Application of two-dimensional nanomaterial/epoxy composite coating in corrosion protection

-

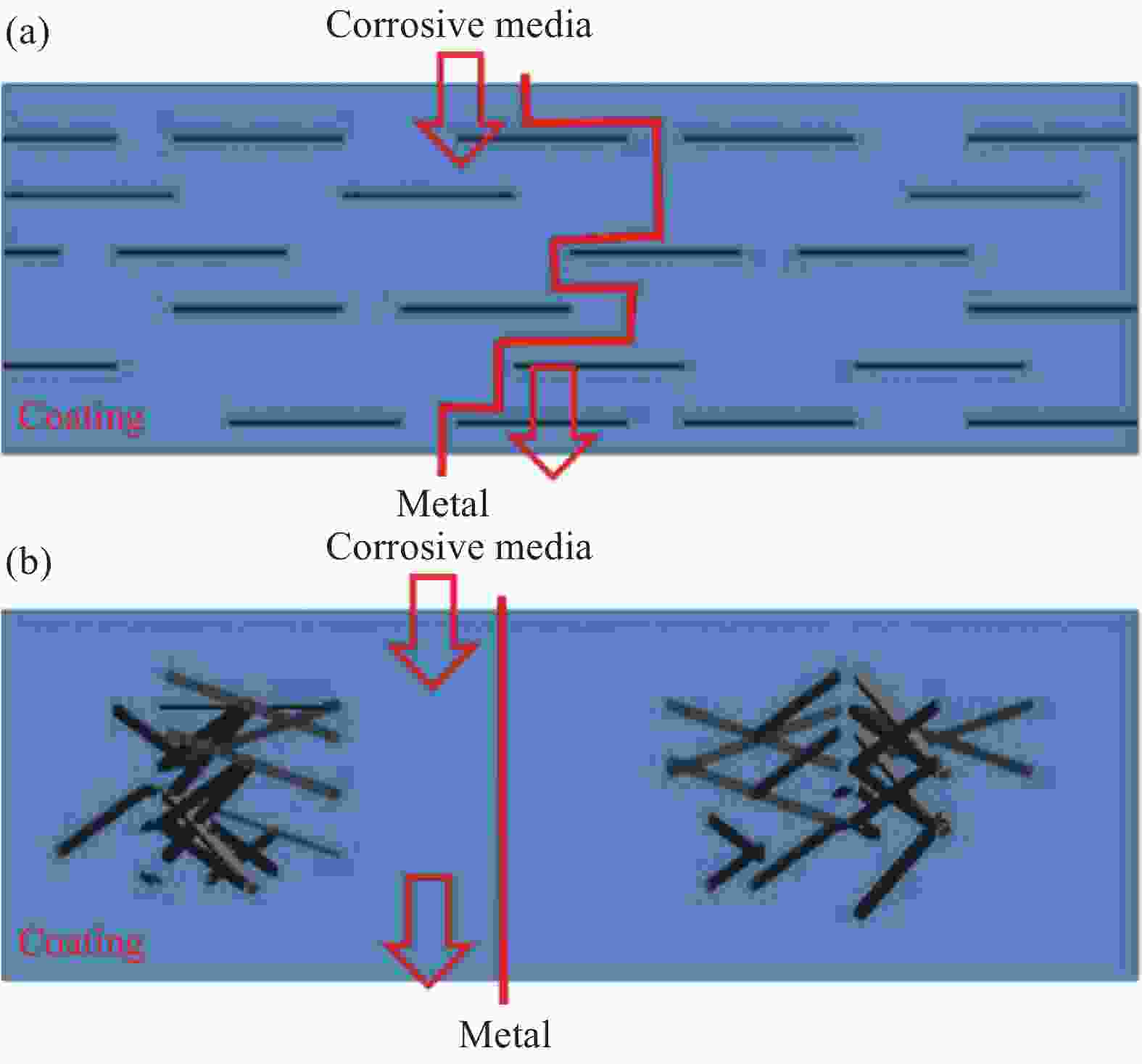

摘要: 二维纳米材料具有片层结构、致密的六方晶格、大的比表面积和优异的热化学稳定性等特点,是作为防腐涂层填料的最佳选择。本论文综述了二维纳米材料在腐蚀防护复合涂层领域的应用。首先介绍了二维纳米材料在环氧树脂防腐涂料的屏障保护作用、抑制保护作用和牺牲保护作用,然后阐述了常见二维纳米材料在环氧树脂防腐涂料中的应用途径和方式。此外,本论文还总结了二维纳米材料在防腐涂料应用中存在的分散、取向以及与金属基体的附着力等问题及其解决办法。最后,对二维纳米材料在环氧树脂防腐涂料中的应用进行了总结和展望。Abstract: Two-dimensional nanomaterials are the best choice for anticorrosive coatings because of their lamellar structure, dense hexagonal lattice, large specific surface area and excellent thermochemical stability. In this paper, the applications of two-dimensional nanomaterials in corrosion protection composite coatings are reviewed. The barrier protection, inhibition protection and sacrifice protection of two-dimensional nanomaterials in epoxy resin anticorrosive coatings are introduced firstly, and then the application ways and methods of common two-dimensional nanomaterials in epoxy resin anticorrosive coatings are expounded. In addition, the problems of dispersion, orientation and adhesion to metal substrate in the application of two-dimensional nanomaterials in anticorrosive coatings and their solutions are also summarized. Finally, the application of two-dimensional nanomaterials in epoxy anticorrosive coatings is summarized and prospected.

-

Key words:

- two-dimensional nanomaterials /

- epoxy resin /

- corrosion protection /

- steel matrix /

- coating

-

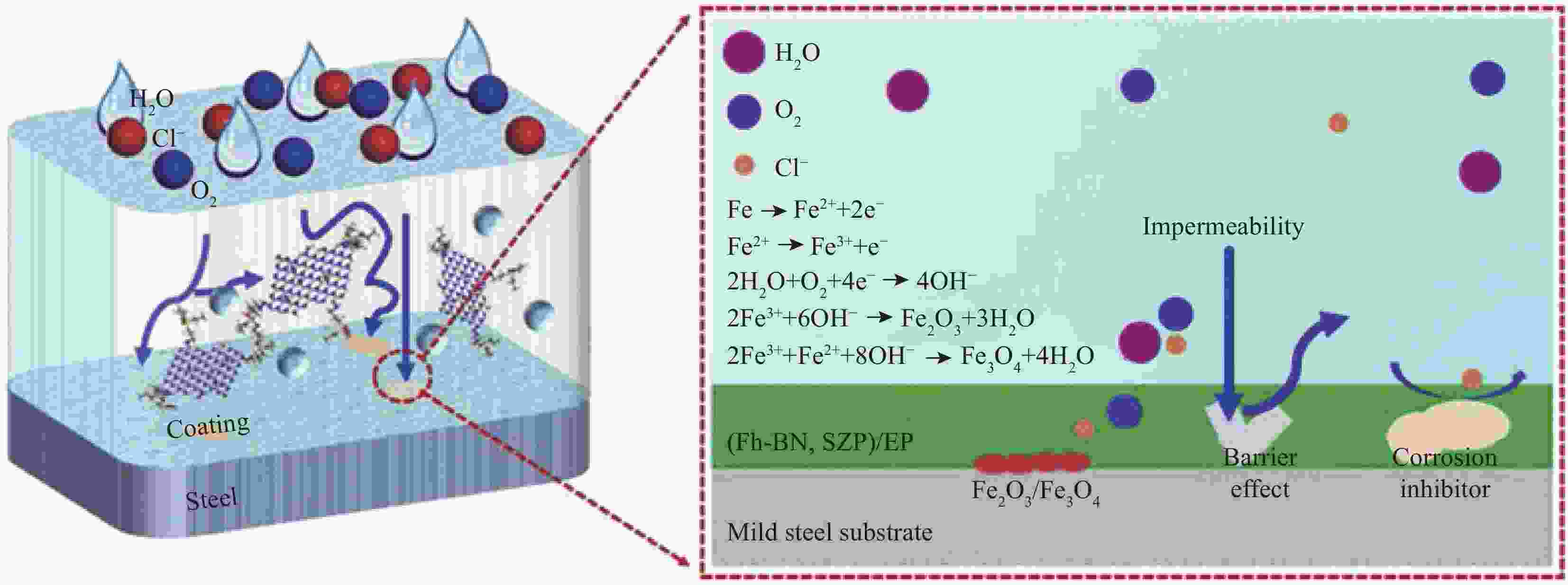

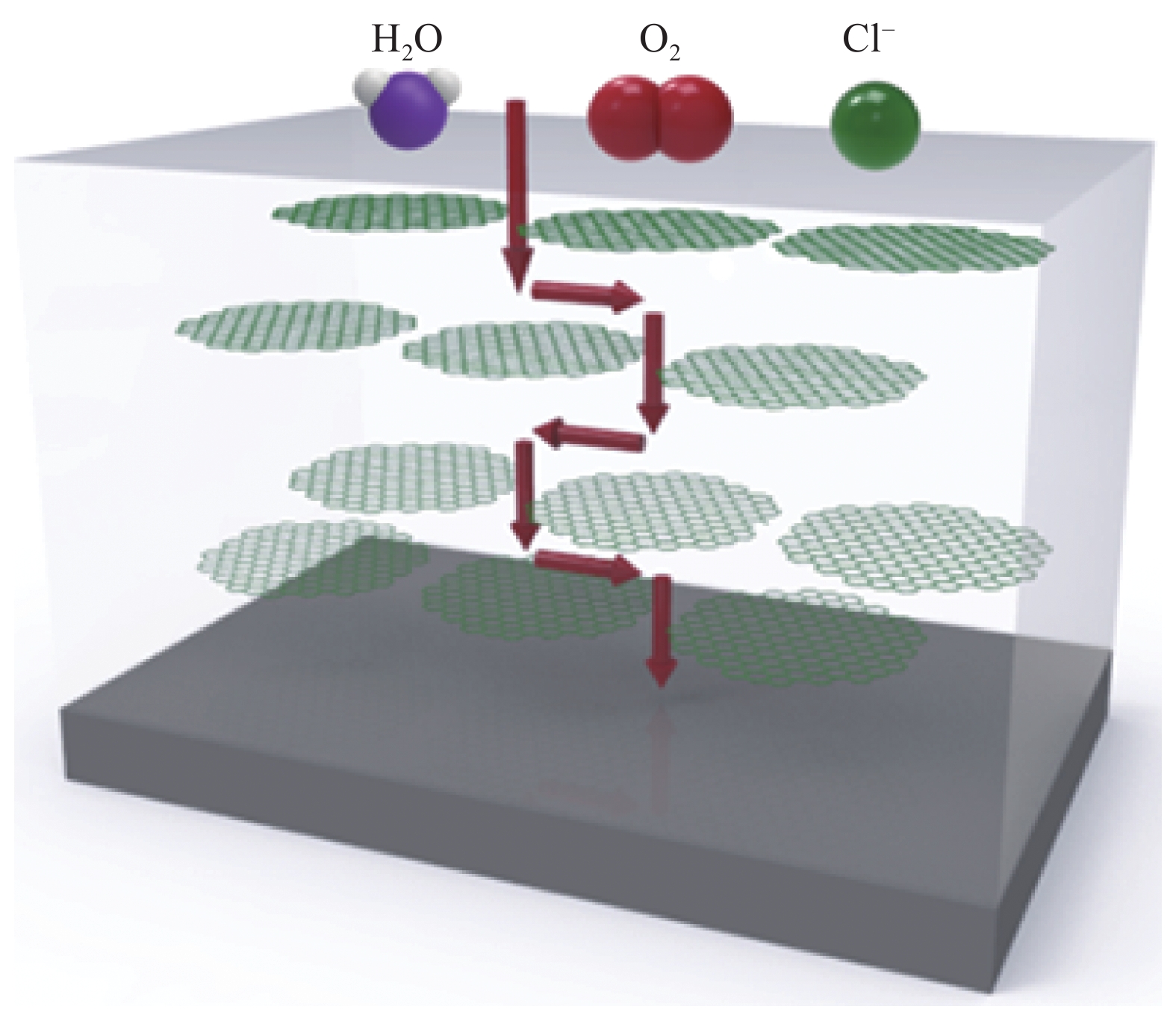

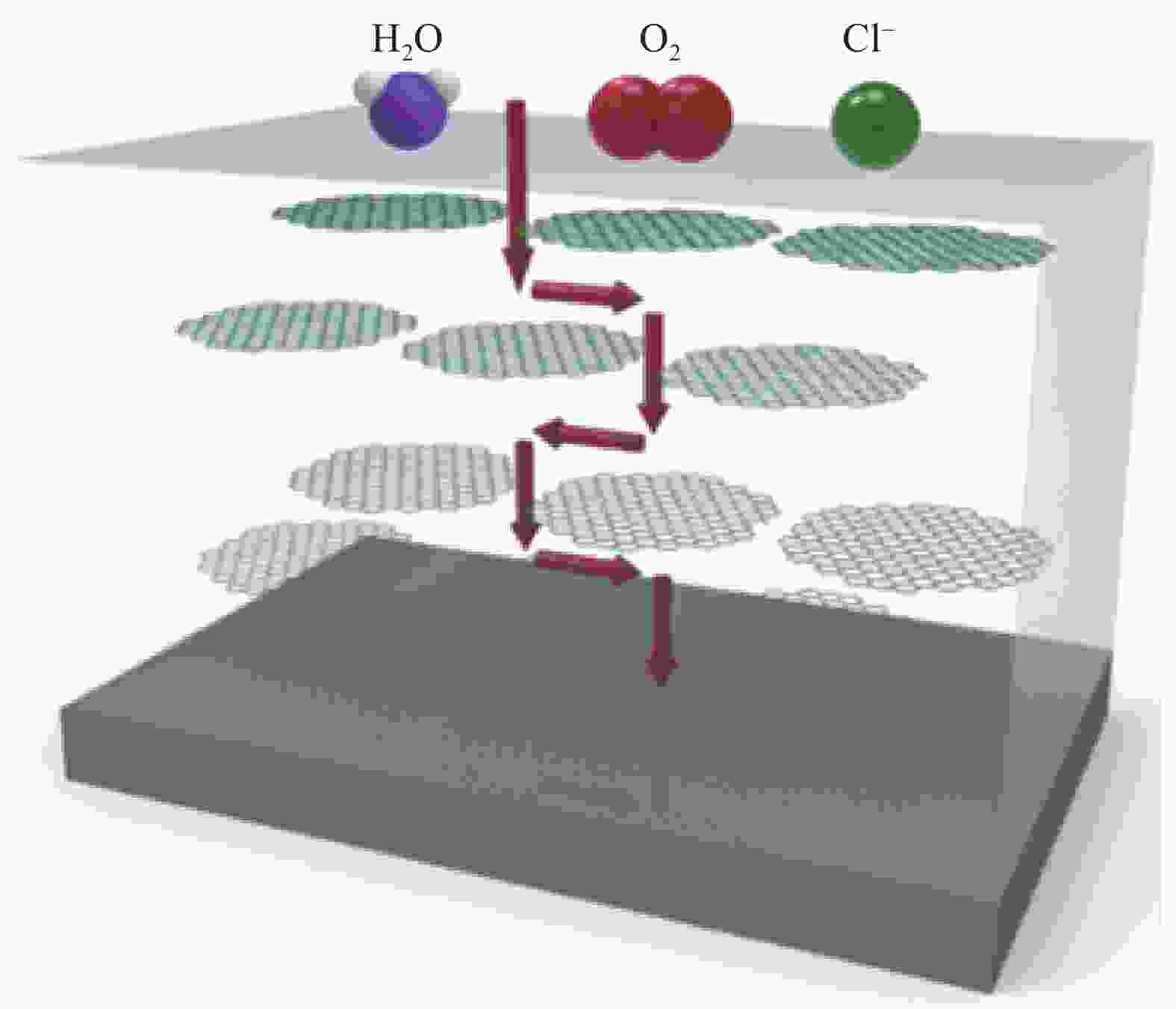

图 2 石墨烯/水性环氧含锌涂层防腐机制示意图: (a) 复合涂层物理屏蔽作用; (b) 石墨烯片的阻隔作用; (c) 锌颗粒的阴极保护作用; (d) 腐蚀锌颗粒[28]

Figure 2. Schematic diagram of anti-corrosion mechanism of graphene/waterborne epoxy zinc-containing coating: (a) Physical shielding effect of composite coating; (b) Barrier effect of graphene sheets; (c) Cathodic protection of zinc particles; (d) Corrosive zinc particles[28]

表 1 二维层状材料在涂层中的防腐效果

Table 1. Anticorrosion effect of two-dimensional layered materials in coatings

Two-dimensional

nanomaterial/Epoxy

anticorrosive coatingCorrosion

environmentMass

fraction ω/wt%Preservative effect Key character Ref. Graphene/Epoxy 3.5wt%NaCl 0.5 Icorr:2.617×10−8 A·cm−2

Ecorr:−0.094 VGood adhesion and excellent corrosion resistance [24] Graphene oxide/Epoxy 3.5wt%NaCl 0.5 Icorr:3.061×10−7 A·cm−2

Ecorr:−0.690 VLow viscosity and good adhesion with steel surface [25] Fluorographene/Epoxy 3.5wt%NaCl 0.5 Icorr:6.199×10−7 A·cm−2

Ecorr:−0.696 VHigh hydrophobicity and good impermeability [26] Hexagonal boron nitride/Epoxy 3.5wt%NaCl 0.5 Icorr:4.960×10−8 A·cm−2

Ecorr:−0.608 VHigh thermal stability and excellent corrosion resistance [17] Molybdenum disulfide/Epoxy resin 3.5wt%NaCl 0.5 Icorr:7.474×10−9 A·cm−2

Ecorr:−0.0928 VGood physical shielding performance and long-term

stable corrosion resistance[42] Notes: Icorr—Corrosion current density; Ecorr—Corrosion potential. -

[1] MURAT A. A review on conducting polymer coatings for corrosion protection[J]. Journal of Adhesion Science and Technology,2016,30(14):1510-1536. doi: 10.1080/01694243.2016.1150662 [2] 刘广程, 林岚辉, 刘宇哲, 等. 环氧树脂改性方法的研究现状及进展[J]. 科技风, 2019(20):275.LIU Guangcheng, LIN Lanhui, LIU Yuzhe, et al. Research status and progress of epoxy resin modification[J]. Technology Wind,2019(20):275(in Chinese). [3] 李雪爱, 王文彪. 浅谈金属腐蚀危害与防护[J]. 化工管理, 2013(12):158. doi: 10.3969/j.issn.1008-4800.2013.12.129LI Xueyi, WANG Wenbiao. A brief discussion on metal corrosion hazard and protection[J]. Chemical Enterprise Management,2013(12):158(in Chinese). doi: 10.3969/j.issn.1008-4800.2013.12.129 [4] 付琬璐, 史胜南, 葛晶, 等. 环氧涂层防腐填料研究进展[J]. 现代化工, 2020, 40(5):56-57, 62.FU Wanlu, SHI Shengnan, GE Jing, et al. Research progress of anticorrosive packing for epoxy coating[J]. Modern Chemical Industry,2020,40(5):56-57, 62(in Chinese). [5] CHOI B H, CHUDNOVSKY A, PARADKAR R, et al. Experimental and theoretical investigation of stress corrosion crack (SCC) growth of polyethylene pipes[J]. Polymer Degradation and Stability, 2009, 94(5): 859-867. [6] UMOREN S A, SOLOMON M M. Protective polymeric films for industrial substrates: A critical review on past and recent applications with conducting polymers and polymer composites/nanocomposites[J]. Progress in Materials Science, 2019, 104: 380-450. [7] DING R, CHEN S, LV J, et al. Study on graphene modified organic anti-corrosion coatings: A comprehensive review[J]. Journal of Alloys and Compounds, 2019, 806: 611-635. [8] HUANG H W, SHENG X X, TIAN Y Q, et al. Two-dimensional nanomaterials for anticorrosive polymeric coatings: A review[J]. Industrial & Engineering Chemistry Research,2020,59(35):15424-15446. [9] ZHU G Y, CUI X K, ZHANG Y, et al. Poly (vinyl butyral)/graphene oxide/poly (methylhydrosiloxane) nanocomposite coating for improved aluminum alloy anticorrosion[J]. Polymer, 2019, 172: 415-422. [10] WANG L Q, QIU N, DIETER-HEINZ H, et al. An experimental studyon cavitation erosion-corrosion performance of ANSI 1020 and ANSI 4135 steel[J]. Journal of Mechanical Science and Technology,2016,30(2):533-539. [11] 何亚飞, 郝立峰, 陆小龙, 等. MoS2纳米片及其增强环氧树脂基复合材料的制备与性能研究[J]. 高分子学报, 2015(2):197-203.HE Yafei, HAO Lifeng, LU Xiaolong, et al. Preparation and properties of MoS2 nanosheets reinforced epoxy resin matrix composites[J]. Acta Polymerica Sinica,2015(2):197-203(in Chinese). [12] CUI G, BI Z X, WANG S H, et al. A comprehensive review on smart anti-corrosive coatings[J]. Progress in Organic Coatings,2020, 148:1 − 26. [13] HUANG S Y, KONG G, YANG B, et al. Effects of graphene on the corrosion evolution of zinc particles in waterborne epoxyzinc-containing coatings[J]. Progress in Organic Coatings,2020, 140:1 − 10. [14] CAO X K, HUANG F, HUANG C, et al. Preparation of graphene nanoplate added zinc-rich epoxy coatings for enhanced sacrificial anode-based corrosion protection[J]. Corrosion Science,2019, 159:1 − 38. [15] 刘立柱, 张佳文, 徐航, 等. 石墨微片/环氧复合防腐涂料的制备及防腐机制[J]. 复合材料学报, 2018, 35(7):1738-1744.LIU Lizhu, ZHANG Jiawen, XU Hang, et al. Preparation and anti-corrosion mechanism of graphite microsheet/epoxy composite coating[J]. Acta Materiae Compositae Sinica,2018,35(7):1738-1744(in Chinese). [16] ZHENG H P, SHAO Y W, WANG Y Q, et al. Reinforcing the corrosion protection property of epoxy coating by using graphene oxide-poly (ureaformaldehyde) composites[J]. Corrosion Science,2017,123:267-277. doi: 10.1016/j.corsci.2017.04.019 [17] WU Y M, YU J J, ZHAO W J, et al. Investigating the anticorrosion behaviors of the water borne epoxy composite coatings with barrier and inhibition roles on mild steel[J]. Progress in Organic Coatings, 2019, 133: 8-18. [18] XU H Y, LI B, HAN X, et al. Synergic enhancement of the anticorrosion properties of an epoxy coating by compo-siting with both graphene and halloysite nanotubes[J]. Journal of Applied Polymer Science,2019,136(21):47562. doi: 10.1002/app.47562 [19] MUJIB S B, MUKHERJEE S, REN Z K, et al. Assessing corrosion resistance of two-dimensional nanomaterial-based coatings on stainless steel substrates[J]. Royal Society Open Science,2020,7(4):200214. doi: 10.1098/rsos.200214 [20] MIN C Y, SHEN X Q, SHI Z, et al. The electrical properties and conducting mechanisms of carbon nanotube/polymer N-anocomposites: A review[J]. Polymer-Plastics Technology and Engineering, 2010, 49(12): 1172-1181. [21] LI W X, XU Z W, CHEN L, et al. A facile method to produce graphene oxide-g-poly(L-lactic acid) as an promising reinforcement for P-LLA nanocomposites[J]. Chemical Engineering Journal, 2014, 237: 291-299. [22] 韩朋, 井晓静, 沈湘黔, 等. 氧化石墨烯、短切碳纤维改性聚偏氟乙烯复合膜的摩擦磨损及介电性能[J]. 机械工程材料, 2013, 37(2):53-56, 61.HAN Peng, JING Xiaojing, SHEN Xiangqian, et al. Friction wear and dielectric properties of polyvinylidene fluoride composite films modified by graphene oxide and carbon fiber[J]. Materials for Mechanical Engineering,2013,37(2):53-56, 61(in Chinese). [23] 闵春英, 聂鹏, 刘颖, 等. 耐高温GO/聚酰亚胺复合材料的制备及摩擦性能[J]. 固体火箭技术, 2014, 37(4):569-573.MIN Chunying, NIE Peng, LIU Ying, et al. Preparation and friction properties of high temperature resistant GO/polyimide composites[J]. Journal of Solid Rocket Technology,2014,37(4):569-573(in Chinese). [24] KAMALON R, KIKKERI N, SHETTY M. Synthesis of graphene oxide-based nanofillers and their influence on the anticorrosion performance of epoxy coating insaline medium[J]. Diamond & Related Materials,2020, 108:1 − 10. [25] WANG H G, REN H S, JING C F, et al. Two birds with one stone: Graphene oxide@sulfonated polyaniline nanocomposites towards high-performance electromagnetic wave absorption and corrosion protection[J]. Composites Science and Technology, 2021, 204:1 − 27 . [26] 窦宝捷, 付英奎, 高秀磊, 等. 氟化石墨烯对环氧树脂涂层耐蚀性能的影响[J]. 表面技术, 2020, 49(8): 241 − 248 .DOU Baojie, FU Yingkui, GAO Xiulei, et al. Effect of fluori-nated ink on corrosion resistance of epoxy resin coating[J]. Surface Technology, 2020, 49(8): 241 − 248(in Chinese). [27] TENG K Y, NI Y, WANG W, et al. Adjustable micro-structure, higher-level mechanical behavior and conductivities of preformed graphene architecture/epoxy composites via RTM route[J]. Composites Part A, 2017, 94: 178 − 188 . [28] VASHIST S K, LUONG J H T. Recent advances in electrochemical biosensing schemes using graphene and graphene-based nanocomposites[J]. Carbon, 2015, 84: 519 − 550 [29] HAYATDAVOUDI H, RAHSEPAR M. A mechanistic study of the enhanced cathodic protection performance of graphene-reinforced zinc rich nanocomposite coating for corrosion protection of carbon steel substrate[J]. Journal of Alloys and Compounds, 2017, 727: 1148 − 1156 . [30] ZHOU F, LI Z T, SHENOY G J, et al. Enhanced room-temperature corrosion of copper in the presence of graphene[J]. ACS Nano,2013,7(8):6639-6947. [31] SCHRIVER M, REGAN W, GANNETT W J, et al. Graphene as a longterm metal oxidation barrier: Worse than nothing[J]. ACS Nano,2013,7(7):5763-5768. doi: 10.1021/nn4014356 [32] DIPAK D, ANDITA N F G, JUI-KUNG C. Revisiting graphene-polymer nanocomposite for enhancing anticorrosion performance: A new insight into interface chemistry and diffusion model N-anoscale[J]. Nanoscale, 2018, 10: 12612-12624. [33] OMER S, ASHOK K. Sundramoorthy, sundaram gunasekaran. Facile and green synthesis of highly conducting graphene paper[J]. Carbon,2018,138:108-117. doi: 10.1016/j.carbon.2018.05.076 [34] LIU J H, YU Q, YU M, et al. Silane modification of titanium dioxide-decorated graphene oxide nanocomposite for enhancing anticorrosion performance of epoxy coatings on AA-2024[J]. Journal of Alloys and Compounds,2018,744:728-739. doi: 10.1016/j.jallcom.2018.01.267 [35] 崔明君. 二维氮化硼纳米片增强复合涂层长周期腐蚀机理方面取得进展[J]. 表面工程与再制造, 2017, 17(6):66. doi: 10.3969/j.issn.1672-3732.2017.06.032CUI Mingjun. Advances in the long-period corrosion mechanism of 2D boron nitride nanosheets reinforcement composite coating[J]. Surface Engineering & Remanufacturing,2017,17(6):66(in Chinese). doi: 10.3969/j.issn.1672-3732.2017.06.032 [36] LIU K, ZHANG G G, PU J B, et al. Impermeability of boron nitride defect sensitive monolayer with atomic oxygen healing ability[J]. Ceramics International, 2018, 44(12): 13888-13893. [37] DING J H, ZHAO H R, ZHENG Y, et al. A long-term anticorrsive coating through graphene passivation[J]. Carbon, 2018, 138: 197-206. [38] HUSAIN E, NARAYANAN T N, TAHA-TIJERINA J J, et al. Marine corrosion protective coatings of hexagonal boron nitride thin films on stainless steel[J]. ACS Applied Materials & Interfaces, 2013, 5(10): 4129-4135. [39] 马浩, 杨瑞霞, 李春静. 层状二硫化钼材料的制备和应用进展[J]. 材料导报, 2017, 31(3):7-14.MA Hao, YANG Ruixia, LI Chunjing. Preparation and application of laminated molybdenum disulfide materials[J]. Materials Reports,2017,31(3):7-14(in Chinese). [40] ZENG G J, LIU M Y, LIU X H, et al. Mussel inspired preparation of MoS2 based polymer nanocomposites: The case of poly PEGMA[J]. North Holland,2016,387:399-405. [41] ARUNKUMAR S, JEGATHISH V, SOUNDHARYA R, et al. Evaluating the performance of MoS2 based materials for corrosion protection of mild steel in an aggressive chloride environment[J]. RSC Advances, 2017, 7(28): 17332-17335. [42] XIA Z B, LIU G Z, DONG Y Q, et al. Anticorrosive epoxy coatings based on polydopamine modified molybdenum disulfide[J]. Progress in Organic Coatings,2019,133:154-160. doi: 10.1016/j.porgcoat.2019.04.056 [43] JING Y J, WANG P Q, YANG Q B, et al. The effect of a functionalized defect-rich molybdenum disulfide nanosheets on anticorrosion performance of epoxy coating[J]. Materials Research Express, 2019, 6(8): 1 − 10 . [44] JING Y J, WANG P Q, YANG Q B, et al. Molybdenum disulfide with poly(dopamine) and epoxy groups as an efficiently anticorrosive reinforcers in epoxy coating[J]. Synthetic Metals,2020, 259:1 − 8. [45] YOU X F, YANG S W, LI J P, et al. Green and mild oxidation: An efficient strategy toward water-dispersible graphene[J]. ACS Applied Materials & Interfaces,2017,9(3):2856-2866. [46] WAN Y J, GONG L X, TANG L C, et al. Mechanical properties of epoxy composites filled with silane-functionalized graphene oxide[J]. Composites Part A,2014,64:79-89. doi: 10.1016/j.compositesa.2014.04.023 [47] ZHANG Z Y, ZHANG W H, LI D S, et al. Mechanical and anticorrosive properties of graphene/epoxy resin composites coating preparedby in-situ method[J]. International Journal of Molecular Sciences,2015,16(1):2239-2251. doi: 10.3390/ijms16012239 [48] CUI M J, REN S M, QIN S L, et al. Processable poly(2-butylaniline)/hexagonal boron nitride nanohybrids for synergetic anticorrosive reinforcement of epoxy coating[J]. Corrosion Science,2018,131:187-198. doi: 10.1016/j.corsci.2017.11.022 [49] 贾涉, 姚正军, 张莎莎, 等. 硅烷改性纳米TiO2-Zn-Al/水性环氧涂层的防腐性能[J]. 复合材料学报, 2018, 35(9):2405-2413.JIA She, YAO Zhengjun, ZHANG Shasha, et al. Anticorrosion properties of TiO2-Zn-Al/water-based epoxy coatings modified by silane[J]. Acta Materiae Compositae Sinica,2018,35(9):2405-2413(in Chinese). [50] POURHASHEM S, VAEZI M R, RASHIDI A. Investigating the effect of SiO2-graphene oxide hybrid as inorganic nanofiller on corrosion protection properties of epoxy coatings[J]. Surface & Coatings Technology, 2017, 311: 282-294. [51] DI H H, YU Z X, MA Y, et al. Graphene oxidedecorated with Fe3O4 nanoparticles with advanced anticorrosive properties of epoxy coatings[J]. Journal of the Taiwan Institute of Chemical Engineers,2016,64:244-251. doi: 10.1016/j.jtice.2016.04.002 [52] ZHANG C L, HE Y, ZHAN Y Q, et al. Poly(dopamine) assisted epoxy functionalization of hexagonalboron nitride for enhancement of epoxy resin anticorrosion perfor-mance[J]. Polymers for Advanced Technologies,2017,28(2):214-221. doi: 10.1002/pat.3877 [53] TIAN B, LIN W Y, ZHUANG P P, et al. Magnetically-in duced alignment of graphene via Landau diamagnetism[J]. Carbon, 2018, 131: 66 −71. [54] DING R, CHEN S, ZHOU N, et al. The diffusion-dynamical and electrochemical effect mechanism of oriented magne-tic graphene on zinc-rich coatings [J]. Journal of Alloys and Compounds, 2019, 784: 756 − 768. [55] LI Z W, LI J, CUI J C, et al. Dispersion and parallel assembly of sulfonated graphene in waterborne epoxy anticorrosion coatings[J]. Journal of Materials Chemistry A, 2019, 7(30): 17937 − 17946. [56] YOUSEFI N, LIN X, ZHENG Q, et al. Simultaneous in situ reduction, self-alignment and covalent bonding in graphene oxide/epoxy composites[J]. Carbon, 2013(59): 406 − 417. [57] SEPIDEH P, MOHAMMAD R V, ALIMORAD R, et al. Distinctive roles of silane coupling agents on the corrosion inhibition performance of graphene oxide in epoxy coatings[J]. Progress in Organic Coatings,2017, 111:47 − 56. [58] PARHIZKAR N, SHAHRABI T, RAMEZANZADEH B. A new approach for enhancement of the corrosion protection properties and interfacial adhesion bonds between the epoxy coating and steel substrate through surface treatment by covalently modified amino functionalized gra-phene oxide film[J]. Corrosion Science,2017, 123:55 − 75. -

下载:

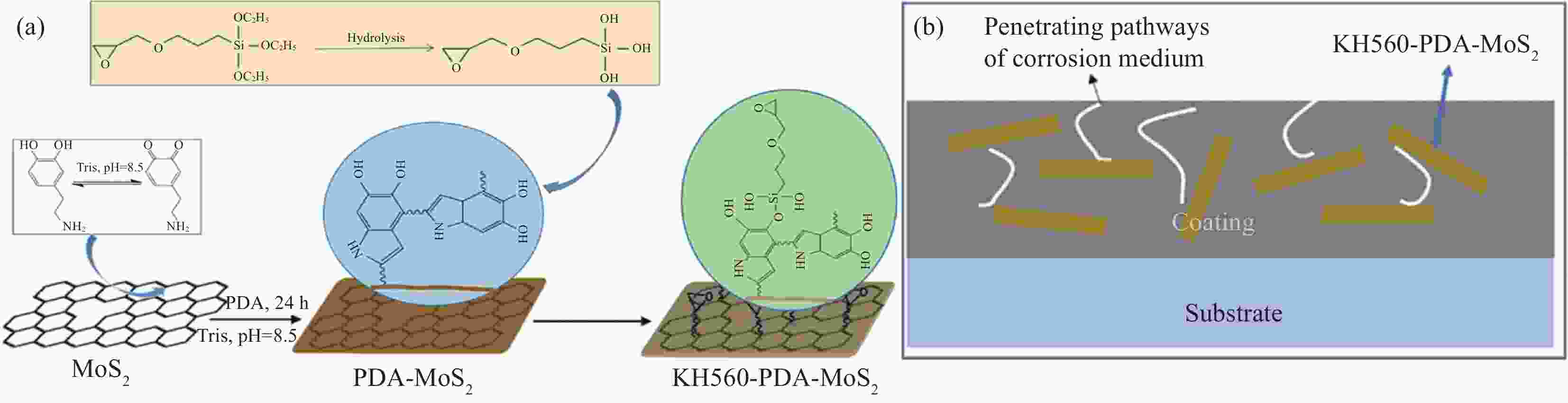

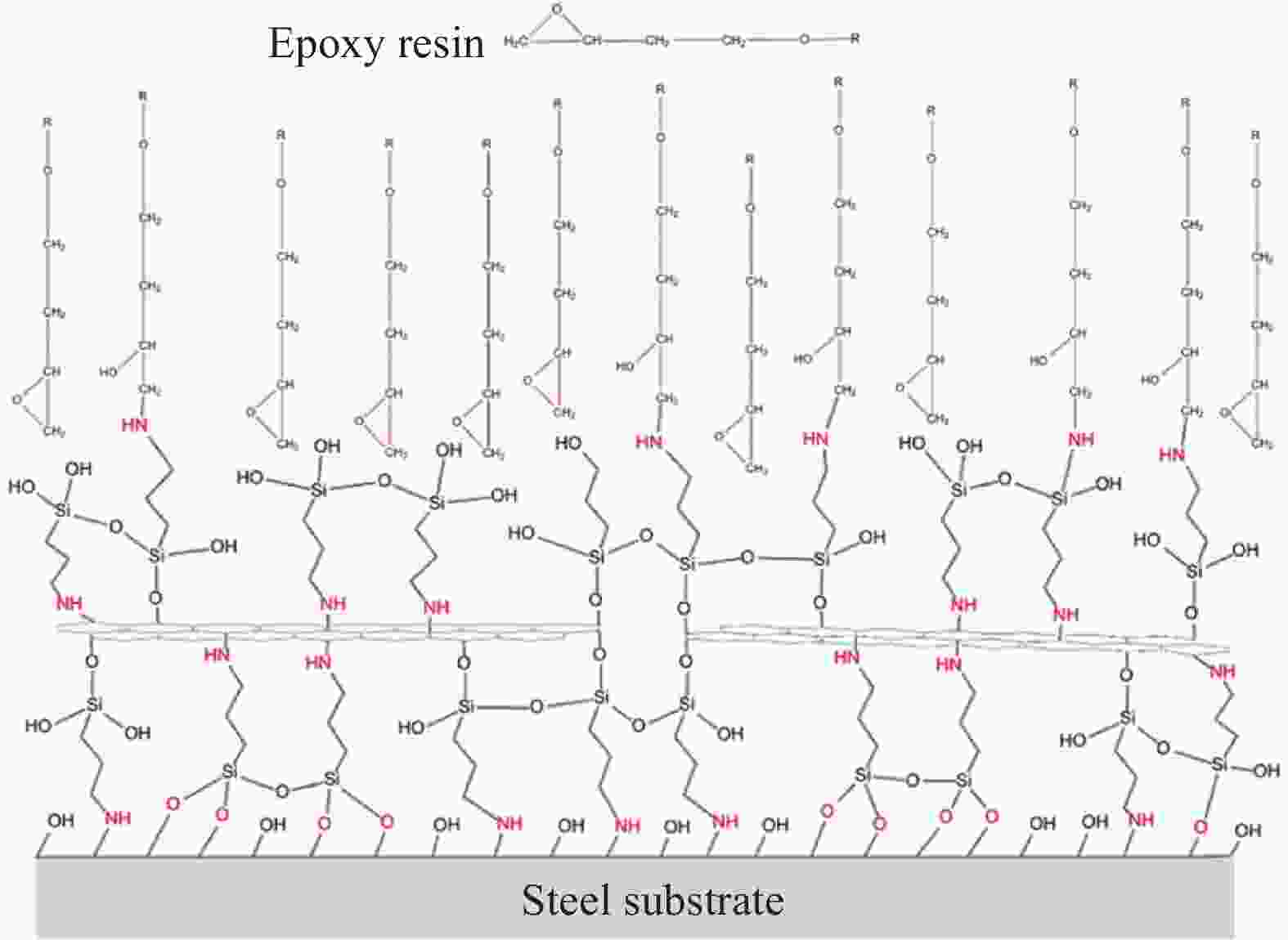

下载: