Preparation and properties of high strength-medium density nanoporous resin-based ablation/insulation integrated composites

-

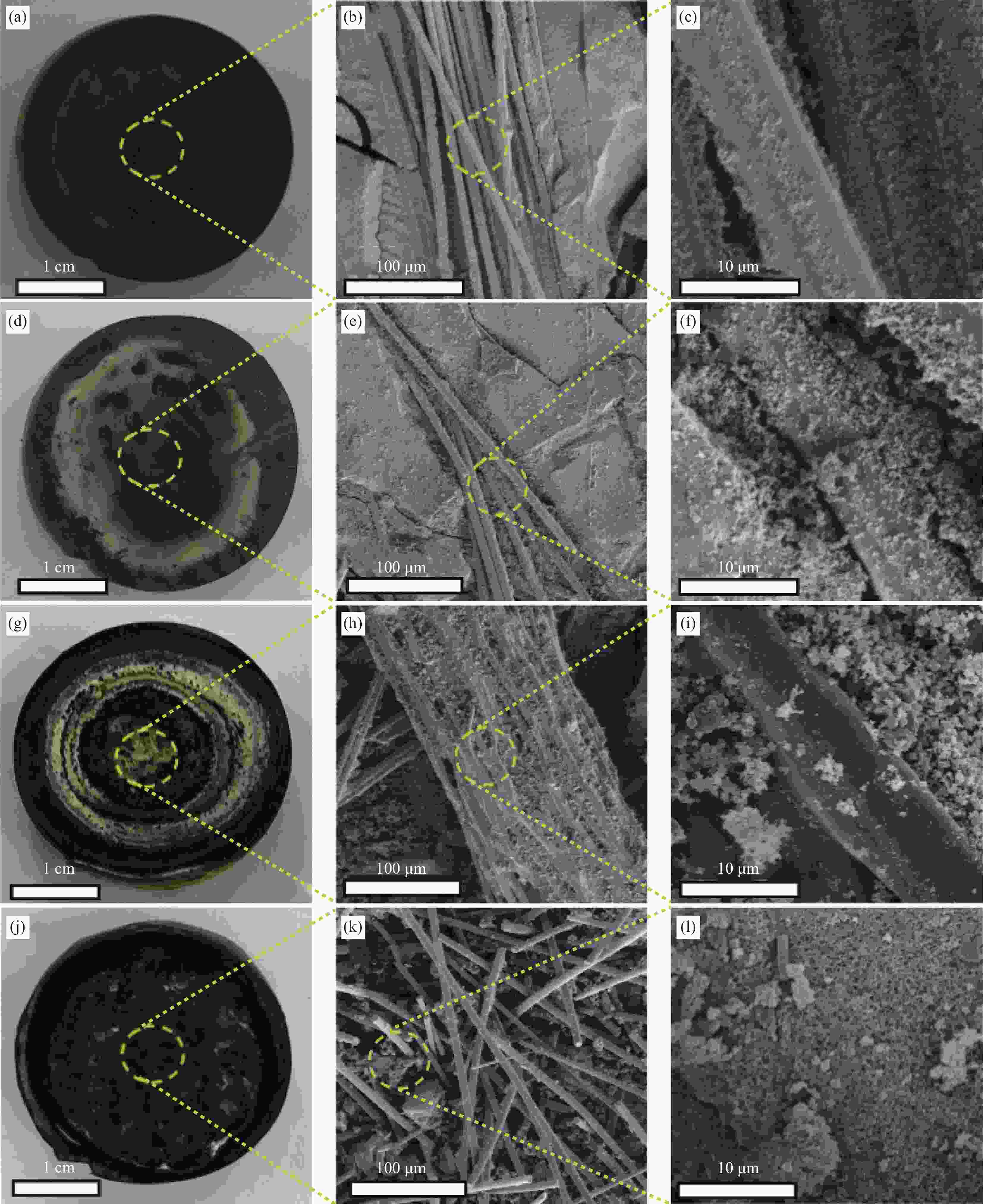

摘要: 针对新一代航天器长时防隔热-高气动剪切的防热需求,以杂化酚醛树脂为基体、纤维布/纤维网胎逐层针刺结构为增强体,通过溶胶-凝胶工艺,制备出一种中密度-高强度-防隔热一体化的纳米孔树脂基复合材料(IPC-90),系统研究了石英纤维(QF/IPC-90)和碳纤维(CF/IPC-90)对复合材料的微观结构、力学性能、静态隔热和烧蚀性能的影响,探讨了其在低-中-高温度下的烧蚀机制。结果表明:纤维布的引入使IPC-90具有优异的力学性能(拉伸曲强度 >120 MPa,弯曲强度 >90 MPa);纳米孔基体和纤维网胎的引入使IPC-90在中密度(~0.95 g/cm3)下具有较低的热导率(室温热导率依次为0.089 W/(m∙K)和0.120 W/(m∙K))。在1000℃静态隔热试验中,两种材料均展现了较好的热稳定性和抗氧化性,其等效热导率分别为0.142 W/(m∙K)和0.186 W/(m∙K)。在2000℃以下氧-丙烷烧蚀试验中,QF/IPC-90和CF/IPC-90的烧蚀主要由基体热解、炭化收缩引起,其1600℃下的线烧蚀率依次为0.0208 mm/s和0.0133 mm/s;在2000℃ 以上氧-乙炔烧蚀试验中,CF/IPC-90的烧蚀由表面超高温炭化-升华主导,而QF/IPC-90则因石英纤维熔融导致其抗烧蚀性下降较为明显,两者在4.2 MW/m2下的线烧蚀率依次为0.073 mm/s和0.186 mm/s。Abstract: To meet the extreme thermal protection requirement of new-generation spacecrafts, nanoporous resin composites (IPC-90) with medium-density, high strength and excellent ablation/insulation properties had been prepared via a sol-gel polymerization using phenolic resin as nanoporous matrix and needled fiber fabric as the reinforcement. The effects of fiber type, namely quartz fiber (QF/IPC-90) and carbon fiber (CF/IPC-90) on the microstructure, mechanical properties, static thermal insulation, and ablation properties of the composites were systematically studied. The as-prepared IPC-90 with medium density of ~0.95 g/cm3 has excellent mechanical properties with tensile strength >120 MPa and bending strength >90 MPa. Due to the introduction of nanopore resin matrix and lightweight fiber felt, the resultant IPC-90 has relatively low room-temperature thermal conductivities (0.089 W/(m∙K) for QF/IPC-90 and 0.120 W/(m∙K) for CF/IPC-90), as well as low effective thermal conductivities at 1000℃. Furthermore, the possible ablation mechanisms under different temperatures were analyzed. It is found that both QF/IPC-90 and CF/IPC-90 have low linear ablation rates under the oxygen-propane ablation test below 2000℃, which are mainly caused by resin matrix pyrolysis and shrinkage. However, under the oxy-acetylene ablation test above 2000℃, the ablation of CF/IPC-90 is dominated by ultrahigh temperature carbonation-sublimation, while the severe ablation of CF/IPC-90 is caused by the melting of quartz fiber. Under the oxy-acetylene ablation of 4.2 MW/m2, the linear ablation rates of CF/IPC-90 and QF/IPC-90 are 0.073 mm/s and 0.186 mm/s, respectively, being similar to the conventional high-density phenolic composites.

-

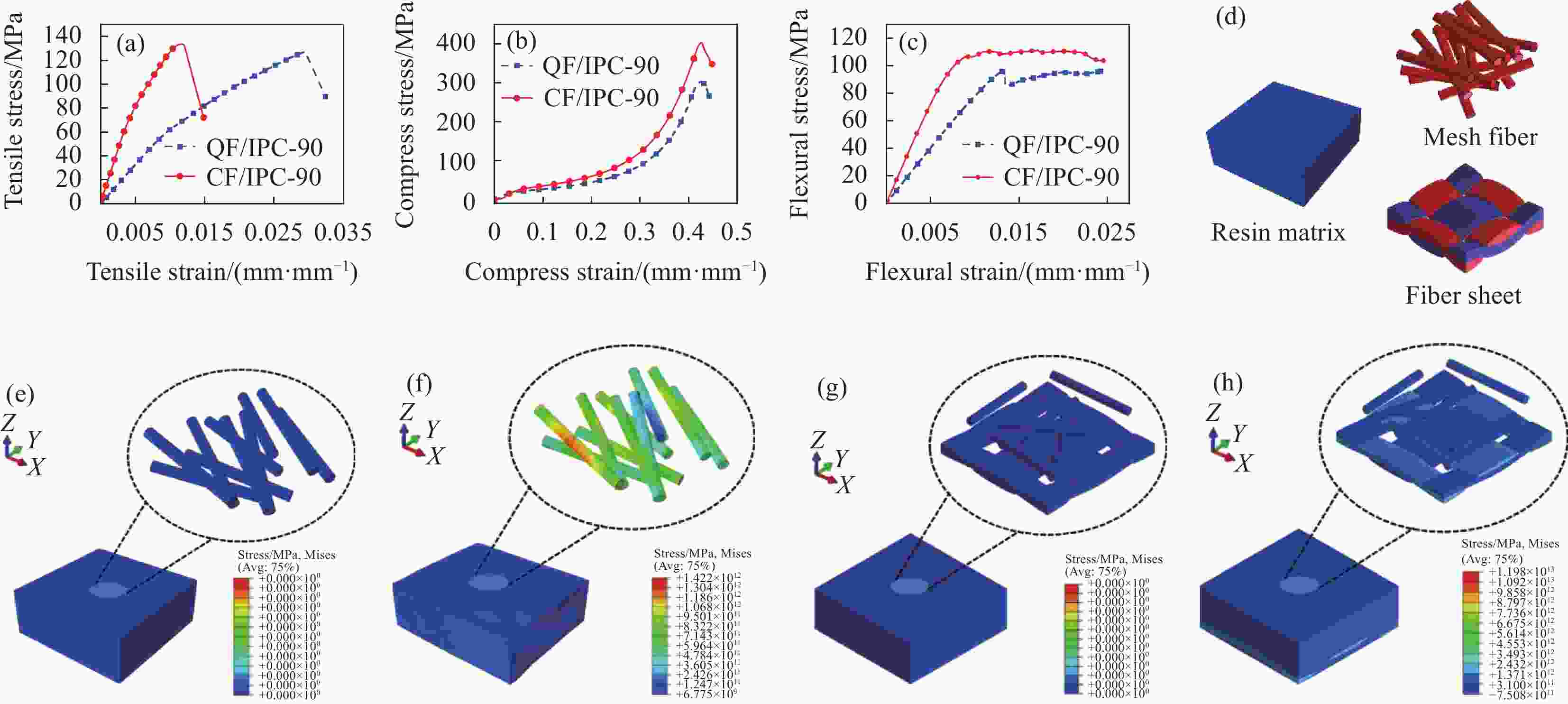

图 1 (a) 纤维预制体结构示意图;((b)、(c)) 石英纤维增强纳米孔酚醛树脂基复合材料(QF/IPC-90)纵向截面图与SEM图像;((d)、(e)) QF/IPC-90纤维树脂结合处和树脂基体SEM图像;(f) 纤维预制体增强纳米孔酚醛树脂基复合材料(IPC-90)孔径分布图

Figure 1. (a) Schematic diagram of fiber preform; ((b), (c)) Longitudinal section and SEM images of quartz fiber reinforced nanopore phenolic resin composite (QF/IPC-90); ((d), (e)) SEM images of fiber/resin binding and matrix of QF/IPC-90 composites; (f) Pore size distribution of fiber reinforced nanopore phenolic resin composite (IPC-90)

CF—Carbon fiber

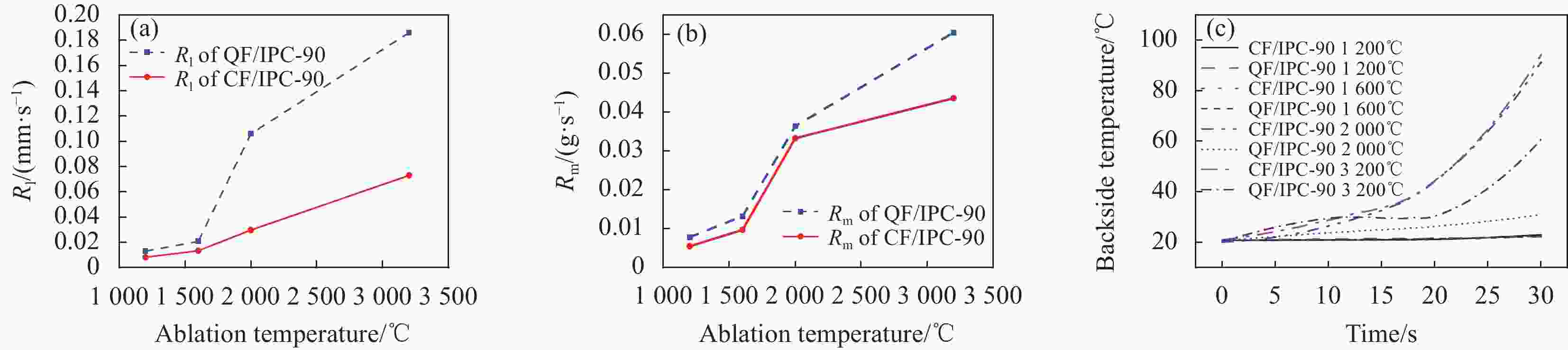

图 2 ((a)~(c)) IPC-90复合材料拉伸、压缩和弯曲应力-应变图;(d) IPC-90复合材料力学有限元建模方法示意图;((e)、(f)) 短纤维增强复合材料模型原始和5%应变下应力;((g)、(h)) 纤维布/短纤维增强复合材料模型原始和5%应变下应力云图

Figure 2. ((a)-(c)) Tensile, compression and bending stress-strain of IPC-90 composites; (d) Schematic diagram of mechanical finite element modeling method for IPC-90 composites; ((e), (f)) Stress contour of short fiber reinforced composite model under original and 5% strain; ((g), (h)) Stress contour of fiber sheet/short fiber reinforced composite model under original and 5% strain

图 3 (a) IPC-90复合材料受热面温度响应曲线;((b)、(c)) QF/IPC-90受热面最终温度云图和热流密度云图;(d) IPC-90复合材料背部温度响应曲线;((e)、(f)) CF/IPC-90受热面最终温度云图和热流密度云图

Figure 3. (a) Heating surface temperature response curves of IPC-90 series composite; ((b), (c)) Final heat flux and temperature contour of QF/IPC-90 heating surface; (d) Backside temperature response curves of IPC-90 series composite; ((e), (f)) Final heat flux and temperature contour of CF/IPC-90 heating surface

NT11—Temperature (K); HEL—Heat flux (W·m−2)

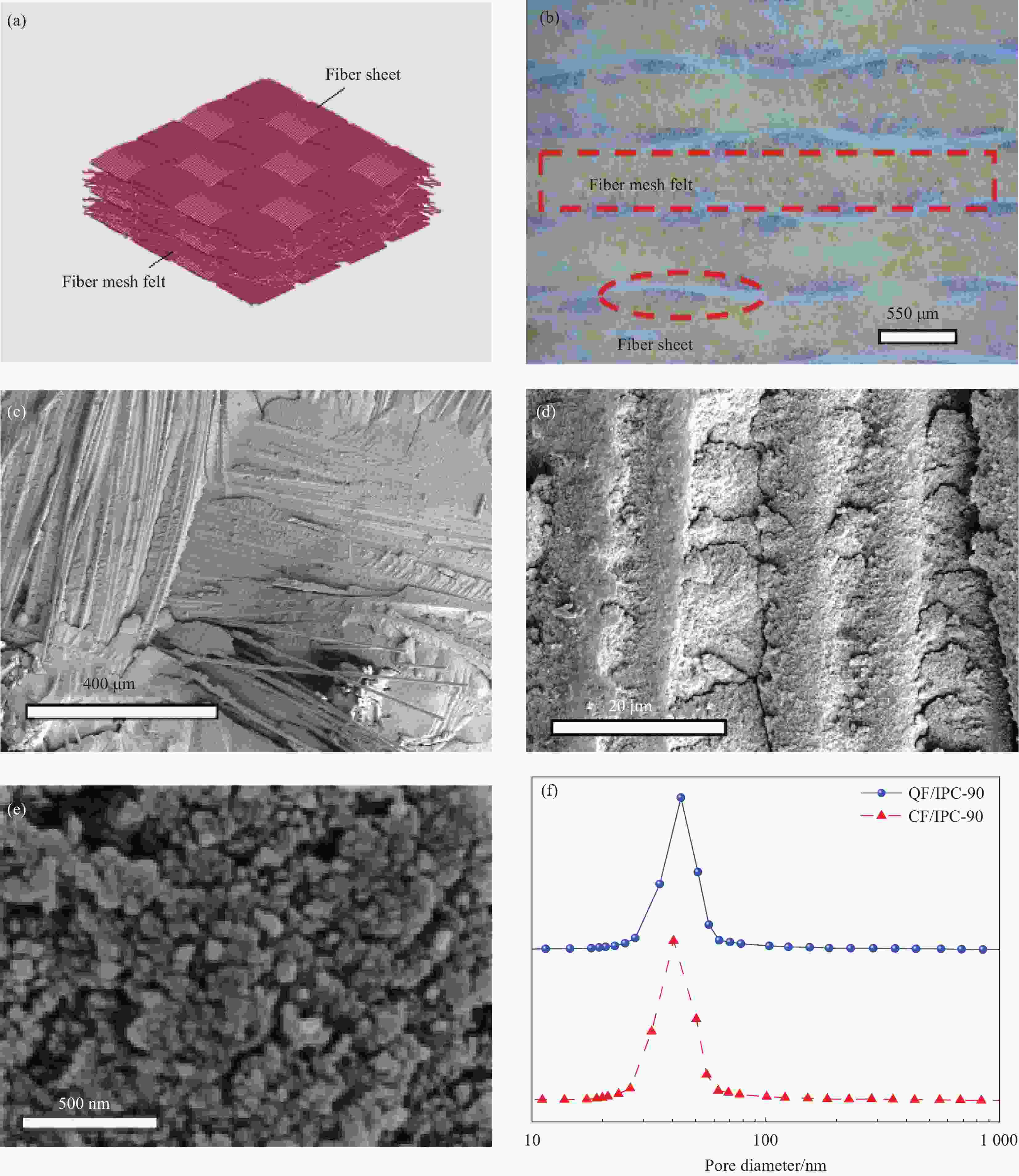

图 6 ((a)~(c)) QF/IPC-90在 1200℃下烧蚀后的宏观形貌图、表面结构和纤维SEM图像;((d)~(f)) CF/IPC-90在1200℃下烧蚀后的宏观形貌图、表面结构和纤维SEM图像;((g)~(i)) QF/IPC-90在 2000℃下烧蚀后的宏观形貌图、表面结构和纤维SEM图像;((j)~(l)) CF/IPC-90在2000℃下烧蚀后的宏观形貌图、表面纤维和基体SEM图像

Figure 6. ((a)-(c)) Macrograph photo and SEM images of surface structure and fiber of QF/IPC-90 after 1200℃ ablation; ((d)-(f)) Macrograph photo and SEM images of surface structure and fiber of CF/IPC-90 after 1200℃ ablation; ((g)-(i)) Macrograph photo and SEM images of surface structure and fiber of QF/IPC-90 after 2000℃ ablation; ((j)-(l)) Macrograph photo and SEM images of surface fiber and matrix of CF/IPC-90 after 2000℃ ablation

图 7 (a) IPC-90在 2000℃下烧蚀后表面物质的XRD图谱;(b) QF/IPC-90 在 2000℃下烧蚀后表面基体的EDS图谱;(c) QF/IPC-90在 2000℃下烧蚀后表面纤维的EDS图谱

Figure 7. (a) XRD pattern of IPC-90 surface substance after ablation under 2000℃; (b) EDS spectrum of surface matrix of QF/IPC-90 after ablation under 2000℃; (c) EDS spectrum of surface fiber of QF/IPC-90 after ablation under 2000℃

表 1 IPC-90的基础物理性质

Table 1. Basic physical properties of IPC-90

Composite Bulk density/

(g∙cm−3)Mass

ratio of

resin/wt%Bulk density

of resin/

(g·cm−3)Most probable

pore/nmPorosity/% Thermal

conductivity/

(W∙(m∙K)−1)Specific heat

capacity/

(J∙(g·K)−1)QF/IPC-90 0.95 52.6 0.63 43 48.1 0.089 1.10 CF/IPC-90 0.93 51.6 0.64 40 47.3 0.120 1.21 表 2 IPC-90复合材料力学性能

Table 2. Mechanical properties of IPC-90 composites

Composite Tensile

strength

in X-Y/

MPaTensile

modulus

in X-Y/

GPaTensile

elongation

at break in X-Y/%Compressive

strength

in Z/MPaCompressive

modulus

in Z/MPaBending

strength in

Z/MPaBending

modulus

in Z/GPaInterlaminar

shear stress/

MPaQF/IPC-90 127.6±2.7 6.58±0.26 2.89±0.11 307.2±3.2 20.0±0.2 93.6±3.3 8.23±0.10 9.0±0.2 CF/IPC-90 131.7±8.3 18.80±0.60 1.11±0.04 414.2±8.0 26.9±2.6 113.7±3.4 14.24±0.31 11.0±0.5 -

[1] 董彦芝, 刘峰, 杨昌昊, 等. 探月工程三期月地高速再入返回飞行器防热系统设计与验证[J]. 中国科学: 技术科学, 2015, 45(2):151-159.DONG Yanzhi, LIU Feng, YANG Changhao, et al. Design and verification of the TPS of the circumlunar free return and reentry flight vehicle for the 3rd phase of Chinese lunar exploration program[J]. Scientia Sinica (Technological),2015,45(2):151-159(in Chinese). [2] 冯志海, 师建军, 孔磊, 等. 航天飞行器热防护系统低密度烧蚀防热材料研究进展[J]. 材料工程, 2020, 48(8):14-24.FENG Zhihai, SHI Jianjun, KONG Lei, et al. Research progress in low-density materials for thermal protection system of aerospace flight vehicles[J]. Journal of Materials Engineering,2020,48(8):14-24(in Chinese). [3] 张宗强, 匡松连, 尚龙, 等. 树脂基复合材料长时间烧蚀防热的应用研究[J]. 宇航材料工艺, 2007, 37(6):29-31. doi: 10.3969/j.issn.1007-2330.2007.06.008ZHANG Zongqiang, KUANG Songlian, SHANG Long, et al. Resin composites on long time ablation and thermal protection[J]. Aerospace Materials & Technology,2007,37(6):29-31(in Chinese). doi: 10.3969/j.issn.1007-2330.2007.06.008 [4] STACKPOOLE M, VENKATAPATHY E, VIOLETTE S. Sustaining PICA for future NASA robotic science missions in-cluding NF-4 and discovery[C]//2018 IEEE Aerospace Conference. Montana, 2018: 1-7. [5] 贾献峰, 王际童, 龙东辉, 等. PICA-X的制备及其炭化前后性能研究[J]. 宇航材料工艺, 2016, 46(6):46-49.JIA Xianfeng, WANG Jitong, LONG Donghui, et al. Preparation and properties of PICA-X before and after carbonization[J]. Aerospace Materials & Technology,2016,46(6):46-49(in Chinese). [6] 程海明. 新型超轻质碳/酚醛烧蚀复合材料的制备与性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.CHENG Haiming. Research on fabrication and properties of novel lightweight carbon/phenolic ablative composite[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [7] ELLERBY D, VENKATAPATHY E, GAGE P, et al. Heatshield for extreme entry environment technology (HEEET) thermal protection system (TPS)[C]//Materials Science & Technology Conference and Exhibition. Portland, 2019: 1359-1366. [8] VENKATAPATHY E, ELLERBY D, GAGE P, et al. Entry system technology readiness for ice-giant probe missions[J]. Space Science Reviews,2020,216(2):1-21. [9] 关春龙, 李壵, 赫晓东. 可重复使用热防护系统防热结构及材料的研究现状[J]. 宇航材料工艺, 2003, 33(6): 7-11, 42.GUAN Chunlong, LI Zhuang, HE Xiaodong. Research status of structures and materials for reusable TPS[J]. Aerospace Materials & Technology, 2003, 33(6): 7-11, 42(in Chinese). [10] MAAHS H G, VAUGHN W L, KOWBEL W. Four advances in carbon-carbon materials technology[C]//The Fourth National Technology Transfer Conference and Exposition. Washington, 2003. [11] 黄竑翔, 王峰, 贺智勇, 等. 飞行器用防热材料的研究进展[J]. 硅酸盐通报, 2021, 40(2):638-644.HUANG Hongxiang, WANG Feng, HE Zhiyong, et al. Development of thermal protection materials for aircraft[J]. Bulletin of the Chinese Ceramic Society,2021,40(2):638-644(in Chinese). [12] HUO C, GUO L, LI Y, et al. Effect of co-deposited SiC nanowires and carbon nanotubes on oxidation resistance for SiC-coated C/C composites[J]. Ceramics International,2017,43(2):1722-1730. doi: 10.1016/j.ceramint.2016.08.196 [13] 王玲玲, 肖春, 王坤杰, 等. 不同制备方法下(C/C)/ZrB2-SiC复合材料的抗烧蚀性能[J]. 复合材料学报, 2019, 36(12):2878-2886.WANG Lingling, XIAO Chun, WANG Kunjie, et al. Ablation performance of (C/C)/ZrB2-SiC composites by different fabrication methods[J]. Acta Materiae Compositae Sinica,2019,36(12):2878-2886(in Chinese). [14] 中国国家标准化管理委员会. 纤维增强塑料拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites—Determination of tensile properties: GB/T 1447—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [15] 中国国家标准化管理委员会. 纤维增强塑料压缩性能试验方法: GB/T 1448—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites—Determination of compressive properties: GB/T 1448—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [16] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites—Determination of flexural properties: GB/T 1449—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [17] 中国国家标准化管理委员会. 纤维增强塑料层间剪切强度试验方法: GB/T 1450—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites—Determination of interlaminar shear strength: GB/T 1450—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [18] 国防科学技术工业委员会. 烧蚀材料烧蚀试验方法: GJB 323A—1996[S]. 北京: 中国标准出版社, 1996.Commission of Science, Technology and Industry for National Defense of the PRC. Test methods for ablation for ablators: GJB 323A—1996[S]. Beijing: Standards Press of China, 1996(in Chinese). [19] 孟祥艳, 刘运传, 周燕萍, 等. 微热量热法测定纤维及树脂基复合材料的比热容[J]. 兵工学报, 2015, 36(10):1962-1966. doi: 10.3969/j.issn.1000-1093.2015.10.019MENG Xiangyan, LIU Yunchuan, ZHOU Yanping, et al. Determination of specific heat capacity of fiber and resin matrix composites by micro-calorimeter[J]. Acta Armamentarii,2015,36(10):1962-1966(in Chinese). doi: 10.3969/j.issn.1000-1093.2015.10.019 [20] 赵建国, 李克智, 李贺军, 等. C/C复合材料比热容和热扩散率的研究[J]. 宇航材料工艺, 2005, 35(6):41-43. doi: 10.3969/j.issn.1007-2330.2005.06.009ZHAO Jianguo, LI Kezhi, LI Hejun, et al. Research on thermal diffusivity and specific heat capacity of C/C composites[J]. Aerospace Materials & Technology,2005,35(6):41-43(in Chinese). doi: 10.3969/j.issn.1007-2330.2005.06.009 [21] 蒋凌澜, 陈阳. 树脂基复合材料在航天飞行器气动热防护上的应用研究[J]. 玻璃钢/复合材料, 2014(7):78-84.JIANG Linglan, CHEN Yang. The application research of resin-based composites for aero-dynamic thermal protection system[J]. Composites Science and Engineering,2014(7):78-84(in Chinese). [22] 阳波. 阻燃增强酚醛玻璃钢[J]. 热固性树脂, 1991(4):25-30.YANG Bo. Flame retardant glass resin-forced phenolic resins[J]. Thermosetting Resin,1991(4):25-30(in Chinese). [23] 张鸿宇, 钱震, 牛波, 等. 低密度纤维增强酚醛气凝胶复合材料的力学特性及断裂机制[J]. 复合材料学报, 2022, 39(8): 3663-3673.ZHANG Hongyu, QIAN Zhen, NIU Bo, et al. Mechanical properties and fracture mechanism of low-density needled fiber preforms reinforced phenolic aerogel composites[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3663-3673(in Chinese). [24] MA C, MA Z, GAO L, et al. Ablation behavior of boron-modified phenolic resin irradiated by high-energy continuous-wave laser and its evolution of carbon structure[J]. Materials & Design,2019,180:107954. [25] JIA P, LIU H, LIU Q, et al. Thermal degradation mechanism and flame retardancy of MQ silicone/epoxy resin composites[J]. Polymer Degradation and Stability,2016,134:144-150. doi: 10.1016/j.polymdegradstab.2016.09.029 [26] HELBER B, TURCHI A, SCOGGINS J B, et al. Experimental investigation of ablation and pyrolysis processes of carbon-phenolic ablators in atmospheric entry plasmas[J]. International Journal of Heat and Mass Transfer,2016,100:810-824. doi: 10.1016/j.ijheatmasstransfer.2016.04.072 [27] LACHAUD J, SCOGGINS J B, MAGIN T E, et al. A generic local thermal equilibrium model for porous reactive materials submitted to high temperatures[J]. International Journal of Heat and Mass Transfer,2017,108:1406-1417. doi: 10.1016/j.ijheatmasstransfer.2016.11.067 [28] 时圣波, 梁军, 刘志刚, 等. 高硅氧/酚醛复合材料烧蚀环境下的吸热机理[J]. 固体火箭技术, 2013, 36(1):113-118.SHI Shengbo, LIANG Jun, LIU Zhigang, et al. Endothermic mechanism of silica/phenolic composite under ablative environment[J]. Journal of Solid Rocket Technology,2013,36(1):113-118(in Chinese). [29] ZHAO Z, LI K, LI W, et al. Preparation, ablation behavior and mechanism of C/C-ZrC-SiC and C/C-SiC composites[J]. Ceramics International,2018,44(7):7481-7490. doi: 10.1016/j.ceramint.2018.01.125 [30] WANG P, LI H, YUAN R, et al. A CrSi2-HfB2-SiC coating providing oxidation and ablation protection over 1973 K for SiC coated C/C composites[J]. Corrosion Science,2020,167:108536. doi: 10.1016/j.corsci.2020.108536 -

下载:

下载: