Preparation and properties of poly(butylene succinate-co-butylene diphenyl ether dicarboxylate)/polybutylene terephthalate composites

-

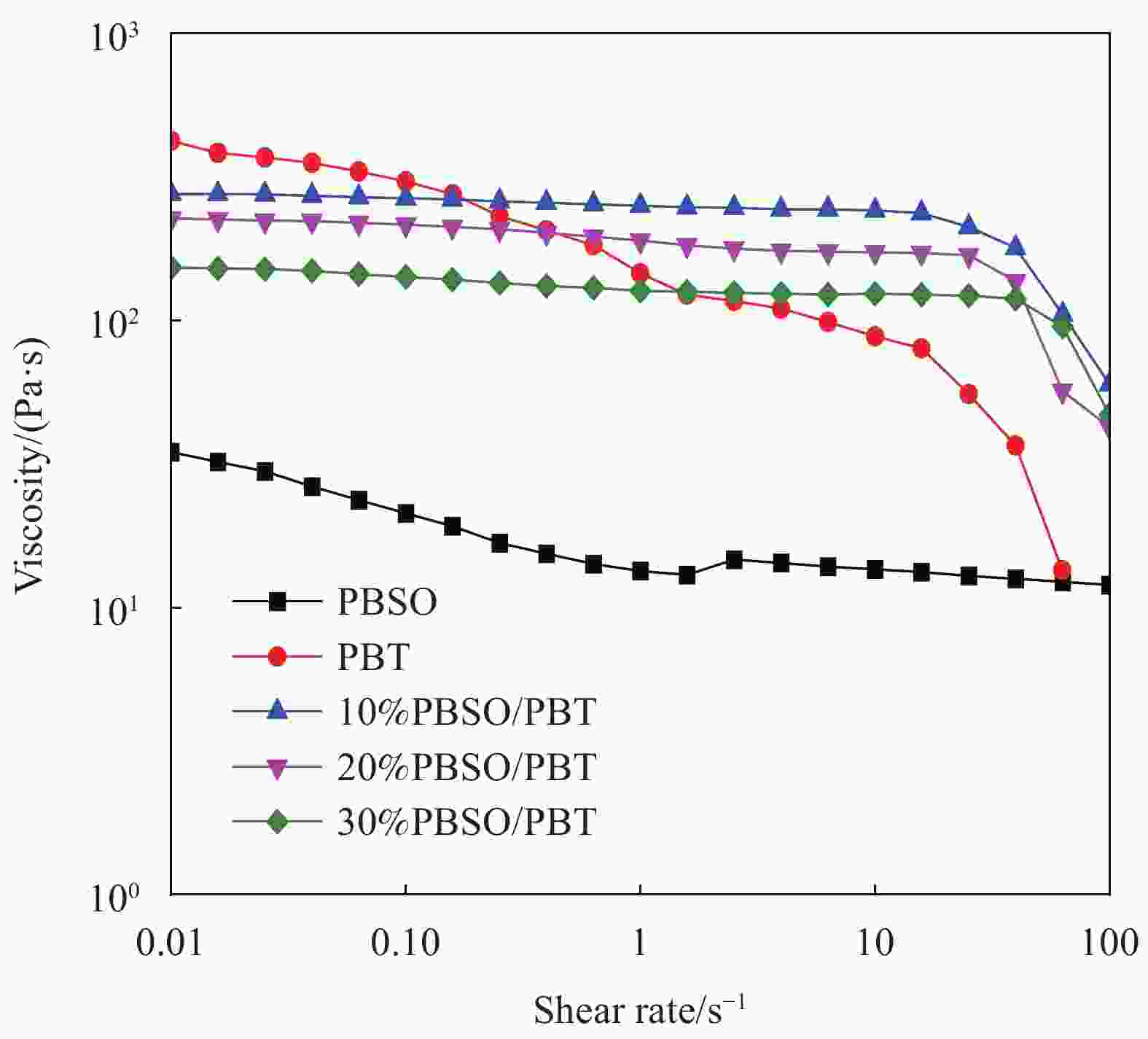

摘要: 聚对苯二甲酸丁二醇酯 (PBT) 是半结晶热塑性聚合物,具有出色的尺寸稳定性、高的刚度和硬度、良好的耐化学性、力学性能和可加工性等优良特点。但其抗冲击性较低、韧性较差。采用将PBT与具有优异韧性的聚(丁二酸丁二醇-co-二苯醚二甲酸丁二醇)酯 (PBSO) 进行熔融共混以改善PBT的韧性。首先以二苯醚二甲酸 (OBBA)、丁二酸 (SA) 和丁二醇 (BDO) 为单体,以钛酸四丁酯为催化剂,采用先酯化后缩聚的两步法合成了PBSO。然后将不同质量比的PBSO与PBT 进行熔融挤出共混,研究复合材料的力学韧性、PBSO与PBT的相容性、结晶行为、热稳定性以及流变性能等。FT-IR、1H NMR、GPC测试分析了所合成PBSO的结构。力学性能测试表明,20wt%PBSO/PBT复合材料的拉伸强度为40.3 MPa,断裂伸长率达到82.1%,断裂能增加到24.7 MPa,冲击强度达到较大值23.2 kJ/m2,具有较高的拉伸强度和良好的韧性。动态热机械分析 (DMA) 和SEM结果发现,PBSO对PBT具有增容效果,PBSO/PBT是部分相容共混体系。差示扫描量热 (DSC) 和广角X射线衍射(WAXD) 结果显示,非晶聚合物PBSO的加入,降低了PBT的结晶度,但未改变PBT的晶体结构。热重分析 ( TGA)分析可知,PBSO/PBT复合材料具有良好的加工热稳定性。

-

关键词:

- 聚(丁二酸丁二醇-co-二苯醚二甲酸丁二醇)酯 /

- PBT /

- 增韧 /

- 相容性 /

- 结晶行为

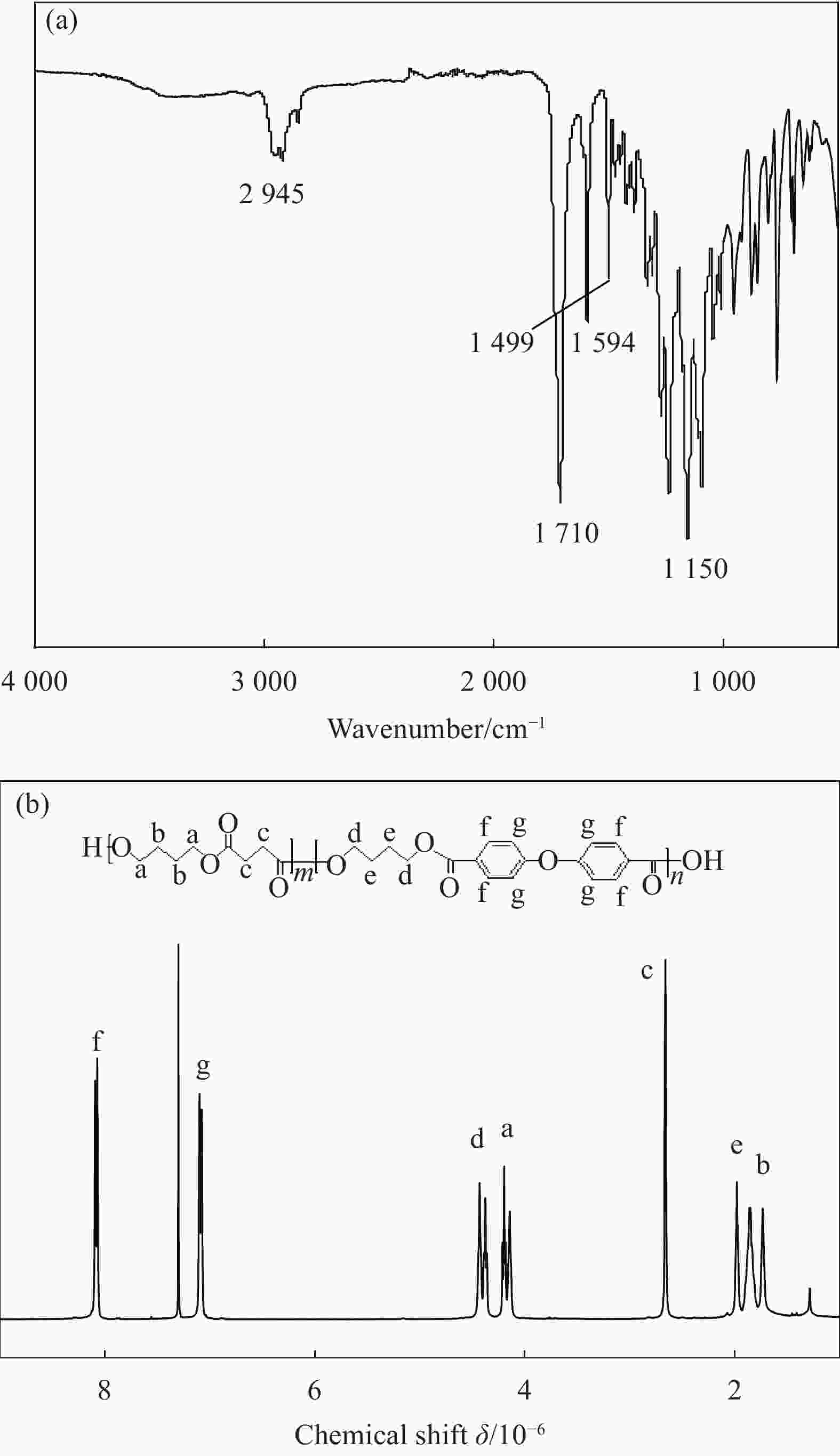

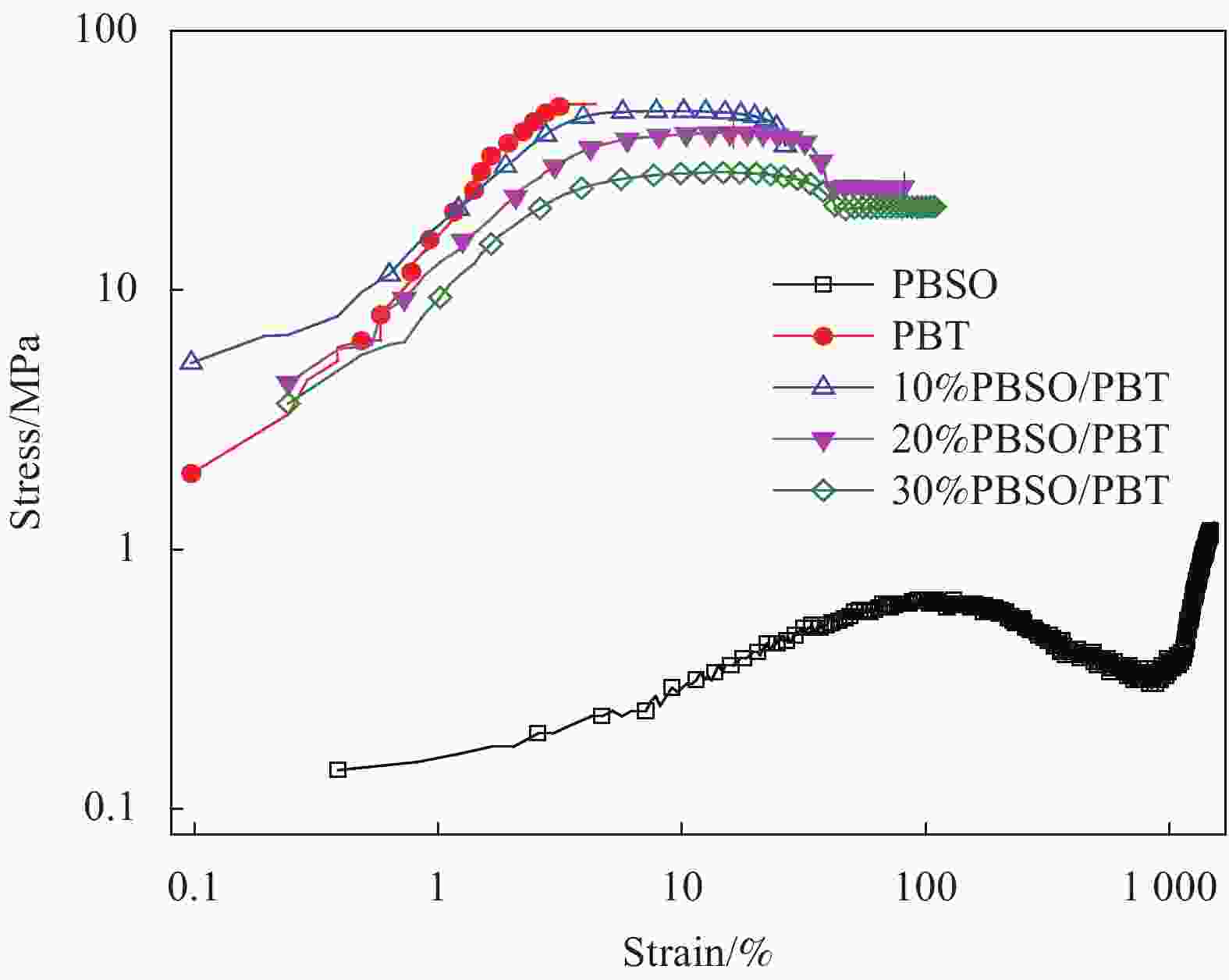

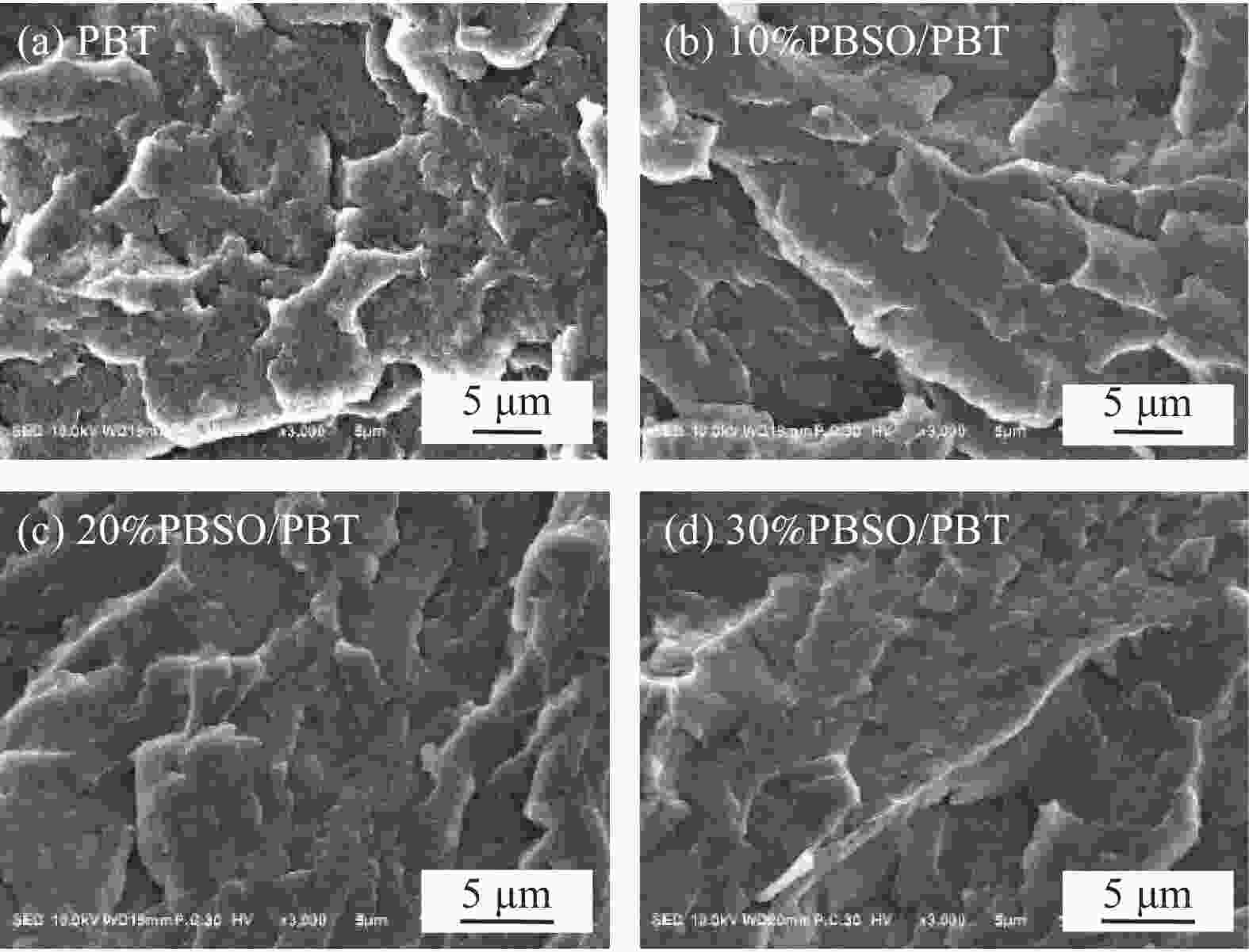

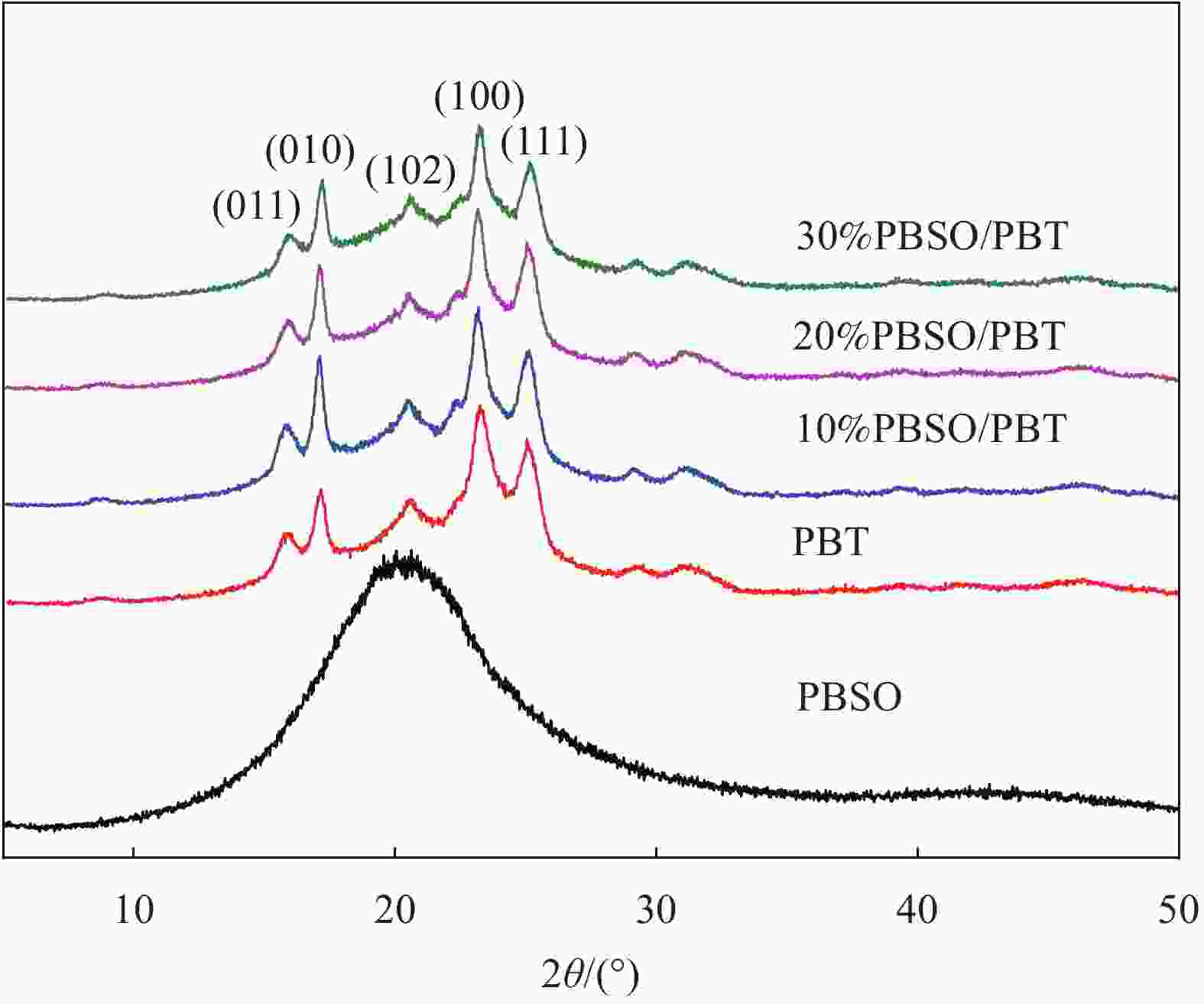

Abstract: Polybutylene terephthalate (PBT) is a semi-crystalline thermoplastic polymer with excellent dimensional stability, high stiffness and hardness, good chemical resistance, mechanical properties and processability. But its impact resistance is low and toughness is poor. PBT was melt blended with poly(butylene succinate-co-butylene diphenyl ether dicarboxylate) (PBSO), which has excellent toughness, to improve the toughness of PBT. Firstly, PBSO was synthesized by a two-step method of esterification and polycondensation, using diphenyl ether dicarboxylic acid (OBBA), succinic acid (SA) and butanediol (BDO) as monomers, and tetrabutyl titanate as catalyst. Then, PBSO/PBT with different mass ratios of PBSO and PBT were blended by melt-extrusion to study the toughening effect of PBSO on PBT. The mechanical toughness of blends, the compatibility of PBSO and PBT, crystallization behavior, thermal stability and rheological properties were studied. The structure of PBSO was characterized by FT-IR, 1H NMR and GPC. The mechanical performance test show that the tensile strength of the 20wt%PBSO/PBT composite material is 40.3 MPa, the elongation at break reach to 82.1%, the breaking energy increas to 24.70 MPa, and the impact strength is 23.2 kJ/m2, indicating a higher tensile strength and good toughness. Dynamic mechanical analysis (DMA) and SEM results indicate that PBSO has a compatibilizing effect on PBT, and PBSO/PBT is a partially compatible blend system. DSC and wide-angle X-ray diffraction (WAXD) results show that the addition of amorphous polymer PBSO reduce the crystallinity of PBT, but do not change the crystal structure of PBT. Thermogravimetric analysis (TGA) analysis demonstrated that the PBSO/PBT composite has a good processing thermal stability. -

图 1 先酯化后缩聚法合成脂肪族-芳香族共聚酯(PBSO)

Figure 1. Synthesis of poly(butylene succinate-co-butylene diphenyl ether dicarboxylate) (PBSO) via two-step process of esterification and polycondensation

OBBA—Diphenyl ether dicarboxylic acid; BDO—Butanediol; PBSO—Poly(butylene succinate-co-butylene diphenyl ether dicarboxylate); SA—Succinic acid; m, n—Degree of polymerization

表 1 不同PBSO含量的聚(丁二酸丁二醇-co-二苯醚二甲酸丁二醇)酯/聚对苯二甲酸丁二醇酯(PBSO/PBT)复合材料

Table 1. Poly(butylene succinate-co-butylene di-phenyl ether dicarboxylate)/polybutylene terephthalate (PBSO/PBT) composites with different content of PBSO

Samples Mass fraction of PBSO/wt% Mass fraction of PBT/wt% PBT 0 100 10%PBSO/PBT 10 90 20%PBSO/PBT 20 80 30%PBSO/PBT 30 70 表 2 PBSO的分子量及其分子量分布

Table 2. Molecular weight and its distribution of PBSO

Sample Mn/(104 g·mol−1) Mw/(104 g·mol−1) PDI PBSO 2.29 4.35 1.90 Notes: Mn—Number average molecular weight; Mw—Weight average molecular weight; PDI—Polydispersity index. 表 3 PBT、PBSO及PBSO/PBT力学性能数据

Table 3. Mechanical properties of PBT, PBSO and PBSO/PBT

Samples Tensile strength/MPa Elongation at break/% Fracture energy/MPa Impact strength/(kJ·m−2) PBSO 1.3 1523.4 7.86 — PBT 52.1 4.4 1.52 4.8 10%PBSO/PBT 49.0 24.6 11.62 12.7 20%PBSO/PBT 40.3 82.1 24.70 23.2 30%PBSO/PBT 28.4 110.2 25.07 24.9 表 4 PBT和PBSO/PBT的热性能和结晶度

Table 4. Thermal properties and percentage crystallinity of PBT and PBSO/PBT

Samples First cooling Second heating Tc/℃ ΔHc/(J·g−1) Tm-1/℃ Tm-2/℃ ΔHm/(J·g−1) Xc-1/% Xc-2/% PBT 194.2 52.2 215.9 225.5 50.7 35.6 44.4 10%PBSO/PBT 189.9 48.4 214.7 223.7 42.8 33.5 41.2 20%PBSO/PBT 189.2 42.9 214.8 222.8 37.1 32.7 38.8 30%PBSO/PBT 186.9 37.9 215.0 222.5 30.7 30.9 36.9 Notes: Tc—Crystallization temperature; ΔHc—Enthalpy of crystallization; Tm-1—First melting tempe rature;Tm-2—Second melting temperature;ΔHm—Melting enthalpy;Xc-1—First crystallinity;Xc-2—Second crystallinity. 表 5 PBT、PBSO及PBSO/PBT的热重分析数据

Table 5. Thermogravimetric analysis data of PBT, PBSO and PBSO/PBT

Samples T5%/℃ Tmax/℃ PBSO 367.4 435.7 PBT 396.3 429.5 10%PBSO/PBT 387.0 428.6 20%PBSO/PBT 384.0 427.9 30%PBSO/PBT 382.6 427.6 Notes: T5%—5% Decomposition temperature;Tmax—Maximum decomposition temperature. -

[1] JUN J B, PARK J G, KIM D, et al. Blends of polybutyleneterephthalate with ethylene-propylene elastomer containing isocyanate functional group[J]. European Polymer Journal,2001,37(3):597-602. doi: 10.1016/S0014-3057(00)00140-3 [2] 董丽杰, 张会轩, 杨海东, 等. EPM-g-GMA接枝率的测定及其增韧PBT的力学性能和形态结构研究[J]. 高分子学报, 2003(2):167-170. doi: 10.3321/j.issn:1000-3304.2003.02.002DONG Lijie, ZHANG Huixuan, YANG Haidong, et al. Toughening of PBT by means of blending with graft copolymer EPM-g-GMA[J]. Acta Polymerica Sinica,2003(2):167-170(in Chinese). doi: 10.3321/j.issn:1000-3304.2003.02.002 [3] SHANG M, WU Y, SHENTU B, et al. Toughening of PBT by POE/POE-g-GMA elastomer through regulating interfacial adhesion and toughening mechanism[J]. Industrial & Engineering Chemistry Research,2019,58(28):12650-12663. [4] 王瑞红, 史宗强, 曹娟娟, 等. POE及POE-g-(GMA-co-St)增韧PBT的制备与性能研究[J]. 化学与黏合, 2012, 34(2):29-32.WANG Ruihong, SHI Zongqiang, CAO Juanjuan, et al. Preparation and properties of POE and POE-g-(GMA-co-St) toughened PBT[J]. Chemistry and Adhesion,2012,34(2):29-32(in Chinese). [5] 毛泽誉, 胡瀚中, 刘岩, 等. PBT/EPDM/EPDM-g-GMA复合材料的形态与性能研究[J]. 塑料工业, 2020, 48(5):145-149. doi: 10.3969/j.issn.1005-5770.2020.05.030MAO Zeyu, HU Hanzhong, LIU Yan, et al. Study on morphology and properties of PBT/EPDM/EPDM-g-GMA blends[J]. China Plastics Industry,2020,48(5):145-149(in Chinese). doi: 10.3969/j.issn.1005-5770.2020.05.030 [6] BAXI R N, PATHAK S U, PESHWE D R. Impact modification of a PET-PBT blend using different impact modifiers[J]. Polymer Journal, 2011, 43(9): 801-808. [7] VAN DUIN M, VAN GURP M, LEEMANS L, et al. Interfacial chemistry and morphology of in-situ compatibilised PA6 and PBT based blends[J]. Macromolecular Symposia,2003,198(1):135-146. doi: 10.1002/masy.200350812 [8] 徐星驰, 张伟, 吴玉成, 等. 排插用高抗冲阻燃PC/PBT合金的制备与性能[J]. 现代塑料加工应用, 2019, 31(1):37-40.XU Xingchi, ZHANG Wei, WU Yucheng, et al. Preparation and properties of high impact and flame retardant PC/PBT alloy for power strip[J]. Modern Plastics Processing and Applications,2019,31(1):37-40(in Chinese). [9] 陆波, 李鹏, 陈立军, 等. ABS/PBT合金增韧改性研究[J]. 工程塑料应用, 2008, 36(1):24-26. doi: 10.3969/j.issn.1001-3539.2008.01.006LU Bo, LI Peng, CHEN Lijun, et al. Study on toughening of ABS/PBT alloys[J]. Engineering Plastics Application,2008,36(1):24-26(in Chinese). doi: 10.3969/j.issn.1001-3539.2008.01.006 [10] 赵彩霞, 李鑫, 范期程, 等. 聚(丁二酸丁二醇-co-二苯醚二甲酸丁二醇)酯的合成及性能[J]. 高分子材料科学与工程, 2019, 35(12):36-43.ZHAO Caixia, LI Xin, FAN Qicheng, et al. Synthesis and properties of poly(butylene succinate-co-oxybisbenzoic)[J]. Polymer Materials Science and Engineering,2019,35(12):36-43(in Chinese). [11] 蔡志远. 聚对苯二甲酸丁二醇酯(PBT)生产工艺控制的探讨[J]. 聚酯工业, 2016, 29(4):22-24. doi: 10.3969/j.issn.1008-8261.2016.04.007CAI Zhiyuan. Discussion about the production process control of PBT plant[J]. Polyester Industry,2016,29(4):22-24(in Chinese). doi: 10.3969/j.issn.1008-8261.2016.04.007 [12] 中国国家标准化管理委员会. 塑料拉伸性能的测定: GB/T 1040—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Plastics-determination of tensile properties: GB/T 1040—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [13] 中国国家标准化管理委员会. 塑料悬臂梁冲击强度的测定: GB/T 1843—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics-determination of izod impact strength: GB/T 1843—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [14] 赵彩霞, 柏祥, 王海涛, 等. 基于不同碳链长度二元酸的脂肪族聚酯的合成及性能[J]. 高分子材料科学与工程, 2018, 34(6):1-8.ZHAO Caixia, BAI Xiang, WANG Haitao, et al. Synthesis and properties of aliphatic polyesters based on dibasic acid with different carbon chain length[J]. Polymer Materials Science and Engineering,2018,34(6):1-8(in Chinese). [15] SHEN Z, LUO F, BAI H, et al. A study on mediating the crystallization behavior of PBT through intermolecular hydrogen-bonding[J]. RSC Advances,2016,6(21):17510-17518. doi: 10.1039/C5RA25438H [16] CORTÁZAR M, IRUIN J J, EGUIAZÁBAL J I. Crystallization and melting behaviour of poly(butylene terephthalate) in poly(butylene terephthalate)/polyarylate blends[J]. Polymer Bulletin,1992,29(3/4):415-422. doi: 10.1007/BF00944839 [17] YEH J T, RUNT J. Multiple melting in annealed poly(butlene terephthalate)[J]. Journal of Polymer Science Part A Polymer Chemistry,2010,27(7):1543-1550. -

下载:

下载: