Nondestructive testing of fiber reinforced polymer-steel interfacial defects based on eddy current thermography

-

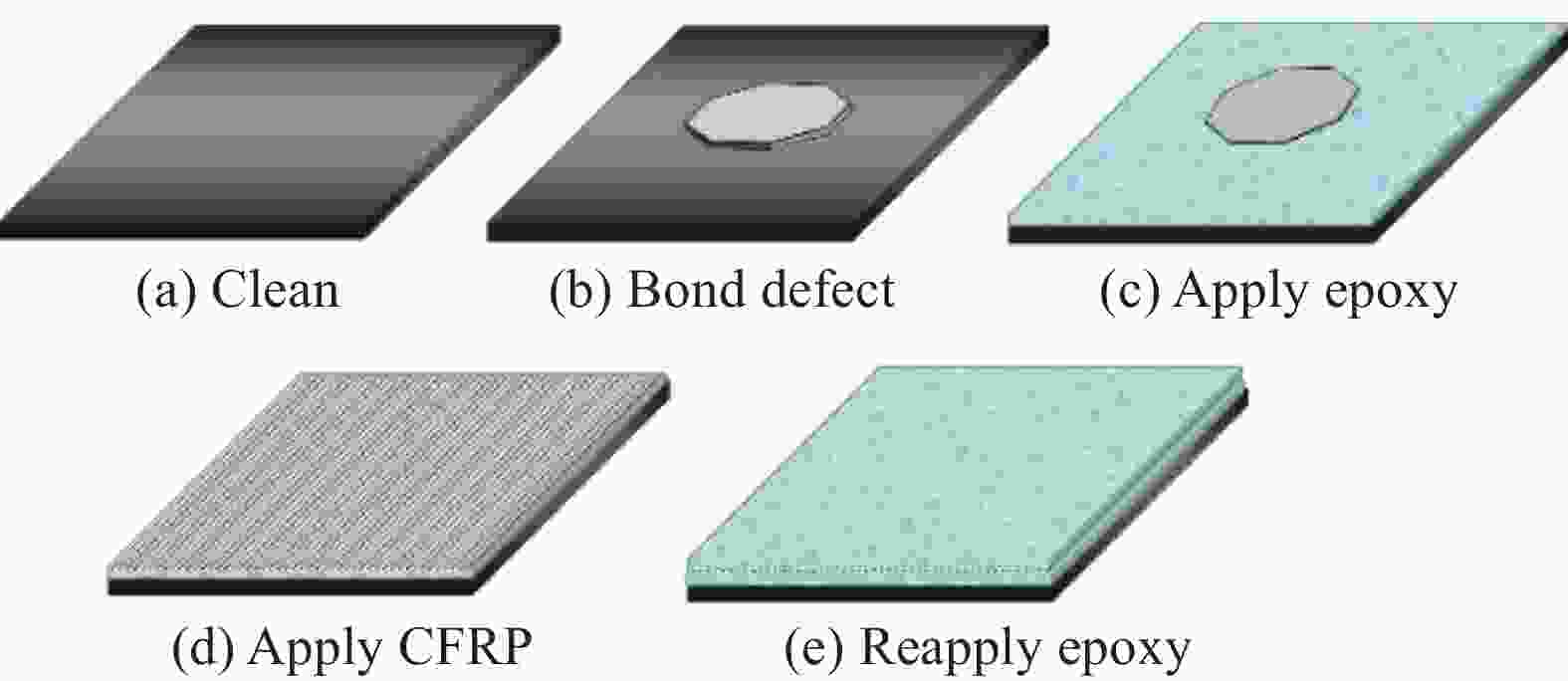

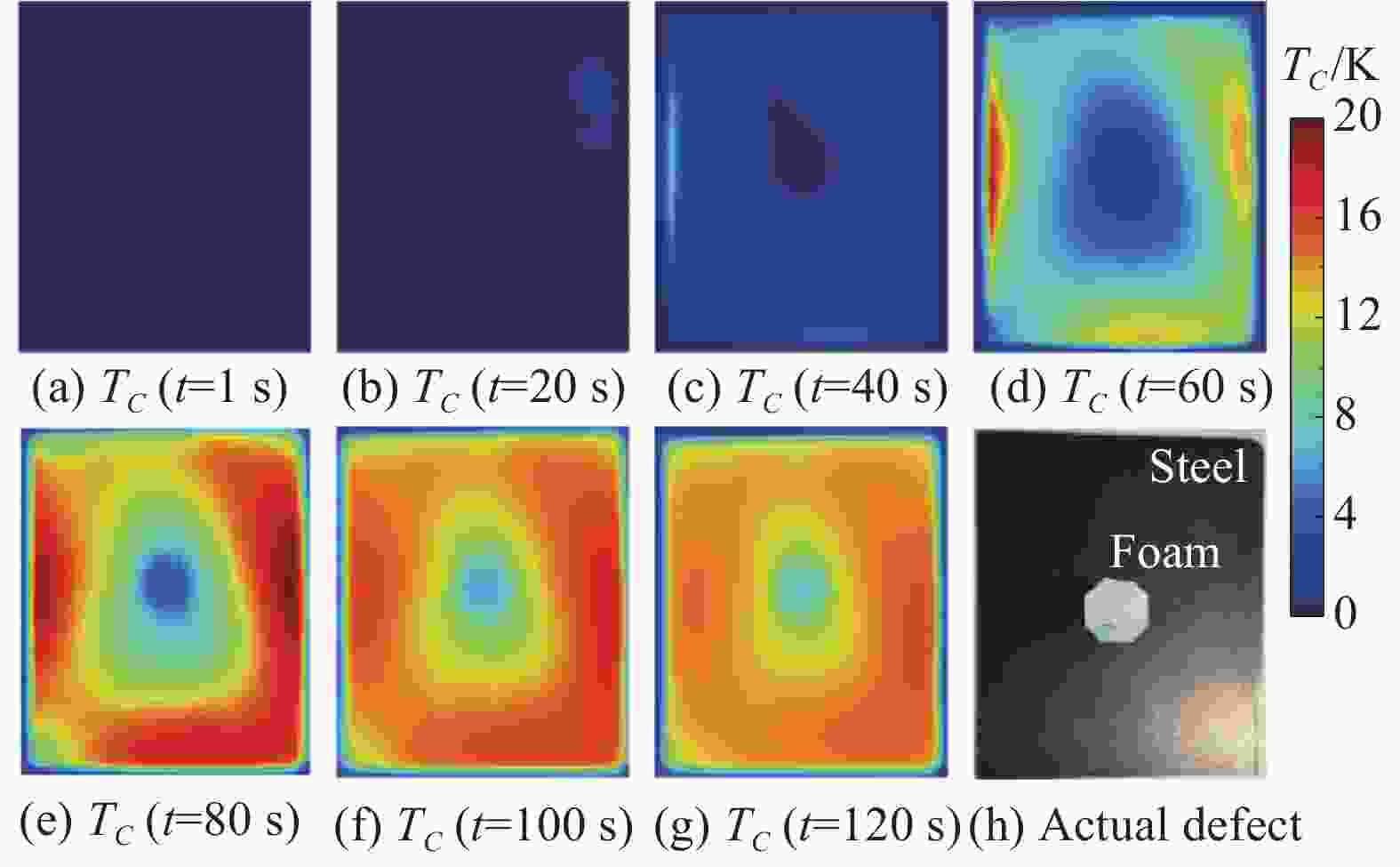

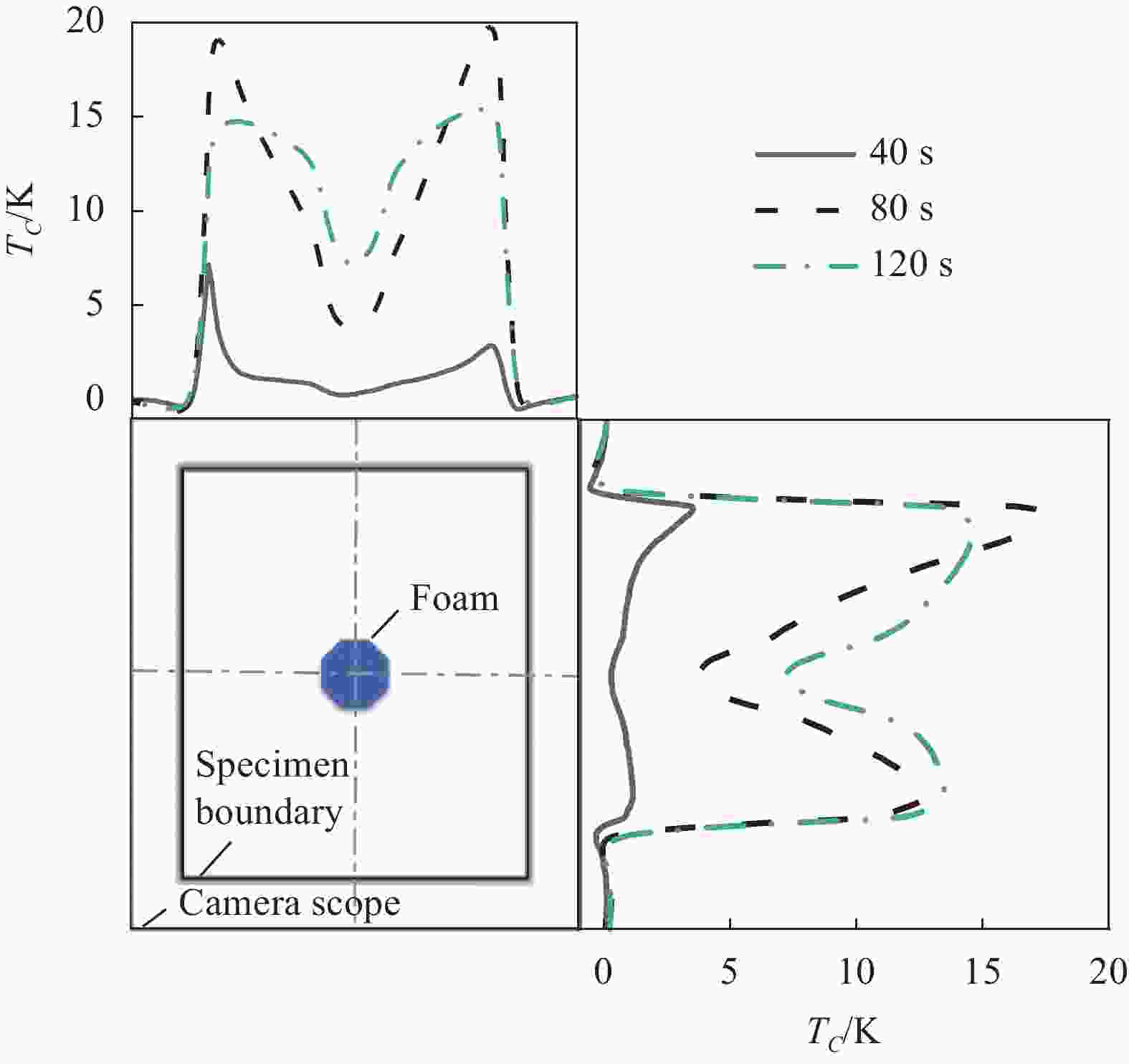

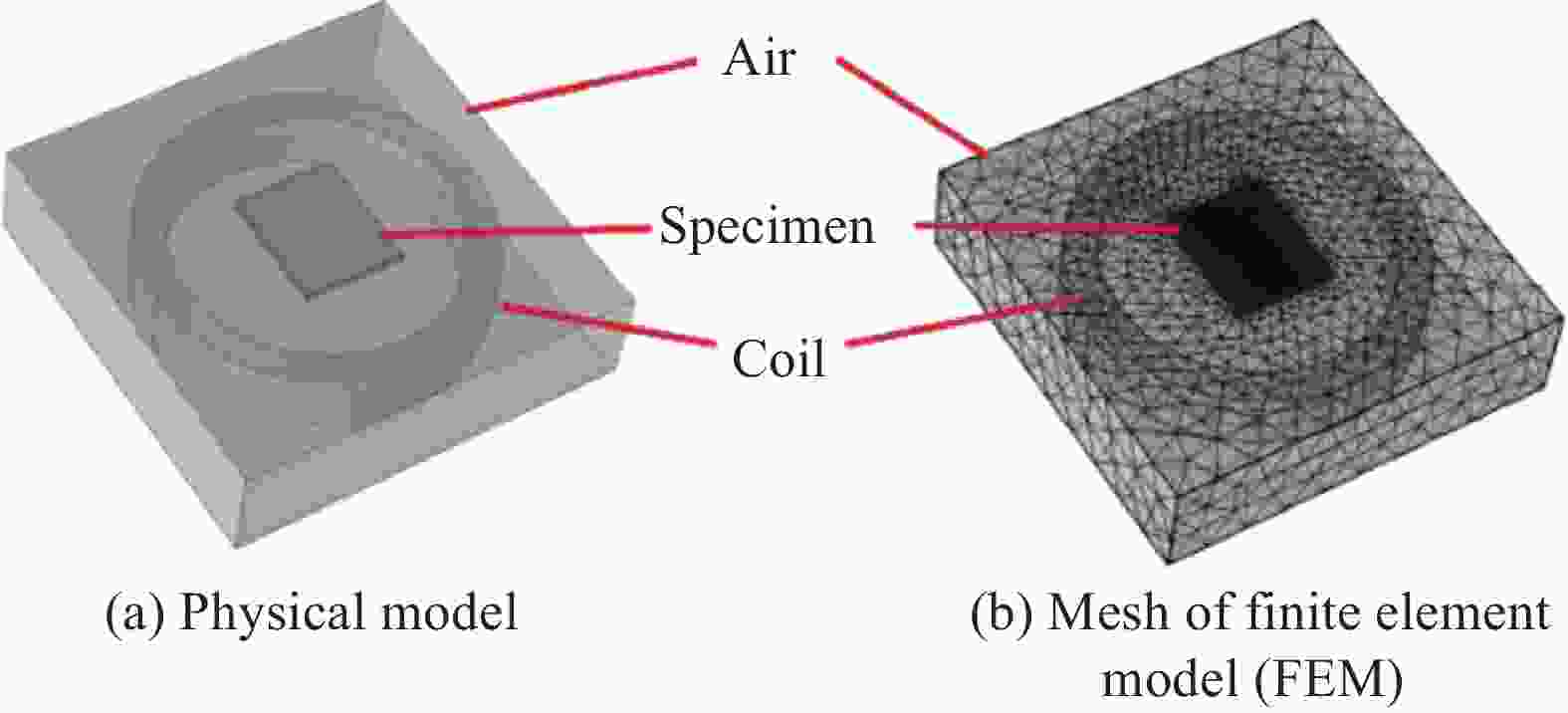

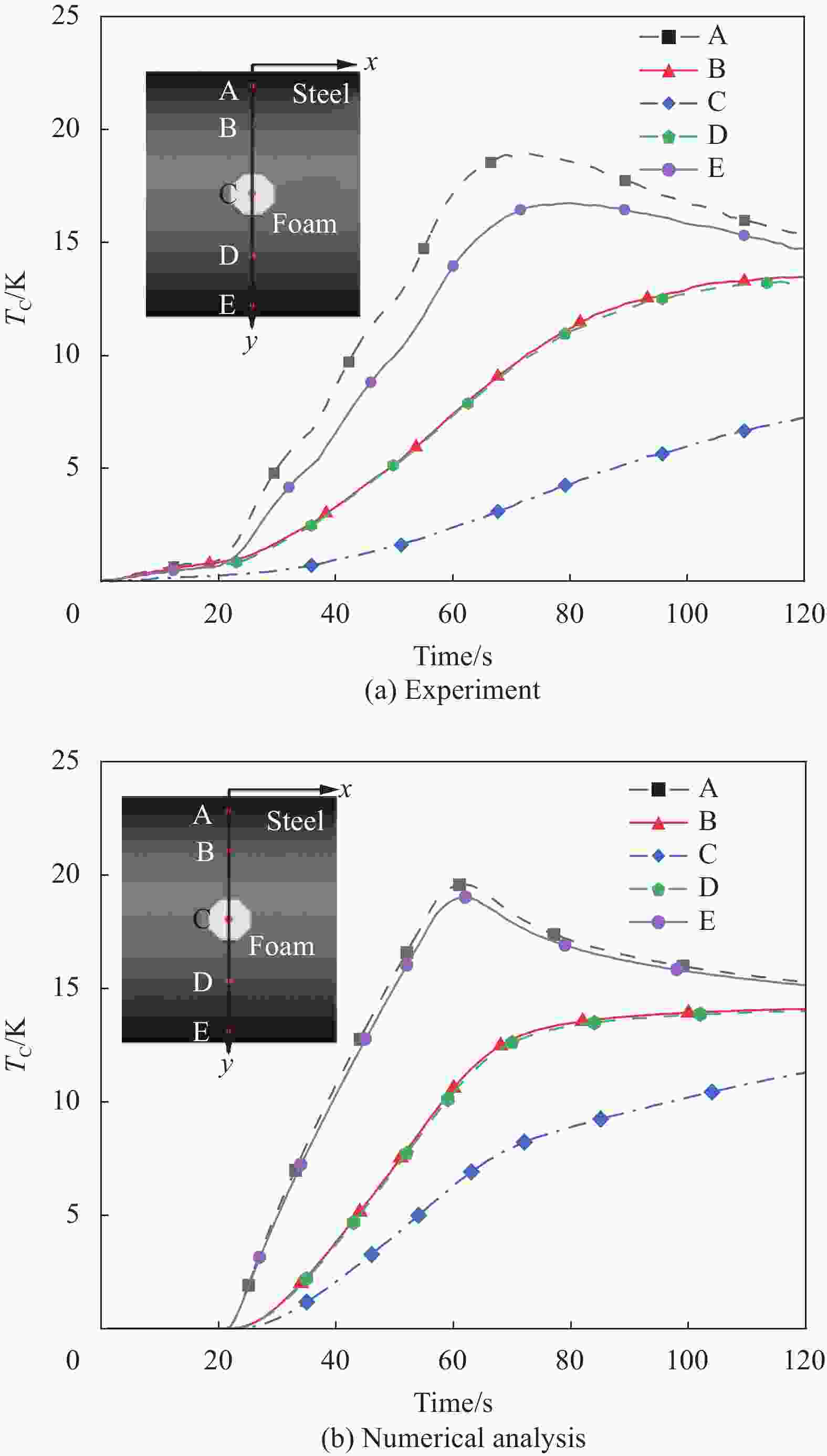

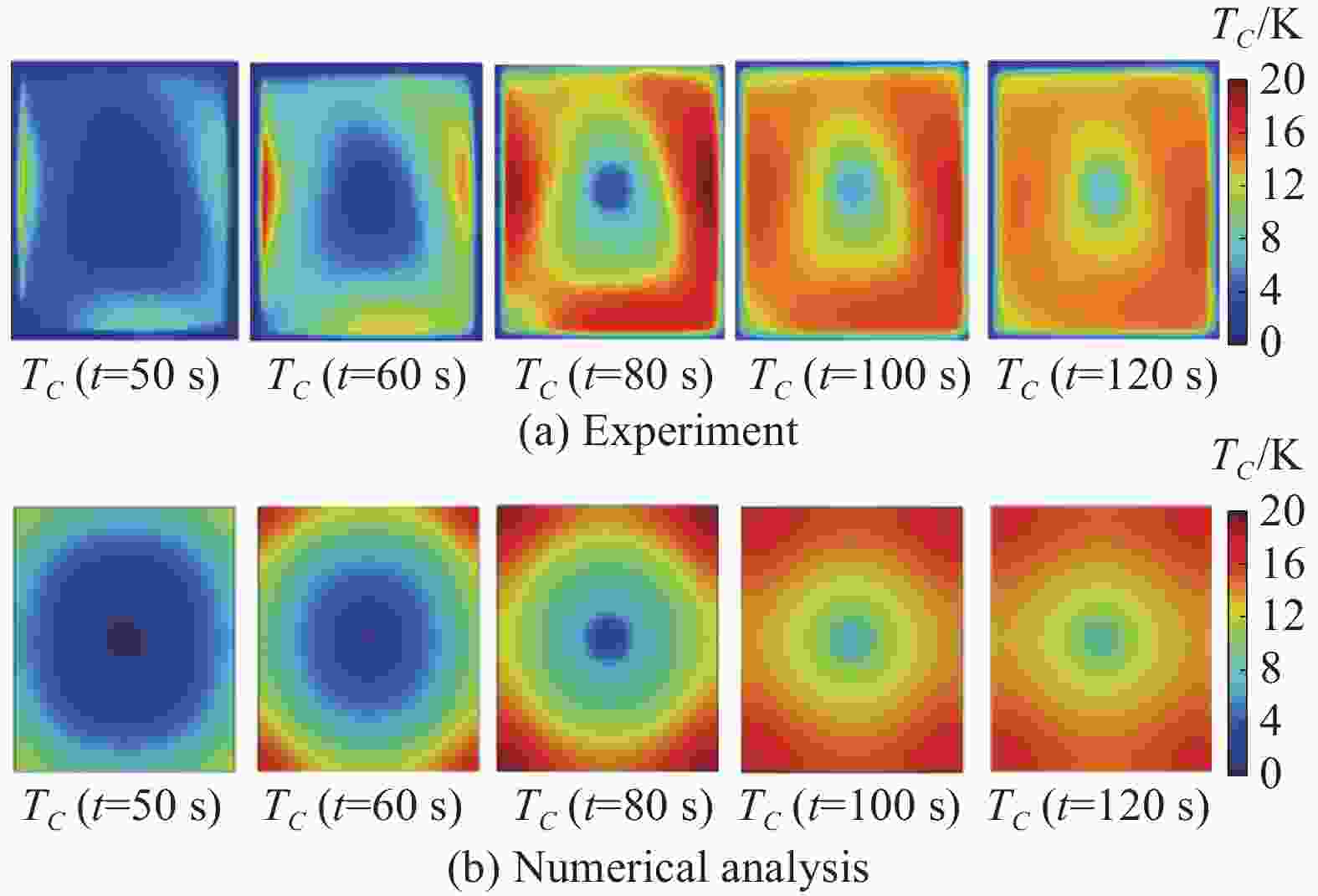

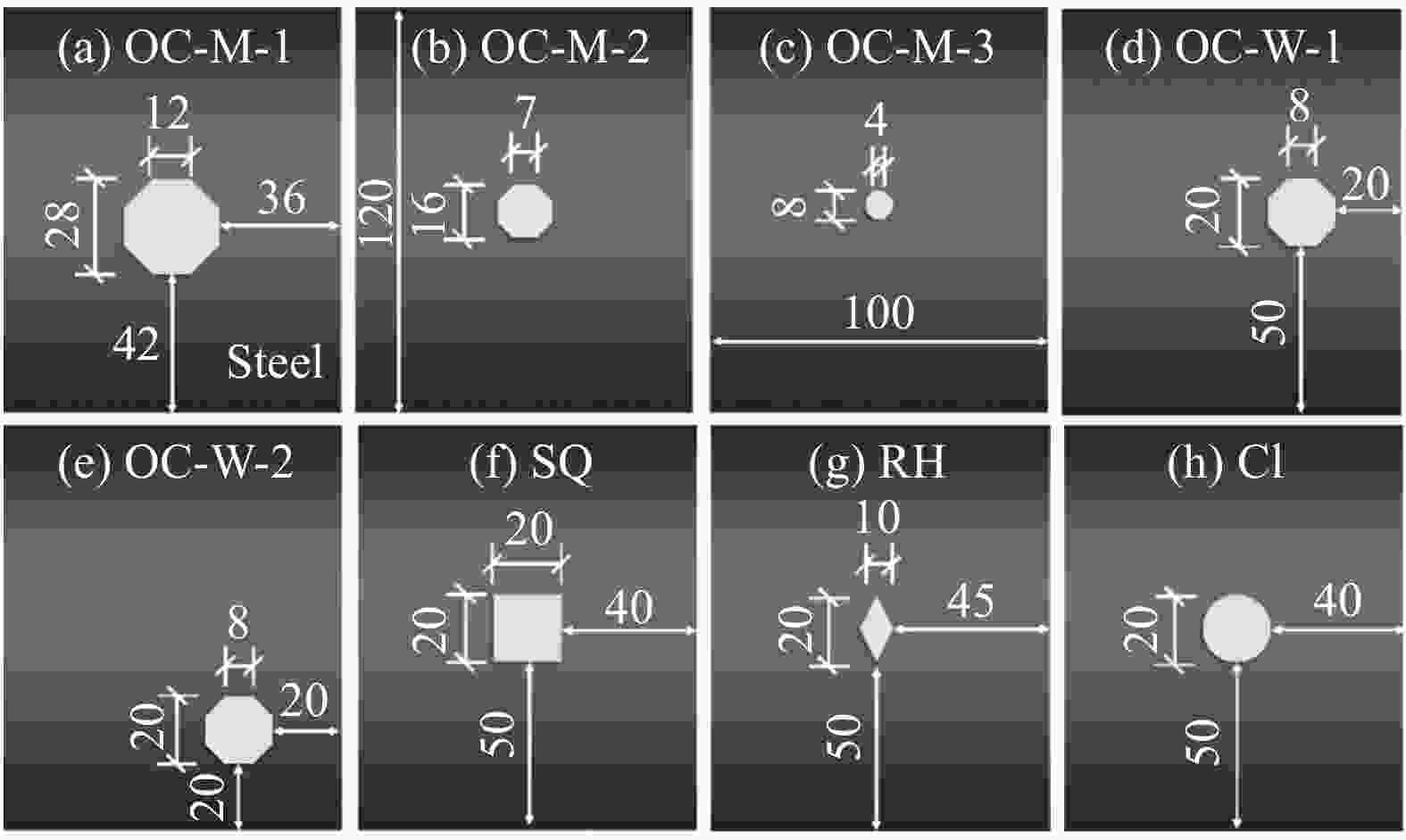

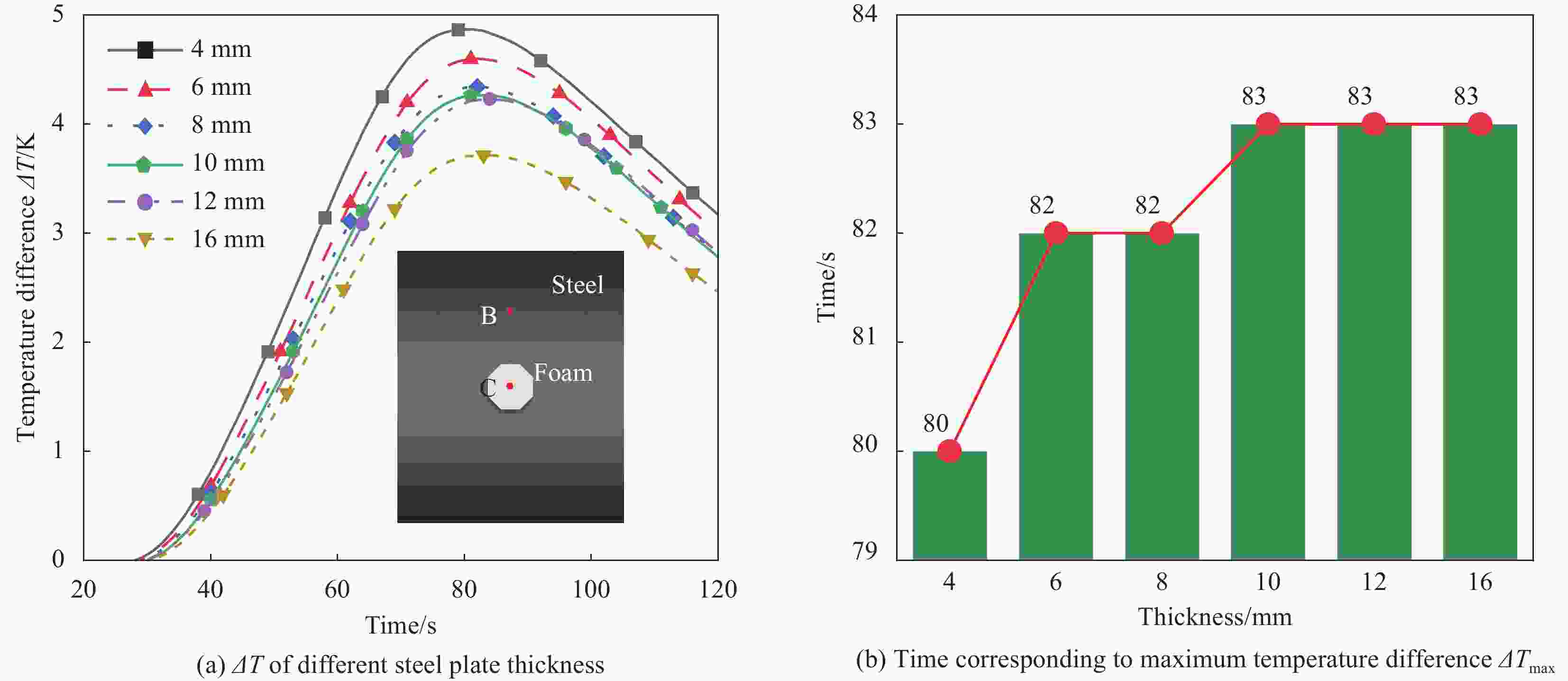

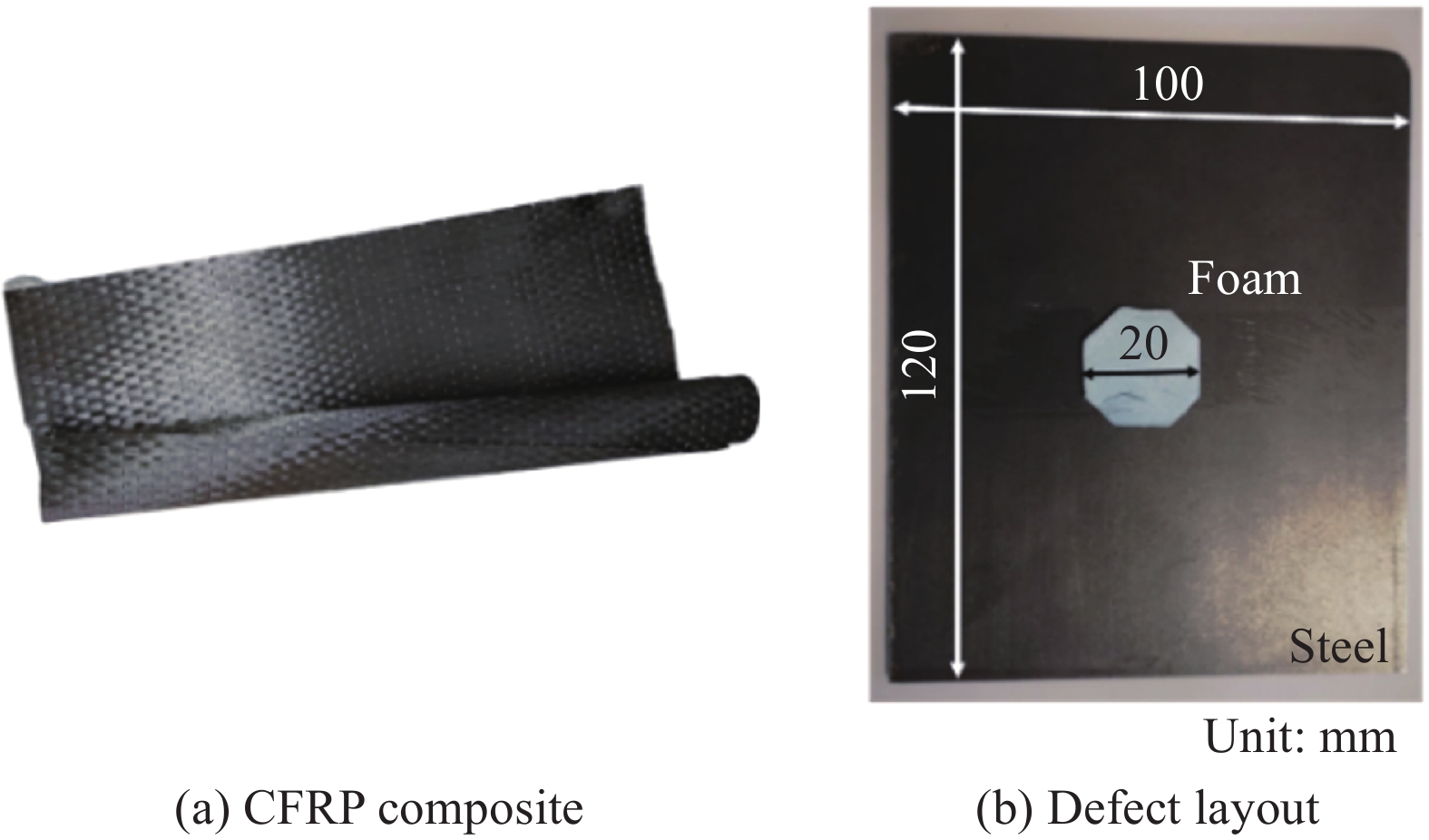

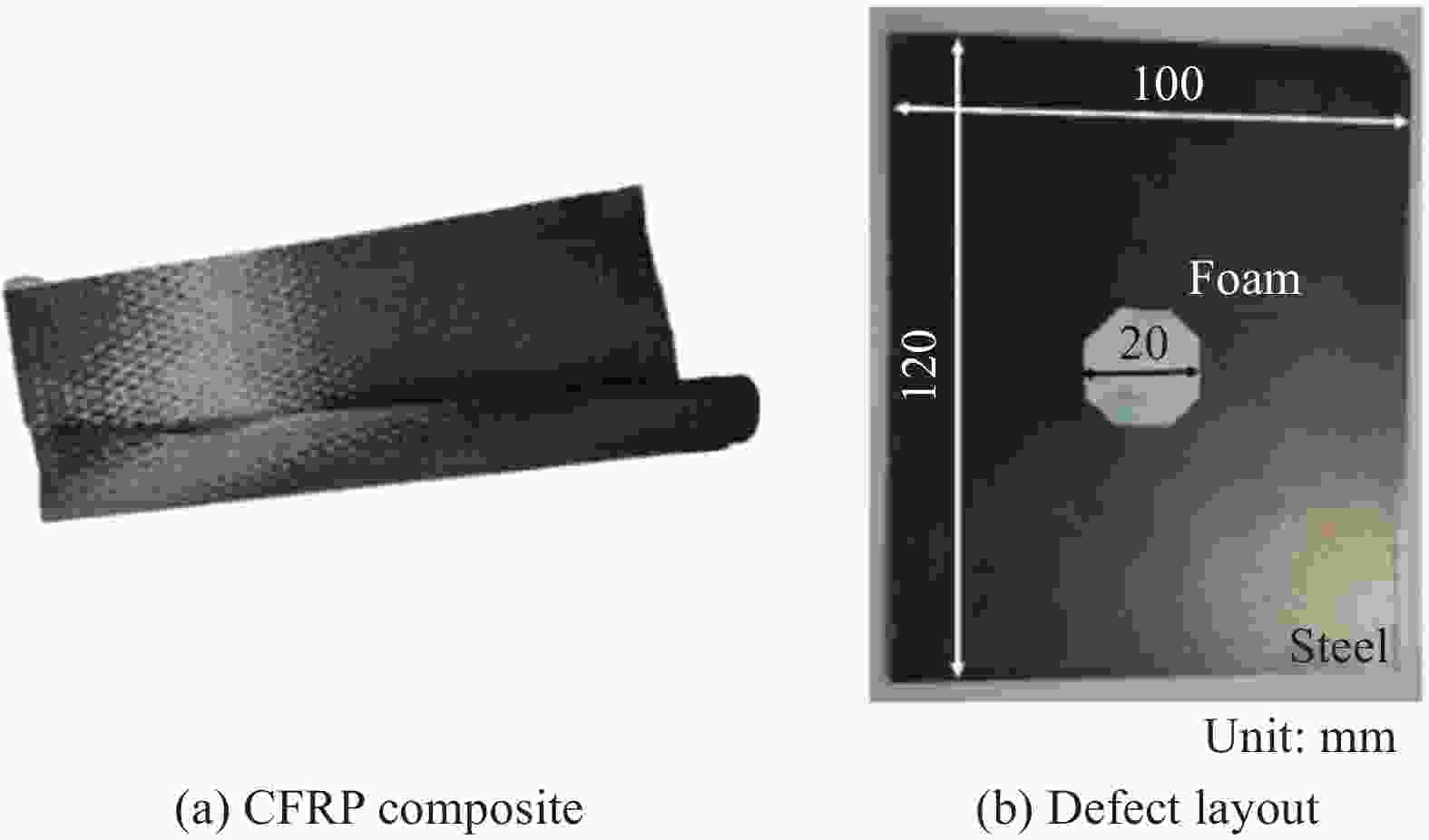

摘要: 纤维增强树脂(Fiber reinforced polymer,FRP)复合材料已在钢结构加固中得到有效应用,但FRP-钢界面脱粘可能触发结构破坏,需无损检测以保证安全运营。基于自研涡流热成像(Eddy current thermography,ECT)系统对FRP-钢界面缺陷成像规律进行试验,并通过多物理场数值模拟揭示其内部生热和传热机制。试验测试了1个带缺陷试件在ECT下的温度响应,同时模拟了多个不同形状、位置和深度的界面缺陷对热成像的影响。试验表明:ECT系统能在80 s内精确检测试件中328 mm2的界面缺陷;边缘效应影响试件边缘和角部在加热阶段的检测精度,但在冷却阶段由于热量重分布而影响变小;热量沿深度方向传导造成的模糊效应降低了深层缺陷检测精度。本文的多物理场数值模型与试验结果吻合较好,并重现了ECT的边缘效应和模糊效应。基于数值模型的参数化分析,揭示了变化加热速率在一定范围内可克服边缘效应和模糊效应,提高FRP-钢内部缺陷探测精确度。Abstract: Fiber reinforced polymer (FRP) has been effectively used in strengthening steel structures, but FRP-steel interfacial debonding may trigger structural failure. Hence nondestructive testing is required to ensure structural safety. Herein one specimen with FRP-steel interfacial debonding was detected based on a self-developed eddy current thermography (ECT) system, and its heat generation and heat transferring mechanism was revealed through multi-physical numerical simulation. The effect of different shapes, locations and shapes of the defect on the temperature response under ECT was investigated through simulation. The results show that the ECT system can accurately detect 328 mm2 in the specimen within 80 s. The edge effect affects the detection accuracy of the edges and corners of the specimen in the heating stage, but it has little effect due to heat redistribution in the sample in the cooling stage. The blur effect caused by heat conduction along the depth direction reduces the detection accuracy of deep defects. Numerical simulation shows good agreement with the experimental tempera-ture response, and reproduces the edge effect and blur effect of ECT. Parametric study using numerical simulation reveals that the heating rate can overcome the edge effect and blur effect in a certain range and improve the accuracy of FRP-steel interfacial defect detection.

-

Material Electromagnetic

properties$ k $/(W·(m·K)−1) $ c $/(J·(g·K)−1) $ \rho $/(kg·m−3) Foam $ {\varepsilon _{\text{r}}} = 1 $ 0.026 1.005 1.204 Epoxy ${\varepsilon _{\text{r} } } \approx 6-0.6{\rm{j} }$ 1.000 3.700 1100 Steel $ {\varepsilon _{\text{r}}} \approx 4.7 - 0.7{\rm{j}} $ 1.700 0.800 2400 CFRP$ \parallel $ $ \sigma = {10^4} $ 7.000 1.200 1600 CFRP$ \perp $ $ {\varepsilon _{\text{r}}} \approx 7 - 2.5{\rm{j}} $ 0.800 1.200 1600 Notes: j—Imaginary unit; $ k $—Thermal conductivity; $ c $—Specific heat; ρ—Density; $ {\varepsilon _{\text{r}}} $—Relative permittivity; $ \sigma $—Electrical conductance; $ \parallel $ and $ \perp $ represent the horizontal and vertical directions of the fibers, respectively. 表 2 试件缺陷详细尺寸

Table 2. Specimen detail size

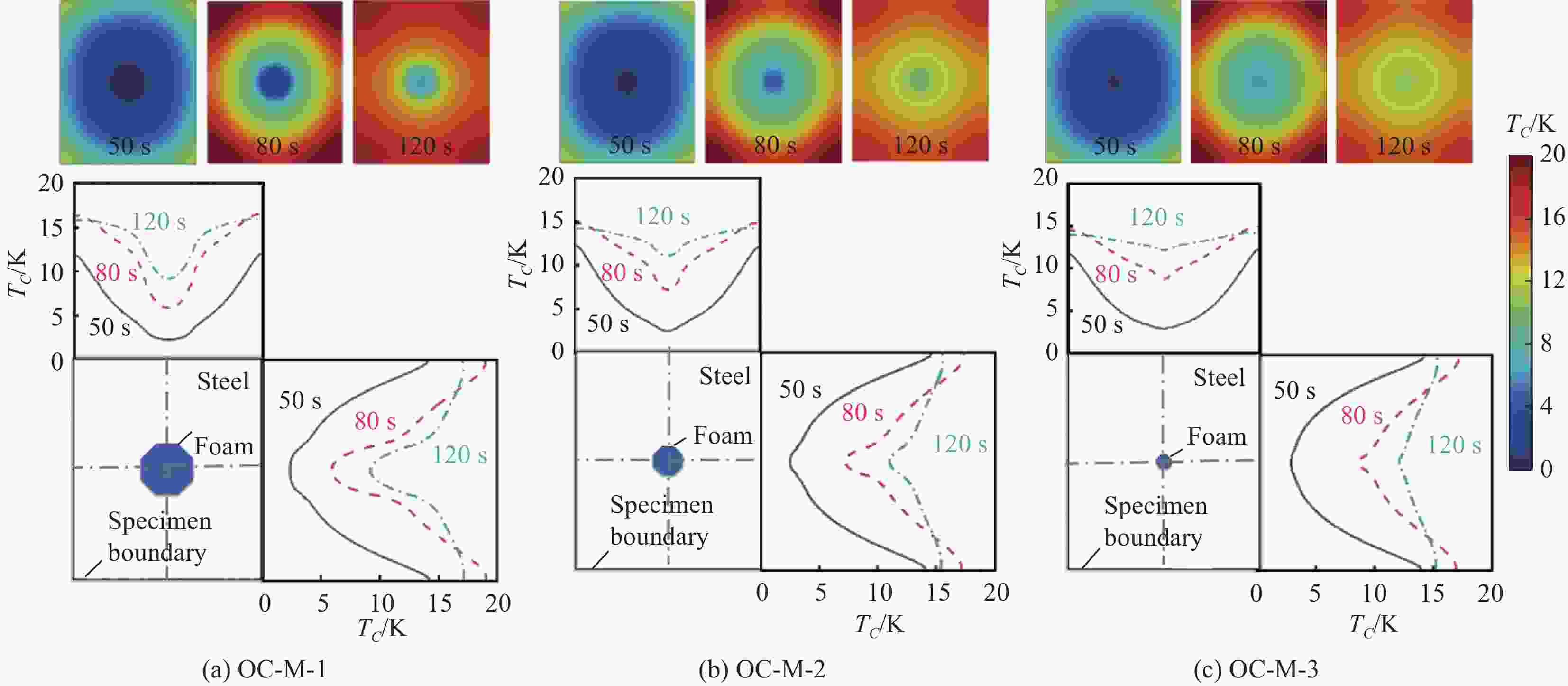

Specimen Defect types Location Area/mm2 OC Octagon Center 328 OC-M-1 Octagon Center 656 OC-M-2 Octagon Center 216 OC-M-3 Octagon Center 56 OC-W-1 Octagon Right 328 OC-W-2 Octagon Lower right 328 SQ Square Center 400 RH Rhombus Center 100 CI Circle Center 314 -

[1] 程璐, 冯鹏, 徐善华, 等. CFRP加固钢结构抗疲劳技术研究综述[J]. 复合材料科学与工程, 2013(4):59-63.CHENG Lu, FENG Peng, XU Shanhua, et al. The technology and research of steel structure strengthened with CFRP[J]. Composites Science and Engineering,2013(4):59-63(in Chinese). [2] FENG P, HU L, ZHAO X L, et al. Study on thermal effects on fatigue behavior of cacked steel plates strengthened by CFRP sheets[J]. Thin-Walled Structures,2014,82:311-320. doi: 10.1016/j.tws.2014.04.015 [3] 郑云, 叶列平, 岳清瑞. FRP加固钢结构的研究进展[J]. 工业建筑, 2005, 35(8):20-25. doi: 10.3321/j.issn:1000-8993.2005.08.005ZHENG Yun, YE Lieping, YUE Qingrui. Progress in research on steel structures with FRP[J]. Industrial Construction,2005,35(8):20-25(in Chinese). doi: 10.3321/j.issn:1000-8993.2005.08.005 [4] HU L, WANG Y, FENG P, et al. Debonding development in cracked steel plates strengthened by CFRP laminates under fatigue loading: Experimental and boundary element method analysis[J]. Thin-Walled Structures,2021,166:108038. doi: 10.1016/j.tws.2021.108038 [5] HU L, ZHAO X, FENG P. Fatigue behavior of cracked high-strength steel plates strengthened by CFRP sheets[J]. Journal of Composites for Construction,2016,20(6):04016043. doi: 10.1061/(ASCE)CC.1943-5614.0000698 [6] LIU J, GUO T, HEBDON M H, et al. Behaviors of GFRP-steel bonded joints under cyclic loading after hygrothermal aging[J]. Construction and Building Materials,2020,242:118106. doi: 10.1016/j.conbuildmat.2020.118106 [7] SCHNERCH D, RIZKALLA S. Flexural strengthening of steel bridges with high modulus CFRP strips[J]. Journal of Bridge Engineering,2008,13(2):192-201. doi: 10.1061/(ASCE)1084-0702(2008)13:2(192) [8] HESHMATI M, HAGHANI R, AL-EMRANI M. Effects of moisture on the long-term performance of adhesively bonded FRP/steel joints used in bridges[J]. Composites Part B: Engineering,2016,92:447-462. doi: 10.1016/j.compositesb.2016.02.021 [9] CROMWELL J R, HARRIES K A, SHAHROOZ B M. Environmental durability of externally bonded FRP materials intended for repair of concrete structures[J]. Construction and Building Materials,2011,25(5):2528-2539. doi: 10.1016/j.conbuildmat.2010.11.096 [10] LI J, LU Y, LEE Y F. Debonding detection in CFRP-reinforced steel structures using anti-symmetrical guided waves[J]. Composite Structures,2020,253:112813. doi: 10.1016/j.compstruct.2020.112813 [11] 陈劲, 陈晓东, 赵辉, 等. 基于红外热成像法和超声波法的钢管混凝土无损检测技术的试验研究与应用[J]. 建筑结构学报, 2021, 42(S2):444-453.CHEN Jin, CHEN Xiaodong, ZHAO Hui, et al. Experimental research and application of non-destructive detecting techniques for concrete-filled steel tubes based on infrared thermal imaging and ultrasonic method[J]. Journal of Building Structures,2021,42(S2):444-453(in Chinese). [12] 索会迎. 超声波无损检测技术应用研究[D]. 南京: 南京邮电大学, 2012.SUO Huiying. The application and research of ultrasonic non-destructive testing technology[D]. Nanjing: Nanjing University of Posts and Telecommunications, 2012(in Chinese). [13] 董方旭, 王从科, 凡丽梅, 等. X射线检测技术在复合材料检测中的应用与发展[J]. 无损检测, 2016, 38(2):67-72. doi: 10.11973/wsjc201602017DONG Fangxu, WANG Congke, FAN Limei, et al. Application and development of X-ray detection technology in composite material detection[J]. Nondestructive Testing,2016,38(2):67-72(in Chinese). doi: 10.11973/wsjc201602017 [14] 徐桂荣, 刘甜甜, 关雪松, 等. 航空产品磁粉检测与渗透检测分析[J]. 兵器材料科学与工程, 2021, 44(6):123-127. doi: 10.14024/j.cnki.1004-244x.20211115.001XU Guirong, LIU Tiantian, GUAN Xuesong, et al. Analysis of magnetic particle testing and penetrant testing for aviation products[J]. Ordnance Material Science and Engi-neering,2021,44(6):123-127(in Chinese). doi: 10.14024/j.cnki.1004-244x.20211115.001 [15] LI T, ALMOND D P, REES D A S. Crack imaging by scanning laser line thermography[J]. AIP Conference Proceedings, American Institute of Physics,2011,1335(1):407-414. [16] 刘颖韬, 郭广平, 曾智, 等. 红外热像无损检测技术的发展历程、现状和趋势[J]. 无损检测, 2017, 39(8):63-70. doi: 10.11973/wsjc201708015LIU Yingtao, GUO Guangping, ZENG Zhi, et al. The development history, status and trends of infrared thermographic nondestructive testing[J]. Nondestructive Testing,2017,39(8):63-70(in Chinese). doi: 10.11973/wsjc201708015 [17] 杨正伟, 谢星宇, 李胤, 等. 激光扫描热成像无损检测关键参数影响分析[J]. 红外与激光工程, 2019, 48(11):91-101.YANG Zhengwei, XIE Xingyu, LI Yin, et al. Influence analysis of key parameters in laser scanning thermography nondestructive testing[J]. Infrared and Laser Engineering,2019,48(11):91-101(in Chinese). [18] SILIPIGNI G, BURRASCANO P, HUTCHINS D A, et al. Optimization of the pulse-compression technique applied to the infrared thermography nondestructive evaluation[J]. NDT & E International,2017,87:100-110. [19] 曾伟, 王海涛, 田贵云, 等. 基于能量分析的激光超声波缺陷检测研究[J]. 仪器仪表学报, 2014, 35(3):650-655. doi: 10.19650/j.cnki.cjsi.2014.03.023ZENG Wei, WANG Haitao, TIAN Guiyun, et al. Research on laser ultrasonic defect signal detection technology based on energy analysis[J]. Chinese Journal of Scientific Instrument,2014,35(3):650-655(in Chinese). doi: 10.19650/j.cnki.cjsi.2014.03.023 [20] 宋培源. 基于红外热成像的结构缺陷检测技术研究[D]. 南京: 东南大学, 2018.SONG Peiyuan. Research on structural defect detection technology based on infrared thermal technology[D]. Nanjing: Southeast University, 2018(in Chinese). [21] TASHAN J, AL-MAHAIDI R, MAMKAK A. Defect size measurement and far distance infrared detection in CFRP-concrete and CFRP-steel systems[J]. Australian Journal of Structural Engineering,2016,17(1):2-13. doi: 10.1080/13287982.2015.1116177 [22] XIE J, WU C, GAO L, et al. Detection of internal defects in CFRP strengthened steel structures using eddy current pulsed thermography[J]. Construction and Building Materials,2021,282:122642. doi: 10.1016/j.conbuildmat.2021.122642 [23] 许颖, 王青原, 罗聪聪, 等. 基于激光热激励红外热成像纤维增强聚合物复合材料加固混凝土结构界面损伤无损检测[J]. 复合材料学报, 2020, 37(2):472-481.XU Ying, WANG Qingyuan, LUO Congcong, et al. Nondestructive debonding detection of fiber reinforced plastics strengthened concrete structure based on infrared thermal imaging with laser thermal excitation[J]. Acta Materiae Compositae Sinica,2020,37(2):472-481(in Chinese). [24] XU C, ZHOU N, XIE J, et al. Investigation on eddy current pulsed thermography to detect hidden cracks on corroded metal surface[J]. NDT & E International,2016,84:27-35. [25] WU J, ZHU J, XIA H, et al. DC-biased magnetization based eddy current thermography for subsurface defect detection[J]. IEEE Transactions on Industrial Informatics,2019,15(12):6252-6259. doi: 10.1109/TII.2019.2891107 [26] PAN M, HE Y, TIAN G, et al. Defect characterisation using pulsed eddy current thermography under transmission mode and NDT applications[J]. NDT & E International,2012,52:28-36. [27] SHI Z, XU X, MA J, et al. Quantitative detection of cracks in steel using eddy current pulsed thermography[J]. Sensors,2018,18(4):1070. doi: 10.3390/s18041070 [28] LIANG T, REN W, TIAN G Y, et al. Low energy impact damage detection in CFRP using eddy current pulsed thermography[J]. Composite Structures ,2016,143:352-361. doi: 10.1016/j.compstruct.2016.02.039 [29] 苏伯泰, 李强, 韩静涛, 等. 基于脉冲涡流热成像钢材表面裂纹检测效果分析[J]. 中国测试, 2018, 44(5):147-151, 158. doi: 10.11857/j.issn.1674-5124.2018.05.028SU Botai, LI Qiang, HAN Jingtao, et al. Effect analysis of steel surface crack inspection based on pulse eddy current thermography[J]. China Measurement & Test,2018,44(5):147-151, 158(in Chinese). doi: 10.11857/j.issn.1674-5124.2018.05.028 [30] TIAN G Y, HE Y, CHENG L, et al. Pulsed eddy current thermography for corrosion characterization[J]. International Journal of Applied Electromagnetics and Mechanics,2012,39(1-4):269-276. doi: 10.3233/JAE-2012-1470 [31] HE Y, TIAN G Y, PAN M, et al. An investigation into eddy current pulsed thermography for detection of corrosion blister[J]. Corrosion Science,2014,78:1-6. doi: 10.1016/j.corsci.2013.09.001 [32] ZOU X, WANG L, WANG J, et al. Nondestructive evaluation of carbon fiber reinforced polymer (CFRP)-steel interfacial debonding using eddy current thermography[J]. Compo-site Structures,2022,284:115133. doi: 10.1016/j.compstruct.2021.115133 [33] LI X, LIU Z, JIANG X, et al. Method for detecting damage in carbon-fibre reinforced plastic-steel structures based on eddy current pulsed thermography[J]. Nondestructive Testing and Evaluation,2018,33(1):1-19. doi: 10.1080/10589759.2016.1254213 [34] 潘孟春, 何赟泽, 陈棣湘. 涡流热成像检测技术[M]. 北京: 国防工业出版社, 2013: 65-73.PAN Mengchun, HE Yunze, CHEN Dixiang. Eddy current thermal imaging detection technology[M]. Beijing: National Defense Industry Press, 2013: 65-73(in Chinese). -

下载:

下载: