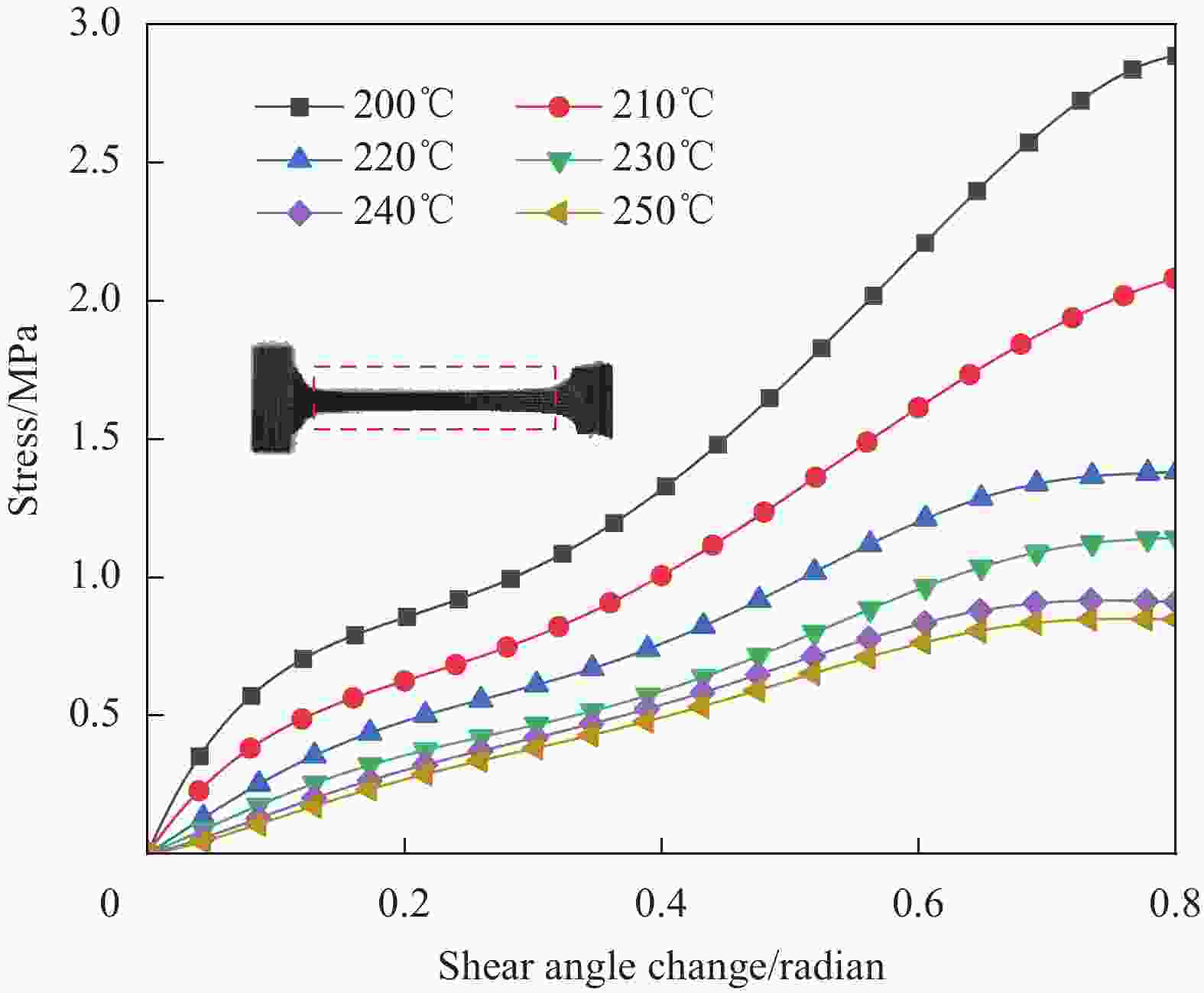

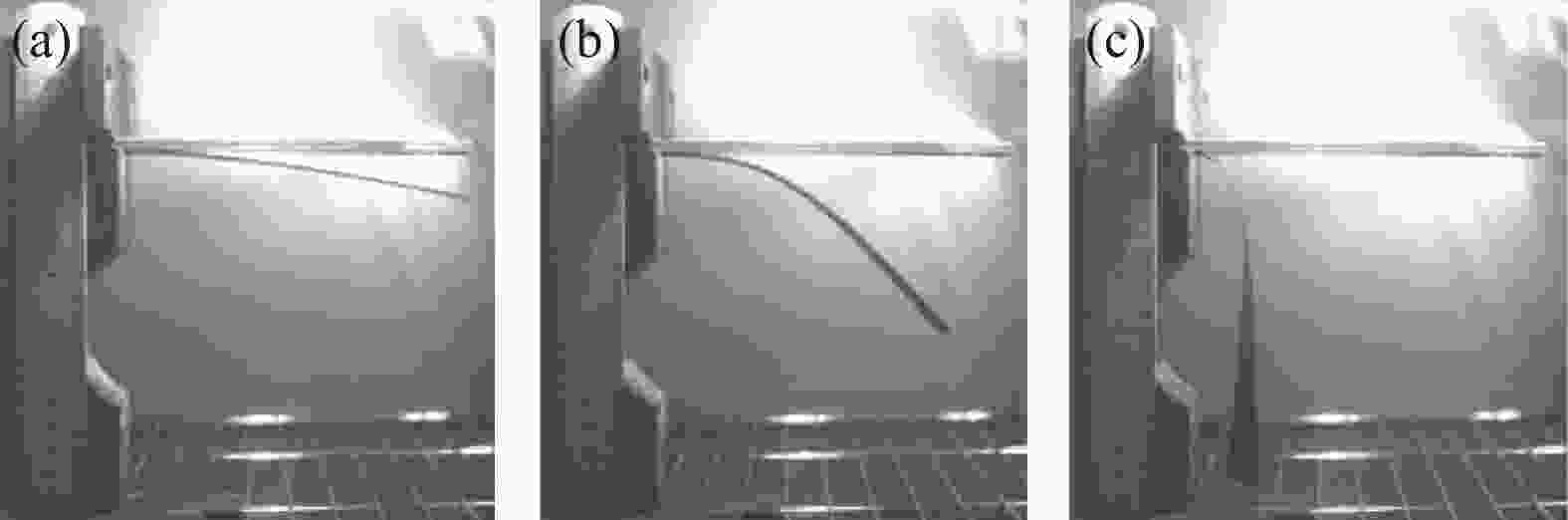

摘要: 热塑性复合材料预制体的赋形质量直接影响结构件的制造质量。由于热塑性基体具有较高的熔融温度和黏度,赋形工艺温度设计不合理会导致褶皱等赋形缺陷,给热塑性复合材料结构高质量成型带来了挑战。现有的热塑性预浸料热成型研究主要基于连续介质力学、离散元、半离散元法,通过建立多机制耦合的本构模型分析热塑性预浸料的各向异性大变形行为,未充分考虑工艺调控对赋形宏观变形过程中褶皱缺陷的影响。发展了一种热塑性预浸料宽温域赋形褶皱缺陷仿真方法。通过表征热塑性机织物预浸料在不同温度、载荷下的力学性能,获取宽温域热塑性预浸料本构参数,基于非正交本构模型,提出了温度对热塑性预浸料赋形褶皱缺陷的作用规律,揭示了赋形过程中宽温域褶皱缺陷的变形机制,获得了赋形温度优化调控方案。研究结果表明:褶皱缺陷的萌生和演化过程由不同温度下的面内剪切和压缩变形行为共同影响,预浸料的褶皱缺陷变形程度随温度的增加而减弱,非正交本构模型的模拟结果与实验结果基本一致。Abstract: The forming quality of thermoplastic composite preforms directly affects the manufacturing quality of structure. Due to the high melting temperature and viscosity of thermoplastic matrix, unreasonable design of forming process temperature will lead to forming defects such as wrinkles, which brings challenges to high-quality forming of thermoplastic composite structures. Currently, the existing researches on thermoforming of thermoplastic prepregs are mainly based on the continuous, the discrete and the semi-discrete approaches, the anisotropic large deformation behavior of thermoplastic prepreg is analyzed by establishing a multi-mechanism coupled constitutive model, which is not fully considered the influence of process control on wrinkle defects during forming macroscopic deformation. In this paper, a simulation method of forming wrinkle defects in thermoplastic prepregs in a wide temperature range was developed. By characterizing the mechanical properties of thermoplastic woven fabric prepregs at different temperatures and loads, the non-orthogonal constitutive model parameters of thermoplastic prepregs in a wide temperature range were obtained. The effect of temperature on forming wrinkle defects in thermoplastic prepregs was proposed, and the deformation mechanism of wrinkle defects in a wide temperature range in the forming process was revealed, and the optimal control scheme of forming temperature was obtained. The research results show that the initiation and evolution of wrinkle defects has been affected by the in-plane shear and compressive deformation behaviors at different temperatures, the deformation degree of wrinkle defects of prepreg has been decreased with the increase of temperature. The simulation results of the non-orthogonal constitutive model are basically closer to the experimental results.

-

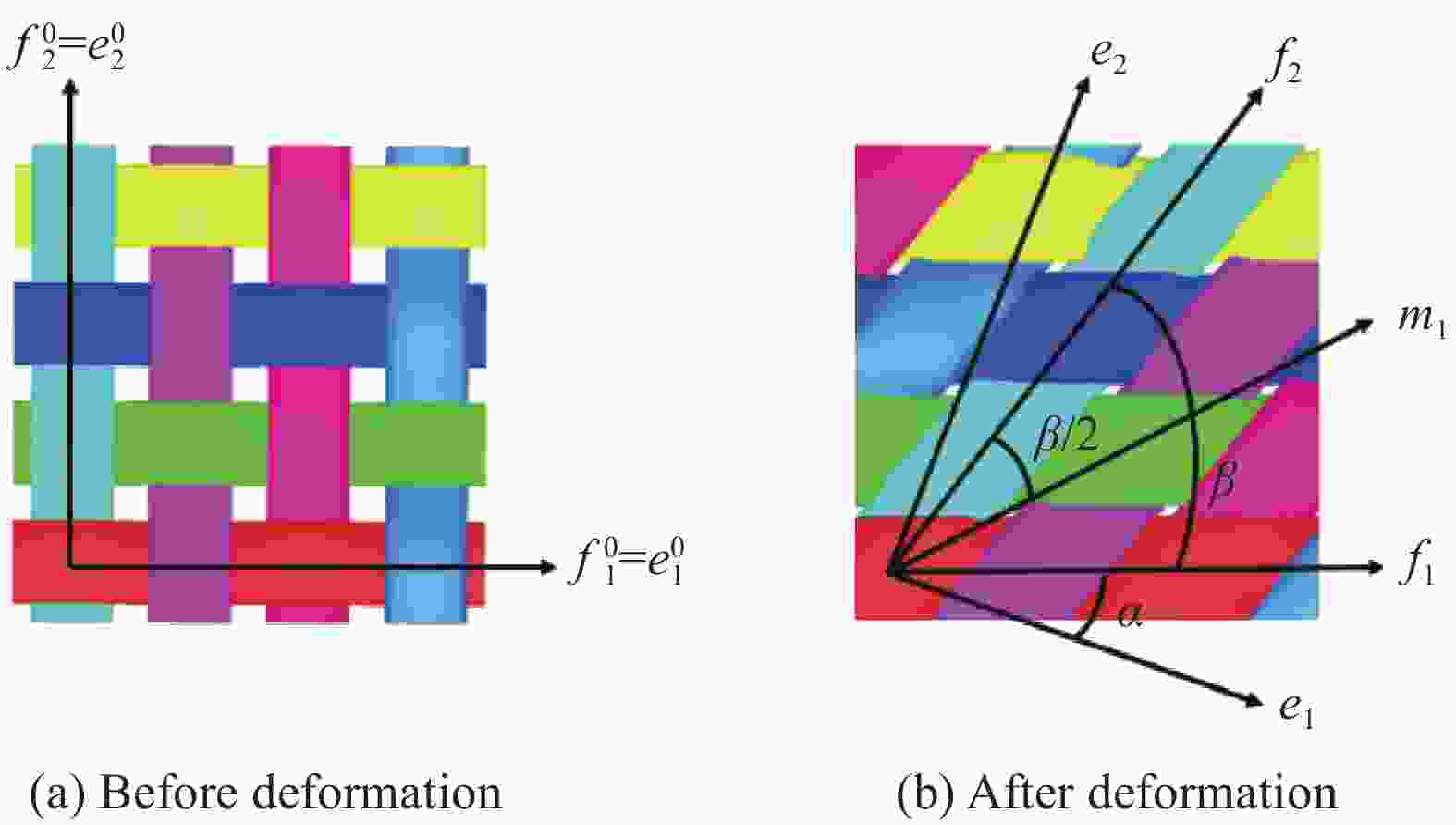

图 8 非正交本构模型不同坐标系定义

Figure 8. Definition of different coordinate systems for non-orthogonal models

$f_1^0$, $f_2^0$—Prepreg initial yarn orientation; $e_1^0$, $e_2^0$—Initial local corotation coordinate system orientation; e1, e2—Direction of the local co-rotating coordinate system after deformation; f1, f2—Prepreg yarn orientation after deformation; α—Angle between f1 and e1; β—Shear angle; m1—Bisector of e1 and e2

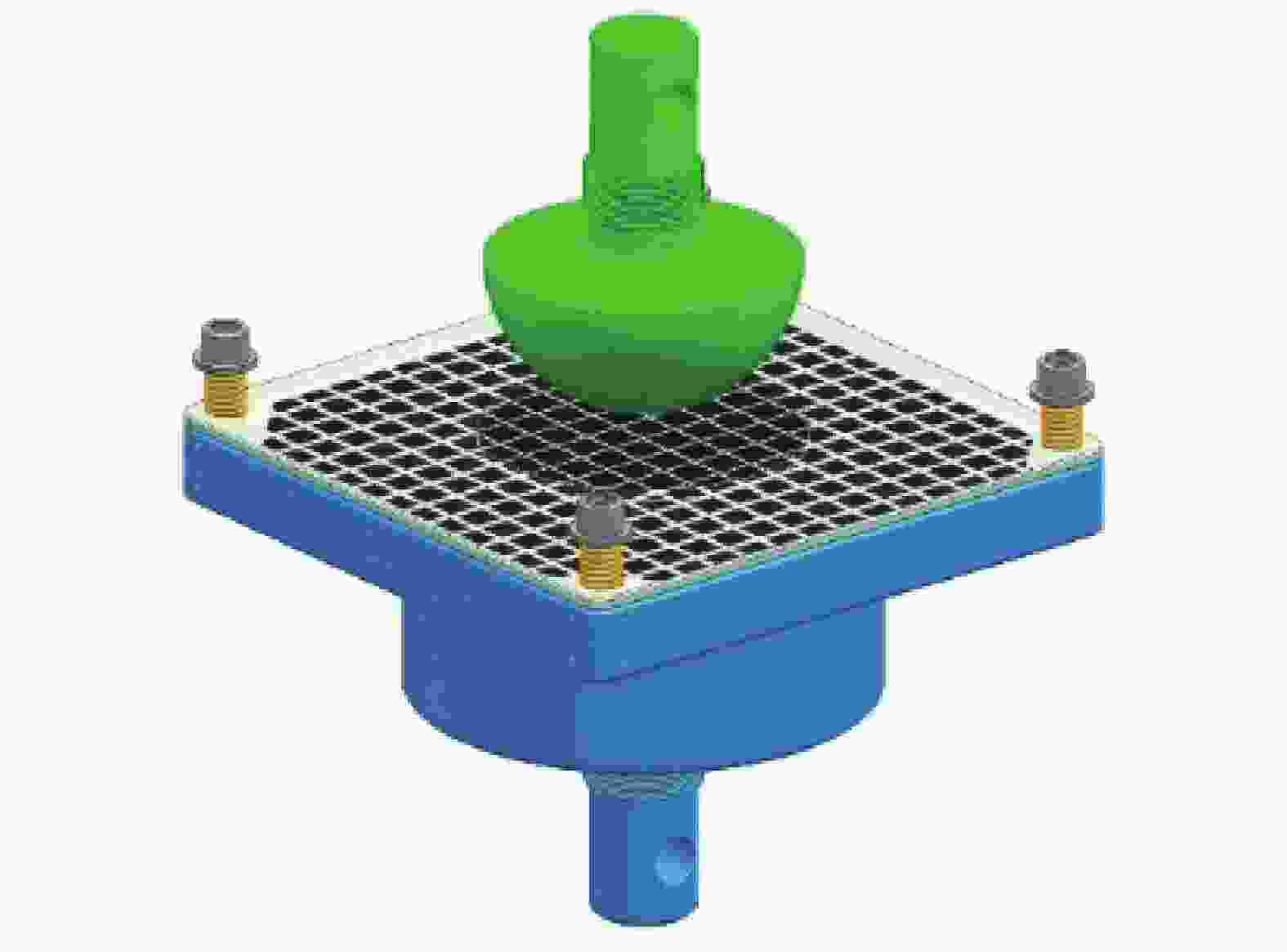

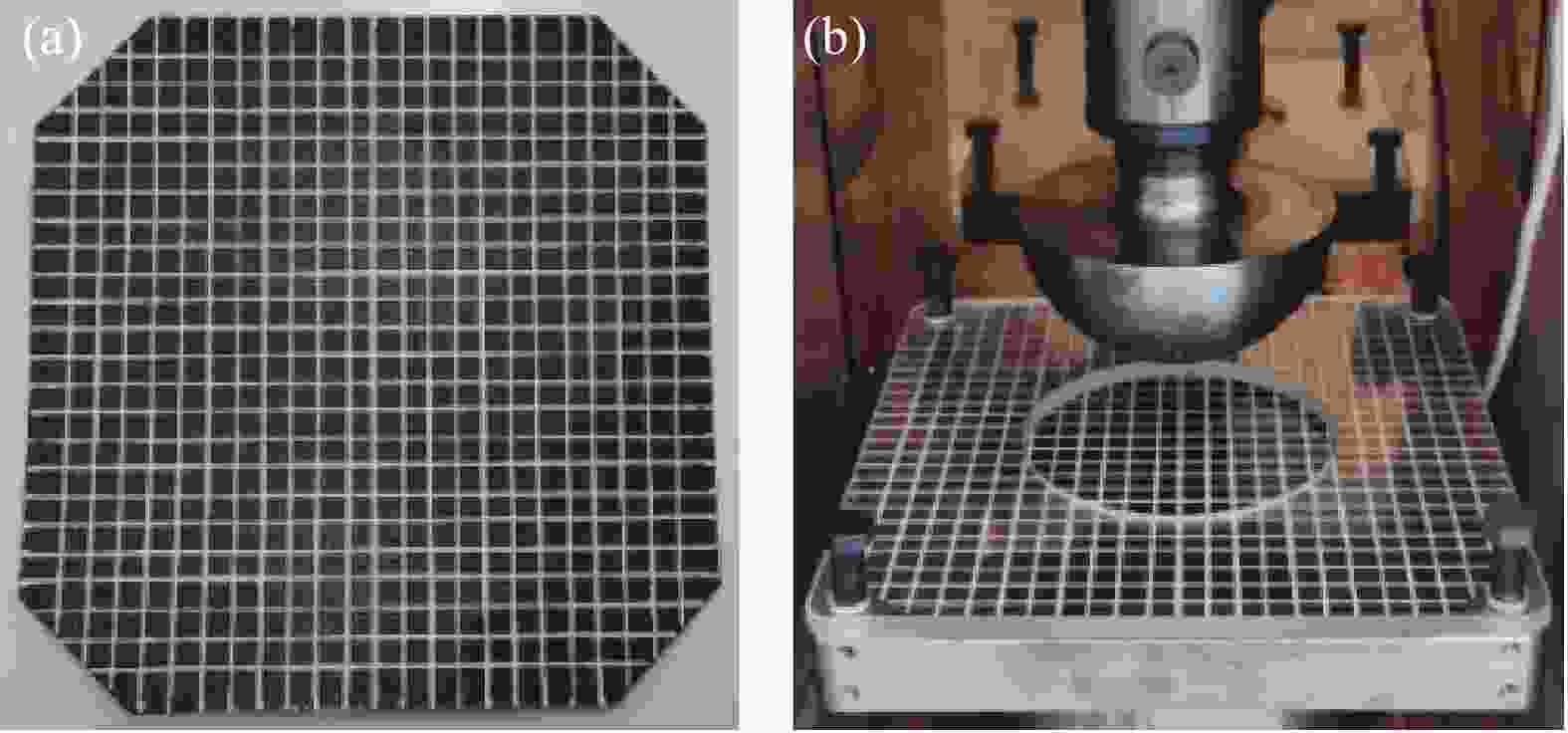

表 1 平纹碳纤维/聚碳酸酯(CF/PC)机织物预浸料参数

Table 1. Parameters of plain weave carbon fiber/polycarbonate (CF/PC) woven fabric prepreg

Parameter Fabric Weave Plain Density/(kg·mm−3) 1.461×10−6 Thickness/mm 0.35 Fiber volume fraction/vol% 45 Glass transition temperature Tg/℃ 150 Melting point Tm/℃ 220 Fabric image

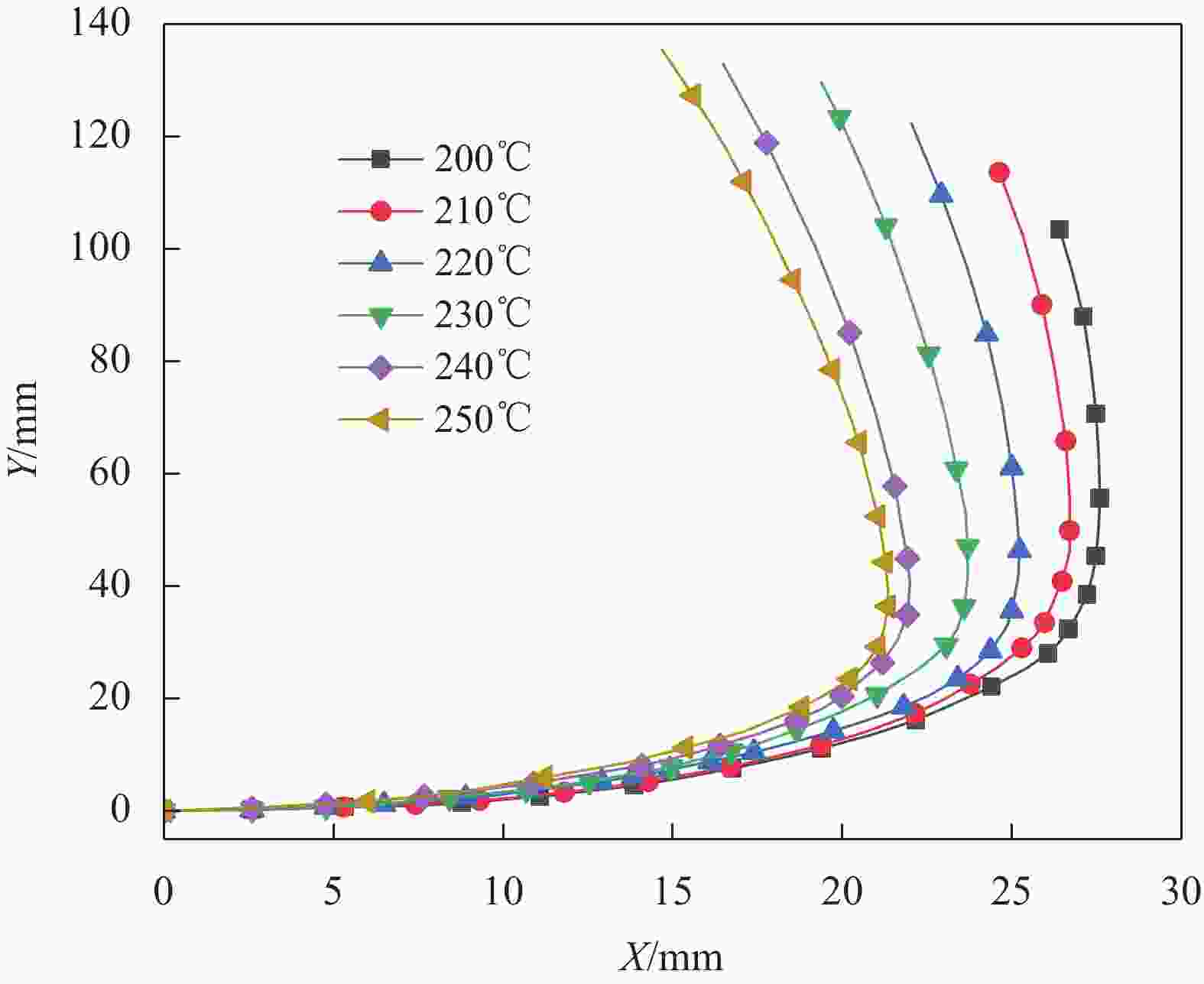

表 2 纤维剪切角变化拟合曲线

Table 2. Fitting curve of fiber shear angle change

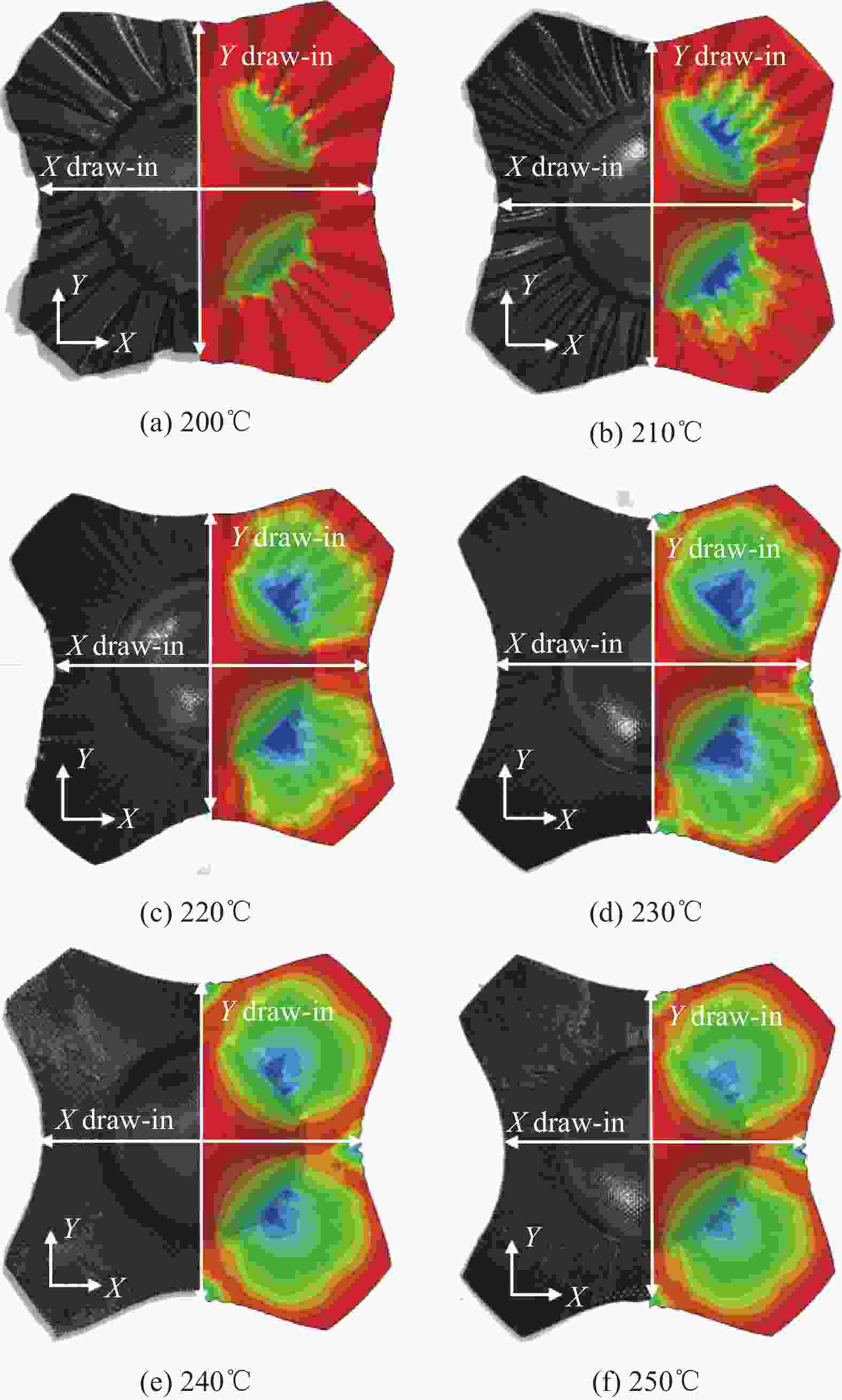

Temperature/℃ Curve fitting parameter Coefficient of determination R2 200 $y=-74.21 x^6+216.57 x^5-275.98 x^4+184.66 x^3-60.72 x^2+10.92 x$ 0.99996 210 $y=-7.86 x^6+48.83 x^5-99.01 x^4+85.52 x^3-32.09 x^2+6.84 x$ 0.99998 220 $y=106.35 x^6-252.89 x^5+208.95 x^4-66.94 x^3+4.25 x^2+2.92 x$ 0.99998 230 $y=74.43 x^6-185.49 x^5+162.48 x^4-57.72 x^3+6.17 x^2+1.83 x$ 0.99997 240 $y=76.99 x^6-189.97 x^5+169.8 x^4-66.76 x^3+10.68 x^2+0.97 x $ 0.99999 250 $y=66.99 x^6-168.78 x^5+155.42 x^4-64.17 x^3+11.36 x^2+0.64 x $ 0.99998 表 3 CF/PC预浸料拉深距离仿真与实验对比

Table 3. Comparison of draw-in values from experiment and simulation of CF/PC prepreg

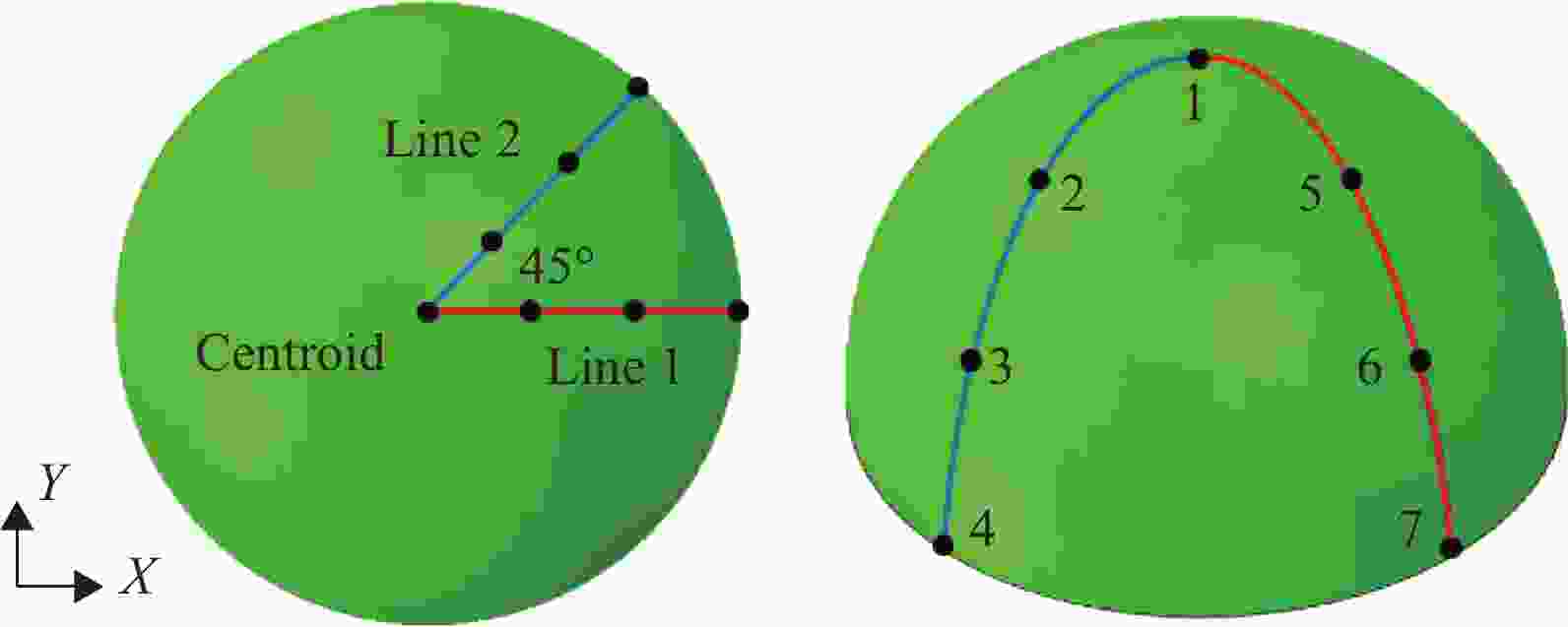

Temperature/℃ X direction/mm Y direction/mm Experiment Simulation Experiment Simulation 200 28.7 28.6 28.8 28.4 210 29.4 29.3 29.5 29.5 220 29.6 29.7 29.6 29.2 230 29.5 29.5 29.7 29.6 240 29.7 29.7 29.8 29.7 250 29.8 29.9 29.9 29.6 表 4 纤维剪切角仿真与实验对比(210℃)

Table 4. Comparison of fiber shear angle values from experiment and simulation (210℃)

Position Shear angle/(°) Error/% Experiment Simulation 1 89.8 89.9 0.11 2 79.3 78.5 1.00 3 68.4 65.6 4.10 4 48.7 46.9 3.70 5 89.8 89.9 0.11 6 89.5 89.6 0.12 7 86.3 86.1 0.23 -

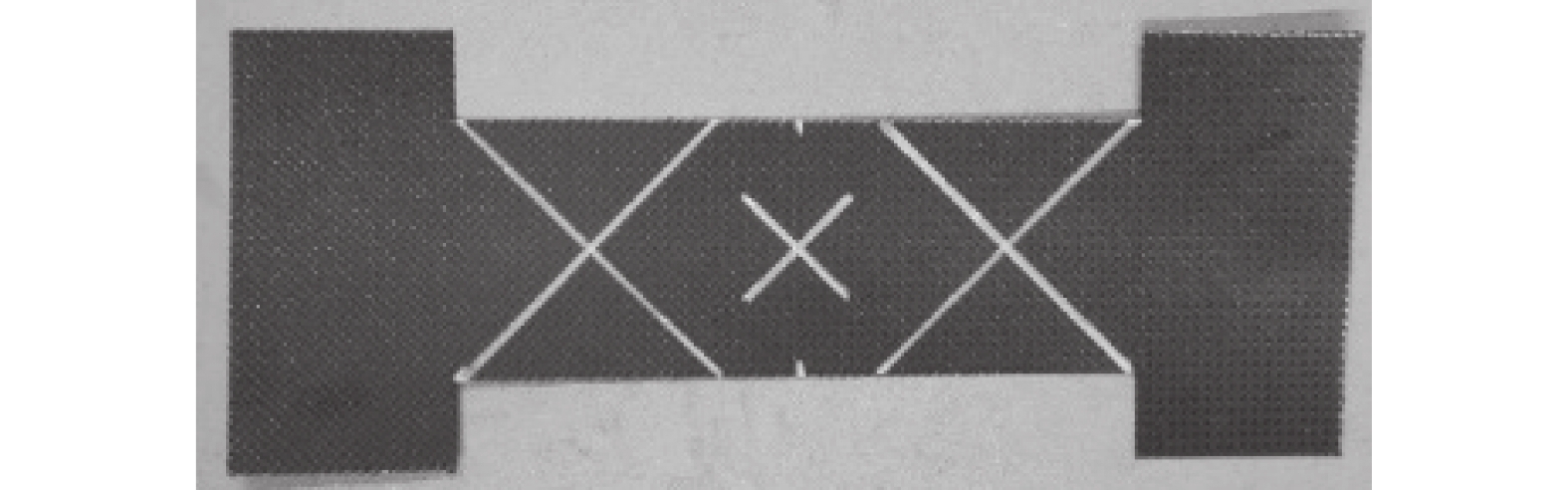

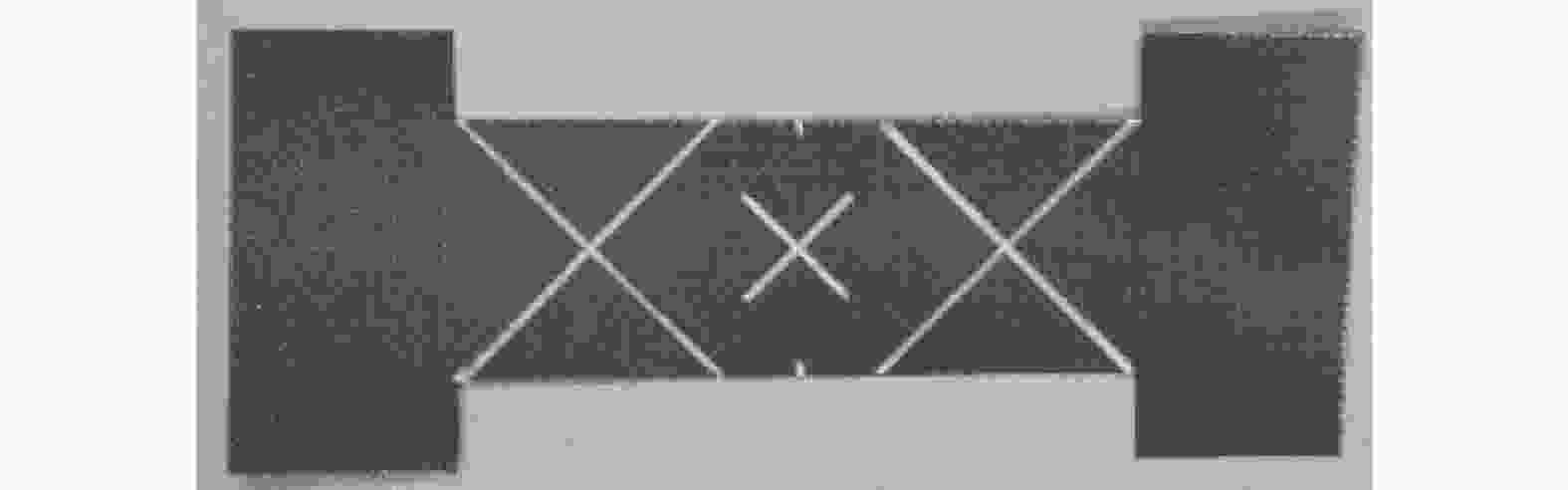

[1] 洪旗, 史耀耀, 路丹妮, 等. 基于灰色关联分析和响应面法的复合材料缠绕成型多目标工艺参数优化[J]. 复合材料学报, 2019, 36(12):2822-2832. doi: 10.13801/j.cnki.fhclxb.20190304.003HONG Qi, SHI Yaoyao, LU Danni, et al. Multi-response parameter optimization for the composite tape winding process based on grey relational analysis and response surface methodology[J]. Acta Materiae Compositae Sinica,2019,36(12):2822-2832(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190304.003 [2] TATSUNO D, YONEYAMA T, KAWAMOTO K, et al. Effect of cooling rate on the mechanical strength of carbon fiber-reinforced thermoplastic sheets in press forming[J]. Journal of Materials Engineering and Performance,2017,26(7):3482-3488. doi: 10.1007/s11665-017-2664-0 [3] GONG Y, SONG Z, NING H, et al. A comprehensive review of characterization and simulation methods for thermo-stamping of 2D woven fabric reinforced thermoplastics[J]. Composites Part B: Engineering,2020,203:108462. doi: 10.1016/j.compositesb.2020.108462 [4] DENIS Y, MORESTIN F, HAMILA N. A hysteretic model for fiber-reinforced composites at finite strains: Fractional derivatives, computational aspects and analysis[J]. Computational Materials Science,2020,181:109716. doi: 10.1016/j.commatsci.2020.109716 [5] GUZMAN-MALDONADO E, HAMILA N, BOISSE P, et al. Thermomechanical analysis, modelling and simulation of the forming of pre-impregnated thermoplastics composites[J]. Composites Part A: Applied Science and Manufacturing,2015,78:211-222. doi: 10.1016/j.compositesa.2015.08.017 [6] KÄRGER L, GALKIN S, DÖRR D, et al. Capabilities of macroscopic forming simulation for large-scale forming processes of dry and impregnated textiles[J]. Procedia Manufacturing,2020,47:140-147. doi: 10.1016/j.promfg.2020.04.155 [7] VAN WEST B P, PIPES R B, KEEFE M. A simulation of the draping of bidirectional fabrics over arbitrary surfaces[J]. Journal of the Textile Institute,1990,81(4):448-460. doi: 10.1080/00405009008658722 [8] JAUFFRÈS D, SHERWOOD J A, MORRIS C D, et al. Discrete mesoscopic modeling for the simulation of woven-fabric reinforcement forming[J]. International Journal of Material Forming,2010,3(2):1205-1216. [9] HAMILA N, BOISSE P. Simulations of textile composite reinforcement draping using a new semi-discrete three node finite element[J]. Composites Part B: Engineering,2008,39(6):999-1010. doi: 10.1016/j.compositesb.2007.11.008 [10] KHAN M A, MABROUKI T, VIDAL-SALLÉ E, et al. Numerical and experimental analyses of woven composite reinforcement forming using a hypoelastic behaviour. Application to the double dome benchmark[J]. Journal of Materials Processing Technology,2010,210(2):378-388. doi: 10.1016/j.jmatprotec.2009.09.027 [11] PENG X Q, CAO J. A continuum mechanics-based non-orthogonal constitutive model for woven composite fabrics[J]. Composites part A: Applied Science and manufacturing,2005,36(6):859-874. doi: 10.1016/j.compositesa.2004.08.008 [12] PENG X, DING F. Validation of a non-orthogonal constitutive model for woven composite fabrics via hemispherical stamping simulation[J]. Composites Part A: Applied Science and Manufacturing,2011,42(4):400-407. doi: 10.1016/j.compositesa.2010.12.014 [13] LIANG B, HAMILA N, PEILLON M, et al. Analysis of thermoplastic prepreg bending stiffness during manufacturing and of its influence on wrinkling simulations[J]. Composites Part A: Applied Science and Manufacturing,2014,67:111-122. doi: 10.1016/j.compositesa.2014.08.020 [14] 张衡. 编织碳纤维增强热塑性复合材料叠层模型及热冲压工艺研究[D]. 上海: 上海交通大学, 2017.ZHANG Heng. Lamination model and thermoforming process investigation of carbon woven fabric reinforced thermoplastic composites[D]. Shanghai: Shanghai Jiao Tong University, 2017(in Chinese). [15] 李哲夫, 谈源, 张俭, 等. 热模压预成型工艺参数对复合材料帽型长桁质量的影响[J]. 复合材料学报, 2021, 38(10):3270-3280. doi: 10.13801/j.cnki.fhclxb.20201215.004LI Zhefu, TAN Yuan, ZHANG Jian, et al. Effects of hot stamp forming process parameters on quality of the hat-shaped structure preforms of composites[J]. Acta Materiae Compositae Sinica,2021,38(10):3270-3280(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201215.004 [16] 付掌印, 林大钧. 不可展曲面近似展开方法的合理性判断标准[J]. 工程图学学报, 2005, 26(6):36-40.FU Zhangyin, LIN Dajun. Some criteria for evaluating the methods of developing undevelopable curved surface[J]. Journal of Engineering Graphics,2005,26(6):36-40(in Chinese). [17] WANG P, HAMILA N, PINEAU P, et al. Thermomechanical analysis of thermoplastic composite prepregs using bias-extension test[J]. Journal of Thermoplastic Composite Materials,2014,27(5):679-698. doi: 10.1177/0892705712454289 [18] BOISSE P, HAMILA N, GUZMAN-MALDONADO E, et al. The bias-extension test for the analysis of in-plane shear properties of textile composite reinforcements and prepregs: A review[J]. International Journal of Material Forming,2017,10(4):473-492. doi: 10.1007/s12289-016-1294-7 [19] HARRISON P, CLIFFORD M J, LONG A C. Shear characterisation of viscous woven textile composites: A comparison between picture frame and bias extension experiments[J]. Composites Science and Technology,2004,64(10-11):1453-1465. doi: 10.1016/j.compscitech.2003.10.015 [20] BOISSE P, HAMILA N, VIDAL-SALLÉ E, et al. Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses[J]. Composites Science and Technology,2011,71(5):683-692. doi: 10.1016/j.compscitech.2011.01.011 [21] 中国纺织工业协会. 纺织品 弯曲性能的测定 第1部分: 斜面法: GB/T 18318.1—2009[S]. 北京: 中国标准出版社, 2009.China National Textile and Apparel Council. Textiles—Determination of bending behavior—Part 1: Incline method: GB/T 18318.1—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [22] MACHADO M, MURENU L, FISCHLSCHWEIGER M, et al. Analysis of the thermomechanical shear behaviour of woven-reinforced thermoplastic-matrix composites during forming[J]. Composites Part A: Applied Science and Manufacturing,2016,86:39-48. doi: 10.1016/j.compositesa.2016.03.032 [23] 李林秀. 热塑性复合材料热冲压成型褶皱缺陷的形成机理研究[D]. 上海: 东华大学, 2020.LI Linxiu. Study on the formation mechanism of wrinkle defects in hot stamping of thermoplastic composites[D]. Shanghai: Donghua University, 2020(in Chinese). [24] ZHANG W, REN H, LIANG B, et al. A non-orthogonal material model of woven composites in the preforming process[J]. CIRP Annals,2017,66(1):257-260. doi: 10.1016/j.cirp.2017.04.112 [25] BOISSE P, GASSER A, HIVET G. Analyses of fabric tensile behaviour: Determination of the biaxial tension-strain surfaces and their use in forming simulations[J]. Composites Part A: Applied Science and Manufacturing,2001,32(10):1395-1414. doi: 10.1016/S1359-835X(01)00039-2 [26] CAO J, AKKERMAN R, BOISSE P, et al. Characterization of mechanical behavior of woven fabrics: Experimental methods and benchmark results[J]. Composites Part A: Applied Science and Manufacturing,2008,39(6):1037-1053. doi: 10.1016/j.compositesa.2008.02.016 [27] LIANG B, SASA G A O, ZHANG W. An integrated preforming-performance model for high-fidelity performance analysis of cured woven composite part with non-orthogonal yarn angles[J]. Chinese Journal of Aeronautics,2022,35(6):367-378. doi: 10.1016/j.cja.2021.09.019 -

下载:

下载: