Progress in intrinsically thermal conductive liquid crystalline epoxy and composites

-

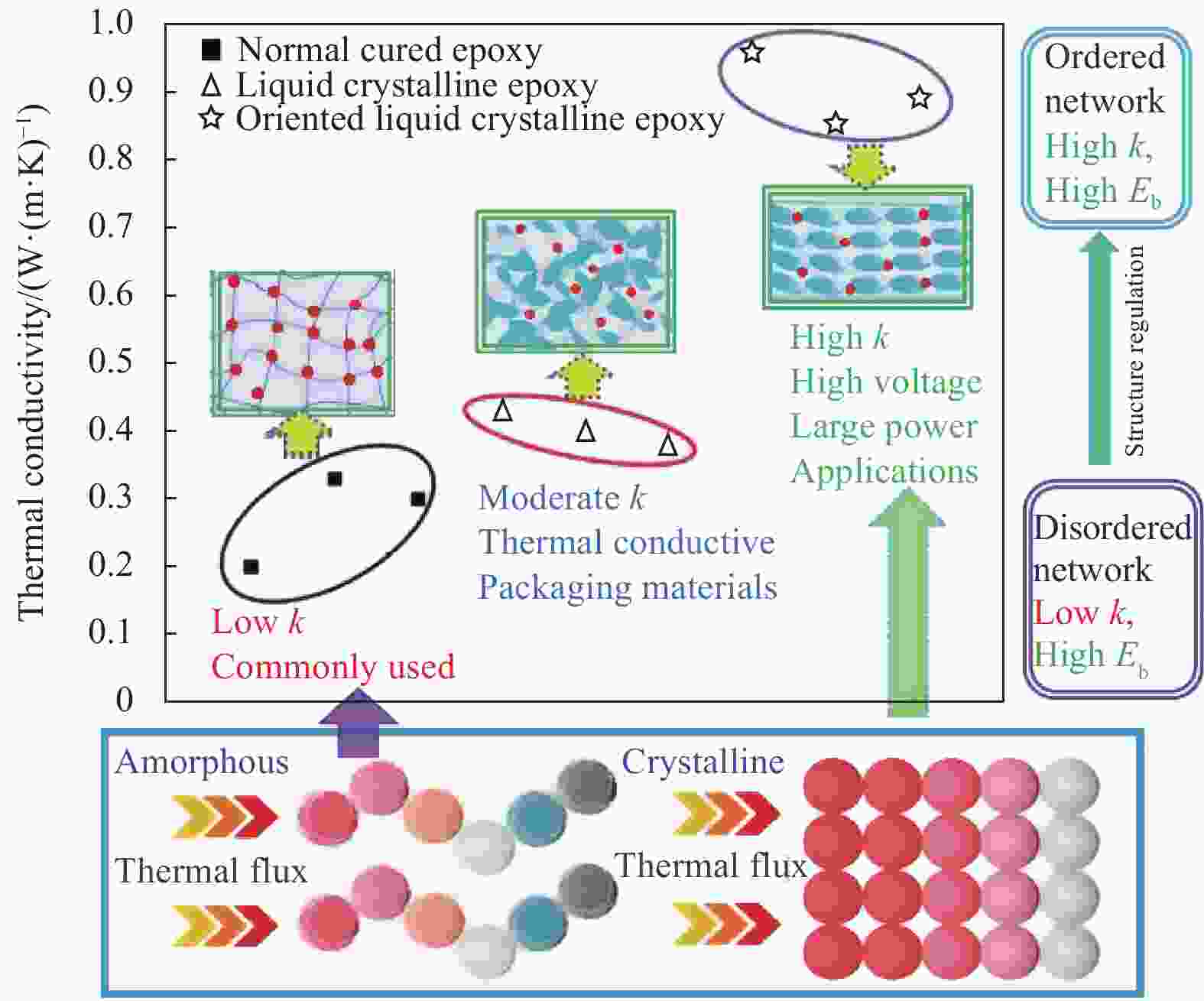

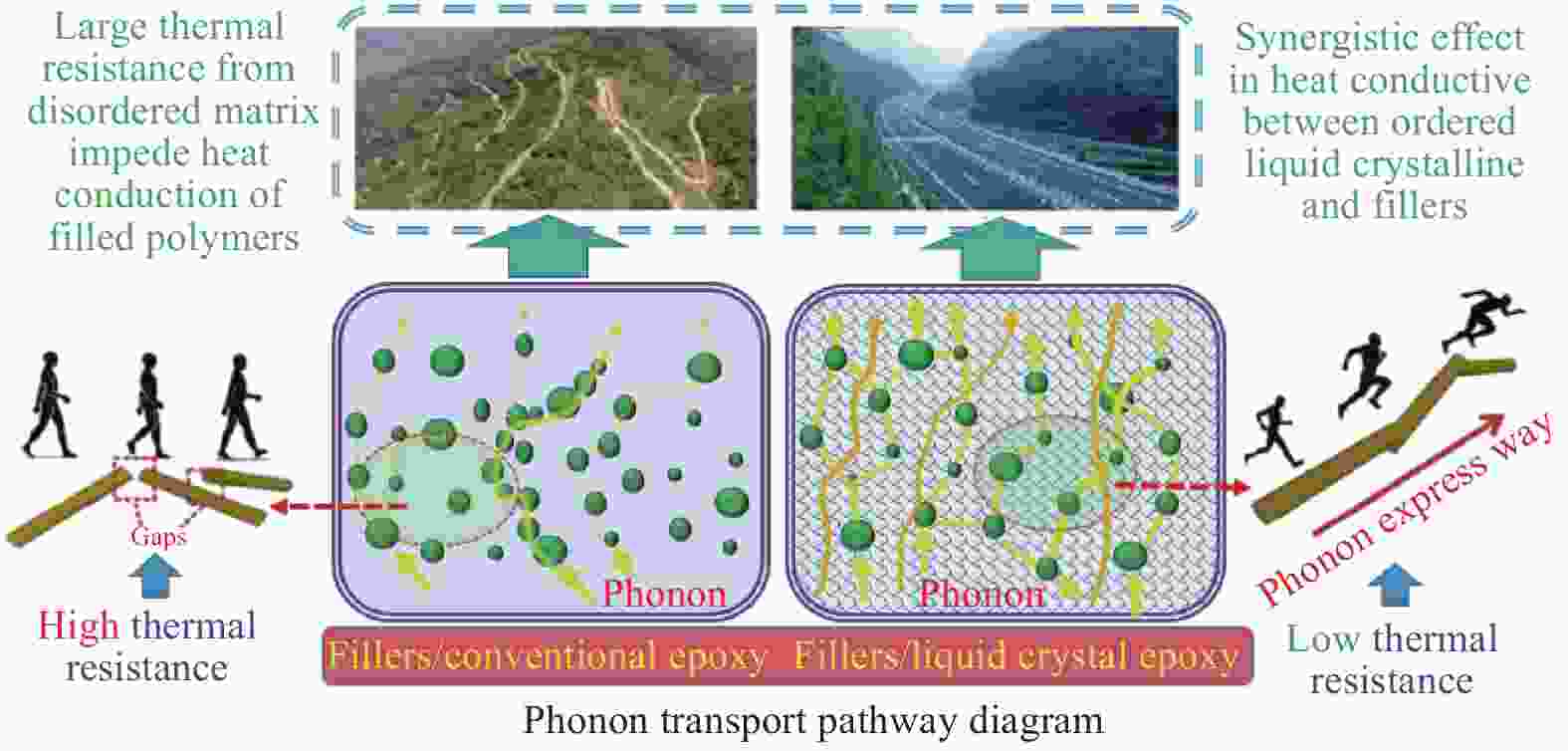

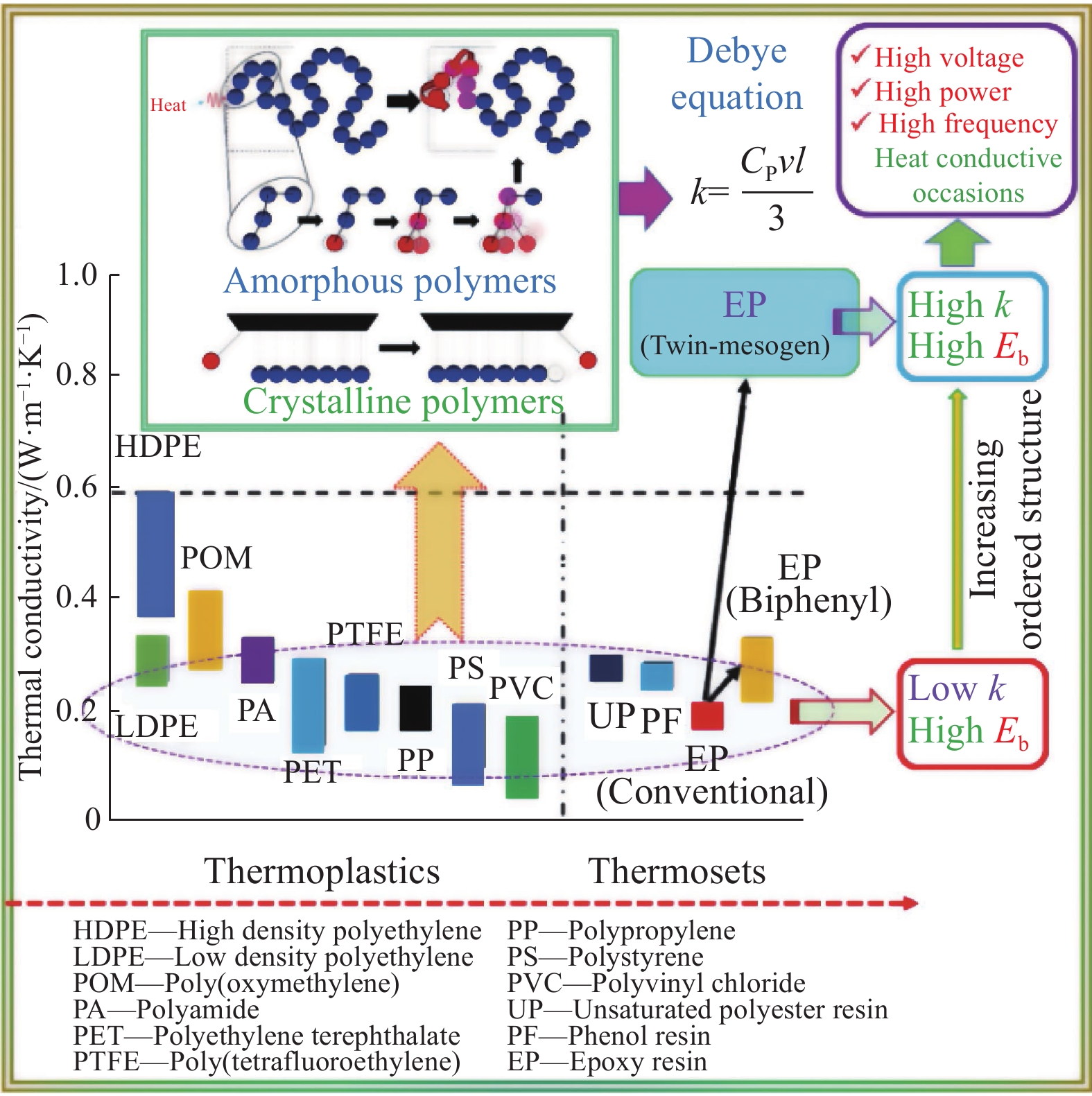

摘要: 散热困难已成为制约微电子器件和电气绝缘设备日趋微型化的关键问题和技术瓶颈。传统导热环氧复合材料因热导率 (k) 与介电强度 (Eb) 之间难以协同提升及联调的矛盾而无法适应大功率、超高频微电子器件及高电压电力设备的绝缘封装的散热需求,而基于液晶 (LCE) 基元调控交联网络的结构有序性来提高k值而制备的本征导热环氧 (ITCE) 则同时具备高k及Eb性能。本论文分析了液晶环氧的微结构及本征导热机制,综述和归纳了基于不同结构液晶基元的ITCE的研究进展,系统分析了本征k的影响因素,探讨了液晶环氧及固化剂结构、温度、液晶基元含量及晶粒尺寸、外场辅助加工等因素对固化环氧的本征k的影响机制,阐述了提高液晶环氧的有序结构及本征k的途径和方法。最后,探讨了当前ITCE研究中存在的问题及展望了ITCE的未来发展方向。相比常规环氧,综合性能优异的ITCE代表了导热环氧的未来发展方向,基于ITCE的导热环氧复合材料在高频、高密度、微电子、高电压及大功率电力设备等领域具有潜在的重要用途。Abstract: Difficulty in prompting heat dissipation has emerged as a critical issue and technical bottleneck restricting further miniaturization of microelectronic devices and electrical insulation equipment. Traditional heat conductive epoxy composites are not qualified for meeting the heat dissipation requirements of high-power, ultra-high-frequency and high-voltage insulating packaging because the thermal conductivity (k) and dielectric strength (Eb) cannot be regulated and improved synergistically. Intrinsically thermal conductive epoxy (ITCE), whose k can be enhanced by regulating ordered structure of cross-linked network containing liquid crystal epoxy (LCE) units, simultaneously exhibits high k and Eb. This paper analyzes the microstructure and intrinsic heat conduction mecha-nism of LCE, and summarizes the latest research progress in ITCE based on different LCE structures. The present work systematically analyzes the influencing factors on k of ITCE, such as structures of LCE and curing agent, temperature, LCE content, grain size, and external field-assisted processing, and expounds the way to improve the ordered structure of LCE and the intrinsic k. Finally, it summarizes the existing problems in current ITCE research and points to the future development direction. ITCE with excellent comprehensive performances represents the future development direction of ITCE, and the ITCE based composites has significant potential applications in high-density packaging microelectronics, high-voltage and high-power power equipment.

-

图 1 常见聚合物的热导率 (k)、导热机制、本征导热环氧 (ITCE) 及应用

Figure 1.

Thermal conductivity (k) of common polymers, mechanism, intrinsically thermal conductive epoxy (ITCE) and applications k—Thermal conductivity; Eb—Dielectric strength; CP—Specific heat capacity per unit volume; ν—Average phonon; l—Phonon mean free path

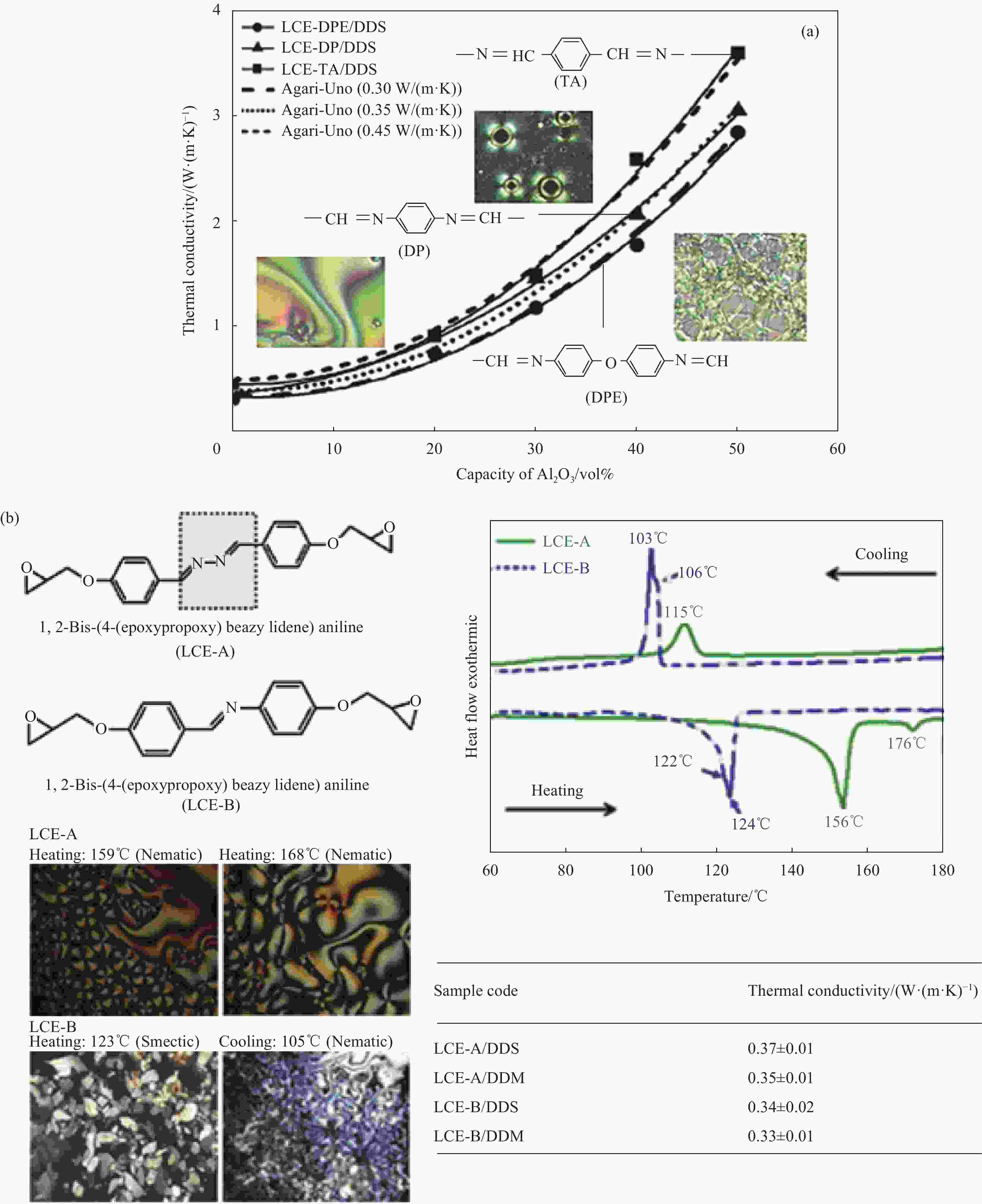

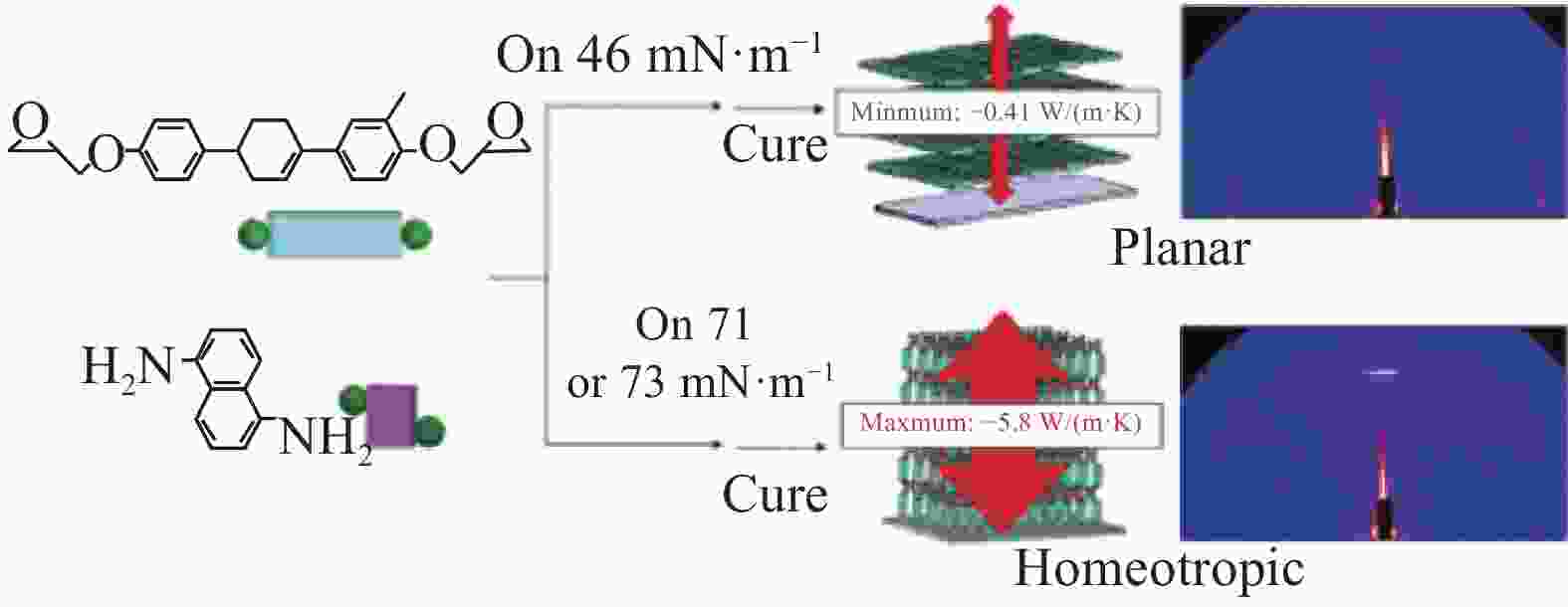

图 4 (a)三类液晶(LC)结构对固化环氧(EP)及复合材料导热影响[15];(b)液晶(LC)基元长度对固化环氧(EP)导热影响[18]

Figure 4. (a) Effects of three LCEPs on k of cured EP and composites[15];(b) Effect of length of LC units on k of cured EP[18]

TA—Terephthalylidene-bis-(4-aminophenol); DP—4′, 4′-Bis-(4-hydroxybenzylidene)-diaminophenylene; DPE—4′, 4′-Bis-(4-hydroxybenzylidene)-diaminodiphenylether; LCE-TA—Terephthalylidene-bis-(4-aminophenol) diglycidyl ether; LCE-DP—4′, 4′-Bis(4-hydroxybenzylidene)-diaminophenylene diglycidyl ether; LCE-DPE—4′, 4′-Bis-(4-hydroxybenzylidene)-diaminodiphenylether diglycidyl ether; DDS—4, 4′-Diaminodiphenylsulfone; DDM—4, 4′-Diaminodiphenylmethane

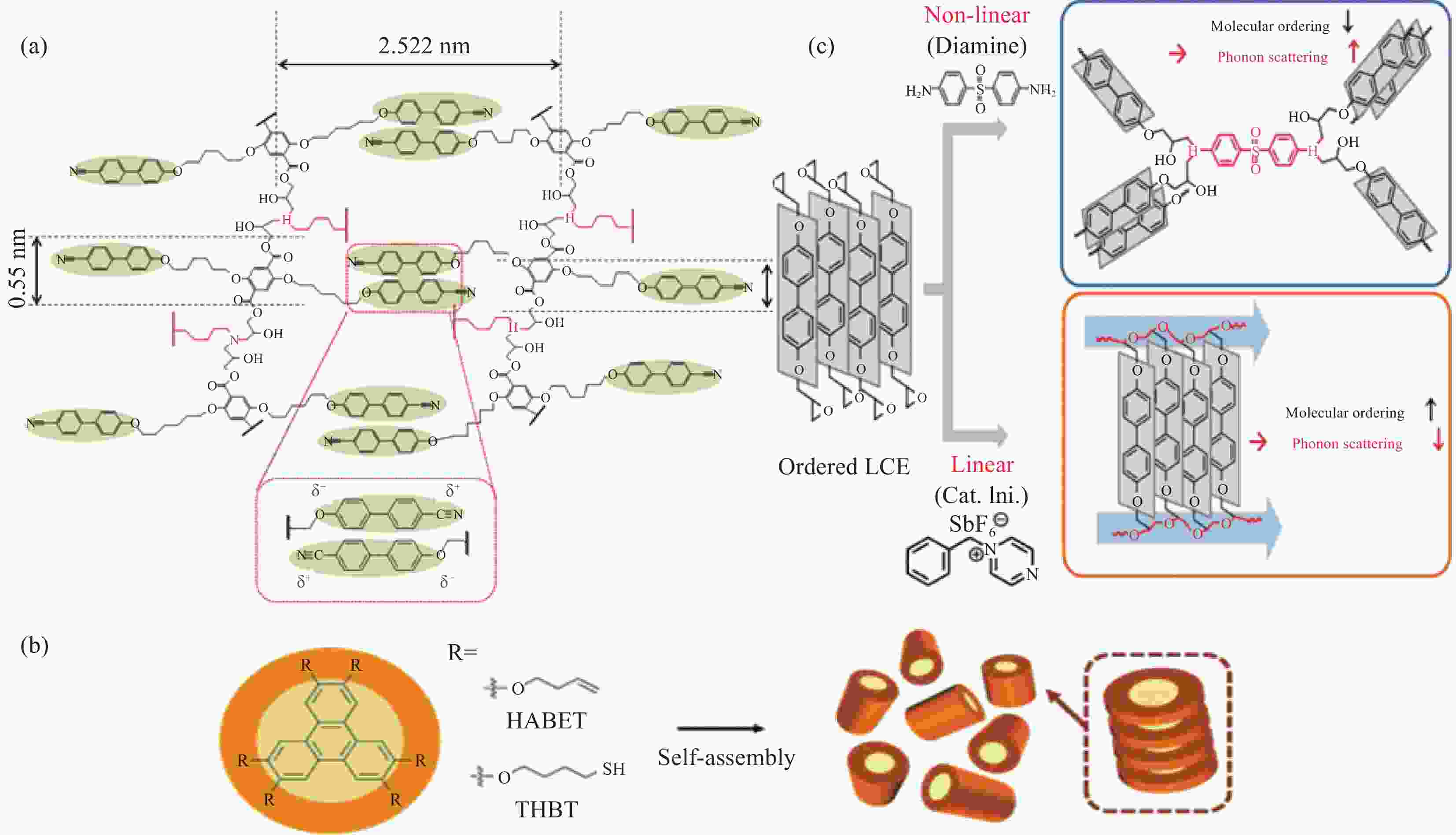

图 5 固化剂及交联方式对不同结构液晶环氧固化物的空间结构影响示意图: (a)基于XRD数据描述固化LCE-CB06分子结构的示意图;(b)稠联苯型LCEP的固化过程 ;(c)使用两种固化方法获得的液晶环氧树脂(LCER)不同微观结构的示意图[4, 23]

Figure 5. Effects of curing agent and crosslinking on microstructure of various LECP: (a) A schematic describing the molecular structure of the cured LCE-CB06 based on the XRD data; (b) Curing process of thick biphenyl type LCEP; (c) Schematic illustration of the different microstructures of liquid crystalline epoxy resin (LCER) obtained using the two curing methods[4, 23]

Cat. Ini.—Cationic initiator

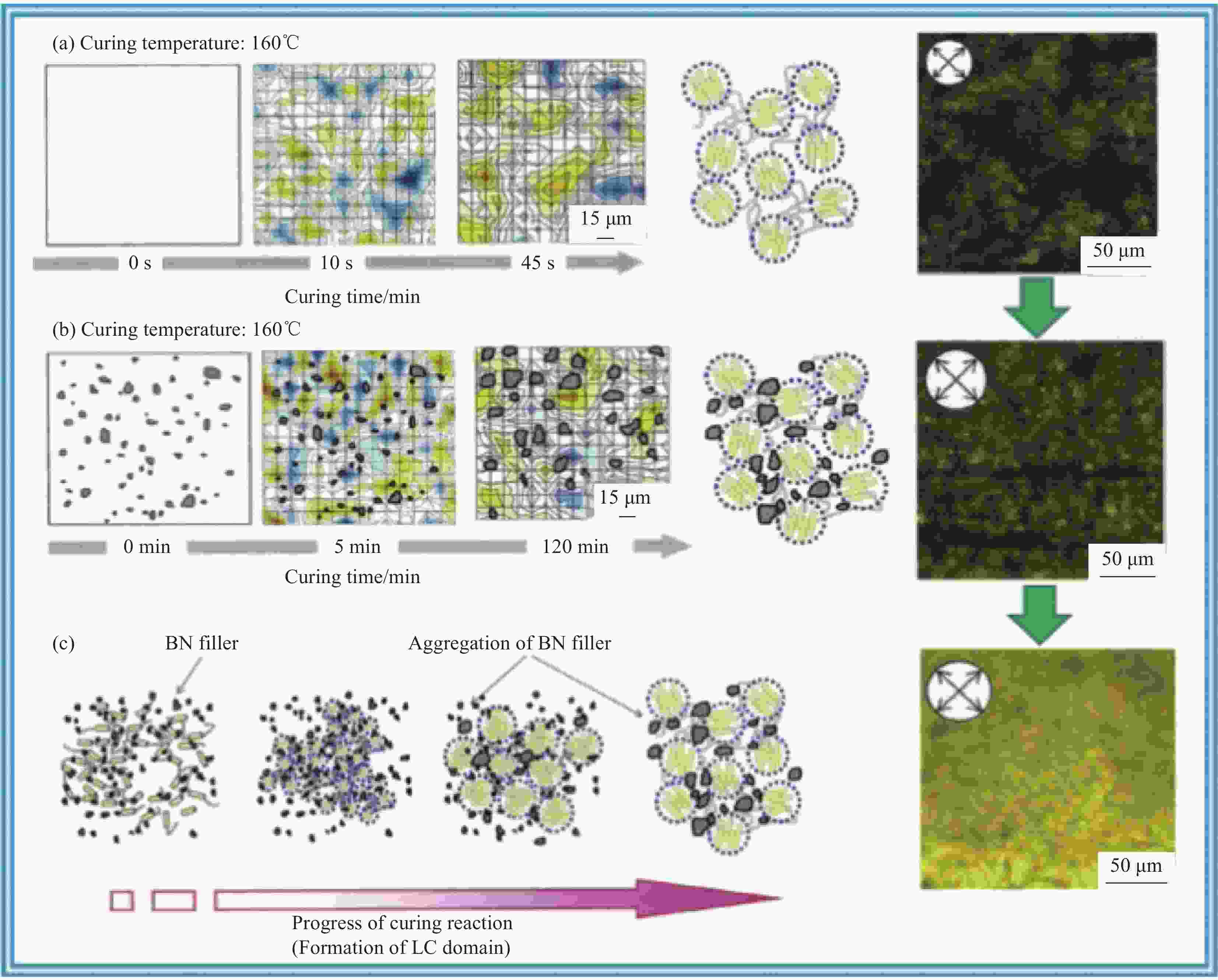

图 8 ((a)~(d)) 球晶形成过程;(e) 含介晶基元的树脂体系中球晶微观形态的示意图;(f) 球晶尺寸对体系导热性能的影响[34]

Figure 8. ((a)-(d))Formation process of spherulite; (e) Schematic representation of microscopic pattern of the spherulites in the mesogen-containing resin system; (f) Effects of grain size on thermal conduction[34]

Process of spherulite formation in epoxy resin monomer-100 (TM-100) film cast from methyl ethyl ketone (MEK) solution recorded by the polarized optical microscope (POM) 1 min (a), 5 min (b), at 100℃ (c) and fully cured at 190℃ (d) for 2 h

表 1 各类LCEP、固化剂结构及固化LCEP的热导率 (k)

Table 1. Several kinds of LCEP, curing agents, and thermal conductivity (k) of cured LCEP

Category LCEP Curing agents k/(W·(m·K)−1) Ref. Main chain type Biphenyl structure LCEP

0.43 [2]

0.19 [11]

0.28 [12]

0.31 [13]

0.51 [14]

0.38 [20]

0.33 [31]

0.41-5.50 [35] Methylene

aromatic

amines

LCEP

0.49 [15]

0.38 [17]

0.39 [21]

0.89 [32]

0.32 [33] Aromatic

ester

LCEP

1.05 [9]

0.29

[20]Side chain type

0.40 [21]

DPMP 1.25 [20]

0.46 [4] Thick

biphenyl

type

— — [7] Note: DPMP—Dipentaerythritol hexakis(3-mercaptopropionate). -

[1] 周文英, 党智敏, 丁小卫, 等. 聚合物基导热复合材料[M]. 北京: 国防工业出版社, 2017: 72-88ZHOU Weiying, DANG Zhimin, DING Xiaowei, et al. Heat conductive polymer composites[M]. Beijing: National Defense Industry Press, 2017: 72-88(in Chinese). [2] WINDBERGER M S, DIMITRIOU E, RENDL S, et al. Temperature-triggered/switchable thermal conductivity of epoxy resins[J]. Polymers,2021,13(1):65-76. [3] NA T, CHE S, SUN Y, et al. Synthesis of a novel biphenyl epoxy resin and its hybrid composite with high thermal conductivity[J]. Acta Materiae Compositae Sinica,2019,136(7):47078-47084. [4] JEONG I, KIM C B, KANG D G, et al. Liquid crystalline epoxy resin with improved thermal conductivity by intermolecular dipole-dipole interactions[J]. Journal of Polymer Science Part A: Polymer Chemistry,2019,57(6):708-715. doi: 10.1002/pola.29315 [5] HONG Y, GOH M. Advances in liquid crystalline epoxy resins for high thermal conductivity[J]. Polymers,2021,13(8):1302-1315. doi: 10.3390/polym13081302 [6] LI S H, YU X X, BAO H, et al. High thermal conductivity of bulk epoxy resin by bottom-up parallel-linking and strain: A molecular dynamics study[J]. Journal of Physical Chemistry C,2018,122(24):13140-13147. doi: 10.1021/acs.jpcc.8b02001 [7] 周文英, 王蕴, 曹国政, 等. 本征导热高分子复合材料的研究进展[J]. 复合材料学报, 2021, 38(7):2038-2055.ZHOU Weiying, WANG Yun, CAO Guozheng, et al. Progress in the intrinsic thermally conductive polymer composites[J]. Acta Materiae Compositae Sinica,2021,38(7):2038-2055(in Chinese). [8] LIN Y, HUANG X Y, CHEN J, et al. Epoxy thermoset resins with high pristine thermal conductivity[J]. High Voltage,2017,2(3):139-146. doi: 10.1049/hve.2017.0120 [9] OHKI Y. Development of epoxy resin composites with high thermal conductivity[J]. IEEE Electrical Insulation Magazine,2010,26(1):48-49. doi: 10.1109/MEI.2010.5383936 [10] RUAN K P, ZHONG X, SHI X, et al. Liquid crystal epoxy resins with high intrinsic thermal conductivities and their composites: A mini-review[J]. Materials Today Physics,2021, 20:100456-100468. [11] TIAN K, YANG S, NIU J, et al. Enhanced thermal conducti-vity and mechanical toughness of the epoxy resin by incorporation of mesogens without nanofillers[J]. IEEE Access,2021,9:31575-31580. doi: 10.1109/ACCESS.2021.3058612 [12] GUO H L, ZHENG J, GAN J, et al. High thermal conducti-vity epoxies containing substituted biphenyl mesogenic[J]. Journal of Materials Science: Materials in Electronics,2016,27(3):2754-2759. doi: 10.1007/s10854-015-4087-8 [13] ZHANG Q, CHEN G K, WU K, et al. Biphenyl liquid crystal epoxy containing flexible chain: Synthesis and thermal properties[J]. Acta Materiae Compositae Sinica,2020,137(38):49143-49155. [14] YANG X T, ZHU J H, YANG D, et al. High-efficiency improvement of thermal conductivities for epoxy composites from synthesized liquid crystal epoxy followed by doping BN fillers[J]. Composites Part B Engineering,2020,185:107784. doi: 10.1016/j.compositesb.2020.107784 [15] GIANG T, KIM J. Effect of backbone moiety in diglycidyl-etherterminated liquid crystalline epoxy on thermal conductivity of epoxy/alumina composite[J]. Journal of Indus-trial and Engineering Chemistry,2015,30:77-84. doi: 10.1016/j.jiec.2015.05.004 [16] OTA S, HARADA M. Thermal conductivity enhancement of liquid crystalline epoxy/MgO composites by formation of highly ordered network structure[J]. Journal of Applied Polymer Science,2021,138(19):50367. doi: 10.1002/app.50367 [17] HARADA M, MORIOKA D, OCHI M. Thermal and mecha-nical properties of tetra-functional mesogenic type epoxy resin cured with aromatic amine[J]. Journal of Applied Polymer Science, 2018, 135(16): 46181-46187. [18] LIN Y S, HSU S L C, HO T H, et al. Synthesis and characteri-zation of liquid crystalline epoxy resins to study the effect of mesogenic length on the physical properties[J]. Journal of Polymer Research,2021,28(2):1-10. [19] GUO H L, LU M, LIANG L, et al. Liquid crystalline epoxies with lateral substituents showing a low dielectric constant and high thermal conductivity[J]. Journal of Electronic Materials,2017,46(2):982-991. doi: 10.1007/s11664-016-5003-6 [20] YANG X T, ZHONG X, ZHANG J L, et al. Intrinsic high thermal conductive liquid crystal epoxy film simulta-neously combining with excellent intrinsic self-healing performance[J]. Journal of Materials Science & Technology,2021,68:209-215. [21] KIM Y, YEO H, YOU N H, et al. Highly thermal conductive resins formed from wide-temperature-range eutectic mixtures of liquid crystalline epoxies bearing diglycidyl moie-ties at the side positions[J]. Polymer Chemistry,2017,8(18):2806-2814. doi: 10.1039/C7PY00243B [22] YEO H, ISLAM A M, YOU N H, et al. Characteristic correlation between liquid crystalline epoxy and alumina filler on thermal conducting properties[J]. Composites Science and Technology,2017,141:99-105. doi: 10.1016/j.compscitech.2017.01.016 [23] ISLAM A M, LIM H, YOU N H, et al. Enhanced thermal conductivity of liquid crystalline epoxy resin using controlled linear polymerization[J]. ACS Macro Letters,2018,7(10):1180-1185. doi: 10.1021/acsmacrolett.8b00456 [24] LIU X J, RAO Z. A molecular dynamics study on heat conduction of crosslinked epoxy resin based thermal interface materials for thermal management[J]. Computational Materials Science,2020,172:109298. doi: 10.1016/j.commatsci.2019.109298 [25] TONGPHENG B, YU J C, ANDERSSON O. Effects of cross-links, pressure and temperature on the thermal properties and glass transition behavior of polybutadiene[J]. Phy-sical Chemistry Chemical Physics,2011,13(33):15047-15054. doi: 10.1039/c1cp20785g [26] GANTENBEIN S, MASANIA K, WOIGK W, et al. Three-dimensional printing of hierarchical liquid-crystal-polymer structures[J]. Nature,2018,561(7722):226-230. doi: 10.1038/s41586-018-0474-7 [27] LI Y Z, BADRINARAYANAN P, KESSLER M R. Liquid crystalline epoxy resin based on biphenyl mesogen: Thermal characterization[J]. Polymer,2013,54(12):3017-3025. doi: 10.1016/j.polymer.2013.03.043 [28] WANG F, HAN L, WANG H, et al. Study on preparation and thermal conductivity of liquid crystal epoxy resin filled with nano-cellulose/BNNSs[C]. Institute of Electrical and Electronics Engineers: 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), 2019: 321-324. [29] HARADA M, HAMAURA N, OCHI M, et al. Thermal conductivity of liquid crystalline epoxy/BN filler composites having ordered network structure[J]. Composites Part B Engineering,2013,55:306-313. doi: 10.1016/j.compositesb.2013.06.031 [30] HUO R, ZHANG Z, ATHIR N, et al. Designing high thermal conductivity of cross-linked epoxy resin via molecular dynamics simulations[J]. Physical Chemistry Chemical Physics,2020,22(35):19735-19745. doi: 10.1039/D0CP02819C [31] KIM G H, LEE D, SHANKER A, et al. High thermal conduc-tivity in amorphous polymer blends by engineered interchain interactions[J]. Nature Materials,2014,14(3):295-300. [32] LIU Y, CHEN J, ZHANG Y, et al. Highly thermal conductive benzoxazine-epoxy interpenetrating polymer networks containing liquid crystalline structures[J]. Journal of Polymer Science Part B: Polymer Physics,2017,55(24):1813-1821. doi: 10.1002/polb.24414 [33] SONG S H, KATAGI H, TAKEZAWA Y. Study on high thermal conductivity of mesogenic epoxy resin with spherulite structure[J]. Polymer,2012,53(20):4489-4492. doi: 10.1016/j.polymer.2012.07.065 [34] HARADA M, OCHI M, TOBITA M, et al. Thermal conduc-tivity properties of liquid-crystalline epoxy resin cured under a magnetic field[J]. Journal of Polymer Science Part B: Polymer Physics,2003,41(14):1739-1743. doi: 10.1002/polb.10531 [35] TANAKA S, HOJO F, TAKEZAWA Y, et al. Highly oriented liquid crystalline epoxy film: Robust high thermal-conduc-tive ability[J]. ACS OMEGA,2018,3(3):3562-3570. doi: 10.1021/acsomega.7b02088 [36] WANG H H, TIAN K, NIU J, et al. Role of cellulose nano-fiber/boron nitride hybrids in the thermal conductivity and dielectric strength of liquid-crystalline epoxy resin[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2021,28(1):11-18. doi: 10.1109/TDEI.2020.008954 [37] 理莎莎, 刘乃亮, 方长青. 氮化物对增强线性酚醛树脂导热性能的对比研究[J]. 包装工程, 2020, 41(5):137-142.LI Shasha, LIU Nailiang, FANG Changqing. Comparative study on thermal conductivity of linear phenolic resin reinforced by nitride[J]. Packing Engineering,2020,41(5):137-142(in Chinese). [38] LI Y, LI C G, ZHANG L, et al. Effect of microscopic-ordered structures on intrinsic thermal conductivity of liquid-crystalline polysiloxane[J]. Journal of Materials Science: Materials in Electronics,2019,30(9):8329-8338. doi: 10.1007/s10854-019-01150-1 [39] KANG D G, KO H, KOO J, et al. Anisotropic thermal interface materials: Directional heat transfer in uniaxially oriented liquid crystal networks[J]. ACS Applied Materials & Interfaces,2018,10(41):35557-35562. [40] 项云, 智庆科, 罗红艳, 等. 导热高分子材料在包装印刷领域的研究进展[J]. 包装工程, 2020, 41(5):148-157.XIANG Yun, ZHI Qingke, LUO Hongyan, et al. Research progress of thermal conductive polymer materials in packaging and printing[J]. Packing Enginnering,2020,41(5):148-157(in Chinese). -

下载:

下载: