Local buckling updating engineering method of hat-stiffened composite panel based on flexural stiffness ratio

-

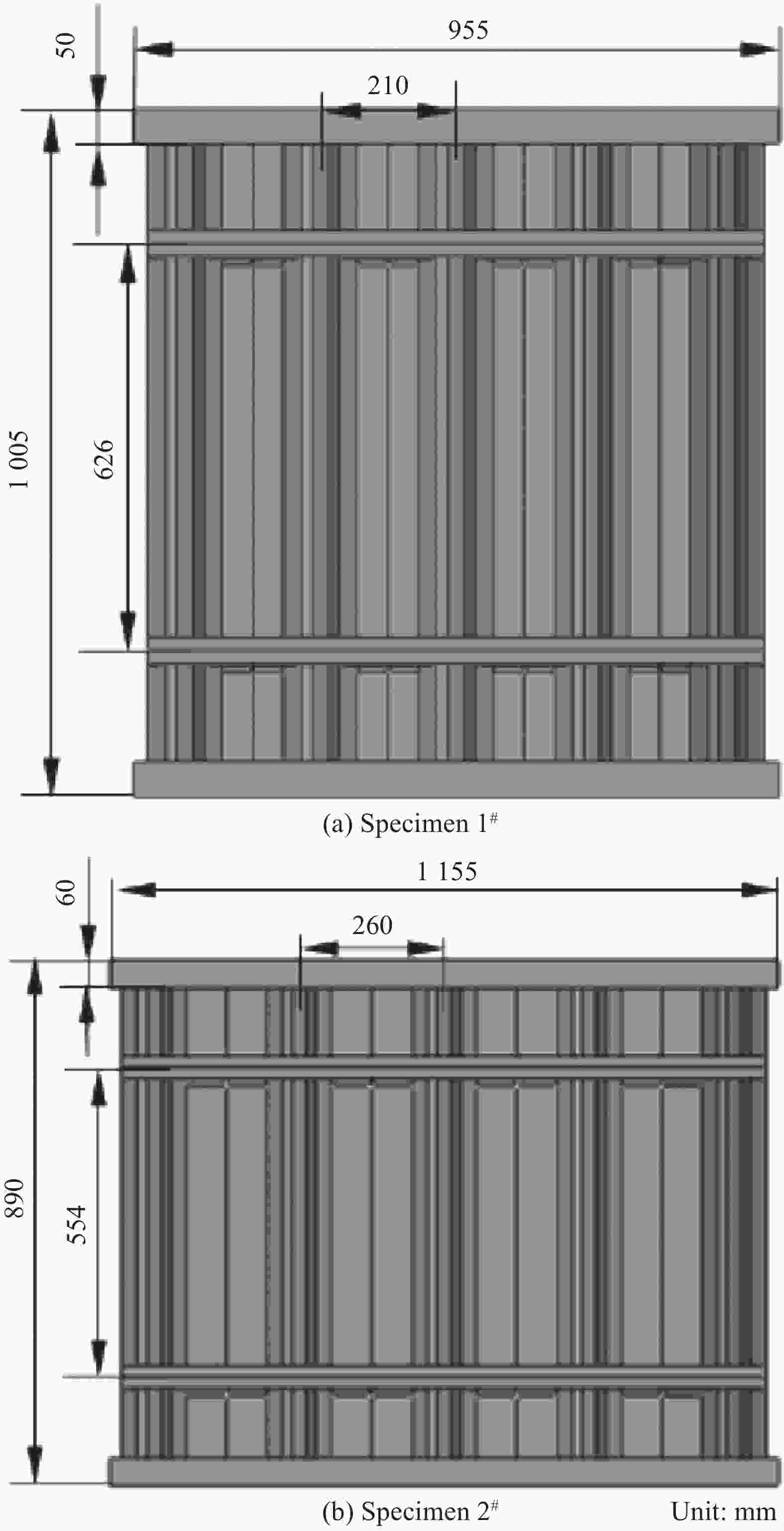

摘要: 为提高复合材料帽形加筋板蒙皮局部屈曲的工程分析方法精度,对典型复合材料帽形加筋板进行了轴压稳定性试验,提出了一种基于弯曲刚度比的复合材料帽形加筋板局部屈曲工程简化分析修正方法,所预测的屈曲载荷与轴压稳定性试验值误差在3%以内。采用有限元方法(FEM)及本文方法对两种构型的带筋条下缘条帽形加筋板进行了对比分析,本文方法与FEM计算误差在10%以内,表明本文提出的修正方法合理有效,满足工程精度要求。采用工程简化分析方法、能量法及本文方法对公开文献的试验数据进行了对比分析,结果表明采用本文方法可将工程简支屈曲分析误差和工程固支屈曲分析误差分别从41.5%、5.3%降低至3.8%,为复合材料帽形加筋板结构初步设计与分析提供了一种新的快速分析思路。Abstract: In order to improve the accuracy of local buckling engineering method of hat-stiffened composite panel, the stability experiment of typical panels under axial compression was first carried out, and then an updating engineering method for local buckling of hat-stiffened composite panel based on flexural stiffness ratio was proposed. The predicted buckling loads differ less than 3% from experimental results. The buckling analysis of two kinds of hat-stiffened panels with bottom flange was carried out by finite element model (FEM) method and the updating method this paper proposed comparatively. The error of compared results is within 10%, which verifies the reasonableness of the proposed method and satisfies the engineering accuracy. Experimental data recorded in public literature were analyzed by engineering simplified method, energy method and the updating method this paper proposed comparatively. Results show that the error by engineering simply and fixedly supported boundary conditions can be reduced from 41.5% and 5.3% to 3.8% respectively, which provides a new rapid analytical method for preliminary design of hat-stiffened composite panel.

-

Key words:

- hat-stiffened panel /

- composites /

- buckling /

- updating method /

- flexural stiffness ratio

-

表 1 单层材料参数

Table 1. Lamina material parameters

Material E11/GPa E22/GPa G12/GPa ν12 X850 162.0 9.1 4.6 0.331 Notes:E11—Elastic modulus in fiber direction; E22—Elastic modulus transverse fiber direction; ν12—Poisson’s ratio; G12—Shear modulus. 表 2 应变片编码方法

Table 2. Coding method of strain gauge

Coding location Coding meaning Coding method First number Specimen number 1—Specimen 1#; 2—Specimen 2# Second number Part type 1—Skin; 2—Stiffener Third number Row number of strain gauge 5 rows on skin, 5 rows on stiffeners, 2 rows on 2 frames, counting from up to down respectively Fourth number Column number of strain gauge 4 columns on inner skin, 9 columns on outer skin, 5 columns on 5 stiffeners, 4 columns on frame, counting from left to right respectively Fifth number Strain gauge on inner skin or outer skin 1—Outer skin; 2—Inner skin Sixth number Strain gauge location on stiffener 1—Crown; 2—Left web; 3—Right web; 4—Left bottom flange; 5—Right bottom flange Seventh number Strain gauge direction 1—0° direction; 2—45° direction; 3—90° direction 表 3 复合材料帽形加筋板轴压稳定性试验值与计算值对比

Table 3. Comparison of calculated and experimental values of local buckling load of hat-stiffened composite panel

No. D Experimental

buckling load /kNEngineering simplified

method/kNUpdating

method/kNError/% Simply

supportedBuilt-in Simply

supportedBuilt-in Updating

method1# 3.501 315 249 383 312 −21.0 21.6 −1.0 2# 3.456 185 154 244 189 −16.8 31.9 2.2 Note: D—Flexural stiffness ratio. 表 4 三筋条帽形加筋板有限元模型几何参数

Table 4. Geometric parameters of finite element models of hat-stiffened panels with three stiffeners

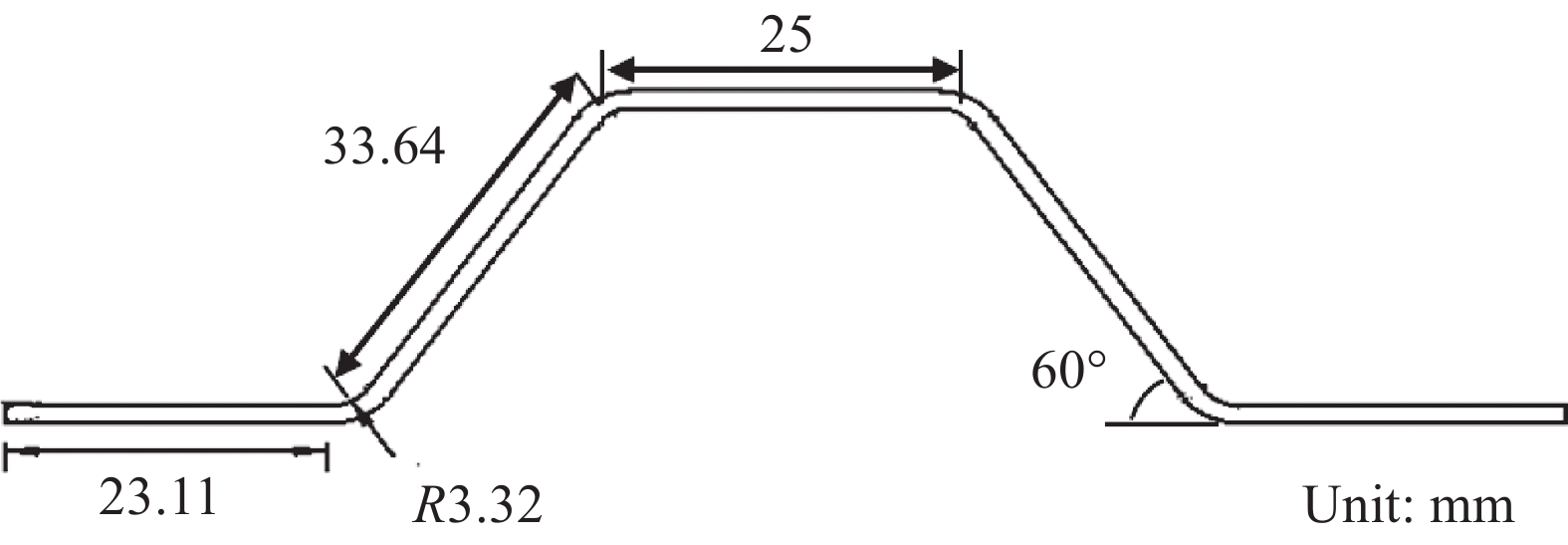

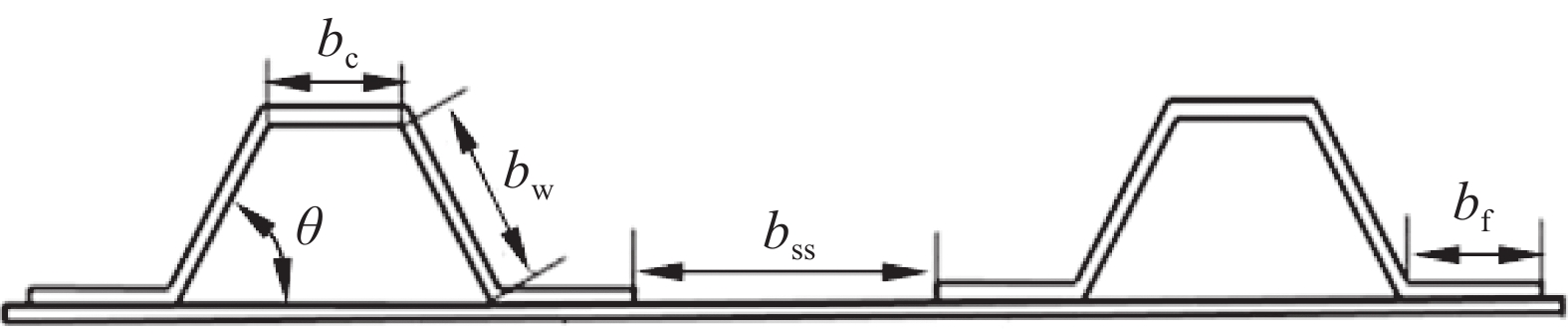

Type a

/mmB

/mmbc

/mmbw

/mmbf

/mmθ/(°) bss

/mm1 300 278 10.4 10.7 16.5 82.9 70 2 590 532 25 33 25 60 103 Notes: a—Length of stiffened panel; B—Width of stiffened panel; bc—Width of stiffener’s crown; bw—Width of stiffener’s web; bf—Width of stiffener’s bottom flange; θ—Angle between stiffener’s web and skin; bss—Width of skin adjacent stiffener. 表 5 三筋条帽形加筋板单层材料参数

Table 5. Lamina material parameters of hat-stiffened panels with three stiffeners

Type E11/GPa E22/GPa G12/ GPa $ {\nu _{12}} $ 1 98 10.8 5.2 0.31 2 154 8.5 4.5 0.35 表 6 三筋条帽形加筋板有限元模型铺层顺序及铺层厚度

Table 6. Stacking sequence and thickness of finite element models of hat-stiffened panels with three stiffeners

No. Skin Crown Web Flange Stacking

sequenceTotal

thickness/

mmStacking

sequenceTotal

thickness/

mmStacking

sequenceTotal

thickness/

mmStacking

sequenceTotal

thickness/

mm1.1 [45/0/0/−45/90]s 1 [09/−45/452/−452]s 2.8 [−45/452/−452]s 1 [03/−45/452/

−45/−45]s1.5 1.2 [45/0/−45/90/

45/−45/0]s1.4 [09/−45/452/−452]s 2.8 [−45/452/−452]s 1 [03/−45/452/

−45/−45]s1.5 1.3 [0/90]3s 1.2 [45/0/90/0/−45/

0/45/90]s1.5 [45/0/90/0/−45/

0/45/90]s1.5 [45/0/90/0/−45/

0/45/90]s1.5 2.1 [45/−45/−45/

90/45/0]s1.2 [45/0/0/−45/90]s 0.9 [45/0/0/−45/90]s 0.9 [45/0/0/−45/90]s 0.9 2.2 [45/−45/902/

45/0/90/0]s1.5 [0/45/0/0/−45/45]s 1.2 [0/45/0/0/−45/45]s 1.2 [0/45/0/0/−45/45]s 1.2 2.3 [45/−45/902/45/

0/90/0]s1.5 [45/0/0/−45/90]s 0.9 [45/0/0/−45/90]s 0.9 [45/0/0/−45/90]s 0.9 表 7 两类帽形加筋板轴压稳定性有限元值与计算值对比

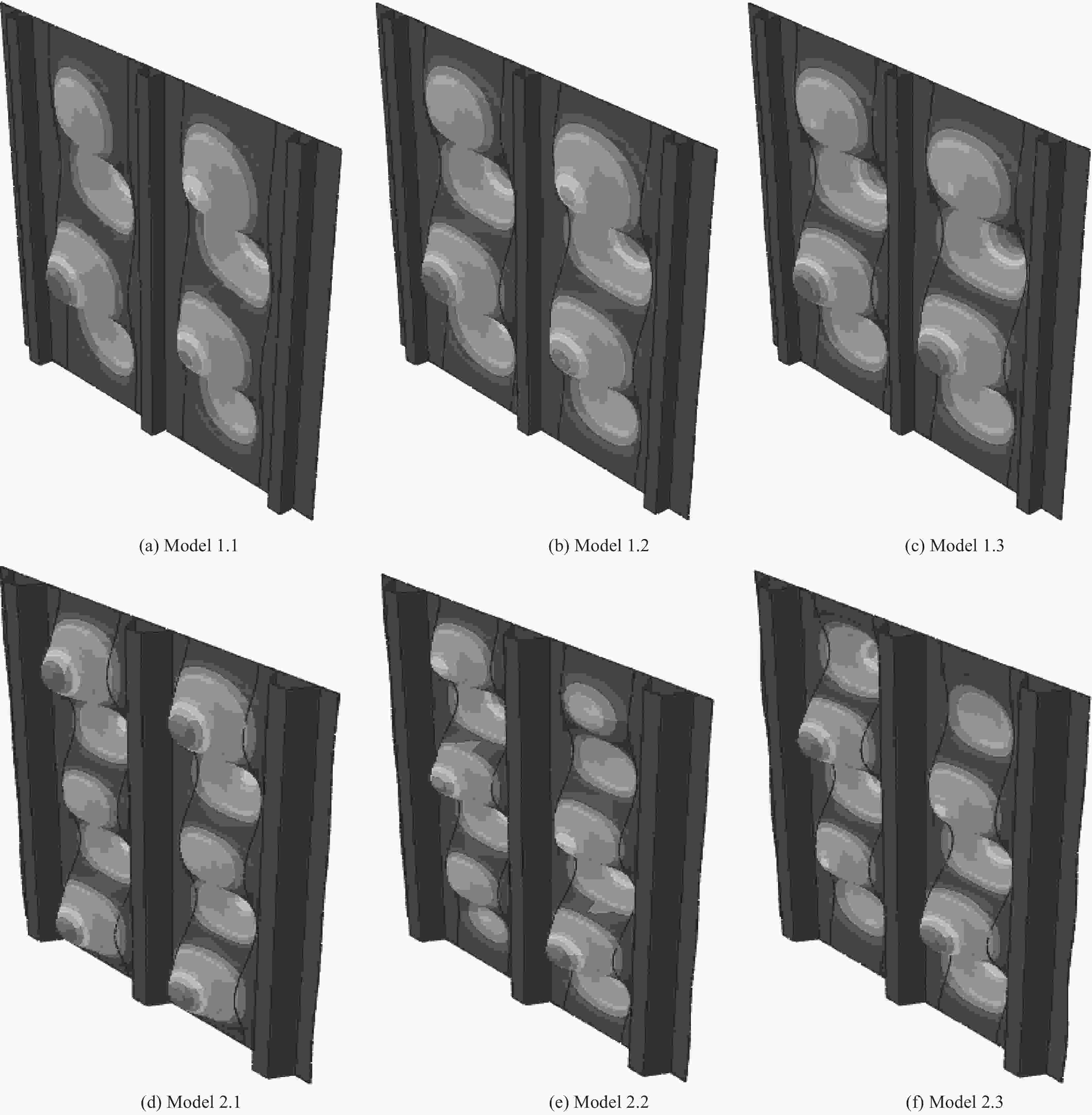

Table 7. Comparison of calculated and FEM values of local buckling load of two kinds of hat-stiffened composite panels

No. D FEM

buckling

load/kNEngineering simplified method/kN Updating method /kN Error/% Simply supported Built-in Simply

supportedBuilt-in Updating method 1.1

1.2

1.3

2.1

2.2

2.32.750

4.713

4.842

4.014

4.019

3.81513.0

38.5

23.9

26.4

52.7

43.27.7

15.9

9.4

16.0

28.5

23.113.1

29.0

19.1

24.7

46.5

37.714.2

38.1

26.0

27.9

54.6

41.2−40.8

−58.7

−60.7

−39.4

−45.9

−46.50.8

−24.7

−20.1

−6.4

−11.8

−12.79.2

−1.0

8.8

5.7

3.6

−4.6表 8 带横框的三筋条帽形加筋板局部屈曲载荷计算值与试验值对比

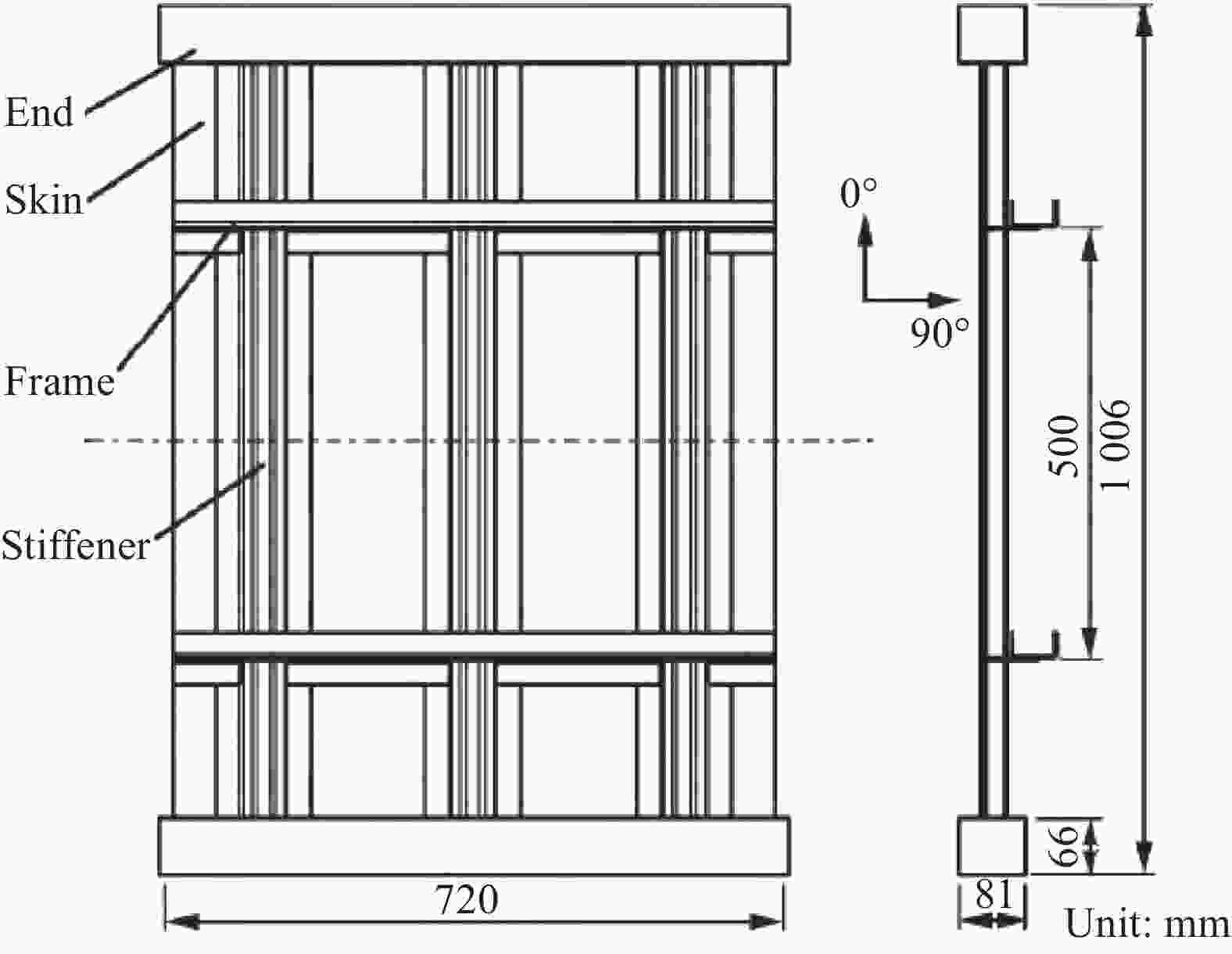

Table 8. Comparison of calculated and experimental values of local buckling load of hat-stiffened panels with three stiffeners and two frames

D Experimental

buckling

load/kNEngineering simplified method/kN Energy method/kN Updating method/kN Error/% Simply supported Built-in Simply supported Built-in Energy method Updating method 3.641 245.0 143.3 258 238.2 235.8 −41.5 5.3 −2.8 −3.8 -

[1] 杨乃宾, 章怡宁. 复合材料飞机结构设计[M]. 北京: 航空工业出版社, 2002.YANG Naibin, ZHANG Yining. Composite aircraft structure design[M]. Beijing: Aviation Industry Press, 2002(in Chinese). [2] CHRISTOS K. 飞机复合材料结构设计与分析[M]. 颜万亿, 译. 上海: 上海交通大学出版社, 2011.CHRISTOS K. Design and analysis of composite structures with application to aerospace structures[M]. YAN Wanyi, translated. Shanghai: Shanghai Jiao Tong University Press, 2011(in Chinese). [3] LIU X, HAN K, BAI R, et al. Buckling measurement and numerical analysis of M-type ribs stiffened composite panel[J]. Thin-Walled Structures,2014,85:117-124. [4] 李蓝天, 赵恂. 复合材料加筋板多失效模式可靠性分析[J]. 湖南科技大学学报(自然科学版), 2017, 32(2):52-57.LI Lantian, ZHAO Xun. Reliability analysis of stiffened composite plates with multiple failure modes[J]. Journal of Hunan University of Science & Technology (Natural Science Edition),2017,32(2):52-57(in Chinese). [5] 陈伟, 许希武. 复合材料双曲率壳屈曲和后屈曲的非线性有限元研究[J]. 复合材料学报, 2008, 25(2):178-187. doi: 10.3321/j.issn:1000-3851.2008.02.030CHEN Wei, XU Xiwu. Buckling and postbuckling response analysis of the doubly-curved composite shell by nonlinear FEM[J]. Acta Materiae Compositae Sinica,2008,25(2):178-187(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.030 [6] 孔斌, 陈普会, 陈炎. 复合材料整体加筋板轴压后屈曲失效评估方法[J]. 复合材料学报, 2014, 31(3):765-771.KONG Bin, CHEN Puhui, CHEN Yan. Post-buckling failure evaluation method of integrated composite stiffened panels under uniaxial compression[J]. Acta Materiae Compo-sitae Sinica,2014,31(3):765-771(in Chinese). [7] 刘从玉, 许希武, 陈康. 考虑脱粘的复合材料加筋板屈曲后屈曲及承载能力数值分析[J]. 复合材料学报, 2010, 27(6):158-166.LIU Congyu, XU Xiwu, CHEN Kang. Buckling, post-buckling and collapse analysis of stiffened composite panels with debonding damage[J]. Acta Materiae Compositae Sinica,2010,27(6):158-166(in Chinese). [8] 邵青, 何宇廷, 张腾, 等. 侧边边界条件对复合材料加筋板轴压载荷下屈曲和后屈曲性能的影响[J]. 复合材料学报, 2014, 31(3):741-748.SHAO Qing, HE Yuting, ZHANG Teng, et al. Influence of side boundary condition on buckling and post-buckling performance of composite stiffened panels under axial[J]. Acta Materiae Compositae Sinica,2014,31(3):741-748(in Chinese). [9] 孙中雷, 张国凡, 李军鹏. 轴压载荷下复合材料加筋板后屈曲承载能力研究[J]. 航空计算技术, 2016, 46(3):63-66. doi: 10.3969/j.issn.1671-654X.2016.03.016SUN Zhonglei, ZHANG Guofan, LI Junpeng. Study on loading capacity of composite panels under uniaxial compression[J]. Aeronautical Computing Technique,2016,46(3):63-66(in Chinese). doi: 10.3969/j.issn.1671-654X.2016.03.016 [10] 《飞机设计手册》总编委会. 飞机设计手册. 第9册. 载荷、强度和刚度[M]. 北京: 航空工业出版社, 2001.Aircraft Design Manual Committee. Aircraft design manual. 9th. Load, strength and stiffenss[M]. Beijing: Aviation Industry Press, 2001(in Chinese). [11] 中国航空研究院. 复合材料结构设计手册[M]. 北京: 航空工业出版社, 2001.Institute of Aeronautics China. Composite structure design handbook[M]. Beijing: Aviation Industry Press, 2001(in Chinese). [12] 中国航空研究院. 复合材料结构稳定性分析指南[M]. 北京: 航空工业出版社, 2002.Institute of Aeronautics China. Stability handbook of composite structure design[M]. Beijing: Aviation Industry Press, 2002(in Chinese). [13] MO Y, GE D, ZHOU J. Experiment and analysis of hat-stringer-stiffened composite curved panels under axial compression[J]. Composite Structures,2015,123:150-160. [14] 葛东云, 莫与明, 何柏灵, 等. 复合材料帽型加筋板轴压试验及承载能力预测[J]. 复合材料学报, 2016, 36(7):1531-1539.GE Dongyun, MO Yuming, HE bailing, et al. Test and ultimate load capacity prediction of hat-stiffened composite panel under axial compression[J]. Acta Materiae Compo-sitae Sinica,2016,36(7):1531-1539(in Chinese). [15] 于振波. 碳纤维复合材料加筋平板压缩屈曲计算方法研究[J]. 江苏科技信息, 2015(22):63-65. doi: 10.3969/j.issn.1004-7530.2015.22.023YU Zhenbo. Research on compression buckling analysis method of flat stiffend panels made of carbon fiber composite material[J]. Jiangsu Science & Technology Information,2015(22):63-65(in Chinese). doi: 10.3969/j.issn.1004-7530.2015.22.023 [16] 杨俊清, 王俊, 孟庆功. 复合材料帽型加筋壁板轴压屈曲工程算法验证研究[J]. 民用飞机设计与研究, 2019(1):18-23.YANG Junqing, WANG Jun, MENG Qinggong. The engineering calculation method of hat-stiffened composite panel under axial compression[J]. Civil Aircraft Design and Research,2019(1):18-23(in Chinese). [17] 汪厚冰, 陈昊, 雷安民, 等. 复合材料帽形加筋壁板轴压屈曲与后屈曲性能[J]. 复合材料学报, 2018, 35(8):2014-2022.WANG Houbing, CHEN Hao, LEI Anming, et al. Buckling and post-buckling performance of hat-stiffened composite panels under axial compression load[J]. Acta Materiae Compositae Sinica,2018,35(8):2014-2022(in Chinese). [18] 陈金睿, 陈普会, 孔斌, 等. 考虑筋条扭转弹性支持的轴压复合材料加筋板局部屈曲分析方法[J]. 南京航空航天大学学报, 2017, 49(1):76-82.CHEN Jinrui, CHEN Puhui, KONG Bin. Local buckling analysis of axially compressed stiffened laminated panels considering rotational restraint of stiffeners[J]. Journal of Nanjing University of Aeronautics & Astronautics,2017,49(1):76-82(in Chinese). -

下载:

下载: