Ti3C2Tx-MXene sizing agent surface modified high modulus carbon fiber and its epoxy resin matrix composites interface properties

-

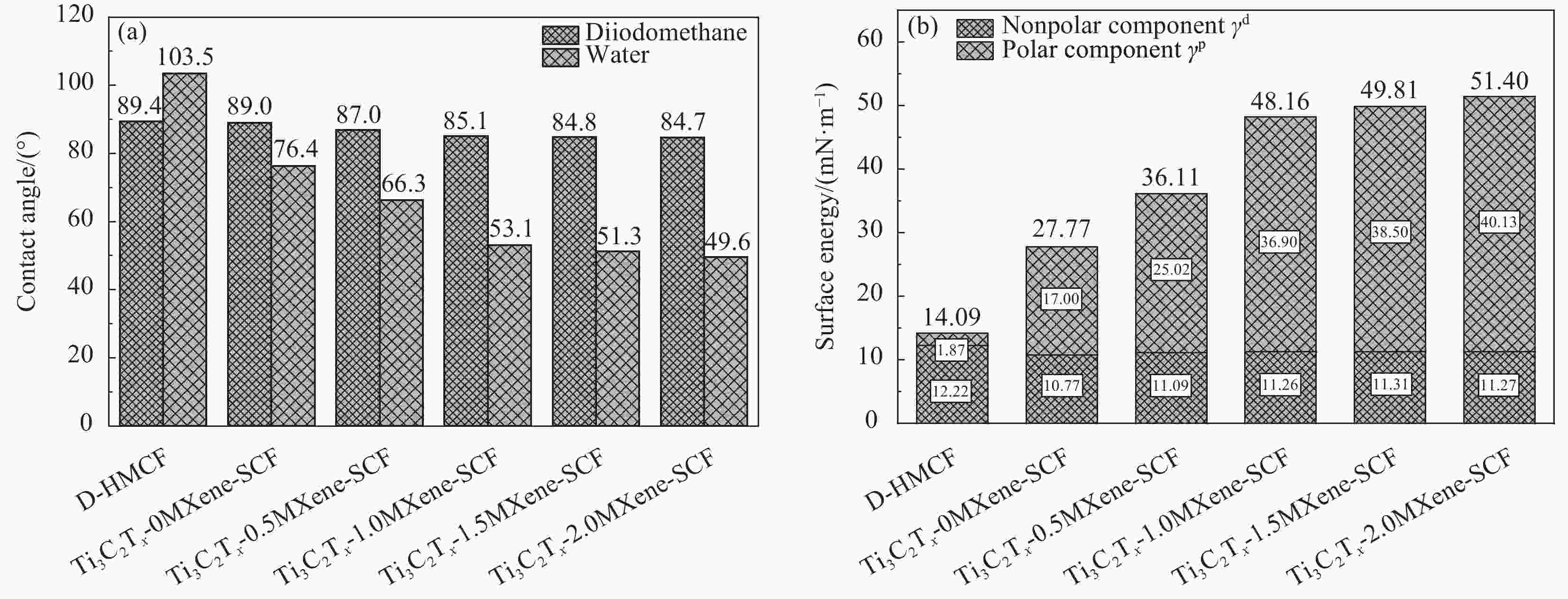

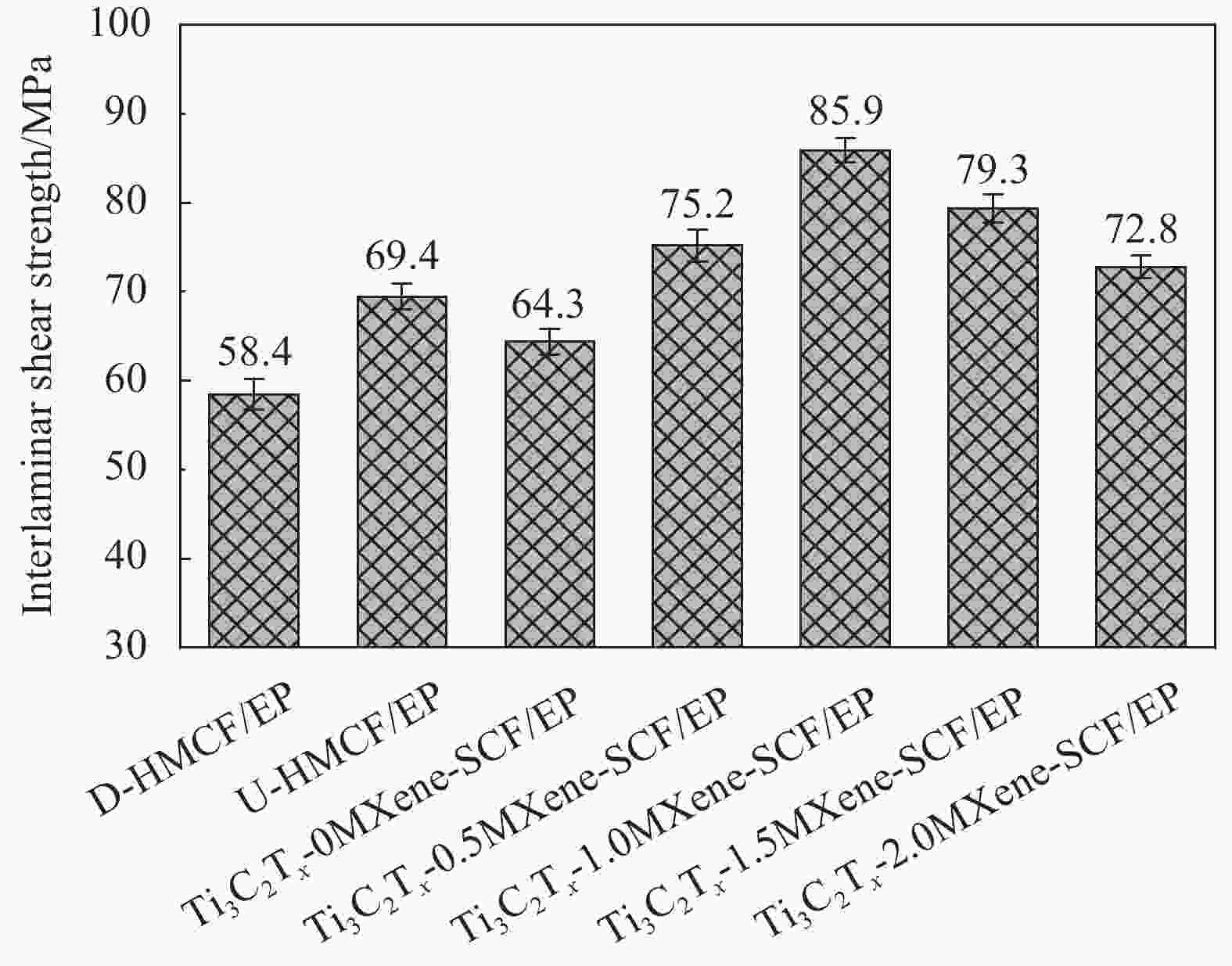

摘要: 为了改善高模量碳纤维(HMCF)表面润湿性及增强其复合材料界面性能,本文采用机械共混法,将尺寸为100~500 nm的少层Ti3C2Tx-MXene水分散液与水性环氧乳液上浆剂进行复配,制备了适用于HMCF的Ti3C2Tx-MXene/环氧树脂(EP)改性环氧乳液复合上浆剂,并以连续上浆技术在HMCF表面构筑了富含Ti3C2Tx-MXene的特性涂层,以期改善HMCF/EP复合材料的界面结合性能。通过SEM、XPS和动态接触角测试对HMCF的表面形貌、表面化学状态和表面润湿性能进行了表征,并以层间剪切强度(ILSS)和断面形貌测试对HMCF/EP复合材料的界面结合状况进行了分析表征,最后以复合材料的剪切破坏模型对Ti3C2Tx-MXene/EP复合上浆剂改性的HMCF/EP复合材料的界面增强机制进行了探讨。结果表明,经Ti3C2Tx-MXene/EP复合上浆剂表面处理后,HMCF表面的O/C(原子比)提高,并赋予其一定量的纳米尺度小凸起微机械结构,改善了HMCF的表面润湿性。当环氧乳液上浆剂固含量为0.8%,Ti3C2Tx-MXene浓度为1.0 mg/mL时,HMCF/EP复合材料的ILSS值提高了23.8%,达到85.9 MPa。

-

关键词:

- 高模量碳纤维 /

- Ti3C2Tx-MXene /

- 上浆剂 /

- 复合材料 /

- 界面性能

Abstract: In order to improve the surface wettability of high modulus carbon fibers (HMCF) and enhance the interfacial properties of their composites, a few-layer Ti3C2Tx-MXene aqueous dispersion with a size of 100-500 nm was mixed with an aqueous epoxy emulsion to prepare an Ti3C2Tx-MXene modified sizing agent for HMCF by mechanical blending method. The continuous sizing technology was used to construct a characteristic coating rich in Ti3C2Tx-MXene on the surface of HMCF in order to improve the interface bonding of HMCF/epoxy resin (EP) composites. The surface morphology, surface chemical state and surface wettability of HMCF were characterized by SEM, XPS and dynamic contact angle test, and the interface bonding of HMCF/EP composites was analyzed and characterized by interlaminar shear strength (ILSS) and cross-sectional morphology tests. Finally, the interface enhancement mechanism of Ti3C2Tx-Mxene/EP sizing agent-modified HMCF/EP composites was investigated with the shear damage models of the composites. The results show that after the surface treatment with Ti3C2Tx-MXene modified sizing agent, the O/C (atomic ratio) of the HMCF surface is increased, and a certain amount of nano-scale convex micromechanical structures are introduced to improve the surface wettability of HMCF. When the solid content of the epoxy emulsion sizing agent is 0.8% and the concentration of Ti3C2Tx-MXene is 1.0 mg/mL, the ILSS of the HMCF/EP composites increases by 23.8% to 85.9 MPa.-

Key words:

- high modulus carbon fiber /

- Ti3C2Tx-MXene /

- sizing agent /

- composite /

- interfacial properties

-

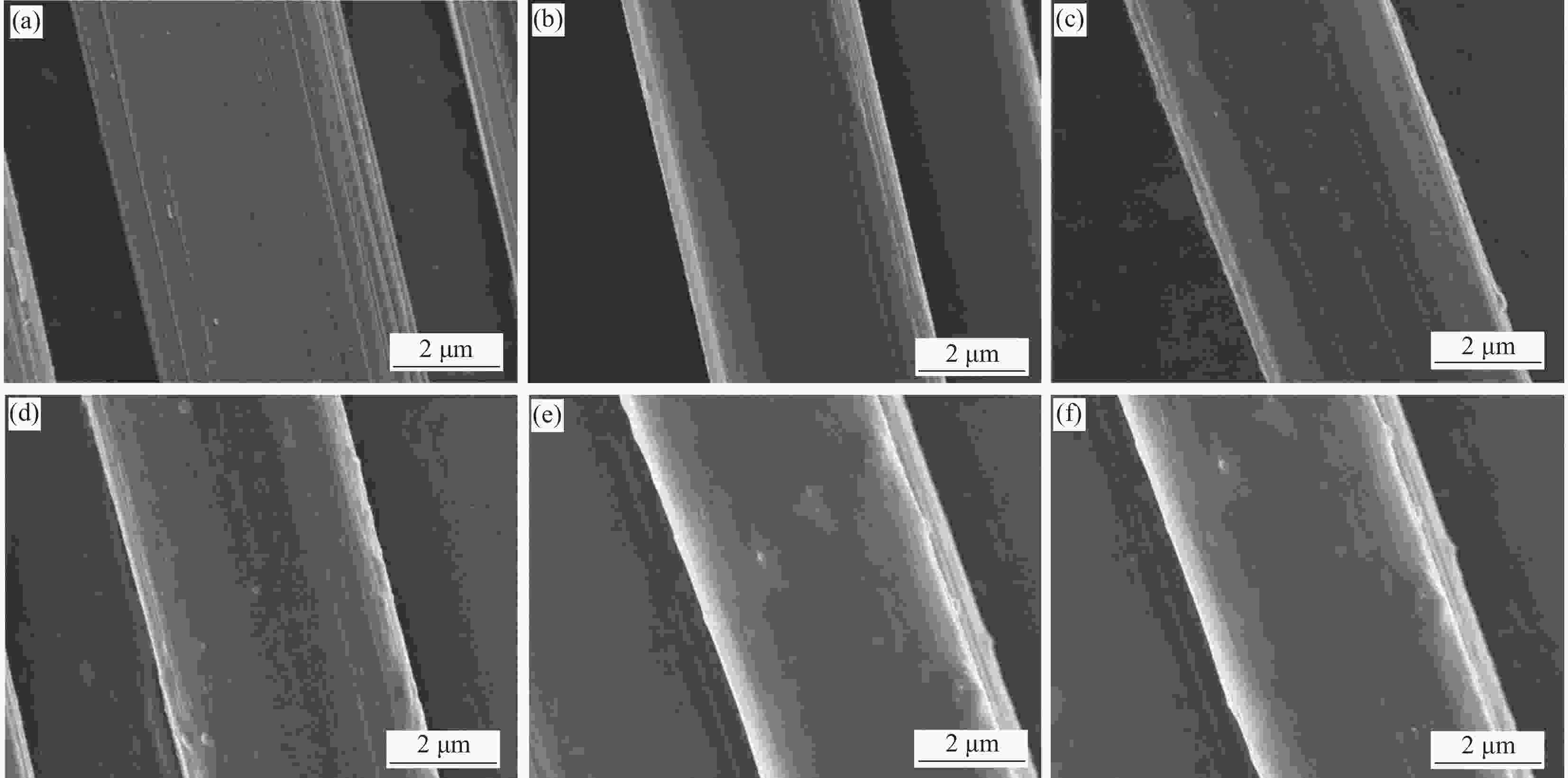

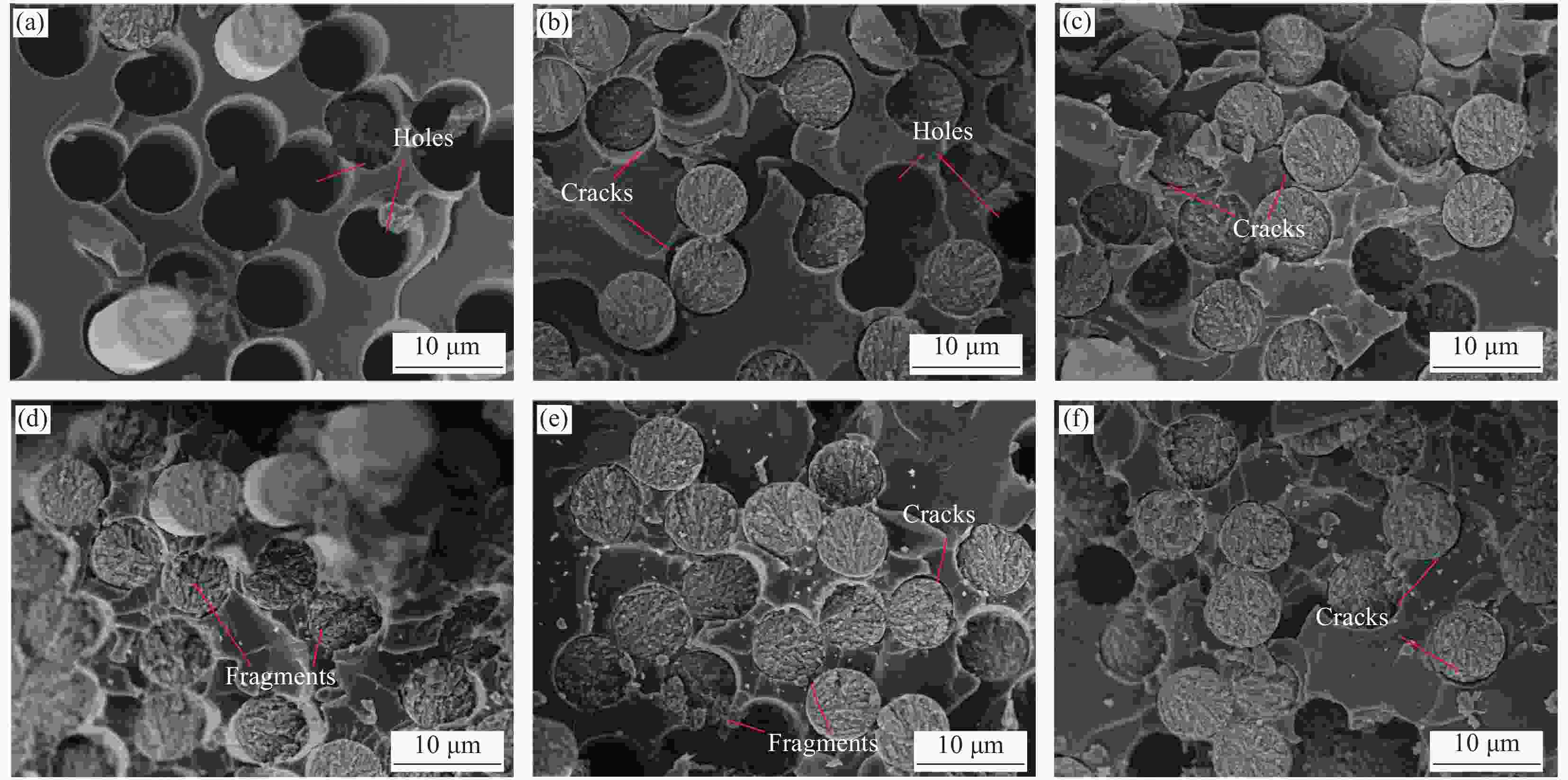

图 4 D-HMCF (a)、Ti3C2Tx-0MXene-SCF (b)、Ti3C2Tx-0.5MXene-SCF (c)、Ti3C2Tx-1.0MXene-SCF (d)、Ti3C2Tx-1.5MXene-SCF (e) 和Ti3C2Tx-2.0MXene-SCF (f) 的SEM图像

Figure 4. SEM images of D-HMCF (a), Ti3C2Tx-0MXene-SCF (b), Ti3C2Tx-0.5MXene-SCF (c), Ti3C2Tx-1.0MXene-SCF (d), Ti3C2Tx-1.5MXene-SCF (e) and Ti3C2Tx-2.0MXene-SCF (f)

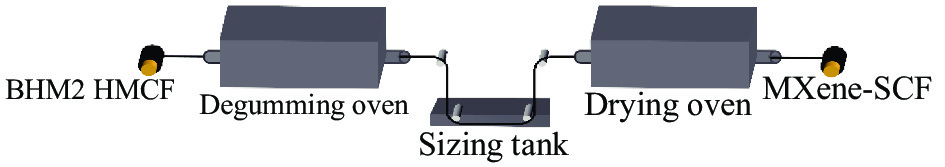

图 8 D-HMCF/EP (a)、Ti3C2Tx-0MXene-SCF/EP (b)、Ti3C2Tx-0.5MXene-SCF/EP (c)、Ti3C2Tx-1.0MXene-SCF/EP (d)、Ti3C2Tx-1.5MXene-SCF/EP (e) 和Ti3C2Tx-2.0MXene-SCF/EP (f) 的断面形貌

Figure 8. Cross-sectional morphologies of D-HMCF/EP (a), Ti3C2Tx-0MXene-SCF/EP (b), Ti3C2Tx-0.5MXene-SCF/EP (c), Ti3C2Tx-1.0MXene-SCF/EP (d), Ti3C2Tx-1.5MXene-SCF/EP (e) and Ti3C2Tx-2.0MXene-SCF/EP (f)

表 1 各样品缩写命名

Table 1. Abbreviations used for various samples prepared

Sample code Details D-HMCF Desized BHM2 carbon fibers U-HMCF BHM2 carbon fibers Ti3C2Tx-0MXene-SCF 0 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fibers Ti3C2Tx-0.5MXene-SCF 0.5 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fibers Ti3C2Tx-1.0MXene-SCF 1.0 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fibers Ti3C2Tx-1.5MXene-SCF 1.5 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fibers Ti3C2Tx-2.0MXene-SCF 2.0 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fibers D-HMCF/EP Desized BHM2 carbon fiber reinforced epoxy composites U-HMCF/EP BHM2 carbon fiber reinforced epoxy composites Ti3C2Tx-0MXene-SCF/EP 0 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fiber reinforced epoxy composites Ti3C2Tx-0.5MXene-SCF/EP 0.5 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fiber reinforced epoxy composites Ti3C2Tx-1.0MXene-SCF/EP 1.0 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fiber reinforced epoxy composites Ti3C2Tx-1.5MXene-SCF/EP 1.5 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fiber reinforced epoxy composites Ti3C2Tx-2.0MXene-SCF/EP 2.0 mg/mL Ti3C2Tx-MXene/EP composite sizing agent sized carbon fiber reinforced epoxy composites 表 2 不同HMCF的C1s特征峰结合能及相对含量

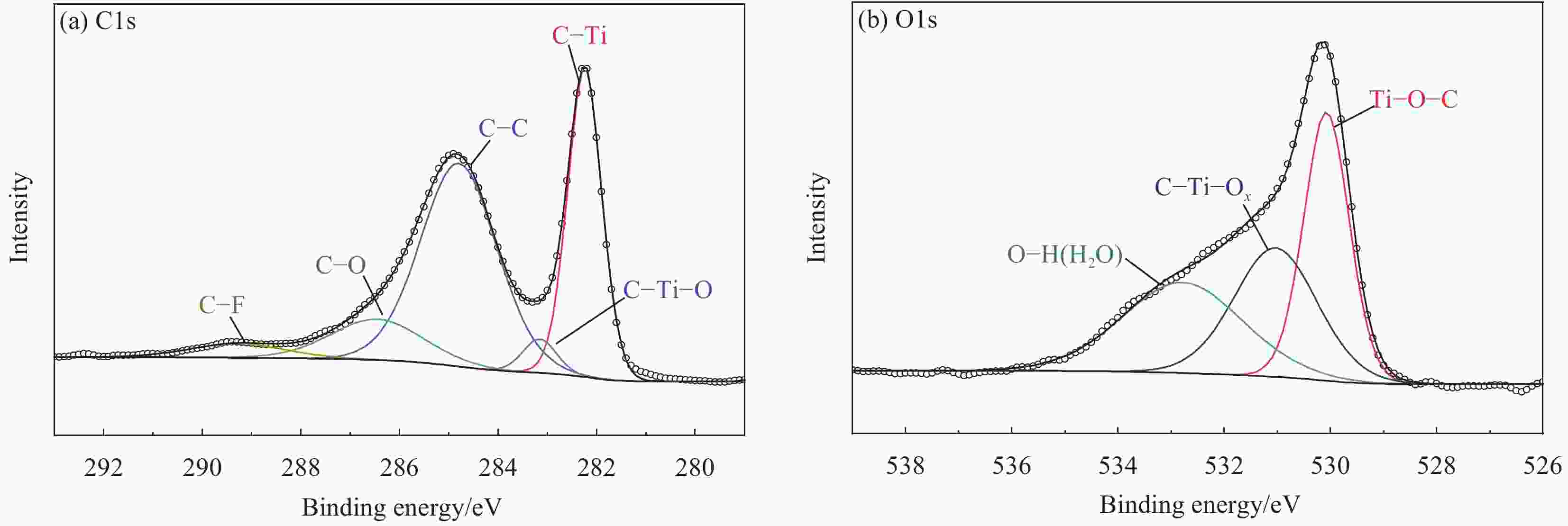

Table 2. C1s characteristic peak binding energy and relative content of different HMCF

Functional group Binding energy/eV Relative content/% D-HMCF/% Ti3C2Tx-0MXene-SCF/% Ti3C2Tx-1.0MXene-SCF/% Ti—C(MXene) 281.9 — — 3.25 C—C 284.6 46.00 45.69 38.37 —HC—CH— 285.5 39.25 37.81 35.10 C—O 286.4 2.37 4.51 15.34 C=O 287.3 3.40 11.46 6.84 —COOH 288.6 3.03 — — π*-π 290.8 5.95 0.53 1.08 -

[1] BARAL N, DAVIES P, BALEY C, et al. Delamination behaviour of very high modulus carbon/epoxy marine composites[J]. Composites Science and Technology,2008,68(3-4):995-1007. doi: 10.1016/j.compscitech.2007.07.022 [2] 沈曾民, 迟伟东, 张学军, 等. 高模量碳纤维的现状及发展(1)[J]. 高科技纤维与应用, 2010, 35(3):5-13. doi: 10.3969/j.issn.1007-9815.2010.03.002SHEN Zengmin, CHI Weidong, ZHANG Xuejun, et al. The current status and development trend of high modulus carbon fibers (1)[J]. Hi-Tech Fiber & Application,2010,35(3):5-13(in Chinese). doi: 10.3969/j.issn.1007-9815.2010.03.002 [3] 陶积柏, 黎昱, 张玉生. 高模量碳纤维在中国宇航结构产品上的应用现状及实现自我保障的建议[J]. 材料科学与工艺, 2015, 23(6):98-103. doi: 10.11951/j.issn.1005-0299.20150618TAO Jibai, LI Yu, ZHANG Yusheng. Application-status of high modulus carbon fiber in domestic aerospace structural products and suggestions for self-supply[J]. Materials Science and Technology,2015,23(6):98-103(in Chinese). doi: 10.11951/j.issn.1005-0299.20150618 [4] HAO R T, JIAO X W, ZHANG X J, et al. Fe3O4/graphene modified waterborne polyimide sizing agent for high modulus carbon fiber[J]. Applied Surface Science,2019,485:304-313. doi: 10.1016/j.apsusc.2019.04.184 [5] LIN J W, XU P, WANG L L, et al. Multi-scale interphase construction of self-assembly naphthalenediimide/multi-wall carbon nanotube and enhanced interfacial properties of high-modulus carbon fiber composites[J]. Composites Science and Technology,2019,184:107855. doi: 10.1016/j.compscitech.2019.107855 [6] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [7] ZHANG S, LIU W B, HAO L F, et al. Preparation of carbon nanotube/carbon fiber hybrid fiber by combining electrophoretic deposition and sizing process for enhancing interfacial strength in carbon fiber composites[J]. Composites Science and Technology,2013,88:120-125. doi: 10.1016/j.compscitech.2013.08.035 [8] KIM K J, KIM J, YU W R, et al. Improved tensile strength of carbon fibers undergoing catalytic growth of carbon nanotubes on their surface[J]. Carbon,2013,54:258-267. doi: 10.1016/j.carbon.2012.11.037 [9] TIWARI S, BIJWE J. Surface treatment of carbon fibers-A review[J]. Procedia Technology,2014,14:505-512. doi: 10.1016/j.protcy.2014.08.064 [10] LI L, YAN C, XU H, et al. Improving the interfacial properties of carbon fiber-epoxy resin composites with a graphene-modified sizing agent[J]. Journal of Applied Polymer Science,2018,136(9):47122. [11] WU G S, MA L C, LIU L, et al. Interface enhancement of carbon fiber reinforced methylphenylsilicone resin composites modified with silanized carbon nanotubes[J]. Materials & Design,2016,89:1343-1349. [12] KARAKASSIDES A, GANGULY A, TSIRKA K, et al. Radially grown graphene nanoflakes on carbon fibers as reinforcing interface for polymer composites[J]. ACS Applied Nano Materials,2020,3(3):2402-2413. doi: 10.1021/acsanm.9b02536 [13] ZHANG X Q, FAN X Y, YAN C, et al. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials and Interfaces,2012,4(3):1543-1552. doi: 10.1021/am201757v [14] LIU L, YAN F, LI M, et al. Improving interfacial properties of hierarchical reinforcement carbon fibers modified by graphene oxide with different bonding types[J]. Composites Part A: Applied Science and Manufacturing,2018,107:616-625. doi: 10.1016/j.compositesa.2018.02.009 [15] YANG Y, LU C X, SU X L, et al. Effect of nano-SiO2 modified emulsion sizing on the interfacial adhesion of carbon fibers reinforced composites[J]. Materials Letters,2007,61(17):3601-3604. doi: 10.1016/j.matlet.2006.11.121 [16] NAGUIB M, KURTOGLU M, PRESSER V, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2[J]. Advanced Materials,2011,23(37):4248-4253. doi: 10.1002/adma.201102306 [17] MALESKI K, MOCHALIN V N, GOGOTSI Y. Dispersions of two-dimensional titanium carbide mxene in organic solvents[J]. Chemistry of Materials,2017,29(4):1632-1640. doi: 10.1021/acs.chemmater.6b04830 [18] TIAN S, CHENG G J, TANG Z F, et al. Fabrication of two-dimensional Ti3C2Tx MXenes by ball milling pretreatment and mild etchant and their microstructure[J]. Ceramics International,2020,46(18):28949-28954. doi: 10.1016/j.ceramint.2020.08.065 [19] LIU L, YING G B, HU C, et al. Functionalization with MXene (Ti3C2) enhances the wettability and shear strength of carbon fiber-epoxy composites[J]. ACS Applied Nano Materials,2019,2(9):5553-5562. doi: 10.1021/acsanm.9b01127 [20] YUAN X Y, JIANG J, WEI H W, et al. PAI/MXene sizing-based dual functional coating for carbon fiber/PEEK composite[J]. Composites Science and Technology,2021,201:108496. doi: 10.1016/j.compscitech.2020.108496 [21] GHIDIU M, LUKATSKAYA M R, ZHAO M Q, et al. Conductive two-dimensional titanium carbide 'clay' with high volumetric capacitance[J]. Nature,2014,516(7529):78-81. doi: 10.1038/nature13970 [22] HONG V M, HUANG H, ZHOU K, et al. Recent progress in layered transition metal carbides and/or nitrides (MXenes) and their composites: Synthesis and applications[J]. Journal of Materials Chemistry A,2017,5(7):3039-3068. doi: 10.1039/C6TA06772G [23] 全国纤维增强塑料标准化技术委员会. 单向纤维增强塑料层间剪切强度试验方法: GB 3357—1982[S]. 北京: 中国标准出版社, 1982.National Technical Committee of Standardization for Fiber Reinfoeced Plastics. Test method for interlaminar shear strength of unidirectional fiber reinforced plastics: GB 3357—1982[S]. Beijing: China Standards Press, 1982(in Chinese). [24] HAN M K, YIN X W, WU H, et al. Ti3C2 MXenes with modified surface for high-performance electromagnetic absorption and shielding in the X-Band[J]. ACS Applied Materials & Interfaces,2016,8(32):21011-21019. [25] HE L X, WANG J L, WANG B B, et al. Large-scale production of simultaneously exfoliated and functionalized MXenes as promising flame retardant for polyurethane[J]. Composites Part B: Engineering,2019,179:107486. doi: 10.1016/j.compositesb.2019.107486 [26] UNTERWEGER C, DUCHOSLAV J, STIFTER D, et al. Characterization of carbon fiber surfaces and their impact on the mechanical properties of short carbon fiber reinforced polypropylene composites[J]. Composites Science and Technology,2015,108:41-47. doi: 10.1016/j.compscitech.2015.01.004 [27] CHI X F, LI M X, LIANG M, et al. Enhanced interfacial interactions of carbon fiber/epoxy resin composites by regulating PEG-E51 and graphene oxide complex sizing at the interface[J]. Polymers for Advanced Technologies,2021,32(9):3458-3473. doi: 10.1002/pat.5357 [28] DENG C, JIANG J J, LIU F, et al. Influence of graphene oxide coatings on carbon fiber by ultrasonically assisted electrophoretic deposition on its composite interfacial property[J]. Surface and Coatings Technology,2015,272:176-181. doi: 10.1016/j.surfcoat.2015.04.008 [29] ZHANG T, ZHAO Y Q, LI H F, et al. Effect of polyurethane sizing on carbon fibers surface and interfacial adhesion of fiber/polyamide 6 composites[J]. Journal of Applied Polymer Science,2018,135(16):46111. doi: 10.1002/app.46111 [30] JIANG D W, LIU L, WU G S, et al. Mechanical properties of carbon fiber composites modified with graphene oxide in the interphase[J]. Polymer Composites,2017,38(11):2425-2432. doi: 10.1002/pc.23828 [31] MA L C, ZHU Y Y, FENG P F, et al. Reinforcing carbon fiber epoxy composites with triazine derivatives functionalized graphene oxide modified sizing agent[J]. Composites Part B: Engineering,2019,176:107078. doi: 10.1016/j.compositesb.2019.107078 [32] PENG Q Y, LI Y B, HE X D, et al. Interfacial enhancement of carbon fiber composites by poly(amido amine) functionalization[J]. Composites Science and Technology,2013,74:37-42. doi: 10.1016/j.compscitech.2012.10.005 [33] LIU P F, YANG Y H. Finite element analysis of the competition between crack deflection and penetration of fiber-reinforced composites using virtual crack closure technique[J]. Applied Composite Materials,2014,21(5):759-771. doi: 10.1007/s10443-013-9375-y -

下载:

下载: