Energy storage performance of cubic SrTiO3 powder/polyvinylidene fluoride dielectric composite films

-

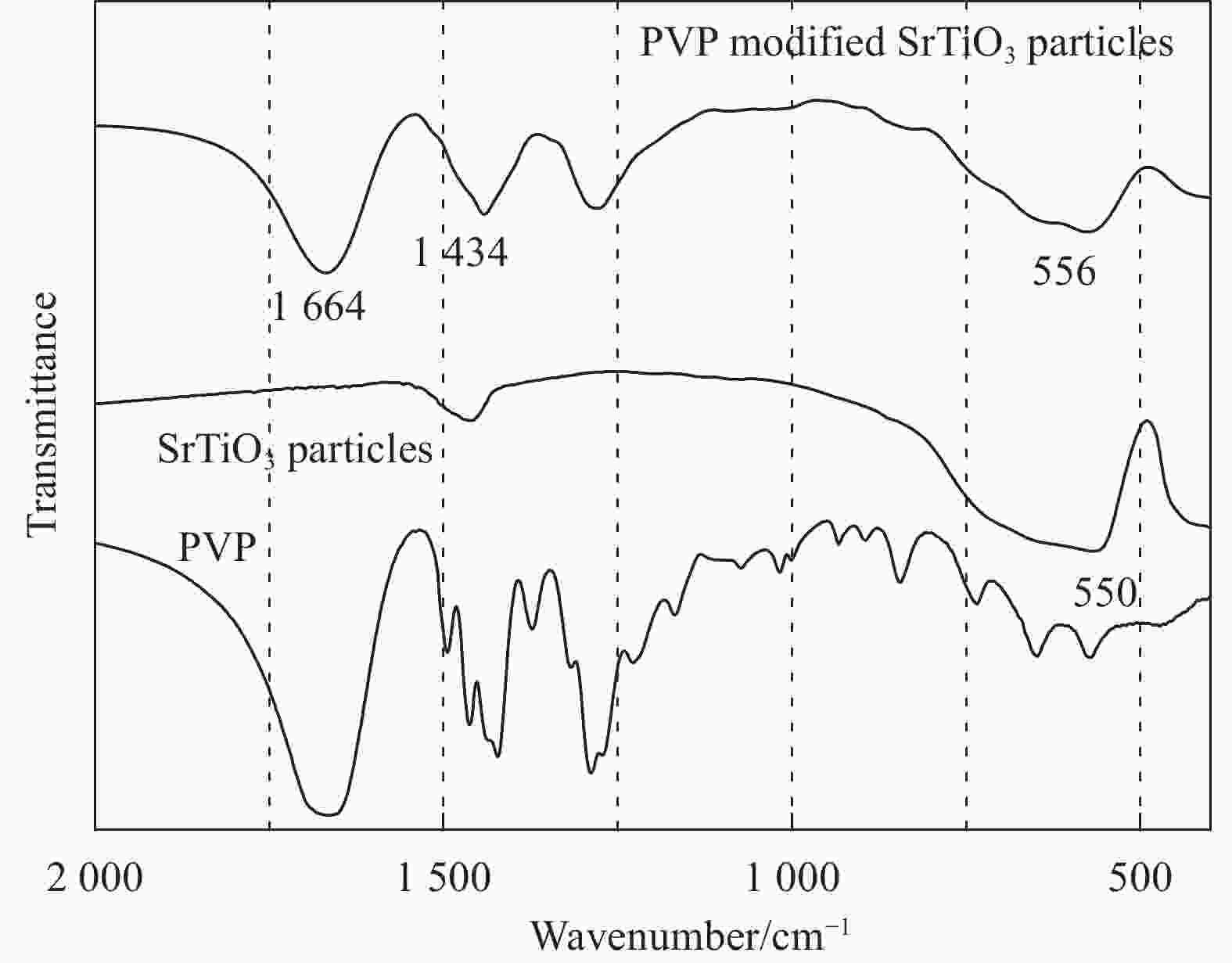

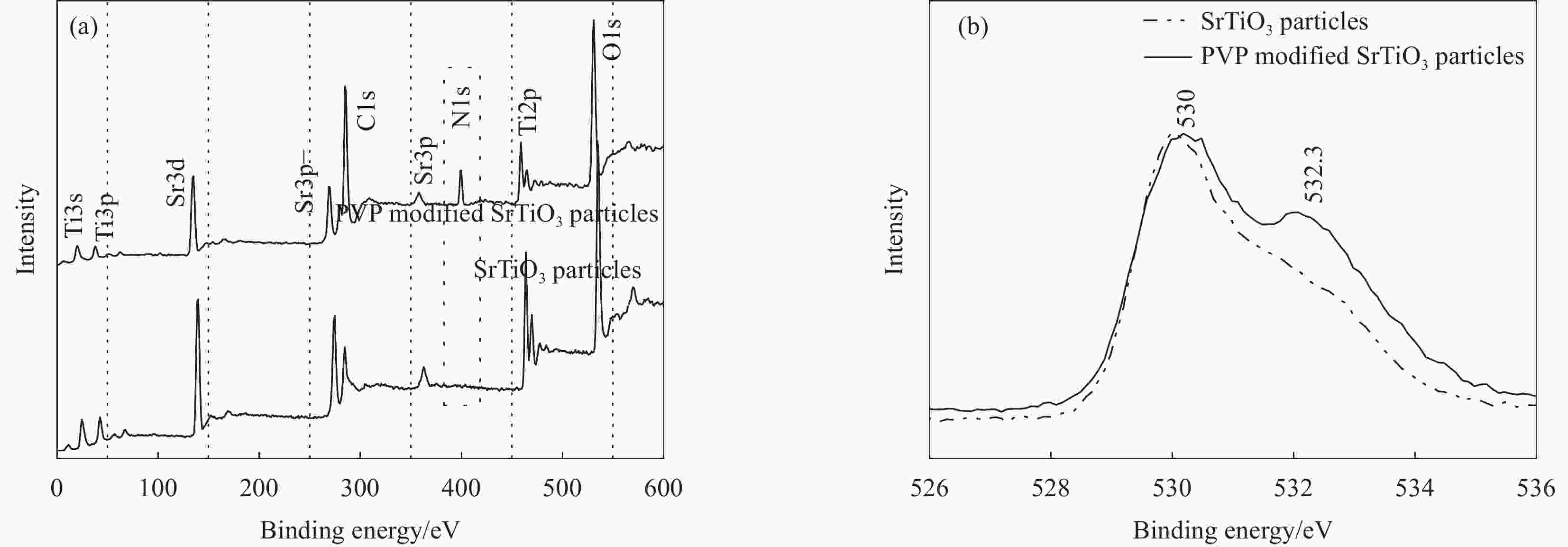

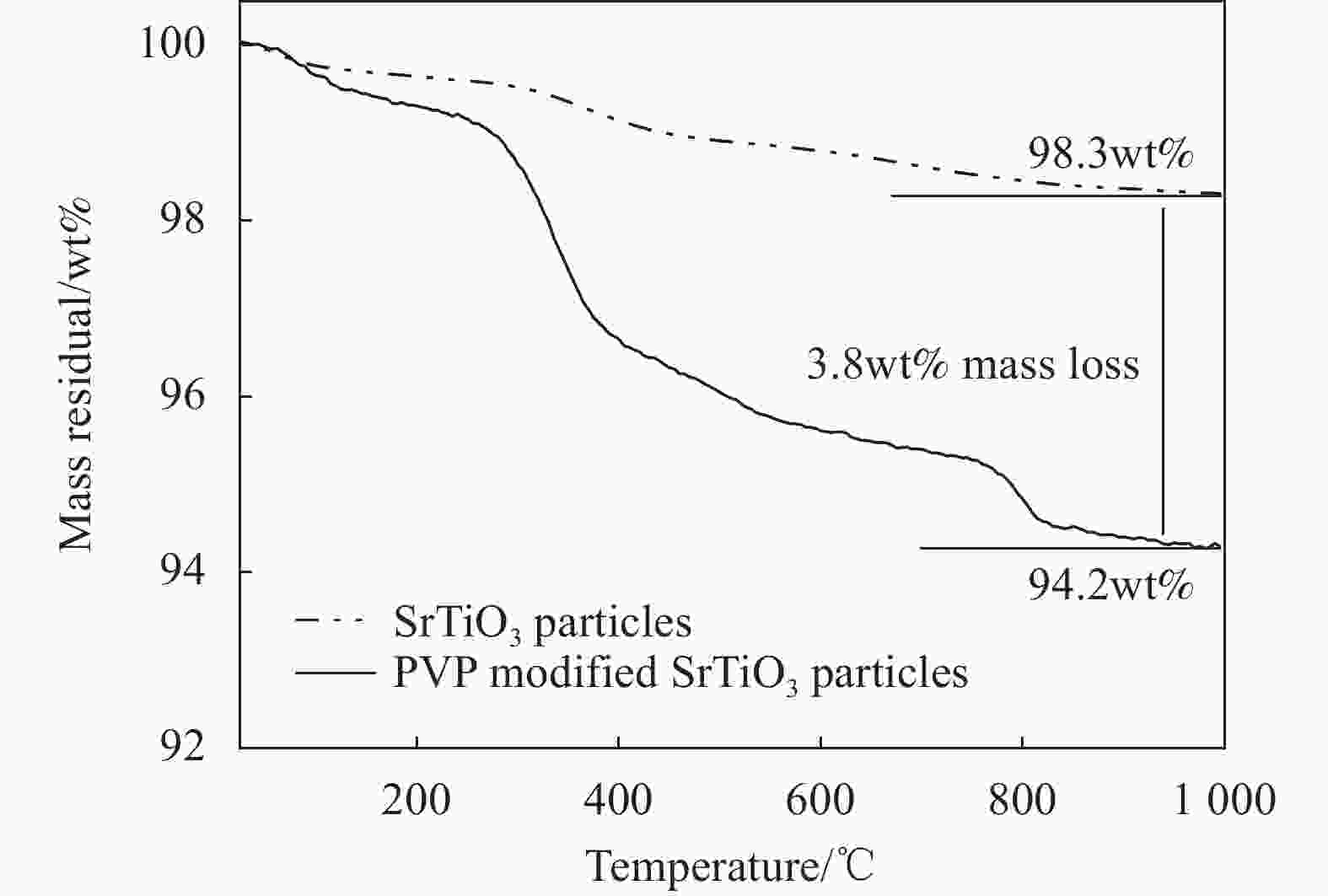

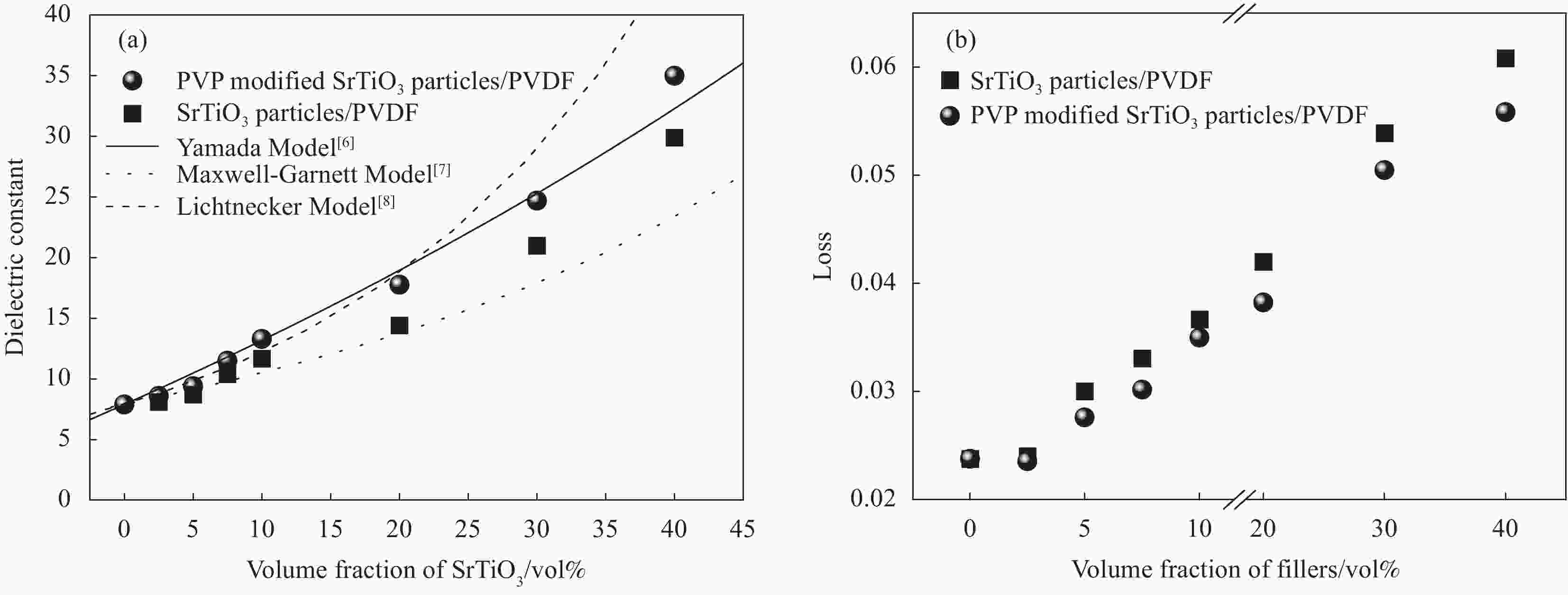

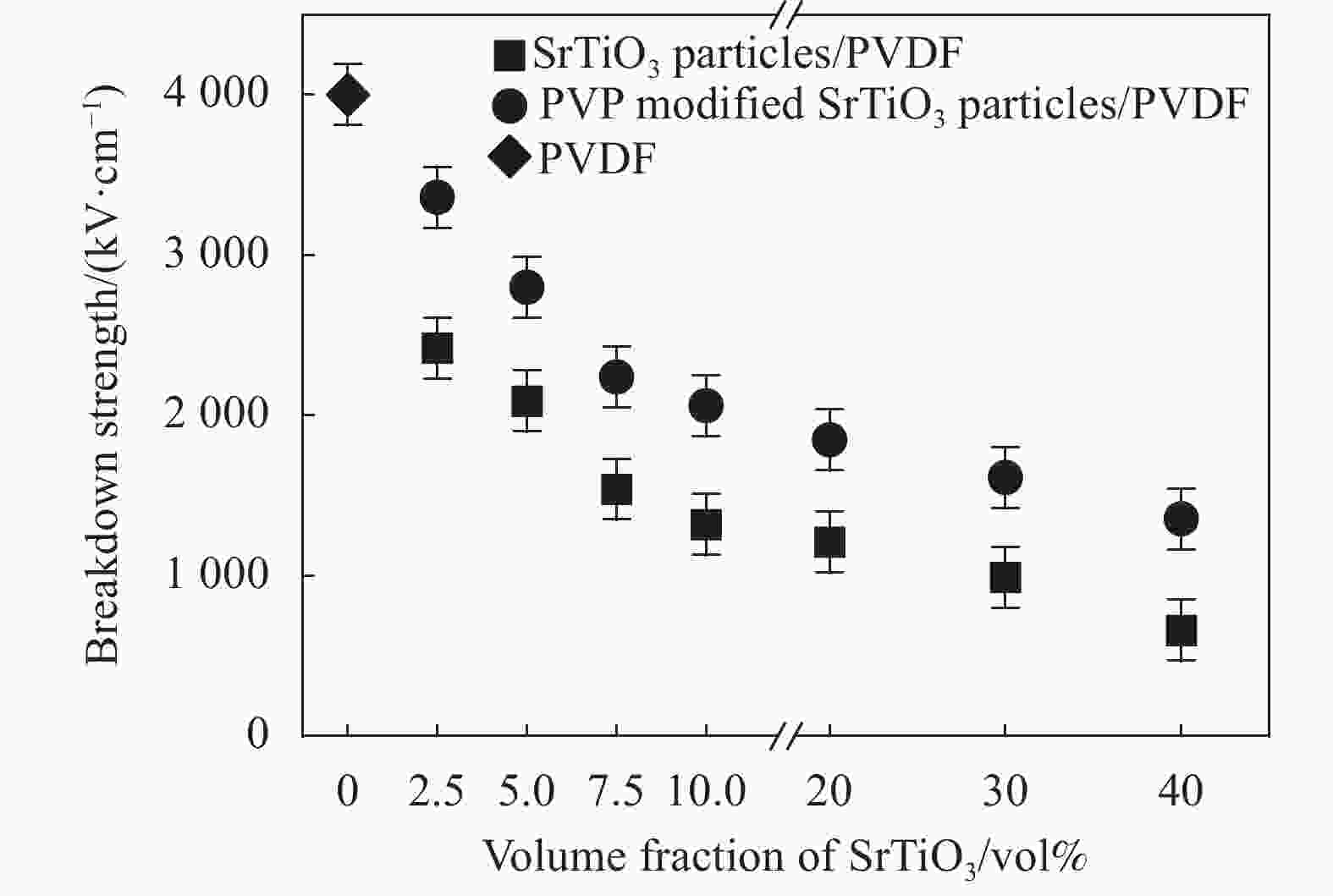

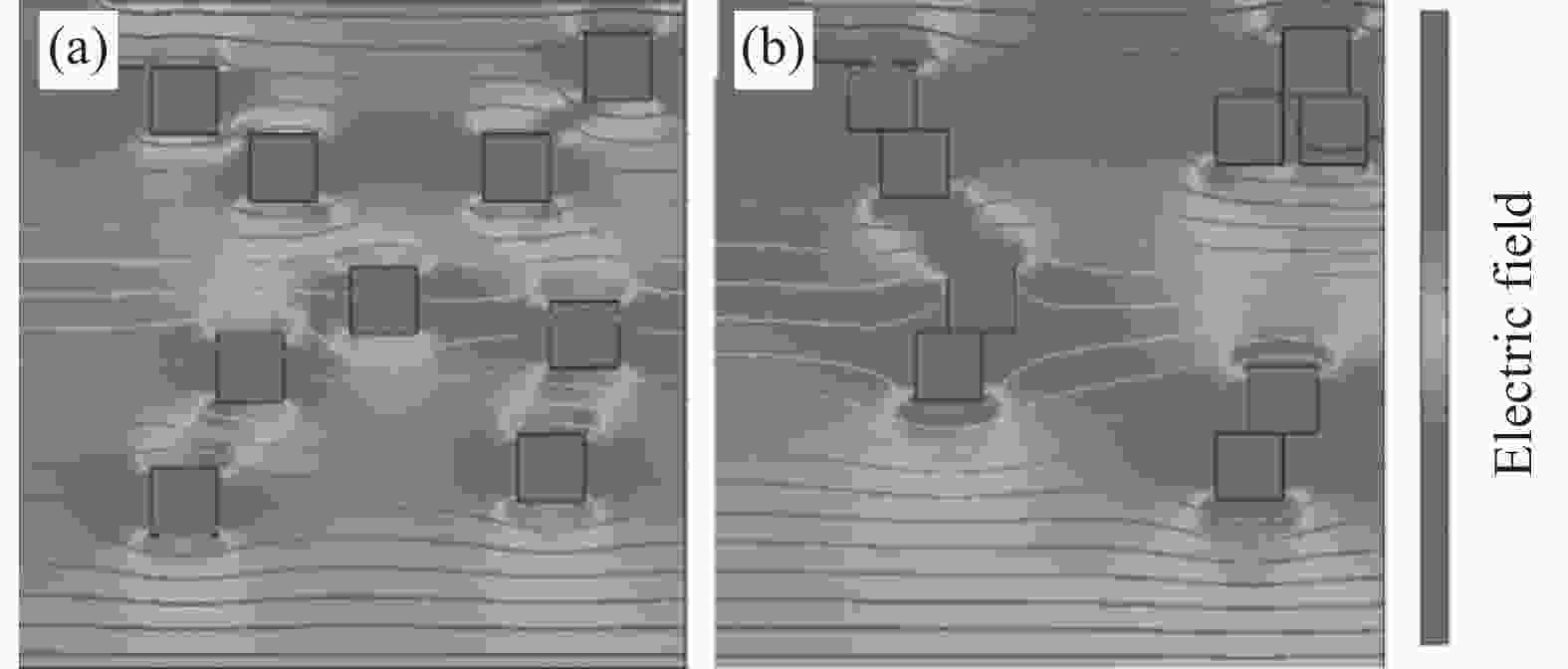

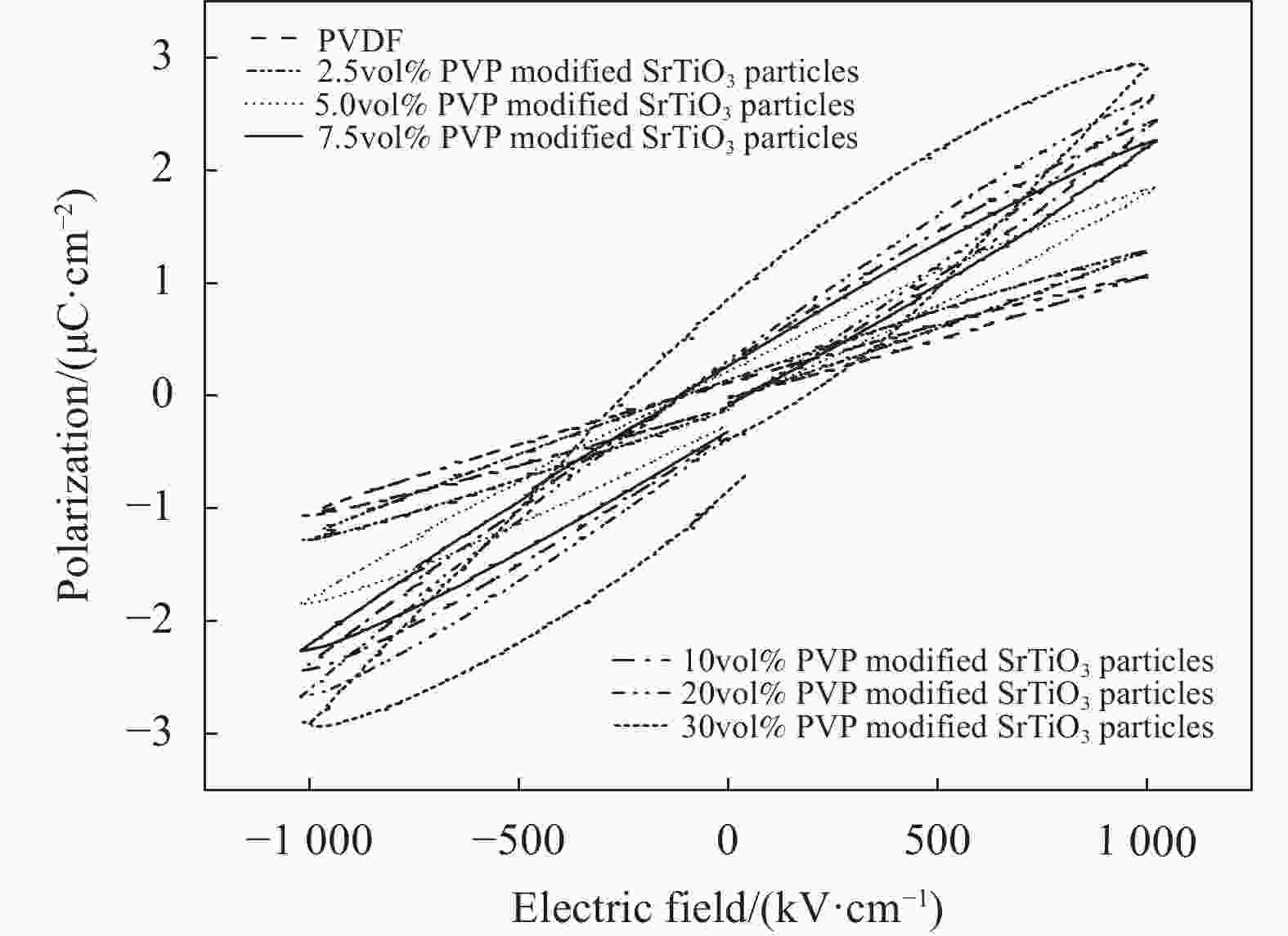

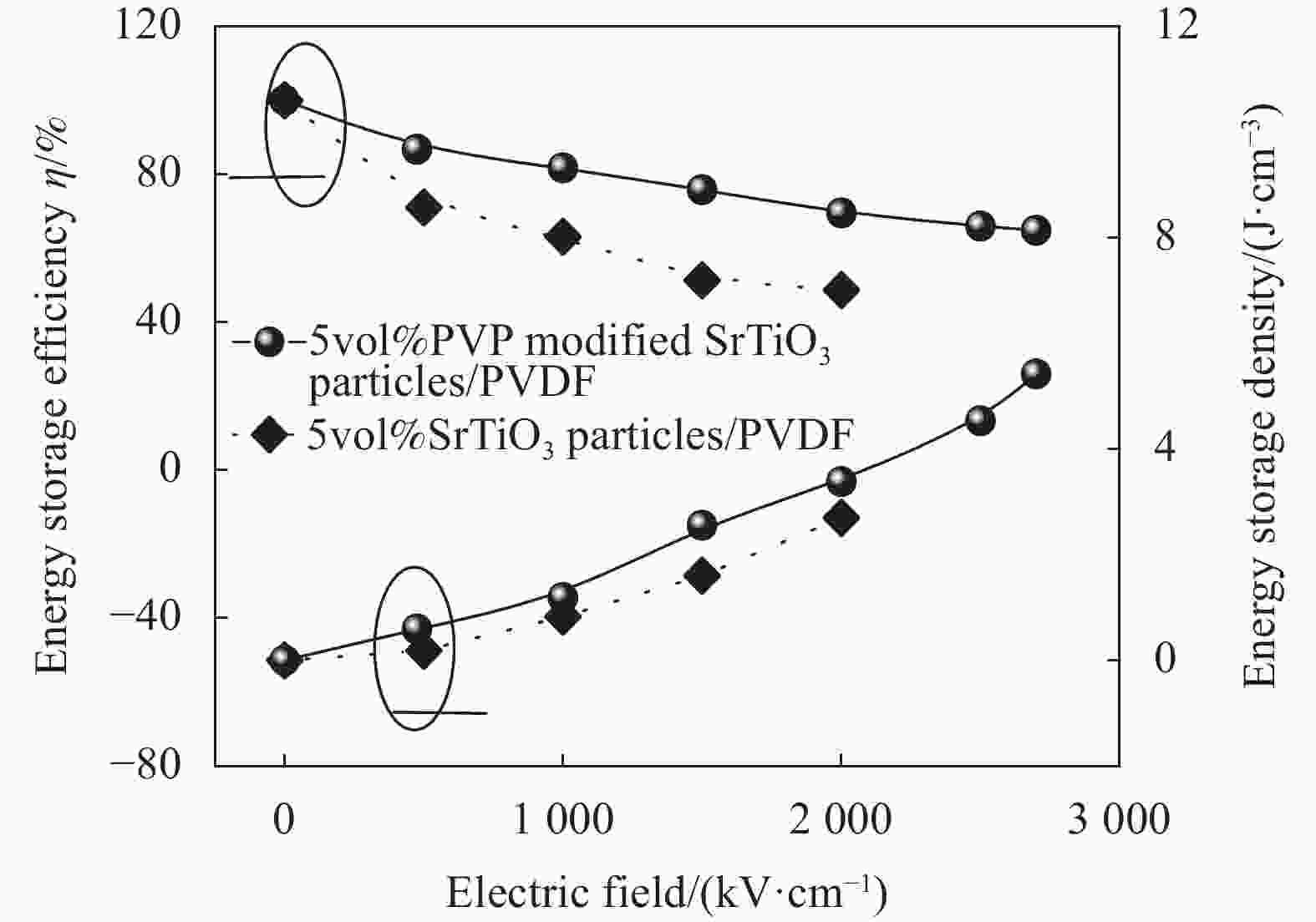

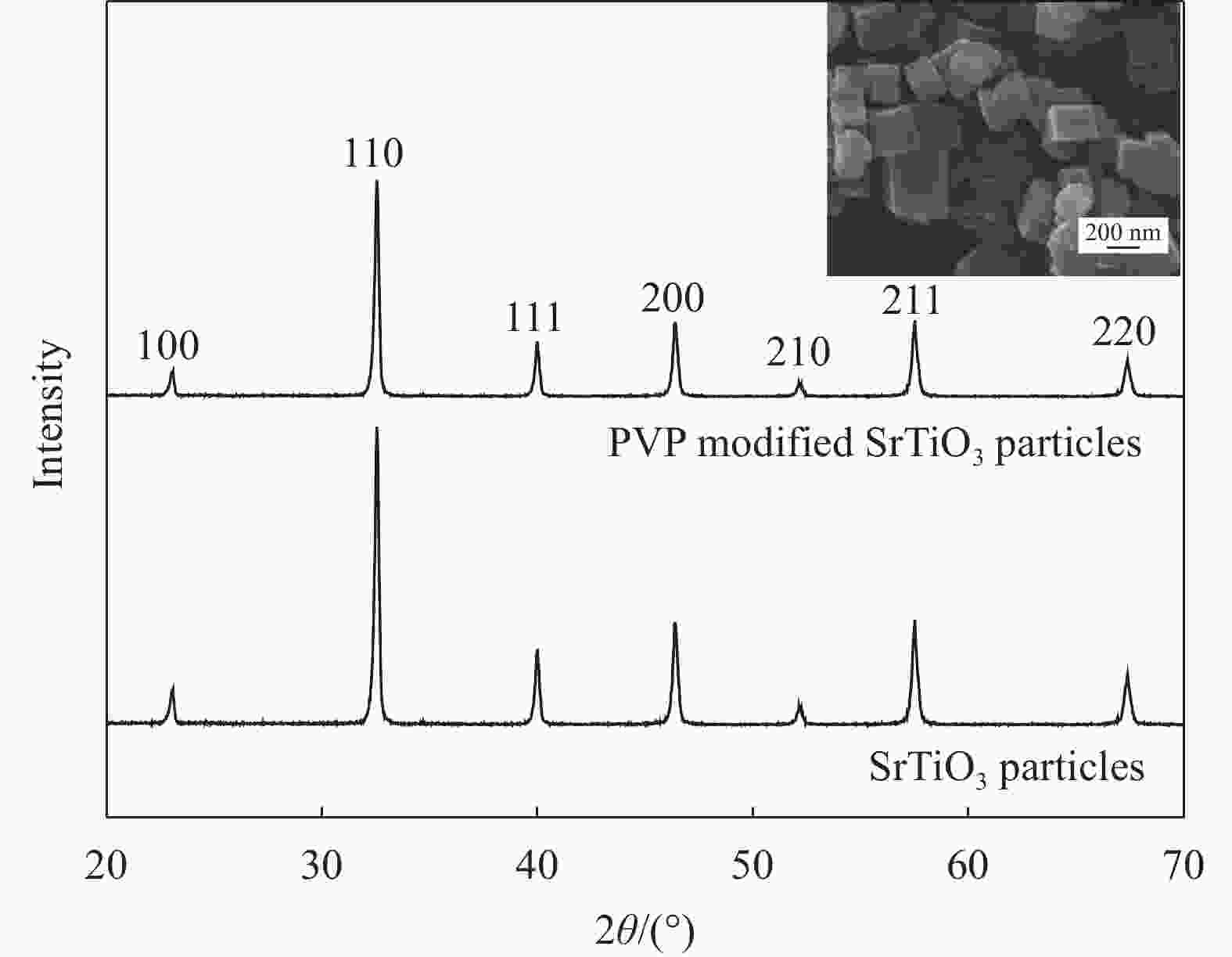

摘要: 高工作场强、高储能效率的电介质储能材料对提高电力设备的性能、减小电力设备体积具有重要影响。采用混合碱法制备出立方体状SrTiO3粉体作为陶瓷填料,采用聚乙烯吡咯烷酮(PVP)表面包覆改性对立方体状SrTiO3粉体进行表面处理,利用流延法制备出了均匀的聚偏氟乙烯(PVDF)电介质复合薄膜。系统研究了表面PVP包覆改性立方体状SrTiO3粉体对PVDF电介质复合薄膜介电性能和储能密度的影响。结果表明:混合碱法制备出的SrTiO3粉体的形貌为立方体状,尺寸为 200~400 nm,粒径分布比较均匀,PVP的官能团和立方体状SrTiO3粉体的表面建立起共价的相互作用,在立方体状SrTiO3粉体表面形成PVP包覆层,可以有效防止立方体状SrTiO3粉体在PVDF电介质复合薄膜中的团聚,同时PVP包覆层可以改善立方体状SrTiO3粉体在PVDF聚合物中分散和结合情况。PVDF电介质复合薄膜具有良好的介电性能和耐击穿性能,PVDF电介质复合薄膜的介电常数随着填充量的增加而增加,当立方体状SrTiO3粉体填充量为40vol%时,电介质复合薄膜的介电常数为34.9。PVDF电介质复合薄膜的储能密度随着填充量的增加而先增加后降低,当表面PVP包覆改性处理立方体状SrTiO3粉体的填充量为5vol%时,电介质复合薄膜的储能密度达5.3 J/cm3。Abstract: Dielectric energy storage materials with high working field strength and high energy storage efficiency have an important impact on improving the performance of power equipment and reducing the volume of power equipment. The cubic SrTiO3 powder was prepared as ceramic filler by the mixed alkali method, and the surface of the cubic SrTiO3 particles was treated by polyvinylpyrrolidone (PVP) surface modification. The uniform polyvinylidene fluoride (PVDF) flexibility composite was prepared by the casting method. The effect of surface PVP modified cubic SrTiO3 filler on the dielectric properties and energy storage density of PVDF dielectric composites was systematically studied. The results show that the morphology of the SrTiO3 powder is cubic and the size is 200-400 nm. The particle size distribution is relatively uniform. The PVP coating layer formed on the surface of the cubic SrTiO3 filler can effectively prevent the agglomeration of the cubic SrTiO3 filler in the PVDF composites. At the same time, the PVP coating layer can improve the dispersion and bonding of the cubic SrTiO3 filler in the PVDF polymer. PVDF dielectric composite has excellent dielectric properties and breakdown strength. The dielectric constant of PVDF composites increases with the increase of the filling amount. When the filling amount of cubic SrTiO3 filler is 40vol%, the dielectric constant of the composite is 34.9. The energy storage density of PVDF dielectric composite increases first and then decreases with the increase of the filling volume. When the filling volume of the cubic SrTiO3 filler modified by the surface PVP is 5vol%, the energy storage density of the composite reaches 5.3 J/cm3.

-

图 6 填充量为5vol%时聚偏氟乙烯(PVDF)电介质复合薄膜的SEM图像:(a) 未表面改性SrTiO3粉体/PVDF电介质复合薄膜;(b) PVP表面包覆改性SrTiO3粉体/PVDF电介质复合薄膜;(c) PVDF电介质复合薄膜

Figure 6. SEM images of polyvinylidene fluoride (PVDF) dielectric composite films at a concentration of 5vol%: (a) Unmodified SrTiO3 powder/PVDF composite films; (b) PVP surface modified SrTiO3 powder/PVDF dielectric composite films; (c) PVDF dielectric composite films

图 7 (a)不同填充量PVP表面包覆改性SrTiO3粉体/PVDF电介质复合薄膜与未表面改性SrTiO3粉体/PVDF电介质复合薄膜的介电常数对比图;(b)两种PVDF电介质复合薄膜的介电损耗对比图

Figure 7. (a) Comparison of dielectric constants of PVP surface modified SrTiO3 powder/PVDF composite films and unmodified SrTiO3 powder/PVDF composite films with different filling amounts of fillers; (b) Comparison of dielectric loss of the PVDF composites films is shown in the inset

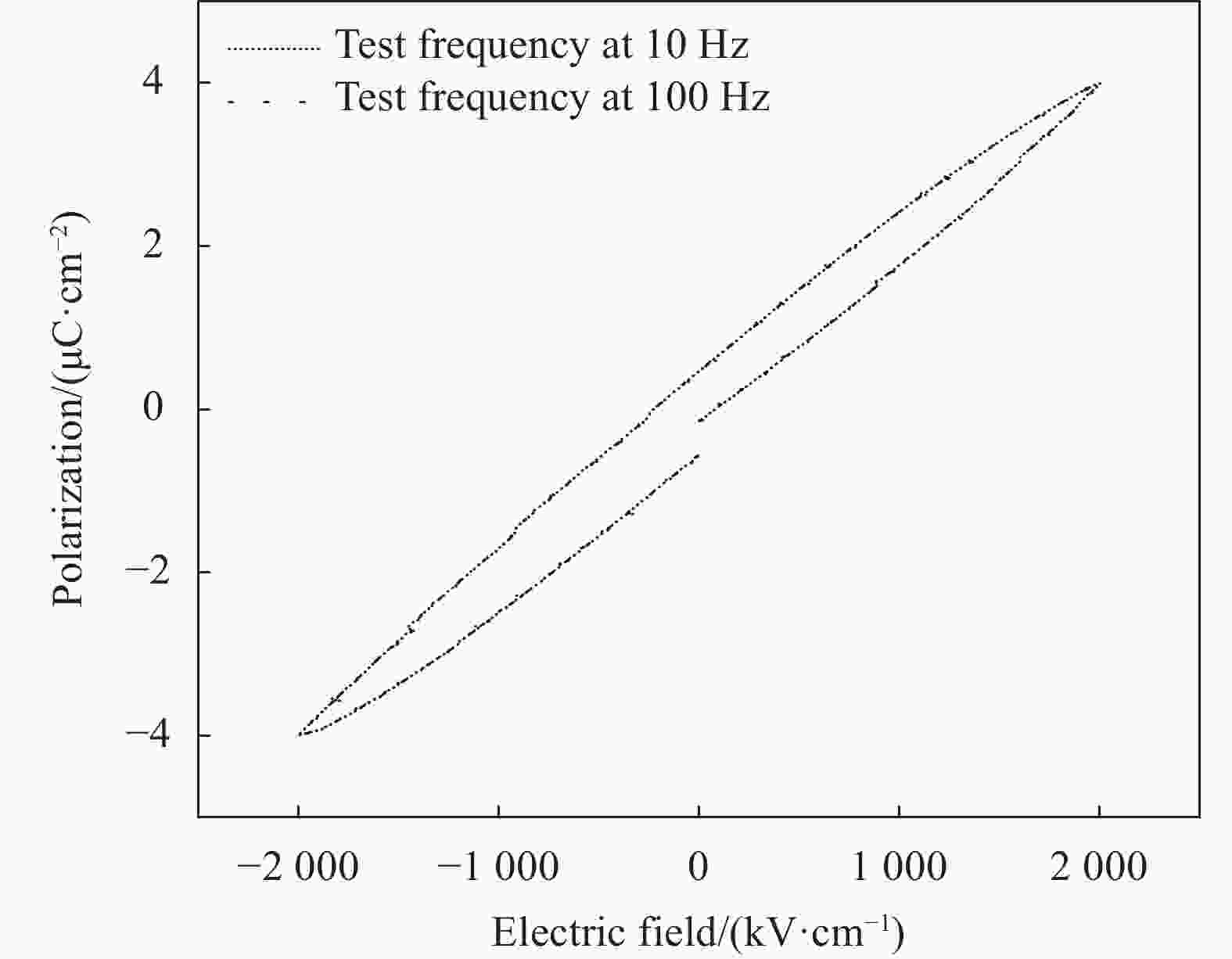

图 12 (a) 不同组分PVDF电解质薄膜最大击穿电场下的P-E曲线图;(b) PVDF和不同填充浓度表面包覆改性SrTiO3粉体/PVDF电介质复合薄膜的储能密度变化曲线

Figure 12. (a) P-E curves of PVDF composites films with different filling concentrations under maximum breakdown field; (b) Energy storage density for PVDF and PVDF composites films with different filling amounts of surface-coated with modified SrTiO3 powder

表 1 前期文献报道钛酸锶钡陶瓷/PVDF复合材料的储能密度与本文实验结果对比

Table 1. Comparison of the energy storage density of PVDF-based composites and the experimental results in this work

Material Surface modification

methodEnergy storage density/

(J·cm–3)Ref. BaTiO3/Poly(vinylidene fluoride-hexafluoropropylene) films Aminomethyl phosphonic acid 3.20 [24] SrTiO3/PVDF films — 3.54 [25] BaTiO3/Poly(vinylidene fluoride-hexafluoropropylene) composite films — 4.89 [26] SrTiO3/PVDF films Polyvinylpyrrolidone 5.30 This work -

[1] DING Y C, WU Q, ZHAO D, et al. Flexible PI/BaTiO3 dielectric nanocomposite fabricated by combining electrospinning and electrospraying[J]. European Polymer Journal,2013,49(9):2567-2571. doi: 10.1016/j.eurpolymj.2013.05.016 [2] HAYASHIDA K, MATSUOKA Y. Highly enhanced dielectric constants of barium titanate-filled polymer composites using polymer-grafted carbon nanotube matrix[J]. Carbon,2013,60:506-513. doi: 10.1016/j.carbon.2013.04.072 [3] WANG Y, ZHOU X, CHEN Q, et al. Recent development of high energy density polymers for dielectric capacitors[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2010,17(4):1036-1042. doi: 10.1109/TDEI.2010.5539672 [4] WEI J, JIANG D, YU W, et al. The effect of Hf doping on the dielectric and energy storage performance of barium titanate based glass ceramics[J]. Ceramics International,2021,47(8):11581-11586. doi: 10.1016/j.ceramint.2020.12.290 [5] XING J, LIU L, SHANG F, et al. Preparation, structure and temperature dependence of spectral properties of Yb3+/Er3+ doped Sr5(PO4)3F transparent glass ceramics[J]. Journal of Alloys and Compounds, 2021, 884: 161018. [6] LIU J, LI M, ZHAO Y, et al. Manipulating H-bonds in glassy dipolar polymers as a new strategy for high energy storage capacitors with high pulse discharge efficiency[J]. Journal of Materials Chemistry A,2019,7(33):19407. doi: 10.1039/C9TA05855A [7] DUN C, KUANG W, KEMPF N, et al. 3D printing of solution-processable 2D nanoplates and 1D nanorods for flexible thermoelectrics with ultrahigh power factor at low-medium temperatures[J]. Advanced Science,2019,6(23):1901788. doi: 10.1002/advs.201901788 [8] GUO F, SHEN X, ZHOU J, et al. Highly thermally conductive dielectric nanocomposites with synergistic alignments of graphene and boron nitride nanosheets[J]. Advanced Functional Materials,2020,30(19):1910826. doi: 10.1002/adfm.201910826 [9] CUI S, CHEN G. Enhanced up-conversion luminescence and optical thermometry characteristics of Er3+/Yb3+ co-doped Sr10(PO4)6O transparent glass-ceramics[J]. Journal of the American Ceramic Society,2020,103(12):6932-6940. doi: 10.1111/jace.17418 [10] LUO S, YU J, YU S, et al. Significantly enhanced electrostatic energy storage performance of flexible polymer composites by introducing highly insulating-ferroelectric microhybrids as fillers[J]. Advanced Energy Materials,2019,9(5):1803204. doi: 10.1002/aenm.201803204 [11] TANG H X, SODANO H A. Ultra high energy density nanocomposite capacitors with fast discharge using Ba0.2Sr0.8TiO3 nanowires[J]. Nano Letters,2013,13(4):1373-1379. doi: 10.1021/nl3037273 [12] TANG H X, LIN Y R, ANDREWS C, et al. Nanocomposites with increased energy density through high aspect ratio PZT nanowires[J]. Nanotechnology,2011,22(1):015702. doi: 10.1088/0957-4484/22/1/015702 [13] ZHOU Z, LIN Y R, TANG H X, et al. Hydrothermal growth of highly textured BaTiO3 films composed of nanowires[J]. Nanotechnology,2013,24(9):095602. doi: 10.1088/0957-4484/24/9/095602 [14] FENG Y, LI W, WANG J, et al. Core-shell structured BaTiO3@carbon hybrid particles for polymer composites with enhanced dielectric performance[J]. Journal of Materials Chemistry A,2015,3(40):20313-20321. doi: 10.1039/C5TA04777C [15] FENG Y, LI W, HOU Y, et al. Enhanced dielectric properties of PVDF-HFP/BaTiO3-nanowire composites induced by interfacial polarization and wire-shape[J]. Journal of Materials Chemistry C,2015,3(6):1250-1260. doi: 10.1039/C4TC02183E [16] HOU Y, DENG Y, WANG Y, et al. Uniform distribution of low content BaTiO3 nanoparticles in poly(vinylidene fluoride) nanocomposite: Toward high dielectric breakdown strength and energy storage density[J]. RSC Advances,2015,5(88):72090-72098. doi: 10.1039/C5RA10438F [17] JIA Q, HUANG X, WANG G, et al. MoS2 nanosheet superstructures based polymer composites for high dielectric and electrical energy storage applications[J]. The Journal of Physical Chemistry C,2016,120(19):10206-10214. doi: 10.1021/acs.jpcc.6b02968 [18] FANG L, WU W, HUANG X, et al. Hydrangea-like zinc oxide superstructures for ferroelectric polymer composites with high thermal conductivity and high dielectric constant[J]. Composites Science and Technology,2015,107:67-74. doi: 10.1016/j.compscitech.2014.12.009 [19] YANG K, HUANG X Y, ZHU M, et al. Combining RAFT polymerization and thiol-ene click reaction for core-shell structured polymer@BaTiO3 nanodielectrics with high dielectric constant, low dielectric loss, and high energy storage capability[J]. ACS Applied Materials & Interfaces,2014,6(3):1812-1822. [20] ZHA J W, DANG Z M, YANG T, et al. Advanced dielectric properties of BaTiO3/polyvinylidene-fluoride nanocompo-sites with sandwich multi-layer structure[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2012,19(4):1312-1317. doi: 10.1109/TDEI.2012.6260006 [21] YAO S H, YUAN J K, ZHOU T, et al. Stretch-modulated carbon nanotube alignment in ferroelectric polymer compo-sites: Characterization of the orientation state and its influence on the dielectric properties[J]. Journal of Physical Chemistry C,2011,115(40):20011-20017. doi: 10.1021/jp205444x [22] 钟少龙, 郑明胜, 邢照亮, 等. 无机颗粒形状对高储能密度有机复合材料介电性能的影响[J]. 复合材料学报, 2020, 37(11):2760-2768. doi: 10.13801/j.cnki.fhclxb.20200728.001ZHONG Shaolong, ZHENG Mingsheng, XING Zhaoliang, et al. Effect of shape of inorganic particles on dielectric pro-perties of polymer composites with high energy density[J]. Acta Materiae Compositae Sinica,2020,37(11):2760-2768(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200728.001 [23] 张慧, 衡婷婷, 房正刚, 等. 高储能陶瓷/聚偏氟乙烯复合电介质的研究进展[J]. 复合材料学报, 2021, 38(7):2107-2122. doi: 10.13801/j.cnki.fhclxb.20201030.002ZHANG Hui, HENG Tingting, FANG Zhenggang, et al. Research progress of high-energy-density ceramic/poly(vinylidene fluoride) composite dielectrics[J]. Acta Materiae Compositae Sinica,2021,38(7):2107-2122(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201030.002 [24] KIM P, DOSS N M, TILLOTSON J P, et al. High energy density nanocomposites based on surface-modified BaTiO3 and a ferroelectric polymer[J]. ACS Nano,2009,3(9):2581-2592. doi: 10.1021/nn9006412 [25] YU K, WANG H, ZHOU Y C, et al. Enhanced dielectric pro-perties of BaTiO3/poly(vinylidene fluoride) nanocompo-sites for energy storage applications[J]. Journal of Applied Physics,2013,113(3):034105. doi: 10.1063/1.4776740 [26] 王璐, 孔文杰, 罗行, 等. BaTiO3纳米线的制备及其复合物介电和储能性能研究[J]. 无机材料学报, 2018, 33(10):1059-1064. doi: 10.15541/jim20180041WANG Lu, KONG Wenjie, LUO Hang, et al. Dielectric and energy storage property of dielectric nanocomposites with BaTiO3 nanofibers[J]. Journal of Inorganic Materials,2018,33(10):1059-1064(in Chinese). doi: 10.15541/jim20180041 -

下载:

下载: