Preparation and properties of dialdehyde cellulose/polyvinyl alcohol composite hydrogel

-

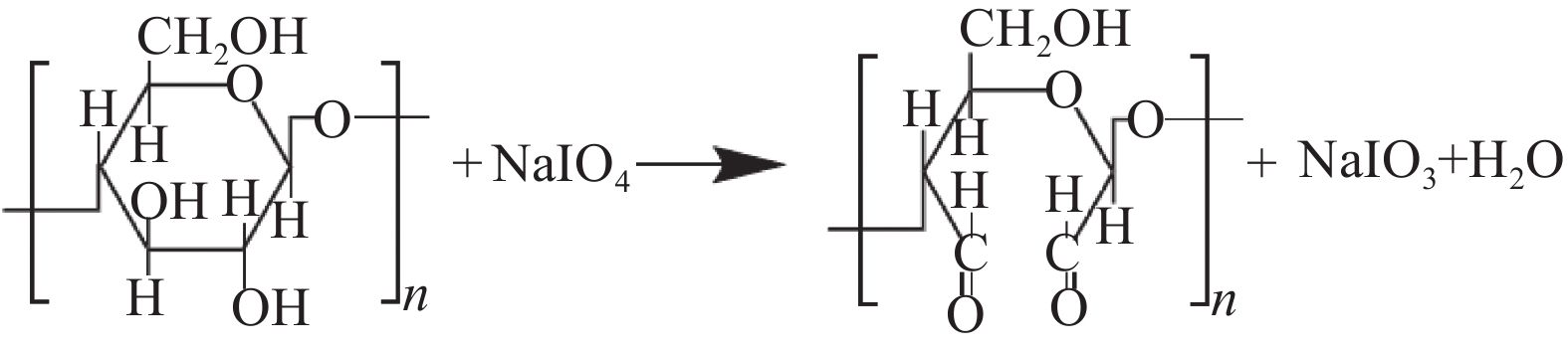

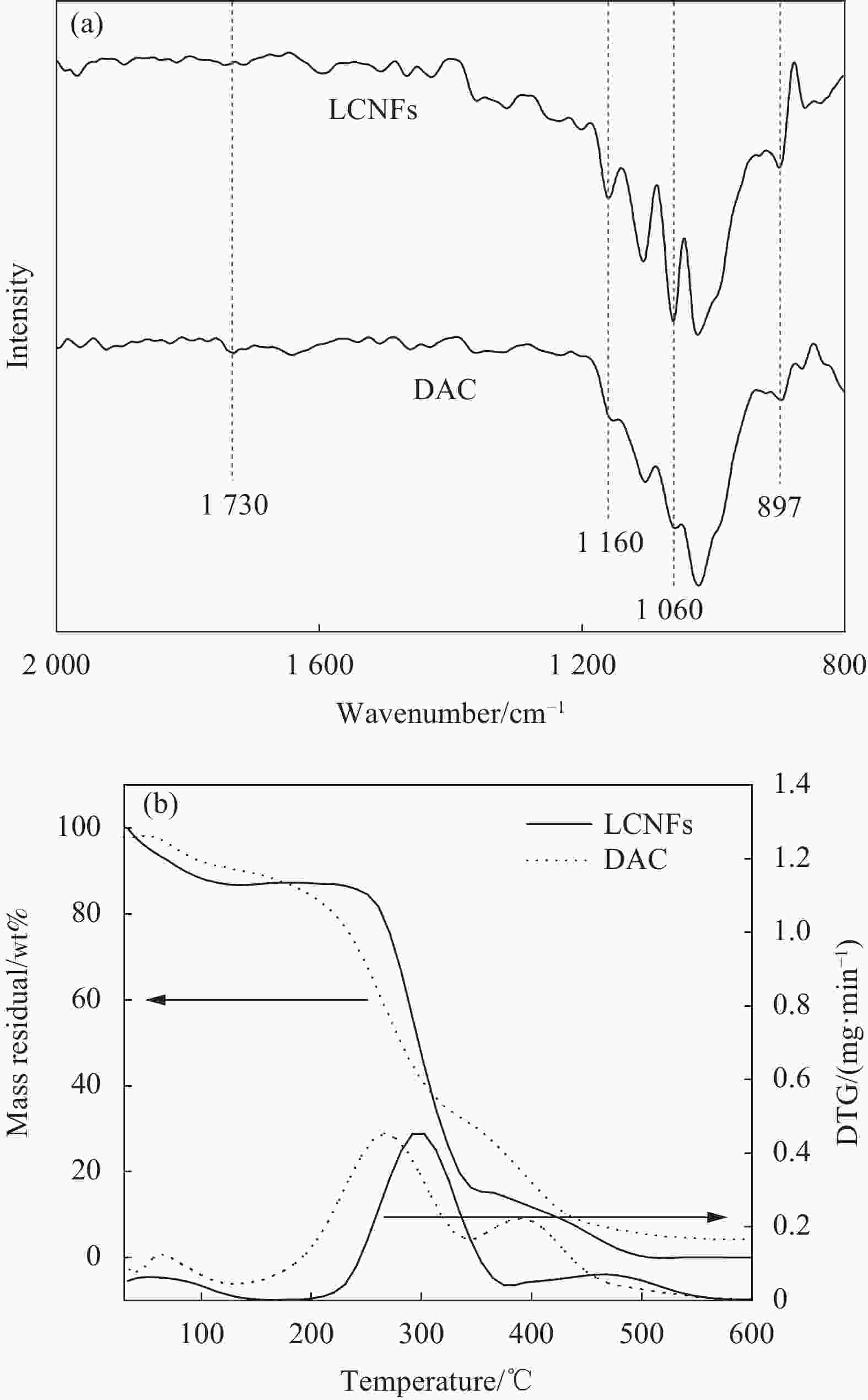

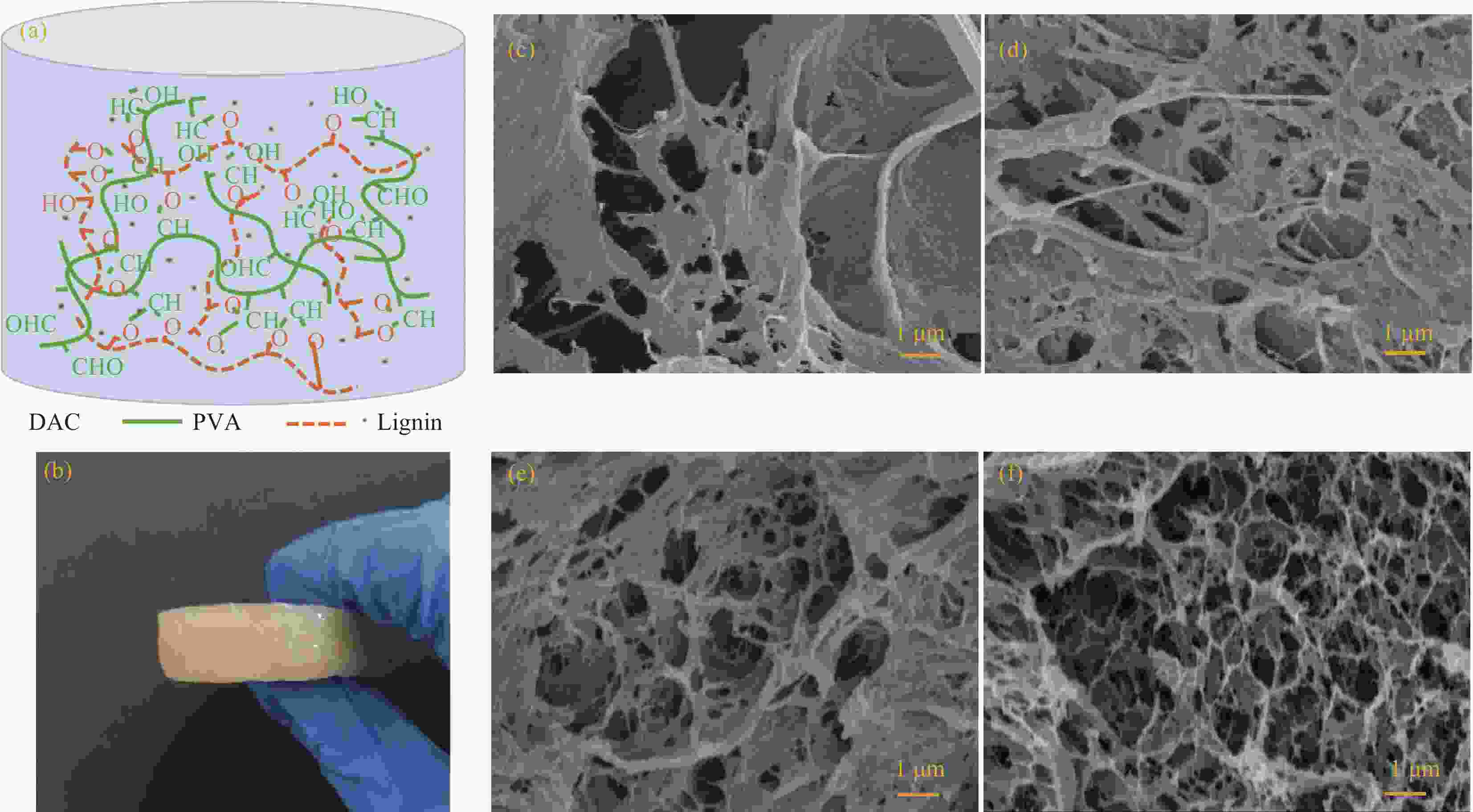

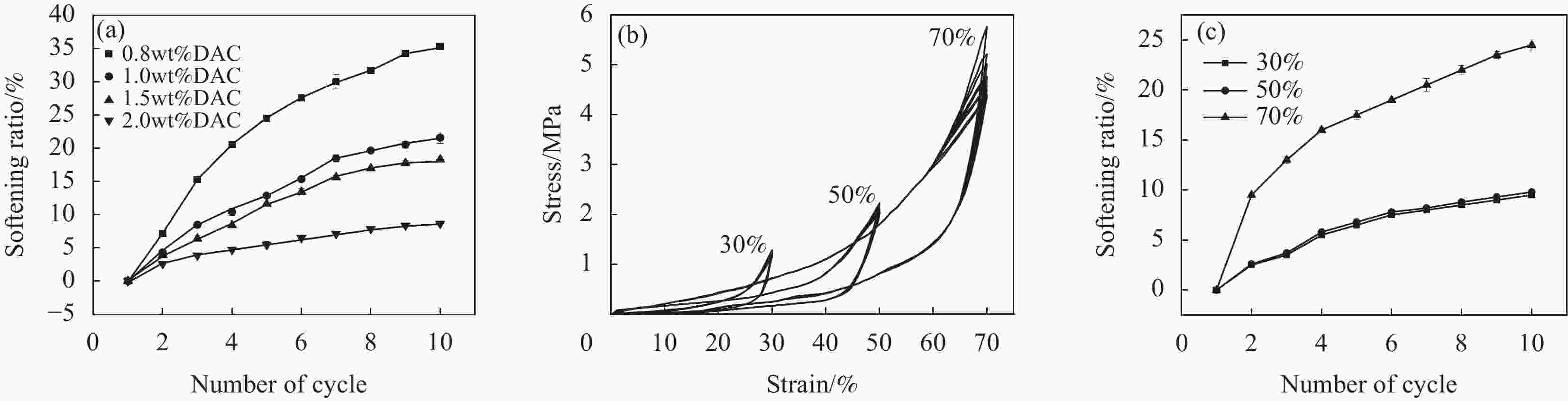

摘要: 开发高性能功能性水凝胶并建立药物缓释模型对医用伤口创面材料的开发具有重要的意义。以小麦秸秆为原料通过对甲苯磺酸(p-TsOH)、高频超声、高碘酸盐氧化制备含木质素的生物交联剂双醛纤维素(2,3-dialdehyde cellulose,DAC);以DAC为交联剂与聚乙烯醇(PVA)通过羟醛缩合反应形成互穿网络结构的DAC/PVA复合水凝胶,研究了DAC含量对复合水凝胶的微观结构、吸水溶胀性能、抗压缩性能及热稳定性的影响;采用物理共混法包埋氨苄青霉素(AP)制备DAC/PVA-AP载药水凝胶并研究其药物释放过程、释放机制及抑菌作用。结果表明,DAC/PVA复合水凝胶的微观结构呈多孔3D网络立体结构,交联密度随DAC含量的增加而增加;复合水凝胶的含水量及溶胀率随着DAC含量的增加而减小,当DAC含量从0.8wt%增加至2.0wt%时,其吸水溶胀率从1823.54%±13.89%降至1105.41%±7.06%;在70%的应变下,1.0wt%DAC/PVA水凝胶的初始抗压强度达到5.765 MPa,抗压缩性能较强;经121℃高温湿热灭菌后,复合水凝胶均能保持完整的形貌,说明其具有优异的耐高温性能;DAC/PVA-AP载药水凝胶的释放模型符合Korsmeyer-Peppas模型,缓释溶液对测试细菌具有良好的抑菌作用。以小麦秸秆为原料制备的互穿网络结构DAC/PVA复合水凝胶具有力学性能好、能耐高温灭菌等优点,在伤口创面敷料等领域具有潜在的应用价值。

-

关键词:

- 生物交联剂 /

- 双醛纤维素(DAC) /

- DAC/PVA复合水凝胶 /

- 抗压缩性能 /

- 耐高温性能 /

- 创面敷料

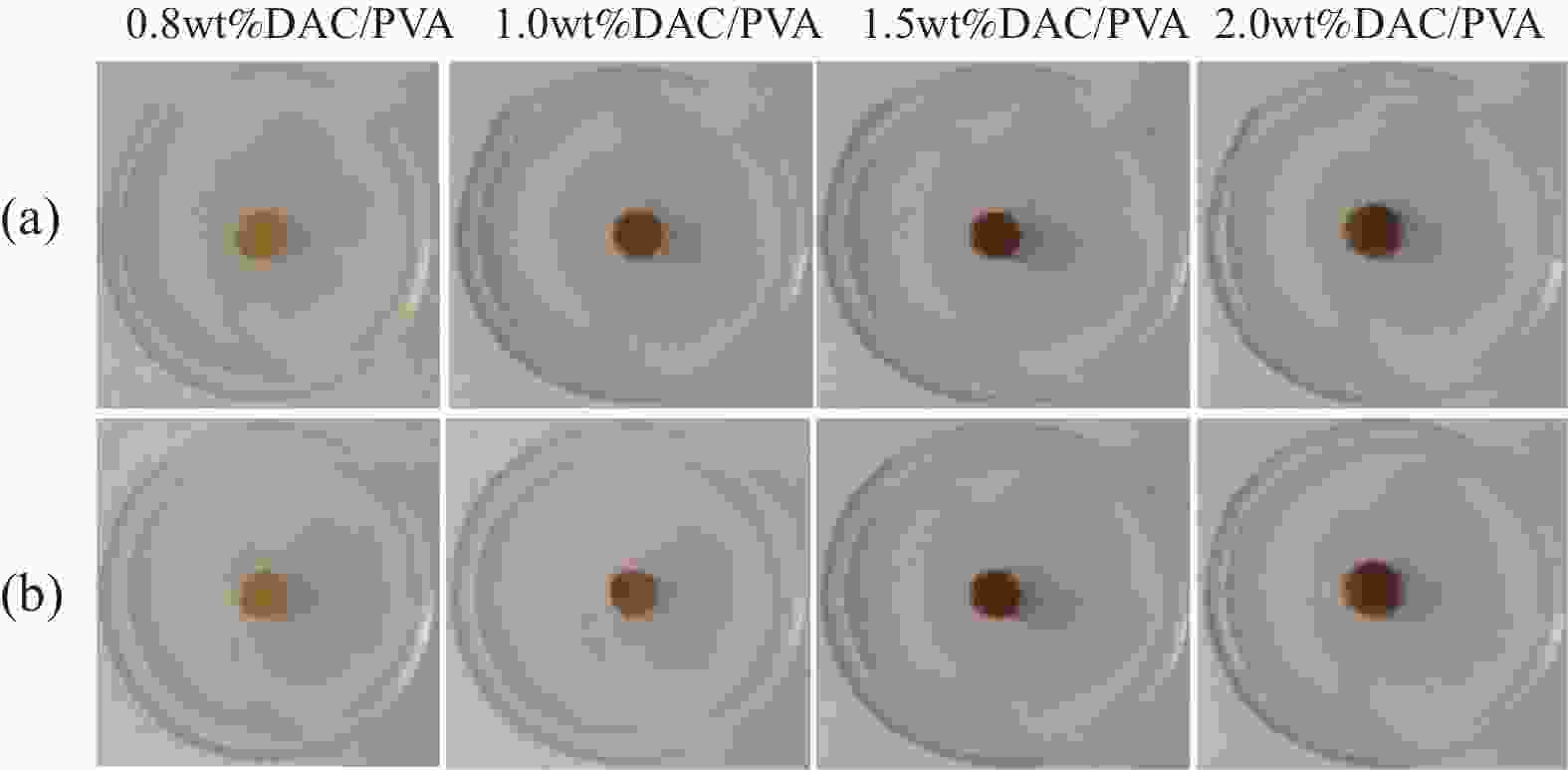

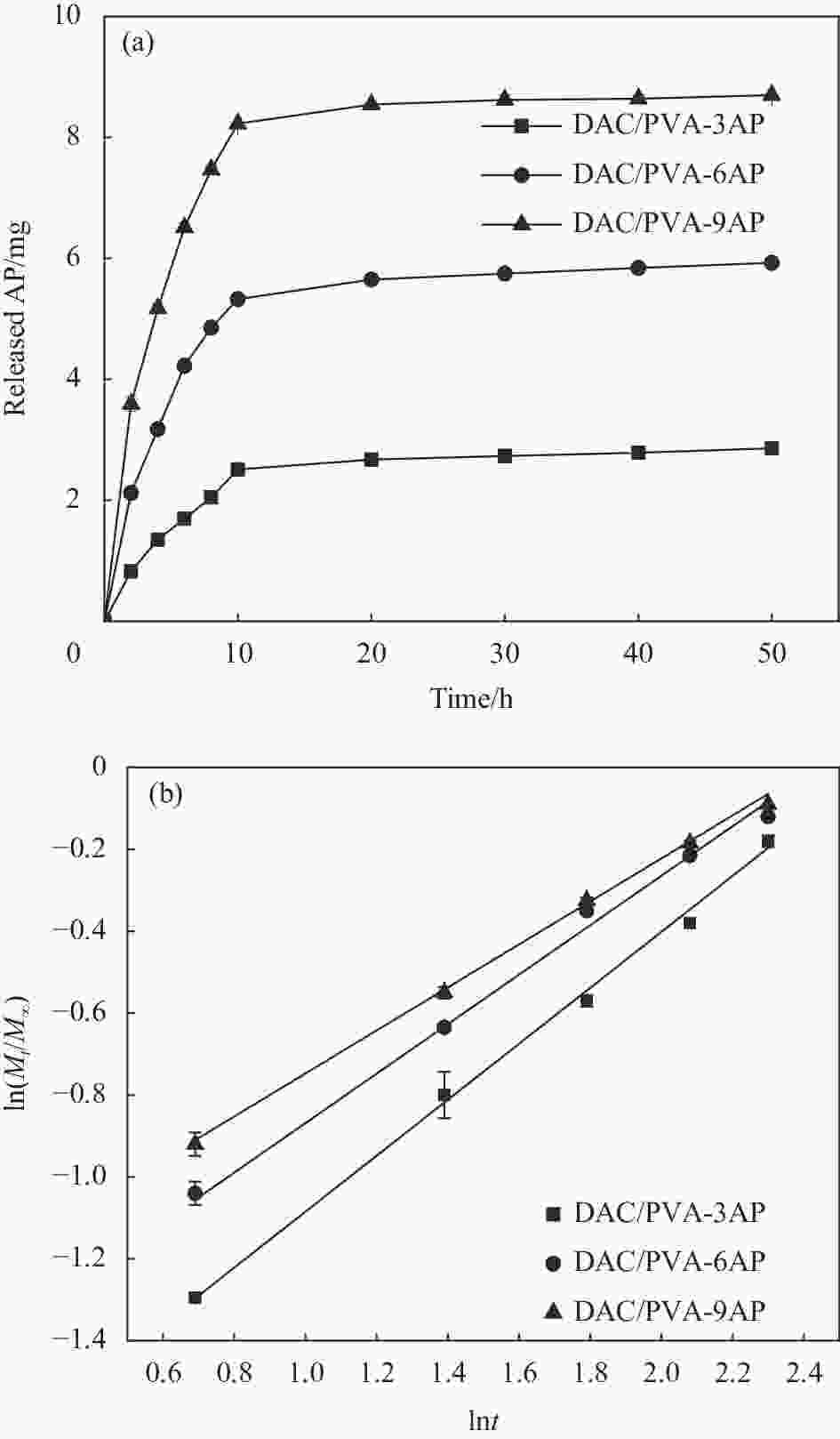

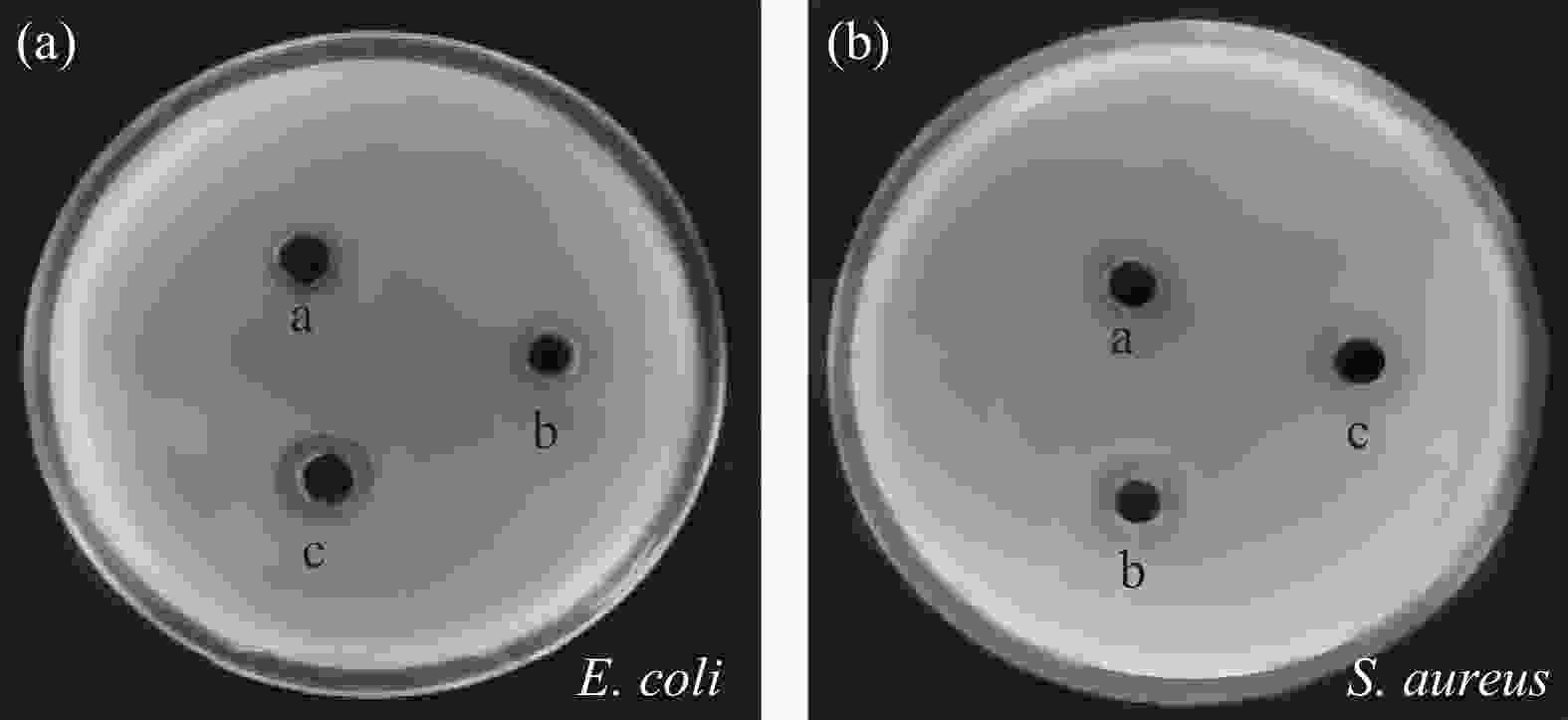

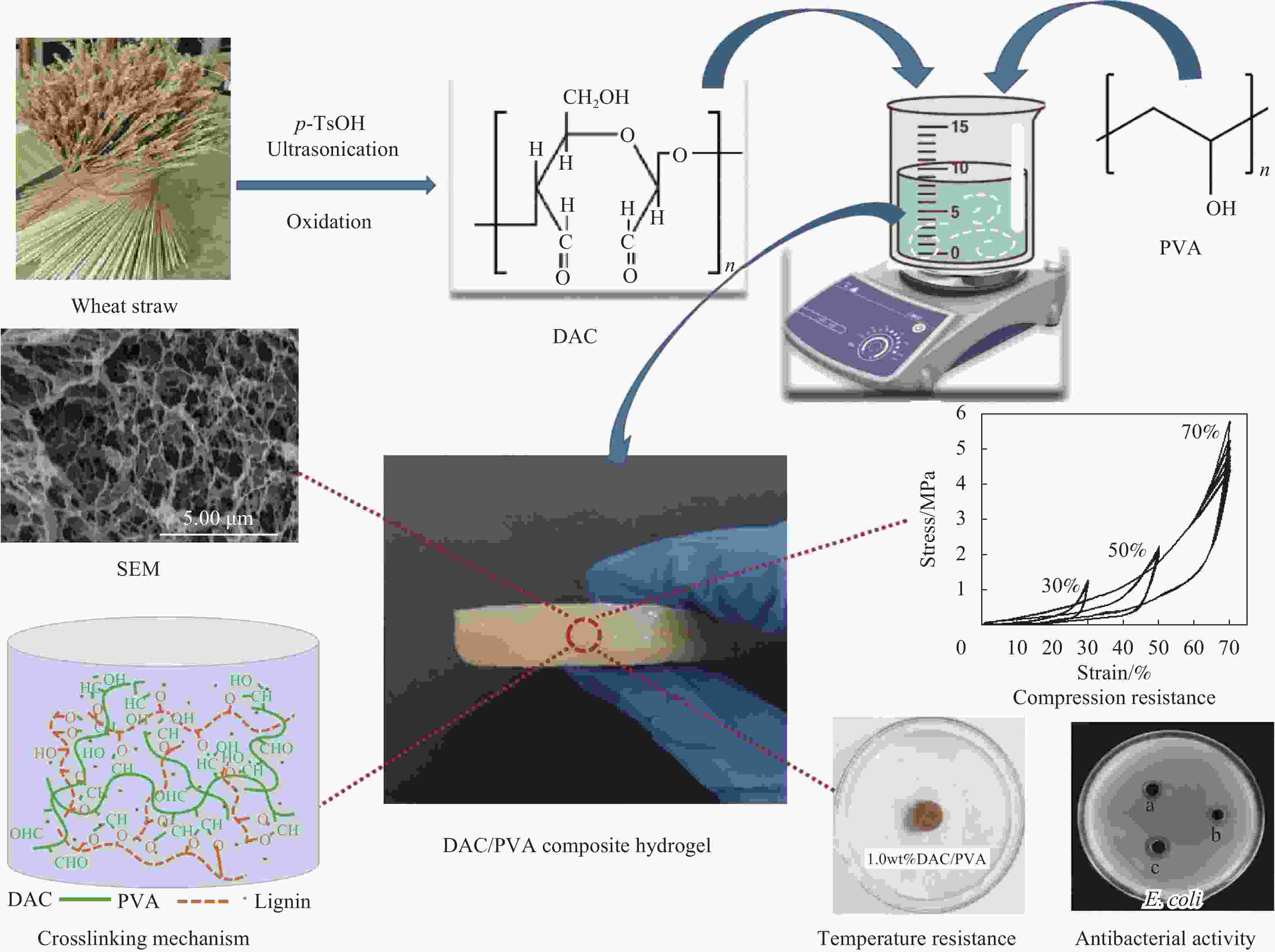

Abstract: Wheat straw was used as raw material to prepare lignin containing 2,3-dialdehyde cellulose (DAC) through sequential treatment of p-toluenesulfonic acid (p-TsOH), ultrasonication, sodium periodate oxidation. DAC was used as crosslinker to prepare 2,3-dialdehyde cellulose/polyvinyl alcohol (DAC/PVA) composite hydrogel through aldol condensation reaction. The microstructures, swelling properties, compression resistance and thermal stability of hydrogels were studied. Ampicillin (AP) was introduced to DAC/PVA composite hydrogel by embedding method to prepare DAC/PVA-AP hydrogel. Drug release process, release mechanism and antibacterial effect were studied as well. The results show that the microstructures of DAC/PVA composite hydrogels show a porous 3D network structure, and the crosslinking density increases with the increase of DAC. The water content and swelling property of composite hydrogel decrease with the increase of DAC. When the DAC concentration increases from 0.8wt% to 2.0wt%, the water absorption swelling rate decreases from 1823.54%±13.89% to 1105.41%±7.06%. The initial compressive strength of 1.0wt%DAC/PVA hydrogel reaches 5.765 MPa under 70% compression strain and present strong compression resistance. After sterilization at 121℃, the composite hydrogels can keep intact morphology, indicating that they have excellent high temperature resistance. The release model of DAC/PVA-AP hydrogel conforms to the Korsmeyer-Peppas model, and the sustained-release solution has a good antibacterial effect on the test bacteria. The DAC/PVA composite hydrogel prepared from wheat straw has a three-dimensional network structure, good mechanical properties and high temperature resistance, and has potential application the field of wound dressings. -

图 5 DAC/PVA复合水凝胶的抗压缩性能:(a) 70%压缩应变下循环压缩10次的软化率;(b) 1.0wt%DAC/PVA水凝胶在不同应变下经过压缩10次的循环压缩曲线;(c) 1.0wt%DAC/PVA水凝胶在不同应变下经过压缩10次的软化率

Figure 5. Compression resistance of DAC/PVA composite hydrogel: (a) Softening ratio after 10 cycles of compression under 70% compression strain; (b) Cyclic compression curves of 1.0wt%DAC/PVA hydrogel under different strains after 10 times of compression; (c) Softening ratio of 1.0wt%DAC/PVA hydrogel after 10 times compression under different strains

表 1 DAC/PVA复合水凝胶的含水量及溶胀率

Table 1. Water content and swelling rate of DAC/PVA composite hydrogels

Hydrogel sample Water content/% Swelling ratio/% 0.8wt%DAC/PVA 82.82±0.04 1823.54±13.89 1.0wt%DAC/PVA 81.21±0.02 1555.16±15.98 1.5wt%DAC/PVA 79.68±0.01 1318.90±14.50 2.0wt%DAC/PVA 79.08±0.01 1105.41±7.06 表 2 DAC/PVA水凝胶释放AP的Korsmeyer-Peppas模型的主要参数

Table 2. Main parameters of Korsmeyer-Peppas model for AP release by DAC/PVA hydrogel

Type of model Samples Fitting parameters K n R2 Mt/M∞=Ktn DAC/PVA-3AP 0.17330 0.65996 0.99808 DAC/PVA-6AP 0.24638 0.57737 0.98744 DAC/PVA-9AP 0.27144 0.54222 0.99911 Notes: K—Drug release rate; n—Drug release diffusion index; R2—Coefficient of association. -

[1] SAU Y C, YUKKEE C P, ANNE-CELIINE K, et al. Additive manufacturing of hydrogel-based materials for next-generation implantable medical devices[J]. Science Robotics,2017,2(2):eaah 6451. doi: 10.1126/scirobotics.aah6451 [2] JINAH K, ANTHONY C, ANUJ C. Extended delivery of ophthalmic drugs by silicone hydrogel contact lenses[J]. Biomaterials,2008,29(14):2259-2269. doi: 10.1016/j.biomaterials.2008.01.030 [3] ELSNER J J, BERDICEVSKY I, ZILBERMAN M. In vitro microbial inhibition and cellular response to novel biodegradable composite wound dressings with controlled release of antibiotics[J]. Acta Biomaterialia,2011,7(1):325-336. doi: 10.1016/j.actbio.2010.07.013 [4] ELBADAWY A K, ELREFAUE S K, CHEN X. A review on polymeric hydrogel membranes for wound dressing applications: PVA-based hydrogel dressings[J]. Journal of Advanced Research,2017,8(3):217-233. doi: 10.1016/j.jare.2017.01.005 [5] 韩颖, 徐玉茵, 田林奇, 等. 聚乙烯醇基水凝胶敷料的研究进展[J]. 中国医疗器械杂志, 2018, 42(6):437-439, 443. doi: 10.3969/j.issn.1671-7104.2018.06.013HAN Ying, XU Yuyin, TIAN Linqi, et al. Research progress of polyvinyl alcohol-based hydrogel dressing[J]. Chinese Journal of Medical Devices,2018,42(6):437-439, 443(in Chinese). doi: 10.3969/j.issn.1671-7104.2018.06.013 [6] AMIRALIAN N, ANNA P K, MEMMOTT P, et al. Isolation of cellulo senanofibrils from Triodia pungens via different mechanical methods[J]. Cellulose,2015,22(4):2483-2498. doi: 10.1007/s10570-015-0688-x [7] ABITBOL T, JOHNSTONE T, THOMOS M, et al. Reinforcement with cellulose nanocrystals of poly(vinyl alcohol) hydrogels prepared by cyclic freezing and thawing[J]. Soft Matter,2011,7(6):2373-2379. doi: 10.1039/c0sm01172j [8] CHANG C Y, ANG L, ZHANG L N. Effects of crosslinking methods on structure and properties of cellulose/PVA hydrogels[J]. Macromolecular Chemistry and Physics,2008,209(12):1266-1273. doi: 10.1002/macp.200800161 [9] 陆升, 程绍玲. 交联NFC/PVA水凝胶的制备及对重金属吸附研究[J]. 山西大学学报(自然科学版), 2020, 43(2):377-384. doi: 10.13451/j.sxu.ns.2019035LU Sheng, CHENG Shaoling. Preparation and adsorption properties of heavy metal ions of crosslinked NFC/PVA hydrogels[J]. Journal of Shanxi University (Natural Science Edition),2020,43(2):377-384(in Chinese). doi: 10.13451/j.sxu.ns.2019035 [10] BIAN H Y, JIAO L, WANG R B, et al. Lignin nanoparticles as nano-spacers for tuning the viscoelasticity of cellulose nanofibril reinforced polyvinyl alcohol-borax hydrogel[J]. European Polymer Journal,2018,107:267-274. doi: 10.1016/j.eurpolymj.2018.08.028 [11] LUKAS M, JAN V, JIRI K, et al. Dialdehyde cellulose crosslinked poly(vinyl alcohol) hydrogels: Influence of catalyst and crosslinker shelf life[J]. Carbohydrate Polymers,2018,198:181-190. doi: 10.1016/j.carbpol.2018.06.035 [12] MONIKA M, LUKAS M, ZDENKA C, et al. Design of dialdehyde cellulose crosslinked poly(vinyl alcohol) hydrogels for transdermal drug delivery and wound dressings[J]. Materials Science and Engineering C,2020,116:111242. doi: 10.1016/j.msec.2020.111242 [13] UNG K, YEONG R L, KANG T H K, et al. Protein adsorption of dialdehyde cellulose-crosslinked chitosan with high amino group contents[J]. Carbohydrate Polymers,2017,163:34-42. doi: 10.1016/j.carbpol.2017.01.052 [14] DOU J, BIAN H, YELLE D J, et al. Lignin containing cellulose nanofibril production from willow bark at 80°C using a highly recyclable acid hydrotrope[J]. Industrial Crops and Products,2019,129:15-23. doi: 10.1016/j.indcrop.2018.11.033 [15] BIAN H, CHEN L, DAI H, et al. Integrated production of lignin containing cellulose nanocrystals (LCNC) and nanofibrils (LCNF) using an easily recyclable dicarboxylic acid[J]. Carbohydrate Polymers,2017,167:167-176. doi: 10.1016/j.carbpol.2017.03.050 [16] YANG M Y, ZHANG X, GUAN S Y, et al. Preparation of lignin containing cellulose nanofibers and its application in PVA nanocomposite films[J]. International Journal of Biological Macromolecules,2020,158(3):1259-1267. doi: 10.1016/j.ijbiomac.2020.05.044 [17] YAN G, ZHANG X, LI M, et al. Stability of soluble dialdehyde cellulose and the formation of hollow microspheres: Optimization and characterization[J]. ACS Sustainable Chemistry & Engineering,2019,7(2):2151-2159. doi: 10.1021/acssuschemeng.8b04825 [18] CHEN G, ZHANG Y, XU D K, et al. Low cycle fatigue and creep-fatigue interaction behavior of nickel-base superalloy GH4169 at elevated temperature of 650°C[J]. Materials Science and Engineering: A,2016,655:175-182. doi: 10.1016/j.msea.2015.12.096 [19] SHAN Y, LEI J C, CHEN S C, et al. Development of gelatin/bacterial cellulose composite sponges as potential natural wound dressings[J]. International Journal of Biological Macromolecules,2019,133:148-155. doi: 10.1016/j.ijbiomac.2019.04.095 [20] 赵春杰, 何春馥, 张薇薇, 等. 紫外分光光度法测定尿中氨苄青霉素的浓度[J]. 沈阳药学院学报, 1988(1):49-52.ZHAO Chunjie, HE Chunfu, ZHANG Weiwei, et al. Determination of ampicillin in urine by ultraviolet spectrophotometry[J]. Journal of Shenyang Pharmaceutical College,1988(1):49-52(in Chinese). [21] 吕苗苗. 功能化双醛纤维素的制备与性能研究[D]. 天津: 天津大学, 2018: 12-13.LV Miaomiao. Preparation and properties of functionalized dialdehyde cellulose[D]. Tianjin: Tianjin University, 2018: 12-13(in Chinese). [22] 徐朝阳, 李健昱, 石小梅, 等. 聚乙二醇改性纳米纤维素/聚乙烯醇复合水凝胶的制备及性能[J]. 复合材料学报, 2017, 34(4):708-713. doi: 10.13801/j.cnki.fhclxb.20160819.001XU Zhaoyang, LI Jianyu, SHI Xiaomei, et al. Preparation and properties of polyethylene glycol modified nanocellulosic/polyvinyl alcohol composite hydrogel[J]. Acta Materiae Compositae Sinica,2017,34(4):708-713(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160819.001 [23] ZHU L X, LIU Y, JIANG Z M, et al. Highly temperature resistant cellulose nanofiber/polyvinyl alcohol hydrogel using aldehyde cellulose nanofiber as cross-linker[J]. Cellulose,2019,26:5291-5303. doi: 10.1007/s10570-019-02435-8 [24] CUI Q, ZHENG Y, LIN Q, et al. Selective oxidation of bacterial cellulose by NO2-HNO3[J]. RSC Advances,2013,4(4):1630-1639. doi: 10.1039/C3RA44516J [25] ZHU L X, QIU J H, SAKAI E, et al. Rapid recovery double cross-linking hydrogel with stable mechanical properties and high resilience triggered by visible light[J]. ACS Applied Materials & Interfaces,2017,9(15):13593-13601. doi: 10.1021/acsami.7b01003 [26] ZHU L X, QIU J H, SAKAI E, et al. Design of a rubbery carboxymethyl cellulose/polyacrylic acid hydrogel via visible-light-triggered polymerization[J]. Macromolecular Materials and Engineering,2017,302(6):513-520. doi: 10.1002/mame.201600509 [27] NAIRI V, MEDDA L, MONDUZZI M, et al. Adsorption and release of ampicillin antibiotic from ordered mesoporous silica[J]. Journal of Colloid and Interface Science,2017,497:217-225. doi: 10.1016/j.jcis.2017.03.021 -

下载:

下载: