Effect of nano-SiO2 particles-silane synergistic modification on mechanical properties and creep properties of basalt fiber/epoxy composites

-

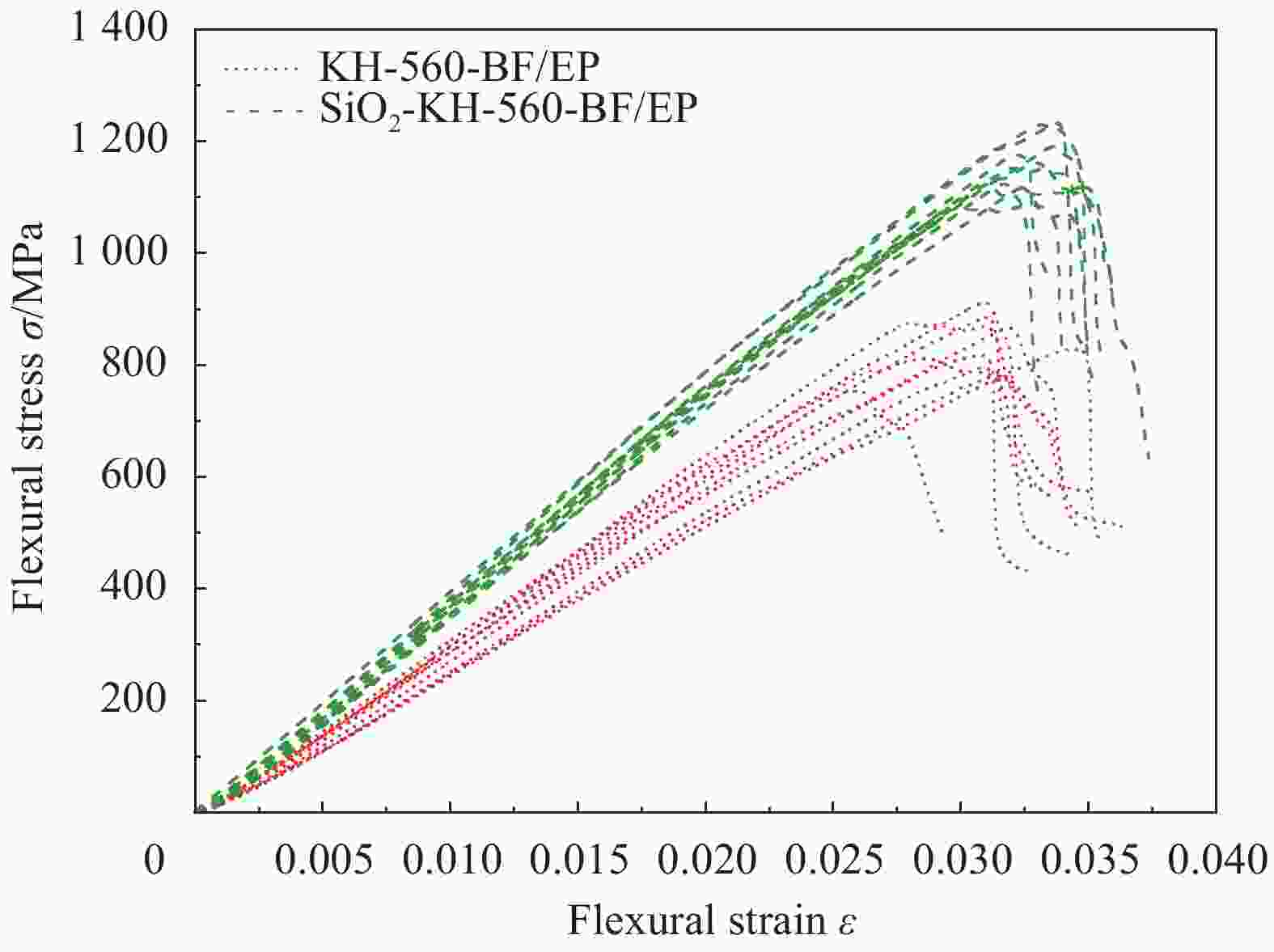

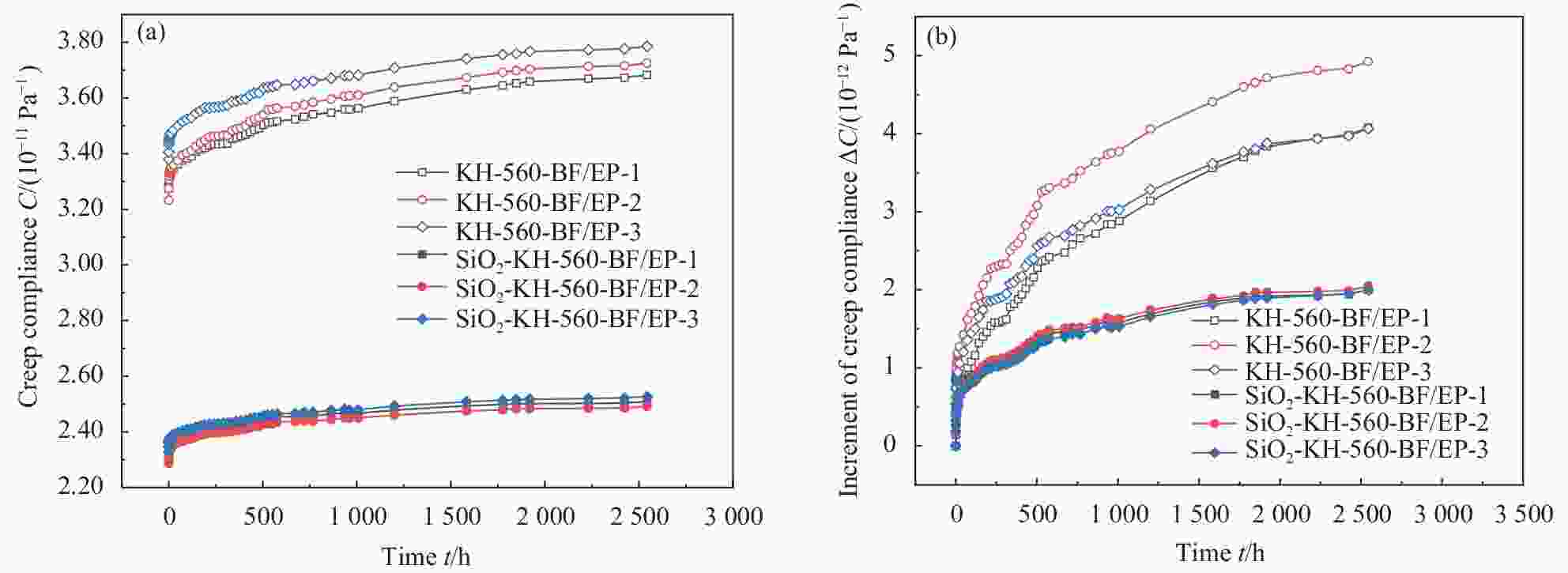

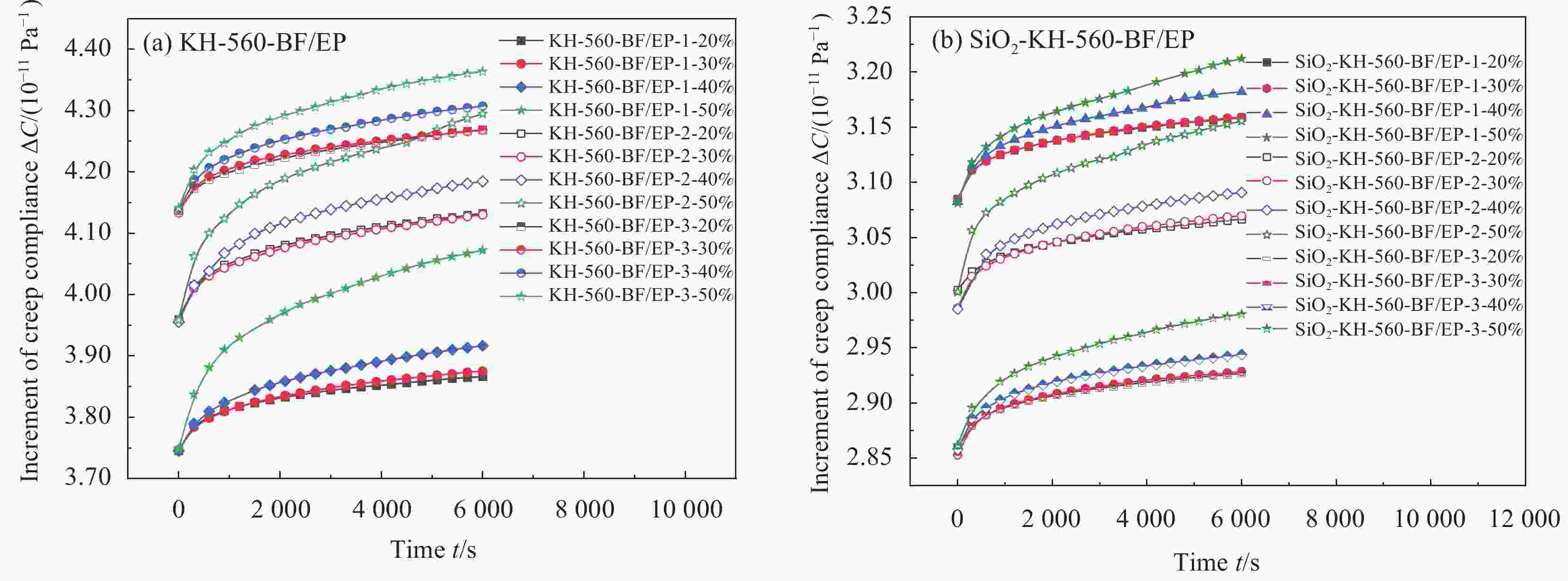

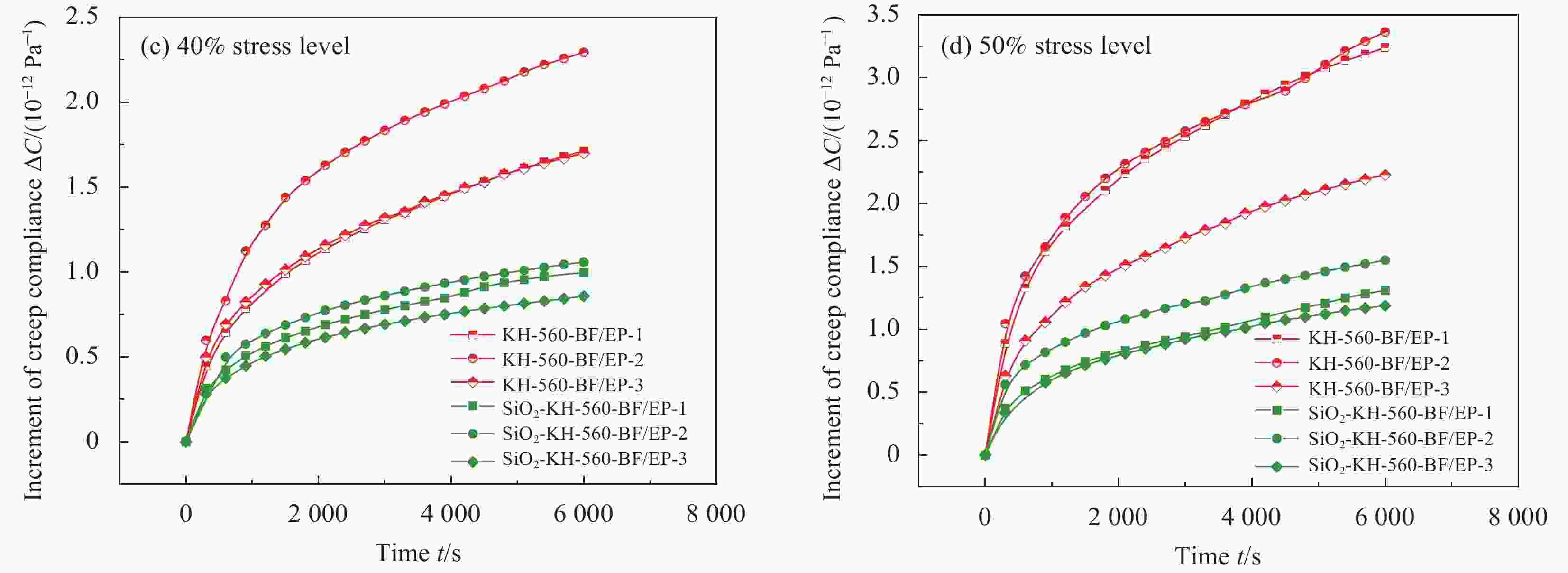

摘要: 分别采用硅烷偶联剂和纳米SiO2粒子-硅烷偶联剂对玄武岩纤维(BF)进行表面改性,通过缠绕成型工艺制备了玄武岩纤维/环氧树脂(BF/EP)复合材料。采用万能材料试验机测定了BF的拉伸性能和BF/EP复合材料的弯曲性能,借助FESEM观察了纤维表面及其复合材料弯曲断裂断口的形貌,自制三点弯曲蠕变测试装置测定了BF/EP复合材料2544 h的长期蠕变性能,采用万能材料试验机在不同应力水平下测定了BF/EP复合材料6000 s的短时蠕变性能,并分析了纤维表面改性对各项力学性能的影响。结果表明,在BF上浆剂中引入纳米SiO2粒子后,纤维的拉伸性能、BF/EP复合材料的弯曲性能均得到有效改善。FESEM形貌显示BF的协同改性提高了纤维与树脂界面的粘结性能;2544 h的低应力长期蠕变实验及6000 s的不同应力水平短时蠕变实验中,均表现出蠕变柔量及其增长速率的显著降低;在20%、30%、40%及50%初始弯曲强度加载时的短时蠕变实验中,由蠕变曲线重合的应力值,可大致得到材料线性蠕变的应力阈值。使用Hooke-Kelvin-Kelvin (HKK)模型可有效描述BF/EP复合材料在低应力水平下的长期蠕变性能,由此可进行其蠕变性能指标的长期预测。

-

关键词:

- 表面改性 /

- 纳米SiO2 /

- 玄武岩纤维/环氧树脂复合材料 /

- 蠕变 /

- 应力水平

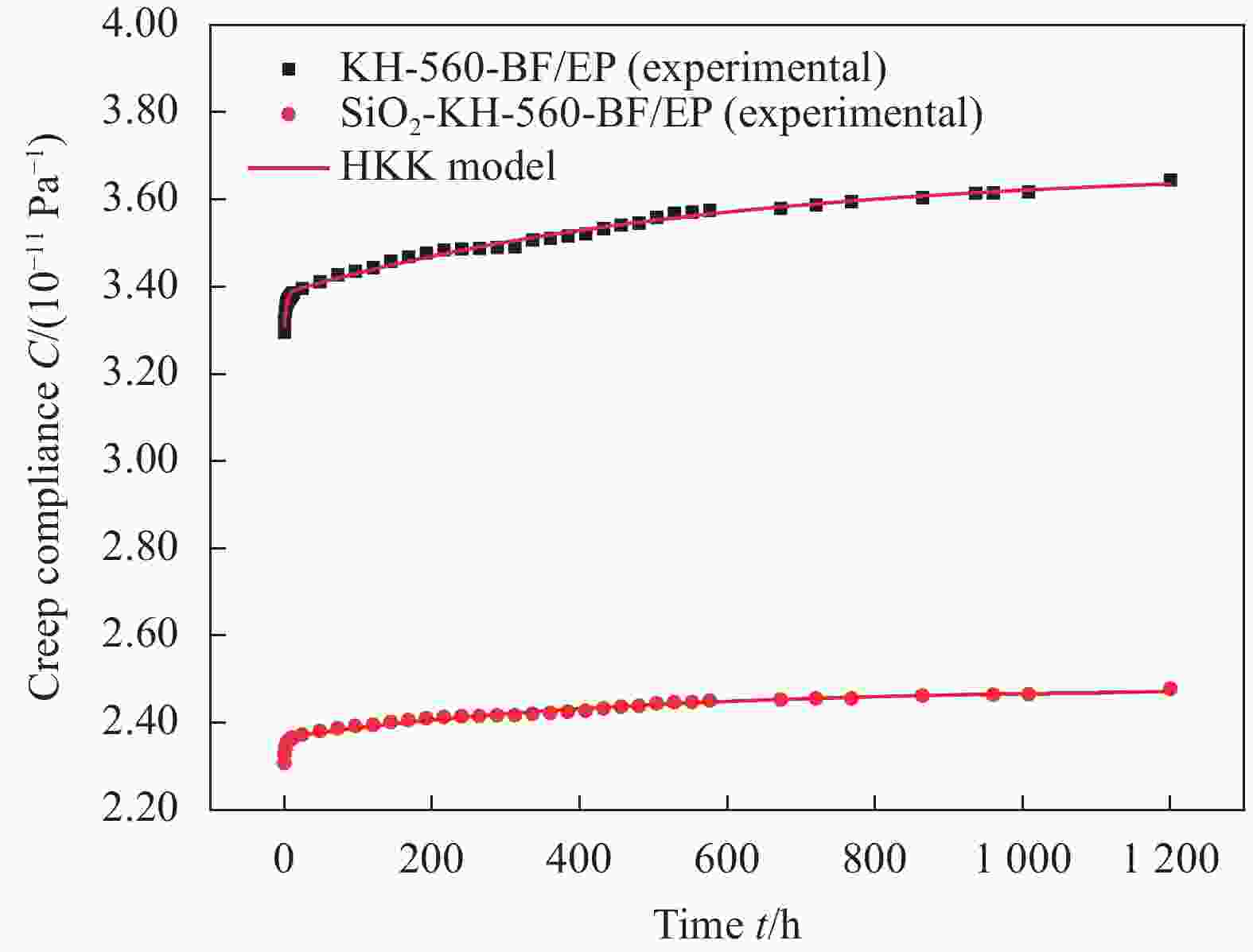

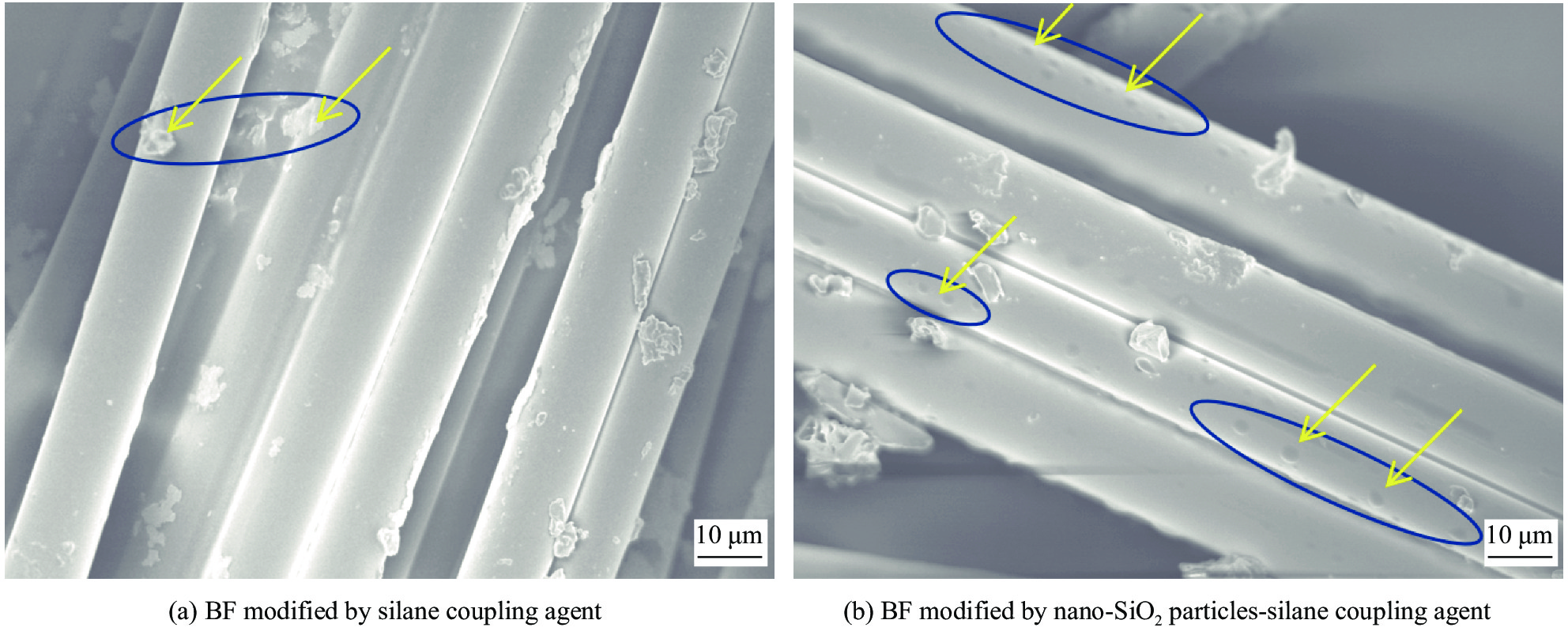

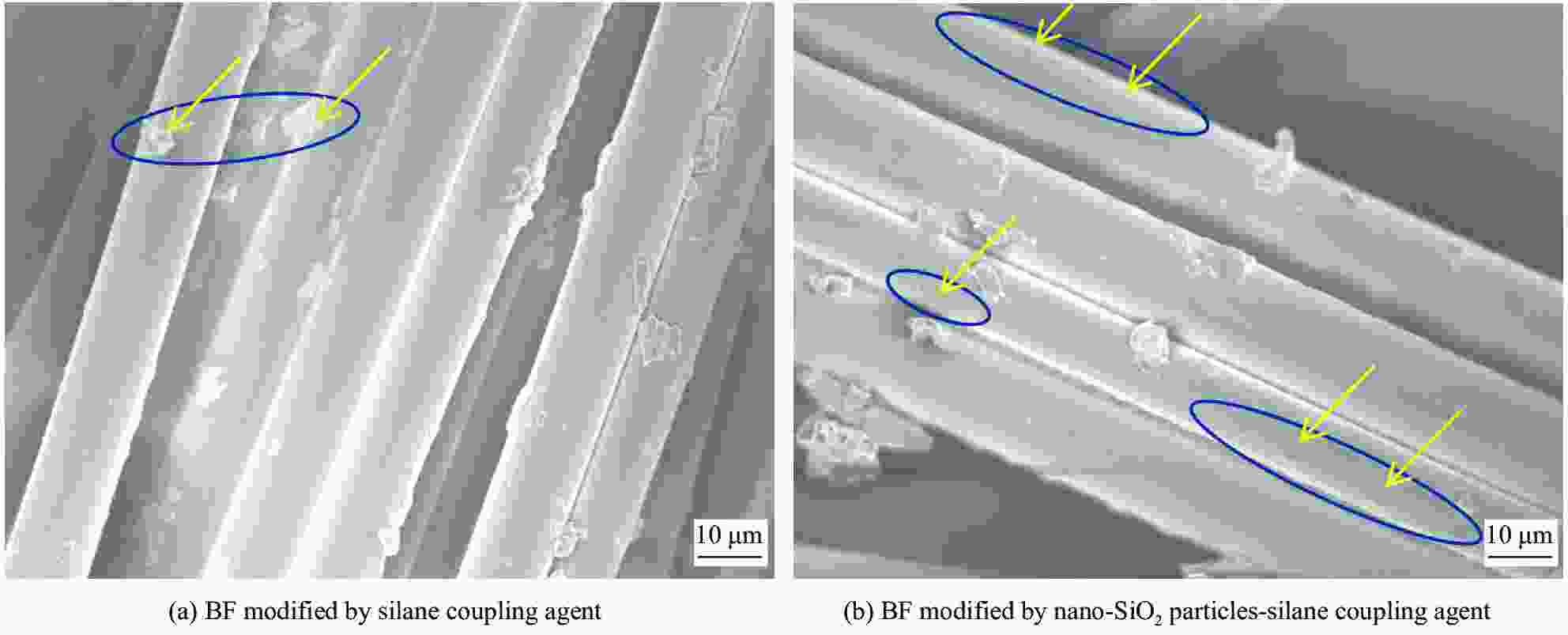

Abstract: Basalt fiber (BF) was modified by silane coupling agent and nano-SiO2 particles-silane coupling agent, respectively. And the basalt fiber/epoxy (BF/EP) composites were prepared by winding process. The tensile properties of BF and the flexural properties of BF/EP composites were tested by universal material testing machine. The morphologies of BF surface and BF/EP composites flexural fracture were observed by FESEM. The long-term (2544 h) creep behaviors of BF/EP composites were tested by self-made three-point flexural creep test device. The short-term (6000 s) creep behaviors of BF/EP composites were tested by universal material testing machine at different stress levels. And the effect of fiber surface modification on the mechanical properties was analyzed. The results show that, with the introduction of nano-SiO2 particles into BF sizing agent, the tensile properties of the fiber and the flexural properties of BF/EP are effectively improved. FESEM morphologies show that the synergistic modification of BF improves the bonding performance between the fiber and the resin. The creep compliance and its growth rate decrease significantly in the long-term creep tests with low stress for 2544 h and in the short-term creep tests with various stress levels for 6000 s. The stress threshold of linear creep of materials can be obtained from the coincidence curves of short-term creep tests at 20%, 30%, 40% and 50% stress levels. The Hooke-Kelvin-Kelvin (HKK) model can effectively describe the long-term creep performance of BF/EP composites at low stress level, so as to carry out the long-term prediction of its creep performance.-

Key words:

- surface modification /

- nano-SiO2 particles /

- basalt fiber/epoxy composites /

- creep /

- stress levels

-

表 1 纳米SiO2-硅烷偶联剂KH-560协同改性玄武岩纤维(BF)正交试验因素水平表

Table 1. Orthogonal test factor and level table of basalt fiber (BF) modified by nano-SiO2-silane coupling agent KH-560

Level Factor Nano-SiO2 dispersion (A) Lubricant (B) KH-560 (C) 1 0 0 0 2 1.5 0.4 0.5 3 5 1 1 表 2 BF丝束强度正交试验分析

Table 2. Orthogonal test analysis of BF bundle strength

Test Column 1A 2B 3C P/(N·(10−6 kg·m−1)−1) 1 1 1 1 0.49 2 1 2 2 0.59 3 1 3 3 0.60 4 2 1 2 0.63 5 2 2 3 0.64 6 2 3 1 0.61 7 3 1 3 0.57 8 3 2 1 0.59 9 3 3 2 0.62 k1 0.560 0.563 0.563 k2 0.627 0.607 0.613 k3 0.593 0.610 0.603 Range 0.067 0.047 0.050 Optimum schem A2 B3 C2 Notes: P−Tensile strength of BF bundle; ki−Average of level i. 表 3 BF及其浸胶纱的拉伸性能

Table 3. Tensile properties of BF and its resin-impregnated yarn

Sample P/(N·(10−6 kg·m−1)−1) σt/MPa Et/GPa KH-560-BF 0.57 2722.8 89.1 SiO2-KH-560-BF 0.66 2859.6 91.7 Notes: KH-560-BF—BF modified by KH-560; SiO2-KH-560-BF—BF modified by nano-SiO2 particles-KH-560; σt—Tensile strength of BF resin-impregnated yarn; Et—Tensile modulus of BF resin-impregnated yarn. 表 4 BF/EP复合材料弯曲性能

Table 4. Flexural properties of BF/EP composites

Sample σf/MPa Ef/GPa KH-560-BF/EP 837.5 26.6 SiO2-KH-560-BE/EP 1165.5 34.2 Notes: KH-560-BF/EP—BF/EP made of BF modified by KH-560; SiO2-KH-560-BF/EP—BF/EP made of BF modified by nano-SiO2 particles; σf-Flexural strength; Ef-Flexural modulus. 表 5 HKK模型拟合参数

Table 5. Fitting parameters of HKK model

Sample E0/GPa E1/GPa E2/GPa η1/(GPa·h) η2/(GPa·h) R2 KH-560-BF/EP 30.18 350.82 1381.22 200466.79 4417.78 0.99 SiO2-KH-560-BF/EP 43.11 881.41 2155.41 404318.58 5889.18 0.99 Notes: Ei—Elastic modulus of each spring model (i=0, 1, 2); ηi— Viscosity coefficient of each Kelvin model (i=1, 2); R2—Goodness of fit. 表 6 BF/EP复合材料蠕变柔量计算值与实验值对比 (2544 h)

Table 6. Comparison of calculated and experimental values of creep compliance of BF/EP composites (2544 h)

Sample Ct/(10−11 Pa−1) Cc/(10−11 Pa−1) Deviations/% KH-560-BF/EP 3.73 3.67 −1.70 SiO2-KH-560-BF/EP 2.51 2.48 −1.19 Notes: Ct—Experimental value of creep compliance; Cc—Calculated value of creep compliance. -

[1] BHAT T, FORTOMARIS D, KANDARE E, et al. Properties of thermally recycled basalt fibres and basalt fibre composites[J]. Journal of Materials Science,2018,53(3):1933-1944. doi: 10.1007/s10853-017-1672-7 [2] 叶国锐, 晏义伍, 曹海琳. 氧化石墨烯改性玄武岩纤维及其增强环氧树脂复合材料性能[J]. 复合材料学报, 2014, 31(6):1402-1408.YE G R, YAN Y W, CAO H L. Basalt fiber modified with graphene oxide and properties of its reinforced epoxy composites[J]. Acta Materiae Compositae Sinica,2014,31(6):1402-1408(in Chinese). [3] FIORE V, SCALICI T, BELLA G D, et al. A review on basalt fibre and its composites[J]. Composites Part B: Engineer-ing,2015,74:74-94. doi: 10.1016/j.compositesb.2014.12.034 [4] 靳婷婷, 申士杰, 李静, 等. 低温等离子处理对玄武岩纤维表面及复合材料性能的影响[J]. 玻璃钢/复合材料, 2015(6):29-35.JIN T T, SHEN S J, LI J, et al. Impact on the surface of basalt fiber and composite material properties of low-temperature plasma treatment[J]. Fiber Reinforced Plastics/Composites,2015(6):29-35(in Chinese). [5] 王晓东, 云斯宁, 张太宏, 等. 硅烷偶联剂表面改性玄武岩纤维增强复合材料研究进展[J]. 材料导报, 2017, 31(5):77-83. doi: 10.11896/j.issn.1005-023X.2017.05.013AdvancesWANG X D, YUN S N, ZHANG T H, et al. Advances in basalt fiber-reinforced composites modified by silane coupling agents[J]. Materials Reports,2017,31(5):77-83(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.05.013Advances [6] 张运华, 姚丽萍, 徐仕进, 等. 表面处理玄武岩纤维增强水泥基复合材料力学性能[J]. 复合材料学报, 2017, 34(5):1159-1166.ZHANG Y H, YAO L P, XU S J, et al. Mechanical properties of cement matrix composites reinforced with surface treated basalt fibers[J]. Acta Materiae Compositae Sinica,2017,34(5):1159-1166(in Chinese). [7] SEPE R, BOLLINO F, BOCCARUSSO L, et al. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites[J]. Composites Part B: Engineering,2018,133:210-217. doi: 10.1016/j.compositesb.2017.09.030 [8] BOZKURT O Y, BULUT M, ERKLIG A, et al. Axial and lateral buckling analysis of fiber reinforced S-glass/epoxy composites containing nano-clay particles[J]. Composites Part B: Engineering,2018,158:82-91. [9] RALPH C, LEMOINE P, ARCHER E, et al. Mechanical properties of short basalt fibre reinforced polypropylene and the effect of fibre sizing on adhesion[J]. Composites Part B: Engineering,2019,176:107260. doi: 10.1016/j.compositesb.2019.107260 [10] FAZELI M, FLOREZ J P, SIMAO R A. Improvement in adhesion of cellulose fibers to the thermoplastic starch matrix by plasma treatment modification[J]. Composites Part B: Engineering,2019,163:207-216. doi: 10.1016/j.compositesb.2018.11.048 [11] YAO Z Q, WANG C G, WANG Y X. In situ growth of CNTs on carbon fiber by chemical vapor deposition[C]//IOP Conference Series: Earth and Environmental Science. Bristol: IOP Publishing, 2019: 012075. [12] TAMRAKAR S, HAQUE B Z, JOHN W, et al. High rate test method for fiber-matrix interface characterization[J]. Polymer Testing,2016,52:174-183. doi: 10.1016/j.polymertesting.2016.04.016 [13] 梁娜, 朱四荣, 陈建中. 一种新的聚合物基复合材料应力松弛经验模型[J]. 复合材料学报, 2017, 34(10):2205-2210.LIANG N, ZHU S R, CHEN J Z. A new empirical model for stress relaxation of polymer matrix[J]. Acta Materiae Compositae Sinica,2017,34(10):2205-2210(in Chinese). [14] NEDJAR B. Directional damage gradient modeling of fiber/matrix debonding in viscoelastic UD composites[J]. Composite Structures,2016,153(10):895-901. [15] 袁燕, 范汶鑫, 王延相, 等. 玄武岩纤维表面生长碳纳米管及其复合材料性能的研究[J]. 材料导报, 2016, 30(S2):32-34, 40.YUAN Y, FAN W X, WANG Y X, et al. Basalt fiber with carbon nanotubes grown on its surface and the corresponding reinforced resin composite[J]. Materials Reports,2016,30(S2):32-34, 40(in Chinese). [16] YU S, OH K H, HONG S H. Enhancement of the mechanical properties of basalt fiber-reinforced polyamide 6, 6 composites by improving interfacial bonding strength through plasma-polymerization[J]. Composites Science and Technology,2019,182:107756. doi: 10.1016/j.compscitech.2019.107756 [17] JIA H, LIU C, QIAO Y, et al. Enhanced interfacial and mechanical properties of basalt fiber reinforced poly (aryl ether nitrile ketone) composites by amino-silane coupling agents[J]. Polymer,2021,230:124028. doi: 10.1016/j.polymer.2021.124028 [18] CHIMENI D Y, HIRSCHBERG V, DUBOIS C, et al. Rheological behavior of composites made from linear medium-density polyethylene and hemp fibers treated by surface-initiated catalytic polymerization[J]. Rheologica Acta,2018,57(6):445-457. [19] WANG X M, PETRU M, YU H. The effect of surface treatment on the creep behavior of flax fiber reinforced composites under hygrothermal aging conditions[J]. Construction and Building Materials,2019,208:220-227. doi: 10.1016/j.conbuildmat.2019.03.001 [20] 韩霞, 王继辉, 倪爱清, 等. 应力水平和纤维角度对CGF/PP复合材料蠕变行为的影响及其Burgers模型参数的数值预测[J]. 复合材料学报, 2019, 36(5):1216-1225.HAN X, WANG J H, NI A Q, et al. Effects of stress levels and fiber orientations on creep behavior of CGF/PP composite and numerical prediction of Burgers model parameters[J]. Acta Materiae Compositae Sinica,2019,36(5):1216-1225(in Chinese). [21] 中国国家标准化管理委员会. 玄武岩纤维无捻粗纱: GB/T 25045—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of the People’s Republic of China. Basalt fiber roving: GB/T 25045—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [22] 中国国家标准化管理委员会. 玻璃纤维无捻粗纱 浸胶纱试样的制作和拉伸强度的测定: GB/T 20310—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Textile glass-Rovings-Manufacture of test specimens and determination of tensile strength of impregnated rovings: GB/T 20310—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [23] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fibre-reinforced plastic composites-Determination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [24] The British Standards Institution. GRP tanks and vessels for use above ground-Part 3: Design and workmanship: EN 13121-3—2016[S]. London: BSI Standards Limited, 2016. [25] 应淑妮. 玄武岩纤维的性能及其增强热塑性复合材料的界面改性[D]. 上海: 华东理工大学, 2011.YING S N. Mechanical performance and interfacial modification of long basalt fiber reinforced thermal plastic composites[D]. Shanghai: East China University of Science and Technology, 2011(in Chinese). [26] 梁娜, 朱四荣, 陈建中. 聚合物基复合材料在低应力下的蠕变模型[C]//第二十一届玻璃钢/复合材料学术交流会论文集. 北京: 《玻璃钢/复合材料》编辑部, 2016: 10-13.LIANG N, ZHU S R, CHEN J Z. Creep model of polymer matrix composites under low stress[C]//The 21st Glass Fiber Reinforced Plastics/Composites Symposium. Beijing: Fiber Reinforced Plastics/Composites Editorial Office, 2016: 10-13(in Chinese). -

下载:

下载: