Effect of sizing agent on interfacial properties of domestic T800 grade carbon fiber reinforced thermosetting composites

-

摘要: 碳纤维具有力学性能优、密度低、耐腐蚀、耐高温等一系列优异性能,近年来被广泛应用于航空、航天等重要领域。相较于国外的高强中模碳纤维,国内虽有T800级碳纤维与之对应,但是国内对高性能碳纤维的研究工作起步晚,研究尚不充分。上浆剂作为碳纤维表面的重要组成部分,对碳纤维的表面性能有着重要的影响,进而影响复合材料的界面性能。本文采用SEM、TGA、XPS等表征手段,研究分析了上浆剂对国产T800级碳纤维的影响,对碳纤维的表面物化特性及其不同先进树脂基复合材料的微观界面性能进行研究,为国产高性能碳纤维的产品发展提供借鉴意义。Abstract: Carbon fiber has a series of excellent properties such as low density, high specific strength, high specific modulus, corrosion resistance, high temperature resistance, and good fatigue resistance. In recent years, it has been widely used in important fields such as aviation and aerospace. Compared with the high-strength medium-mold carbon fiber abroad, although there is T800 grade carbon fiber in China, the research work on high-performance carbon fiber in China has started late, and the research is not enough, and the products are not comparable to those in foreign countries. Sizing agent , as an important part of carbon fiber surface, has an important effect on the surface properties of carbon fiber and the interfacial properties of composites. The effect of sizing agent on domestic T800 carbon fiber was studied and analyzed by means of SEM, TGA and XPS. In this work, the surface characteristics of carbon fiber and the microscopic interface of the composite material has been studied, which provide a reference for the development of domestic high-performance carbon fiber products.

-

Key words:

- carbon fiber /

- sizing agent /

- composites /

- interface property /

- mechanical property

-

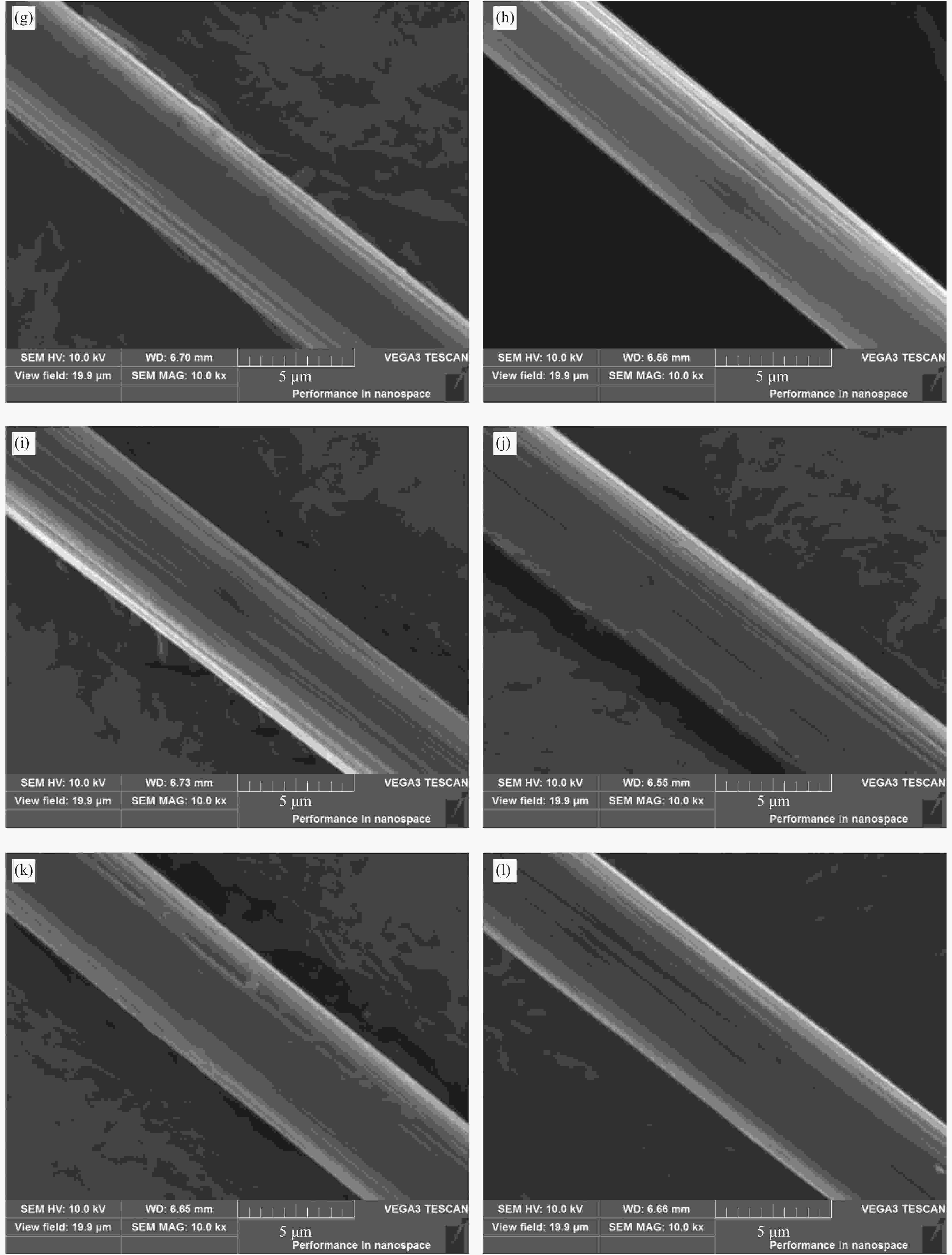

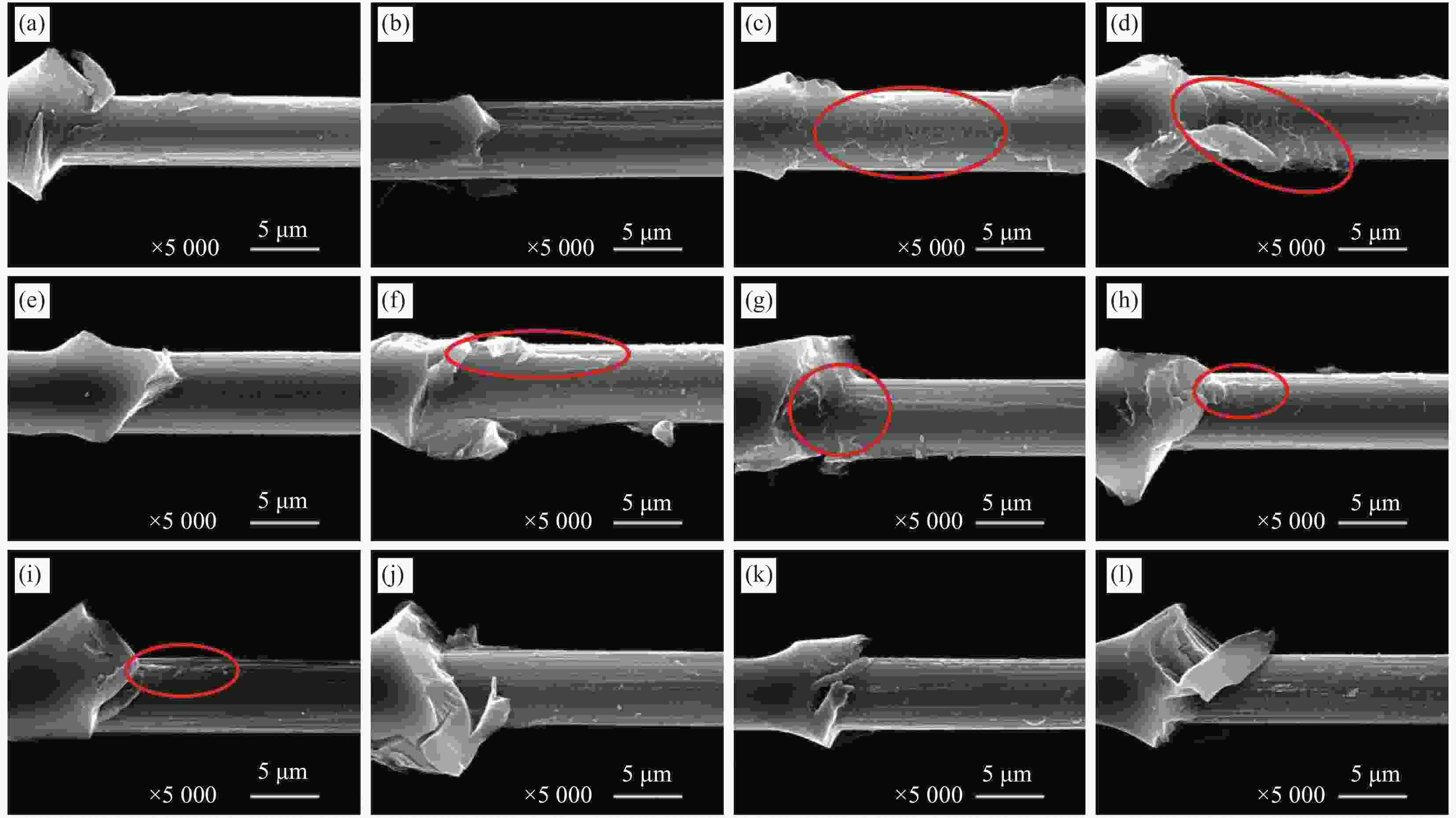

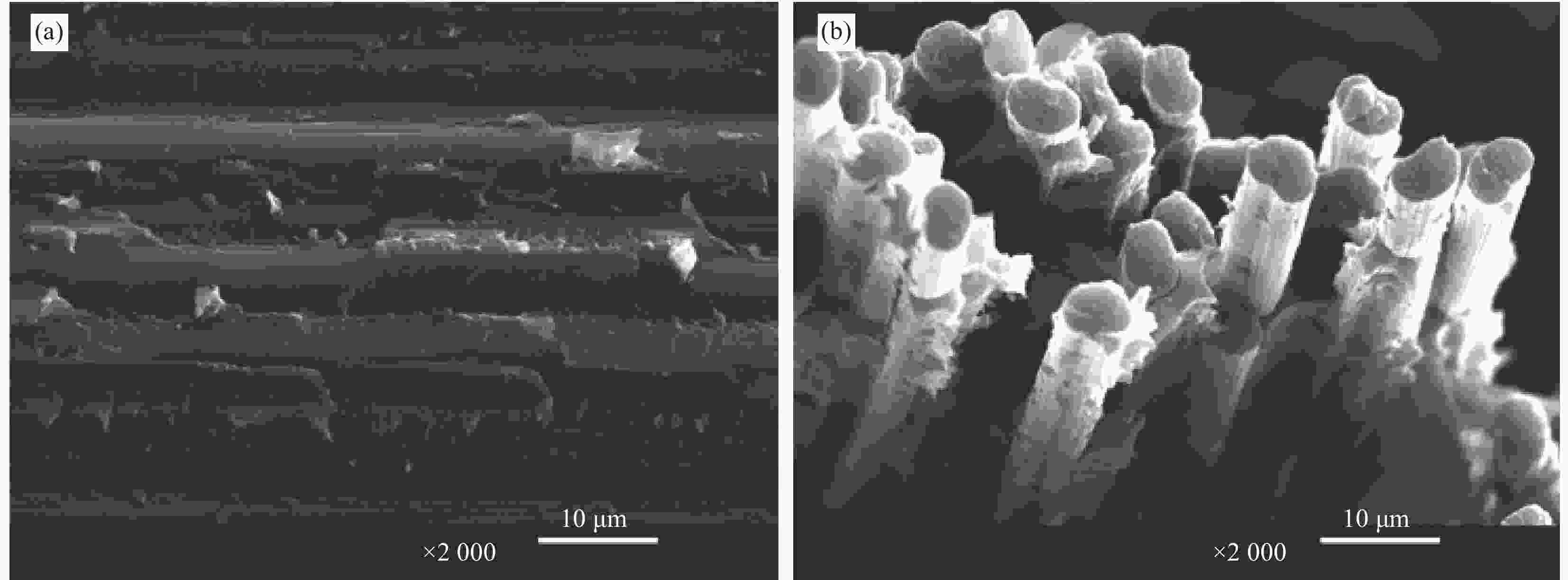

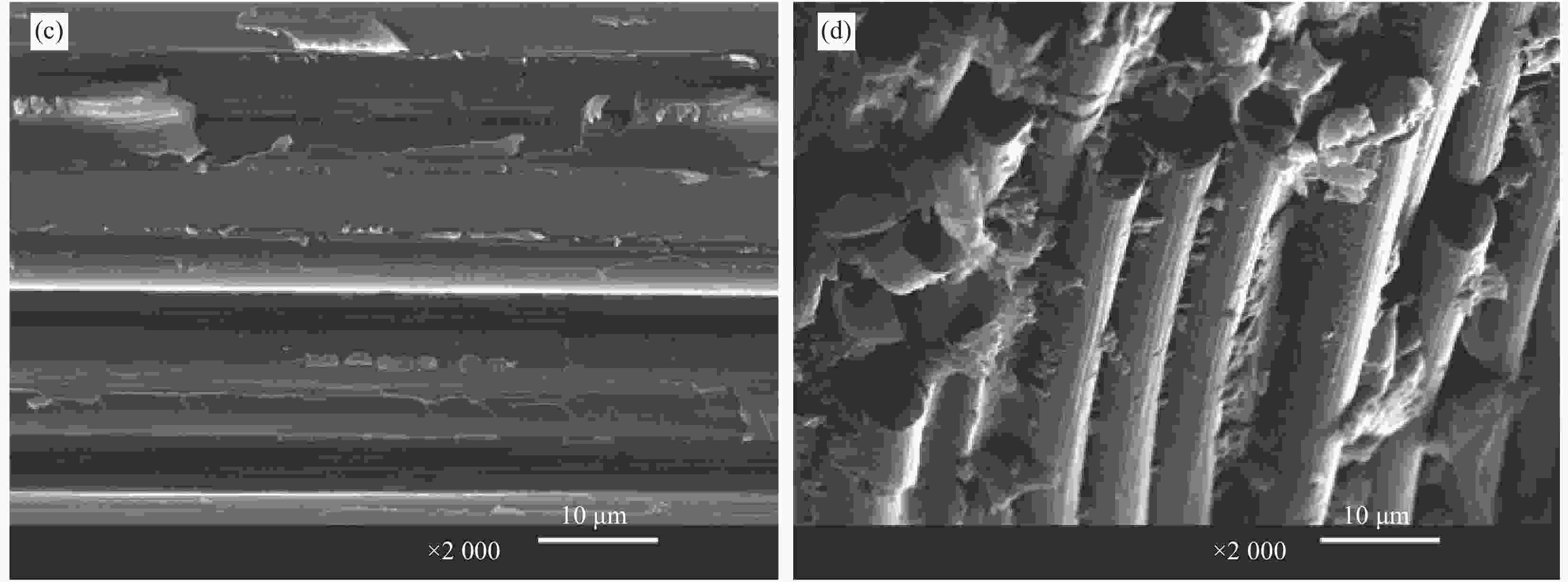

图 8 碳纤维增强树脂基复合材料的微脱粘断面形貌:(a) 800-1/A;(b) 800-1/B;(c) 800-2/A;(d) 800-2/B;(e) 800-3/A;(f) 800-3/B;(g) 800-4/A;(h) 800-4/B;(i) 800-5/A;(j) 800-5/B;(k) 800-6/A;(l) 800-6/B

Figure 8. Interfacial shear strength fracture appearance of carbon fiber reinforced resin matrix composites: (a) 800-1/A; (b) 800-1/B; (c) 800-2/A; (d) 800-2/B; (e) 800-3/A; (f) 800-3/B; (g) 800-4/A; (h) 800-4/B; (i) 800-5/A; (j) 800-5/B; (k) 800-6/A; (l) 800-6/B

表 1 碳纤维表面上浆处理

Table 1. Sizing treatment of carbon fiber

Carbon fiber Molecular weight Sizing agent content/% 800-1 Low 1.3 800-2 High 1.3 800-3 Low 1.4 800-4 High 1.4 800-5 Low 1.6 800-6 High 1.6 表 2 六种碳纤维上浆量测试结果

Table 2. Test results of sizing agent content of six kinds of carbon fibers

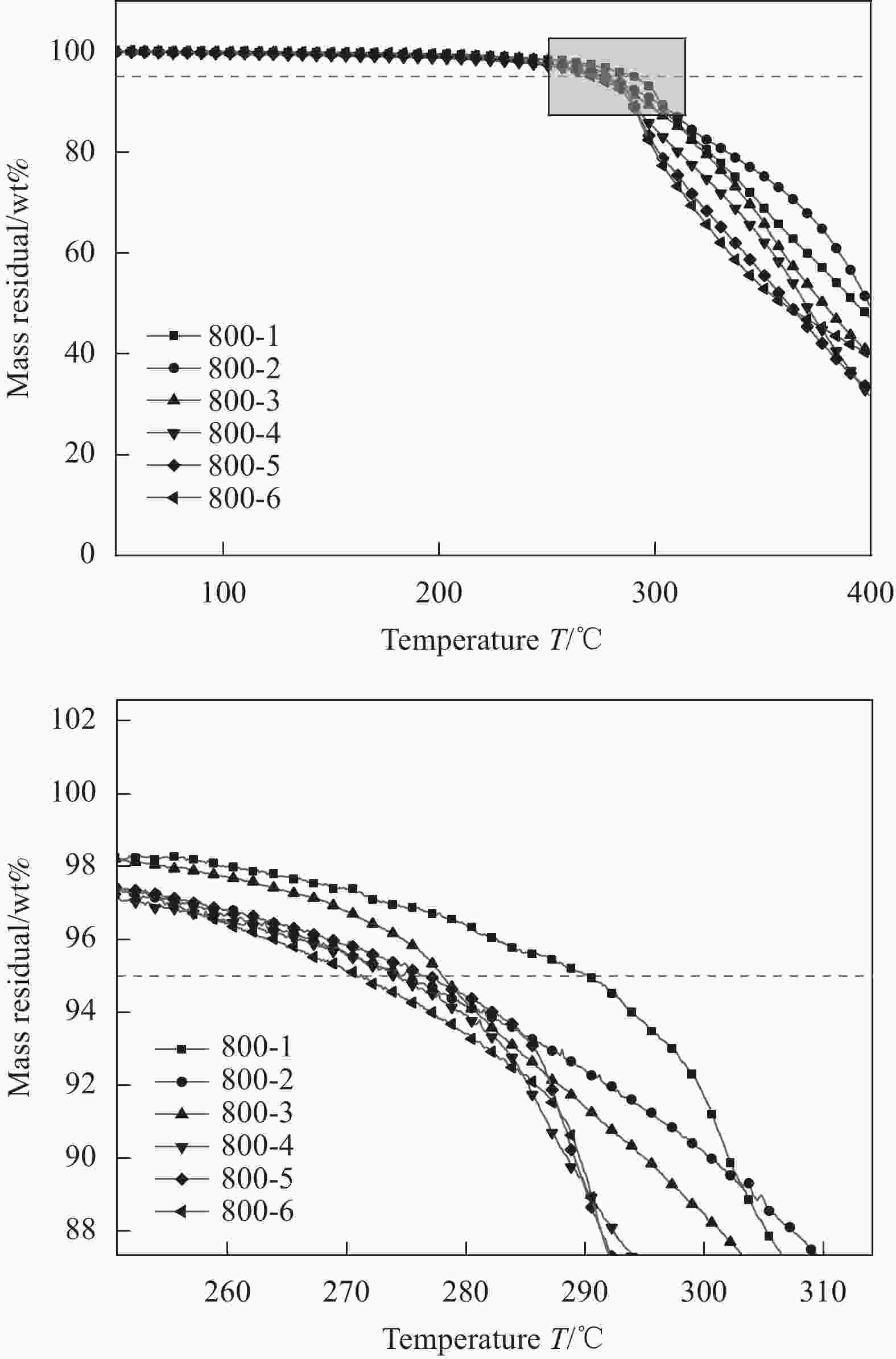

Carbon fiber Sizing agent content/% 800-1 1.30 800-2 1.32 800-3 1.36 800-4 1.39 800-5 1.63 800-6 1.63 表 3 碳纤维表面上浆剂失重5wt%时的热分解温度

Table 3. Thermal decomposition temperature at 5wt% mass loss of carbon fiber surface sizing agent

Sizing agent 5wt% mass thermal

decomposition temperature/℃800-A1 290.2 800-A2 274.5 800-A3 278.2 800-A4 274.2 800-A5 276.6 800-A6 271.1 表 4 碳纤维表面元素成分及含量

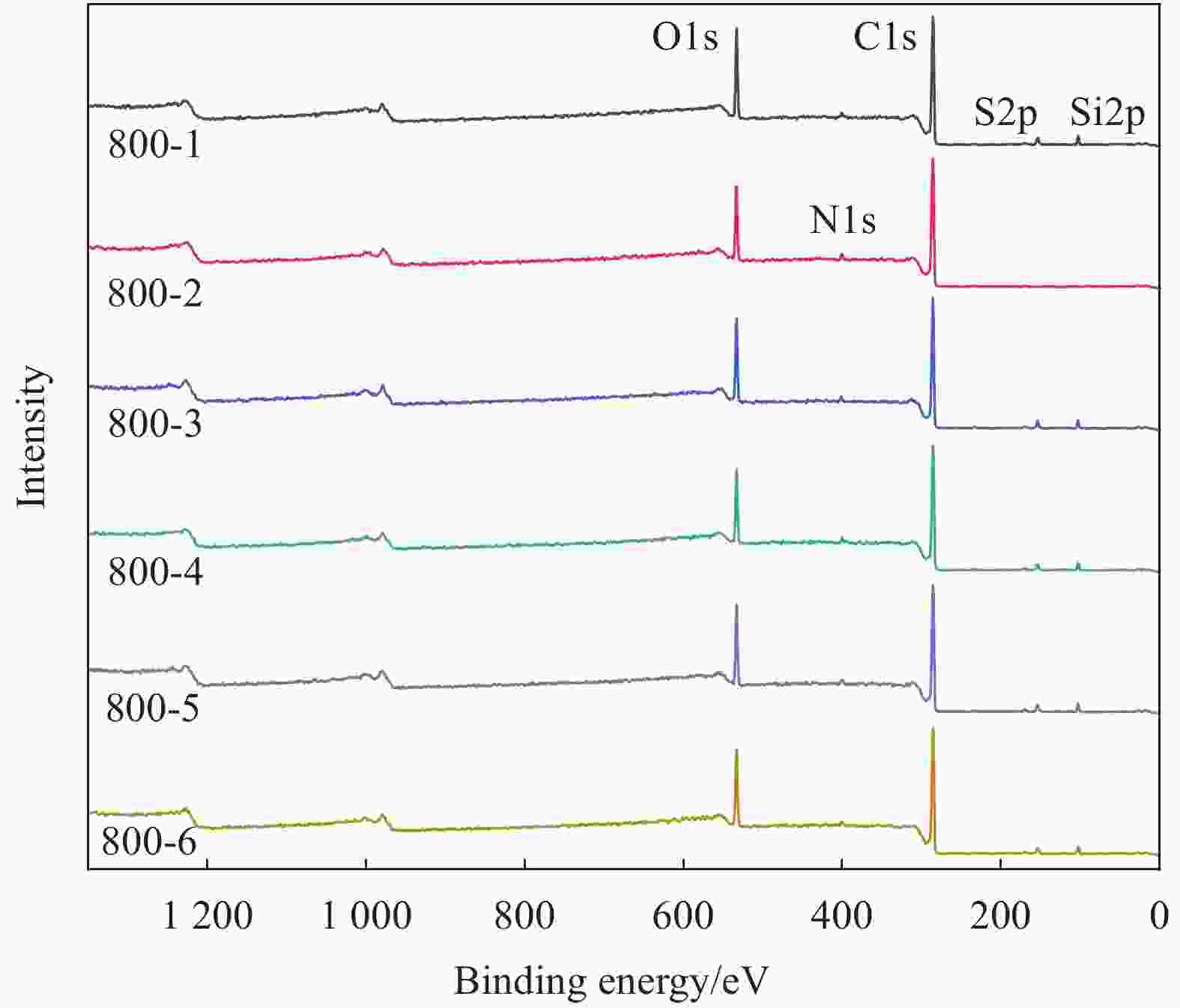

Table 4. Surface element composition and content of carbon fiber

Carbon fiber C1s

284.8 eVO1s

532.7 eVN1s

400.9 eVS2p

168.6 eVSi2p

102.3 eVO/C 800-1 75.37 18.47 1.74 0.40 4.02 0.245 800-2 80.33 16.41 2.85 0.41 0 0.204 800-3 76.19 17.34 2.02 0.56 3.90 0.228 800-4 77.31 16.25 2.28 0 4.15 0.210 800-5 75.67 17.26 1.96 0.62 4.50 0.228 800-6 77.27 16.41 1.96 0.52 3.84 0.212 表 5 上浆后碳纤维表面XPS的C1s拟合峰结果

Table 5. XPS C1s spectrum of carbon fiber

Carbon fiber —C—C— or

—C—H/%

284.8 eV—C—OH or

—C—OR/%

286.3 eV—C=O/%

287.8 eV—COOH or —COOR/%

288.9 eVActive C/% 800-1 56.85 33.34 1.58 8.23 43.15 800-2 54.15 35.30 0.42 10.13 45.85 800-3 60.63 29.47 1.85 8.05 39.37 800-4 52.57 25.06 11.97 10.40 47.43 800-5 66.09 22.69 3.53 7.69 33.91 800-6 60.64 31.89 0.03 7.44 39.36 表 6 碳纤维表面的浸润性能测试结果

Table 6. Wetting property test results of carbon fiber surface

Carbon fiber Parameter m A resin B resin 800-1 0.724 0.735 800-2 0.721 0.720 800-3 0.715 0.718 800-4 0.736 0.715 800-5 0.719 0.725 800-6 0.739 0.728 表 7 碳纤维增强复合材料宏观力学性能

Table 7. Macroscopic mechanical properties of carbon fiber reinforced composites

Sample ILSS/MPa Flexural strength/MPa 800/A resin 111.75 1800 800/B resin 87.43 1900 Note: ILSS—Interlaminar shear strength. -

[1] 王茂章, 贺福. 碳纤维的制造、性质及其应用[M]. 北京: 科学出版社, 1984.WANG Maozhang, HE Fu. Fabrication, properties and application of carbon fiber[M]. Beijing: Science Press, 1984(in Chinese). [2] 上官倩芡, 蔡泖华. 碳纤维及其复合材料的发展及应用[J]. 上海师范大学学报(自然科学版), 2008(3):275-279.SHANGGUAN Qianqian, CAI Maohua. Development and applications of carbon fiber and its composites[J]. Journal of Shanghai Normal University (Natural Sciences),2008(3):275-279(in Chinese). [3] 陈祥宝. 先进树脂基复合材料的发展和应用[J]. 航空材料学报, 2003(z1):198-204. doi: 10.3969/j.issn.1005-5053.2003.z1.046CHEN Xiangbao. The development and applications of advanced polymer matrix composites[J]. Journal of Aeronautical Materials,2003(z1):198-204(in Chinese). doi: 10.3969/j.issn.1005-5053.2003.z1.046 [4] 沈真. 碳纤维市场分析和产业发展建议[J]. 高科技纤维与应用, 2015, 40(3):15-21. doi: 10.3969/j.issn.1007-9815.2015.03.003SHEN Zhen. Carbon fibre market analysis and suggestions to industrial development[J]. Hi-Tech Fiber & Application,2015,40(3):15-21(in Chinese). doi: 10.3969/j.issn.1007-9815.2015.03.003 [5] 李建利, 张新元, 张元, 等. 碳纤维的发展现状及开发应用[J]. 成都纺织高等专科学校学报, 2016, 33(2):158-164.LI Jianli, ZHANG Xinyuan, ZHANG Yuan, et al. Development status and application of carbon fiber[J]. Journal of Chengdu Textile College,2016,33(2):158-164(in Chinese). [6] 张东兴, 黄龙男. 聚合物基复合材料科学与工程[M]. 哈尔滨: 哈尔滨工业大学出版社, 2018.ZHANG Dongxing, HUANG Longnan. Polymer matrix composites science and engineering[M]. Harbin: Harbin Institute of Technology Press, 2018(in Chinese). [7] 谢曼, 干勇, 王慧. 面向2035的新材料强国战略研究[J]. 中国工程科学, 2020, 22(5):1-9.XIE Man, GAN Yong, WANG Hui. Research on new material power strategy by 2035[J]. Strategic Study of CAE,2020,22(5):1-9(in Chinese). [8] 包建文, 钟翔屿, 张代军, 等. 国产高强中模碳纤维及其增强高韧性树脂基复合材料研究进展[J]. 材料工程, 2020, 48(8):33-48.BAO Jianwen, ZHONG Xiangyu, ZHANG Daijun, et al. Progress in high strength intermediate modulus carbon fiber and its high toughness resin matrix composites in China[J]. Journal of Materials Engineering,2020,48(8):33-48(in Chinese). [9] 李书乡, 马全胜, 张顺. 中国高性能碳纤维产业的创新发展[J]. 科技导报, 2018, 36(19):73-80.LI Shuxiang, Ma Quansheng, ZHANG Shun. Development of high performance carbon fiber industry in China[J]. Science& Technology Review,2018,36(19):73-80(in Chinese). [10] 李斌太, 邢丽英, 包建文, 等. 先进复合材料国防科技重点实验室的航空树脂基复合材料研发进展[J]. 航空材料学报, 2016, 36(3):92-100. doi: 10.11868/j.issn.1005-5053.2016.3.010LI Bintai, XING Liying, BAO Jianwen, et al. Research and development progress of national key laboratory of advanced composites on advanced aeronautical resin matrix composites[J]. Journal of Aeronautical Materials,2016,36(3):92-100(in Chinese). doi: 10.11868/j.issn.1005-5053.2016.3.010 [11] LUO Y, ZHAO Y, DUAN Y, et al. Surface and wettability property analysis of CCF300 carbon fibers with different sizing or without sizing[J]. Materials & Design,2011,32(2):941-946. [12] 肇研, 段跃新, 肖何. 上浆剂对碳纤维表面性能的影响[J]. 材料工程, 2007(z1):121-126. doi: 10.3969/j.issn.1001-4381.2007.z1.029ZHAO Yan, DUAN Yuexin, XIAO He. Study on the surface properties of carbon fibers affected by sizing agent[J]. Journal of Materials Engineering,2007(z1):121-126(in Chinese). doi: 10.3969/j.issn.1001-4381.2007.z1.029 [13] 张凤翻. 国产碳纤维规模化生产及应用值得注意的几个问题[J]. 高科技纤维与应用, 2005(6):1-6. doi: 10.3969/j.issn.1007-9815.2005.06.001ZHANG Fengfan. The concerns need to be considered on the industrial applications of the domestic carbon fiber[J]. Hi-Tech Fiber& Application,2005(6):1-6(in Chinese). doi: 10.3969/j.issn.1007-9815.2005.06.001 [14] 徐梁华, 曹维宇, 胡良全. 聚丙烯腈基碳纤维[M]. 北京: 国防工业出版社, 2018.XU Lianghua, CAO Weiyu, HU Liangquan. Polyacrylonitrile-based carbon fiber[M]. Beijing: National Defense Industry Press, 2018(in Chinese). [15] 于广, 魏化震, 李大勇, 等. 碳纤维上浆剂及其对复合材料界面性能的影响研究进展[J]. 工程塑料应用, 2019, 47(2):143-147. doi: 10.3969/j.issn.1001-3539.2019.02.026YU Guang, WEI Huazhen, LI Dayong, et al. Research progress of carbon fiber sizing agent and its effects on interface properties of composites[J]. Engineering Plastics Application,2019,47(2):143-147(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.02.026 [16] 刘会兵. 电化学改性与上浆剂施覆对碳纤维表面的协同处理研究[D]. 天津: 天津工业大学, 2018.LIU Huibing. Co-treatment of carbon fiber surface by electrochemical modification and sizing agent application[D]. Tianjin: Tiangong University, 2018(in Chinese). [17] CHEN J, LIU J, WANG D, et al. Preparation of sizing agents for carbon fiber adapt to various polymer matrix[J]. Advanced Materials Research,2011,306-307:750-753. doi: 10.4028/www.scientific.net/AMR.306-307.750 [18] ZHANG R, HUANG Y, LIU L, et al. Effect of the molecular weight of sizing agent on the surface of carbon fibres and interface of its composites[J]. Applied Surface Science,2011,257(6):1840-1844. doi: 10.1016/j.apsusc.2010.08.102 [19] PAIPETIS A, GALIOTIS C. Effect of fibre sizing on the stress transfer efficiency in carbon/epoxy model composites[J]. Composites Part A: Applied Science and Manufacturing,1996,27(9):755-767. doi: 10.1016/1359-835X(96)00054-1 [20] 中华人民共和国工业和信息化部. 纤维增强塑料 短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国标准出版社, 2010.Ministry of Industry and Information Technology. Fiber-reinforced plastics composites-Determination of apparent interlaminar shear strength by short beam method: JC/T 773—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [21] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料弯曲性能试验方法: GB/T 3356—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of China. Test method for f1exural properties of orientational fiber reinforced plymer metrix conposite materials: GB/T 3356—2014[S]. Beijing: China Standards Press, 2014(in Chinese). -

下载:

下载: