In-plane shear properties of multi-axial pultruded composites at elevated temperatures

-

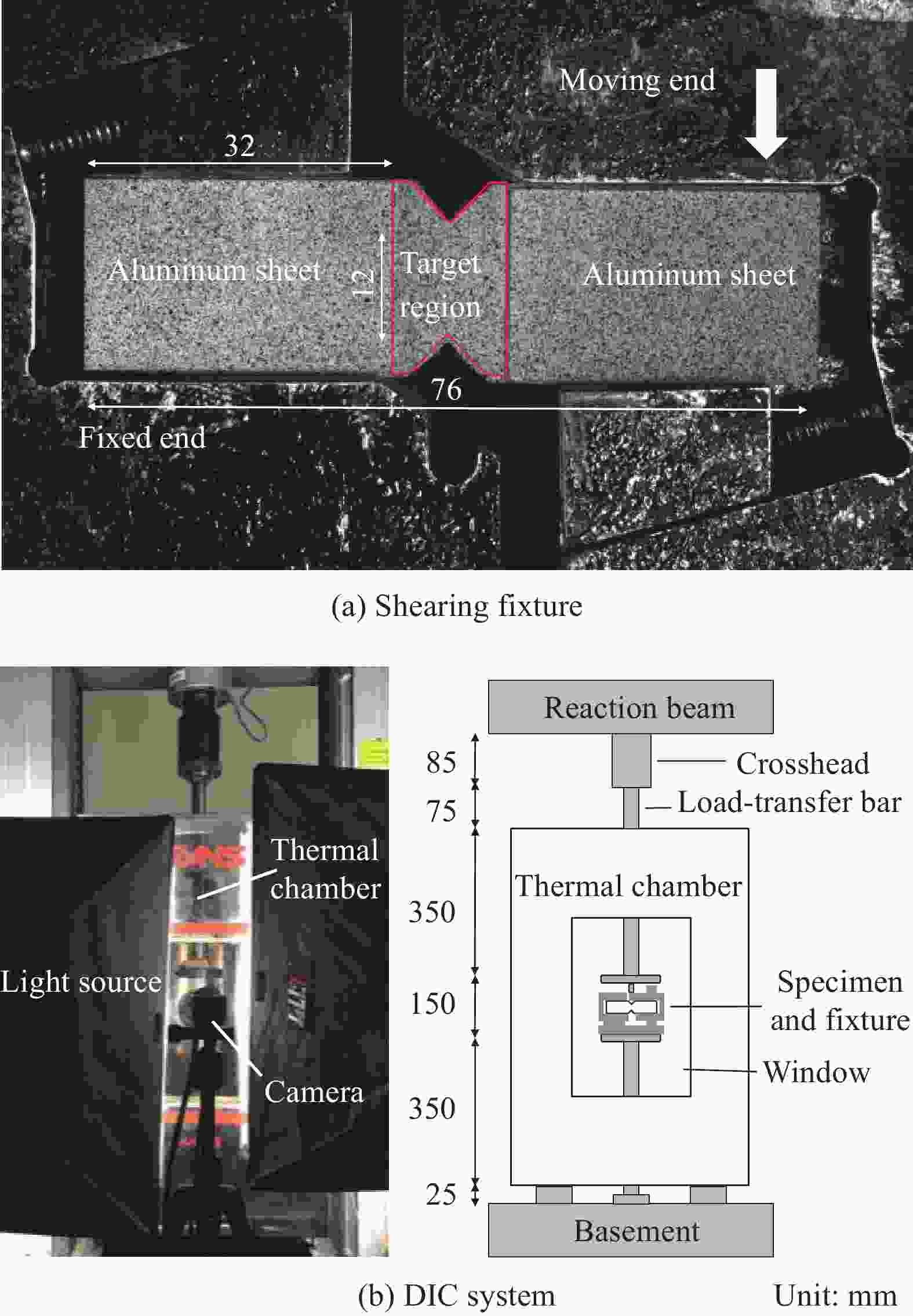

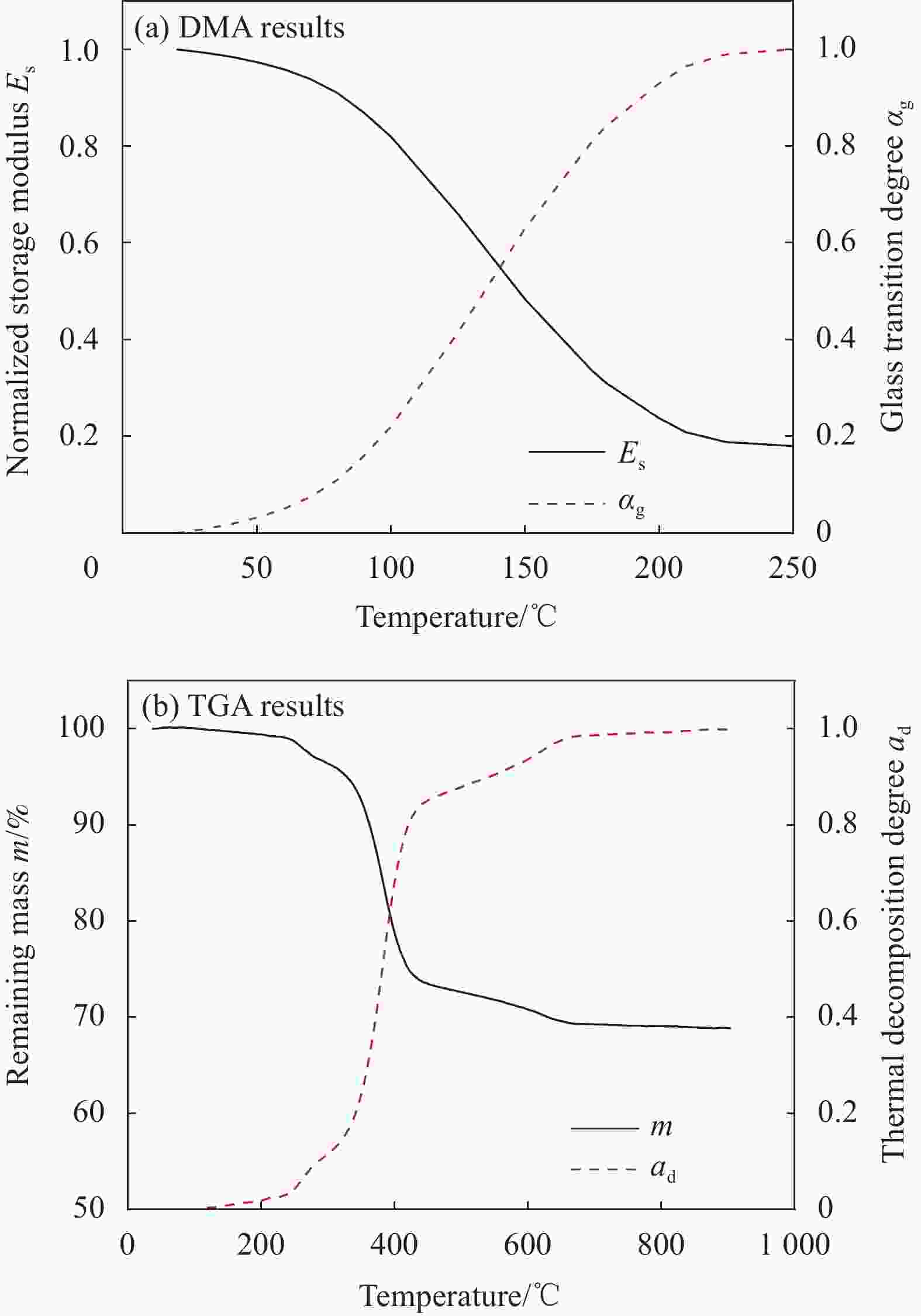

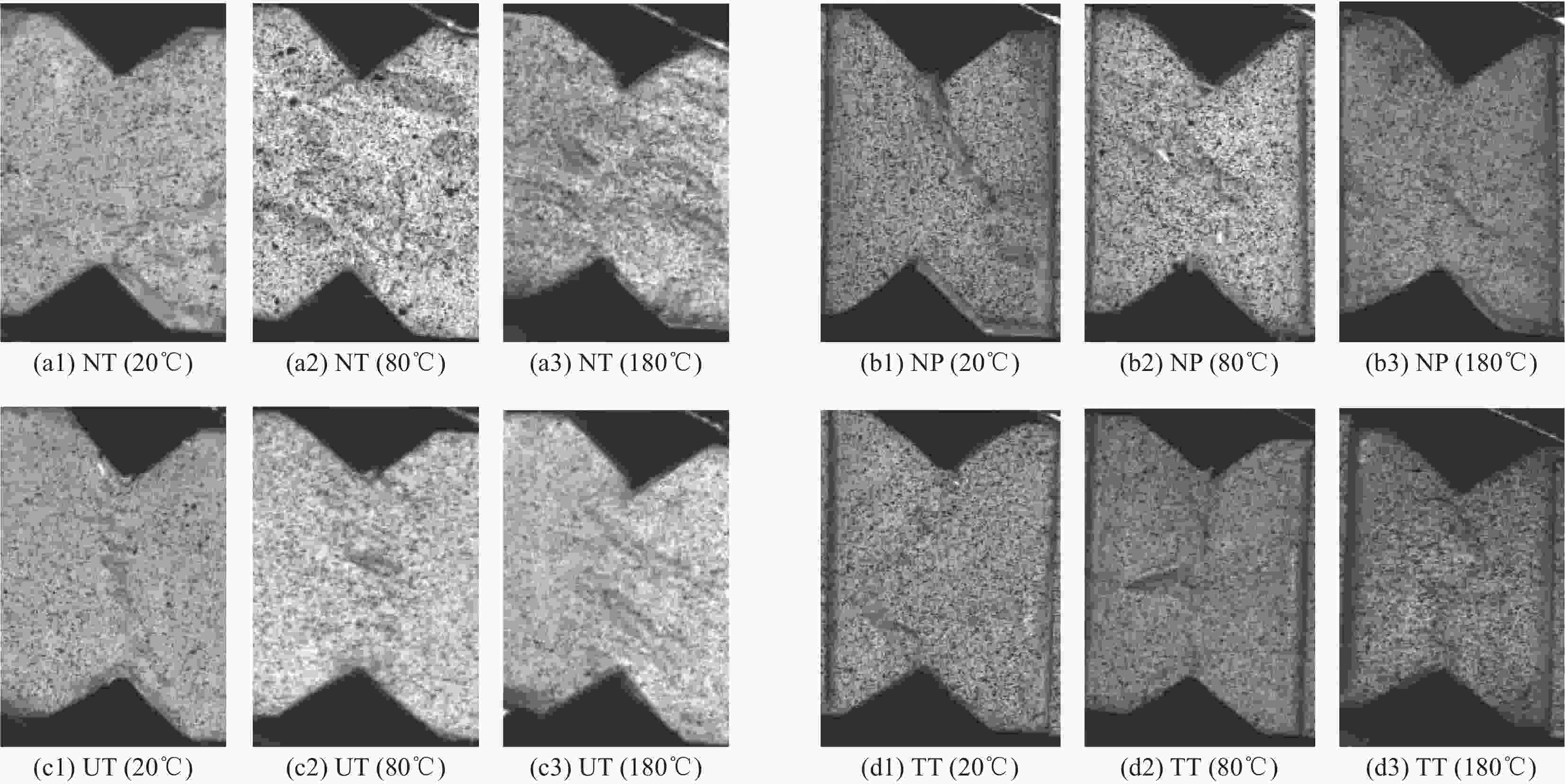

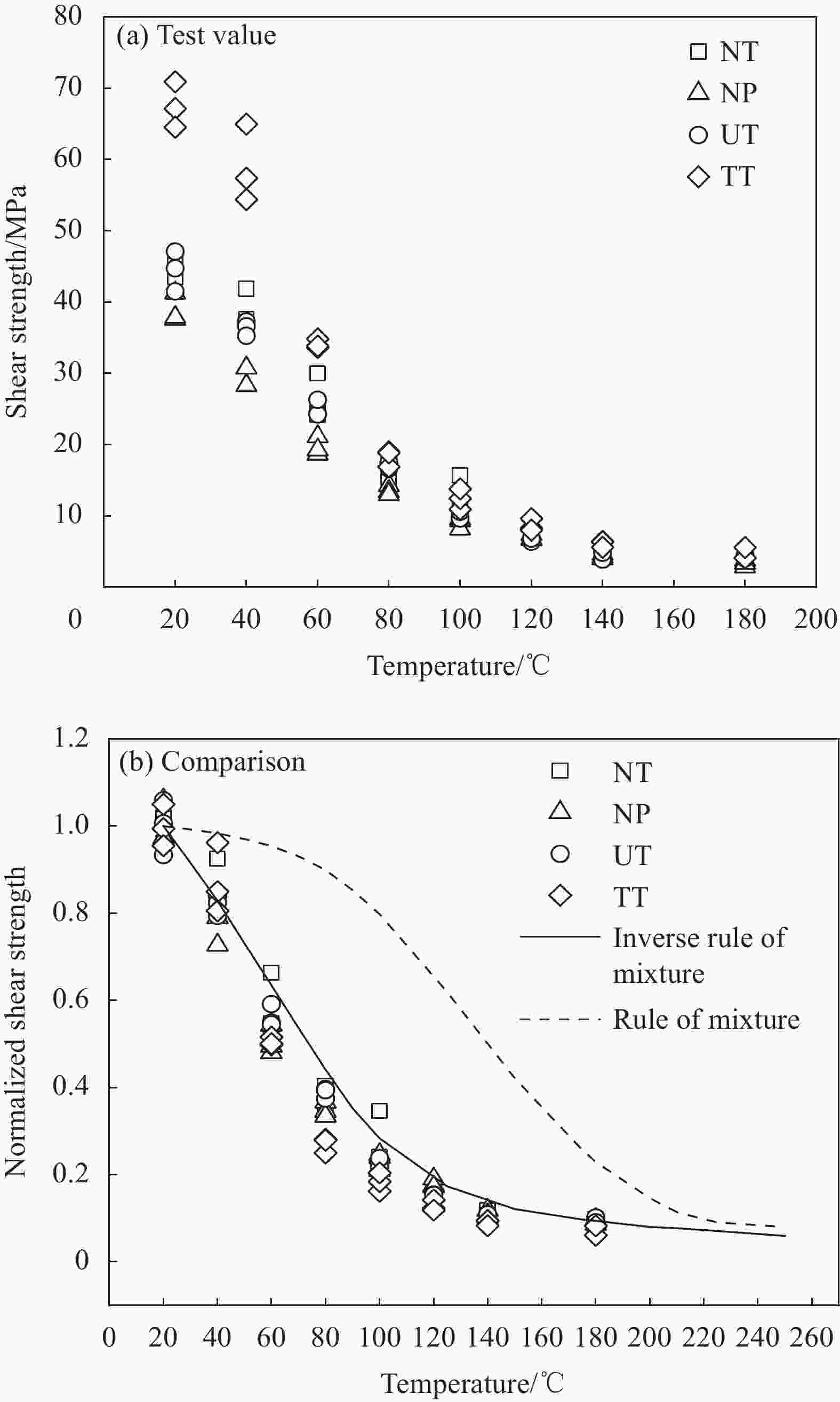

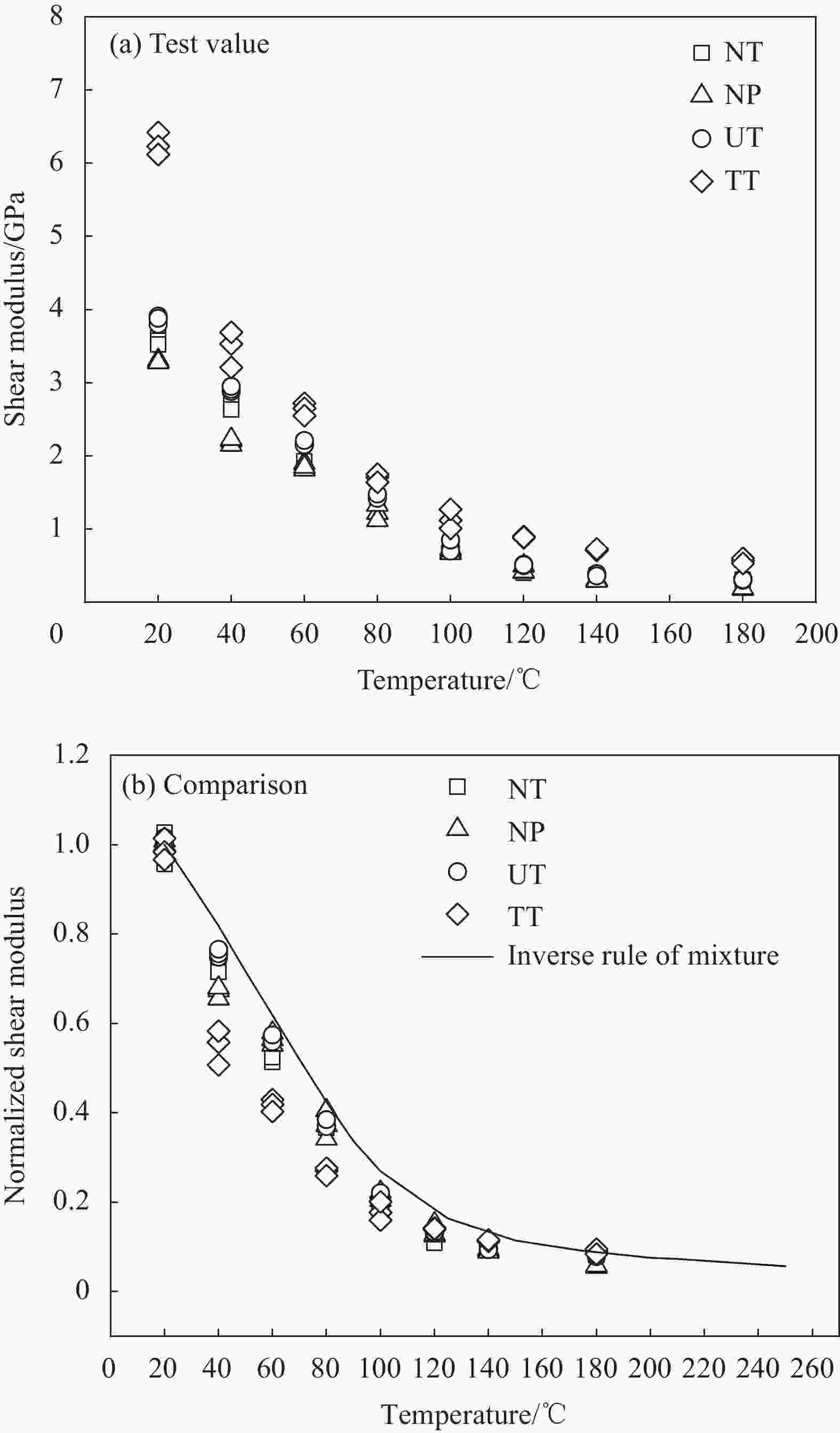

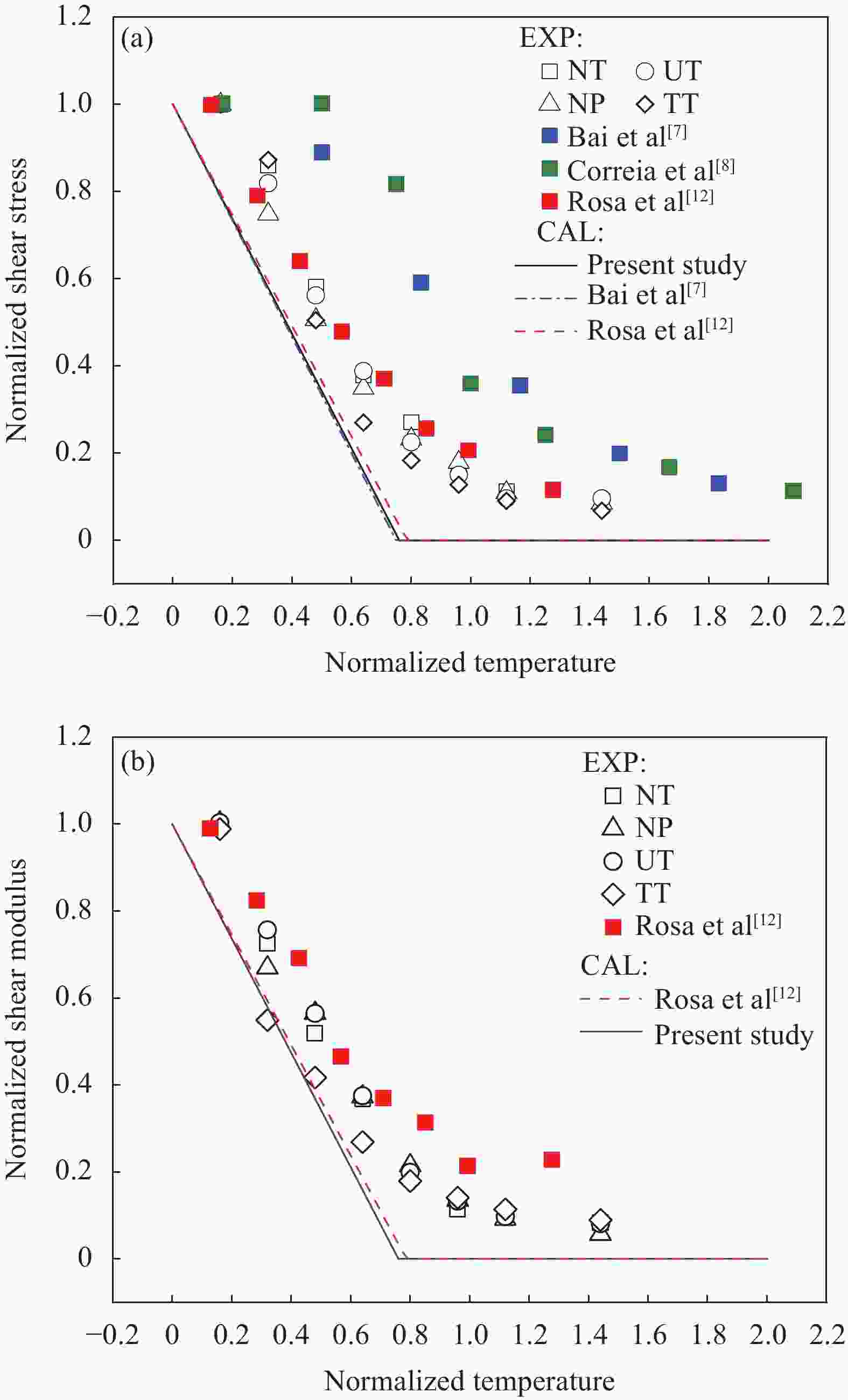

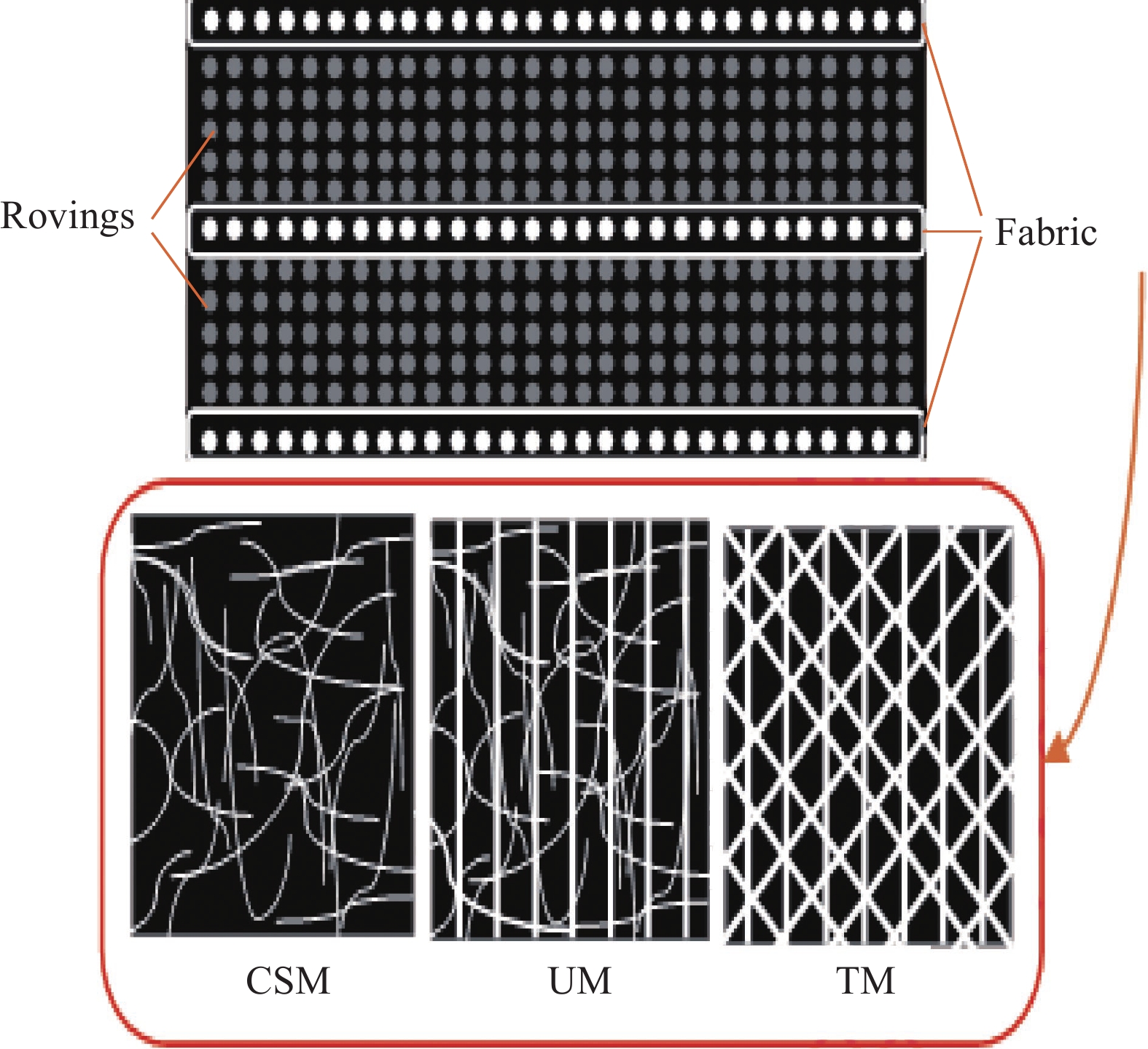

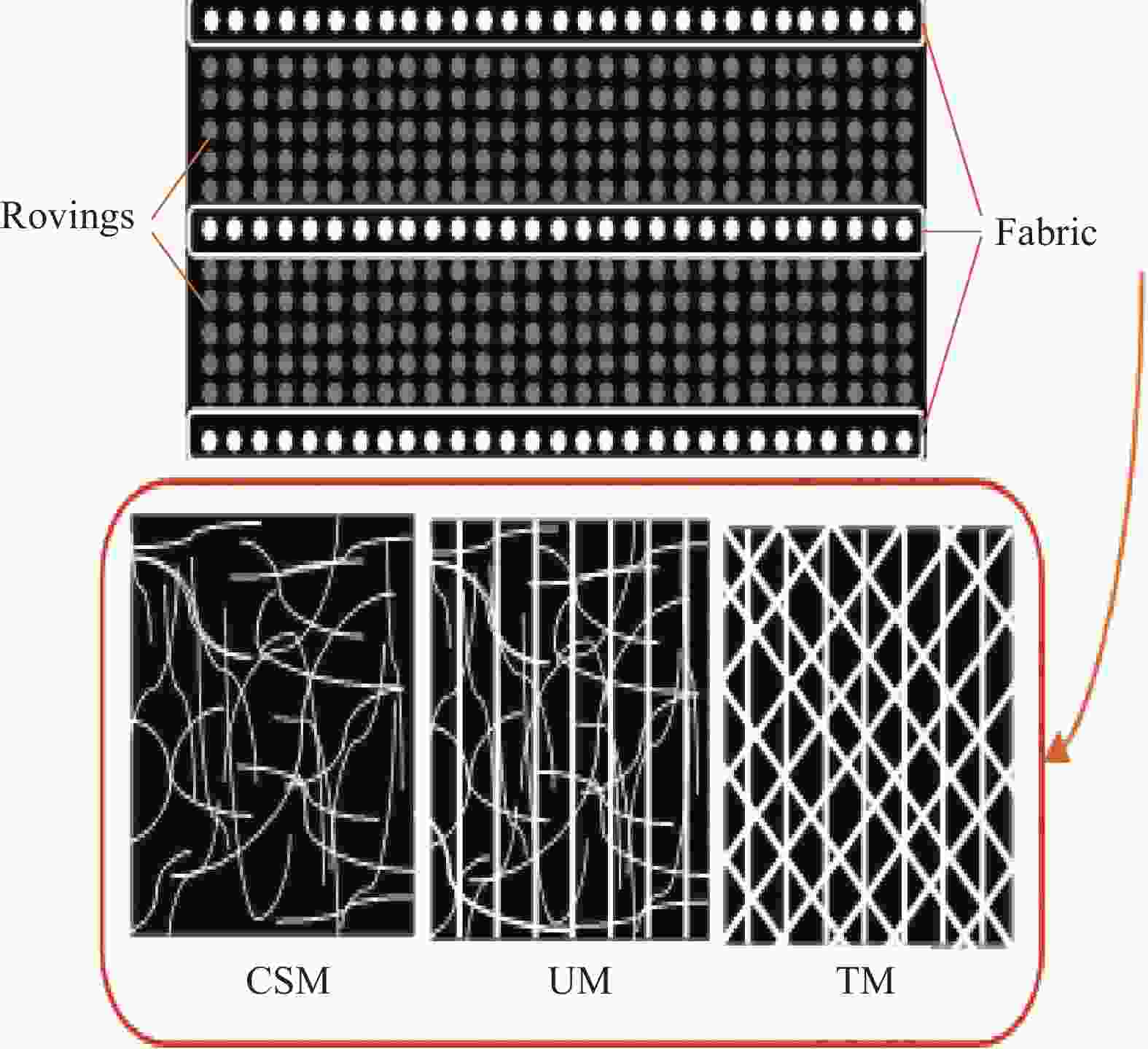

摘要: 为研究纤维布、剪切面、温度对多轴向拉挤复合材料抗剪性能的影响,对短切毡(剪切面垂直于或平行于纤维方向)增强的传统拉挤复合材料及90°单轴布和±45°/90°三轴布增强的多轴向拉挤复合材料,进行了常温及高温下的面内抗剪试验。结果表明,破坏模式主要为斜对角方向的微屈曲、脱层和剪切失效,并取决于纤维布和剪切面。纤维布对抗剪性能有着重要影响,常温下三轴布增强试件的平均抗剪强度为67.5 MPa,远远好于单轴布及短切毡增强试件(44.4 MPa和45.2 MPa)。剪切面对抗剪性能有一定的影响,常温下剪切面垂直于纤维方向的短切毡增强试件的平均抗剪强度好于平行于纤维方向的强度(38.9 MPa)。然而,随着温度的升高,各组试件的抗剪性能迅速降低,同时各组抗剪性能的差异也逐渐减小。基于热动力学理论和并联定律的单向复合材料抗剪性能计算模型总体上也适用于多轴向拉挤复合材料。最后,在相关试验的基础上提出了适用于高温下多轴向拉挤复合材料抗剪强度、剪切模量的计算公式。研究结果可为高温下的多轴向拉挤复合材料抗剪设计提供依据。Abstract: In order to investigate the influences of fiber-mat, shear plain and temperature on the shearing properties of multi-axial pultruded composite materials, the in-plain shear experiments on the traditional composites strengthened with chopped strand mats (shear plane perpendicular to or parallel to fiber direction), as well as the multi-axial pultruded composites strengthened with 90° uniaxial mat and ±45°/90° triaxial mat, were carried out at elevated temperatures. The results show that the main failure modes are diagonal micro buckling, debonding and shear failure, depending on the mat and shear plain. The shear properties significantly depend on the woven. Under ambient temperature, the average shear strength of specimens strengthened with the triaxial mat is 67.5 MPa, which is significantly greater than those of the specimens strengthened with the uniaxial mat and the chopped strand mat, which are 44.4 MPa and 45.2 MPa, respectively. The shear properties also depend on the shear plain. Under ambient temperature, the average shear strength of the chopped strand mat reinforced specimens with the shear plane perpendicular to the fiber direction is higher than that of the specimens parallel to the fiber direction (38.9 MPa). However, with the increase in temperature, the shear properties for all group specimens reduce rapidly while the difference in each group gradually becomes smaller. The calculation model for shear property of uniaxial pultruded composites based on thermal kinetic theory and parallel law is generally suitable for multi-axial pultruded composites. Finally, a formula was proposed for the calculation of shear strength and shear modulus of multi-axial pultruded composites at elevated temperatures. The research results could provide a basis for the shear design of multi-axial pultruded composites at elevated temperatures.

-

表 1 试验工况

Table 1. Test configurations

ID Reinforced fabric Number of layers Density/(kg·m−3) Shear plane Target temperature/℃ NT CSM 3 1893 Perpendicular to the fiber 20, 40, 60, 80, 100, 120, 140, 180 NP CSM 3 1893 Parallel to the fiber 20, 40, 60, 80, 100, 120, 140, 180 UT UM 3 1836 Perpendicular to the fiber 20, 40, 60, 80, 100, 120, 140, 180 TT TM 3 1928 Perpendicular to the fiber 20, 40, 60, 80, 100, 120, 140, 180 Notes: In specimen ID, the first letter: N—Chopped strand mat; U—Uniaxial mat; T—Triaxial mat; the second letter: T—Perpendicular to the fiber; P—Parallel to the fiber. 表 2 E6386T玻璃单丝/EL-400不饱和聚酯多轴向拉挤复合材料剪切强度、模量预测模型输入值

Table 2. Input parameters for prediction of shear properties of E6386T glass fiber/EL-400 unsaturated polyester multi-axial pultruded composites

Strength retention rate Modulus retention rate τg/τg τl/τg τd/τg Gg/Gg Gl/Gg Gd/Gg 1.00 0.09 0.01 1.00 0.08 0.01 Notes: τ—Shear strength; G—Shear modulus; Subscripts g, l and d—Glassy state, viscous state and decomposition state, respectively. -

[1] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-37. doi: 10.3321/j.issn:1000-131X.2006.03.004YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-37(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [2] 刘伟庆, 方海, 方园. 纤维增强复合材料及其结构研究进展[J]. 建筑结构学报, 2019, 40(4):1-16.LIU Weiqing, FANG Hai, FANG Yuan. Research progress of fiber-reinforced composites and structures[J]. Journal of Building Structures,2019,40(4):1-16(in Chinese). [3] 齐玉军, 熊伟, 刘伟庆, 等. 新型FRP拉挤夹芯型材及其结构应用初探[J]. 玻璃钢/复合材料, 2014(12):25-31.QI Yujun, XIONG Wei, LIU Weiqing, et al. A review on innovative pultruded FRP composite sandwich profiles and structural utilization[J]. Fiber Reinforced Plastics/Composites,2014(12):25-31(in Chinese). [4] TURVEY G J, ZHANG Y. Shear failure strength of web-flange junctions in pultruded GRP WF profiles[J]. Construction and Building Materials,2006,20(1-2):81-89. doi: 10.1016/j.conbuildmat.2005.06.045 [5] BAI Y, KELLER T, WU C. Pre-buckling and post-buckling failure at web-flange junction of pultruded GFRP beams[J]. Materials and Structures,2013,46(7):1143-1154. doi: 10.1617/s11527-012-9960-9 [6] NHUT P V, YORESTA F S, KITANE Y, et al. Improving the shear strength of bolted connections in pultruded GFRP using glass fiber sheets[J]. Composite Structures,2021,255:112896. doi: 10.1016/j.compstruct.2020.112896 [7] BAI Y, KELLER T. Modeling of strength degradation for fiber-reinforced polymer composites in fire[J]. Journal of Composite Materials,2009,43(21):2371-2385. doi: 10.1177/0021998309344642 [8] CORREIA J R, GOMES M M, PIRES J M, et al. Mechanical behaviour of pultruded glass fibre reinforced polymer composites at elevated temperature: Experiments and model assessment[J]. Composite Structures,2013,98:303-313. doi: 10.1016/j.compstruct.2012.10.051 [9] GIBSON A G, WU Y S, EVANS J T, et al. Laminate theory analysis of composites under load in fire[J]. Journal of Composite Materials,2006,40(7):639-658. doi: 10.1177/0021998305055543 [10] MAHIEUX C A, REIFSNIDER K L, CASE S W. Property modeling across transition temperatures in PMC’s: Part I. Tensile properties[J]. Applied Composite Materials,2001,8(4):217-234. doi: 10.1023/A:1011282704357 [11] WANG K, YOUNG B, SMITH S T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures[J]. Engineering Structures,2011,33(7):2154-2161. doi: 10.1016/j.engstruct.2011.03.006 [12] ROSA I C, MORGADO T, CORREIA J R, et al. Shear behavior of GFRP composite materials at elevated temperature[J]. Journal of Composites for Construction,2018,22(3):4018010. doi: 10.1061/(ASCE)CC.1943-5614.0000839 [13] WU C, BAI Y, MOTTRAM J T. Effect of elevated tempera-tures on the mechanical performance of pultruded FRP joints with a single ordinary or blind bolt[J]. Journal of Composites for Construction,2016,20(2):4015045. doi: 10.1061/(ASCE)CC.1943-5614.0000608 [14] 清华大学, 中冶建筑研究总院有限公司. 复合材料拉挤型材结构技术规范: T/CECS 692—2020[S]. 北京: 中国建筑工业出版社, 2020.Tsinghua University, Central Research Institute of Building and Construction CO., LTD. MCC Group. Technical specification for structure of pultruded fiber reinforced polymer composites: T/CECS 692—2020[S]. Beijing: China Architecture & Building Press, 2020(in Chinese). [15] ASTM. Test methods for constituent content of composite materials: ASTM D3171[S]. West Conshohocken: ASTM International, 2015. [16] ASTM. Standard test method for shear properties of composite materials by the V-notched beam method: D5379/D5379M−19[S]. West Conshohocken: ASTM International, 2010. [17] KELLER T, TRACY C, ZHOU A. Structural response of liquid-cooled GFRP slabs subjected to fire–Part I: Material and post-fire modeling[J]. Composites Part A: Applied Science and Manufacturing,2006,37(9):1286-1295. doi: 10.1016/j.compositesa.2005.08.006 [18] GIBSON A G, BROWNE T N, FEIH S, et al. Modeling composite high temperature behavior and fire response under load[J]. Journal of Composite Materials,2012,46(16):2005-2022. doi: 10.1177/0021998311429383 [19] KIM Y J, QIAN K Z. Compressive behavior of non-slender hollow GFRP structural shapes in thermomechanical loading[J]. Composite Structures,2017,160:813-823. doi: 10.1016/j.compstruct.2016.10.085 [20] BAI Y, KELLER T. Time dependence of material properties of FRP composites in fire[J]. Journal of Composite Materials,2009,43(12):2469-2484. -

下载:

下载: